建筑材料外文翻译及译文

- 格式:doc

- 大小:41.00 KB

- 文档页数:7

建筑材料英文Building Materials。

Building materials are the foundation of any construction project. They are the essential components that determine the strength, durability, and aesthetic appeal of a building. In this document, we will explore the different types of building materials commonly used in construction and their key characteristics.1. Concrete。

Concrete is one of the most widely used building materials in the world. It is a composite material made of cement, water, and aggregates such as sand and gravel. Concrete has high compressive strength and is resistant to fire, water, and weathering. It is commonly used in the construction of foundations, walls, and floors.2. Steel。

Steel is another essential building material known for its strength and versatility. It is commonly used in the construction of structural frameworks, beams, columns, and reinforcement bars. Steel structures are durable, resistant to corrosion, and can withstand heavy loads. They are also flexible and can be easily shaped and fabricated to meet specific design requirements.3. Brick。

普通硅酸盐水泥中掺入硅灰和石膏对水化反应的影响在混凝土设计中掺加活性矿物替代是一个很重要的环节。

但这样的使用并不是总是适合的,由于水化反应放出的热量偶尔会影响混凝土的质量,从而影响h 混凝土结构的耐久性。

在具有两种不同矿物成分的普通硅酸盐水泥中掺加高达20%的硅灰的对其的影响是显而易见的。

添加过多的石膏,三氧化硫的含量就会达到7.0%。

在这个研究上最先进的技术是导热量热法和拉蒂尼测试,提供的方法是要设定时间和x射线衍射。

结果表明,用硅灰取代水泥的百分数为20%的时会影响水泥浆体的流动性。

根据标准稠度和时间来衡量需水量的多少。

这些效果的发展取决于熟料的矿物组成。

二氧化硅会直接和间接的影响水化反应:后者是因为在早期火山灰质活性的增加,前者是因为它的形态(微小的球体)和比表面积大。

每克硅酸盐水泥在早期总的水化热释放量在显著地上升,硅灰被认为对热效应起一个协同作用,随之而来的风险是产生细小的裂缝。

在石膏过量的情况下,水化反应的加快和衰减会使每克硅酸盐水泥产生更大的水化热,特别是在硅酸盐水泥的CA的含量大时。

3关键字:石膏,水化热,波特兰水泥,硅灰水泥的研究范围从个人分析到每个组件阶段,研究高度复杂的系统以及他们所有的变量,联合研究硅酸盐熟料组件与石膏(CaSO4.2H2O)的交互作用来测量凝结时间,例如,已经发现:• 在硅酸盐水泥中C3A和C4A都会与石膏发生反应,但是由于C3A更容易与石膏反应,所以水泥中大量的C3A被很快反应掉。

