园林专业外文翻译2

- 格式:doc

- 大小:31.00 KB

- 文档页数:5

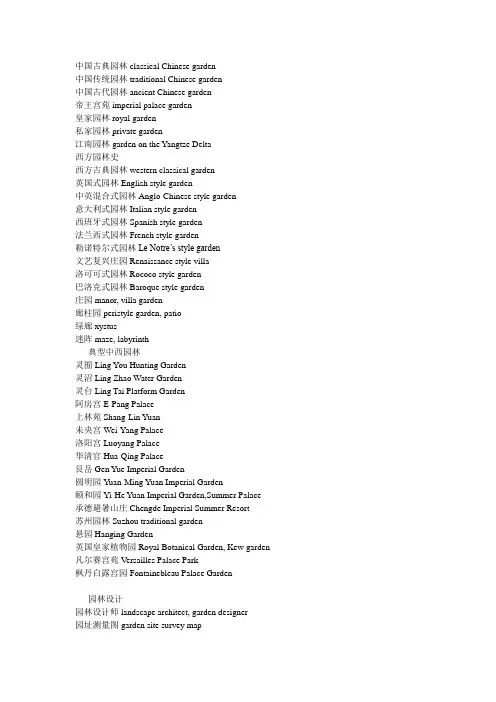

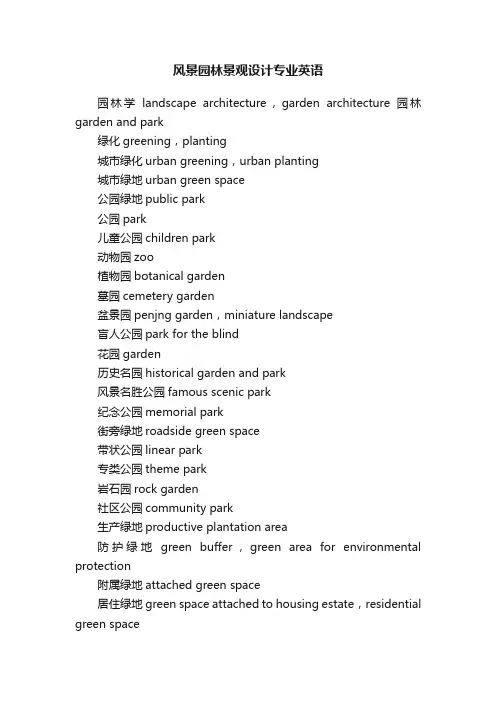

中国古典园林classical Chinese garden中国传统园林traditional Chinese garden中国古代园林ancient Chinese garden帝王宫苑imperial palace garden皇家园林royal garden私家园林private garden江南园林garden on the Yangtze Delta西方园林史西方古典园林western classical garden英国式园林English style garden中英混合式园林Anglo-Chinese style garden意大利式园林Italian style garden西班牙式园林Spanish style garden法兰西式园林French style garden勒诺特尔式园林Le Notre’s style garden文艺复兴庄园Renaissance style villa洛可可式园林Rococo style garden巴洛克式园林Baroque style garden庄园manor, villa garden廊柱园peristyle garden, patio绿廊xystus迷阵maze, labyrinth典型中西园林灵囿Ling You Hunting Garden灵沼Ling Zhao Water Garden灵台Ling Tai Platform Garden阿房宫E-Pang Palace上林苑Shang-Lin Yuan未央宫Wei-Yang Palace洛阳宫Luoyang Palace华清官Hua-Qing Palace艮岳Gen Yue Imperial Garden圆明园Yuan-Ming Yuan Imperial Garden颐和园Yi-He Yuan Imperial Garden,Summer Palace 承德避暑山庄Chengde Imperial Summer Resort苏州园林Suzhou traditional garden悬园Hanging Garden英国皇家植物园Royal Botanical Garden, Kew garden 凡尔赛宫苑Versailles Palace Park枫丹白露宫园Fontainebleau Palace Garden园林设计园林设计师landscape architect, garden designer园址测量图garden site survey map地形图topographic map, contour map种植设计planting design地形改造设计topographical reform design种植大样图detail planting design造价分析cost analysis园林形式garden style规整式园林formal garden style非规整园林informal garden style几何式园林geometric garden style自然式园林natural garden style混合式园林mixed garden style近代巴洛克式园林modern Baroque style马克斯抽象园林R.B. Marx abstract garden园林区划garden area division园林分区规划garden block planning庭院花园courtyard garden前庭front yard, forecourt后庭back yard, rear yard中庭patio厨园kitchen yard沉[床]园sunken garden窗园window garden墙园wall garden宅园home garden台地园terrace garden冬园winter garden切花园cut flower garden屋顶花园roof garden后花园back yard garden园林地形改造topographical reform of garden 土山earth piled hill, artificial mound假山rockery, artificial rockwork太湖石Taihu Lake stone, water modelled stone 黄石yellowish brown stone人造假山石artificial stone, man-made stone 孤赏石monolith, standing stone掇山piled stone hill, hill making叠石stones laying板石flag stone散点石scattered stone抱角石corner stone屋基石foundation stone排衙石guard stone屏石screen stone石岸rock bank石阶stone steps汀步stepping stone on water surface附壁石stone appended to wall石花台stone flower bed石凳stone bench假山石挡土墙rock retaining wall干砌石dry stone wall假山石楼梯rock stairway石亭stone pavilion石洞stone cavern石窟grotto置石stone arrangement, stone layout拱石arch stone拱顶石key stone园林水景water scenes of garden水体water body水面water surface水池pool水塘pond喷泉fountain喷水池fountain pool涉水池wading pool倒影池mirror pool, reflecting pool睡莲池water-lily pool喷水管布置piping schema钓鱼塘fishing pond高水位池塘high water table pond池边坐人矮墙seat wall surrounded pool 隐头喷泉secret fountain岛园island garden半岛园peninsula garden小岛isle瀑布waterfall小瀑布cascade湖lake矶rock projecting over water水帘洞water curtain cave园桥garden bridge拱桥arch bridge石板桥stone slab bridge木板桥plank bridge圆木桥log bridge亭桥pavilion bridge曲桥zigzag bridge壁泉wall fountain饮水喷头drinking fountain植物配植plant arrangement树木配植arrangement of trees and shrubs 群植group planting, mass planting孤植specimen planting, isolated planting 丛植clump planting组植group planting林植forest planting列植linear planting对植opposite planting, coupled planting 环植circular planting带植belt planting散植scattered planting, loose planting边界种植boundary planting整形种植architectural planting角隅种植corner planting景框种植planting as enframent门卫种植guard planting篱恒种植fence planting障景种植screen planting背景种植background planting林下种植underwood planting路边种植roadside planting绿篱hedge树墙espalier庭荫树shade tree园景树specimen tree风景林amenity forest, ornamental forest 行道树avenue tree, street tree纪念林memorial forest整型树topiary tree花篱flower hedge’刺篱thorny plants hedge常绿绿篱evergreen hedge落叶绿篱deciduous hedge高篱high hedge沟中边篱hah-hah fence图案矮篱pattern dwarf hedge迷宫绿篱labyrinth hedge整剪绿篱clipped hedge自然式花篱natural flowering hedge边篱boundary fence园篱garden fence, garden hedge纯林pure forest混交林 mixed forest林间隙地 open space in woodland杂木林 spinney树冠覆盖面 tree canopy草坪 lawn整形草坪 formal lawn开花草坪 flowering lawn牧场草坪 meadowy land花坛 flower bed路边花坛 roadside flower bed带状花坛 ribbon flower bed时钟花坛 flower clock盆栽花坛 potted flower bed, basined flower bed高设花台raised flower bed毛毡花坛 carpet bed镶嵌花坛 mosaic bed铺石花坛 paved bed灌木花坛 shrub bed图案花坛群 parterre草药花坛 herbaceous flower bed花结花坛 knot bed整形花坛 formal flower bed花境 flower border花桶flower tub植树箱planting box活动花坛movable flower bed瓶饰garden vase灌木花境shrub border混合花境mixed border园林道路设计garden road design, garden path design 漫步路trail, footway小径alley, path川草坪岛lawn island安全岛traffic island, refuge island转弯曲度turning curvature转弯半径turning radius踏面landing pitch步石stepping stone涉水踏步wading step错铺路crazy paving path随意组合方石板路flag stone path paved at random花纹路pattern path林荫路mall林荫大道boulevard花园路parkway林间小道path in woodland种植池planting bed树干保护套栏tree guard树池坐凳矮墙seatwall-surrounded planting 路面线纹score line。

