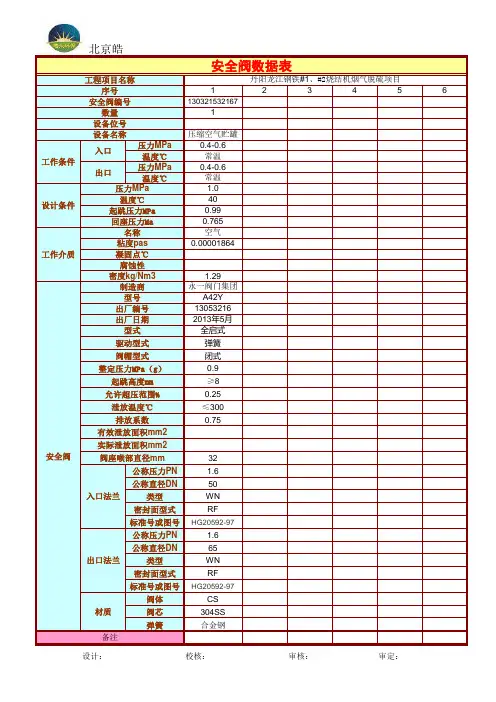

安全阀数据表

- 格式:xlsx

- 大小:87.49 KB

- 文档页数:2

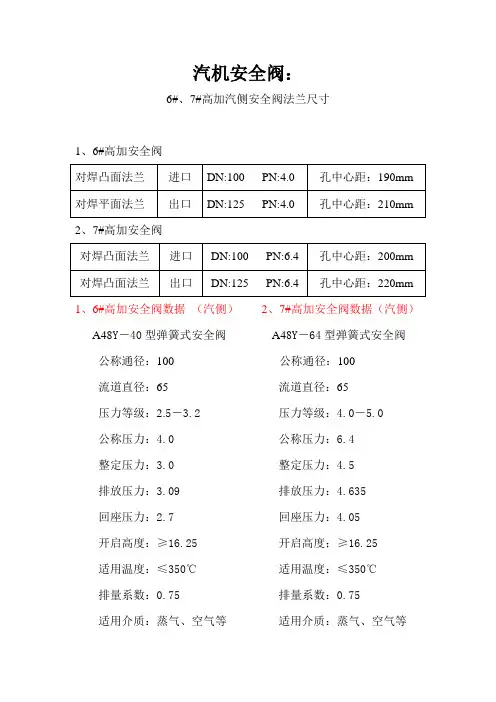

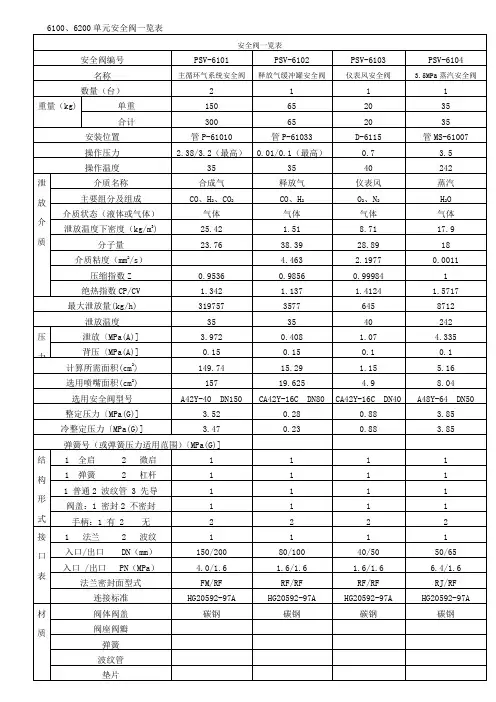

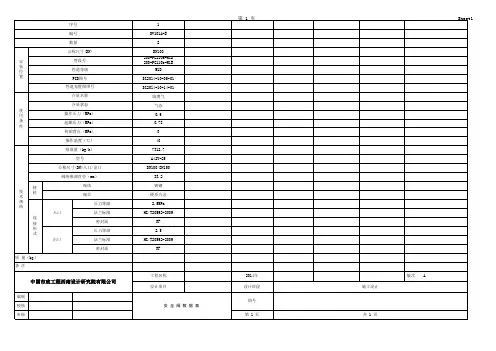

汽机安全阀:6#、7#高加汽侧安全阀法兰尺寸1、6#高加安全阀2、7#高加安全阀1、6#高加安全阀数据(汽侧)2、7#高加安全阀数据(汽侧)A48Y-40型弹簧式安全阀A48Y-64型弹簧式安全阀公称通径:100 公称通径:100流道直径:65 流道直径:65压力等级:2.5-3.2 压力等级:4.0-5.0公称压力:4.0 公称压力:6.4整定压力:3.0 整定压力:4.5排放压力:3.09 排放压力:4.635回座压力:2.7 回座压力:4.05开启高度:≥16.25 开启高度;≥16.25适用温度:≤350℃适用温度:≤350℃排量系数:0.75 排量系数:0.75适用介质:蒸气、空气等适用介质:蒸气、空气等3、6#蒸汽冷却器安全阀数据(主给水管道上)A61Y-320型弹簧式安全阀公称通径:20流道直径:8压力等级:22-25公称压力:32整定压力:24排放压力:26.4回座压力:20.4开启高度:≥0.4适用温度:≤300℃排量系数:0.15适用介质:气体、水、油品等4、2#低加安全阀数据(汽侧)5、3#低加安全阀数据(汽侧)CA48Y-16C型弹簧式安全阀C A48Y-16C型弹簧式安全阀公称通径:50 公称通径:50流道直径:32 流道直径:32压力等级:0.4-0.6 压力等级:0.4-0.6公称压力:1.6 公称压力:1.6整定压力:0.5 整定压力:0.5抽汽额定压力:0.067 抽汽额定压力:0.132排放压力:0.515 排放压力:0.515回座压力:0.45 回座压力:0.45开启高度:≥8.0 开启高度;≥8.0适用温度:≤350℃适用温度:≤350℃排量系数:0.7 排量系数:0.7适用介质:蒸气、空气等适用介质:蒸气、空气等6、4#低加安全阀数据(危急疏水管道上)7、1#低加安全阀数据(危急疏水管道上)(水侧)CA48Y-16C型弹簧式安全阀A41H-40型弹簧式安全阀公称通径:80 公称通径:32流道直径:50流道直径:25压力等级:0.6-0.8 压力等级:2.5-3.2公称压力:1.6 公称压力:4.0整定压力:0.7 整定压力:3.2抽汽额定压力:0.48排放压力:0.721 排放压力:3.52回座压力:0.63 回座压力:2.72开启高度:≥12.5 开启高度:≥1.25适用温度:≤350℃适用温度:≤300℃排量系数:0.7 排量系数:0.15适用介质:蒸气、空气等适用介质:蒸气、空气等8、2#低加安全阀数据(水侧)CA48Y-40C型弹簧式安全阀公称通径:32流道直径:20压力等级:4.0-5.0公称压力:6.4整定压力:4.0排放压力:4.12回座压力:3.6开启高度:≥5.0适用温度:≤350℃排量系数:0.7适用介质:蒸气、空气等9、除氧器安全阀(2个)A48Y-16cPN1.6MpaDN200使用温度350℃起跳压力:1.13Mpa。

