COMPARISON OF CYCLIC AND BURST TEST RESULT WITH FE SIMULATION OF A LOCALLY THINNED PIPE BEND

- 格式:pdf

- 大小:1.07 MB

- 文档页数:10

全文分为作者个人简介和正文两个部分:作者个人简介:Hello everyone, I am an author dedicated to creating and sharing high-quality document templates. In this era of information overload, accurate and efficient communication has become especially important. I firmly believe that good communication can build bridges between people, playing an indispensable role in academia, career, and daily life. Therefore, I decided to invest my knowledge and skills into creating valuable documents to help people find inspiration and direction when needed.正文:浮来山千年银杏树的四季变化英语作文全文共3篇示例,供读者参考篇1The Ancient Ginkgo Trees of Mount Fulai: A Yearly Journey Through the SeasonsAs a student who has grown up in the shadow of the majestic Mount Fulai, I have had the privilege of witnessingfirsthand the remarkable transformation of the ancient ginkgo trees that adorn its slopes. These living relics, standing tall and proud, have weathered the test of time, their resilience a testament to the enduring beauty of nature.Spring's AwakeningAs the winter chill begins to dissipate, the ginkgo trees on Mount Fulai awaken from their slumber, ready to embrace the warmth of the new season. The bare branches, which have been stripped of their foliage during the colder months, slowly come to life, adorned with delicate green buds that unfurl like tiny flags heralding the arrival of spring.It is during this time that the mountain takes on a vibrant, emerald hue, as the ginkgo trees join the chorus of rebirth that echoes through the landscape. The air is filled with the sweet fragrance of blossoming flowers, mingling with the earthy scent of the forest floor, creating a symphony of aromas that delights the senses.Summer's Lush EmbraceAs the days grow longer and the sun's rays become more intense, the ginkgo trees of Mount Fulai bask in the glory of summer. Their fan-shaped leaves, a rich shade of green, spreadout in a magnificent canopy, providing cool respite from the heat for hikers and nature enthusiasts alike.It is during this season that the trees truly come into their own, standing tall and proud, their branches swaying gently in the warm breeze. The paths that wind through the mountain are lined with these living giants, creating a verdant tunnel that transports visitors to a realm of tranquility and serenity.Autumn's Golden SplendorAs the summer heat gives way to the crisp coolness of autumn, the ginkgo trees of Mount Fulai undergo a breathtaking transformation. Their leaves, once a vibrant green, slowly begin to turn a brilliant golden hue, painting the mountainside in a tapestry of warm, autumnal tones.It is during this time that the ancient ginkgo trees truly shine, their golden crowns standing in stark contrast against the deep blues and grays of the autumn sky. The air is filled with the gentle rustling of falling leaves, creating a natural orchestra that accompanies the crunch of footsteps on the leaf-strewn paths.Winter's Quiet ReposeAs the last leaves flutter to the ground, the ginkgo trees of Mount Fulai prepare for the long winter ahead. Their barebranches, stripped of their golden finery, stand as silent sentinels against the backdrop of snow-capped peaks and frosted landscapes.It is during this season that the mountain takes on a hushed, almost reverent air, with the ancient ginkgo trees standing as reminders of the cyclical nature of life. Their stark silhouettes against the winter sky are a sight to behold, a testament to their resilience and endurance in the face of nature's harshest conditions.A Living LegacyAs I reflect on the changing seasons and the ancient ginkgo trees that have graced Mount Fulai for centuries, I am struck by the profound connection between these living relics and the history of our region. These trees have witnessed the ebb and flow of civilizations, standing as silent witnesses to the passage of time and the ever-changing landscape.They remind us of the importance of preserving our natural heritage, for they are not mere plants, but living links to our past, present, and future. Each season brings with it a new chapter in the story of these ancient ginkgo trees, a tale woven into the very fabric of Mount Fulai, and one that will continue to be told for generations to come.As I gaze upon these majestic trees, I am filled with a sense of wonder and gratitude, for they have taught me the true meaning of resilience, beauty, and the enduring power of nature. The ancient ginkgo trees of Mount Fulai are more than just trees; they are living embodiments of the cycles of life, reminding us that even in the face of adversity, beauty and renewal are always possible.篇2The Ancient Ginkgo of Fuliaoyama: A Journey Through the SeasonsHigh atop the mist-shrouded peak of Fuliaoyama in western Tokyo stands a living relic of the ancient world. The famed ginkgo tree, estimated to be over a millennium old, stands as a solitary monument to the enduring majesty of nature. Through the turning of the seasons, this towering botanical survivor bears witness to the eternal cycle of life, death, and rebirth that defines our planet. Let me take you on a journey through the year in the life of this arboreal wonder.SpringAs the cold grip of winter reluctantly loosens its hold, the first tender buds appear on the ginkgo's gnarled branches likeemerald pearls awaiting their unveiling. The newly formed leaves, soft as a baby's skin, unfurl in the gentle spring breezes, slowly at first, then in a torrent of vivid green renewal. The tree seems to shrug off the weight of its years as its canopy thickens, basking in the return of the warm sun's nourishing rays.It is a time of reawakening in nature, when colors and fragrances long subdued burst forth in a symphonic celebration of life's perpetual recommencement. I enjoy wandering the ancient forest paths at this time of year, inhaling the rich, loamy scents and listening to the raucous chatter of birds building their seasonal homes. The natural world appears renewed, energized, the circle once more unbroken.SummerThe days grow long and sultry as summer casts its blazing spell over the mountain. Yet the colossal ginkgo stands unperturbed, its dense fan-shaped leaves offering welcome poolsof shade to weary hikers traversing the trails. I've spent many a hot afternoon reclining against the tree's furrowed trunk, feeling the reassuring solidity of a life force persevering through untold eons of time.When the summer rains come, the deep green of the ginkgo's foliage takes on an almost iridescent glow in theshimmering droplets. A crisp, clean scent pervades the air as the storm passes, a primal ozonic incense offered up to the heavens. Through drought, deluge, or searing heat, the ancient tree remains steadfast, a verdant bulwark against the unrelenting onslaught of the seasons.AutumnBut it is in autumn when the ginkgo truly transforms into nature's grandest spectacle. As the temperatures begin their descent, the deep green mantle of summer gives way to a polychrome kaleidoscope of unrestrained brilliance. Golden yellow fans, deeper burnt oranges, and streaks of blazing crimson spill forth first at the highest branches before cascading down in a torrent of incandescent color.The scarlet-tinged ginkgo leaves, unlike the mulched brown offerings from other trees, remain defiantly vibrantly for weeks. They cloak the mountainside in a shimmering amber tapestry before fluttering earthward in gentle zephyrs, creating a dense carpet to insulate and nourish the ancient tree's roots over the harsh winter to come. I savor these autumnal days most, wandering beneath the fiery canopy, my senses heightened by nature's grand farewell.WinterAt last, even the ginkgo's tenacious foliage submits to the inevitable, and the tree stands in monumental silhouette once more against the steel gray skies of winter. Snow frosts the intricate latticework of branches with ethereal white lace. I've huddled beneath the frozen sentrylike boughs on many a blustery evening as dusk envelops the mountain, finding an austere beauty in the ginkgo's stripped splendor.Yet the tree's core remains vibrant and resilient even in this most desolate season. Its thick, corded roots reach deep into the bones of the mountain itself, undaunted by the harshest frosts. Within its dense inner sanctum, the miraculous blueprint for resurrection is carefully conserved, awaiting its cyclical reawakening with the return of spring's verdant summons.So grows the eternal continuum, the seamless transitions from birth, to death, to birth anew. The ancient ginkgo bears perpetual witness, its cyclic renaissance a soothing balm for the transitory concerns that distract us in our daily lives. This living monument of immutable time is both my teacher and my muse, reminding me that for those who embrace the natural rhythms, each season's passing is a mere transition, never an ending. With patience and rugged perseverance, yet another renaissanceawaits just over the horizon. Like a true friend, the ancient ginkgo will be there to greet me again with open arms.