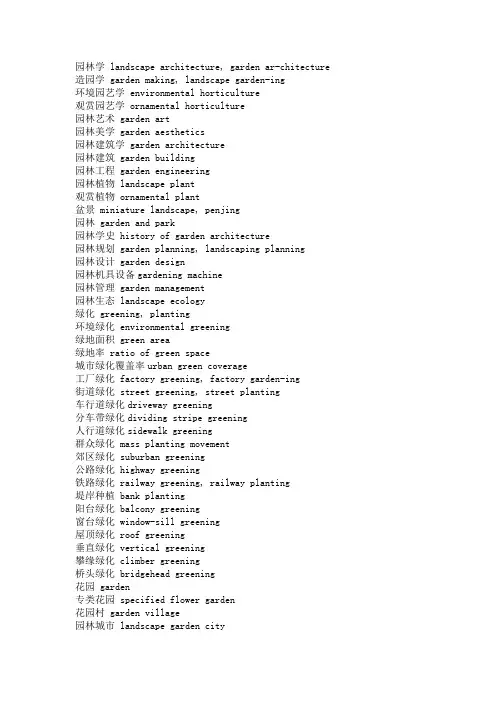

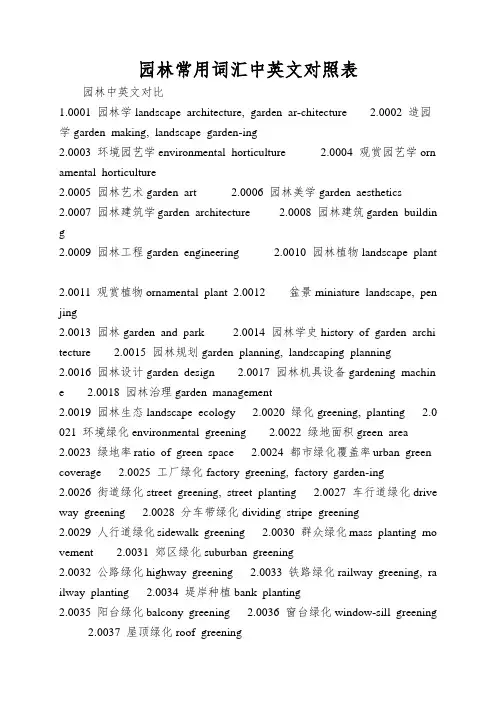

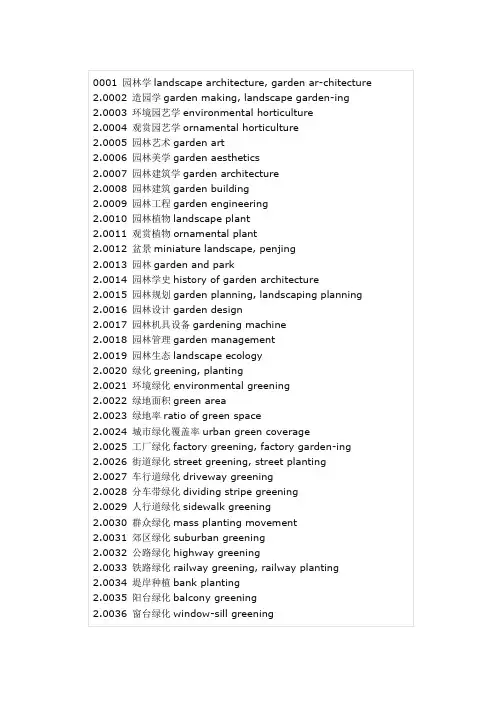

园林学 landscape architecture, garden ar-chitecture 造园学 garden making, landscape garden-ing环境园艺学 environmental horticulture观赏园艺学 ornamental horticulture园林艺术 garden art园林美学 garden aesthetics园林建筑学 garden architecture园林建筑 garden building园林工程 garden engineering园林植物 landscape plant观赏植物 ornamental plant盆景 miniature landscape, penjing园林 garden and park园林学史 history of garden architecture园林规划 garden planning, landscaping planning园林设计 garden design园林机具设备gardening machine园林管理 garden management园林生态 landscape ecology绿化 greening, planting环境绿化 environmental greening绿地面积 green area绿地率 ratio of green space城市绿化覆盖率urban green coverage工厂绿化 factory greening, factory garden-ing街道绿化 street greening, street planting车行道绿化driveway greening分车带绿化dividing stripe greening人行道绿化sidewalk greening群众绿化 mass planting movement郊区绿化 suburban greening公路绿化 highway greening铁路绿化 railway greening, railway planting堤岸种植 bank planting阳台绿化 balcony greening窗台绿化 window-sill greening屋顶绿化 roof greening垂直绿化 vertical greening攀缘绿化 climber greening桥头绿化 bridgehead greening花园 garden专类花园 specified flower garden花园村 garden village园林城市 landscape garden city蔷薇园 rose garden松柏园 conifer garden球根园 bulb garden宿根园 perennial garden假山园 rock garden, Chinese rockery狩猎场 hunting ground街心花园 street crossing center garden小游园 petty street garden水景园 water garden铺地园 paved garden野趣园 wild plants botanical garden野生植物园wild plants garden乡趣园 rustic garden盆景园 penjing garden, miniature land-scape 动物园 zoo, zoological garden墓园 cemetery garden沼泽园 bog and marsh garden水生植物园aquatic plants garden学校园 school garden室内花园 indoor garden芳香花园 fragrant garden盲人花园 garden for the blind公园 park, public park城市公园 city park, urban park区公园 regional park儿童公园 children park体育公园 sports park森林公园 forest park纪念公园 memorial park烈士纪念公园martyr memorial park综合公园 comprehensive park文化公园 cultural park文化休憩公园cultural and recreation park中央公园 central park天然公园 natural park海滨公园 seaside park, seabeach park古迹公园 historic site park河滨公园 riverside park湖滨公园 lakeside park路边公园 roadside park, street park娱乐公园 amusement park雕塑公园 sculpture park休憩公园 recreation park疗养公园 sanatorium park国家公园 national park邻里公园 neighborhood park特种公园 special park植物园 botanical garden植物公园 abeled plants park高山植物园 alpine garden热带植物园 tropical plants garden药用植物园 medical plants garden, herb garden绿地 green space公共绿地 public green space单位绿地 unit green area城市绿地 urban green space街道广场绿地street and square green area居住区绿地 residential quarter green area防护绿地 green area for environmental protection 郊区绿地 suburban green space街坊绿地 residential block green belt附属绿地 attached green space生产绿地 productive plantation area苗圃 nursery风景 landscape, scenery自然景观 natural landscape人文景观 human landscape, scenery of humanities 草原景观 prairie landscape山岳景观 mountain landscape, alpine landscape地理景观 geographical landscape湖泊景观 lake view郊区景观 suburban landscape地质景观 geological landscape喀斯特景观 karst landscape植物景观 plants landscape, flora landscape中国古典园林classical Chinese garden中国传统园林traditional Chinese garden中国古代园林ancient Chinese garden中国山水园 Chinese mountain and water garden帝王宫苑 imperial palace garden皇家园林 royal garden私家园林 private garden江南园林 garden on the Yangtze Delta西方古典园林 western classical garden英国式园林 English style garden中英混合式园林Anglo-Chinese style garden意大利式园林 Italian style garden西班牙式园林 Spanish style garden法兰西式园林 French style garden勒诺特尔式园林Le Notre's style garden文艺复兴庄园 Renaissance style villa洛可可式园林 Rococo style garden巴洛克式园林 Baroque style garden圆明园 Yuan-Ming Yuan Imperial Garden颐和园 Yi-He Yuan Imperial Garden,Summer Palace 承德避暑山庄Chengde Imperial Summer Resort苏州园林 Suzhou traditional garden悬园 Hanging Garden英国皇家植物园Royal Botanical Garden, Kew garden 凡尔赛宫苑 Versailles Palace Park枫丹白露宫园 Fontainebleau Palace Garden园林艺术景 view, scenery, feature远景 distant view近景 nearby view障景 obstructive scenery, blocking view借景 borrowed scenery, view borrowing对景 opposite scenery, view in opposite place缩景 miniature scenery, abbreviated scenery漏景 leaking through scenery框景 enframed scenery尾景 terminal feature主景 main feature副景 secondary feature配景 objective view夹景 vista line, vista前景 front view背景 background景序 order of sceneries景点 feature spot, view spot仰视景观 upward landscape俯视景观 downward landscape季相景观 seasonal phenomena气象景观 meteorological diversity scenery视野 visual field秋色fall color, autumn color园林空间 garden space开敞空间 wide open space, wide space动观 in-motion viewing静观 in-position viewing视错觉 visual illusion园林艺术布局artistic layout of garden对称平衡 symmetrical balance不对称平衡asymmetrical balance左右对称 bilateral symmetry辐射对称 radial symmetry透景线 perspective line轴线 axis, axial line主轴 main axis副轴 auxiliary axis暗轴 hidden axis, invisible axis树冠线 skyline园林色彩艺术 art of garden colors单色谐调 monochromatic harmony复色谐调 compound chromatic harmony对比色突出 contrast colors accent近似色谐调 approximate colors harmony暖色 warm color冷色 cool color色感 color sense城市绿地系统规划 urban green space system planning 绿地系统 green space system公共绿地定额 public green space quota公共绿地指标 public green space norm绿地布局 green space layout吸引圈 attractive circle吸引距离 attractive distance有效半径 effective radius绿地资源 green space resource绿地效果 green space effect绿地规划程序 planning procedure of the green space 空间规划 space planning形象规划 image plan实施规划 implementary plan必要生活空间 necessary living space块状绿地 green plot点状绿地 green spot放射状绿地 radiate green space公园规划 park planning园林总体规划 garden master planning总平面规划 site planning园林分区 garden zoning安静休息区 tranquil rest area儿童活动区 children playing space儿童游戏场 children playground, playlot体育运动区 sports activities area野餐区 picnic place散步区 pedestrian space群众集会区mass meeting square观赏植物区ornamental plants area观赏温室区display greenhouse area, display conservatory area 草坪区 lawn space绿荫区 shade tree section历史古迹区 historical relics area青少年活动区 youngsters activities area诱鸟区 bird sanctuary area钓鱼区 fishing center野营区 camp site游人中心 visitors center服务中心 service center探险游乐场 adventure ground文化活动区 cultural activities area道路系统 approach system, road system环形道路系统 circular road system方格形道路系统 latticed road system放射形道路系统 radiate road system自然式道路系统 informal road system规整式道路系统 formal road system混合式道路系统 mixed style road system园林规划图 garden planning map园林规划说明书 garden planning direction城市公园系统 urban park system公园分布 distribution of parks公园类型 park type, park category公园间距 distance between parks公园形式 park styles游览区 excursion area, open-to-public area非游览区 no-admittance area办公区 administrative area服务区 service center动休息区 dynamic rest space静休息区 static rest space娱乐演出区 entertaining performance place主要入口 main entrance次要入口 secondary entrance人流量 visitors flowrate车流量 vehicle flowrate公园道路 park road公园水陆面积比率land-water ratio游人容纳量 visitors capacity风景资源调查landscape resource evaluation风景学 scenicology风景规划 landscape plan风景设计 landscape design游览路线 touring route旅游资源 tourism resource旅游地理 tourism geography旅游地质 tourism geology历史名城 famous historical city文化名城 famous cultural city文化遗址 ancient cultural relic天然博物馆 natural open museum风景地貌 natural geomorphology造型地貌 imaginative geomorphologic figuration风景区 scenic spot, scenic area风景名胜 famous scenery, famous scenic site特异景观风景区specific natural scenes area民族风俗风景区scenic spot of minority customs高山风景区 alpine scenic spot海滨风景区 seabeach scenic spot森林风景区 forest scenic spot高山草甸风景区alpine tundra landscape spot峡谷风景区 valley scenic spot江河风景区 river landscape district湖泊风景区 lake round scenic spot温泉风景区 hot spring scenic spot瀑布风景区 waterfall scenic spot禁伐禁猎区 region forbidden to tree cutting and hunting 封山育林区 region closed for afforestation天池风景区 crater lake scenic spot自然保护区 nature protection area科学保护区 protection area for scientific research天然纪念物 natural monument生物圈保护区 biosphere protection area园林设计园林设计师 landscape architect, garden designer园址测量图 garden site survey map地形图 topographic map, contour map种植设计 planting