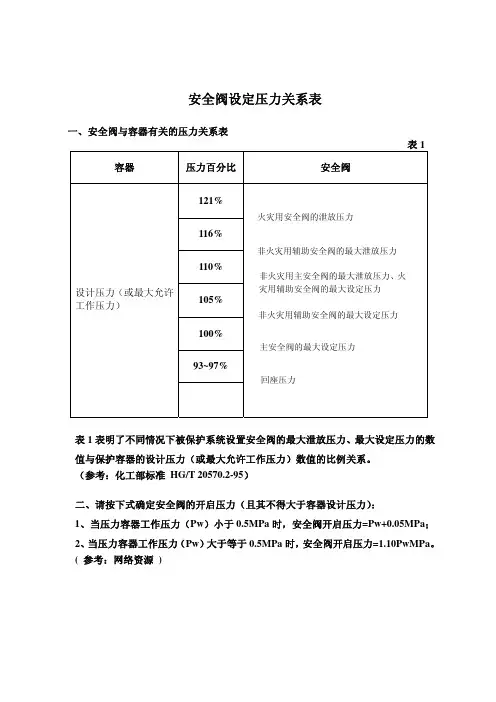

安全阀设定压力关系表

一、安全阀与容器有关的压力关系表

表1

容器

压力百分比安全阀

121% 116%

110%

105% 100%

93~97%

设计压力(或最大允许工作压力)

火灾用安全阀的泄放压力

非火灾用辅助安全阀的最大泄放压力

非火灾用主安全阀的最大泄放压力、火

灾用辅助安全阀的最大设定压力 非火灾用辅助安全阀的最大设定压力

主安全阀的最大设定压力

回座压力

表1表明了不同情况下被保护系统设置安全阀的最大泄放压力、最大设定压力的数值与保护容器的设计压力(或最大允许工作压力)数值的比例关系。

(参考:化工部标准 HG/T 20570.2-95)

二、请按下式确定安全阀的开启压力(且其不得大于容器设计压力):

1、当压力容器工作压力(Pw )小于0.5MPa 时,安全阀开启压力=Pw+0.05MPa ;

2、当压力容器工作压力(Pw )大于等于0.5MPa 时,安全阀开启压力=1.10PwMPa 。

( 参考:网络资源 )。

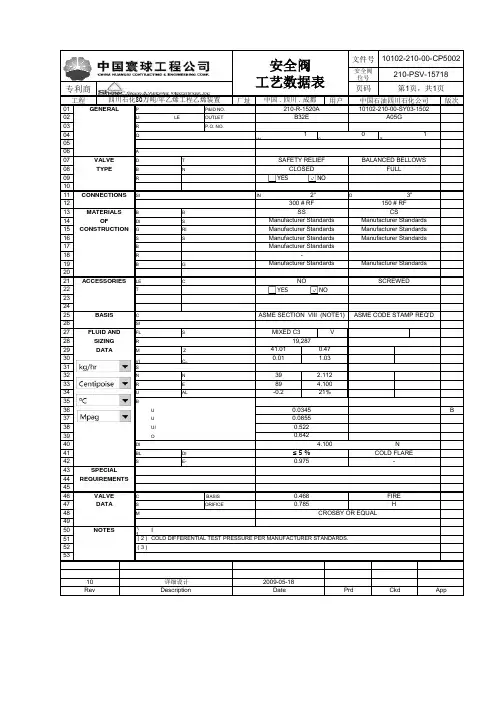

01GENERALPROTECTED EQUIPMENT P&ID NO. 02 LINE CLASS INLETOUTLET 03 REQ'N NO.P.O. NO.04 QUANTITY WORKINGSPARETOTAL05 06 APPLICABLE SPECIFICATIONS07VALVE DESIGN TYPE08TYPEBONNET TYPE NOZZLE TYPE 09 RESILIENT SEAT 10 11CONNECTIONS SIZE - END CONNECTION INLETOUTLET12 13MATERIALSBODY BONNET 14OFDISC SEAT / NOZZLE 15CONSTRUCTIONGUIDE RINGS16 SPRING SPRING COATING 17 BELLOWS 18 RESILIENT SEAT 19 BOLTING GASKET 20 21ACCESSORIESLEVER CAP 22 TEST GAG23 24 25BASIS CODE REQUIREMENT / CODE STAMP 26 SIZING BASIS 27FLUID AND FLUIDSTATE28SIZING REQUIRED CAPACITY 29DATAMW / SG @ T Z30 VISCOSITY @ TC P / C V @STP31 SPECIAL PROPERTIES 32 NOR OP TEMP NOR OP PRESS 33 REL TEMP SET PRESS34OUTLET TEMP ALLOW OVERPRESS35 BACKPRESSURE:36SUPERIMPOSED - CONSTANT B 37SUPERIMPOSED - VARIABLE38BUILT-UP 39TOTAL40 DIFFERENTIAL SET PRESSURE ( NOTE 2 )41 BLOWDOWN DISPOSITION 42DISCH. COEF. (K)DE-RATE FACTOR 43SPECIAL 44REQUIREMENTS45 46VALVE CALCULATED AREA (in.2) BASIS 47DATASELECTED AREA (in.2)ORIFICE48 MANUFACTURER - MODEL49 50NOTES( 1 ) MINIMUM COMPLIANCE: API 520, 526, 527 and ANSI B16.551 52 53≤ 5 %COLD FLARE0.6420.01CROSBY OR EQUALCOLD DIFFERENTIAL TEST PRESSURE PER MANUFACTURER STANDARDS.( 2 )( 3 )0.08550.522 4.100H0.468FIRE 0.785--0.219,28741.010.471.03MIXED C3VASME SECTION VIII (NOTE1)ASME CODE STAMP REQ'DManufacturer StandardsManufacturer Standards -NOSCREWEDManufacturer Standards Manufacturer StandardsManufacturer StandardsCSManufacturer Standards Manufacturer Standards Manufacturer Standards Manufacturer Standards 2"3"FULL工程四川石化80万吨/年乙烯工程乙烯装置厂址中国 . 四川 . 成都B32E210-R-1520A10102-210-00-SY03-1502用户中国石油四川石化公司版次A05G SSCLOSED 11BALANCED BELLOWS300 # RF 0.03450.97539 2.11289 4.10021%页码第1页,共1页150 # RF SAFETY RELIEF安全阀工艺数据表文件号10102-210-00-CP5002安全阀位号210-PSV-15718专利商Prd Ckd App10 详细设计2009-05-18Rev Description Datekg/hr Centipoise YESNOºC MpagYES NO。