篇3The Ancient Ginkgo of Furaisani: A Year in the LifeAs I gaze out over the serene grounds of Chion-in Temple in Kyoto, my eyes are inevitably drawn to the towering ginkgo tree that dominates the landscape. This remarkable living fossil, estimated to be over a thousand years old, stands as a testament to the enduring beauty and resilience of nature. Throughout the changing seasons, the ancient ginkgo of Furaisani undergoes a mesmerizing transformation, reminding us of the cyclical rhythm of life itself.Spring's AwakeningAfter the long, frigid embrace of winter, the first whispers of spring herald the ginkgo's reawakening. As the warm sunrays caress the earth, tiny emerald buds begin to emerge from the seemingly lifeless branches. It is a sight of profound hope, as if the tree itself is exhaling a sigh of relief, ready to embrace the vibrant hues of the new season.With each passing day, the tender leaves unfurl, their delicate fans unfurling to greet the world. The ginkgo's foliagetakes on a brilliant shade of green, so vivid and radiant that it seems to glow from within. This verdant canopy casts a dappled pattern of light and shadow on the ancient temple grounds, creating a serene and inviting atmosphere for visitors and worshippers alike.As spring reaches its peak, the ginkgo tree becomes a verdant oasis amidst the bustling city of Kyoto. Its branches sway gently in the cool breeze, as if performing a graceful dance to welcome the new season. The air is filled with the sweet, earthy scent of freshly unfurled leaves, a fragrance that evokes memories of childhood adventures in the great outdoors.Summer's Lush EmbraceAs the days grow longer and warmer, the ginkgo tree settles into the lush embrace of summer. Its leaves, now fully matured, take on a deeper, richer hue of emerald, casting a cool shade over the temple grounds. Visitors and locals alike seek refuge beneath its sprawling canopy, finding solace from the sweltering heat and respite from the hustle and bustle of city life.During this season, the ginkgo tree stands as a majestic guardian, its branches reaching skyward as if in silent prayer. The gentle rustling of its leaves creates a soothing melody, an accompaniment to the tranquil ambiance of Chion-in Temple.Beneath its boughs, one can almost feel the passage of time slowing down, inviting contemplation and introspection.As summer reaches its zenith, the ginkgo tree becomes a living embodiment of nature's abundance. Its leaves, thick and lush, provide a nurturing canopy for the myriad creatures that call this ancient sanctuary home. Birds flit among the branches, weaving intricate melodies, while squirrels scamper playfully along the gnarled trunk, adding to the symphony of life that surrounds this remarkable tree.Autumn's Golden SplendorAs the days grow shorter and the air takes on a crisp, autumnal chill, the ginkgo tree begins its most spectacular transformation. Its lush green foliage gradually gives way to a breathtaking display of golden hues, as if the tree itself is setting ablaze with the fiery colors of autumn.The leaves, once a verdant emerald, take on a rich, burnished tone, their fans turning a stunning array of yellows, oranges, and reds. This vibrant tapestry is a true spectacle, drawing visitors from near and far to witness the ginkgo's annual show of brilliance.As the weeks pass, the golden leaves begin to flutter gracefully to the ground, carpeting the temple grounds in a shimmering blanket of warmth. Each step through this autumnal wonderland is accompanied by a gentle crunch, a symphony of nature's own making. The air is filled with the earthy scent of fallen leaves, a fragrance that evokes memories of cozy evenings spent by the fireplace.Despite the beauty of this seasonal transformation, there is a bittersweet undertone to autumn's arrival. For as the ginkgo tree sheds its radiant foliage, it reminds us of the impermanence of all things, and the inevitability of change.Winter's Quiet ResilienceAs the chill of winter descends upon Kyoto, the ginkgo tree stands bare, its branches stripped of their colorful adornments. Yet, even in this stark, seemingly lifeless state, the ancient ginkgo exudes a quiet resilience and a profound sense of endurance.Its twisted and gnarled trunk, a testament to the countless seasons it has weathered, takes on a haunting beauty in the winter light. The intricate patterns of its bark, formed over centuries of growth, become more pronounced, inviting one to trace the tree's history with their fingertips.Despite the icy winds and occasional snowfall, the ginkgo tree remains steadfast, its roots firmly anchored in the earth. It is a reminder of the enduring strength of nature, and the capacity of life to persist even in the harshest of conditions.As the winter solstice approaches, the ginkgo tree takes on a solemn, almost reverent atmosphere. Its bare branches stretch skyward, their silhouettes etched against the pale winter sky. In this tranquil state, the tree invites quiet contemplation, a moment to reflect on the cycles of life and the resilience of the natural world.Throughout the ebb and flow of the seasons, the ancient ginkgo of Furaisani stands as a living embodiment of nature's enduring beauty and resilience. Its annual transformation is a testament to the cyclical rhythm of life itself, reminding us of the importance of embracing change and finding wonder in the most humble of moments.As I sit beneath its boughs, watching the ever-shifting tapestry of colors and textures, I am filled with a profound sense of gratitude for this remarkable living fossil. For in its enduring presence, the ginkgo tree teaches us invaluable lessons about perseverance, adaptation, and the interconnectedness of all life. It is a living reminder that even in the face of adversity, beautyand resilience can flourish, inspiring us to embrace theever-changing tapestry of the natural world with wonder and reverence.。

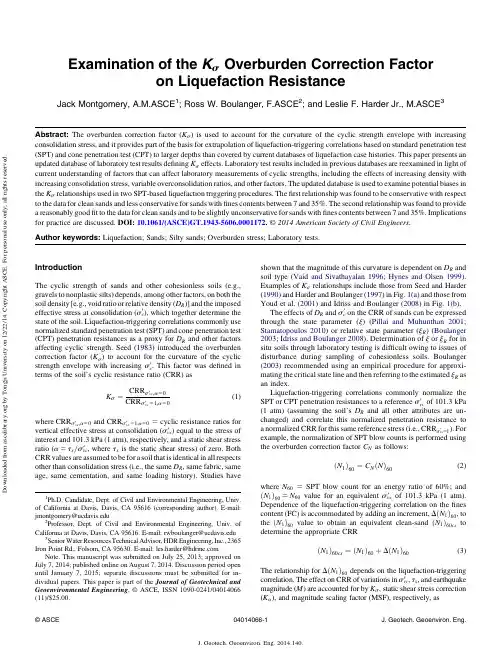

Variable amplitude fatigue of bonded aluminum jointsA.E.Nolting *,P.R.Underhill,D.L.DuQuesnayDepartment of Mechanical Engineering,Royal Military College of Canada,P.O.Box 17000Station Forces,Kingston,Ont.,Canada K7K 7B4Received 1June 2006;received in revised form 16January 2007;accepted 21January 2007Available online 2April 2007AbstractThe effect of variable amplitude loading on the fatigue life and failure mode of adhesively bonded double strap (DS)joints made from clad and bare 2024-T3aluminum was investigated.Under constant amplitude loading,the clad specimens failed through the adhesive or the substrate at high and low stress levels,respectively.The presence of overload cycles shifted the failure mode towards adhesive failure.The specimens made from bare aluminum failed only in the adhesive.Effective stress range vs.failure life curves developed for the bare and clad specimens were used in conjunction with a linear damage summation to predict the failure lives of double strap specimens sub-jected to two variable amplitude aircraft load spectra with reasonable accuracy.