design园林形式 garden style规整式园林 formal garden style非规整园林 informal garden style几何式园林 geometric garden style自然式园林 natural garden style混合式园林 mixed garden style园林区划 garden area division园林分区规划 garden block planning宅园 home garden台地园 terrace garden冬园 winter garden切花园 cut flower garden屋顶花园 roof garden后花园 back yard garden园林地形改造 topographical reform of garden 土山 earth piled hill, artificial mound假山 rockery, artificial rockwork太湖石 Taihu Lake stone, water modelled stone 黄石 yellowish brown stone人造假山石 artificial stone, man-made stone 假山石楼梯 rock stairway石亭 stone pavilion石洞 stone cavern石窟 grotto置石 stone arrangement, stone layout拱石 arch stone拱顶石 key stone园林水景 water scenes of garden水体 water body水面 water surface水池 pool水塘 pond喷泉 fountain喷水池 fountain pool涉水池 wading pool倒影池 mirror pool, reflecting pool睡莲池 water-lily pool隐头喷泉 secret fountain岛园 Island garden半岛园 peninsula garden小岛 isle瀑布 waterfall小瀑布 cascade湖 lake水帘洞 water curtain cave园桥 garden bridge拱桥 arch bridge石板桥 stone slab bridge木板桥 plank bridge圆木桥 log bridge亭桥 pavilion bridge曲桥 zigzag bridge壁泉 wall fountain饮水喷头 drinking fountain植物配植 plant arrangement树木配植 arrangement of trees and shrubs 群植 group planting, mass planting孤植 specimen planting, isolated planting 丛植 clump planting组植 group planting林植 forest planting列植 linear planting对植 opposite planting, coupled planting 环植 circular planting带植 belt planting散植 scattered planting, loose planting 边缘种植 edge planting边界种植 boundary planting整形种植 architectural planting基础种植 foundation planting角隅种植 corner planting景框种植 planting as enframent门卫种植 guard planting篱恒种植 fence planting障景种植 screen planting背景种植 background planting林下种植 underwood planting路边种植 roadside planting园景树 specimen tree风景林 amenity forest, ornamental forest 行道树 avenue tree, street tree高篱 high hedge沟中边篱 hah-hah fence图案矮篱 pattern dwarf hedge迷宫绿篱 labyrinth hedge整剪绿篱 clipped hedge自然式花篱 natural flowering hedge边篱 boundary fence园篱 garden fence, garden hedge纯林 pure forest混交林 mixed forest林间隙地 open space in woodland杂木林 spinney树冠覆盖面 tree canopy草坪 lawn整形草坪 formal lawn开花草坪 flowering lawn牧场草坪 meadowy land花坛 flower bed路边花坛 roadside flower bed带状花坛 ribbon flower bed时钟花坛 flower clock盆栽花坛 potted flower bed, basined flower bed高设花台 raised flower bed毛毡花坛 carpet bed镶嵌花坛 mosaic bed铺石花坛 paved bed灌木花坛 shrub bed图案花坛群 parterre草药花坛 herbaceous flower bed花结花坛 knot bed整形花坛 formal flower bed灌木花境 shrub border混合花境 mixed border园林道路设计garden road design, garden path design 漫步路 trail, footway林荫路 mall林荫大道 boulevard花园路 parkway林间小道 path in woodland种植池 planting bed传统园林建筑 traditional garden building凉亭 summer shelter活树亭 arbor, tent arbor蘑菇亭 mushroom pavilion茅亭 thatched pavilion竹亭 bamboo pavilion茶亭 tea booth, tea kiosk扶手栏杆 handrail坐凳栏杆 seat rail石碑 stone tablet, stele园林露天剧场 open garden theater园林露天舞池 open garden dancing place露天音乐台 outdoor music stand园林小品 small garden ornaments磁砖壁画 painted tile mural tablet园椅 garden chair, garden seat园凳 garden bench园桌 garden table园灯 garden lamp日规 sundial鸟浴 bird bath鸟舍 bird cottage, nestle box鸟笼 bird cage, bird coop悬篮 hanging basket树棚 living-tree pergola花架 pergola园林施工 garden layout, garden construction种植工程 planting engineering观赏树木 ornamental tree and shrub观叶植物 foliage plant观果植物 fruit-effect plant观枝干植物 plants with ornamental trunks and branches 指示植物 indicating plant主景植物 accent plant耐湿植物 damp tolerant plant抗风植物 wind-resistant plant耐盐碱植物 saline-alkali tolerant plant市花 city flower市树 city tree国花 national flower国树 national tree芳香植物 fragrant plant抗污染植物 pollution resistant plant环保植物 environment protecting plant高山植物 alpine plant岩生植物 rock plant攀缘植物 climbing plant, climber地被植物 ground cover plant阴生植物 shade plant装饰植物 decorative plant装缘植物 edging plant绿蓠植物 hedge plant草坪植物 lawn plant, lawn grass花坛植物 bedding plant球根植物 bulbous plant宿根植物 perennial plant, perennial水生植物 aquatic plant, hydrophyte旱生植物 xerophyte沼泽植物 bog plant, swamp plant室内装饰植物 indoor decorative plant, house plant切花 cut flower垂枝植物 pendulous plant, weeping plant缠绕植物 twiner, twinning plant针叶植物 needle-leaved plant阔叶植物 broad-leaved plant斑叶植物 variegate-leaved plant松柏植物 conifer常绿植物 evergreen plant半常绿植物 semi-evergreen plant不耐寒植物 tender plant半耐寒植物 half-hardy plant耐寒植物 hardy plant耐旱植物 drought enduring plant山石材料 stone material昆山石 Kunshan stone钟乳石 stalactite灵壁石 Lingbi stone英德石 Yingde stone青石 Qing stone宣石 Xuan stone房山石 Fangshan stone观赏动物 ornamental animal观赏鸟类 ornamental bird观赏兽类 ornamental beast观赏昆虫类 ornamental insect园林机具设备园林机械 garden machine园林工具 garden instrument, garden implement园林设备 garden equipment花坛分界隔板 plastic bed divider种植容器 planting container圆木桩 log peg喷射装置 jet bubbler滴灌 trickle irrigator, drip irrigator环动喷灌器 circle sprinkler圆筒喷灌器 rotor sprinkler自控器 automatic controller管端喷灌器 hose end sprinkler固定喷灌器 stationary sprinkler喷雾喷灌器 mist sprinkler, spray head sprinkler喷灌覆盖面 sprinkler coverage草坪加肥器 lawn feeder施肥喷灌器 combined feeder and sprinkler液肥混合调配器 liquid fertilizer mixer-proportioner滴水喷头 emitter, dripper水土保持塑料网 erosion control plastic net苗木包装材料nursery stock package material麻布袋 burlap bag铁丝篮 wire basket篮状种植器 basket container塑料苗木桶 plastic nurserican播种盘 seed tray网孔盆 mesh pot含肥泥炭盆 fertile peat pot盆栽机 potting machine换盆机 repotting machine再生纸种植器 reclaimed paper container纤维育苗器 wood fiber plant grower泥炭压制播种饼 peat seeding pellet, peat seeding starter 松土除草机 cultivator旋转锄 rotary hoe切叶机 foliage cutter翻地犁 uncovering plough盖土机 mounted spreader前悬装土机 front mounted loader后缀装土机 rear mounted loader旋轴剪草机 spindle mower栽植机 planting machine植物覆盖 plant mulching覆盖物分散机 mulch spreader种子液肥喷洒机 hydro seeder修枝剪 pruning shear播种器 garden seeder球根种植器 bulb planter土壤酸度探测器 pH-value computer巴效分析器 fertilizer analyzer嫁接刀 grafting knife温室设备 greenhouse equipment盆栽灌水系统 pot watering system温室气候控制器 greenhouse climate controller温室覆盖 greenhouse covering喷雾自控系统 automatic mist control system二氧化碳发生器 C02 generator温度报警钟 temperature alarm游览车 park sightseeing bus引剪草机 lawn mower动力剪草机 power lawnmower畜力剪草机 horse lawnmower手推剪草机 hand lawnmower游人调查 visitors investigation游人统计 visitors statistics游人分析 garden visitors analysis游人管理 visitors management导游图 tourist map导游解说 tour description and direction劳动管理 labour management物资管理 material handling, goods handling设备管理 equipment management, facility management财务管理 financial management安全管理 safety management环境监测 environmental monitor植物养护管理 plant maintenance and management园林技术管理 garden technical management质量管理 quality management园貌维修 garden feature maintenance植物整形修剪 plant trimming and pruning植物病虫防治 disease and insect control园林管理规划 management plan游人意见处理 treatment of visitors opinions游人规则 visitors regulation园内交通管理 traffic control in park园外交通管理 traffic control out of park entrance汽车停车规则 parking rules自行车停放规则 bicycle parking rules开放时间 opening time日常清洁卫生管理 daily sanitation and hygiene management 人类生态环境 human ecological environment自然系统 natural system自然资源 natural resource自然保护 conservation of nature自然保存 natural preservation环境保护 environmental protection环境容量 environment capacity环境适宜性 environment fitness环境空气质量标准 ambient air quality共生 symbiosis互惠共生 mutualism公害 public nuisance生态绝灭 ecological extinction生态系统 ecosystem生态圈 ecosphere生态灾难 ecological disaster环境质量 environmental quality环境压力 environment stress生命维持系统 life-support system反馈系统 feedback system自养生物 autotroph异养生物 heterotroph食物链 foodchain生物圈 biosphere濒危植物 endangered plant, threatened plant 主体群落 major community人工群落 artificial community绿色革命 green revolution户外娱乐资源 outdoor recreation resource原始环境系统 wilderness environment system近代环境系统 modern environment system乡村生活模式 country life-pattern烟害 smoke pollution, fume pollution雾害 fog pollution霜害 frost injury水污染 water pollution土壤污染 soil pollution, soil contamination 园林小气候 garden microclimate环境保护植物 environmental conservation plant 引气候调节 climatic regulation自动调节机能 homeostasis生态平衡 ecological homeostasis森林生态系统 forest ecosystem草原生态系统 prairie ecosystem滞尘植物 dust holding plant。

