USP 711 溶出度2012年2月最新美国药典溶出度检查

- 格式:pdf

- 大小:1.85 MB

- 文档页数:8

<711> DISSOLUTION溶出度(USP39-NF34 Page 540) General chapter Dissolution <711> is being harmonized with the corresponding texts of the European Pharmacopoeia and/or the Japanese Pharmacopoeia. These pharmacopeias have undertaken to not make any unilateral change to this harmonized chapter.通则<711>溶出度与欧盟药典和日本药典中的相应部分相统一。

这三部药典承诺不做单方面的修改。

Portions of the present general chapter text that are national USP text, and therefore not part of the harmonized text, are marked with symbols to specify this fact.本章中的部分文字为本国USP内容,并没有与其他药典统一。

此部分以()标注。

This test is provided to determine compliance with the dissolution requirements where stated in the individual monograph for dosage forms administered orally. In this general chapter, a dosage unit is defined as 1 tablet or 1 capsule or the amount specified. Of the types of apparatus designs described herein, use the one specified in the individual monograph. Where the label states that an article is enteric coated and a dissolution or disintegration test does not specifically state that it is to be applied to delayed-release articles and is included in the individual monograph, the procedure and interpretation given for Delayed-Release Dosage Forms are applied, unless otherwise specified in the individual monograph.本测试用于检测药品口服制剂的溶出度是否符合各论中的规定。

美国药典附录《771》溶出度中收载的混合样品测定法可以借

鉴

周帼雄;何铭新;张玫

【期刊名称】《中国药品标准》

【年(卷),期】2003(004)001

【摘要】@@ 美国药典24版和25版附录〈771〉DISSOLUTION中增加了Procedure for a Pooled Sample for Capsules,Uncoated Tablets,and Plain Coated Tablets.有如下规定:

【总页数】1页(P63-63)

【作者】周帼雄;何铭新;张玫

【作者单位】江苏省药品检验所,南京,210008;广州市药品检验所,广州,510160;江苏省药品检验所,南京,210008

【正文语种】中文

【中图分类】R95

【相关文献】

1.《美国药典》35版附录"《62》非无菌产品微生物检查:控制菌检查法"中两个问题的探讨 [J], 刘洪祥;曹晓云

2.中、美、日、欧的法定溶出度测定法之比较 [J], 余仲平

3.对《中国药典》红霉素片溶出度检查中溶出量测定法的疑问 [J], 钱亚萍

4.溶出度释放度测定法在《中国药典》1995年版中的应用 [J], 吴志敏;吴宝祥;张

瑞琦;张蕴;韩英玉;吴志远;吴景时

5.地质样品中8种痕量贵金属元素的等离子体质谱快速测定法 [J], 李一夫

因版权原因,仅展示原文概要,查看原文内容请购买。

![[精品]对乙酰氨基酚片溶出度测定](https://uimg.taocdn.com/8619601c443610661ed9ad51f01dc281e53a563c.webp)

[精品]对乙酰氨基酚片溶出度测定对乙酰氨基酚片是一种非处方药,用于缓解疼痛、退烧、减轻关节炎和牙痛等。

在药品质量控制方面,溶出度测定是测定药品释放活性成分的关键方法之一,可用于评估药品的有效性和一致性。

本实验旨在采用美国药典(USP)提供的方法,测定对乙酰氨基酚片的溶出度。

1.实验原理溶出度是指药品中活性成分从药片或胶囊中释放出来的比例。

药品的溶出度对药效产生影响,因此,需要对它进行检测以确保药品质量达到标准。

常用的溶出度测定方法包括旋转篮法和流动池法。

旋转篮法适用于药片和胶囊,有利于模拟胃肠道的运动。

而流动池法适用于注射剂和眼药水等液体制剂。

本实验采用的是旋转篮法,将对乙酰氨基酚片放入篮中,放到模拟胃肠道的容器中,并在旋转的条件下采集样品,测定其对乙酰氨基酚溶出度。

2.实验步骤2.1 准备a.先将篮子和箔纸放在烘箱中烘干,预热至50℃左右。

b.称取一定量的对乙酰氨基酚片粉末,将其压制成药片。

c.提取篮子和箔纸,稍稍冷却,然后将篮子置于箔纸上,放回烘箱中预热至50℃。

d.取一定量的模拟胃液,将其预热至37℃。

2.2 实验操作a.取一个已称好药片,将其放入篮子中,然后盖上篮子盖子,确保药片合适地固定在篮子中。

b.用钢丝将篮子悬挂在模拟胃液的容器中,保证篮子不接触容器底部。

c.启动旋转器,设置旋转速度为50rpm,开始测定。

d.每个时间点收集一个样品。

将采样器插入模拟胃液中,确保其到达药片所在的位置(通常为时间的1/3、2/3和3/3),并将样品收集到样品瓶中,以供后续分析。

e.持续测定至90分钟,并在每个时间点记录剩余的药片和溶出度数据。

f.一旦测定完成,将篮子和样品在干燥的环境下过夜。

2.3数据处理a.逐一记录采集的样品的时间和对乙酰氨基酚溶出量。

b.将数据绘制成输药时间与对乙酰氨基酚溶出量的关系图。

c.计算药物的平均溶出度,这是从剩余药物的总质量中计算出来的。

3.实验注意事项a.对乙酰氨基酚片的制备需准确称取药材,不得有误差。

药品溶出度的限度

药品溶出度的限度可以根据欧洲药典(EP)、美国药典(USP)等药典标准来确定。

根据这些标准,一般要求药品在一定时间范围内,溶出的量达到一定的百分比。

具体的限度取决于药品的性质、用途和剂型等因素。

例如,对于口服固体制剂,药典要求通常规定在30分钟至120分钟内,药品的释放量应达到某个百分比,如EP要求在45分钟内释出至少75%的活性成分。

对于注射剂或其他需要快速溶出药效的制剂,药典通常要求90%的药品在特定时间内(如30分钟)溶解。

此外,一些国家和地区可能有自己的药典标准,药品溶出度的限度可能会有所不同。

因此,具体的药品溶出度的限度应根据适用的药典标准进行评估和确定。

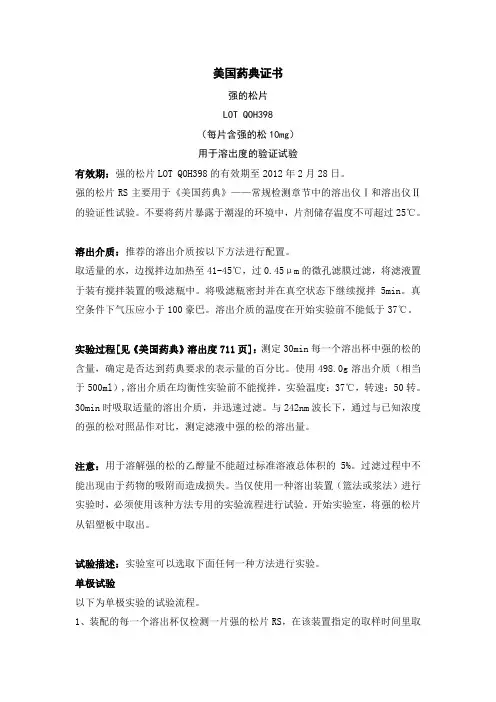

美国药典证书强的松片LOT QOH398(每片含强的松10mg)用于溶出度的验证试验有效期:强的松片LOT QOH398的有效期至2012年2月28日。

强的松片RS主要用于《美国药典》——常规检测章节中的溶出仪Ⅰ和溶出仪Ⅱ的验证性试验。

不要将药片暴露于潮湿的环境中,片剂储存温度不可超过25℃。

溶出介质:推荐的溶出介质按以下方法进行配置。

取适量的水,边搅拌边加热至41-45℃,过0.45μm的微孔滤膜过滤,将滤液置于装有搅拌装置的吸滤瓶中。

将吸滤瓶密封并在真空状态下继续搅拌5min。

真空条件下气压应小于100豪巴。

溶出介质的温度在开始实验前不能低于37℃。

实验过程[见《美国药典》溶出度711页]:测定30min每一个溶出杯中强的松的含量,确定是否达到药典要求的表示量的百分比。

使用498.0g溶出介质(相当于500ml),溶出介质在均衡性实验前不能搅拌。

实验温度:37℃,转速:50转。

30min时吸取适量的溶出介质,并迅速过滤。

与242nm波长下,通过与已知浓度的强的松对照品作对比,测定滤液中强的松的溶出量。

注意:用于溶解强的松的乙醇量不能超过标准溶液总体积的5%。

过滤过程中不能出现由于药物的吸附而造成损失。

当仅使用一种溶出装置(篮法或浆法)进行实验时,必须使用该种方法专用的实验流程进行试验。

开始实验室,将强的松片从铝塑板中取出。

试验描述:实验室可以选取下面任何一种方法进行实验。

单极试验以下为单极实验的试验流程。

1、装配的每一个溶出杯仅检测一片强的松片RS,在该装置指定的取样时间里取样,并计算溶出度。

将溶出度值进行对数转换,并计算其相应的均数及标准偏差。

对于12或14个溶出杯的仪器,无需进行更多的试验。

2、对于少于12个溶出杯的仪器,使用更多的片剂重复步骤1(完成12片或14片的检测),将计算得出的溶出度值进行对数转换,并计算其均数及标准偏差。

3、分别计算步骤1及步骤2均数的平均值和标准偏差的平均值.(对于有12个或14个溶出杯的溶出仪,仅适用步骤1的均数及标准偏差)4、将步骤3的结果折算成几何平均数(GM)和相对标准偏差(CV%),详见计算举例。

中美药典通则对比:

1.定义和范围:中美药典通则方法在定义和范围上有所不同。

例如,美国药典(USP)涵盖了药品、医疗器械、食品补充剂、生物制品等领域的检测方法,而中国药典(ChP)主要针对药品的检测方法。

2.检测项目:中美药典通则方法的检测项目也有所不同。

例如,

USP对某些药品的溶出度、释放度等进行了更详细的规定,而ChP则对药品的含量、有关物质等进行了更严格的要求。

3.检测方法:在具体的检测方法上,中美药典通则方法也存在

差异。

例如,对于同一种药品,USP和ChP可能采用不同的色谱条件、流动相组成、检测波长等。

此外,在溶出度试验中,USP和ChP也可能采用不同的溶出介质、转速等条件。

4.更新频率:中美药典通则方法的更新频率也有所不同。

USP

更新较快,每年都有大量的通则方法进行更新或修订。

而ChP 的更新相对较慢,可能每年只更新一小部分通则方法。

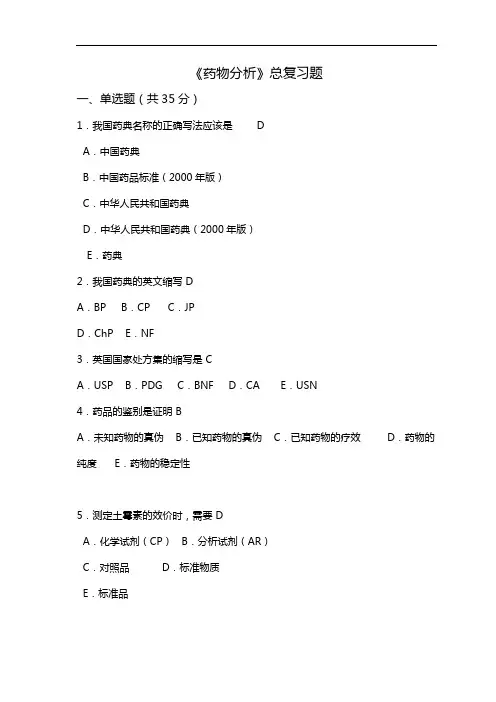

《药物分析》总复习题一、单选题(共35分)1.我国药典名称的正确写法应该是 DA.中国药典B.中国药品标准(2000年版)C.中华人民共和国药典D.中华人民共和国药典(2000年版)E.药典2.我国药典的英文缩写 DA.BP B.CP C.JPD.ChP E.NF3.英国国家处方集的缩写是 CA.USP B.PDG C.BNF D.CA E.USN4.药品的鉴别是证明 BA.未知药物的真伪 B.已知药物的真伪 C.已知药物的疗效 D.药物的纯度 E.药物的稳定性5.测定土霉素的效价时,需要 DA.化学试剂(CP) B.分析试剂(AR)C.对照品 D.标准物质E.标准品6.中国药典(2000年版)规定称取2.0g药物时,系指称取 D A.2.0g B.2.1g C.1.9gD.1.95g~2.05g E.1.9g~2.1g7.中国药典(2000年版)规定称取0.1g药物时,系指称取 E A.0.15g B.0.095g C.0.11gD.0.095g~0.15g E.0.06g~0.14g8.含锑药物的砷盐检查方法为 CA.古蔡法B.碘量法C.白田道夫法D.Ag-DDCE.契列夫法9.药物中杂质的限量是指 EA.杂质是否存在B.杂质的合适含量C.杂质的最低量D.杂质检查量E.杂质的最大允许量10.中国药典中收载的砷盐检查方法为 DA.摩尔法B.碘量法C.白田道夫法D.Ag-DDCE.契列夫法11.含锑药物的砷盐检查方法为 CA.古蔡法B.碘量法C.白田道夫法D.Ag-DDCE.契列夫法12.药物中杂质的限量是指 EA.杂质是否存在B.杂质的合适含量C.杂质的最低量D.杂质检查量E.杂质的最大允许量13.中国药典中收载的砷盐检查方法为 D A.摩尔法 B.碘量法 C.白田道夫法D.Ag-DDCE.契列夫法14.药品的鉴别是证明 BA.未知药物的真伪 B.已知药物的真伪C.已知药物的疗效 D.药物的纯度E.药物的稳定性15.相对标准差表示的应是 CA.准确度 B.回收率 C.精密度D.纯净度 E.限度_ 16.用移液管量取的25ml溶液,应记成 CA.25ml B.25.0ml C.25.00mlD.25.000ml E.25±1ml17.以下三个数字0.5362、0.0014、0.25之和应为 AA.0.79 B.0.788 C.0.787D.0.7876 E.0.818.表示两变量指标A与C之间线性相关程度常用A.相关规律 B.比例常数 C.相关常数 D.相关系数 E.精密度19.减小偶然误差的方法是A.做空白试验 B.做对照实验C.做回收试验 D.增加平行测定次数E.选用多种测定方法20. 苯巴比妥中检查的特殊杂质是 DA. 巴比妥B. 间氨基酚C. 水杨酸D. 中性或碱性物质E. 氨基酚21. 司可巴比妥钠《中国药典》规定的含量测定方法为 BA. 中和法B. 溴量法C. 碘量法D. 紫外分光法E. 高锰酸钾法22. 于Na2CO3溶液中加AgNO3试液,开始生成白色沉淀经振摇即溶解,继续加AgNO3试液,生成的沉淀则不再溶解,该药物应是 EA . 盐酸可待因 B. 咖啡因 C. 新霉素D. 维生素CE. 异戊巴比妥23. 与NaNO2~H2SO4反应生成橙黄至橙红色产物的药物是 AA. 苯巴比妥B. 司可巴比妥C. 巴比妥D. 硫喷妥钠E. 硫酸奎宁24. 中国药典(2000年版)采用AgNO3滴定液(0.1 mol/L)滴定法测定苯巴比妥的含量时,指示终点的方法应是: DA. K2CrO4溶液B. 荧光黄指示液C. Fe(III)盐指示液D. 电位法指示终点法E. 永停滴定法25. 银量法测定苯巴比妥钠含量时,若用自身指示法来判断终点,样品消耗标准溶液的摩尔比应为: CA. 1:2B. 2:1C. 1:1D. 1:4E. 以上都不对26. 下列巴比妥类药物水溶液中酸性最小的药物是 DA. 苯巴比妥B. 巴比妥C. 异戊巴比妥D. 异戊巴比妥钠E. 以上都不对27. 用酸量法测定巴比妥类药物含量时,适用的溶剂为 DA. 碱性B. 水C. 酸水D. 醇-水E. 以上都不对28. 司可巴比妥钠(分子量为260.27)采用溴量法测定含量时,每l ml溴滴定液(0.1 mol/L)相当于司可巴比妥钠的毫克(mg)数为 EA.1.301B. 2.603C. 26.03D. 52.05E. 13.0129. ChP(2000)注射用硫喷妥钠采用的含量测定方法为 AA. 紫外分光光法B. 银量法C. 酸碱滴定法D. 比色法E. 差示分光光度法30. 凡取代基中含有双键的巴比妥类药物,如司可巴比妥钠,中国药典(1990年版)采用的方法是 DA. 酸量法B. 碱量法C. 银量法D. 溴量法E. 比色法31.巴比妥类药物在吡啶溶液中与铜吡啶试液作用,生成配位化合物,显绿色的药物是 EA. 苯巴比妥B. 异戊巴比妥C. 司可巴比妥D. 巴比妥E. 硫喷妥钠32. 硫喷妥钠与铜盐的鉴别反应生成物为 CA. 紫色B. 绿色C. 蓝色D. 黄色E. 紫堇色33. 维生素B1的鉴别方法是 BA.三氯化铁反应B. 硫色素反应C. 柯柏反应D.与碱性酒石酸铜试液反应E. 双缩脲反应34. 维生素E《中国药典》规定的含量测定方法为 EA.非水溶液滴定法B.旋光法C.HPLC法D.紫外分光法E.GC法35. 硫酸链霉素、硫酸青大霉素的鉴别方法是 CA.三氯化铁反应B. 硫色素反应C. 茚三酮反应D.与碱性酒石酸铜试液反应E. 双缩脲反应36. 硫酸链霉素、硫酸青大霉素的鉴别方法是 EA.三氯化铁反应B. 硫色素反应C. 茚三酮反应D.与碱性酒石酸铜试液反应E. 双缩脲反应37. 醋酸地塞米松的鉴别方法是 DA. 三氯化铁反应B. 水解反应C. 柯柏反应D. 与碱性酒石酸铜试液反应E. 双缩脲反应38. 丙酸睾酮《中国药典》规定的含量测定方法为 CA. 非水溶液滴定法B. 溴酸钾法C. HPLC法D. 紫外分光法E. 旋光法39. 检查热源的制剂是 EA.片剂B. 胶囊剂C. 软膏剂D.颗粒剂E. 注射剂40. 硬脂酸镁对下列哪中含量测定方法有干扰 AA.非水溶液滴定法B. 旋光法C.碘量法D.亚硝酸钠滴定法E.汞量法[B型题]1~4A.ChP B. C. D. E.1.美国药典 USP2.英国药典 BP3.日本药局方 JP4.美国国家处方集 NF5~85.药品的质量标准应处在药典的正文6.对溶解度的解释应处在药典的凡例7.通用检测方法应处在药典的附录8.制剂通则附录9-131. 铁盐检查 NH4SCN试液2. 硫酸盐检查 BaCl2试液3. 氯化物检查稀HNO34. 砷盐检查 Ag-DDC试液14-17A.C.E. NH4SCN试液5. 重金属检查硫代乙酰胺试液6. 硫酸盐检查 BaCl2试液7. 氯化物检查 AgNO3试液8. 砷盐检查 KI-SnCl2试液18-221. 铁盐检查 NH4SCN试液2. 硫酸盐检查 BaCl2试液3. 氯化物检查稀HNO34. 砷盐检查 Ag-DDC试液23-27E. NH4SCN试液5. 重金属检查硫代乙酰胺试液6. 硫酸盐检查 BaCl2试液7. 氯化物检查 AgNO3试液8. 砷盐检查 KI-SnCl2试液28-321.1.2252 1.232.2.5351 2.543.2.5348 2.534.2.5068 2.5133-375.以同量的溶剂替代供试品同法进行测定试验空白试验6.在供试液中加入已知量的标准物或已知量的被测物后,同法进行测定试验回收试验7.用已知量的纯物质作为试样,同法进行测定试验对照试验8.取少许水杨酸,加水溶解,加三氯化铁试液,显紫堇色鉴别试验38-421. 司可巴比妥钠与碘试液的加成反应2. 苯巴比妥亚硝酸钠-硫酸反应3. 硫喷妥钠硫元素反应4. 对乙酰氨基酚水解后重氮化-偶合反应43-47可用以下方法鉴别的药物是:5.与亚硝酸钠—硫酸反应生成橙黄色,随即转为橙红色苯巴比妥6.与甲醛—硫酸反应生成玫瑰红色环苯巴比妥7.与碘试液发生加成反应,使碘试液橙黄色消失司可巴比妥8. 在氢氧化钠液中可与铅离子反应生成白色沉淀,加热后,沉淀变成黑色硫喷妥钠用于鉴别反应的药物硫喷妥钠苯巴比妥9. 与碱溶液共沸产生氨气硫喷妥钠苯巴比妥10. 在碱性溶液中与硝酸银试液反应生成白色沉淀硫喷妥钠苯巴比妥11. 在碱性溶液中与Pb2+离子反应,加热后有黑色沉淀硫喷妥钠12. 与甲醛-硫酸反应生成玫瑰红色环苯巴比妥13. 在酸性溶液中与三氯化铁反应显紫堇色均不可54-58A。