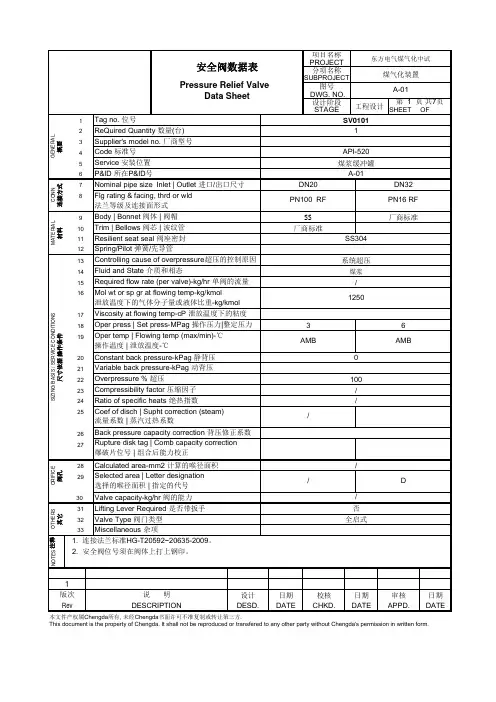

SUBPROJECT图号DWG. NO.设计阶段STAGE1234567891011121314151617181920212223242526272829313233设计日期校核日期审核日期RevDESD.DATECHKD.DATEAPPD.DATE本文件产权属Chengda 所有, 未经Chengda 书面许可不准复制或转让第三方.煤气化装置Pressure Relief ValveA-01Data Sheet工程设计第 1 页共7页SHEET OFG E N E R A L 概要Tag no. 位号SV0101ReQuired Quantity 数量(台)1Supplier's model no. 厂商型号Code 标准号API-520C O N N 连接方式Nominal pipe size Inlet | Outlet 进口/出口尺寸DN20DN32Flg rating & facing, thrd or wld 法兰等级及连接面形式PN100 RF Service 安装位置煤浆缓冲罐P&ID 所在P&ID 号A-01PN16 RF M A T E R I A L 材料Body | Bonnet 阀体 | 阀帽SS 厂商标准Trim | Bellows 阀芯 | 波纹管厂商标准Resilient seat seal 阀座密封SS304Spring/Pilot 弹簧/先导管S I Z I N G B A S I S / S E R V I C E C O N D I T I O N S 尺寸依据/操作条件Controlling cause of overpressure 超压的控制原因系统超压Fluid and State 介质和相态煤浆Required flow rate (per valve)-kg/hr 单阀的流量/Mol wt or sp gr at flowing temp-kg/kmol泄放温度下的气体分子量或液体比重-kg/kmol Variable back pressure-kPag 动背压1250Viscosity at flowing temp-cP 泄放温度下的粘度Oper press | Set press-MPag 操作压力|整定压力36Oper temp | Flowing temp (max/min)-℃操作温度 | 泄放温度-℃AMBAMBConstant back pressure-kPag 静背压0Back pressure capacity correction 背压修正系数Overpressure % 超压100Compressibility factor 压缩因子/Ratio of specific heats 绝热指数/Coef of disch | Supht correction (steam)流量系数 | 蒸汽过热系数/O R I F I C E 阀孔Calculated area-mm2 计算的喉径面积/Selected area | Letter designation 选择的喉径面积 | 指定的代号/Rupture disk tag | Comb capacity correction 爆破片位号 | 组合后能力校正O T H E R S 其它Lifting Lever Required 是否带扳手否Valve Type 阀门类型全启式Miscellaneous 杂项D30Valve capacity-kg/hr 阀的能力/N O T E S 注释1. 连接法兰标准HG-T20592~20635-2009。