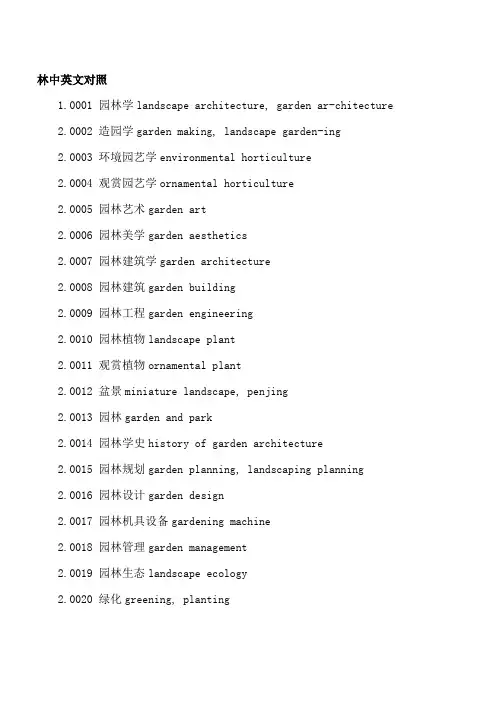

园林中英文对照1.0001 园林学landscape architecture, garden ar-chitecture2.0002 造园学garden making, landscape garden-ing2.0003 环境园艺学environmental horticulture2.0004 观赏园艺学ornamental horticulture2.0005 园林艺术garden art2.0006 园林美学garden aesthetics2.0007 园林建筑学garden architecture2.0008 园林建筑garden building2.0009 园林工程garden engineering2.0010 园林植物landscape plant2.0011 观赏植物ornamental plant2.0012 盆景miniature landscape, penjing2.0013 园林garden and park2.0014 园林学史history of garden architecture2.0015 园林规划garden planning, landscaping planning2.0016 园林设计garden design2.0017 园林机具设备gardening machine2.0018 园林管理garden management2.0019 园林生态landscape ecology2.0020 绿化greening, planting2.0021 环境绿化environmental greening2.0022 绿地面积green area2.0023 绿地率ratio of green space2.0024 城市绿化覆盖率urban green coverage2.0025 工厂绿化factory greening, factory garden-ing2.0026 街道绿化street greening, street planting2.0027 车行道绿化driveway greening2.0028 分车带绿化dividing stripe greening2.0029 人行道绿化sidewalk greening2.0030 群众大规模绿化mass planting movement2.0031 郊区绿化suburban greening2.0032 公路绿化highway greening2.0033 铁路绿化railway greening, railway planting2.0034 堤岸种植bank planting2.0035 阳台绿化balcony gardening2. 0。