石膏的用量会受到所设置的凝结时间的限制,导致所形成的钙矾石会比预期的要少。

•石膏也加快了钙硅酸盐的水化速率,同时在水花过程中争夺硫酸根离子,虑到大量的硫酸盐包含在CSH凝胶中。

2至6%的石膏在加速水化硅酸三钙的形成,2%至4%在促进水泥石的水化。

石膏含量高有助于形成大量的钙矾石,然而这会阻止凝结时间和硬化,这些明显的变化是因为微观结构的膨胀和开裂。

石膏含量低,反过来,会形成更多的硫酸盐,降低了水化反应的强度,从而阻碍了C3A的的分解。

中文3295字Components of A Building and Tall Buildings1. AbstractMaterials and structural forms are combined to make up the various parts of a building, including the load-carrying frame, skin, floors, and partitions. The building also has mechanical and electrical systems, such as elevators, heating and cooling systems, and lighting systems. The superstructure is that part of a building above ground, and the substructure and foundation is that part of a building below ground.The skyscraper owes its existence to two developments of the 19th century: steel skeleton construction and the passenger elevator. Steel as a construction material dates from the introduction of the Bessemer converter in 1885.Gustave Eiffel (1832-1932) introduced steel construction in France. His designs for the Galerie des Machines and the Tower for the Paris Exposition of 1889 expressed the lightness of the steel framework. The Eiffel Tower, 984 feet (300 meters) high, was the tallest structure built by man and was not surpassed u ntil 40 years later by a series of American skyscrapers.Elisha Otis installed the first elevator in a department store in New York in 1857.In 1889, Eiffel installed the first elevators on a grand scale in the Eiffel Tower, whose hydraulic elevators could transport 2,350 passengers to the summit every hour.2. Load-Carrying FrameUntil the late 19th century, the exterior walls of a building were used as bearing walls to support the floors. This construction is essentially a post and lintel type, and it is still used in frame construction for houses. Bearing-wall construction limited the height of building because of the enormous wall thickness required;for instance, the 16-story Monadnock Building built in the 1880’s in Chicago had walls 5 feet (1.5 meters) thick at the lower floors. In 1883, William Le Baron Jenney (1832-1907) supported floors on cast-iron columns to form a cage-like construction. Skeleton construction, consisting of steel beams and columns, was first used in 1889. As a consequence of skelet on construction, the enclosing walls become a “curtain wall” rather than serving a supporting function. Masonry was the curtain wall material until the 1930’s, when light metal and glass curtainwalls were used. After the introduction of buildings continued to increase rapidly.All tall buildings were built with a skeleton of steel until World War Ⅱ. After the war, the shortage of steel and the improved quality of concrete led to tall building being built of reinforced concrete. Marina Tower (1962) in Chicago is the tallest concrete building in the United States;its height—588 feet (179 meters)—is exceeded by the 650-foot (198-meter) Post Office Tower in London and by other towers.A change in attitude about skyscraper construction has brought a return to the use of the bearing wall. In New York City, the Columbia Broadcasting System Building, designed by Eero Saarinen in 1962,has a perimeter wall consisting of 5-foot (1.5meter) wide concrete columns spaced 10 feet (3 meters) from column center to center. This perimeter wall, in effect, constitutes a bearing wall. One reason for this trend is that stiffness against the action of wind can be economically obtained by using the walls of the building as a tube;the World Trade Center building is another example of this tube approach. In contrast, rigid frames or vertical trusses are usually provided to give lateral stability.3. SkinThe skin of a building consists of both transparent elements (windows) and opaque elements (walls). Windows are traditionally glass, although plastics are being used, especially in schools where breakage creates a maintenance problem. The wall elements, which are used to cover the structure and are supported by it, are built of a variety of materials: brick, precast concrete, stone, opaque glass, plastics, steel, and aluminum. Wood is used mainly in house construction;it is not generally used for commercial, industrial, or public building because of the fire hazard.4. FloorsThe construction of the floors in a building depends on the basic structural frame that is used. In steel skeleton construction, floors are either slabs of concrete resting on steel beams or a deck consisting of corrugated steel with a concrete topping. In concrete construction, the floors are either slabs of concrete on concrete beams or a series of closely spaced concrete beams (ribs) in two directions topped with a thin concrete slab, giving the appearance of a waffle on its underside. The kind of floor that is used depends on the span between supporting columns or walls and the function of the space. In an apartment building, for instance, where walls and columns are spaced at 12 to 18 feet (3.7 to 5.5 meters), the most popular construction is a solid concrete slab with no beams. The underside of the slab serves as the ceiling for the space below it. Corrugated steel decks are often used in office buildings because the corrugations, when enclosed by another sheet of metal, form ducts for telephone and electrical lines.5. Mechanical and Electrical SystemsA modern building not only contains the space for which it is intended (office, classroom, apartment) but also contains ancillary space for mechanical and electrical systems that help toprovide a comfortable environment. These ancillary spaces in a skyscraper office building may constitute 25% of the total building area. The importance of heating, ventilating, electrical, and plumbing systems in an office building is shown by the fact that 40% of the construction budget is allocated to them. Because of the increased use of sealed building with windows that cannot be opened, elaborate mechanical systems are provided for ventilation and air conditioning. Ducts and pipes carry fresh air from central fan rooms and air conditioning machinery. The ceiling, which is suspended below the upper floor construction, conceals the ductwork and contains the lighting units. Electrical wiring for power and for telephone communication may also be located in this ceiling space or may be buried in the floor construction in pipes or co nduits.There have been attempts to incorporate the mechanical and electrical systems into the architecture of building by frankly expressing them;for example, the American Republic Insurance Company Building(1965) in Des Moines, Iowa, exposes both the ducts and the floor structure in an organized and elegant pattern and dispenses with the suspended ceiling. This type of approach makes it possible to reduce the