SAFESafety valvesARI-SAFE - Full lift- / Standard - safety valveARI-SAFEFull lift safety valve D/G Standard safety valve F• Type-test approved acc. to TRD and AD2000-A2Direct loaded with spring:• TÜV · SV · . . -663 · D/G Figure 901-912• TÜV · SV · . . -729 · F Figure 901/911• Further approvals: see insideFig. 901902911912Page 2ARI-SAFEStandard safety valve for the heating technology• Type-test approved acc. to TRD 721Direct loaded with spring:• TÜV · SV · . . -688 · D/G/H Figure 903• TÜV · SV · . . -688 · D Figure 904Fig. 903904Page 6ARI-SAFE-PStandard safety valve D/G/F• Type-test approved acc. to TRD and AD2000-A2Direct loaded with spring:• TÜV · SV · . . -811 · D/G Figure 921-924• TÜV · SV · . . -821 · F Figure 921/923Fig. 921922923924Page 10ARI-SAFE-TCFull lift safety valve D/G Standard safety valve F• Type-test approved acc. to TRD and AD2000-A2Direct loaded with spring:• TÜV · SV · . . -995 · D/G Figure 941-943• TÜV · SV · . . -1005 · F Figure 941/943Fig. 941942943Page 14ARI-SAFE-TCStandard safety valve for the heating technology• Type-test approved acc. to TRD 721Direct loaded with spring:• TÜV · SV · . . -997 · D/G/H Figure 945• TÜV · SV · . . -997 · D Figure 946Fig. 945946Page 16ARI-SAFE-TCPStandard safety valve D/G/F• Type-test approved acc. to AD2000-A2Direct loaded with spring:• TÜV · SV · . . -1041 · D/G/F Figure 961-963Fig. 961962963Page 18ARI-SAFE-TCSStandard safety valve D/G/F• Type-test approved acc. to AD2000-A2Direct loaded with spring:• TÜV · SV · . . -1041 · D/G/F Figure 951-953FOR HORIZONTAL APPLICATIONFig. 951952953Page 20Features:• Direct loaded with spring • Wear resistant seat/disc • Precision disc alignment and guide • Possible with soft seal disc • Possible with EPDM bellow • Possible with stainless steel bellow• All common thread types (SAFE-TC/TCP/TCS)Fig. 900Fig. 940Fig. 920Fig. 950 / 960Edition 02/06 - Data subject to alteration Data sheet 0900001锅炉设计师自己建立的微信平台微信公众号:guolujishu主要分享热力计算、强度计算及水动力计算方面的知识关键点,一起学习,共同进步!2DN20 / 3225 / 4032 / 5040 / 6550 / 8065 / 10080 / 125100 / 150125 / 200150 / 250Weight (kg)8,510142028405380125165Weight, bellow design (kg)9,511,51622,532475990----without metal bellow with metal bellowSuperimposed back pressure no backpressure allowedon request Built up back pressure max. 10% from set pressure (gauge)(higher on request)on requestARI-SAFE -Full lift safety valve D/GStandard safety valve FFig. .. .901closed lifting device closed bonnetFig. .. .902open lifting device open bonnet Fig. .. .911gastight cap closed bonnet Fig. .. .912open lifting device closed bonnet FigureNom. pressure Material Nominal diameterTemperature range FlangesFlangeholes/-thick-ness tolerances 12.901 / 902 / 911 / 912PN 16 / 16EN-JL1040DN 20/32 up to DN 150/250- 10°C up to +300°C DIN EN 1092-2DIN 2533 / 253325.901 / 902 / 911 / 912PN 40 / 16EN-JS1049DN 20/32 up to DN 100/150- 10°C up to +350°C DIN EN 1092-2DIN 28607 / 2860535.901 / 902 / 911 / 912PN 40 / 16 1.0619+N DN 20/32 up to DN 150/250- 10°C up to +450°C DIN EN 1092-1DIN 2545 / 254355.901 / 911PN 40 / 16 1.4408DN 20/32 up to DN 100/150- 60°C up to +400°C DIN EN 1092-1DIN 2545 / 2543Type-test approvalFull lift valve:TÜV · SV · . . -663 · D/G(Stand. valve 0,2-0,5 bar)set gauge pressure see …Capacity“Standard valve:TÜV · SV · . . -729 · FDN 20-150Requirement Acc. to EN ISO 4126-1, VdTÜV-leaflet 100, AD2000-A2, TRD 421, material selection observe TRB 801 No. 45!Application EN-JL1040, EN-JS1049,1.0619+N steam, neutral gases, vapours and liquids1.4408steam, aggressive gases, vapours and liquidsConstruction Safety valve, spring loaded, direct loadedSizingFor steam, air and water see capacity tables, calculation acc. to EN ISO 4126-1, TRD 421 and AD2000-A2,necessary information for valve layout:Medium gasform:Mass flow (kg/h), molar mass (kg/kmol), temperature (°C), set gauge pressure (bar), back gauge pressure (bar)Medium liquid:Mass flow (kg/h), density (kg/m3), viscosity, temperature (°C), Set gauge pressure (bar), back gauge pressure (bar)Order data:ARI-SAFE-safety valve - Figure ....., DN ... / ..., PN .. / .., Material ........, set gauge pressure .... barSAFEEdition 01/06 - Data subject to alteration3Spring ranges in bar (gauge)DN 20DN 25 - 50DN 65DN 80DN 100DN 125DN 1500,2 - 0,50,2 - 0,50,2 - 0,50,2 - 0,50,2 - 0,50,2 - 0,40,2 - 0,50,52 - 10,52 - 10,52 - 10,52 - 10,52 - 10,42 - 0,750,52 - 11,05 - 1,51,05 - 1,51,05 - 1,51,05 - 1,51,05 - 1,50,77 - 1,11,05 - 1,51,55 - 2,51,55 - 21,55 - 21,55 - 21,55 - 21,15 - 1,51,55 - 1,92,55 - 4,52,05 - 2,72,05 - 2,72,05 - 2,72,05 - 2,51,55 - 1,91,95 - 2,34,6 - 8,52,75 - 3,62,75 - 3,62,75 - 3,62,55 - 31,95 - 2,52,35 - 2,78,6 - 193,7 - 53,7 - 53,7 - 53,05 - 3,62,55 - 2,952,75 - 3,319,1 - 285,1 - 95,1 - 95,1 - 93,7 - 5 3 - 43,35 - 4,128,1 - 359,1 - 169,1 - 169,1 - 145,1 - 94,1 - 5,74,2 - 5,535,1 - 4016,1 - 2216,1 - 2214,1 - 199,1 - 145,8 - 8,25,6 - 7,422,1 - 2822,1 - 2819,1 - 2514,1 - 198,3 - 127,5 - 1128,1 - 3419,1 - 2412,1 - 1711,1 - 1617,1 - 2416,1 - 2124,1 - 2721,1 - 26Stainless steel version max. 24 bar for saturated steam.Set gauge-pressureI Saturated steam in kg/hII Air 0°C and 1.013 bara in Nm 3/hbarDN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 100DN 125DN 150I III III III III III III III III III II0,281951261482102463243805065948551003129515202024237525102945349041000,412014318522330737047357073989112501505189022802960356536304380505060900,5132161207252344419529646827100914001705212025853310403540704970566069100,6147182230284383472590728923113515601920236029103690454544705520622076750,81742182723414535676988731090136518402305279034904360546052406555728091151203255317398526661811101912701590214026903245407550706370603075758385105301,527234442553870789410901378170021502875364043555510680086108050101951120014180230538847760779210081220155019002425322041004880621076259700101251289014080179202,53664685727319501215146018702285292538654945585574909145117001199015330166602130034245446628501100141016952175264534004475575067758700106001360013880178401930024800453569283710801390180021402770335043305650731085701108013400173001755022725244003160056408341000130016652160256533304000521067708800102601334016000208402100027350292503800067459751165152019402530299039004665609078901030011950156001865024370245003190034050444007850111513301745221029003400446553206970900011790136001786021300279002790036600388005090089571255149519652485326038205030598078601010013280153002010023900314303135041200436005730091060139516602185275536304245559066308740112001477016950223702650034960348004580048400638001011651540182024003025399046656150729096101230016250186502460029150385003825050500532007020011127016801985262533004360508067207940105001340017750