Ó2007Elsevier Ltd.All rights reserved.Keywords:Aluminum;Bonding;Adhesive;Cladding;Variable amplitude;Fatigue;Aircraft1.IntroductionThe use of adhesive bonding as a joining method and for patch repairs is increasing in many industries,includ-ing automotive and aerospace.Bonded patch repairs are often performed in the aerospace industry to restore stiff-ness to under-designed areas or locations that have been damaged by corrosion and/or fatigue cracks [1].Bonded doublers are advantageous compared to mechanically fas-tened doublers because their application method does not require the creation of new rivet or bolt holes which could be detrimental to the structure [1].Other advantages include a reduction in fretting between the doubler and the substrate [2]and protection against crevice corrosion [1,3].However,there is a perceived unreliability associated with adhesive bonding that limits its use in industry.When subjected to cyclic loading,fatigue cracks can initiate in the adhesive or at the adhesive/adherend interface.These cracks can propagate and eventually cause failure of the bond.Debonding typically initiates at the edge of thepatches where the stress concentration and peel stresses are highest [4–6]and proceeds towards the center of the patch.Exposure to water,extreme temperature changes or chemicals can accelerate the debonding process by weakening the adhesive and/or the bond interface [7–9].The bond strength is also quite sensitive to surface prepa-ration [3,10]and it can be difficult to achieve ideal bond-ing conditions in the field.Recent research has also indicated that patching over clad material can result in substrate failures at the edges of bonded patches [11,12].However,the Royal Australian Air Force reports that many of their patch repairs have been in service for longer than 20years without durability issues arising from envi-ronmental or fatigue damage [1].To increase confidence in the reliability of bonded joints in fatigue sensitive areas,it is important to develop reliable methods for predicting fatigue lives.These calculations are complicated by a number of factors that are inherent to bonded joints.For example,there are multiple failure modes for a bonded joint,including cohesive or interface failure through the adhesive and failure of the adherends.The transfer of force through the adhesive often results in mixed mode loading,especially in non-symmetric joints.0142-1123/$-see front matter Ó2007Elsevier Ltd.All rights reserved.doi:10.1016/j.ijfatigue.2007.01.027*Corresponding author.Tel.:+19024273434;fax:+19024273435.E-mail address:anolting@ (A.E.Nolting)./locate/ijfatigueAvailable online at International Journal of Fatigue 30(2008)178–187International Journalof FatigueA comprehensive list of the issues plaguing fatigue analysis of bonded joints is given by de Goeij et al.[13].Most of the research into the fatigue behaviour of adhe-sive bonds concentrates on constant amplitude loading. Jethwa and Kinloch[14]conducted fatigue tests on adhe-sively bonded double cantilever beam specimens to pro-duce maximum Mode I strain energy vs.crack growth rate(G Imax vs.d a/d N)curves for different environmental conditions.As an extension of this work,Curley et al.[15]usedfinite element analysis and analytical solutions to determine the total strain energy(G TOTAL=G I+G II) in cracked single lap shear joints.They used the G TOTAL analysis and the G I max vs.d a/d N curves to predict the fati-gue lives of the single lap shear specimens.The fatigue life predictions based on both thefinite element analysis and the analytical solutions of G TOTAL were in good agreement with test results.Dessureault and Spelt[16]examined the correlation between the threshold strain energy release rate in fatigue(G th)and the quasi-static critical energy release rate(G c)for specimens with different loading modes(Mode I,II and mixed Mode I–II).They found that in terms of %G c,mixed mode loading was more damaging than single mode loading.They also found that crack propagation rates were very sensitive to strain energy release and con-cluded that damage tolerance design methods were not appropriate for adhesive bonds.Johnson and Mall[17]cal-culated the total strain energy release rate in the adhesive layer of bonded joints usingfinite element methods.They found that the threshold strain energy release rate,G th, was similar for joints with varying geometries.They also concluded that bonded joints should be designed below the fatigue growth threshold because small changes in the applied stresses resulted in large changes in crack growth, which made the analysis very sensitive to slight errors in the applied loads.Many of the structures that utilize adhesive bonding are subjected to variable amplitude loading.It has been well documented that fatigue damage in metal is dependent on load history.Tensile overload cycles of near yield mag-nitude and compressive overloads have been shown to accelerate crack growth[18,19]while crack growth retarda-tion has been observed on long cracks following tensile overloads that were well below the yield strength of the material[20–22].Fatigue life predictions need to take into account the effect of variable amplitude loading in order to obtain accurate results.There are some phenomenological fatigue models that account for accelerated fatigue damage by introducing a‘cycle mix’term into the cumulative dam-age summation[23,24].The cycle mix term adds to the damage summation when a large change in the mean stress occurs.The terms are usually calibrated to a specific load-ing spectrum using empirically determined constants. DuQuesnay et al.[25,26]used crack closure and an effective stress range damage parameter to explain the effect of var-iable amplitude loading on fatigue damage.They assumed that a crack only causes damage when it is open at the tip. Consequently,if a crack is fully open over the entire load-ing cycle,it will cause the most damage that a cycle of that stress range can possibly cause.Since the crack opening stress is affected by the load history,the stress range over which a crack is open and the damage that the cycle causes are also affected by the load history.DuQuesnay et al. developed effective stress range vs.failure life(D S effvs. N f)curves for fully open loading cycles[26]which represent the maximum amount of damage that could be caused at a given stress range.A linear cumulative damage summation conducted using the D S effvs.N f curves therefore represents the maximum amount of damage that the variable ampli-tude loading spectrum can cause.This approach has been shown to produce an accurate or at least conservative esti-mation of fatigue life[27].In Mode II shear loading,crack closure is caused by the interference of asperities on the crack faces as they slide over one another.Topper et al.[28]found that applying a mean stress normal to the crack interfaces would decrease the interference of the interfaces and increase the damage caused by a given shear stress range.They found that nor-mal stresses applied constantly or as periodic overloads had the same effect of increasing the effective stress range of the cycles.Variable amplitude loading is such an important issue in fatigue life prediction of metal structures that it is reason-able to assume that variable amplitude loading will also affect crack growth in bonded structures.However,the research on variable amplitude loading of adhesively bonded joints is quite limited when compared to the research on constant amplitude loading.Erpolat et al.[23]used the Palgrem–Miner theory(P–M)and an extended P–M theory to predict the service life of various variable amplitude loading spectra.Both the P–M rule and the extended P–M rule consistently produced uncon-servative fatigue life predictions.Incorporating a‘cycle mix factor’into the damage summation produced life esti-mates that were in much better agreement with test results. Yang and Du[29]used a statistical model and constant amplitude data to determine the life of variable amplitude loading spectra.Afitting parameter was used to calibrate the model and Yang and Du state that this parameter might have to be adjusted for each different spectrum. Using a fracture mechanics approach,Ashcroft[30]and Erpolat et al.[31]studied the effect of periodic overload spectra on crack growth in epoxy/carbonfibre reinforced polymer strap lap and double cantilever beam joints, respectively.In both studies,the authors produced strain energy release rate vs.crack growth rate curves(D G vs.d a/d N)using constant amplitude loading.These curves were then used to predict the crack growth of specimens subjected to periodic overload spectra.The predictions underestimated the crack growth,and both studies con-cluded that the overload cycles accelerated the damage caused by the smaller cycles.Ashcroft[30]introduced a parameter w to shift the crack growth curve to the left.This increased the damage predicted by the D G vs.d a/d N curve and consolidated the predicted and observed crack growthA.E.Nolting et al./International Journal of Fatigue30(2008)178–187179rates.The parameter w is dependent on the relative number and magnitude of the overloads,and therefore must be determined for every spectrum.The majority of work on the fatigue behaviour of bonded joints has not examined the effect of a cladding layer on the failure mode.DuQuesnay et al.