cost of the building and permits innovations, such as in the span of the structure.6. Soils and FoundationsAll building are supported on the ground, and therefore the nature of the soil becomes an extremely important consideration in the design of any building. The design of a foundation depends on many soil factors, such as type of soil, soil stratification, thickness of soil lavers and their compaction, and groundwater conditions. Soils rarely have a single composition;they generally are mixtures in layers of varying thickness. For evaluation, soils are graded according to particle size, which increases from silt to clay to sand to gravel to rock. In general, the larger particle soils will support heavier loads than the smaller ones. The hardest rock can support loads up to 100 tons per square foot(976.5 metric tons/sq meter), but the softest silt can support a load of only 0.25 ton per square foot(2.44 metric tons/sq meter). All soils beneath the surface are in a state of compaction;that is, they are under a pressure that is equal to the weight of the soil column above it. Many soils (except for most sands and gavels) exhibit elastic properties—they deform when compressed under load and rebound when the load is removed. The elasticity of soils is often time-dependent, that is, deformations of the soil occur over a length of time which may vary fr om minutes to years after a load is imposed. Over a period of time, a building may settle if it imposes a load on the soil greater than the natural compaction weight of the soil. Conversely, a building may heave if it imposes loads on the soil smaller than the natural compaction weight. The soil may also flow under the weight of a building;that is, it tends to be squeezed out.Due to both the compaction and flow effects, buildings tend settle. Uneven settlements, exemplified by the leaning towers in Pisa and Bologna, can have damaging effects—the building may lean, walls and partitions may crack, windows and doors may become inoperative, and, in theextreme, a building may collapse. Uniform settlements are not so serious, although extreme conditions, such as those in Mexico City, can have serious consequences. Over the past 100 years, a change in the groundwater level there has caused some buildings to settle more than 10 feet (3 meters). Because such movements can occur during and after construction, carefu l analysis of the behavior of soils under a building is vital.The great variability of soils has led to a variety of solutions to the foundation problem. Where firm soil exists close to the surface, the simplest solution is to rest columns on a small sla b of concrete(spread footing). Where the soil is softer, it is necessary to spread the column load over a greater area;in this case, a continuous slab of concrete(raft or mat) under the whole building is used. In cases where the soil near the surface is unable to support the weight of the building, piles of wood, steel, or concrete are driven down to firm soil.The construction of a building proceeds naturally from the foundation up to the superstructure. The design process, however, proceeds from the roof down to the foundation (in the direction of gravity). In the past, the foundation was not subject to systematic investigation. A scientific approach to the design of foundations has been developed in the 20th century. Karl Terzaghi of the United States pioneered studies that made it possible to make accurate predictions of the behavior of foundations, using the science of soil mechanics coupled with exploration and testing procedures. Foundation failures of the past, such as the classical example of the le aning tower in Pisa, have become almost nonexistent. Foundations still are a hidden but costly part of many buildings.Although there have been many advancements in building construction technology in general, spectacular achievements have been made in the design and construction of ultrahigh-rise buildings.The early development of high-rise buildings began with structural steel framing. Reinforced concrete and stressed-skin tube systems have since been economically and competitively used in a number of structures for both residential and commercial purposes. The high-rise buildings ranging from 50 to 110 stories that are being built all over the United States are the result of innovations and development of new structural systems.Greater height entails increased column and beam sizes to make buildings more rigid so that under wind load they will not sway beyond an acceptable limit. Excessive lateral sway may cause serious recurring damage to partitions, ceilings, and other architectural details. In additi on, excessive sway may cause discomfort to the occupants of the building because of their perception of such motion. Structural systems of reinforced concrete, as well as steel, take full advantage of the inherent potential stiffness of the total building and therefore do not require additional stiffening to limit the sway.In a steel structure, for example, the economy can be defined in terms of the total average quantity of steel per square foot of floor area of the building. Curve A in Fig.1 represents t he average unit weight of a conventional frame with increasing numbers of stories. Curve B represents theaverage steel weight if the frame is protected from all lateral loads. The gap between the upper boundary and the lower boundary represents the premium for all lateral loads. The gap between the upper boundary and the lower boundary represents the premium for height for the traditional column-and-beam frame. Structural engineers have developed structural systems with a view to eliminating this premium.7. Tube in tubeAnother system in reinforced concrete for office buildings combines the traditional shear wall construction with an exterior framed tube. The system consists of an outer framed tube of very closely spaced columns and an interior rigid shear wall tube enclosing the central service area. The system (Fig.2), known as the tube-in-tube system, made it possible to design the world’s present tallest (714 ft or 218 m) lightweight concrete building (the 52-story One Shell Plaza Building in Houston) for the unit price of a traditional shear wall structure of only 35 stories.Systems combining both concrete and steel have also been developed, an example of which is the composite system developed by Skidmore, Owings & Merrill in which an exterior closely spaced framed tube in concrete envelops an interior steel framing, thereby combining the advantages of both reinforced concrete and structural steel systems. The story One Shell Square Building in New Orleans is based on this system.建筑的组成部分1 摘要材料和结构类型是构成建筑物各方面的组成部分,包括承重结构、围护结构、楼地面和隔墙。