Official February 1, 2012〈711〉 Dissolution 1material 1; a motor; a metallic drive shaft; and a cylindrical 〈711〉 DISSOLUTIONbasket. The vessel is partially immersed in a suitable water bath of any convenient size or heated by a suitable device such as a heating jacket. The water bath or heating device permits holding the temperature inside the vessel atThis general chapter is harmonized with the correspond-37±0.5° during the test and keeping the bath fluid in con-ing texts of the European Pharmacopoeia and/or the Japa-stant, smooth motion. No part of the assembly, including nese Pharmacopoeia . These pharmacopeias have undertaken the environment in which the assembly is placed, contrib-not to make any unilateral change to this harmonized utes significant motion, agitation, or vibration beyond that chapter.due to the smoothly rotating stirring element. An apparatus Portions of the present general chapter text that are na-that permits observation of the specimen and stirring ele-tional USP text, and therefore not part of the harmonized ment during the test is preferable. The vessel is cylindrical,text, are marked with symbols (33) to specify this fact.with a hemispherical bottom and 3with one of the follow-This test is provided to determine compliance with the ing dimensions and capacities: for a nominal 3 capacity of 1dissolution requirements 3where stated in the individual L, the height is 160 to 210 mm and its inside diameter is monograph 3 for dosage forms administered orally. In this 98 to 106 mm; 3for a nominal capacity of 2 L, the height is general chapter, a dosage unit is defined as 1 tablet or 1280 to 300 mm and its inside diameter is 98 to 106 mm;capsule or the amount specified. 3Of the types of apparatus and for a nominal capacity of 4 L, the height is 280 to 300described herein, use the one specified in the individual mm and its inside diameter is 145 to 155 mm 3. Its sides monograph. Where the label states that an article is en-are flanged at the top. A fitted cover may be used to retard teric-coated, and where a dissolution or disintegration test evaporation.2 The shaft is positioned so that its axis is not that does not specifically state that it is to be applied to more than 2 mm at any point from the vertical axis of the delayed-release articles is included in the individual mono-vessel and rotates smoothly and without significant wobble graph, the procedure and interpretation given for Delayed-that could affect the results. A speed-regulating device is Release Dosage Forms is applied unless otherwise specified used that allows the shaft rotation speed to be selected and in the individual monograph. For hard or soft gelatin cap-maintained at the specified rate 3given in the individual sules and gelatin-coated tablets that do not conform to the monograph 3 within ±4%.Dissolution specification, repeat the test as follows. Where Shaft and basket components of the stirring element are water or a medium with a pH of less than 6.8 is specified fabricated of stainless steel, type 316, or other inert mate-as the Medium in the individual monograph, the same Me-rial, to the specifications shown in Figure 1. A basket having dium specified may be used with the addition of purified a gold coating of about 0.0001 inch (2.5 µm) thick may be pepsin that results in an activity of 750,000 Units or less used. A dosage unit is placed in a dry basket at the begin-per 1000 mL. For media with a pH of 6.8 or greater, pan-ning of each test. The distance between the inside bottom creatin can be added to produce not more than 1750 USP of the vessel and the bottom of the basket is maintained at Units of protease activity per 1000 mL.25±2 mm during the test.1The materials should not sorb, react, or interfere with the specimen being Change to read:tested.2If a cover is used, it provides sufficient openings to allow ready insertion of the thermometer and withdrawal of specimens.USP Reference Standards 〈11〉—••(RB 1-Feb-2012) USP Pred-nisone Tablets RS.3Change to read:APPARATUSApparatus 1 (Basket Apparatus)The assembly consists of the following: a vessel, which may be covered, made of glass or other inert, transparentFigure 1. Basket stirring element.the inside bottom of the vessel is maintained during thetest. The metallic or suitably inert, rigid blade and shaft Apparatus 2 (Paddle Apparatus)comprise a single entity. A suitable two-part detachable de-sign may be used provided the assembly remains firmly Use the assembly from Apparatus 1, except that a paddle engaged during the test. The paddle blade and shaft may formed from a blade and a shaft is used as the stirring be coated with a suitable coating so as to make them inert. element. The shaft is positioned so that its axis is not more The dosage unit is allowed to sink to the bottom of the than 2 mm from the vertical axis of the vessel at any point vessel before rotation of the blade is started. A small, loose and rotates smoothly without significant wobble that could piece of nonreactive material, such as not more than a few affect the results. The vertical center line of the blade turns of wire helix, may be attached to dosage units that passes through the axis of the shaft so that the bottom of would otherwise float. An alternative sinker device is shown the blade is flush with the bottom of the shaft. The paddle in Figure 2a. Other validated sinker devices may be used. conforms to the specifications shown in Figure 2. The dis-tance of 25±2 mm between the bottom of the blade andOfficial February 1, 2012〈711〉 Dissolution3ing the environment in which the assembly is placed, con-tributes significant motion, agitation, or vibration beyondthat due to the smooth, vertically reciprocating cylinder. Adevice is used that allows the reciprocation rate to be se-lected and maintained at the specified dip rate 3given inthe individual monograph3 within ±5%. An apparatus thatpermits observation of the specimens and reciprocating cyl-inders is preferable. The vessels are provided with an evap-oration cap that remains in place for the duration of thetest. The components conform to the dimensions shown inFigure 3 unless otherwise specified 3in the individualmonograph3.Figure 2. Paddle stirring element.Figure 2a. Alternative sinker. All dimensions are expressedin mm.Apparatus 3 (Reciprocating Cylinder)NOT ACCEPTED BY THE JAPANESE PHARMACOPOEIAFigure 3. Apparatus 3 (reciprocating cylinder).The assembly consists of a set of cylindrical, flat-bot-tomed glass vessels; a set of glass reciprocating cylinders;inert fittings (stainless steel type 316 or other suitable ma-Apparatus 4 (Flow-Through Cell) terial), and screens that are made of suitable nonsorbingand nonreactive material and that are designed to fit theThe assembly consists of a reservoir and a pump for the tops and bottoms of the reciprocating cylinders; and a mo-Dissolution Medium; a flow-through cell; and a water bath tor and drive assembly to reciprocate the cylinders verticallythat maintains the Dissolution Medium at 37±0.5°. Use the inside the vessels and, if desired, index the reciprocatingspecified cell size 3as given in the individual monograph3. cylinders horizontally to a different row of vessels. The ves-The pump forces the Dissolution Medium upwardssels are partially immersed in a suitable water bath of anythrough the flow-through cell. The pump has a delivery convenient size that permits holding the temperature atrange between 240 and 960 mL per hour, with standard 37±0.5° during the test. No part of the assembly, includ-flow rates of 4, 8, and 16 mL per minute. It must deliver aconstant flow (±5% of the nominal flow rate); the flow pro-file is sinusoidal with a pulsation of 120±10 pulses perminute. A pump without pulsation may also be used. Dis-solution test procedures using a flow-through cell must becharacterized with respect to rate and any pulsation.The flow-through cell (see Figures 4 and 5), of transpar-ent and inert material, is mounted vertically with a filtersystem (specified in the individual monograph) that pre-vents escape of undissolved particles from the top of thecell; standard cell diameters are 12 and 22.6 mm; the bot-tom cone is usually filled with small glass beads of about 1-mm diameter with one bead of about 5 mm positioned atthe apex to protect the fluid entry tube; and a tabletholder (see Figures 4 and 5) is available for positioning ofspecial dosage forms, for example, inlay tablets. The cell isimmersed in a water bath, and the temperature is main-tained at 37±0.5°.Figure 5. Apparatus 4, small cell for tablets and capsules(top), tablet holder for the small cell (bottom). (All meas-urements are expressed in mm unless noted otherwise.)The apparatus uses a clamp mechanism and two O-ringsto assemble the cell. The pump is separated from the disso-lution unit in order to shield the latter against any vibra-tions originating from the pump. The position of the pumpshould not be on a level higher than the reservoir flasks.Tube connections are as short as possible. Use suitably inerttubing, such as polytef, with about 1.6-mm inner diameterand chemically inert flanged-end connections.APPARATUS SUITABILITYThe determination of suitability of a test assembly to per-Figure 4. Apparatus 4, large cell for tablets and capsules form dissolution testing must include conformance to the (top), tablet holder for the large cell (bottom). (All meas-dimensions and tolerances of the apparatus as given above. urements are expressed in mm unless noted otherwise.)In addition, critical test parameters that have to be moni-tored periodically during use include volume and tempera-ture of the Dissolution Medium, rotation speed (Apparatus 1and Apparatus 2), dip rate (Apparatus 3), and flow rate ofmedium (Apparatus 4).Determine the acceptable performance of the dissolutiontest assembly periodically.3The suitability for the individualOfficial February 1, 2012〈711〉 Dissolution 5apparatus is demonstrated by the Performance Verification ment for minimum amount dissolved is met. Specimens are Test .to be withdrawn only at the stated times within a tolerance of ±2%.Performance Verification Test, Apparatus 1 and 2—Test USP Prednisone Tablets RS according to the operating 3Procedure for a Pooled Sample for Immediate-conditions specified. The apparatus is suitable if the results Release Dosage Forms —Use this procedure where Proce-obtained are within the acceptable range stated in the dure for a Pooled Sample is specified in the individual mono-technical data sheet specific to the lot used and the appa-graph. Proceed as directed for Immediate-Release Dosage ratus tested.Forms under Apparatus 1 and Apparatus 2 in the Procedure section. Combine equal volumes of the filtered solutions of Performance Verification Test, Apparatus 3—•[To the six or twelve individual specimens withdrawn, and use come.]•(RB 1-Feb-2012)the pooled sample as the test specimen. Determine the av-Performance Verification Test, Apparatus 4—[To erage amount of the active ingredient dissolved in the come.]3pooled sample.3PROCEDUREEXTENDED -RELEASE DOSAGE FORMSProceed as directed for Immediate-Release Dosage Forms .Apparatus 1 and Apparatus 2Dissolution Medium—Proceed as directed for Immedi-ate-Release Dosage Forms .Time—The test-time points, generally three, are ex-pressed in hours.IMMEDIATE -RELEASE DOSAGE FORMSPlace the stated volume of the Dissolution Medium (±1%)DELAYED -RELEASE DOSAGE FORMS NOT ACCEPTED BY THEin the vessel of the specified apparatus 3given in the indi-JAPANESE PHARMACOPOEIA vidual monograph 3, assemble the apparatus, equilibrate the Dissolution Medium to 37±0.5°, and remove the thermom-Use Method A or Method B and the apparatus specified eter. Place 1 dosage unit in the apparatus, taking care to 3in the individual monograph 3. All test times stated are to exclude air bubbles from the surface of the dosage unit,be observed within a tolerance of ±2%, unless otherwise and immediately operate the apparatus at the specified rate specified.3given in the individual monograph 3. Within the time inter-Method A—val specified, or at each of the times stated, withdraw a Procedure 3(unless otherwise directed in the individual specimen from a zone midway between the surface of the monograph)3—Dissolution Medium and the top of the rotating basket or blade, not less than 1 cm from the vessel wall. [NOTE —ACID STAGE —Place 750 mL of 0.1 N hydrochloric acid in Where multiple sampling times are specified, replace the the vessel, and assemble the apparatus. Allow the medium aliquots withdrawn for analysis with equal volumes of fresh to equilibrate to a temperature of 37±0.5°. Place 1 dosage Dissolution Medium at 37° or, where it can be shown that unit in the apparatus, cover the vessel, and operate the replacement of the medium is not necessary, correct for apparatus at the specified rate 3given in the monograph 3.the volume change in the calculation. Keep the vessel cov-After 2 hours of operation in 0.1 N hydrochloric acid,ered for the duration of the test, and verify the tempera-withdraw an aliquot of the fluid, and proceed immediately ture of the mixture under test at suitable times.] Perform as directed under Buffer Stage .the analysis 3as directed in the individual monograph 3 us-Perform an analysis of the aliquot using a suitable assay ing a suitable assay method.3 Repeat the test with addi-method. 