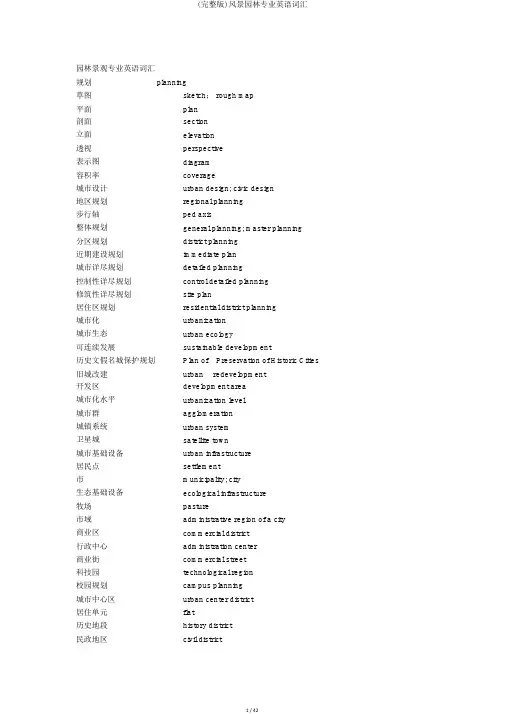

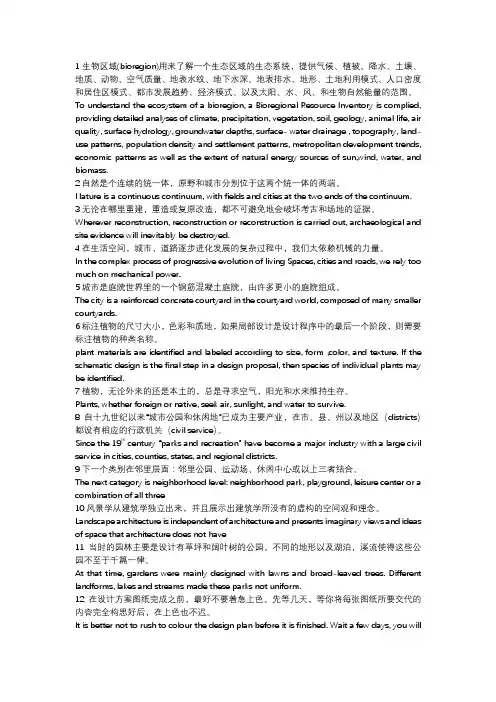

园林景观专业英语词汇规划planning草图sketch; rough map平面plan剖面section立面elevation透视perspective表示图diagram容积率coverage城市设计urban design; civic design地区规划regional planning步行轴ped axis整体规划general planning; master planning分区规划district planning近期建设规划immediate plan城市详尽规划detailed planning控制性详尽规划control detailed planning修筑性详尽规划site plan居住区规划residential district planning城市化urbanization城市生态urban ecology可连续发展sustainable development历史文假名城保护规划Plan of Preservation of Historic Cities 旧城改建urban redevelopment开发区development area城市化水平urbanization level城市群agglomeration城镇系统urban system卫星城satellite town城市基础设备urban infrastructure居民点settlement市municipality; city生态基础设备ecological infrastructure牧场pasture市域administrative region of a city商业区commercial district行政中心administration center商业街commercial street科技园technological region校园规划campus planning城市中心区urban center district居住单元flat历史地段history district民政地区civil district水警区居住区规划护林区工业区林木种子公园迅速公路城市美学游憩空间系统工程城市更新理论waters guard district residential district planning ranger districtindustrial districttree seed orchard thruwayurban esthetics esplanadesystems engineering urban renewal theory绿地 / 绿化带绿化覆盖率绿地率工厂绿化广场绿化居住区绿化谷底植栽场公共建筑绿化室内绿化城市绿化城市绿化系统公共绿地专用绿地防备绿地greenbeltpercentage of greenery coverageratio of green spacelandscaping within factorylandscaping of squarelandscaping of residential areaimproved vegetation & wild lifelandscaping around public buildingindoor gardenurban virescenceurban green space systempublic green spacespecified green spacegreen buffer建筑空间剧院茶馆(馆)专卖店博物馆电影院商场体育馆青少年宫图书室棋牌室健身房书店客堂露台浴室architectureshow place; theatercaff ; tea shopmonopolistic shopmuseumcinema ; movie houseemporium; shopping mallpalaestracallan house; children ’s palacelibraryrelaxation roomgymnasiumbook storeparlorbalconybathroom橱柜合院式建筑餐厅进口厨房屋顶小孩房小孩游玩室起居室门廊换衣室歇息室私人花园居民共享地带工人房比率元素会议中心/ 玩具室cabinetcourtyard buildingdining-room; dining hallentrancekitchenroofkid roomdollhouseliving roomporchchange roompavilionprivate gardenresidentshared zoneservants hallscaleelementconference center园林景观view of the garden乔木灌木铺石地下车库曲线形铺地庭园标记牌庭院瀑布步道园桥园林草本植物藤本植物蔓本植物砌石铺地亭,阁榭植被花坛大广场arborshrubband stonecar park bellowcurved paving bands cartilage; Garth(sign) courtyard identification sign courtyardfallfootpathgarden bridgegarden and parkherbagelianeliananatural cut stonepavepavilionpavilion on terraceplantingplanting bedsplaza台platform栈道deck promenade灯柱pole lights小水池pool雕塑sculpture小广场small square小水景small water feature林荫树shade trees楼storied building小溪流stream行道树street trees踏石stepping stone踏步terrace steps木制平台timber deck草坪turf ; grass园廊veranda空地void水景waterscape园墙wall in garden滨水地域waterfront茶亭tea house木亭log cabin遮阳亭shade structure水岸edge湾bay渡口ferry挡土墙retaining wall人行道pavement卵石pebble半岛peninsula常用的景观英文1.主进口大门/ 岗亭 (车行& 人行 ) MAIN ENTRANCE GATE/GUARD HOUSE (FOR VEHICLE& PEDESTRIAN )2.次进口/ 岗亭(车行&人行) 2ND ENTRANCE GATE/GUARD HOUSE (FOR VEHICLE& PEDESTRIAN )3.商业中心进口ENTRANCE TO SHOPPING CTR.4.水景 WATER FEATURE5.小型露天剧场MINI AMPHI-THEATRE6.迎宾景观 -1 WELCOMING FEATURE-17.观景木台TIMBER DECK (VIEWING)8.竹园 BAMBOO GARDEN9.闲步广场WALKWAY PLAZA10.露天咖啡廊OUT DOOR CAFE11.巨大迎宾水景 -2 GRAND WELCOMING FEATURE-212.木桥 TIMBER BRIDGE13.石景、水瀑、洞窟、观景台ROCK'SCAPE WATERFALL'S GROTTO/ VIEWING TERRACE14.吊桥 HANGING BRIDGE15.休憩台地 (低处 ) LOUNGING TERRACE (LOWER )16.休憩台地 (高处 ) LOUNGING TERRACE (UPPER )17.特点踏步 FEATURE STEPPING STONE18.野趣小溪 RIVER WILD19.小孩乐园 CHILDREN'S PLAYGROUND20.旱冰道 SLIDE21.羽毛球场 BADMINTON COURT22.旱景 DRY LANDSCAPE23.日艺园 JAPANESE GARDEN24.旱喷泉 DRY FOUNTAIN25.观景台 VIEWING DECK26.游泳池 SWIMMING POOL27.极可意 JACUZZI28.嬉水池 WADING POOL29.小孩泳池 CHILDREN'S POOL30.曲折水墙WINDING WALL31.石景雕塑 ROCK SCULPTURE32.中心广场 CENTRAL PLAZA33.健身广场 EXERCISE PLAZA34.桥 BRIDGE35.沟通广场MEDITATING PLAZA36.兴趣树阵 TREE BATTLE FORMATION37.泊车场 PARING AREA38.特点花架 TRELLIS39.雕塑小道SCULPTURE TRAIL40.(高尔夫 )轻击区 PUTTING GREEN41.高尔夫球会所GOLF CLUBHOUSE42.每栋建筑进口ENTRANCE PAVING TO UNIT43.篮球场 BASKETBALL COURT44.网球场 TENNIS COURT45.阶梯 ***/ 栽种槽 TERRACING SEATWALL/PLANTER46.广场 MAIN PLAZA47.丛林、瀑布FOREST GARDEN WATERFALL48.石景园 ROCKERY GARDEN49.旱溪 DRY STREAM50.凉亭 PAVILION51.户外淋浴 OUTDOOR SHOWER52.拉膜构造TENSILE STRUCTURE53.台阶 STAIR54.高尔夫球车泊车场PARKING ( GOLF CAR )55.健身站 EXERCISE STATION56.晨跑小道 JOGGING FOOTPATH57.车道 / 人行道 DRIVEWAY /SIDEWALK58.人行闲步道PROMENADE59.瀑布及跳舞喷泉(进口广场 ) WATER FALL AND DANCING FOUNTAIN ( ENTRY PLAZA )60.特点进口ENTRY FEATURE 61石.景广场ROCKERY PLAZA常用造价英语词汇估量 / 花费估量: estimate/cost estimate;估量种类: types of estimate;详尽估量:是误差幅度最小的估量,defined estimate;设备估量: equipment estimate;剖析估量: analysis estimate;报价估量: roposal estimate;控制估量: control estimate;早期控制估量:interim control estimate/initial control estimate赞同的控制估量:initial approved cost审定估量: check estimate初次审定估量:first check estimate二次审定估量:production check estimate人工时估量: man hour estimate资料花费 / 直接资料花费:material cost/direct material cost设备花费 / 设备购置花费:equipment cost/purchased cost of equipment散装资料花费 / 散装资料购置花费:bulk material cost/purchased cost of bulk material施工花费: construction cost施工人工花费:labor cost/construction force cost设备安装人工花费:labor cost associated with equipment散装资料施工安装人工花费:labor cost associated with bulk materials人工时估量定额:standard manhours施工人工时估量定额:standard labor manhours标准工时定额:standard hours劳动生产率: labor productivity/productivity factor/productivity ratio修正的人工时估量值:adjusted manhours人工时单价: manhours rate施工监察花费:cost of construction supervision施工间接花费:cost of contruction indirects分包合同花费 / 现场施工分包合同花费:subcontract cost/field subcontract cost企业本部花费:home office cost企业管理花费:overhead非薪资花费: non payroll开车服务花费:cost of start-up services其余花费: other cost收益 / 预期收益: profit/expected profit服务酬劳: service gains风险: risk风险剖析: risk analysis风险备忘录: risk memorandum未可预示费: contingency基本未可预示费:average contingency最狂风险未可预示费:maximum risk contingency用户更改 / 合同更改: cilent change/contract change认同的用户更改:approved client change待定的用户更改:pending client change项目更改: project change内部更改: internalchange赞同的更改: authoried change强迫性更改: mandatory change选择性更改: optional change内部花费变换:internal transfer认同的估计花费:anticipated approved cost涨价值: escalation项目花费汇总报告:project cost summary report项目实行花费状态报告:project operation cost status report 总价合同: lump sum contract偿付合同: reimbursible contract估量: budget02.1 总论园林学 landscape architecture, garden architecture造园学 garden making, landscape gardening环境园艺学 environmental horticulture赏析园艺学 ornamental horticulture园林艺术 garden art园林美学 garden aesthetics园林建筑学 garden architecture园林建筑 garden building园林工程 garden engineering园林植物 landscape plant赏析植物 ornamental plant盆景 miniature landscape, penjing园林 garden and park园林学史 history of garden architecture园林规划 garden planning, landscaping planning园林设计 garden design园林机具设备 gardening machine园林管理 garden management园林生态 landscape ecology绿化 greening, planting环境绿化 environmental greening绿地面积 green area绿地率 ratio of green space城市绿化覆盖率 urban green coverage工厂绿化 factory greening, factory garden-ing街道绿化 street greening, street planting车行道绿化 driveway greening分车带绿化 dividing stripe greening人行道绿化 sidewalk greening民众绿化 mass planting movement郊区绿化 suburban greening公路绿化 highway greening铁路绿化 railway greening, railway planting堤岸栽种 bank planting露台绿化 balcony greening窗台绿化 window-sill greening屋顶绿化 roof greening垂直绿化 vertical greening攀登绿化 climber greening桥头绿化 bridgehead greening花园 garden专类花园 specified flower garden花园村 garden village园林城市 landscape garden city蔷薇园 rose garden松柏园 conifer garden球根园 bulb garden宿根园 perennial garden假山园 rock garden, Chinese rockery打猎场 hunting ground街心花园 street crossing center garden小游园 petty street garden水景园 water garden铺地园 paved garden野趣园 wild plants botanical garden野生植物园 wild plants garden乡趣园 rustic garden盆景园 penjing garden, miniature landscape动物园 zoo, zoological garden墓园 cemetery garden2.0061 沼泽园 bog and marsh garden2.0062 水生植物园aquatic plants garden学校园 school garden室内花园 indoor garden芬芳花园 fragrant garden盲人花园 garden for the blind公园 park, public park城市公园 city park, urban park区公园 regional park小孩公园 children park体育公园 sports park丛林公园 forest park纪念公园 memorial park烈士纪念公园 martyr memorial park综合公园 comprehensive park文化公园 cultural park文化休憩公园 cultural and recreation park中央公园 central park天然公园 natural park海滨公园 seaside park, seabeach park遗迹公园 historic site park河畔公园 riverside park湖滨公园 lakeside park路边公园 roadside park, street park娱乐公园 amusement park雕塑公园 sculpture park休憩公园 recreation park休养公园 sanatorium park国家公园 national park邻居公园 neighborhood park特种公园 special park植物园 botanical garden植物公园 abeled plants park高峰植物园alpine garden热带植物园tropical plants garden药用植物园 medical plants garden, herb garden 绿地 green space公共绿地 public green space单位绿地 unit green area城市绿地 urban green space街道广场绿地 street and square green area居住区绿地 residential quarter green area防备绿地 green area for environmental protection 郊区绿地 suburban green space邻居绿地 residential block green belt隶属绿地 attached green space生产绿地 productive plantation area苗圃 nursery景色 landscape, scenery自然景观 natural landscape人文景观 human landscape, scenery of humanities 草原景观 prairie landscape山岳景观 mountain landscape, alpine landscape 地理景观 geographical landscape湖泊景观 lake view郊区景观 suburban landscape地质景观 geological landscape喀斯特景观 karst landscape植物景观 plants landscape, flora landscape中国园林史中国古典园林 classical Chinese garden中国传统园林 traditional Chinese garden中国古代园林 ancient Chinese garden中国山川园 Chinese mountain and water garden 帝王宫苑 imperial palace garden皇家园林 royal garden私人园林 private garden江南园林 garden on the Yangtze Delta西方园林史西方古典园林 western classical garden英国式园林 English style garden中英混淆式园林 Anglo-Chinese style garden意大利式园林 Italian style garden西班牙式园林 Spanish style garden法兰西式园林 French style garden勒诺特尔式园林 Le Notre’ s style garden文艺中兴庄园 Renaissance style villa洛可可式园林 Rococo style garden巴洛克式园林 Baroque style garden庄园 manor, villa garden廊柱园 peristyle garden, patio绿廊 xystus迷阵 maze, labyrinth典型中西园林灵囿 Ling You Hunting Garden灵沼 Ling Zhao Water Garden灵台 Ling Tai Platform Garden阿房宫 E-Pang Palace上林苑 Shang-Lin Yuan未央宫 Wei-Yang Palace洛阳宫 Luoyang Palace华好官 Hua-Qing Palace艮岳 Gen Yue Imperial Garden圆明园 Yuan-Ming Yuan Imperial Garden颐和园 Yi-He Yuan Imperial Garden,Summer Palace承德避暑山庄 Chengde Imperial Summer Resort苏州园林 Suzhou traditional garden悬园 Hanging Garden英国皇家植物园 Royal Botanical Garden, Kew garden凡尔赛宫苑 Versailles Palace Park枫丹白露宫园 Fontainebleau Palace Garden02.3 园林艺术景 view, scenery, feature远景 distant view近景 nearby view障景 obstructive scenery, blocking view借景 borrowed scenery, view borrowing对景 opposite scenery, view in opposite place缩景 miniature scenery, abbreviated scenery漏景 leaking through scenery框景 enframed scenery尾景 terminal feature主景 main feature副景 secondary feature背景 objective view夹景 vista line, vista远景 front view背景 background景序 order of sceneries景点 feature spot, view spot仰望景观 upward landscape俯视景观 downward landscape季相景观 seasonal phenomena气象景观 meteorological diversity scenery视线 visual field秋景 fall color, autumn color园林空间 garden space开敞空间 wide open space, wide space关闭空间 enclosure space境界 artistic conception, poetic imagery苍古 antiquity空灵 spaciousness, airiness动观 in-motion viewing静观 in-position viewing视错觉 visual illusion园林艺术布局 artistic layout of garden对称均衡 symmetrical balance不对称均衡 asymmetrical balance左右对称 bilateral symmetry辐射对称 radial symmetry透景线 perspective line轴线 axis, axial line主轴 main axis 2.0200 副轴 auxiliary axis暗轴 hidden axis, invisible axis树冠线 skyline园林色彩艺术 art of garden colors单色谐调 monochromatic harmony复色谐调 compound chromatic harmony对照色突出 contrast colors accent近似色谐调 approximate colors harmony暖色 warm color冷色 cool color色感 color sense城市绿地系统规划 urban green space system planning 绿地系统 green space system公共绿地定额 public green space quota公共绿地指标 public green space norm绿地布局 green space layout吸引圈 attractive circle吸引距离 attractive distance有效半径 effective radius绿地资源 green space resource绿地成效 green space effect绿地规划程序 planning procedure of the green space 空间规划 space planning形象规划 image plan实行规划 implementary plan必需生活空间 necessary living space空暇生活空间 leisure time living space利用频度 usage frequency树种规划 planning of trees and shrubs绿地种类 type of green space环状绿型 annular green space块状绿地 green plot点状绿地 green spot放射状绿地 radiate green space楔状绿地 wedge-shaped green space缓冲绿地 buffer green space防音绿地 noise proof green space科学景观论 scientific landscape theory园林保存地 reserve garden公园规划 park planning园林整体规划 garden master planning总平面规划 site planning园林分区 garden zoning寂静歇息区 tranquil rest area小孩活动区 children playing space小孩游戏场 children playground, playlot体育运动区 sports activities area野餐区 picnic place漫步区 pedestrian space民众集合区 mass meeting square赏析植物区 ornamental plants area赏析温室区 display greenhouse area, display conservatory area 草坪区 lawn space绿荫区 shade