Architecture in a Climate of ChangePage52-Page62Low energy techniques for housingIt would appear that,for the industrialised countries,the best chance of rescue lies with the built environment because buildings in use or in the course of erection are the biggest single indirect source of carbon emissions generated by burning fossil fuels,accounting for over 50 per cent of total emissions.If you add the transport costs generated by buildings the UK government estimate is 75 per cent.It is the built environment which is the sector that can most easily accommodate fairly rapid change without pain.In fact,upgrading buildings, especially the lower end of the housing stock,creates a cluster of interlocking virtuous circles. Construction systemsHaving considered the challenge presented by global warming and the opportunities to generate fossil-free energy,it is now time to consider how the demand side of the energy equation can respond to that challenge.The built environment is the greatest sectoral consumer of energy and,within that sector,housing is in pole position accounting for 28 per cent of all UK carbon dioxide (CO2) emissions.In the UK housing has traditionally been of masonry and since the early 1920s this has largely been of cavity construction.The purpose was to ensure that a saturated external leaf would have no physical contact with the inner leaf apart from wall ties and that water would be discharged through weep holes at the damp-proof course level.Since the introduction of thermal regulations,initially deemed necessary to conserve energy rather than the planet,it has been common practice to introduce insulation into the cavity.For a long time it was mandatory to preserve a space within the cavity and a long rearguard battle was fought by the traditionalists to preserve this‘sacred space’.Defeat was finally conceded when some extensive research by the Building Research Establishment found that there was no greater risk of damp penetration with filled cavities and in fact damp through condensation was reduced.Solid masonry walls with external insulation are common practice in continental Europe and are beginning to make an appearance in the UK.In Cornwall the Penwith Housing Association has built apartments of this construction on the sea front, perhaps the most challenging of situations.The advantages of masonry construction are:● It is a tried and tested technology familiar to house building companies of all sizes.● It is durable and generally risk free as regards catastrophic failure–though not entirely.A few years ago the entire outer leaf of a university building in Plymouth collapsed due to the fact that the wall ties had corroded.● Exposed brickwork is a low maintenance system; maintenance demands rise considerably if it receives a rendered finish.● From the energy efficiency point of view,masonry homes have a relatively high thermal mass which is considerably improved if there are high density masonryinternal walls and concrete floors.Framed constructionVolume house builders are increasingly resorting to timber-framed construction with a brick outer skin,making them appear identical to full masonry construction.The attraction is the speed of erection especially when elements are fabricated off site. However,there is an unfortunate history behind this system due to shortcomings in quality control.This can apply to timber which has not been adequately cured or seasoned.Framed buildings need to have a vapour barrier to walls as well as roofs. With timber framing it is difficult to avoid piercing the barrier.There can also be problems achieving internal fixings.For the purist,the ultimate criticism is that it is illogical to have a framed building clad in masonry when it cries out for a panel,boarded,slate or tile hung external finish.Pressed steel frames for homes are now being vigorously promoted by the steel industry.The selling point is again speed of erection but with the added benefit of a guaranteed quality in terms of strength and durability of the material.From the energy point of view,framed buildings can accommodate high levels of insulation but have relatively poor thermal mass unless this is provided by floors and internal walls.Innovative techniquesPermanent Insulation Formwork Systems (PIFS) are beginning to make an appearance in Britain.The principle behind PIFS is the use of precision moulded interlocking hollow blocks made from an insulation material,usually expanded polystyrene.They can be rapidly assembled on site and then filled with pump grade concrete.When the concrete has set the result is a highly insulated wall ready for the installation of services and internal and exterior finishes.They can achieve a U-value as low as 0.11 W/m2K.Above three storeys the addition of steel reinforcement is necessary. The advantages of this system are:● Design flexibility; almost any plan shape is possible.● Ease and speed of erection;skill requirements are modest which is why it has proved popular with the self-build sector.Experienced erectors can achieve 5 m2 per man hour for erection and placement of concrete.