3The procedure is specified in the individual tional dosage form units.monograph.3If automated equipment is used for sampling or the ap-BUFFER STAGE —[NOTE —Complete the operations of adding paratus is otherwise modified, verification that the modified the buffer and adjusting the pH within 5 minutes.]apparatus will produce results equivalent to those obtained With the apparatus operating at the rate specified 3in the with the standard apparatus described in this general chap-monograph 3, add to the fluid in the vessel 250 mL of 0.20ter is necessary.M tribasic sodium phosphate that has been equilibrated to Dissolution Medium—A suitable dissolution medium is 37±0.5°. Adjust, if necessary, with 2N hydrochloric acid used. Use the solvent specified 3in the individualor 2N sodium hydroxide to a pH of 6.8 ± 0.05. Continue monograph 3. The volume specified refers to measurements to operate the apparatus for 45 minutes, or for the speci-made between 20° and 25°. If the Dissolution Medium is a fied time 3given in the individual monograph 3. At the end buffered solution, adjust the solution so that its pH isof the time period, withdraw an aliquot of the fluid, and within 0.05 unit of the specified pH 3given in the individual perform the analysis using a suitable assay method. 3The monograph 3. [NOTE —Dissolved gases can cause bubbles to procedure is specified in the individual monograph. The form, which may change the results of the test. If dissolved test may be concluded in a shorter time period than that gases influence the dissolution results, dissolved gases specified for the Buffer Stage if the requirement for the min-should be removed prior to testing.4]imum amount dissolved is met at an earlier time.3Time—Where a single time specification is given, the Method B—test may be concluded in a shorter period if the require-Procedure 3(unless otherwise directed in the individual monograph)3—3Test specimens are filtered immediately upon sampling unless filtration is demonstrated to be unnecessary. Use an inert filter that does not cause ACID STAGE —Place 1000 mL of 0.1 N hydrochloric acid in adsorption of the active ingredient or contain extractable substances that the vessel, and assemble the apparatus. Allow the medium would interfere with the analysis.4One method of deaeration is as follows: Heat the medium, while stirring to equilibrate to a temperature of 37±0.5°. Place 1 dosage gently, to about 41°, immediately filter under vacuum using a filter having a unit in the apparatus, cover the vessel, and operate the porosity of 0.45 µm or less, with vigorous stirring, and continue stirring apparatus at the rate specified 3in the monograph 3. After 2under vacuum for about 5 minutes. Other validated deaeration techniques hours of operation in 0.1 N hydrochloric acid, withdraw anfor removal of dissolved gases may be used.aliquot of the fluid, and proceed immediately as directed DELAYED -RELEASE DOSAGE FORMSunder Buffer Stage .Perform an analysis of the aliquot using a suitable assay Proceed as directed for Delayed-Release Dosage Forms,method. 3The procedure is specified in the individual Method B under Apparatus 1 and Apparatus 2 using one monograph.3row of vessels for the acid stage media and the following BUFFER STAGE —[NOTE —For this stage of the procedure, use row of vessels for the buffer stage media and using the buffer that previously has been equilibrated to a tempera-volume of medium specified (usually 300 mL).ture of 37±0.5°.] Drain the acid from the vessel, and add Time —Proceed as directed for Immediate-Release Dosage to the vessel 1000 mL of pH 6.8 phosphate buffer, pre-Forms under Apparatus 1 and Apparatus 2.pared by mixing 0.1 N hydrochloric acid with 0.20 M tri-basic sodium phosphate (3:1) and adjusting, if necessary,with 2N hydrochloric acid or 2N sodium hydroxide to a Apparatus 4 (Flow-Through Cell)pH of 6.8 ± 0.05. [NOTE —This may also be accomplished by removing from the apparatus the vessel containing the acid and replacing it with another vessel containing the buffer IMMEDIATE -RELEASE DOSAGE FORMSand transferring the dosage unit to the vessel containing the buffer.]Place the glass beads into the cell specified 3in theContinue to operate the apparatus for 45 minutes, or for monograph 3. Place 1 dosage unit on top of the beads or, if the specified time 3given in the individual monograph 3. At specified 3in the monograph 3, on a wire carrier. Assemble the end of the time period, withdraw an aliquot of the the filter head, and fix the parts together by means of a fluid, and perform the analysis using a suitable assaysuitable clamping device. Introduce by the pump the Disso-method. 3The procedure is specified in the individual mon-lution Medium warmed to 37±0.5° through the bottom of ograph. The test may be concluded in a shorter time pe-the cell to obtain the flow rate specified 3in the individual riod than that specified for the Buffer Stage if the require-monograph 3 and measured with an accuracy of 5%. Col-ment for minimum amount dissolved is met at an earlier lect the eluate by fractions at each of the times stated.time.3Perform the analysis as directed 3in the individualmonograph 3. Repeat the test with additional dosage-form Apparatus 3 (Reciprocating Cylinder)units.Dissolution Medium —Proceed as directed for Immedi-ate-Release Dosage Forms under Apparatus 1 and Apparatus 2.NOT ACCEPTED BY THE JAPANESE PHARMACOPOEIATime —Proceed as directed for Immediate-Release Dosage IMMEDIATE -RELEASE DOSAGE FORMS Forms under Apparatus 1 and Apparatus 2.Place the stated volume of the Dissolution Medium ineach vessel of the apparatus, assemble the apparatus, equi-EXTENDED -RELEASE DOSAGE FORMSlibrate the Dissolution Medium to 37±0.5°, and remove the thermometer. Place 1 dosage-form unit in each of the six Proceed as directed for Immediate-Release Dosage Forms reciprocating cylinders, taking care to exclude air bubbles under Apparatus 4.from the surface of each dosage unit, and immediately op-Dissolution Medium —Proceed as directed for Immedi-erate the apparatus as specified 3in the individualate-Release Dosage Forms under Apparatus 4.monograph 3. During the upward and downward stroke,Time —Proceed as directed for Immediate-Release Dosage the reciprocating cylinder moves through a total distance Forms under Apparatus 4.of 9.9 to 10.1 cm. Within the time interval specified, or at each of the times stated, raise the reciprocating cylinders and withdraw a portion of the solution under test from a DELAYED -RELEASE DOSAGE FORMSzone midway between the surface of the Dissolution Me-dium and the bottom of each vessel. Perform the analysis as Proceed as directed for Delayed-Release Dosage Forms directed 3in the individual monograph 3. If necessary, repeat under Apparatus 1 and Apparatus 2, using the specified the test with additional dosage-form units.media.Dissolution Medium —Proceed as directed for Immedi-Time —Proceed as directed for Delayed-Release Dosage ate-Release Dosage Forms under Apparatus 1 and Apparatus Forms under Apparatus 1 and Apparatus 2.2.Time —Proceed as directed for Immediate-Release Dosage Forms under Apparatus 1 and Apparatus 2.INTERPRETATIONEXTENDED -RELEASE DOSAGE FORMSImmediate-Release Dosage FormsProceed as directed for Immediate-Release Dosage Forms under Apparatus 3.Unless otherwise specified 3in the individualmonograph 3, the requirements are met if the quantities of Dissolution Medium —Proceed as directed for Extended-active ingredient dissolved from the dosage units tested Release Dosage Forms under Apparatus 1 and Apparatus 2.conform to Acceptance Table 1. Continue testing through Time —Proceed as directed for Extended-Release Dosage the three stages unless the results conform at either S 1 or Forms under Apparatus 1 and Apparatus 2.S 2. The quantity, Q , is the amount of dissolved active ingre-dient 3specified in the individual monograph 3, expressed as a percentage of the labeled content of the dosage unit; the 5%, 15%, and 25% values in Acceptance Table 1 are per-Official February 1, 2012〈711〉 Dissolution 7centages of the labeled content so that these values and Q Acceptance Table 2are in the same terms.Number Level TestedCriteriaAcceptance Table 1No individual value lies outside each of the stated ranges and no individual value is Number L 16less than the stated amount at the final Stage Tested Acceptance Criteriatest time.S 16Each unit is not less than Q + 5%.The average value of the 12 units (L 1 + L 2)Average of 12 units (S 1 + S 2) is equal to or lies within each of the stated ranges and S 26greater than Q, and no unit is less than Q is not less than the stated amount at the − 15%.final test time; none is more than 10% of Average of 24 units (S 1 + S 2 +S 3) is equal L 26labeled content outside each of the stat-to or greater than Q , not more than 2S 312ed ranges; and none is more than 10%units are less than Q − 15%, and no unit of labeled content below the stated is less than Q − 25%.amount at the final test time.The average value of the 24 units (L 1 + L 23Immediate-Release Dosage Forms Pooled Sample—+ L 3) lies within each of the stated Unless otherwise specified in the individual monograph, the ranges, and is not less than the stated requirements are met if the quantities of active ingredient amount at the final test time; not more dissolved from the pooled sample conform to the accom-than 2 of the 24 units are more than panying Acceptance Table for a Pooled Sample. Continue 10% of labeled content outside each of testing through the three stages unless the results conform the stated ranges; not more than 2 of the at either S 1 or S 2. The quantity, Q , is the amount of dis-L 31224 units are more than 10% of labeled solved active ingredient specified in the individual mono-content below the stated amount at the graph, expressed as a percentage of the labeled content.final test time; and none of the units is more than 20% of labeled contentAcceptance Table for a Pooled Sampleoutside each of the stated ranges or more than 20% of labeled content below the Number stated amount at the final test time.Stage TestedAcceptance CriteriaAverage amount dissolved is not less than S 16Q + 10%.Average amount dissolved (S 1 + S 2) is Delayed-Release Dosage FormsS 26equal to or greater than Q + 5%.Average amount dissolved (S 1 + S 2 + S 3) is S 312equal to or greater than Q .NOT ACCEPTED BY THE JAPANESE PHARMACOPOEIA 3Acid Stage—Unless otherwise specified 3in the individ-ual monograph 3, the requirements of this portion of the Extended-Release Dosage Formstest are met if the quantities, based on the percentage of the labeled content, of active ingredient dissolved from the Unless otherwise specified 3in the individualunits tested conform to Acceptance Table 3. Continue test-monograph 3, the requirements are met if the quantities of ing through all levels unless the results of both acid and active ingredient dissolved from the dosage units tested buffer stages conform at an earlier level.conform to Acceptance Table 2. Continue testing through the three levels unless the results conform at either L 1 or L 2.Acceptance Table 3Limits on the amounts of active ingredient dissolved are expressed in terms of the percentage of labeled content.Number The limits embrace each value of Q i , the amount dissolved Level TestedCriteriaat each specified fractional dosing interval. Where more No individual value exceeds 10% dis-A 16than one range is specified 3in the individual monograph 3,solved.the acceptance criteria apply individually to each range.Average of the 12 units (A 1 + A 2) is not A 26more than 10% dissolved, and no indi-vidual unit is greater than 25% dissolved.Average of the 24 units (A 1 + A 2 + A 3) is not more than 10% dissolved, and no in-A 312dividual unit is greater than 25% dis-solved.Buffer Stage—Unless otherwise specified 3in the individ-ual monograph 3, the requirements are met if the quantities of active ingredient dissolved from the units tested conform to Acceptance Table 4. Continue testing through the three levels unless the results of both stages conform at an earlier level. The value of Q in Acceptance Table 4 is 75% dissolved unless otherwise specified 3in the individual monograph 3.The quantity, Q , 3specified in the individual monograph 3 is the total amount of active ingredient dissolved in both the Acid and Buffer Stages , expressed as a percentage of thelabeled content. The 5%, 15%, and 25% values in Accep-tance Table 4 are percentages of the labeled content so that these values and Q are in the same terms.Acceptance Table 4NumberLevel Tested CriteriaB16Each unit is not less than Q + 5%.Average of 12 units (B1 + B2) is equal to or B26greater than Q, and no unit is less than Q– 15%.Average of 24 units (B1 + B2 + B3) is equalto or greater than Q, not more than 2 B312units are less than Q – 15%, and no unitis less than Q – 25%.。