tree section历史遗迹区 historical relics area青少年活动区 youngsters activities area诱鸟区 bird sanctuary area垂钓区 fishing center野营区 camp site游人中心 visitors center服务中心 service center探险游玩场 adventure ground文化活动区 cultural activities area道路系统 approach system, road system环形道路系统 circular road system方格形道路系统latticed road system放射形道路系统radiate road system自然式道路系统informal road system规整式道路系统formal road system混淆式道路系统 mixed style road system园林规划图 garden planning map园林规划说明书garden planning direction城市公园系统 urban park system公园散布 distribution of parks公园种类 park type, park category公园间距 distance between parks公园形式 park styles旅行区 excursion area, open-to-public area非旅行区 no-admittance area办公区 administrative area服务区 service center动歇息区 dynamic rest space静歇息区 static rest space娱乐演出区 entertaining performance place主要进口 main entrance次要进口 secondary entrance人流量 visitors flowrate车流量 vehicle flowrate公园道路 park road公园水陆面积比率 land-water ratio游人容纳量 visitors capacity景色资源检查 landscape resource evaluation景色学 scenicology景色规划 landscape plan景色设计 landscape design旅行路线 touring route旅行资源 tourism resource旅行地理 tourism geography旅行地质 tourism geology历史名城 famous historical city文假名城 famous cultural city文化旧址 ancient cultural relic天然博物馆 natural open museum景色地貌 natural geomorphology造型地貌 imaginative geomorphologic figuration 景色区 scenic spot, scenic area景色名胜 famous scenery, famous scenic site特奇观观景色区 specific natural scenes area民族民俗景色区 scenic spot of minority customs 高峰景色区 alpine scenic spot海滨景色区 seabeach scenic spot丛林景色区 forest scenic spot高峰草甸景色区 alpine tundra landscape spot 峡谷景色区 valley scenic spot江河景色区 river landscape district湖泊景色区 lake round scenic spot温泉景色区 hot spring scenic spot瀑布景色区 waterfall scenic spot禁伐禁猎区 region forbidden to tree cutting and hunting封山育林区 region closed for afforestation天池景色区 crater lake scenic spot自然保护区 nature protection area科学保护区 protection area for scientific research天然纪念物 natural monument生物圈保护区 biosphere protection area02.5 园林设计园林设计师 landscape architect, garden designer园址丈量图 garden site survey map地形图 topographic map, contour map栽种设计 planting design地形改造设计 topographical reform design栽种大样图 detail planting design造价剖析 cost analysis园林形式 garden style规整式园林 formal garden style非规整园林 informal garden style几何式园林 geometric garden style自然式园林 natural garden style混淆式园林 mixed garden style近代巴洛克式园林 modern Baroque style马克斯抽象园林 R.B. Marx abstract garden园林区划 garden area division园林分区规划 garden block planning庭院花园 courtyard garden前庭 front yard, forecourt后庭 back yard, rear yard中庭 patio厨园 kitchen yard沉 [ 床]园 sunken garden窗园 window garden墙园 wall garden宅园 home garden台地园 terrace garden冬园 winter garden切花园 cut flower garden屋顶花园 roof garden后花园 back yard garden园林地形改造 topographical reform of garden土山 earth piled hill, artificial mound假山 rockery, artificial rockwork太湖石 Taihu Lake stone, water modelled stone黄石 yellowish brown stone人造假山石 artificial stone, man-made stone 孤赏石 monolith, standing stone掇山 piled stone hill, hill making叠石 stones laying板石 flag stone散点石 scattered stone抱角石 corner stone屋基石 foundation stone排衙石 guard stone屏石 screen stone石岸 rock bank石阶 stone steps汀步 stepping stone on water surface附壁石 stone appended to wall石花台 stone flower bed石凳 stone bench假山石挡土墙 rock retaining wall干砌石 dry stone wall假山石楼梯 rock stairway石亭 stone pavilion石洞 stone cavern石窟 grotto置石 stone arrangement, stone layout拱石 arch stone拱顶石 key stone园林水景 water scenes of garden水体 water body水面 water surface水池 pool水塘 pond喷泉 fountain喷水池 fountain pool渡水池 wading pool倒影池 mirror pool, reflecting pool睡莲池 water-lily pool喷水管部署 piping schema垂钓塘 fishing pond高水位池塘 high water table pond池边坐人矮墙 seat wall surrounded pool隐头喷泉 secret fountain岛园 island garden半岛园 peninsula garden小岛 isle瀑布 waterfall小瀑布 cascade湖 lake矶 rock projecting over water水帘洞 water curtain cave园桥 garden bridge拱桥 arch bridge石板桥 stone slab bridge木板桥 plank bridge圆木桥 log bridge亭桥 pavilion bridge曲桥 zigzag bridge壁泉 wall fountain饮水喷头 drinking fountain植物配植 plant arrangement树木配植 arrangement of trees and shrubs 群植 group planting, mass planting孤植 specimen planting, isolated planting 丛植 clump planting组植 group planting林植 forest planting列植 linear planting对植 opposite planting, coupled planting环植 circular planting带植 belt planting散植 scattered planting, loose planting边沿栽种 edge planting界限栽种 boundary planting整形栽种 architectural planting基础栽种 foundation planting角隅栽种 corner planting景框栽种 planting as enframent门卫栽种 guard planting篱恒栽种 fence planting障景栽种 screen planting背景栽种 background planting林下栽种 underwood planting路边栽种 roadside planting绿篱 hedge树墙 espalier庭荫树 shade tree园景树 specimen tree景色林 amenity forest, ornamental forest行道树 avenue tree, street tree纪念林 memorial forest整型树 topiary tree花篱 flower hedge ’刺篱 thorny plants hedge常绿绿篱 evergreen hedge落叶绿篱 deciduous hedge高篱 high hedge沟中边篱 hah-hah fence图案矮篱 pattern dwarf hedge迷宫绿篱 labyrinth hedge整剪绿篱 clipped hedge自然式花篱 natural flowering hedge边篱 boundary fence园篱 garden fence, garden hedge纯林 pure forest混交林 mixed forest林空隙地 open space in woodland杂木林 spinney树冠覆盖面 tree canopy草坪 lawn整形草坪 formal lawn开花草坪 flowering lawn牧场草坪 meadowy land花坛 flower bed路边花坛 roadside flower bed带状花坛 ribbon flower bed时钟花坛 flower clock盆种花坛 potted flower bed, basined flower bed 高设花台 raised flower bed毛毡花坛 carpet bed镶嵌花坛 mosaic bed铺石花坛 paved bed灌木花坛 shrub bed图案花坛群 parterre草药花坛 herbaceous flower bed花结花坛 knot bed整形花坛 formal flower bed花境 flower border花桶 flower tub植树箱 planting box活动花坛 movable flower bed瓶饰 garden vase灌木花境 shrub border混淆花境 mixed border园林道路设计 garden road design, garden path design闲步路 trail, footway小径 alley, path川草坪岛 lawn island安全岛 traffic island, refuge island转曲折度 turning curvature转弯半径 turning radius踏面 landing pitch步石 stepping stone渡水踏步 wading step错铺路 crazy paving path任意组合方石板路 flag stone path paved at random花纹路 pattern path林荫路 mall林荫大道 boulevard花园路 parkway林间小道 path in woodland栽种池 planting bed树池保护格栅 tree grate树干保护套栏 tree guard树池坐凳矮墙 seatwall-surrounded planting路面线纹 score line传统园林建筑 traditional garden building凉亭 summer shelter活树亭 arbor, tent arbor蘑菇亭 mushroom pavilion茅亭 thatched pavilion竹亭 bamboo pavilion茶亭 tea booth, tea kiosk回廊 cloister水廊 corridor on water曲廊 zigzag veranda扒山廊 sloping gallery楼廊 two-storied gallery画舫 painted pleasure boat石舫 stone boat不击舟 immovable pleasure boat诗条石 poem-engraved stone slab月洞门 moon gate2.0531 扶手栏杆handrail2.0532 坐凳栏杆seat rail石碑 stone tablet, stele园林露天剧场 open garden theater园林露天舞池 open garden dancing place露天音乐台 outdoor music stand瞭望台 prospect deck生殖温室 plant propagation greenhouse展览温室 public conservatory月池 new-moon pool园林小品 small garden ornaments磁砖壁画 painted tile mural tablet园椅 garden chair, garden seat园凳 garden bench园桌 garden table园灯 garden lamp日规 sundial鸟浴 bird bath鸟舍 bird cottage, nestle box鸟笼 bird cage, bird coop悬篮 hanging basket野鸟喂食器 bird feeder额匾 horizontal inscribed board楹联 couplet written on scroll, couplet on pillar引露天烤炉 open barbecue树棚 living-tree pergola花架 pergola花格架 trellis, treillage点景牌楼 naming pailou, decorated archway园林施工 garden layout, garden construction栽种工程 planting engineering大树移植 big tree transplanting裸根移植 bare root transplanting土球移植 ball transplanting沟植 trench planting假植 heeling in, temporary planting播种草坪 seeding lawn铺草皮块草坪 sodding lawn假山工程 rockery engineering掇山五法 five methods" of rock piling平分均衡法 method of making the rock equa-tional and balanced前轻后重法 method of making the front part of rock lighter than the back part 上轻下重法 method of lowering the center of gravity of rocks纹理一致法 method of unifying the rock veins石料一致法 method of unifying the rock mate-rials赏析树木 ornamental tree and shrub观叶植物 foliage plant观果植物 fruit-effect plant观枝干植物 plants with ornamental trunks and branches 指示植物 indicating plant主景植物 accent plant耐湿植物 damp tolerant plant抗风植物 wind-resistant plant耐盐碱植物saline-alkali tolerant plan市花 city flower市树 city tree国花 national flower国树 national tree芬芳植物 fragrant plant抗污染植物pollution resistant plant环保植物 environment protecting plant高峰植物 alpine plant岩生植物 rock plant攀登植物 climbing plant, climber地被植物 ground cover plant阴生植物 shade plant装修植物 decorative plant装缘植物 edging plant绿蓠植物 hedge plant草坪植物 lawn plant, lawn grass花坛植物 bedding plant球根植物 bulbous plant宿根植物 perennial plant, perennial水生植物 aquatic plant, hydrophyte旱生植物 xerophyte沼泽植物 bog plant, swamp plant室内装修植物 indoor decorative plant, house plant切花 cut flower垂枝植物 pendulous plant, weeping plant环绕植物 twiner, twinning plant针叶植物 needle-leaved plant阔叶植物 broad-leaved plant斑叶植物 variegate-leaved plant松柏植物 conifer常绿植物 evergreen plant半常绿植物semi-evergreen plant不耐寒植物tender plant半耐寒植物half-hardy plant耐寒植物 hardy plant耐旱植物 drought enduring plant山石资料 stone material昆山石 Kunshan stone钟乳石 stalactite灵壁石 Lingbi stone英德石 Yingde stone青石 Qing stone宣石 Xuan stone房山石 Fangshan stone赏析动物 ornamental animal赏析鸟类 ornamental bird赏析兽类 ornamental beast赏析昆虫类 ornamental insect02.8 园林机具设备园林机械 garden machine园林工具 garden instrument, garden implement园林设备 garden equipment花坛分界隔板plastic bed divider栽种容器 planting container圆木桩 log peg发射装置 jet bubbler滴灌 trickle irrigator, drip irrigator环动喷灌器circle sprinkler圆筒喷灌器rotor sprinkler自控器 automatic controller管端喷灌器hose end sprinkler固定喷灌器stationary sprinkler喷雾喷灌器 mist sprinkler, spray head sprinkler喷灌覆盖面sprinkler coverage草坪加肥器lawn feeder施肥喷灌器 combined feeder and sprinkler液肥混淆分配器 liquid fertilizer mixer-proportioner滴水喷头 emitter, dripper水土保持塑料网 erosion control plastic net苗木包装资料 nursery stock package material麻布袋 burlap bag铁丝篮 wire basket篮状栽种器basket container塑料苗木桶plastic nurserican播种盘 seed tray网孔盆 mesh pot含肥泥炭盆fertile peat pot盆栽机 potting machine换盆机 repotting machine重生纸栽种器reclaimed paper container纤维育苗器 wood fiber plant grower泥炭压制播种饼 peat seeding pellet, peat seeding starter松土除草机cultivator旋转锄 rotary hoe切叶机 foliage cutter翻地犁 uncovering plough盖土机 mounted spreader前悬装土机front mounted loader后缀装土机rear mounted loader旋轴剪草机spindle mower栽种机 planting machine植物覆盖 plant mulching覆盖物分别机mulch spreader种子液肥喷洒机hydro seeder修枝剪 pruning shear播种器 garden seeder球根栽种器bulb planter土壤酸度探测器pH-value computer巴效剖析器fertilizer analyzer嫁接刀 grafting knife温室设备 greenhouse equipment盆栽注水系统pot watering system温室天气控制器greenhouse climate controller温室覆盖 greenhouse covering喷雾自控系统 automatic mist control system二氧化碳发生器C02 generator温度报警钟temperature alarm旅行车 park sightseeing bus引剪草机 lawn mower动力剪草机power lawnmower畜力剪草机horse lawnmower手推剪草机hand lawnmower游人检查 visitors investigation游人统计 visitors statistics游人剖析 garden visitors analysis游人管理 visitors management导游图 tourist map2.0701 导游讲解tour descri ption and direction2.0702 劳动管理labour management物质管理 material handling, goods handling设备管理 equipment management, facility management财务管理 financial management安全管理 safety management环境监测 environmental monitor植物保养管理 plant maintenance and management园林技术管理garden technical management质量管理 quality management园貌维修 garden feature maintenance植物整形修剪 plant trimming and pruning植物病虫防治 disease and insect control园林管理规划management plan游人建议办理 treatment of visitors opinions游人规则 visitors regulation园内交通管理 traffic control in park园外交通管理 traffic control out of park entrance汽车泊车规则parking rules自行车停放规则bicycle parking rules开放时间 opening time平时洁净卫生管理 daily sanitation and hygiene management 人类生态环境human ecological environment自然系统 natural system自然资源 natural resource自然保护 conservation of nature自然保存 natural preservation环境保护 environmental protection环境容量 environment capacity环境适合性 environment fitness环境空气质量标准 ambient air quality共生 symbiosis互惠共生 mutualism公害 public nuisance生态绝灭 ecological extinction生态系统 ecosystem生态圈 ecosphere生态灾害 ecological disaster环境质量 environmental quality环境压力 environment stress生命保持系统life-support system反应系统 feedback system自养生物 autotroph异养生物 heterotroph食品链 foodchain生物圈 biosphere濒危植物 endangered plant, threatened plant主体群落 major community人工群落 artificial community绿色革命 green revolution户外娱乐资源outdoor recreation resource原始环境系统wilderness environment system近代环境系统modern environment system农村生活模式country life-pattern烟害 smoke pollution, fume pollution雾害 fog pollution霜害 frost injury水污染 water pollution土壤污染 soil pollution, soil contamination园林小天气garden microclimate环境保护植物environmental conservation plant引天气调理climatic regulation自动调理机能homeostasis生态均衡 ecological homeostasis丛林生态系统forest ecosystem草原生态系统prairie ecosystem滞尘植物 dust holding plant其余:AAccessibility 可达性Accessible route 易达的路线advance notice 预先通知aerial photogrammetry航空拍照丈量aerobic digesters 需氧消化池aesthetic considerations审美方面的考虑brick and concrete block walls砖和混凝土砌块墙stone walls 石头墙wood and metal fences木头和金属栅栏aesthetic controls审美控制aggregate base 混淆基础AIA 美国建筑师协会Anaerobic digesters 厌氧分解池APA 美国规划师协会arterial streets骨干道as-built records施工记录ASLA 美国景观建筑师协会athletic facility运动设备average walking distance 均匀步行距离axioms 原理。