[11]tested sin-gle lap shear specimens constructed of both bare and clad 2024-T3aluminum under constant amplitude loading. They found that as the applied stress range decreased, the failure mode of the clad specimens changed from fail-ure of the adhesive to failure of the substrate.The substrate failures initiated in the cladding layer at the edge of the patch and propagated into the substrate.To accurately predict the failure mode of adhesive bonds in service load-ing,the effect of variable amplitude loading on the failure mode must be determined.The purpose of this paper is to examine the effect of overload cycles and variable amplitude loading on the fati-gue behaviour of bare and clad adhesively bonded double strap joints.Four sets of fatigue tests were conducted.Thefirst set was constant amplitude tests that compared the fatigue behaviour of bare and clad joints.The next ser-ies of tests subjected the specimens to periodic overload spectra to determine the effect of overload cycles on fatigue life and failure mode.The third test series was effective stress range vs.fatigue life tests,as described by DuQue-snay et al.[26].These were periodic overload tests that are designed to estimate the upper bound of the damage caused by the small cycles in the loading spectrum.The effective stress range vs.failure life curve was used in con-junction with a linear cumulative damage summation to calculate the fatigue lives of specimens subjected to variable amplitude loading spectra.In the fourth series of tests, specimens were subjected to those variable amplitude load-ing spectra and the test results compared to the calculated fatigue lives.2.Test methodologyDouble strap(DS)specimens were constructed from 3.2mm thick2024-T351aluminum alloy sheet in either the bare or clad condition.The aluminum used to make the bare or clad specimens came from the same heat of material.The thickness of the cladding layer was measured using a charge coupled device(CCD)camera that inter-faced with an optical microscope.The thickness of the cladding layer was measured to be0.09mm with a stan-dard deviation of0.005mm.The specimens were made in 150mm wide plates that were cut intofive fatigue speci-mens after the bonding process was completed(Fig.1). The cut sides were milled and lightly sanded in the longitu-dinal direction with400grit sandpaper.Thefinal dimen-sions of the double strap specimens are given in Fig.1. Unclad(bare)aluminum was used for the patches,while either bare or clad aluminum was used for the substrate. The loading direction of the substrate was aligned with the rolling direction of the material.An FM73epoxyfilm adhesive in a knit carrier cloth was used to bond the specimens.The bonding technique,which used a30min warm water soak at50°C and a mercapto-propyltrimethoxysilane surface pretreatment,is described in detail in Underhill et al.[32].The thickness of the adhe-sive was measured using a CCD camera that interfaced with an optical microscope.The thickness of the adhesive was found to be0.13mm with a standard deviation of 0.027mm.The width of the specimens,the substrate thick-ness and the length of the overlap were measured and the applied loads were calculated from the desired stress and the measured specimen dimensions.Reported shear stress values refer to the nominal shear stress in the specimen, as calculated using the area between the patches and the substrate on the side with the shortest overlap(Fig.2). The axial stress values were calculated using the applied load and the area of the substrate material only.The failure mode of each test was reported as a number from0to6,where0represented a fully adhesive failure,6 was a substrate failure and1–5were adhesive failures with varying amounts of damage caused to the cladding layer. Examples of different damage levels are shown in Fig.3. Fig.3a–c show side views of adhesive-failure fracture sur-face,while Fig.3d shows an end view of a substrate-failure fracture surface.Fatigue testing was conducted in load control on servo-hydraulic load frames with closed loop control systems. The test frequency was chosen to minimize the duration of the tests and to keep the errors below1%of the overload cycles.This resulted in test frequencies that variedbetween Fig.1.Double strap specimens,all dimensions inmm.Fig.2.Area used to calculate the nominal shear stress.180 A.E.Nolting et al./International Journal of Fatigue30(2008)178–1875and 15Hz.A number of test series were conducted and are described in the following sections.2.1.Constant amplitude testsConstant amplitude fatigue tests (Fig.4a)were con-ducted at R =0for both the bare and clad alloys.The max-imum stress of the test varied from 22MPa nominal shear stress to the runout stress,with a runout defined as 5·106cycles without failure.The axial stress in the sub-strate at 22MPa nominal shear corresponds to approxi-mately 255MPa of axial stress in the substrate,which is below the yield stress (360MPa)of bare 2024-T3alumi-num [26].2.2.Periodic overload testsA series of tests were conducted to investigate the effect of periodic overloads on the fatigue life and failure mode ofthe double strap specimens.The test spectra consisted of a repeated block of cycles containing an overload cycle fol-lowed by a fixed number of small cycles,as shown in Fig.4b.The magnitudes of the overload and small cycles were held constant at 22and 14MPa nominal shear,respectively,and the minimum stress of all the cycles was 0MPa.These stress levels were chosen because during R =0constant amplitude testing,the clad specimens failed exclusively by adhesive failure at 22MPa and by substrate failure at 14MPa.The number of small cycles following the overload varied between tests and was either 40,80,400or 2000cycles.2.3.Effective stress vs.fatigue life testingThe third series of tests were conducted to produce an ‘effective stress vs.failure life’curve for the double strap specimens (Fig.4c).An effective stress vs.failure life curve represents the damage caused by fully open (i.e.,fullydam-Fig.3.Examples of specimen failure types:(a)Rank 0(fully adhesive failure),constant amplitude loading 0–22MPa shear,N f =1.0·104cycles;(b)Rank 2,constant amplitude loading 0–20MPa shear,N f =3.0·104cycles;(c)Rank 5,variable amplitude loading,1cycle 0–22MPa shear followed by 2000cycles 0–14MPa shear,N f =7.1·105cycles and (d)Rank 6(substrate failure),constant amplitude loading 0–16MPa,N f =1.4·105cycles.A.E.Nolting et al./International Journal of Fatigue 30(2008)178–187181aging)loading cycles and can be used to obtain accurate,or at least conservative,fatigue life predictions using linear cumulative damages summations [26].The opening stress of the crack is depressed by introducing overload cycles.This allows the small cycles following the overload to be fully damaging.The equivalent failure life of the small cycles (N eq )is calculated for each test by forcing the Pal-grem–Miner equation to equal one,subtracting the damage caused by the overload cycles and solving for the failure life of the small cycles,(N fsc )Damage summation ¼1¼N sc N fsc þN olN fol ð1Þsuch that N eq ¼N fsc¼N sc1ÀN olfolwhere N sc and N ol are the number of small cycles and over-load cycles applied to the test specimen,respectively,and N fol is the failure life of the overload cycle,calculated as the average of at least three constant amplitude tests.The maximum stress of all the cycles in these periodic overload tests was kept constant at 22MPa nominal shear and the number of small cycles between overloads was kept constant at 80cycles (Fig.4).The shear stress range of thesmall cycles (i.e.,the minimum stress of the small cycles)varied between tests.2.4.Variable amplitude testingIn the last series of tests,the specimens were subjected to one of two variable amplitude aircraft loading spectra.The first spectrum was taken from the CF 18Hornet fighter and had 2498cycles representing 28.9flight hours.The normal-ized spectrum had a maximum tensile stress of 1.000and a minimum stress of À0.115.The spectrum was scaled to make the maximum and minimum stresses in the spectrum 22MPa and À2.5MPa,respectively.The second spectrum was taken from the CC 130Hercules transport aircraft.It represents moderate aircraft usage,contains 38,253cycles and corresponds to 126flight hours.The normalized spec-trum,which had a maximum tensile stress of 1.000and minimum stress of À0.704,was scaled to make the maxi-mum and minimum stress in the spectrum 22and À15.5MPa nominal shear,respectively.3.Results3.1.Constant amplitude testingThe results of the constant amplitude testing for the bare and clad 2024-T3double strap specimens are presented in