USP溶出度试验开发和验证(中英文对照版)(1092)溶出度实验的开发和验证【中英文对照版】INTRODUCTION前言Purpose目的The Dissolution Procedure: Developmentand Validation <1092> provides a comprehensive approach covering items to considerfor developing and validating dissolution procedures and the accompanyinganalytical procedures. It addresses the use of automation throughout the testand provides guidance and criteria for validation. It also addresses thetreatment of the data generated and the interpretation of acceptance criteriafor immediate- and modified-release solid oral dosage forms.溶出实验:开发和验证(1092)指导原则提供了在溶出度方法开发和验证过程中以及采用相应分析方法时需要考虑的因素。

本指导原则贯穿溶出度实验的全部过程,并对方法提供了指导和验证标准。

同时它还涉及对普通制剂和缓释制剂所生成的数据和接受标准进行说明。

Scope范围Chapter <1092> addresses the development andvalidation of dissolution procedures, with a focus on solid oral dosage forms.Many of the concepts presented, however, may be applicable to other dosageforms and routes of administration. General recommendations are given with theunderstanding that modifications of the apparatus and procedures as given in USP general chapters need to be justified.<1092>章节讨论了溶出度实验的开发和验证,重点是口服固体制剂。

中、美、英三国新版药典溶出度、释放度检查方法比较许鸣镝胡琴摘要:目的通过对中国药典、美国药典和英国药典中溶出度、释放度测定方法的比较,使广大药物分析工作者了解其异同,为新药开发及进出口检验服务。

方法就其历史沿革,最新版所采用的仪器装置和结果判定等方面进行比较和讨论。

结果三国药典收载的仪器装置各有异同,结果判定差异较大,应引起注意。

结论如何能准确有效地监控药物释放过程,仍是有待深入研究和完善的课题。

关键词溶出度;释放度;中国药典;美国药典;英国药典中图分类号:R921 文献标识码:E文章编号:1001-2494(2000)07-0491-04溶出度和释放度是指药物从片剂、胶囊剂和其它缓释、控释制剂中,在规定介质内,在一定条件下的溶出速度和溶出程度,是评价药物制剂质量的内在指标,是制剂质量控制的重要手段。

在药检工作中,经常要查阅中国药典、美国药典和英国药典。

中国药典是我国药品的最高法典,而美国药典和英国药典由于历史悠久,技术先进又具有代表性,在世界各国有较大影响。

有些国家没有药典,而以美国药典和英国药典为标准,在世界药品贸易中也常以其标准来要求。

综观新版三国药典所收载的溶出度、释放度检查方法在很多方面趋向一致,但又在某些方面存在差别。

下面仅就其历史沿革,最新版所采用的仪器装置和结果判定要求等方面进行比较和讨论。

1 历史沿革1.1 中国药典中国药典在1985年版引入溶出度检查法时,设定篮法、桨法及类似于流室法的装置等3种装置,1990年版仅保留了前2种装置,1995年版中增订了小杯法装置,并引入了释放度检查法,至2000年版又增加了测定透皮贴剂释放度所需的桨碟装置,方法发展很快。