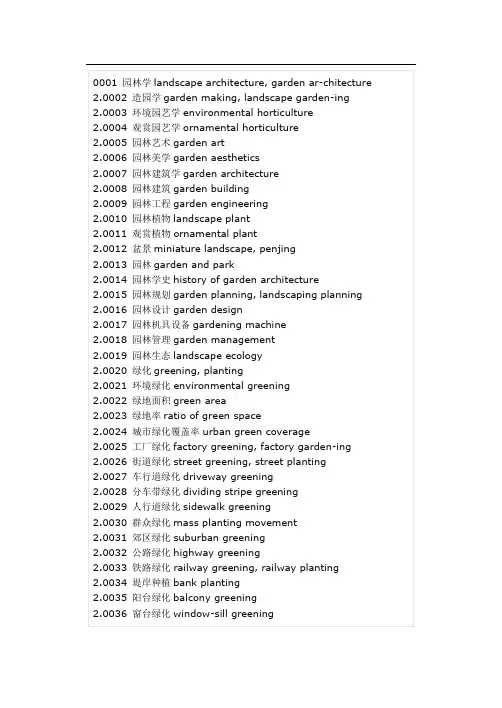

0001 园林学landscape architecture, garden ar-chitecture 2.0002 造园学garden making, landscape garden-ing2.0003 环境园艺学environmental horticulture2.0004 观赏园艺学ornamental horticulture2.0005 园林艺术garden art2.0006 园林美学garden aesthetics2.0007 园林建筑学garden architecture2.0008 园林建筑garden building2.0009 园林工程garden engineering2.0010 园林植物landscape plant2.0011 观赏植物ornamental plant2.0012 盆景miniature landscape, penjing2.0013 园林garden and park2.0014 园林学史history of garden architecture2.0015 园林规划garden planning, landscaping planning 2.0016 园林设计garden design2.0017 园林机具设备gardening machine2.0018 园林管理garden management2.0019 园林生态landscape ecology2.0020 绿化greening, planting2.0021 环境绿化environmental greening2.0022 绿地面积green area2.0023 绿地率ratio of green space2.0024 城市绿化覆盖率urban green coverage2.0025 工厂绿化factory greening, factory garden-ing 2.0026 街道绿化street greening, street planting2.0027 车行道绿化driveway greening2.0028 分车带绿化dividing stripe greening2.0029 人行道绿化sidewalk greening2.0030 群众绿化mass planting movement2.0031 郊区绿化suburban greening2.0032 公路绿化highway greening2.0033 铁路绿化railway greening, railway planting2.0034 堤岸种植bank planting2.0035 阳台绿化balcony greening2.0036 窗台绿化window-sill greening2.0037 屋顶绿化roof greening2.0038 垂直绿化vertical greening2.0039 攀缘绿化climber greening2.0040 桥头绿化bridgehead greening2.0041 花园garden2.0042 专类花园specified flower garden2.0043 花园村garden village2.0044 园林城市landscape garden city2.0045 蔷薇园rose garden2.0046 松柏园conifer garden2.0047 球根园bulb garden2.0048 宿根园perennial garden2.0049 假山园rock garden, Chinese rockery2.0050 狩猎场hunting ground2.0051 街心花园street crossing center garden2.0052 小游园petty street garden2.0053 水景园water garden2.0054 铺地园paved garden2.0055 野趣园wild plants botanical garden2.0056 野生植物园wild plants garden2.0057 乡趣园rustic garden2.0058 盆景园penjing garden, miniature land-scape 2.0059 动物园zoo, zoological garden2.0060 墓园cemetery garden2.0061 沼泽园bog and marsh garden2.0062 水生植物园aquatic plants garden2.0063 学校园school garden2.0064 室内花园indoor garden2.0065 芳香花园fragrant garden2.0066 盲人花园garden for the blind2.0067 公园park, public park2.0068 城市公园city park, urban park2.0069 区公园regional park2.0070 儿童公园children park2.0071 体育公园sports park2.0072 森林公园forest parkcnlbbs2006-05-29 14:062.0080 海滨公园seaside park, seabeach park2.0081 古迹公园historic site park2.0082 河滨公园riverside park2.0083 湖滨公园lakeside park2.0084 路边公园roadside park, street park2.0085 娱乐公园amusement park2.0086 雕塑公园sculpture park2.0087 休憩公园recreation park2.0088 疗养公园sanatorium park2.0089 国家公园national park2.0090 邻里公园neighborhood park2.0091 特种公园special park2.0092 植物园botanical garden2.0093 植物公园abeled plants park2.0094 高山植物园alpine garden2.0095 热带植物园tropical plants garden2.0096 药用植物园medical plants garden, herb garden2.0097 绿地green space2.0098 公共绿地public green space2.0099 单位绿地unit green area2.0100 城市绿地urban green space2.0101 街道广场绿地street and square green area2.0102 居住区绿地residential quarter green area2.0103 防护绿地green area for environmental protection2.0104 郊区绿地suburban green space2.0105 街坊绿地residential block green belt2.0106 附属绿地attached green space2.0107 生产绿地productive plantation area2.0108 苗圃nursery2.0109 风景landscape, scenery2.0110 自然景观natural landscape2.0111 人文景观human landscape, scenery of humanities 2.0112 草原景观prairie landscape2.0113 山岳景观mountain landscape, alpine landscape 2.0114 地理景观geographical landscape2.0115 湖泊景观lake view2.0116 郊区景观suburban landscape2.0117 地质景观geological landscape2.0118 喀斯特景观karst landscape2.0119 植物景观plants landscape, flora landscape02.2 园林史02.2.1 中国园林史2.0120 中国古典园林classical Chinese garden2.0121 中国传统园林traditional Chinese garden2.0122 中国古代园林ancient Chinese garden2.0123 中国山水园Chinese mountain and water garden 2.0124 帝王宫苑imperial palace garden2.0125 皇家园林royal garden2.0126 私家园林private garden2.0127 江南园林garden on the Yangtze Delta02.2.2 西方园林史2.0128 西方古典园林western classical garden2.0129 英国式园林English style garden2.0130 中英混合式园林Anglo-Chinese style garden2.0131 意大利式园林Italian style garden2.0132 西班牙式园林Spanish style garden2.0133 法兰西式园林French style garden2.0134 勒诺特尔式园林Le Notre’s style garden2.0135 文艺复兴庄园Renaissance style villa2.0136 洛可可式园林Rococo style gardencnlbbs2006-05-29 14:0702.2.3 典型中西园林2.0142 灵囿Ling You Hunting Garden2.0143 灵沼Ling Zhao Water Garden2.0144 灵台Ling Tai Platform Garden2.0145 阿房宫E-Pang Palace2.0146 上林苑Shang-Lin Yuan2.0147 未央宫Wei-Yang Palace2.0148 洛阳宫Luoyang Palace2.0149 华清官Hua-Qing Palace2.0150 艮岳Gen Yue Imperial Garden2.0151 圆明园Yuan-Ming Yuan Imperial Garden2.0152 颐和园Yi-He Yuan Imperial Garden,Summer Palace2.0153 承德避暑山庄Chengde Imperial Summer Resort2.0154 苏州园林Suzhou traditional garden2.0155 悬园Hanging Garden2.0156 英国皇家植物园Royal Botanical Garden, Kew garden2.0157 凡尔赛宫苑Versailles Palace Park2.0158 枫丹白露宫园Fontainebleau Palace Garden02.3 园林艺术2.0159 景view, scenery, feature2.0160 远景distant view2.0161 近景nearby view2.0162 障景obstructive scenery, blocking view2.0163 借景borrowed scenery, view borrowing2.0164 对景opposite scenery, view in opposite place2.0165 缩景miniature scenery, abbreviated scenery 2.0166 漏景leaking through scenery2.0167 框景enframed scenery2.0168 尾景terminal feature2.0169 主景main feature2.0170 副景secondary feature2.0171 配景objective view2.0172 夹景vista line, vista2.0173 前景front view2.0174 背景background2.0175 景序order of sceneries2.0176 景点feature spot, view spot2.0177 仰视景观upward landscape2.0178 俯视景观downward landscape2.0179 季相景观seasonal phenomena2.0180 气象景观meteorological diversity scenery 2.0181 视野visual field2.0182 秋色fall color, autumn color2.0183 园林空间garden space2.0184 开敞空间wide open space, wide space2.0185 封闭空间enclosure space2.0186 意境artistic conception, poetic imagery2.0187 苍古antiquity2.0188 空灵spaciousness, airiness2.0189 动观in-motion viewing2.0190 静观in-position viewing2.0191 视错觉visual illusion2.0192 园林艺术布局artistic layout of garden2.0193 对称平衡symmetrical balance2.0194 不对称平衡asymmetrical balance2.0195 左右对称bilateral symmetry2.0196 辐射对称radial symmetry2.0197 透景线perspective line2.0198 轴线axis, axial line2.0199 主轴main axis 2.0200 副轴auxiliary axis 2.0201 暗轴hidden axis, invisible axis2.0202 树冠线skyline2.0203 园林色彩艺术art of garden colors2.0204 单色谐调monochromatic harmony2.0205 复色谐调compound chromatic harmony2.0206 对比色突出contrast colors accent2.0207 近似色谐调approximate colors harmony2.0208 暖色warm color2.0209 冷色cool color2.0210 色感color sense2.0211 城市绿地系统规划urban green space system planning 2.0212 绿地系统green space system2.0213 公共绿地定额public green space quota2.0214 公共绿地指标public green space norm2.0215 绿地布局green space layout2.0216 吸引圈attractive circle2.0217 吸引距离attractive distance2.0218 有效半径effective radius2.0219 绿地资源green space resource2.0220 绿地效果green space effect2.0221 绿地规划程序planning procedure of the green space 2.0222 空间规划space planning2.0223 形象规划image plan2.0224 实施规划implementary plan2.0225 必要生活空间necessary living space2.0226 余暇生活空间leisure time living space2.0227 利用频度usage frequency2.0228 树种规划planning of trees and shrubs2.0229 绿地类型type of green space2.0230 环状绿型annular green space2.0231 块状绿地green plot2.0232 点状绿地green spot2.0233 放射状绿地radiate green space2.0234 楔状绿地wedge-shaped green space2.0235 缓冲绿地buffer green space2.0236 防音绿地noiseproof green space2.0237 科学景观论scientific landscape theory2.0238 园林保留地reserve garden2.0239 公园规划park planning2.0240 园林总体规划garden master planning2.0241 总平面规划site planning2.0242 园林分区garden zoning2.0243 安静休息区tranquil rest area2.0244 儿童活动区children playing space2.0245 儿童游戏场children playground, playlot2.0246 体育运动区sports activities area2.0247 野餐区picnic place2.0248 散步区pedestrian space2.0249 群众集会区mass meeting square2.0250 观赏植物区ornamental plants area2.0251 观赏温室区display greenhouse area, display conservatory area2.0252 草坪区lawn space2.0253 绿荫区shade tree section2.0254 历史古迹区historical relics area2.0255 青少年活动区youngsters activities area2.0256 诱鸟区bird sanctuary area2.0257 钓鱼区fishing center2.0258 野营区camp site2.0259 游人中心visitors center2.0260 服务中心service center2.0261 探险游乐场adventure ground2.0262 文化活动区cultural activities area2.0263 道路系统approach system, road system2.0264 环形道路系统circular road system2.0265 方格形道路系统latticed road system2.0266 放射形道路系统radiate road system2.0267 自然式道路系统informal road system2.0268 规整式道路系统formal road system2.0269 混合式道路系统mixed style road system 2.0270 园林规划图garden planning map2.0271 园林规划说明书garden planning direction 2.0272 城市公园系统urban park system2.0273 公园分布distribution of parks2.0274 公园类型park type, park category2.0275 公园间距distance between parks2.0276 公园形式park styles2.0277 游览区excursion area, open-to-public area 2.0278 非游览区no-admittance area2.0279 办公区administrative area2.0280 服务区service center2.0281 动休息区dynamic rest space2.0282 静休息区static rest space2.0283 娱乐演出区entertaining performance place 2.0284 主要入口main entrance2.0285 次要入口secondary entrance2.0286 人流量visitors flowrate2.0287 车流量vehicle flowrate2.0288 公园道路park road2.0289 公园水陆面积比率land-water ratio2.0290 游人容纳量visitors capacity2.0291 风景资源调查landscape resource evaluation 2.0292 风景学scenicology2.0293 风景规划landscape plan2.0294 风景设计landscape design2.0295 游览路线touring route2.0296 旅游资源tourism resource2.0297 旅游地理tourism geography2.0298 旅游地质tourism geology2.0299 历史名城famous historical city2.0300 文化名城famous cultural city2.0301 文化遗址ancient cultural relic2.0302 天然博物馆natural open museum2.0303 风景地貌natural geomorphology2.0304 造型地貌imaginative geomorphologic figuration2.0305 风景区scenic spot, scenic area2.0306 风景名胜famous scenery, famous scenic site2.0307 特异景观风景区specific natural scenes area2.0308 民族风俗风景区scenic spot of minority customs2.0309 高山风景区alpine scenic spot2.0310 海滨风景区seabeach scenic spot2.0311 森林风景区forest scenic spot2.0312 高山草甸风景区alpine tundra landscape spot2.0313 峡谷风景区valley scenic spot2.0314 江河风景区river landscape district2.0315 湖泊风景区lake round scenic spot2.0316 温泉风景区hot spring scenic spot2.0317 瀑布风景区waterfall scenic spot2.0318 禁伐禁猎区region forbidden to tree cutting and hunting 2.0319 封山育林区region closed for afforestation2.0320 天池风景区crater lake scenic spot2.0321 自然保护区nature protection area2.0322 科学保护区protection area for scientific research2.0323 天然纪念物natural monument2.0324 生物圈保护区biosphere protection areacnlbbs2006-05-29 14:08 02.5 园林设计2.0325 园林设计师landscape architect, garden designer2.0326 园址测量图garden site survey map2.0327 地形图topographic map, contour map2.0328 种植设计planting design2.0329 地形改造设计topographical reform design2.0330 种植大样图detail planting design2.0331 造价分析cost analysis2.0332 园林形式garden style2.0333 规整式园林formal garden style2.0334 非规整园林informal garden style2.0335 几何式园林geometric garden style2.0336 自然式园林natural garden style2.0337 混合式园林mixed garden style2.0338 近代巴洛克式园林modern Baroque style2.0339 马克斯抽象园林R.B. Marx abstract garden2.0340 园林区划garden area division2.0341 园林分区规划garden block planning2.0342 庭院花园courtyard garden2.0343 前庭front yard, forecourt2.0344 后庭back yard, rear yard2.0345 中庭patio2.0346 厨园kitchen yard2.0347 沉[床]园sunken garden2.0348 窗园window garden2.0349 墙园wall garden2.0350 宅园home garden2.0351 台地园terrace garden2.0352 冬园winter garden2.0353 切花园cut flower garden2.0354 屋顶花园roof garden2.0355 后花园back yard garden2.0356 园林地形改造topographical reform of garden 2.0357 土山earth piled hill, artificial mound2.0358 假山rockery, artificial rockwork2.0359 太湖石Taihu Lake stone, water modelled stone 2.0360 黄石yellowish brown stone2.0361 人造假山石artificial stone, man-made stone 2.0362 孤赏石monolith, standing stone2.0363 掇山piled stone hill, hill making2.0364 叠石stones laying2.0365 板石flag stone2.0366 散点石scattered stone2.0367 抱角石corner