203002690031750420004160055100580007660012137518202150284535704730550072908590113801450019240220002915034350455004510059700627008310013148019602310307038405090592078509250122701560020730236503140037000490004850064400675008950014158021002475329041105460634084009900131501670022200253503365039600526005200069000723009600015169022452640350043855830676089801055014030178002370027000359004220056100554007360077000102400161790238528003725465561907170954011200149001895025200287003820044800596005880078200818001088001719002530296539504930656075901010011850158002005026700303504040047400631006220082900866001153001820002670313041705200692080101067012500166502115028100320504270050100667006570087500914001217001921002800329543905470730084301124013150175502225029600337004490052700702006910092100962001281002022102950346046105750766088501180013800184002335031150354004720055300737007260096800101000134600212320309036204830602080209250123701450019300245003265037100494005790077300760001014001058001410002224203230379050506290839097001293015150202002560034150388005170060600808007950010600011090014750024263535154120549068409120105001406016450219702785037100421005620065900879008650011530012060016040025274036554280571071209490109501462017100228502895038600438005850090200120000125500166900262850380044505930739098501135015190178002373030050401009370012460013030017330028306040804780637079501060012250163201910025500323004310030327043605120681085001132013100174502045027250TÜV · SV · . . -663 · D/GCalculation acc. to TRD 421 and AD2000-A2DN125, DN150 higher pressures on request323490464054507250906012050139501857021800290003449257700127901970030800405770Fig. 901 / 902 / 911 / 912Capacity saturated steam / air incl. 10% overpressurem a x . s e t p r e s s u r e s t a i n l e s s s t e e l v e r s i o nEdition 06/04 - Data subject to alteration4Fig. .. .901closed lifting deviceclosed bonnetFig. .. .902open lifting deviceopen bonnetFig. .. .911gastight capclosed bonnetFig. .. .912open lifting deviceclosed bonnetSAFEEdition 04/03 - Data subject to alteration5Stainless steel-bellow: Spring ranges in bar (gauge)DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 1003,0 - 3,72,5 - 3,32,5 - 3,22,6 - 3,62,8 - 3,42,5 - 3,72,5 - 3,32,5 - 3,53,8 - 4,63,4 - 4,63,3 - 4,03,7 - 4,53,5 - 4,53,8 - 4,63,4 - 4,53,6 - 4,24,7 - 6,34,7 - 5,44,1 - 5,54,6 - 5,64,6 - 8,44,7 - 5,94,6 - 5,84,3 - 4,96,4 - 8,45,5 - 7,05,6 - 6,45,7 - 7,58,5 - 10,06,0 - 8,05,9 - 7,55,0 - 5,68,5 - 10,27,1 - 9,06,5 - 7,97,6 - 10,010,1 - 11,58,1 - 10,07,6 - 8,95,7 - 7,010,3 - 13,09,1 - 11,78,0 - 11,510,1 - 12,511,6 - 16,010,1 - 18,09,0 - 10,57,1 - 8,013,1 - 17,011,8 - 16,011,6 - 18,512,6 - 16,016,1 - 18,510,6 - 13,08,1 - 9,317,1 - 27,516,1 - 22,018,6 - 25,016,1 - 22,018,6 - 23,013,1 - 14,09,4 - 11,522,1 - 30,011,6 - 13,0Design with bellow as standard valve (only Fig. 901/911)DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 100DN 125DN 150d o in mm 1822,529364558,57290106125A o in mm 225439866110181590268840726362882512272Gauge press.Water 20°C in t/h bar DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 100DN 125DN 1500,23,285,138,5313,120,530,846,773,094,9132,00,55,198,1213,520,832,548,873,9115,0150,0209,017,3511,519,129,445,969,0104,0163,0212,0295,0210,416,227,041,664,997,5148,0231,0300,0417,0312,719,933,050,979,5119,0181,0283,0368,0511,0414,722,938,158,791,8138,0209,0326,0424,0590,0516,425,742,665,5102,0154,0233,0365,0474,0660,0618,028,146,772,0112,0169,0256,0400,0520,0723,0719,430,450,477,7121,0182,0276,0432,0562,0781,0820,832,553,983,1130,0195,0295,0461,0600,0835,0922,034,457,288,1138,0207,0313,0490,0637,0885,01023,236,360,392,9145,0218,0330,0516,0671,0933,01124,438,063,297,4152,0229,0346,0540,0703,0977,01225,439,766,0102,0159,0239,0362,0565,0735,01022,01326,541,468,7106,0165,0249,0376,0587,0764,01062,01427,542,971,3110,0172,0258,0391,0611,0794,01104,01629,445,976,3117,0184,0276,0418,0653,0849,01181,01831,248,780,9125,0195,0293,0443,0692,0900,01252,01932,049,982,9128,0200,0300,0454,0710,0923,01284,02032,851,385,3131,0205,0308,0467,0730,0949,01320,02133,752,687,4135,0210,0316,0479,0748,0973,01350,02436,056,293,4144,0225,0338,0512,0800,01040,01443,02536,757,495,3147,0229,0345,0522,01059,01473,02637,458,597,2150,0234,0352,01080,01502,02738,259,699,0153,0238,0358,01100,02838,960,7101,0155,0243,0365,03040,262,9104,0161,0251,0TÜV · SV · . . -729 · F3241,564,8108,0166,0259,03442,866,9111,0171,0268,04046,4Fig. 901 / 911Capacity water incl. 10% overpressurem a x . s e t p r e s s u r e s t a i n l e s s s t e e l v e r s i o nEdition 08/01 - Data subject to alteration6ARI-SAFE -Heating-safety valve - Figure 903* > 10 bar 25.903 EN-JS1049 or 35.903 1.0619+N Figure Nom. pressure Material Nominal diameter Temperature range Flanges Flangeholes/-thick-ness tolerances 12.903PN 16 / 16EN-JL1040DN 20/32 up to DN 150/250- 10°C up to +120°C DIN EN 1092-2DIN 2533 / 2533Type-test approvalFigure 903spring loaded TÜV · SV · . . -688 · D/G/H Heating-safety valveSet gauge pressure see …Capacity“Requirement Acc. to TRD 721 Part 6, material selection observe TRD! (EN-JL1040 max. 10 bar)*Application Acc. to DIN EN 12828 Heating systems in buidlingsConstruction Standard safety valve, spring loaded, direct loaded metal seat with EPDM insert, EPDM-bellow,closed spring bonnet with control hole, open lifting device, stainless steel seat and spindle Sizing Acc. to TRD Part 6.2.5, see capacity-tables Figure 903Order data:ARI-SAFE-safety valve - Figure ....., DN ... / ..., PN .. / .., Material ........, Set gauge pressure .... barThe safety valves are available with pressure rates 0,5 bar.SAFESpecial version:Drainhole with plugDN20 / 3225 / 4032 / 5040 / 6550 / 8065 / 10080 / 125100 / 150125 / 200150 / 250Weight (kg)8,59,513,52026395382125165EPDM-disc, soft seal insert;(Design DN 20 - 100)(Design DN 125 - 150)EPDM-bellowEdition 01/06 - Data subject to alteration7Set gaugepressure in bar Capacity Saturated steam in kg/h Heating capacity in kWInlet diameter DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 100DN 125DN 1501,0kg/hkW 203124317193526321811495127077421401310324519805070309560303680838551201,5kg/h kW 272164425257707427109065817001030287517404355263068004110805048701120067702,0kg/h kW 3051834772857924741220731190011403220193048802920762545701012560601408084302,5kg/h kW 3662175723409505651460870228513603865230058553480914554401199071201666099003,0kg/h kW 42425066239111006491695100026451560447526406775400010600625013880819019300114003,5kg/h kW 48228375444212507351930113030151770510029907720453012050707015600915021700127004,0kg/h kW 535312837488139081021401250335019505650330085705000134007800175501020024400142004,5kg/h kW 