● The finished product has high structural strength together with considerable thermal mass and high insulation value.Solar designPassive solar designSince the sun drives every aspect of the climate it is logical to describe the techniques adopted in buildings to take advantage of this fact as‘solar design’. The most basic response is referred to as‘passive solar design’.In this case buildings are designed to take full advantage of solar gain without any intermediate operations.Access to solar radiation is determined by a number of conditions:● the sun’s position relative to the principal facades of the building(solar altitude and azimuth);● site orientation and slope;● existing obstructions on the site;● potential for overshadowing from obstructions outside the site boundary.One of the methods by which solar access can be evaluated is the use of some form of sun chart.Most often used is the stereographic sun chart in which a series of radiating lines and concentric circles allow the position of nearby obstructions to insolation,such as other buildings,to be plotted.On the same chart a series of sun path trajectories are also drawn(usually one arc for the 21st day of each month); also marked are the times of the day.The intersection of the obstructions’outlines and the solar trajectories indicate times of transition between sunlight and shade. Normally a different chart is constructed for use at different latitudes (at about two degree intervals).Sunlight and shade patterns cast by the proposed building itself should also be considered.Graphical and computer prediction techniques may be employed as well as techniques such as the testing of physical models with a heliodon.Computer modelling of shadows cast by the sun from any position is offered by Integrated Environmental Solutions (IES) with its‘Suncast’program.This is a user-friendly program which should be well within normal undergraduate competence. The spacing between buildings is important if overshading is to be avoided during winter months when the benefit of solar heat gain reaches its peak.On sloping sites there is a critical relationship between the angle of slope and the level of overshading.For example, if overshading is to be avoided at a latitude of 50 N,rows of houses on a 10 north-facing slope must be more than twice as far apart than on 10 south-facing slope.Trees can obviously obstruct sunlight.However,if they are deciduous,they perform the dual function of permitting solar penetration during the winter whilst providing a degree of shading in the summer.Again spacing between trees and buildings is critical.Passive solar design can be divided into three broad categories:● direct gain;● indirect gain;● attached sunspace or conservatory.Each of the three categories relies in a different way on the‘greenhouse effect’as a means of absorbing and retaining heat.The greenhouse effect in buildings is that process which is mimicked by global environmental warming.In buildings,the incident solar radiation is transmitted by facade glazing to the interior where it is absorbed by the internal surfaces causing warming.However,re-emission of heat back through the glazing is blocked by the fact that the radiation is of a much longer wavelength than the incoming radiation.This is because the re-emission is from surfaces at a much lower temperature and the glazing reflects back such radiation to the interior.Direct gainDirect gain is the design technique in which one attempts to concentrate the majority of the building’s glazing on the sun-facing facade.Solar radiation is admitted directly into the space concerned.Two examples 30 years apart are the author’s housein Sheffield,designed in 1967 and the Hockerton Project of 1998 by Robert and Brenda Vale.The main design characteristics are:● Apertures through which sunlight is admitted should be on the solar side of the building, within about 30 of south for the northern hemisphere.● Windows facing west may pose a summer overheating risk.● Windows should be at least double glazed with low emissivity glass (Low E) as now required by the UK Building Regulations.● The main occupied living spaces should be located on the solar side of the building.● The floor should be of a high thermal mass to absorb the heat and provide thermal inertia,which reduces temperature fluctuations inside the building.● As regards the benefits of thermal mass,for the normal daily cycle of heat absorption and emission,it is only about the first 100 mm of thickness which is involved in the storage process.Thickness greater than this provides marginal improvements in performance but can be useful in some longer-term storage options.● In the case of solid floors,insulation should be beneath the slab.● A vapour barrier should always be on the warm side of any insulation.● Thick carpets should be avoided over the main sunlit and heatabsorbing portion of the floor if it serves as a thermal store.However,with suspended timber floors a carpet is an advantage in excluding draughts from a ventilated underfloor zone. During the day and into the evening the warmed floor should slowly release its heat, and the time period over which it happens makes it a very suitable match to domestic circumstances when the main demand for heat is in the early evening.As far as the glazing is concerned,the following features are recommended: ● Use of external shutters and/or internal insulating panels might be considered to reduce night-time heat loss.● To reduce the potential of overheating in the summer,shading may be provided by designing deep eaves or external louvres. Internal blinds are the most common technique but have the disadvantage of absorbing radiant heat thus adding to the internal temperature.