1.2 美国药典美国药典自1970年版(第18版)率先引入溶出度检查法,最初只设转篮法装置,且无图例。

1975年版(第19版)增加了转篮法的图例,但与现在试验的篮法装置也不相同。

1980年版(第20版)增设了桨法装置和改造后的崩解仪两种装置,未给出图例,也无统一的仪器配件尺寸规格。

溶出度测定法标准操作规程目的:建立溶出度测定法标准操作规程。

适用范围:溶出度测定。

责任:质检员实施本操作规程,检验室主任负责监督本规程正确执行。

程序:1.简述1.1溶出度(中国药典2000年版二部附录X C)是指药物从片剂或胶囊剂等口服固体制剂在规定溶剂中溶出的速度和程度。

它是评价药物口服固体制剂质量的一个指标,是一种模拟口服固体制剂在胃肠道中崩解和溶出的体外简易试验方法。

1.2溶出度测定法是将某种固体制剂的一定量分别置于溶出度仪的转篮(或烧杯)中,在37.0±0.5℃恒温下,在规定的转速、溶剂中依法操作,在规定的时间内测定其溶出的量。

1.3本方法适用于片剂、胶囊剂及颗粒剂的测定。

1.4中国药典2000年版收载三种测定方法,第一法转篮法第二法桨法及第三法小杯法。

1.5凡检查溶出度的制剂,不再进行崩解时限的检查。

2.仪器与用具2.1溶出度仪2.1.1仪器的组成溶出度仪主要由电动机、恒温水浴、篮体、篮轴、搅拌桨、圆底烧杯及杯盖组成,详见中国药典2000年版二部附录X C。

2.1.2仪器的装置与使用按仪器使用说明书及中国药典的规定进行安装与使用。

2.1.3仪器的校正为使同一药物的溶出度测定得到良好的再现性,应对新安装的溶出度仪采用溶出度校正片进行校正,对已使用过的仪器也应定期(或在出现异常情况时)进行校正。

2.1.3.1溶出度校正片分崩解型和非崩解型两种,崩解型为泼尼松片,非崩解型为水杨酸片。

目前国内仅有非崩解型校正片。

2.1.3.2校正前,应先调式所用仪器。

2.1.3.3溶剂:磷酸盐缓冲液(PH7.4)。

配制方法见中国药典2000年版二部附录XV D,要求PH值为7.40±0.05,临用前脱气。

2.1.3.4对照品溶液的制备取溶出度校正用水杨酸片1片,精密称定,置乳体中,研细,精密称取适量(约相当于水杨酸10mg),置100ml量瓶中,加乙醇1ml,摇匀,加溶剂适量,经超声处理30分钟,使水杨酸溶解,加溶剂到刻度,摇匀,经滤纸(不宜使用滤膜)滤过,取续滤液为对照品溶液。

药物溶出度试验方法的验证概述药物溶出度试验是一项重要的药物质量控制方法,用于评估药物在特定溶媒中的溶出速度和程度。

本文将探讨药物溶出度试验方法的验证,确保试验结果准确可靠。

一、试验方法选择药物溶出度试验方法的选择应根据药物特性、制剂类型和产品要求等因素综合考虑。

常见的试验方法包括美国药典(USP)溶出度试验、欧洲药典(EP)溶出度试验和中国药典(CP)溶出度试验等。

二、验证参数的确定验证药物溶出度试验方法时,需明确以下参数:1. 单一或多个试验条件:例如,使用不同pH值、温度和搅拌速度等条件进行试验;2. 药物释放曲线的判定:通过选定特定时间点或选定时间段内累积药物释放量的百分比等方法进行判定;3. 溶出度试验仪器的准确性和重复性:对于采用自动化仪器进行试验的情况,需验证仪器的准确性和重复性,并进行适当的校准或调整。

三、实验操作步骤药物溶出度试验的实验操作步骤包括以下几个方面:1. 试剂准备:准备适当的溶媒,并根据试验方法要求进行调整;2. 试验器具准备:根据试验方法选用合适的试验仪器,并进行适当的校准和清洁;3. 试验条件设定:根据验证参数确定的试验条件进行设定,包括温度、搅拌速度等;4. 样品准备:制备样品溶液,确保样品溶液的浓度适当;5. 试验进行:将样品溶液加入试验器具中,开始试验,并记录试验时间;6. 结果分析:根据试验方法要求,进行药物释放曲线的分析和数据处理。

四、数据处理与结果分析药物溶出度试验的数据处理和结果分析要根据试验方法的要求进行。

一般来说,需要计算溶出度曲线的均值、标准差、变异系数等参数,并与设定的试验条件进行比较。

此外,还需对实验结果进行统计学分析,如方差分析等,以判断试验方法是否可靠。

五、验证报告撰写药物溶出度试验方法的验证应编写验证报告,报告内容一般包括以下几个方面:1. 验证目的和背景:明确验证的目的和背景;2. 验证参数和试验条件:列出已确定的验证参数和试验条件;3. 样品准备和试验操作:详细描述样品准备和试验操作步骤;4. 数据处理和结果分析:对试验数据进行处理和分析,并阐述结果的可靠性和合理性;5. 结论和建议:根据验证结果,给出验证结论和相关建议;6. 附录:附上试验记录和相关数据等。