588341920533153088523551360368021306215360094105460147108520193001110026850156005,0kg/h kW 64037010005781665960256514804000231067703900102605910160009240210001210029250169005,5kg/h kW 694398108562218001030277515904340249073304200111006370173509950227701300031660182006,0kg/h kW 7454261165666194011002990170046652660789045001195068201865010600245001400034050194006,5kg/h kW 8004541250709207511803200181049952840844047901279072602000011300262201490036450207007,0kg/h kW 8504811330752221012503400193053203000900050801360077002130012000279001580038800220007,5kg/h kW 9045091415795234513203615203056503180955053701447081402260012700296601670041250232008,0kg/h kW 95753614958372485139038202140598033501010056601530085802390013400313501760043600245009,0kg/h kW 1060590166092127551530424523606630368511200623016950943526500147403480019340484002690010,0kg/h kW 116564318201000302516704665257072904010123006790186501030029150160003825021100532002930011,0kg/h kW 127069519851085330018005080278079404340134007340203001110031750174004160022800580003170012,0kg/h kW 137574521501165357019405500299085904670145007890220001200034350187004510024500627003400013,0kg/h kW 148079823101250384020705920319092504990156008430236501280037000200004850026200675003640014,0kg/h kW 158085024751325411022006340339099005300167008970253501360039600212005200027900723003870015,0kg/h kW 1690900264014054385233067603590105505620178009500270001440042200225005540029500770004100016,0kg/h kW179095028001480465524607170379011200593018950100002870015200448002370058800311008180043300Calculated acc. to TRD 721 Part 6 and AD2000-A2Fig. 903Capacity saturated steam incl. 10% overpressureCapacity - water in kg/h Sizing: 1 l/h ^= 1 kW Set gaugepressure in bar12345678910111213141516DN 207300104001270014700164001800019400210002200023000245002550026500275002800029500DN 2511500160002000023000255002800030500325003450036500380004000041500425004400046000Sizing safety valves for the volume flow of water expansion (DIN 4751 p2 - item 8.1)Spring ranges in bar (gauge)DN 20DN 25 - 50DN 65DN 80DN 100DN 125DN 1500,2 - 0,50,2 - 0,50,2 - 0,50,2 - 0,50,2 - 0,50,2 - 0,40,2 - 0,50,52 - 10,52 - 10,52 - 10,52 - 10,52 - 10,42 - 0,750,52 - 11,05 - 1,51,05 - 1,51,05 - 1,51,05 - 1,51,05 - 1,50,77 - 1,11,05 - 1,51,55 - 2,51,55 - 21,55 - 21,55 - 21,55 - 21,15 - 1,51,55 - 1,92,55 - 4,52,05 - 2,72,05 - 2,72,05 - 2,72,05 - 2,51,55 - 1,91,95 - 2,34,6 - 8,52,75 - 3,62,75 - 3,62,75 - 3,62,55 - 31,95 - 2,52,35 - 2,78,6 - 163,7 - 53,7 - 53,7 - 53,05 - 3,62,55 - 2,952,75 - 3,35,1 - 95,1 - 95,1 - 93,7 - 5 3 - 43,35 - 4,19,1 - 169,1 - 169,1 - 145,1 - 94,1 - 5,74,2 - 5,514,1 - 169,1 - 145,8 - 8,25,6 - 7,414,1 - 168,3 - 127,5 - 1112,1 - 1611,1 - 16Edition 06/04 - Data subject to alteration8ARI-SAFE -Low pressure steam-safety valve - Figure 904Figure Nom. pressure Material Nominal diameter Temperature range Flanges Flangeholes/-thick-ness tolerances 12.904PN 16 / 16EN-JL1040DN 20/32 up to DN 150/250- 10°C up to +120°C DIN EN 1092-2DIN 2533 / 2533Type-test approval Figure 904spring loaded TÜV · SV · . . -688 · D Low pressure steam-safety valveSet gauge pressure see …Capacity“Requirement Acc. toTRD 721 Part 5Application For low pressure steamgenerators up to 1 bar, DIN 4750 and DIN EN 12828 Heating systems in buidlingsConstruction Standard safety valve, spring loaded, direct loaded, EPDM-bellow, closed bonnet with control hole, open lifting device,stainless steel seat and spindle Sizing See capacity-tables Figure 904Order data:ARI-SAFE-safety valve - Figure ....., DN ... / ..., PN .. / .., Material ........, set gauge pressure .... barSAFEDN20 / 3225 / 4032 / 5040 / 6550 / 8065 / 10080 / 125100 / 150125 / 200150 / 250Weight Fig. 904 (kg)8,59,513,52026395382125165Fig. 904Metal seal; EPDM-bellow(Design DN 20 - 100)(Design DN 125 - 150)Edition 02/06 - Data subject to alteration9Fig. 904CapacityConversionrates:1 kW = 860 kcal/h* = 0,86 Mcal/h* = 3,6 MJ/h * not lawful units1 Mcal/h* = 1000 kcal/h* = 1,163 kWARI-SAFE- Figure 904 spring loaded, 0,2 - 1 bar set pressure.Set gauge-pressure CapacitySaturated steam in kg/hFigure 904bar DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 100DN 125DN 1500,2kg/h 7211318728945176311551805224131160,3kg/h 9214423936857597214722300286739860,4kg/h 110172286440688116317622753338047000,5kg/h 125196325501783132520063135385853650,6kg/h 142223370569889150322773557431760040,7kg/h 158248412634990167525373964474866030,8kg/h 1732714506931082183027724331520172330,9kg/h 1792924857461166197129864666561678091,0kg/h203317526811127021403245507060308385Edition 01/06 - Data subject to alteration10DN20253240506580100Weight (kg)55,589,511,515,520,533Weight, bellow design (kg)5,46910,512,817,52337without metal bellow with metal bellow Superimposed back pressure no backpressure allowedon request Built up back pressuremax. 10% from set pressure (gauge)(higher on request)on requestARI-SAFE-P -Standard safety valve D/G/FFig. .. .921closed lifting device closed bonnetFig. .. .922open lifting device closed bonnet Fig. .. .923gastight cap closed bonnet Fig. .. .924open lifting device open bonnetFigureNom. pressure Material Nominal diameter Temperature range FlangesFlangeholes/-thick-ness tolerances 12.921 / 922 / 923/ 924PN 16EN-JL1040DN 20 up to DN 100- 10°C up to +300°C DIN EN 1092-2DIN 253335.921 / 922 / 923 / 924PN 40 1.0619+N DN 20 up to DN 100- 10°C up to +450°C DIN EN 1092-1DIN 254555.921 / 923PN 401.4408DN 20 up to DN 100- 60°C up to +400°C DIN EN 1092-1DIN 2545Type-test approvalStandard valve:TÜV · SV · . . -811 · D/G Figure 921 - 924Set gauge pressure see …Capacity“Standard valve:TÜV · SV · . . -821 · FFigure 921 / 923Requirement Acc. to EN ISO 4126-1, VdTÜV-leaflet 100, AD2000-A2, TRD 421, material selection observe TRB No.45!Application EN-JL1040; 1.0619+N steam, neutral gases, vapours and liquids 1.4408steam, aggressive gases, vapours and liquidsConstruction Safety valve, spring loaded, direct loadedSizingFor steam, air and water see capacity tables, calculation acc. to EN ISO 4126-1, TRD 421 and AD2000-A2,necessary information for valve layout:Medium gasform:Mass flow (kg/h), molar mass (kg/kmol), temperature (°C), set gauge pressure (bar), back gauge pressure (bar)Medium liquid:Mass flow (kg/h), density (kg/m3), viscosity, temperature (°C), set gauge pressure (bar), back gauge pressure (bar)Order data:ARI-SAFE-P-safety valve - Figure ....., DN ...., PN ...., Material ........, set gauge pressure .... barSAFE-PEdition 01/06 - Data subject to alteration1)DN 20 - 0,3barStainless steel version max. 24 bar for saturated steam Set gauge-pressure I Saturated steam in kg/hII Air 0°C and 1.013 bara in Nm 3/hbar DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 