Fig.5,with the failure mode indicated by the shape of the symbols.Each data point represents one fatigue test.All of the bare specimens,and the clad specimens subjected to high stress levels,failed by adhesive failure.As the cyclic stress applied to the clad specimens decreased,the failure mode remained essentially adhesive,but increasing amounts of damage to the cladding layer was observed on the bonded surfaces.At the lowest stresses,the clad specimens failed by substrate failure.The fatigue lives of the bare and clad specimens were similar at higher stress levels.At lower stress levels,the clad specimens had shorter fatigue lives than the corresponding bare specimens.This is clearly illustrated in therunoutFig.4.Loading spectra:(a)constant amplitude;(b)periodic overload;and (c)effective stress –failure lifetesting.Fig.5.Constant amplitude shear stress vs.failure life.182 A.E.Nolting et al./International Journal of Fatigue 30(2008)178–187stresses for the bare and clad specimens,which were11and 8MPa shear,respectively.The axial stress in the clad spec-imens at runout was90MPa,which is below the reported fatigue limit of160MPa for smooth,bare2024-T351spec-imens at R=0[26].The fracture surfaces were examined with a light micro-scope at40·magnification.The bare specimen surfaces revealed cohesive failures which initiated at the edge of the patch close to the substrate/adhesive interface.The knit carrier cloth weakened the adhesive and caused the crack path to deviate through the knit carrier clothfibres (Fig.6a and b).As the crack propagated,it moved from the substrate/adhesive interface to the patch/adhesive interface.The clad specimens that experienced adhesive or transi-tional failures had apparent adhesive failures initiating at the substrate/adhesive interface at the edge of the patch. Cohesive failure occurred through thefibres of the knit car-rier cloth(Fig.6b).As with the bare specimens,the loca-tion of debonding switched from the substrate/adhesive interface to the patch/adhesive interface.Damage in the form of cladding pull-out occurred on the cladding layer at low applied stresses(Fig.3a and b).Thefirst occurrences of pull-out appeared near the edge of the patch.As the cyc-lic loads applied to the specimens decreased,the size,num-ber and distance from the patch edge of the cladding pull-out increased.The most severe damage was still observed at the edge of the patch,and the severity(size and number) of the pull-out decreased further away from the patch edge. The pulled-out material was attached to the adhesive on the mating failure surface.On the specimens that failed by substrate failure,fatigue cracks were observed to have initiated in the cladding layer at the edge of the patch.The substrate failures at the high-est stress level showed multiple initiation sites(Fig.7a).As the stress level dropped,the number of initiation sites decreased(Fig.7b).3.2.Periodic overload spectraPeriodic overload tests were conducted to determine if the presence of overload cycles affected the damage caused by the smaller cycles and the failure mode of the specimens. The former was examined by conducting a linear cumula-tive damage summation for each of the tests in this series. The linear damage summation assumes that damage caused by any individual cycle is not affected by the load history of the specimen.If this is true,then the damage summationP nfof any individual test should tend to 1,where n is the number of each unique cycle appliedto Fig.6.Typical adhesive failure surfaces:(a)bare specimens and(b)cladspecimens.Fig.7.Crack initiation in the clad layer:(a)constant amplitude,12–0MPa,N f=4.7·105cycles and(b)constant amplitude,10–0MPa, N f=8.0·105cycles.A.E.Nolting et al./International Journal of Fatigue30(2008)178–187183the specimen and N f is the number of those cycles that will cause failure in constant amplitude loading.A damage summation of less than1indicates that the presence of overloads increases the damage caused by the small cycles, whereas a damage summation greater than1indicates that the presence of overload cycles decreases the damage caused by the small cycles.The linear damage summation was calculated for each test using the following equationDamage sum¼N fn scscN fscþ1scN fol!ð2ÞThe fatigue lives of the constant amplitude overload cycles and the small cycles,N fol and N fsc,respectively,were each taken as the average of at least three constant amplitude tests.N f is the number of cycles to failure for each individ-ual test,while n sc is the number of small cycles applied be-tween overload cycles.The results of the PM damage summation are presented in Fig.8.Each data point in Fig.8represents one fatigue test.The damage summations for both the bare and clad specimens were generally below1,indicating that the pres-ence of overload cycles increases the damage caused by the small cycles.The damage summation increased as the num-ber of small cycles between overloads increased,until it reached approximately1at2000small cycles between over-loads.This suggests that the small cycles directly following the overload cycle are the most damaging and that the effect of the overload cycle becomes negligible if the occur-rence of the overload cycles is sufficiently low.This is con-sistent with observations of metals cycled under periodic overload spectra[18,21].The failure mode of the clad specimens was also affected by the presence of periodic overload cycles.Constant amplitude(CA)testing at22and14MPa resulted in fully adhesive and substrate failures,respectively.However, the periodic overload tests produced only transitional fail-ures.The amount of cladding damage observed on the frac-ture surfaces increased as the number of small cycles between overloads increased.No substrate failures were observed for the specimens tested with periodic overload spectra,even when the effect of the overloads on the dam-age summation was negligible.This indicates that the pres-ence of any overloads will change the failure mode from substrate to transitional,and the more frequently the over-loads occur,the less cladding damage will be present on the bonding surfaces.This series of test was also used to determine the number of small cycles that should be applied following the over-load cycle in the effective stress range vs.failure life testing spectra.The damage caused by the small cycles at40and 80cycles following the overload was approximately con-stant(Fig.8).During effective stress range vs.failure life testing,it is necessary that all of the small cycles in the loading spectrum be fully open and therefore fully effective. The damage summation in Fig.8did not change between 40and80small cycles,which implies that all of the small cycles in those spectra were fully open.Eighty small cycles between overloads was chosen for the effective stress range vs.failure life tests to ensure that all of the small cycles were fully open and to maximize the damage caused by the small cycles in that loadingspectrum.Fig.8.Palgrem–Miner damage summation of periodic overloadtests.Fig.9.Constant amplitude and effective life data for bare2024-T3aluminum.Fig.10.Constant amplitude and effective life data for clad2024-T3aluminum.184 A.E.Nolting et al./International Journal of Fatigue30(2008)178–1873.3.Effective stress vs.fatigue life curve testingThe equivalent fatigue lives of the small cycles calculated from this series of tests using Eq.