● Heat reflecting or absorbing glass may be used to limit overheating.The downside is that it also reduces heat gain at times of the year when it is beneficial. ● Light shelves can help reduce summer overheating whilst improving daylight distribution.Direct gain is also possible through the glazing located between the building interior and attached sunspace or conservatory;it also takes place through upper level windows of clerestory designs.In each of these cases some consideration is required concerning the nature and position of the absorbing surfaces.In the UK climate and latitude as a general rule of thumb room depth should not be more than two and a half times the window head height and the glazing area should be between about 25 and 35 per cent of the floor area.Indirect gainIn this form of design a heat absorbing element is inserted between the incident solar radiation and the space to be heated;thus the heat is transferred in an indirectway.This often consists of a wall placed behind glazing facing towards the sun,and this thermal storage wall controls the flow of heat into the building.The main elements● High thermal mass element positioned between sun and internal spaces,the heat absorbed slowly conducts across the wall and is liberated to the interior some time later.● Materials and thickness of the wall are chosen to modify the heat flow.In homes the flow can be delayed so that it arrives in the evening matched to occupancy periods. Typical thicknesses of the thermal wall are 20–30 cm.● Glazing on the outer side of the thermal wall is used to provide some insulation against heat loss and help retain the solar gain by making use of the greenhouse effect.● The area of the thermal storage wall element should be about 15–20 per cent of the floor area of the space into which it emits heat.● In order to derive more immediate heat benefit,air can be circulated from the building through the air gap between wall and glazing and back into the room.In this modified form this element is usually referred to as a Trombe wall. Heat reflecting blinds should be inserted between the glazing and the thermal wall to limit heat build-up in summer.In countries which receive inconsistent levels of solar radiation throughout the day because of climatic factors (such as in the UK),the option to circulate air is likely to be of greater benefit than awaiting its arrival after passage through the thermal storage wall.At times of excess heat gain the system can provide alternative benefits with the air circulation vented directly to the exterior carrying away its heat,at the same time drawing in outside air to the building from cooler external spaces.Indirect gain options are often viewed as being the least aesthetically pleasing of the passive solar options,partly because of the restrictions on position and view out from remaining windows,and partly as a result of the implied dark surface finishes of the absorbing surfaces.As a result,this category of the three prime solar design technologies is not as widely used as its efficiency and effectiveness would suggest.Attached sunspace/conservatoryThis has become a popular feature in both new housing and as an addition to existing homes.It can function as an extension of living space,a solar heat store,a preheater for ventilation air or simply an adjunct greenhouse for plants.On balance it is considered that conservatories are a net contributor to global warming since they are often heated.Ideally the sunspace should be capable of being isolated from the main building to reduce heat loss in winter and excessive gain in summer.The area of glazing in the sunspace should be 20–30 per cent of the area of the room to which it is attached.The most adventurous sunspace so far encountered is in the Hockerton housing development which will feature later.Ideally the summer heat gain should be used to charge a seasonal thermal storage element to provide background warmth in winter.At the very least,air flow paths between the conservatory and the main building should be carefully controlled.Active solar thermal systemsA distinction must be drawn between passive means of utilising the thermal heat of the sun, discussed earlier,and those of a more‘active’nature Active systems take solar gain a step further than passive solar.They convert direct solar radiation into another form of energy.Solar collectors preheat water using a closed circuit calorifier.The emergence of Legionella has highlighted the need to store hot water at a temperature above 60 C which means that for most of the year in temperate climes active solar heating must be supplemented by some form of heating.Active systems are able to deliver high quality energy.However,a penalty is incurred since energy is required to control and operate the system known as the ‘parasitic energy requirement’.A further distinction is the difference between systems using the thermal heat of the sun,and systems,such as photovoltaic cells, which convert solar energy directly into electrical power.For solar energy to realise its full potential it needs to be installed on a district basis and coupled with seasonal storage.One of the largest projects is at Friedrichshafen.The heat from 5600 m2 of solar collectors on the roofs of eight housing blocks containing 570 apartments is transported to a central heating unit or substation.It is then distributed to the apartments as required.The heated living area amounts to 39 500 m2.Surplus summer heat is directed to the seasonal heat store which,in this case, is of the hot water variety capable of storing 12 000 m3.The scale of this storage facility is indicated by Figure 5.9.The heat delivery of the system amounts to 1915 MWh/year and the solar fraction is 47 per cent.The month by month ratio between solar and fossil-based energy indicates that from April to November inclusive,solar energy accounts for almost total demand,being principally domestic hot water.In places with high average temperatures and generous sunlight,active solar has considerable potential not just for heating water but also for electricity generation.This has particular relevance to less and least developed countries.环境变化影响下的建筑学房屋设计中的低能耗技术显而易见,在工业化国家,最好的营救机会依赖于建筑环境,因为不论是在使用的建筑或者是在建设的建筑,都是最大的、单一的、间接地由化石燃料的燃烧所引起的碳排放的源头,而这些站了所有排放的50%。