Official February 1, 2012〈711〉 Dissolution 1material 1; a motor; a metallic drive shaft; and a cylindrical 〈711〉 DISSOLUTIONbasket. The vessel is partially immersed in a suitable water bath of any convenient size or heated by a suitable device such as a heating jacket. The water bath or heating device permits holding the temperature inside the vessel atThis general chapter is harmonized with the correspond-37±0.5° during the test and keeping the bath fluid in con-ing texts of the European Pharmacopoeia and/or the Japa-stant, smooth motion. No part of the assembly, including nese Pharmacopoeia . These pharmacopeias have undertaken the environment in which the assembly is placed, contrib-not to make any unilateral change to this harmonized utes significant motion, agitation, or vibration beyond that chapter.due to the smoothly rotating stirring element. An apparatus Portions of the present general chapter text that are na-that permits observation of the specimen and stirring ele-tional USP text, and therefore not part of the harmonized ment during the test is preferable. The vessel is cylindrical,text, are marked with symbols (33) to specify this fact.with a hemispherical bottom and 3with one of the follow-This test is provided to determine compliance with the ing dimensions and capacities: for a nominal 3 capacity of 1dissolution requirements 3where stated in the individual L, the height is 160 to 210 mm and its inside diameter is monograph 3 for dosage forms administered orally. In this 98 to 106 mm; 3for a nominal capacity of 2 L, the height is general chapter, a dosage unit is defined as 1 tablet or 1280 to 300 mm and its inside diameter is 98 to 106 mm;capsule or the amount specified. 3Of the types of apparatus and for a nominal capacity of 4 L, the height is 280 to 300described herein, use the one specified in the individual mm and its inside diameter is 145 to 155 mm 3. Its sides monograph. Where the label states that an article is en-are flanged at the top. A fitted cover may be used to retard teric-coated, and where a dissolution or disintegration test evaporation.2 The shaft is positioned so that its axis is not that does not specifically state that it is to be applied to more than 2 mm at any point from the vertical axis of the delayed-release articles is included in the individual mono-vessel and rotates smoothly and without significant wobble graph, the procedure and interpretation given for Delayed-that could affect the results. A speed-regulating device is Release Dosage Forms is applied unless otherwise specified used that allows the shaft rotation speed to be selected and in the individual monograph. For hard or soft gelatin cap-maintained at the specified rate 3given in the individual sules and gelatin-coated tablets that do not conform to the monograph 3 within ±4%.Dissolution specification, repeat the test as follows. Where Shaft and basket components of the stirring element are water or a medium with a pH of less than 6.8 is specified fabricated of stainless steel, type 316, or other inert mate-as the Medium in the individual monograph, the same Me-rial, to the specifications shown in Figure 1. A basket having dium specified may be used with the addition of purified a gold coating of about 0.0001 inch (2.5 µm) thick may be pepsin that results in an activity of 750,000 Units or less used. A dosage unit is placed in a dry basket at the begin-per 1000 mL. For media with a pH of 6.8 or greater, pan-ning of each test. The distance between the inside bottom creatin can be added to produce not more than 1750 USP of the vessel and the bottom of the basket is maintained at Units of protease activity per 1000 mL.25±2 mm during the test.1The materials should not sorb, react, or interfere with the specimen being Change to read:tested.2If a cover is used, it provides sufficient openings to allow ready insertion of the thermometer and withdrawal of specimens.USP Reference Standards 〈11〉—••(RB 1-Feb-2012) USP Pred-nisone Tablets RS.3Change to read:APPARATUSApparatus 1 (Basket Apparatus)The assembly consists of the following: a vessel, which may be covered, made of glass or other inert, transparentFigure 1. Basket stirring element.the inside bottom of the vessel is maintained during thetest. The metallic or suitably inert, rigid blade and shaft Apparatus 2 (Paddle Apparatus)comprise a single entity. A suitable two-part detachable de-sign may be used provided the assembly remains firmly Use the assembly from Apparatus 1, except that a paddle engaged during the test. The paddle blade and shaft may formed from a blade and a shaft is used as the stirring be coated with a suitable coating so as to make them inert. element. The shaft is positioned so that its axis is not more The dosage unit is allowed to sink to the bottom of the than 2 mm from the vertical axis of the vessel at any point vessel before rotation of the blade is started. A small, loose and rotates smoothly without significant wobble that could piece of nonreactive material, such as not more than a few affect the results. The vertical center line of the blade turns of wire helix, may be attached to dosage units that passes through the axis of the shaft so that the bottom of would otherwise float. An alternative sinker device is shown the blade is flush with the bottom of the shaft. The paddle in Figure 2a. Other validated sinker devices may be used. conforms to the specifications shown in Figure 2. The dis-tance of 25±2 mm between the bottom of the blade andOfficial February 1, 2012〈711〉 Dissolution3ing the environment in which the assembly is placed, con-tributes significant motion, agitation, or vibration beyondthat due to the smooth, vertically reciprocating cylinder. Adevice is used that allows the reciprocation rate to be se-lected and maintained at the specified dip rate 3given inthe individual monograph3 within ±5%. An apparatus thatpermits observation of the specimens and reciprocating cyl-inders is preferable. The vessels are provided with an evap-oration cap that remains in place for the duration of thetest. The components conform to the dimensions shown inFigure 3 unless otherwise specified 3in the individualmonograph3.Figure 2. Paddle stirring element.Figure 2a. Alternative sinker. All dimensions are expressedin mm.Apparatus 3 (Reciprocating Cylinder)NOT ACCEPTED BY THE JAPANESE PHARMACOPOEIAFigure 3. Apparatus 3 (reciprocating cylinder).The assembly consists of a set of cylindrical, flat-bot-tomed glass vessels; a set of glass reciprocating cylinders;inert fittings (stainless steel type 316 or other suitable ma-Apparatus 4 (Flow-Through Cell) terial), and screens that are made of suitable nonsorbingand nonreactive material and that are designed to fit theThe assembly consists of a reservoir and a pump for the tops and bottoms of the reciprocating cylinders; and a mo-Dissolution Medium; a flow-through cell; and a water bath tor and drive assembly to reciprocate the cylinders verticallythat maintains the Dissolution Medium at 37±0.5°. Use the inside the vessels and, if desired, index the reciprocatingspecified cell size 3as given in the individual monograph3. cylinders horizontally to a different row of vessels. The ves-The pump forces the Dissolution Medium upwardssels are partially immersed in a suitable water bath of anythrough the flow-through cell. The pump has a delivery convenient size that permits holding the temperature atrange between 240 and 960 mL per hour, with standard 37±0.5° during the test. No part of the assembly, includ-flow rates of 4, 8, and 16 mL per minute. It must deliver aconstant flow (±5% of the nominal flow rate); the flow pro-file is sinusoidal with a pulsation of 120±10 pulses perminute. A pump without pulsation may also be used. Dis-solution test procedures using a flow-through cell must becharacterized with respect to rate and any pulsation.The flow-through cell (see Figures 4 and 5), of transpar-ent and inert material, is mounted vertically with a filtersystem (specified in the individual monograph) that pre-vents escape of undissolved particles from the top of thecell; standard cell diameters are 12 and 22.6 mm; the bot-tom cone is usually filled with small glass beads of about 1-mm diameter with one bead of about 5 mm positioned atthe apex to protect the fluid entry tube; and a tabletholder (see Figures 4 and 5) is available for positioning ofspecial dosage forms, for example, inlay tablets. The cell isimmersed in a water bath, and the temperature is main-tained at 37±0.5°.Figure 5. Apparatus 4, small cell for tablets and capsules(top), tablet holder for the small cell (bottom). (All meas-urements are expressed in mm unless noted otherwise.)The apparatus uses a clamp mechanism and two O-ringsto assemble the cell. The pump is separated from the disso-lution unit in order to shield the latter against any vibra-tions originating from the pump. The position of the pumpshould not be on a level higher than the reservoir flasks.Tube connections are as short as possible. Use suitably inerttubing, such as polytef, with about 1.6-mm inner diameterand chemically inert flanged-end connections.APPARATUS SUITABILITYThe determination of suitability of a test assembly to per-Figure 4. Apparatus 4, large cell for tablets and capsules form dissolution testing must include conformance to the (top), tablet holder for the large cell (bottom). (All meas-dimensions and tolerances of the apparatus as given above. urements are expressed in mm unless noted otherwise.)In addition, critical test parameters that have to be moni-tored periodically during use include volume and tempera-ture of the Dissolution Medium, rotation speed (Apparatus 1and Apparatus 2), dip rate (Apparatus 3), and flow rate ofmedium (Apparatus 4).Determine the acceptable performance of the dissolutiontest assembly periodically.3The suitability for the individualOfficial February 1, 2012〈711〉 Dissolution 5apparatus is demonstrated by the Performance Verification ment for minimum amount dissolved is met. Specimens are Test .to be withdrawn only at the stated times within a tolerance of ±2%.Performance Verification Test, Apparatus 1 and 2—Test USP Prednisone Tablets RS according to the operating 3Procedure for a Pooled Sample for Immediate-conditions specified. The apparatus is suitable if the results Release Dosage Forms —Use this procedure where Proce-obtained are within the acceptable range stated in the dure for a Pooled Sample is specified in the individual mono-technical data sheet specific to the lot used and the appa-graph. Proceed as directed for Immediate-Release Dosage ratus tested.Forms under Apparatus 1 and Apparatus 2 in the Procedure section. Combine equal volumes of the filtered solutions of Performance Verification Test, Apparatus 3—•[To the six or twelve individual specimens withdrawn, and use come.]•(RB 1-Feb-2012)the pooled sample as the test specimen. Determine the av-Performance Verification Test, Apparatus 4—[To erage amount of the active ingredient dissolved in the come.]3pooled sample.3PROCEDUREEXTENDED -RELEASE DOSAGE FORMSProceed as directed for Immediate-Release Dosage Forms .Apparatus 1 and Apparatus 2Dissolution Medium—Proceed as directed for Immedi-ate-Release Dosage Forms .Time—The test-time points, generally three, are ex-pressed in hours.IMMEDIATE -RELEASE DOSAGE FORMSPlace the stated volume of the Dissolution Medium (±1%)DELAYED -RELEASE DOSAGE FORMS NOT ACCEPTED BY THEin the vessel of the specified apparatus 3given in the indi-JAPANESE PHARMACOPOEIA vidual monograph 3, assemble the apparatus, equilibrate the Dissolution Medium to 37±0.5°, and remove the thermom-Use Method A or Method B and the apparatus specified eter. Place 1 dosage unit in the apparatus, taking care to 3in the individual monograph 3. All test times stated are to exclude air bubbles from the surface of the dosage unit,be observed within a tolerance of ±2%, unless otherwise and immediately operate the apparatus at the specified rate specified.3given in the individual monograph 3. Within the time inter-Method A—val specified, or at each of the times stated, withdraw a Procedure 3(unless otherwise directed in the individual specimen from a zone midway between the surface of the monograph)3—Dissolution Medium and the top of the rotating basket or blade, not less than 1 cm from the vessel wall. [NOTE —ACID STAGE —Place 750 mL of 0.1 N hydrochloric acid in Where multiple sampling times are specified, replace the the vessel, and assemble the apparatus. Allow the medium aliquots withdrawn for analysis with equal volumes of fresh to equilibrate to a temperature of 37±0.5°. Place 1 dosage Dissolution Medium at 37° or, where it can be shown that unit in the apparatus, cover the vessel, and operate the replacement of the medium is not necessary, correct for apparatus at the specified rate 3given in the monograph 3.the volume change in the calculation. Keep the vessel cov-After 2 hours of operation in 0.1 N hydrochloric acid,ered for the duration of the test, and verify the tempera-withdraw an aliquot of the fluid, and proceed immediately ture of the mixture under test at suitable times.] Perform as directed under Buffer Stage .the analysis 3as directed in the individual monograph 3 us-Perform an analysis of the aliquot using a suitable assay ing a suitable assay method.3 Repeat the test with addi-method. 