100IIIIIIIIIIIIIIIIIIIIIIII0,21)2024232733384451851001421671952293053580,423283441485865781261522092522903494505460,527323947556874901441762392923324055206320,6303743536277821021621992673303724595807170,83645516373911001251892373234044355456808521415258738410611414421827437046650063178598626886971231391781882403624616107778301061130016573951231371761972532653405106588601103118015141840236541191541712212463183304286408261070138514701902230029705142185205266295383396515765995128016651760229027503580616621723831134344846060289011651495195020502680320041807189248272356391513525689101513301700223023403065365047908213279305401440577590776114015001910251526303450410053909236311340446490642655863126516702120280029103840455060001025934237049153570772095013901835233030803200422550006600123064054405816308378501125164021702750364537805000590078001435246850567173096798013001890251031704200435057806800900016400530570761825109611051475214028453590477049206550770010200184455936408519201226123516452390318040005340550073208600114502049065670594110201356136518202640352044305900608081009500126502254071877010311110148514951995289038554850646566608870104001385024585781840112112101615163021703140419052707030724096501130015100256098128751167126016801690225032704360548073107530100401176015680266308449101211131017451760234034004530570075957820104001220016300286809079751302140518751890252036504860612081608400112001310017500307309691045139015052000202026903900520065508720899012000140001870032775103211101480160021302150287041605540698092909580127501500019900351126162023303130604010130139002170036115516652390321562201042014300223604012831840265035606880115001585024700Fig. 921 / 922 / 923 / 924Capacity saturated steam / air incl. 10% overpressurem a x . s e t p r e s s u r e s t a i n l e s s s t e e l v e r s i o nSpring ranges in bar (gauge)DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 1000,3 - 0,50,2 - 0,60,2 - 0,550,2 - 0,40,2 - 0,40,2 - 0,50,2 - 0,60,2 - 0,50,52 - 1,00,62 - 1,10,57 - 0,80,42 - 0,60,42 - 0,60,52 - 1,20,62 - 1,20,52 - 1,11,05 - 1,41,15 - 2,00,82 - 1,20,62 - 1,10,62 - 1,21,25 - 2,01,25 - 2,11,15 - 1,71,45 - 1,92,05 - 2,71,25 - 2,01,15 - 1,81,25 - 1,82,05 - 2,72,15 - 2,61,75 - 2,41,95 - 2,52,75 - 3,72,05 - 3,31,85 - 2,71,85 - 2,52,75 - 3,42,65 - 3,22,45 - 3,12,55 - 3,53,8 - 5,03,35 - 5,22,75 - 4,32,55 - 3,23,45 - 4,53,25 - 4,23,15 - 4,03,55 - 4,05,1 - 8,05,3 - 8,04,4 - 6,03,25 - 4,54,6 - 5,54,3 - 5,54,1 - 5,04,1 - 5,58,1 - 10,58,1 - 11,56,1 - 9,04,6 - 8,55,6 - 6,85,6 - 6,55,1 - 8,05,6 - 7,010,6 - 15,011,6 - 16,59,1 - 12,08,6 - 13,06,9 - 8,56,6 - 9,08,1 - 11,07,1 - 10,515,1 - 23,016,6 - 22,012,1 - 17,013,1 - 17,08,6 - 14,09,1 - 12,011,1 - 17,510,6 - 17,023,1 - 35,022,1 - 30,017,1 - 30,017,1 - 23,014,1 - 23,012,1 - 16,517,6 - 27,517,1 - 25,035,1 - 40,030,1 - 40,030,1 - 40,023,1 - 34,023,1 - 34,016,6 - 20,027,6 - 40,025,1 - 37,034,1 - 40,034,1 - 40,020,1 - 33,037,1 - 40,033,1 - 40,0Fig. .. .921closed lifting device closed bonnet Fig. .. .922open lifting device closed bonnet Fig. .. .923gastight cap closed bonnet Fig. .. .924open lifting device open bonnetSAFE-P1)DN20 - 0,3 barGauge press.Water20°C in t/h bar DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 1000,21)0,860,971,41,953,636,338,3613,060,51,111,542,213,095,7410,013,2220,611,572,173,134,378,1214,1518,6929,222,223,074,426,1711,4820,026,441,332,723,765,427,5614,0724,532,450,643,144,356,268,7316,2428,337,458,453,514,867,09,7618,1631,641,865,363,855,327,6610,6919,8934,645,871,674,165,758,2811,5521,537,449,577,384,456,148,8512,3523,040,052,982,694,726,529,3913,124,442,456,187,6104,976,879,8913,8125,744,759,192,4125,447,5310,8415,1228,149,064,8100,2145,888,1311,7116,3430,452,969,9109,3166,298,6912,5117,4632,556,674,8116,8186,679,2213,2718,5234,460,079,3123,9207,039,7214,019,5336,363,383,6130,6227,3710,1914,720,538,166,387,7137,0247,710,6415,3321,439,869,391,6143,1257,8610,8615,6421,840,670,793,3146,0268,011,0615,9222,241,372,095,1148,6288,311,4716,5223,142,974,798,7154,2308,611,8817,123,944,477,3102,2159,7359,2812,8318,4725,847,983,5110,4172,5369,413,018,726,148,784,7111,9174,9409,9213,7119,7527,651,389,3118,0184,4Fig. 921 / 923Capacity water incl. 10% overpressurem a x . s e t p r e s s u r e s t a i n l e s s s t e e l v e r s i o nStainless steel-bellow: Spring ranges in bar (gauge)DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 1003,0 - 5,53,0 - 4,83,0 - 4,53,0 - 4,53,0 - 3,53,0 - 3,53,0 - 3,53,0 - 4,55,6 - 8,04,9 - 6,04,6 - 8,04,6 - 5,73,6 - 5,03,6 - 4,33,6 - 4,94,6 - 6,58,1 - 12,06,1 - 8,08,1 - 11,05,8 - 10,05,1 - 7,04,4 - 5,95,0 - 7,06,6 - 10,012,1 - 21,08,1 - 12,511,1 - 14,510,1 - 16,07,1 - 10,56,0 - 7,57,1 - 9,010,1 - 18,021,1 - 27,512,6 - 16,014,6 - 21,016,1 - 22,010,6 - 15,57,6 - 8,89,1 - 11,018,1 - 35,027,6 - 40,016,1 - 20,521,1 - 40,022,1 - 31,015,6 - 20,08,9 - 14,011,1 - 14,720,6 - 30,031,1 - 40,020,1 - 40,014,1 - 21,014,8 - 18,830,1 - 40,021,1 - 30,018,9 - 35,030,1 - 40,0Design with bellow as standard valve (only Fig. 921/923)DN 20DN 25DN 32DN 40DN 50DN 65DN 80DN 100d o in mm 1215182029364455A o in mm 2113177254314661101815202376ARI-SAFE-TC -Full lift safety valve D/GStandard safety valve FFig. 25 .941 closed lifting deviceFig. 25 .942open lifting deviceFig. 25 .943gastight capFigure Nom. pressure Material Nominal diameter Temperature range Thread25.941 / 942 / 943PN 40EN-JS1049DN 15 up to DN 25- 10°C up to +350°C DIN ISO 228 Part 1 55.941 / 943PN 40 1.4408DN 15 up to DN 25- 60°C up to +400°C DIN ISO 228 Part 1Type-test approval Full lift valve:TÜV · SV · . . -995 · D/G Figure 941 - 943Set gauge pressure see…Capacity“Standard valve:TÜV · SV · . . -1005 · F Figure 941 / 943Requirement Acc. to EN ISO 4126-1, VdTÜV-leaflet 100, AD2000-A2, TRD 421Application EN-JS1049steam, neutral gases, vapours and liquids 1.4408steam, aggressive gases, vapours and liquidsConstruction Safety valve, spring loaded, direct loadedSizing for steam, air and water see capacity tables, calculation acc. to EN ISO 4126-1, TRD 421 and AD2000-A2 necessary information for valve layout:Medium gasform:Mass flow (kg/h), molar mass (kg/kmol), temperature (°C), set gauge pressure (bar), back gauge pressure (bar)Medium liquid:Mass flow (kg/h), density (kg/m3), viscosity, temperature (°C), set gauge pressure (bar), back gauge pressure (bar)Order data:ARI-SAFE-TC-safety valve - Figure ....., DN ... , PN .. , Material ........, set gauge pressure .... barSAFE-TCDN152025Weight (kg)3,53,53,8Weight, bellow design (kg)4,44,44,7without metal bellow with metal bellow Superimposed back pressure no backpressure allowed on requestBuilt up back pressure max. 10% from set pressure (gauge)(higher on request)on request。