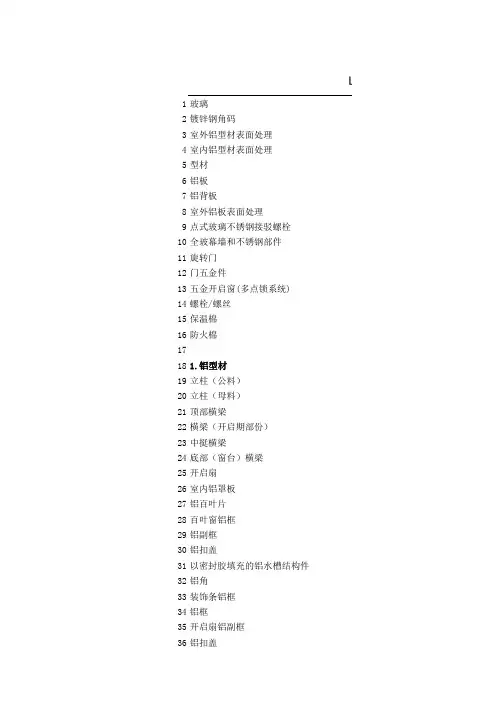

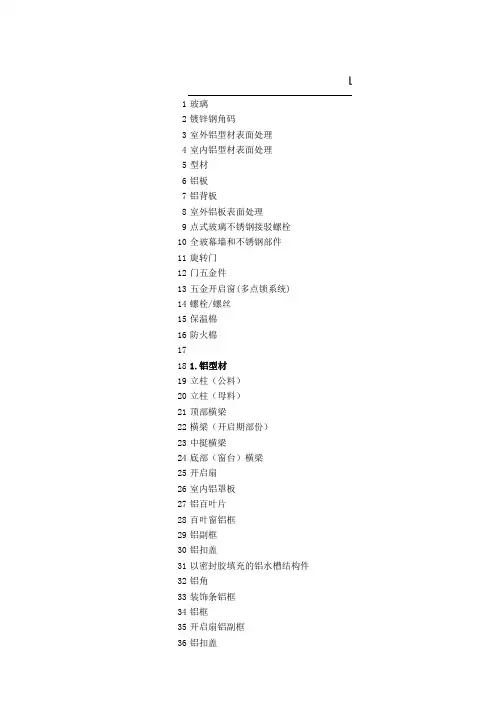

1玻璃2镀锌钢角码3室外铝型材表面处理4室内铝型材表面处理5型材6铝板7铝背板8室外铝板表面处理9点式玻璃不锈钢接驳螺栓10全玻幕墙和不锈钢部件11旋转门12门五金件13五金开启窗(多点锁系统)14螺栓/螺丝15保温棉16防火棉17181.铝型材19立柱(公料)20立柱(母料)21顶部横梁22横梁(开启期部份)23中挺横梁24底部(窗台)横梁25开启扇26室内铝罩板27铝百叶片28百叶窗铝框29铝副框30铝扣盖31以密封胶填充的铝水槽结构件32铝角33装饰条铝框34铝框35开启扇铝副框36铝扣盖建LEGEND OF MAERIALS37横向装饰条38横向装饰条托架39铝压条40内部装饰铝套41铝芯套42432.钢结构44由外墙承建商负责的钢结构45由工程师指定的焊缝46由总承建商负责的钢结构47矩形管48493.金属板材50指定颜色的铝板51不锈钢防鸟网52防烟涂料/板53铝盖54支撑防火材料用镀锌片55防水铝板56石材支撑铝槽57镀锌钢板58铝角59铝板支撑角铝60指定颜色的铝槽61风管连接套62634.托架64铝托架(含锯齿形定位垫片) 65热浸镀锌钢托架66预埋镀锌铁板/角码67铝制挂托架68铝套69铝角码70调节螺丝71供调节用长螺孔72限制板块移动的铝块73固定镀锌钢折板74755.紧固件(螺栓,螺母,垫圈)76不锈钢螺栓77不锈钢螺母78不锈钢垫圈79不锈钢弹簧垫圈80不锈钢自锁螺母81不锈钢自攻螺丝82不锈钢机器螺丝83不锈钢调整螺栓84多点锁85锁箱(手柄可拆卸)86不锈钢铆钉87清洁/维修铰索扣88射钉89后补锚栓90916.表面处理92氟碳喷涂处理93粉喷处理94涂漆钢结构95热镀锌钢结构96977.玻璃98中空玻璃(结构胶必须能承担设计风压) 99单层玻璃100夹胶玻璃1013M防爆膜1021038.密封胶104双组份结构密封胶105耐候胶106双面胶条107框架拼接密封胶108泡沫棒109单组份结构密封胶110密封胶密封111密气密封胶1121139.砖石结构114混凝土楼板/梁115混凝土反梁116楼板结构顶点11711810.填充材料119聚氯丁圆头胶条120聚氯丁耐候胶条121聚氯丁耐候雨披水胶条122硅酮玻璃/石材垫块123水汽隔断124与硅酮胶相容的橡胶垫块125可膨胀三元乙丙挤压型批水板12612711.绝缘材料128隔热材料129防火材料130隔热断桥(PA66)13113212.其它133泄水孔134等压孔135楼板建筑顶点136由外墙承包商负责的防水涂料137绝缘片138相应结构及湿度变形而预先采取的措施139由总承建商负责的结构140高强度塑胶/尼龙垫片(套)141卷帘护箱142通风管道由其它承包商承建143吊顶由其它承包商承建144石材145由其它承包商负责的防水层146由其它承包商负责的室内装饰147横梁后边线148外部竖向装饰条149立柱后边线150支撑铝板建筑材料符号表LEGEND OF MAERIALS(Glass)- LocalGMS bracket to kerfExtrusions Finishes ExteriorExtrusions Finishes InteriorAluminium ExtrusionAluminium PanelAluminium Back panExterior Aluminium panel finishStainless Steel Flush Bolt for point fixing glass Glass Wall and S/S ComponentsRevolving DoorDoor IronmongeryHardware - Operable Vents multipoint lockBolt/screwInsulationFirestopALUMINIUM EXTRUSIONMALE MULLIONFEMALE MULLIONHEAD EXTRUSIONTRANSOM WITH VENT SASHINTERMEDIATE TRANSOMSILL TRANSOMOPERABLE VENDALUMINIUM INTERIOR TRIMALUMINIUM LOUVRE BLADEALUMINIUM LOUVRE FRAMEALUMINIUM GLAZING ADAPTERALUMINIUM COVER DEADALUMINIUM STRUCTLRAL GUTTER SLEEVE SET IN SEALANT ALUMINIUM ANGLEALUMINIUM FEATURE FIN FRAMEALUMINIUM BOX SECTIONALUMINIUM CPERABLE VENT STOPALUMINIUM CLIP-ON COVERALUMINIUM HORIZONTAL PEATURE CAPPING