stone2.0368 屋基石foundation stone2.0369 排衙石guard stone2.0370 屏石screen stone2.0371 石岸rock bank2.0372 石阶stone steps2.0373 汀步stepping stone on water surface 2.0374 附壁石stone appended to wall2.0375 石花台stone flower bed2.0376 石凳stone bench2.0377 假山石挡土墙rock retaining wall2.0378 干砌石dry stone wall2.0379 假山石楼梯rock stairway2.0380 石亭stone pavilion2.0381 石洞stone cavern2.0382 石窟grotto2.0383 置石stone arrangement, stone layout 2.0384 拱石arch stone2.0385 拱顶石key stone2.0386 园林水景water scenes of garden2.0387 水体water body2.0388 水面water surface2.0389 水池pool2.0390 水塘pond2.0391 喷泉fountain2.0392 喷水池fountain pool2.0393 涉水池wading pool2.0394 倒影池mirror pool, reflecting pool2.0395 睡莲池water-lily pool2.0396 喷水管布置piping schema2.0397 钓鱼塘fishing pond2.0398 高水位池塘high water table pond2.0399 池边坐人矮墙seat wall surrounded pool 2.0400 隐头喷泉secret fountain2.0401 岛园island garden2.0402 半岛园peninsula garden2.0403 小岛isle2.0404 瀑布waterfall2.0405 小瀑布cascade2.0406 湖lake2.0407 矶rock projecting over water2.0408 水帘洞water curtain cave2.0409 园桥garden bridge2.0410 拱桥arch bridge2.0411 石板桥stone slab bridge2.0412 木板桥plank bridge2.0413 圆木桥log bridge2.0414 亭桥pavilion bridge2.0415 曲桥zigzag bridge2.0416 壁泉wall fountain2.0417 饮水喷头drinking fountain2.0418 植物配植plant arrangement2.0419 树木配植arrangement of trees and shrubs 2.0420 群植group planting, mass planting2.0421 孤植specimen planting, isolated planting 2.0422 丛植clump planting2.0423 组植group planting2.0424 林植forest planting2.0425 列植linear planting2.0426 对植opposite planting, coupled planting 2.0427 环植circular planting2.0428 带植belt planting2.0429 散植scattered planting, loose planting 2.0430 边缘种植edge planting2.0431 边界种植boundary planting2.0432 整形种植architectural planting2.0433 基础种植foundation planting2.0434 角隅种植corner planting2.0435 景框种植planting as enframent2.0436 门卫种植guard planting2.0437 篱恒种植fence planting2.0438 障景种植screen planting2.0439 背景种植background planting2.0440 林下种植underwood planting2.0441 路边种植roadside planting2.0442 绿篱hedge2.0443 树墙espalier2.0444 庭荫树shade tree2.0445 园景树specimen tree2.0446 风景林amenity forest, ornamental forest 2.0447 行道树avenue tree, street tree2.0448 纪念林memorial forest2.0449 整型树topiary tree2.0450 花篱flower hedge’2.0451 刺篱thorny plants hedge2.0452 常绿绿篱evergreen hedge2.0453 落叶绿篱deciduous hedge2.0454 高篱high hedge2.0455 沟中边篱hah-hah fence2.0456 图案矮篱pattern dwarf hedge2.0457 迷宫绿篱labyrinth hedge2.0458 整剪绿篱clipped hedge2.0459 自然式花篱natural flowering hedge2.0460 边篱boundary fence2.0461 园篱garden fence, garden hedge2.0462 纯林pure forest2.0463 混交林mixed forest2.0464 林间隙地open space in woodland2.0465 杂木林spinney2.0466 树冠覆盖面tree canopy2.0467 草坪lawn2.0468 整形草坪formal lawn2.0469 开花草坪flowering lawn2.0470 牧场草坪meadowy land2.0471 花坛flower bed2.0472 路边花坛roadside flower bed2.0473 带状花坛ribbon flower bed2.0474 时钟花坛flower clock2.0475 盆栽花坛potted flower bed, basined flower bed2.0476 高设花台raised flower bed2.0477 毛毡花坛carpet bed2.0478 镶嵌花坛mosaic bed2.0479 铺石花坛paved bed2.0480 灌木花坛shrub bed2.0481 图案花坛群parterre2.0482 草药花坛herbaceous flower bed2.0483 花结花坛knot bed2.0484 整形花坛formal flower bed2.0485 花境flower border2.0486 花桶flower tub2.0487 植树箱planting box2.0488 活动花坛movable flower bed2.0489 瓶饰garden vase2.0490 灌木花境shrub border2.0491 混合花境mixed border2.0492 园林道路设计garden road design, garden path design 2.0493 漫步路trail, footway2.0494 小径alley, path2.0495 川草坪岛lawn island2.0496 安全岛traffic island, refuge island2.0497 转弯曲度turning curvature2.0498 转弯半径turning radiuscnlbbs2006-05-29 14:09 2.0499 踏面landing pitch2.0500 步石stepping stone2.0501 涉水踏步wading step2.0502 错铺路crazy paving path2.0503 随意组合方石板路flag stone path paved at random 2.0504 花纹路pattern path2.0505 林荫路mall2.0506 林荫大道boulevard2.0507 花园路parkway2.0508 林间小道path in woodland2.0509 种植池planting bed2.0510 树池保护格栅tree grate2.0511 树干保护套栏tree guard2.0512 树池坐凳矮墙seatwall-surrounded planting2.0513 路面线纹score line2.0514 传统园林建筑traditional garden building2.0515 凉亭summer shelter2.0516 活树亭arbor, tent arbor2.0517 蘑菇亭mushroom pavilion2.0518 茅亭thatched pavilion2.0519 竹亭bamboo pavilion2.0520 茶亭tea booth, tea kiosk2.0521 回廊cloister2.0522 水廊corridor on water2.0523 曲廊zigzag veranda2.0524 扒山廊sloping gallery2.0525 楼廊two-storied gallery2.0526 画舫painted pleasure boat2.0527 石舫stone boat2.0528 不击舟immovable pleasure boat2.0529 诗条石poem-engraved stone slab2.0530 月洞门moon gate2.0531 扶手栏杆handrail2.0532 坐凳栏杆seat rail2.0533 石碑stone tablet, stele2.0534 园林露天剧场open garden theater2.0535 园林露天舞池open garden dancing place2.0536 露天音乐台outdoor music stand2.0537 眺望台prospect deck2.0538 繁殖温室plant propagation greenhouse2.0539 展览温室public conservatory2.0540 月池new-moon pool2.0541 园林小品small garden ornaments2.0542 磁砖壁画painted tile mural tablet2.0543 园椅garden chair, garden seat2.0544 园凳garden bench2.0545 园桌garden table2.0546 园灯garden lamp2.0547 日规sundial2.0548 鸟浴bird bath2.0549 鸟舍bird cottage, nestle box2.0550 鸟笼bird cage, bird coop2.0551 悬篮hanging basket2.0552 野鸟喂食器bird feeder2.0553 额匾horizontal inscribed board2.0554 楹联couplet written on scroll, couplet on pillar 2.0555 引露天烤炉open barbecue2.0556 树棚living-tree pergola2.0557 花架pergola2.0558 花格架trellis, treillage2.0559 点景牌楼naming pailou, decorated archway 2.0560 园林施工garden layout, garden construction 2.0561 种植工程planting engineering2.0562 大树移植big tree transplanting2.0563 裸根移植bare root transplanting2.0564 土球移植ball transplanting2.0565 沟植trench planting2.0566 假植heeling in, temporary planting2.0567 播种草坪seeding lawn2.0568 铺草皮块草坪sodding lawn2.0569 假山工程rockery engineeringcnlbbs2006-05-29 14:102.0576 观赏树木ornamental tree and shrub2.0577 观叶植物foliage plant2.0578 观果植物fruit-effect plant2.0579 观枝干植物plants with ornamental trunks and branches 2.0580 指示植物indicating plant2.0581 主景植物accent plant2.0582 耐湿植物damp tolerant plant2.0583 抗风植物wind-resistant plant2.0584 耐盐碱植物saline-alkali tolerant plant2.0585 市花city flower2.0586 市树city tree2.0587 国花national flower2.0588 国树national tree2.0589 芳香植物fragrant plant2.0590 抗污染植物pollution resistant plant2.0591 环保植物environment protecting plant2.0592 高山植物alpine plant2.0593 岩生植物rock plant2.0594 攀缘植物climbing plant, climber2.0595 地被植物ground cover plant2.0596 阴生植物shade plant2.0597 装饰植物decorative plant2.0598 装缘植物edging plant2.0599 绿蓠植物hedge plant2.0600 草坪植物lawn plant, lawn grass2.0601 花坛植物bedding plant2.0602 球根植物bulbous plant2.0603 宿根植物perennial plant, perennial2.0604 水生植物aquatic plant, hydrophyte2.0605 旱生植物xerophyte2.0606 沼泽植物bog plant, swamp plant2.0607 室内装饰植物indoor decorative plant, house plant 2.0608 切花cut flower2.0609 垂枝植物pendulous plant, weeping plant2.0610 缠绕植物twiner, twinning plant2.0611 针叶植物needle-leaved plant2.0612 阔叶植物broad-leaved plant2.0613 斑叶植物variegate-leaved plant2.0614 松柏植物conifer2.0615 常绿植物evergreen plant2.0616 半常绿植物semi-evergreen plant2.0617 不耐寒植物tender plant2.0618 半耐寒植物half-hardy plant2.0619 耐寒植物hardy plant2.0620 耐旱植物drought enduring plant2.0621 山石材料stone material2.0622 昆山石Kunshan stone2.0623 钟乳石stalactite2.0624 灵壁石Lingbi stone2.0625 英德石Yingde stone2.0626 青石Qing stone2.0627 宣石Xuan stone2.0628 房山石Fangshan stone2.0629 观赏动物ornamental animal2.0630 观赏鸟类ornamental bird2.0631 观赏兽类ornamental beast2.0632 观赏昆虫类ornamental insect02.8 园林机具设备2.0633 园林机械garden machine2.0634 园林工具garden instrument, garden implement 2.0635 园林设备garden equipment2.0636 花坛分界隔板plastic bed divider2.0637 种植容器planting container2.0638 圆木桩log peg2.0639 喷射装置jet bubbler2.0640 滴灌trickle irrigator, drip irrigator2.0641 环动喷灌器circle sprinkler2.0642 圆筒喷灌器rotor sprinkler2.0643 自控器automatic controller2.0644 管端喷灌器hose end sprinkler2.0645 固定喷灌器stationary sprinkler2.0646 喷雾喷灌器mist sprinkler, spray head sprinkler 2.0647 喷灌覆盖面sprinkler coverage2.0648 草坪加肥器lawn feeder2.0649 施肥喷灌器combined feeder and sprinkler2.0650 液肥混合调配器liquid fertilizer mixer-proportioner 2.0651 滴水喷头emitter, dripper2.0652 水土保持塑料网erosion control plastic net2.0653 苗木包装材料nursery stock package material2.0654 麻布袋burlap bag2.0655 铁丝篮wire basket2.0656 篮状种植器basket container2.0657 塑料苗木桶plastic nurserican2.0658 播种盘seed tray2.0659 网孔盆mesh pot2.0660 含肥泥炭盆fertile peat pot2.0661 盆栽机potting machine2.0662 换盆机repotting machine2.0663 再生纸种植器reclaimed paper container2.0664 纤维育苗器wood fiber plant grower2.0665 泥炭压制播种饼peat seeding pellet, peat seeding starter 2.0666 松土除草机cultivator2.0667 旋转锄rotary hoe2.0668 切叶机foliage cutter2.0669 翻地犁uncovering plough2.0670 盖土机mounted spreader2.0671 前悬装土机front mounted loader2.0672 后缀装土机rear mounted loader2.0673 旋轴剪草机spindle mower2.0674 栽植机planting machine2.0675 植物覆盖plant mulching2.0676 覆盖物分散机mulch spreader2.0677 种子液肥喷洒机hydro seeder2.0678 修枝剪pruning shear2.0679 播种器garden seeder2.0680 球根种植器bulb planter2.0681 土壤酸度探测器pH-value computer2.0682 巴效分析器fertilizer analyzer2.0683 嫁接刀grafting knife2.0684 温室设备greenhouse equipment2.0685 盆栽灌水系统pot watering system2.0686 温室气候控制器greenhouse climate controller2.0687 温室覆盖greenhouse covering2.0688 喷雾自控系统automatic mist control system2.0689 二氧化碳发生器C02 generator2.0690 温度报警钟temperature alarm2.0691 游览车park sightseeing bus2.0692 引剪草机lawn mower2.0693 动力剪草机power lawnmower2.0694 畜力剪草机horse lawnmower2.0695 手推剪草机hand lawnmower2.0696 游人调查visitors investigation2.0697 游人统计visitors statistics2.0698 游人分析garden visitors analysis2.0699 游人管理visitors management2.0700 导游图tourist map2.0701 导游解说tour descri ption and direction2.0702 劳动管理labour management2.0703 物资管理material handling, goods handling2.0704 设备管理equipment management, facility management 2.0705 财务管理financial management2.0706 安全管理safety management2.0707 环境监测environmental monitor2.0708 植物养护管理plant maintenance and management2.0709 园林技术管理garden technical management2.0710 质量管理quality management2.0711 园貌维修garden feature maintenance2.0712 植物整形修剪plant trimming and pruning2.0713 植物病虫防治disease and insect control2.0714 园林管理规划management plan2.0715 游人意见处理treatment of visitors opinions2.0716 游人规则visitors regulation2.0717 园内交通管理traffic control in park2.0718 园外交通管理traffic control out of park entrance2.0719 汽车停车规则parking rules2.0720 自行车停放规则bicycle parking rules2.0721 开放时间opening time2.0722 日常清洁卫生管理daily sanitation and hygiene managementcnlbbs2006-05-29 14:112.0723 人类生态环境human ecological environment2.0724 自然系统natural system2.0725 自然资源natural resource2.0726 自然保护conservation of nature2.0727 自然保存natural preservation2.0728 环境保护environmental protection2.0729 环境容量environment capacity2.0730 环境适宜性environment fitness2.0731 环境空气质量标准ambient air quality2.0732 共生symbiosis2.0733 互惠共生mutualism2.0734 公害public nuisance2.0735 生态绝灭ecological extinction2.0736 生态系统ecosystem2.0737 生态圈ecosphere2.0738 生态灾难ecological disaster2.0739 环境质量environmental quality2.0740 环境压力environment stress2.0741 生命维持系统life-support system2.0742 反馈系统feedback system2.0743 自养生物autotroph2.0744 异养生物heterotroph2.0745 食物链foodchain2.0746 生物圈biosphere2.0747 濒危植物endangered plant, threatened plant 2.0748 主体群落major community2.0749 人工群落artificial community2.0750 绿色革命green revolution2.0751 户外娱乐资源outdoor recreation resource2.0752 原始环境系统wilderness environment system 2.0753 近代环境系统modern environment system2.0754 乡村生活模式country life-pattern2.0755 烟害smoke pollution, fume pollution2.0756 雾害fog pollution2.0757 霜害frost injury2.0758 水污染water pollution2.0759 土壤污染soil pollution, soil contamination2.0760 园林小气候garden microclimate2.0761 环境保护植物environmental conservation plant2.0762 引气候调节climatic regulation2.0763 自动调节机能homeostasis2.0764 生态平衡ecological homeostasis2.0765 森林生态系统forest ecosystem2.0766 草原生态系统prairie ecosystem2.0767 滞尘植物dust holding plant出师表两汉:诸葛亮先帝创业未半而中道崩殂,今天下三分,益州疲弊,此诚危急存亡之秋也。