(1)are plotted with the constant amplitude data in Figs.9and 10for the bare and clad aluminum,respectively.Each data point in these graphs represents one fatigue test.As expected,the equiv-alent fatigue lives of the small cycles in the periodic over-load tests were more damaging and therefore had shorter fatigue lives than constant amplitude tests with the same applied stress range.A curve fit which includes the effective stress range vs.failure life data and the constant amplitude data at 22MPa was used to calculate the fatigues lives of the specimens in variable amplitude loading in Section 3.4.When these curve fits for the bare and clad specimens are plotted on the same axis,it becomes evident that despite the different failure modes,the fatigue lives of the bare and clad specimens are essentially the same (Fig.11).All of the bare specimens failed by adhesive failure.As with the constant amplitude data,the failure mode of the clad specimens evolved from fully adhesive to transitional to substrate failures as the applied stress decreased.How-ever,these transitions occurred at lower stress levels during the effective stress life testing.This was caused by the pres-ence of the overload cycles,which,as shown in the periodic overload data,caused the failure mode to shift towards the ‘adhesive failure’end of the failure mode spectrum.3.4.Variable amplitude testingThe fatigue lives and failure modes of the variable amplitude testing are presented in Table 1.All of the bare specimens and the clad specimens subjected to the CC-130loading spectrum failed by fully adhesive failure.The clad specimens subjected to the CF-18spectrum failed mostly by adhesive failure,with a minor amount of damage to the cladding layer on the failure surface.The difference in the failure mode of the clad specimens between the two loading spectra is attributed to the magnitude of the largest cycle in the spectrum,which was considerably larger for the CC-130loading spectrum.The expected fatigue lives of the specimens were calcu-lated using a cumulative damage summation and the effec-tive stress range vs.fatigue life curves of the clad and bare materials as shown in Fig.11.Variable amplitude fatigue life predictions based on constant amplitude fatigue life data have been reported to give unconservative fatigue life predictions [23,33].However,when effective stress range vs.failure life data (which represents the most damage that can occur at a give stress range)is used,fatigue life predictions based on linear damage summations should produce accu-rate or conservative fatigue life predictions [27].The spec-tra were rainflow-counted and all cycles with a stress range smaller than 4MPa were assumed to cause no dam-age and were not included in the damage summations.The largest cycle in the CC-130spectrum ranged from 22to 15.5MPa nominal shear.The fatigue lives of cycles with stress ranges beyond 22MPa nominal shear were extrapo-lated from the effective stress range vs.fatigue life data.Since the bare and clad specimens had similar fatigue lives under adhesive failure,the bare specimen data were used in the clad specimen calculation for all cycles with a stress range greater than 22MPa nominal shear.Constant ampli-tude tests with maximum and minimum loads of 22and –15.5MPa,respectively were conducted on the bare and clad specimens to confirm that the extrapolated fatigue life values were reasonably accurate.The constant amplitude tests yielded fatigue lives of 933and 1287cycles for the bare specimens and 1593and 581cycles for the clad spec-imens.The fatigue life of this cycle as extrapolated from the bare effective stress range vs.life curve was 771cycles.The extrapolated value is within a factor of two of the test results,indicating that it is reasonable to use the extrapo-lated values.The results of the fatigue life calculations are also presented in Table 1.The effective stress range vs.fatigue life curves for the bare and clad materials were similar,despite the difference in failure mode at lower stress levels and thus the calculated fatigue lives for the bare and clad materials were alsoTable 1Variable amplitude test results Substrate conditionFatigue life N fCalculated fatigue life N fcalcFailure modeCF-F18Spectrum Mostly adhesive Clad7.8·10512.0·105Rank 16.0·105Rank 27.2·105Rank 1Bare5.7·1058.1·105Fully adhesive5.8·1055.1·105CC-130Spectrum Clad 1.0·1061.6·106Fully adhesive 0.84·106Bare1.1·106 1.5·106Fully adhesive1.4·106Fig.11.Effective stress vs.fatigue life curves for clad and bare 2024-T3aluminum.A.E.Nolting et al./International Journal of Fatigue 30(2008)178–187185。

Chaboche Nonlinear Kinematic Hardening ModelSheldon ImaokaMemo Number:STI0805AANSYS Release:12.0.1May4,20081IntroductionThe Chaboche nonlinear kinematic hardening model was added in ANSYS 5.6to complement the existing isotropic and kinematic hardening rules that users relied on.Despite its availability for nearly ten years as of the time of this writing,the Chaboche model has enjoyed limited popularity,in part because of the perceived complexity of calibrating the material parameters. This memo hopes to introduce the basics related to the Chaboche nonlinear kinematic model.Please note that many material parameters for the examples shown in this memo were taken from Reference[5].The author highly recommends obtaining a copy of this book,as it is a useful reference not only for the non-linear kinematic hardening model but also for plasticity and viscoplasticity in general.2Background on Material Behavior2.1Linear vs.Nonlinear Kinematic HardeningThe yield function for the nonlinear kinematic hardening model TB,CHABOCHE is shown below:F= 32({s}−{α})T[M]({s}−{α})−R=0(1) In the above equation,which can be found in Section4of Reference[2],{s} is the deviatoric stress,{α}refers to the back stress,and R represents the yield stress.The back stress is related to the translation of the yield surface, and there is little in Equation(1)that distinguishes it from other kinematic hardening models at this point.1Sheldon’s Tips Chaboche Nonlinear Kinematic Hardening The back stress{α}for the Chaboche model is calculated as follows:{α}=ni=1{αi}(2a){∆α}i=23C i{∆ǫpl}−γi{αi}∆ˆǫpl+1C idC idθ∆θ{α}(2b)whereˆǫpl is the accumulated plastic strain,θis temperature,and C i andγi are the Chaboche material parameters for n number of pairs.In Equation (2b),one may note that thefirst term is the hardening modulus.On the other hand,the second term of the evolution of the back stress is a“recall term”that produces a nonlinear effect.The input consists of defining the elastic properties(e.g.,elastic modulus, Poisson’s ratio)via MP,EX and MP,NUXY,then issuing TB,CHABOCHE,,ntemp,n, where ntemp is the number of temperature sets and n is the number of kine-matic models.Any temperature-dependent group of constants are preceded with the TBTEMP command defining the temperature,while the material pa-rameters for that temperature are entered via the TBDATA command.The first constant is R,or the yield stress of the material—this value may be overridden if an isotropic hardening model is added,as covered in Subsec-tion2.5.The second and third material constants are C1andγ1—these may be followed by additional pairs of C i andγi,depending on the number n of kinematic models requested.2Sheldon’s Tips Chaboche Nonlinear Kinematic Hardening2.2Initial Hardening Modulus3Figure 1:Linear Kinematic Hardening The material parameter C i is the initial hardening modulus .For a single kinematic hardening model (n =1),if γ1is set to zero,the pa-rameter C 1will describe the slope of stress versus equivalent plastic strain.This would represent a linear kinematic hardening model .1One can also reproduce the same behavior with the bilinear kine-matic hardening model (TB,BKIN ),as shown in Figure 1—plots of alinear kinematic hardening model with TB,CHABOCHE as well as TB,BKIN are superimposed,showing identical results.However,one should note that the tangent modulus E tan specified in TB,BKIN is based on total strain,whereas C i in TB,CHABOCHE is based on equivalent plastic ing a stress value σ′>R ,the relationship between C i and E tan is expressed in Equation (3):E tan =σ′−R σ′−R C 1+σ′E elastic −RE elastic(3)It is worth pointing out that there are various plasticity models in ANSYS,where some,such as TB,BKIN ,use equivalent total strain,and others,such as TB,PLASTIC ,use equivalent plastic strain.The Chaboche model in ANSYS uses equivalent plastic strain,and the author prefers this approach,as the elastic modulus and Poisson’s ratio completely describe the elastic behavior,while the nonlinear constitutive model fully defines the plastic behavior.1The term “linear”refers to the relationship of stress and equivalent plastic strain.For ANSYS plasticity models such as “bilinear”or “multilinear”kinematic hardening,these terms describe the relationship between stress and equivalent total strain.3Sheldon’s Tips Chaboche Nonlinear Kinematic Hardening2.3Nonlinear Recall ParameterThe second material parameter,γi,controls the rate at which the hardening modulus decreases with increasing plastic strain.By examining Equation (2b),one can see that the back stress increment{˙α}becomes lower as plastic strain increases.Specifically,a limiting value of C i/γi exists,indicating that the yield surface cannot translate anymore,which manifests itself as a hardening modulus of zero at large plastic strains.A comparison of TB,BKIN with the Chaboche model,including a non-zeroγ1parameter,is shown in Figure2(a).Despite the Chaboche hardening modulus initially being the same as the linear kinematic model,the hard-ening modulus decreases,the rate of which is defined byγi.Figure2(b)is the same plot but at larger strains.One can