安全阀公称通径与流道直径对照表摘要:1.安全阀公称通径与流道直径的概念2.安全阀公称通径与流道直径的关系3.安全阀公称通径对照表正文:一、安全阀公称通径与流道直径的概念安全阀是一种保护设备,用于在系统压力超过规定值时自动排放介质,以保证系统的安全运行。

在安全阀中,有几个重要的尺寸参数,包括公称通径、流道直径等。

公称通径,又称平均外径,是指安全阀(管口)标准化以后的标准直径,以dn 表示,单位为mm。

它是参考的一个数值,与加工尺寸呈不严格的关系。

公称通径的数值是取阀门的外径与内径的平均值,习惯上也称为口径。

流道直径,定义为安全阀对应于流道面积的直径,亦称为喉径。

流道直径应该小于公称通径,其具体数值需要参考相应的标准规范。

二、安全阀公称通径与流道直径的关系安全阀的公称通径与流道直径之间的关系,根据安全阀的类型和设计要求有所不同。

一般来说,全启式安全阀的公称直径比流道直径大二级,微启式安全阀的公称直径比流道直径大一级。

以全启式安全阀为例,如果安全阀直径dn50mm,那么流道直径就是dn32mm,中间相隔dn40mm;如果安全阀直径dn80mm,那么流道直径就是dn50mm,中间相隔dn65mm。

而微启式安全阀的公称直径比流道直径大一级,例如,如果安全阀直径dn50mm,那么流道直径就是dn40mm;如果安全阀直径dn80mm,那么流道直径就是dn65mm,以此类推。

三、安全阀公称通径对照表安全阀公称通径对照表(公称通径对照表dn10)列出了不同公称通径对应的流道直径和喉径。

这些数据可以帮助工程师在设计和选用安全阀时,根据系统的具体要求,选择合适的安全阀尺寸。

总结:安全阀公称通径与流道直径是安全阀的两个重要尺寸参数。

它们之间的关系取决于安全阀的类型和设计要求。