3The procedure is specified in the individual tional dosage form units.monograph.3If automated equipment is used for sampling or the ap-BUFFER STAGE —[NOTE —Complete the operations of adding paratus is otherwise modified, verification that the modified the buffer and adjusting the pH within 5 minutes.]apparatus will produce results equivalent to those obtained With the apparatus operating at the rate specified 3in the with the standard apparatus described in this general chap-monograph 3, add to the fluid in the vessel 250 mL of 0.20ter is necessary.M tribasic sodium phosphate that has been equilibrated to Dissolution Medium—A suitable dissolution medium is 37±0.5°. Adjust, if necessary, with 2N hydrochloric acid used. Use the solvent specified 3in the individualor 2N sodium hydroxide to a pH of 6.8 ± 0.05. Continue monograph 3. The volume specified refers to measurements to operate the apparatus for 45 minutes, or for the speci-made between 20° and 25°. If the Dissolution Medium is a fied time 3given in the individual monograph 3. At the end buffered solution, adjust the solution so that its pH isof the time period, withdraw an aliquot of the fluid, and within 0.05 unit of the specified pH 3given in the individual perform the analysis using a suitable assay method. 3The monograph 3. [NOTE —Dissolved gases can cause bubbles to procedure is specified in the individual monograph. The form, which may change the results of the test. If dissolved test may be concluded in a shorter time period than that gases influence the dissolution results, dissolved gases specified for the Buffer Stage if the requirement for the min-should be removed prior to testing.4]imum amount dissolved is met at an earlier time.3Time—Where a single time specification is given, the Method B—test may be concluded in a shorter period if the require-Procedure 3(unless otherwise directed in the individual monograph)3—3Test specimens are filtered immediately upon sampling unless filtration is demonstrated to be unnecessary. Use an inert filter that does not cause ACID STAGE —Place 1000 mL of 0.1 N hydrochloric acid in adsorption of the active ingredient or contain extractable substances that the vessel, and assemble the apparatus. Allow the medium would interfere with the analysis.4One method of deaeration is as follows: Heat the medium, while stirring to equilibrate to a temperature of 37±0.5°. Place 1 dosage gently, to about 41°, immediately filter under vacuum using a filter having a unit in the apparatus, cover the vessel, and operate the porosity of 0.45 µm or less, with vigorous stirring, and continue stirring apparatus at the rate specified 3in the monograph 3. After 2under vacuum for about 5 minutes. Other validated deaeration techniques hours of operation in 0.1 N hydrochloric acid, withdraw anfor removal of dissolved gases may be used.aliquot of the fluid, and proceed immediately as directed DELAYED -RELEASE DOSAGE FORMSunder Buffer Stage .Perform an analysis of the aliquot using a suitable assay Proceed as directed for Delayed-Release Dosage Forms,method. 3The procedure is specified in the individual Method B under Apparatus 1 and Apparatus 2 using one monograph.3row of vessels for the acid stage media and the following BUFFER STAGE —[NOTE —For this stage of the procedure, use row of vessels for the buffer stage media and using the buffer that previously has been equilibrated to a tempera-volume of medium specified (usually 300 mL).ture of 37±0.5°.] Drain the acid from the vessel, and add Time —Proceed as directed for Immediate-Release Dosage to the vessel 1000 mL of pH 6.8 phosphate buffer, pre-Forms under Apparatus 1 and Apparatus 2.pared by mixing 0.1 N hydrochloric acid with 0.20 M tri-basic sodium phosphate (3:1) and adjusting, if necessary,with 2N hydrochloric acid or 2N sodium hydroxide to a Apparatus 4 (Flow-Through Cell)pH of 6.8 ± 0.05. [NOTE —This may also be accomplished by removing from the apparatus the vessel containing the acid and replacing it with another vessel containing the buffer IMMEDIATE -RELEASE DOSAGE FORMSand transferring the dosage unit to the vessel containing the buffer.]Place the glass beads into the cell specified 3in theContinue to operate the apparatus for 45 minutes, or for monograph 3. Place 1 dosage unit on top of the beads or, if the specified time 3given in the individual monograph 3. At specified 3in the monograph 3, on a wire carrier. Assemble the end of the time period, withdraw an aliquot of the the filter head, and fix the parts together by means of a fluid, and perform the analysis using a suitable assaysuitable clamping device. Introduce by the pump the Disso-method. 3The procedure is specified in the individual mon-lution Medium warmed to 37±0.5° through the bottom of ograph. The test may be concluded in a shorter time pe-the cell to obtain the flow rate specified 3in the individual riod than that specified for the Buffer Stage if the require-monograph 3 and measured with an accuracy of 5%. Col-ment for minimum amount dissolved is met at an earlier lect the eluate by fractions at each of the times stated.time.3Perform the analysis as directed 3in the individualmonograph 3. Repeat the test with additional dosage-form Apparatus 3 (Reciprocating Cylinder)units.Dissolution Medium —Proceed as directed for Immedi-ate-Release Dosage Forms under Apparatus 1 and Apparatus 2.NOT ACCEPTED BY THE JAPANESE PHARMACOPOEIATime —Proceed as directed for Immediate-Release Dosage IMMEDIATE -RELEASE DOSAGE FORMS Forms under Apparatus 1 and Apparatus 2.Place the stated volume of the Dissolution Medium ineach vessel of the apparatus, assemble the apparatus, equi-EXTENDED -RELEASE DOSAGE FORMSlibrate the Dissolution Medium to 37±0.5°, and remove the thermometer. Place 1 dosage-form unit in each of the six Proceed as directed for Immediate-Release Dosage Forms reciprocating cylinders, taking care to exclude air bubbles under Apparatus 4.from the surface of each dosage unit, and immediately op-Dissolution Medium —Proceed as directed for Immedi-erate the apparatus as specified 3in the individualate-Release Dosage Forms under Apparatus 4.monograph 3. During the upward and downward stroke,Time —Proceed as directed for Immediate-Release Dosage the reciprocating cylinder moves through a total distance Forms under Apparatus 4.of 9.9 to 10.1 cm. Within the time interval specified, or at each of the times stated, raise the reciprocating cylinders and withdraw a portion of the solution under test from a DELAYED -RELEASE DOSAGE FORMSzone midway between the surface of the Dissolution Me-dium and the bottom of each vessel. Perform the analysis as Proceed as directed for Delayed-Release Dosage Forms directed 3in the individual monograph 3. If necessary, repeat under Apparatus 1 and Apparatus 2, using the specified the test with additional dosage-form units.media.Dissolution Medium —Proceed as directed for Immedi-Time —Proceed as directed for Delayed-Release Dosage ate-Release Dosage Forms under Apparatus 1 and Apparatus Forms under Apparatus 1 and Apparatus 2.2.Time —Proceed as directed for Immediate-Release Dosage Forms under Apparatus 1 and Apparatus 2.INTERPRETATIONEXTENDED -RELEASE DOSAGE FORMSImmediate-Release Dosage FormsProceed as directed for Immediate-Release Dosage Forms under Apparatus 3.Unless otherwise specified 3in the individualmonograph 3, the requirements are met if the quantities of Dissolution Medium —Proceed as directed for Extended-active ingredient dissolved from the dosage units tested Release Dosage Forms under Apparatus 1 and Apparatus 2.conform to Acceptance Table 1. Continue testing through Time —Proceed as directed for Extended-Release Dosage the three stages unless the results conform at either S 1 or Forms under Apparatus 1 and Apparatus 2.S 2. The quantity, Q , is the amount of dissolved active ingre-dient 3specified in the individual monograph 3, expressed as a percentage of the labeled content of the dosage unit; the 5%, 15%, and 25% values in Acceptance Table 1 are per-Official February 1, 2012〈711〉 Dissolution 7centages of the labeled content so that these values and Q Acceptance Table 2are in the same terms.Number Level TestedCriteriaAcceptance Table 1No individual value lies outside each of the stated ranges and no individual value is Number L 16less than the stated amount at the final Stage Tested Acceptance Criteriatest time.S 16Each unit is not less than Q + 5%.The average value of the 12 units (L 1 + L 2)Average of 12 units (S 1 + S 2) is equal to or lies within each of the stated ranges and S 26greater than Q, and no unit is less than Q is not less than the stated amount at the − 15%.final test time; none is more than 10% of Average of 24 units (S 1 + S 2 +S 3) is equal L 26labeled content outside each of the stat-to or greater than Q , not more than 2S 312ed ranges; and none is more than 10%units are less than Q − 15%, and no unit of labeled content below the stated is less than Q − 25%.amount at the final test time.The average value of the 24 units (L 1 + L 23Immediate-Release Dosage Forms Pooled Sample—+ L 3) lies within each of the stated Unless otherwise specified in the individual monograph, the ranges, and is not less than the stated requirements are met if the quantities of active ingredient amount at the final test time; not more dissolved from the pooled sample conform to the accom-than 2 of the 24 units are more than panying Acceptance Table for a Pooled Sample. Continue 10% of labeled content outside each of testing through the three stages unless the results conform the stated ranges; not more than 2 of the at either S 1 or S 2. The quantity, Q , is the amount of dis-L 31224 units are more than 10% of labeled solved active ingredient specified in the individual mono-content below the stated amount at the graph, expressed as a percentage of the labeled content.final test time; and none of the units is more than 20% of labeled contentAcceptance Table for a Pooled Sampleoutside each of the stated ranges or more than 20% of labeled content below the Number stated amount at the final test time.Stage TestedAcceptance CriteriaAverage amount dissolved is not less than S 16Q + 10%.Average amount dissolved (S 1 + S 2) is Delayed-Release Dosage FormsS 26equal to or greater than Q + 5%.Average amount dissolved (S 1 + S 2 + S 3) is S 312equal to or greater than Q .NOT ACCEPTED BY THE JAPANESE PHARMACOPOEIA 3Acid Stage—Unless otherwise specified 3in the individ-ual monograph 3, the requirements of this portion of the Extended-Release Dosage Formstest are met if the quantities, based on the percentage of the labeled content, of active ingredient dissolved from the Unless otherwise specified 3in the individualunits tested conform to Acceptance Table 3. Continue test-monograph 3, the requirements are met if the quantities of ing through all levels unless the results of both acid and active ingredient dissolved from the dosage units tested buffer stages conform at an earlier level.conform to Acceptance Table 2. Continue testing through the three levels unless the results conform at either L 1 or L 2.Acceptance Table 3Limits on the amounts of active ingredient dissolved are expressed in terms of the percentage of labeled content.Number The limits embrace each value of Q i , the amount dissolved Level TestedCriteriaat each specified fractional dosing interval. Where more No individual value exceeds 10% dis-A 16than one range is specified 3in the individual monograph 3,solved.the acceptance criteria apply individually to each range.Average of the 12 units (A 1 + A 2) is not A 26more than 10% dissolved, and no indi-vidual unit is greater than 25% dissolved.Average of the 24 units (A 1 + A 2 + A 3) is not more than 10% dissolved, and no in-A 312dividual unit is greater than 25% dis-solved.Buffer Stage—Unless otherwise specified 3in the individ-ual monograph 3, the requirements are met if the quantities of active ingredient dissolved from the units tested conform to Acceptance Table 4. Continue testing through the three levels unless the results of both stages conform at an earlier level. The value of Q in Acceptance Table 4 is 75% dissolved unless otherwise specified 3in the individual monograph 3.The quantity, Q , 3specified in the individual monograph 3 is the total amount of active ingredient dissolved in both the Acid and Buffer Stages , expressed as a percentage of thelabeled content. The 5%, 15%, and 25% values in Accep-tance Table 4 are percentages of the labeled content so that these values and Q are in the same terms.Acceptance Table 4NumberLevel Tested CriteriaB16Each unit is not less than Q + 5%.Average of 12 units (B1 + B2) is equal to or B26greater than Q, and no unit is less than Q– 15%.Average of 24 units (B1 + B2 + B3) is equalto or greater than Q, not more than 2 B312units are less than Q – 15%, and no unitis less than Q – 25%.。