see the hardening modulus for the Chaboche model decreasing to zero.For this case,the yield stress was assumed to be520MPa.For the Chaboche model, C1=140,600whileγ1=380.Since the limiting value of the back stress{α}is C1γ1=370,one would expect that the asymptotic value would beR+α=890MPa,which matches with the results shown in Figure2(b)..5(a)Small Strain1(b)Larger StrainFigure2:Comparison of Linear and Nonlinear Kinematic Hardening4Sheldon’s Tips Chaboche Nonlinear Kinematic Hardening 2.4Multiple Kinematic Hardening Models1Figure3:Two Kinematic Models A single nonlinear kinematic hard-ening model is described by the two material parameters,C1and γ1,discussed in Subsections2.2and 2.3,respectively.However,a single kinematic model may not be suf-ficient to describe the complex re-sponse of a given material,so with TB,CHABOCHE,up to n=5kine-matic models may be superimposed. This superposition of simple mod-els is another salient feature of theChaboche model,and this idea will be expanded upon in the next subsection.Figure3shows a comparison of three results of stress versus plastic strain —single kinematic models“CHAB and“CHAB1B”are plotted with a two-model version“CHAB The“CHAB model contains the same material parameters as“CHAB and“CHAB1B,”and one may be able to visualize how these two kinematic models are superimposed(assuming constant yield stress R)to create the more complex stress-strain response of“CHAB2.”2.5Combined HardeningThe main usage of the Chaboche model is for cyclic loading applications,as will be discussed shortly.Similar to other kinematic hardening models in ANSYS,the yield surface translates in principal stress space,and the elastic domain remains unchanged.For example,when the loading is reversed for a simple tensile specimen,yielding is assumed to occur atσmax−2R,where σmax is the maximum stress prior to unloading—this is the well-known Bauschinger effect.The Chaboche kinematic hardening model,however,can be used in con-junction with an isotropic hardening model.The isotropic hardening model describes the change in the elastic domain for the material,and the user can select from one of the following:•TB,BISO:Bilinear isotropic hardening,where the user specifies the yield stress and tangent modulus(with respect to total strain)•TB,MISO:Multilinear isotropic hardening,where the user specifies up5Sheldon’s Tips Chaboche Nonlinear Kinematic Hardeningto100stress vs.total strain data points•TB,PLASTIC,,,,MISO:Nonlinear plasticity,where the user specifies up to100stress vs.plastic strain data points•TB,NLISO,,,,VOCE:Voce hardening law,where R=k+R oˆǫpl+ R∞ 1−e−bˆǫpl .Material parameters k,R o,R∞,and b are supplied by the user.1.52.5(a)Voce Hardening.5(b)Voce and ChabocheFigure4:Combined HardeningThe Voce hardening law can be thought of as containing two terms—a linear term R oˆǫpl and an asymptotic term R∞ 1−e−bˆǫpl .A sample model is shown in Figure4(a),where“VOCE1A”is the linear term,“VOCE1B”is the asymptotic term,and“VOCE2”is the complete pare Figure4(a)with Figure3,and note the similarities for the case of monotonic, proportional loading.It may be useful to compare the Voce and two-term nonlinear kinematic hardening models further for monotonic loading situations,in order to better understand the material parameters.The initial yield stress k should bedefined the same for both.R∞=C1γ1describes the limiting,asymptoticvalue that is added to the initial yield stress k.The rate at which this decays is defined by b=γ1.The hardening modulus at very large strains is defined by R o=C2,and for the Chaboche model,γ2=0.Two“equivalent,”sample models are compared in Figure4(b),and one can see that the stress-strain response is the same.Of course,the present discussion comparing the two constitutive models is meant to aid the reader in obtaining a better6Sheldon’s Tips Chaboche Nonlinear Kinematic Hardeningunderstanding of the material parameters rather than to incorrectly imply that the two models are interchangeable for cyclic loading applications.The combination of kinematic and isotropic hardening in the Chaboche references 2typically use a form similar to the Voce hardening law but with-out the constant hardening modulus term:R =k +Q 1−e −b ˆǫpl(4)20Figure 5:Cyclic Hardening To understand how this isotropichardening term is used,consider the case of a strain-controlled load-ing of a test specimen.For cyclic hardening,with ±ǫmax loading,the stress response of a sample model is shown in Figure 5.Note that with progressive number of cycles,the elastic domain expands —this difference in the change in the yield stress is described by the addition of the isotropic hardening term.Also,note that with more cycles,the change in the elastic domain stabilizes.This is why the R o term is neglected for many situations,as the elastic domain does not keep increasing indefinitely.To use calibrated material constants,simply specify k ,R ∞=Q ,and b .The user is not limited to using the Voce hardening law (TB,NLISO,,,,VOCE )with the Chaboche nonlinear kinematic hardening model —use of other isotropic hardening models is permitted.Also,please keep in mind that the value of R ∞=Q is typically a function of the strain range,so the material parameters should be reflective of the expected operational strain ranges.2.6Anisotropic Yield FunctionIt is worth pointing out that the Chaboche model in ANSYS (TB,CHABOCHE )assumes a von Mises yield surface by default.The Hill anisotropic yield function (TB,HILL )may be used in conjunction with TB,CHABOCHE ,although details of this will not be covered in the present memo.2See Refs.[3],[4],and [5]7Sheldon’s Tips Chaboche Nonlinear Kinematic Hardening3Calibration of Single ModelPer page 226of Reference [5],tension-compression tests of symmetric,strain-controlled tests can be used to obtain the material parameters k ,C 1,and γ1.The stabilized hysteresis loops corresponding to different strain amplitudes should be used.The following steps (taken from the above reference)can be used to determine the material parameters:1.Determine the yield stress k from the elastic domain (k is usually half the elastic domain size).2.For a given test,determine the plastic strain range ∆ǫpl .3.For a given test,determine the stress range ∆σ.4.Plotting ∆σ2−k against ∆ǫpl2for the multiple tests,estimate the asymp-totic value corresponding to C 1γing the expression ∆σ2−k =C 1γ1tanh(γ1∆ǫpl2),fit the results to solve for C 1and γ1.This can be done,for example,in Microsoft Excel us-ing the Solver Add-In.Note that curve-fitting procedures often benefit from reasonable initial values.Since C 1is the initial hardening modu-lus,the slope after the yield stress can be taken as an estimate of C 1,and through the relation of C 1γ1determined in Step 4,an initial value of γ1can be obtained.3.1Example Using Several StabilizedCyclesCyclic TestS t r e s sFigure 6:Strain-Controlled TestAn example of stress versus plastic strain is shown in Figure 6,where the test specimen is loaded ±ǫa .Looking at the stabilized hysteresis loop,one can see that the elastic do-main is roughly (300+760)=1,060MPa,so the yield stress k can be estimated as 530MPa.The stress range ∆σis around 2×760=1,520MPa.The plastic strain range ∆ǫpl is estimated to be 2×.21%=0.42%.When two additional strain-controlled,cyclic tests are performed,thefollowing sets of data were obtained:(a)k 2=500,∆σ22=840,∆ǫpl 22=0.37%8Sheldon’s Tips Chaboche Nonlinear KinematicHardeningCurve-Fit Data0.0010.0020.0030.0040.0050.0060.0070.0080.0090.01∆εpl/2∆σ/2- kFigure 7:Curve-Fit Dataand (b)k 3=540,∆σ32=900,∆ǫpl32=0.5625%.All three data points areplotted as red dots in Figure 7,with the abscissa being ∆ǫpl2and the ordinatebeing ∆σ2−k .Using Step 4in Section 3,the asymptotic value was estimated to be ≤400MPa.The yield stress k was estimated to be 530MPa based on k 1,k 2,and k 3values.From Figure 6,the initial hardening modulus C 1was estimated as 164,000MPa,so γ1=410—these were used as starting values.The constants C 1=122,000MPa and γ1=314were then obtained —the curve-fit data matches reasonably well with the presented data,and the parameters could be refined further,if needed.3.2Example Using Single Stabilized CycleIf only data from a single strain-controlled test is available,material inden-tification can still be performed,although the derived parameters are best suited for that particular strain range.9Sheldon’s Tips Chaboche Nonlinear Kinematic HardeningUsing the example shown in Figure 6,assume that stress and plastic strain points for the stabilized loop are tabulated as follows:ǫpl i σi (MPa)-0.0021300-0.0014800.05900.0016800.0021760Table 1:Sample Plastic Strain vs.Stress PointsThere are two items that need adjustment:the plastic strain values ǫpl should start from zero,and the stress needs to be converted to the back stress {α}.Shift the plastic strain values such that the first point starts from zero.For the back stress,determine the elastic range (recall from Subsection 3.1that this was determined to be 1060MPa),then subtract the stress by the yield stress,or half the value of the elastic domain.The resulting values are shown below:ǫpl i αi (MPa)0.0-2300.0011-500.0021600.00311500.0042230Table 2:Corrected Plastic Strain vs.Back StressTo determine the C 1and γ1constants,one may consider using the back stress relation αi =C 1γ1 1−e−γ1ǫpli ,although this expression assumes zero initial back stress.Since the model contains non-zero back stress,the first data point is used in the following equation to solve for the other pairs:αi =C 1γ11−e −γ1ǫpl i +α1e −γ1ǫpl i for i >1(5)One can use Microsoft Excel’s Solver Add-In or any other means to perform a fit to determine C 1and γ1.The considerations noted earlier about using the slope after yielding as the initial value of C 1,along with estimating an initial value of γ1from the asymptotic value,still apply,as these will aid any curve-fitting procedure.10Sheldon’s Tips Chaboche Nonlinear Kinematic Hardening For this example,the author obtained values of C1=120,500MPa and γ1=280.While these values differ slightly from C1=122,000MPa and γ1=314obtained in Subsection3.1,please note that(a)the author did not use a digitizer to determine the data points but used rough,visual estimates, and(b)the curve-fit data obtained from several stabilized cycles should be more representative of behavior over a wider strain range.As an alternative or supplement to the option presented in Subsection 3.1,the user may also use the approach outlined in this subsection to man-ually obtain C1andγ1coefficients for various strain ranges to better under-stand the variation of the material parameters that may be present.3.3Example Using Single Tension CurveA user may only have data from a single tension test but may wish to use the nonlinear kinematic hardening model.While this is not recommended since there is no cyclic test data with which to correlate the material parameters, such an approach may be suitable for situations dealing with a few cycles.Plastic strain and stress data will be estimated from thefirst curve of Figure6,which would represent a single tensile loading case:ǫpl iσi(MPa)0.05200.00055800.0016300.00156800.0022720Table3:Plastic Strain vs.Stress for First CurveAs with the situation presented in Subsection3.2,the stress needs to be converted to the back stress.The yield surface should be determined(for example,by using0.2%offset),and this scalar value should be subtracted from the stress values in Table3.Then,{αi}values for each data point can be matched against the following equation:αi=C1γ1 1−e−γ1ǫpl i(6)The user can solve for values of C i andγi—the same procedure to obtain initial values and to perform the curve-fit as explained above still apply for the uniaxial tension case.For this particular set of data that11Sheldon’s Tips Chaboche Nonlinear Kinematic Hardening was approximated from the first curve of Figure 6,the author obtained C 1=135,300MPa and γ1=380.The use of the single uniaxial test data for this specific example resulted in higher estimates of C 1and γ1compared with those obtained in Subsections 3.1and 3.2,although the asymptoticvalue C 1γ1=356MPa is actually the smallest of the three.As noted above,the lack of cyclic test data prevents validation of the derived material parameters for general cyclic applications.Consequently,the author strongly recommends creating a simple one-element model to simulate the cyclic behavior of the calculated material paramters —in this way,the user can see what the numerical cyclic behavior will be for the set of material parameters.With a simple model,the user may also vary the loading for larger strain ranges in order to understand the response in strain ranges for which no test data is present.3.4Comparison ofResultsCyclic TestS t r e s s Figure 8:Comparison of DataFigure 8shows the original data compared with the three sets of cal-culated material parameters.As one can see,the results for this strain range match reasonably well for all three cases,despite some vari-ation in the C 1and γ1values.How-ever,the parameters derived frommultiple stabilized cycles would beexpected to give the best correlationfor different strain ranges.4Rate-Dependent VersionIn ANSYS 12.0.1,a rate-dependent form of the Chaboche model was intro-duced.This is accessed via adding TB,RATE,,,,CHABOCHE in conjunction with the regular TB,CHABOCHE definition without isotropic hardening.The rate-dependent additions to the Chaboche model (Equations (1)and (2))are shown below:˙ǫpl = σ−RK 1m (7)R =K 0+R 0ˆǫpl +R ∞ 1−e−b ˆǫpl (8)12Sheldon’s Tips Chaboche Nonlinear Kinematic Hardening where thefirst4constants for TB,RATE,,,,CHABOCHE are K0,R0,R∞,and b(isotropic hardening Equation(8))while the last2constants are m and K(rate-dependent Equation(7)).These6material constants are input via the TBDATA command.From looking at the above equations,one can see that the rate-dependent Chaboche model incorporates a strain-rate dependent term(similar to Peirce or Perzyna options)with Voce hardening.5ConclusionBackground information on the Chaboche material model was presented in this memo,along with a basic discussion of the calibration of the material constants for a single nonlinear kinematic hardening model.While phenomena such as rachetting,shakedown,mean stress relaxation, and cyclic softening were not introduced,the information in this memo may serve as a starting point for users wishing to combine multiple nonlinear kinematic hardening models or to define combined(isotropic and kinematic) hardening laws.The reader is encouraged to review the cited references, including[1],for additional details on cyclic plasticity and its definition and usage in ANSYS.Revisions to this Document•STI0805A(November14,2009):Updated for12.0.1.Updated Equa-tion(2),added Section4.Added additional information concerning input in Section1.References[1]ANSYS,Inc.Advanced Structural Nonlinearities,First edition,2005.Inventory Number:002205,ANSYS9.0.[2]ANSYS,Inc.Theory Reference for ANSYS and ANSYS Workbench11.0,2007.[3]Jean-Louis Chaboche.Constitutive Equations for Cyclic Plasticity andCyclic Viscoplasticity.International Journal of Plasticity,5:247–302, 1989.13Sheldon’s Tips Chaboche Nonlinear Kinematic Hardening [4]Jean-Louis Chaboche.On Some Modifications of Kinematic Hardeningto Improve the Description of Ratchetting Effects.International Journal of Plasticity,7:661–678,1991.[5]Jean Lemaitre and Jean-Louis Chaboche.Mechanics of Solid Materials.Cambridge University Press,English edition,1990.14Sheldon’s Tips General InformationSheldon’s Tips and TricksSheldon’s Tips and Tricks are available at the following URL:/sheldon tips/Please remember that,with each release of ANSYS,new features and tech-niques may be introduced,so please refer to the ANSYS documentation as well as your local ANSYS support office to verify that these tips are the most up-to-date method of performing tasks.Disclaimer:the author has made attempts to ensure that the informa-tion contained in this memo is accurate.However,the author assumes no liability for any use(or misuse)of the information presented in this docu-ment or accompanyingfiles.Please refer to for the latest version of this document.Also,this memo and any accompanying inputfiles are not official ANSYS,Inc.documentation.ANSYS TrainingANSYS,Inc.as well as ANSYS Channel Partners provide training classes for ANSYS,Workbench,CFX,FLUENT,ANSYS LS-DYNA,AUTODYN, ASAS,AQWA,TAS,and ICEM CFD rmation on training classes and schedules can be found on the following page:/services/ts-courses.aspANSYS Customer PortalCustomers on active maintenance(TECS)can register for a user account and access the ANSYS Customer Portal.Here,browsing documentation, downloading software(including service packs),and submitting technical support incidents are possible:/customer/XANSYS Mailing ListThe XANSYS mailing list is a forum for exchanging ideas,providing and receiving assistance from other users,and general discussions related to ANSYS and Workbench.(Note that it is recommended to contact your local ANSYS support office for technical support.)You can obtain more information by visiting the following URL:/15。