HORIZONTAL FEATURE FIN BRACKETALUMINIUM PRESSUREALUMINIUM INTERIOR TRIM SLEEVEALUMINIUM STRUCTLRAL SLEEVESTEELWORKSECONDARY STEEL BY FACADE CONTRACTORWELDING AS NOMINATED BY ENGINEERSTEEL BY MAIN CONTRACTORSTEEL BOX SECTIONSHEET METALFORMED ALUMINIUM SHEET TO SELECTED COLOUR STAINLESS STEEL BIRDWIRE MESHSMOKE SEAL/FLASHINGALUMINIUM FORMED CAPPINGFIRE INSULATION SUPPORT BRACKET (GALANIZED STEEL ALUMINIUM FLASHINGPRESSED ALUMINIUM STONE SUPPORT CHANNEL FORMED GSM SHEETPRESSING ALUMINIUM ANGLEALUMINIUM CAPPING SUPPORTPRESSED ALUMINIUM CHANNEL TO SELECTED COLOUR DUCT CONNECTING SLEEVEBRACKETALUMINIUM BRACKET (W/SERRATED WASHER) GALVANISED STEEL BRACKETCAST-IN GALVANISED STEEL PLATE/ANGLE ALUMINIUM HOOK-ON BRACKETALUMINIUM SLEEVEALUMINIUM ANGLE BRACKETADJUSTMENT SCREWSLOTTED HOLES FOR ADJUSTMENTANTI-UPLIFT BRACKETFORMED STEEL CHANNEL/ANGLEFIXING(BOLTS,NUTS,WASHERS)STAINLESS STEEL BOLTSTAINLESS STEEL NUTSTAINLESS STEEL WASHERSTAINLESS STEEL SPRING WASHERSTAINLESS STEEL SELF-LOCKING NUTSTAINLESS STEEL SELF-TAPPING SCREWSTAINLESS STEEL MACHINE SCREWSTAINLESS STEEL JACKING BOLTMULTI-POINT LOCKING DEVICELOCK BOX W/REMOVABLE HANDELSTAINLESS STEEL POP RIVETCLEANING/MAINTENANCE GONDOLA LANYARO RESTRAINTSHOT PINMASONARY ANCHORFINISHPVF2 FINISHPOWER COAT FINISHPAINTED STEELHOT DIPPED GALVANISED STEELGLASSDOUBLE GLAZED UNIT (STRUCTURAL SEALANT MUST TAKE DESIGN WIND LOADMONOLITHIC GLASSLAMINATED GLASS3M FILMSEALANTSTWO-PART STRUCTURAL SEALANTWEATHER SEAL SEALANTDOUBLED SIDED TAPEFRAME JOINT SEALANTSEALANT BACKER RODONE-PART STRUCTURAL SEALANTSILICONE SEALEDAIR SEALMASONRYCONCRETE SLAB/BEAMCONCRETE UPSTANDTOP OF SLABGASKETNEOPRENE BULB GASKETNEOPRENE WEATHER SEAL GASKETNEOPRENE RAIN-SCREEN FLAPSILICONE GLASS/STONE SETTING BLOCKAIR & WATER BAFFLESILICONE COMPATIBLE HARD DUROMETER RUBBER SHIM EXTRUDED EPDM EXPANDABLE FLASHINGINSULATIONTHERMAL INSULATIONFIRE INSULATOINTHERMAL BREAK(PA66)MISCELLANEOUSWEEPHOLEPRESSURE EQUALIZATION HOLETOP OF FINISHED FLOORWATERPROOFING BY FACADE CONTRACTORISOLATION SHIM/TAPEPROVISION FOR BUILDING & THERMAL MOVEMENT STRUCTURE BY MAIN CONTRACTORHIGH IMPACT PLASTIC/NYLON SHIM OR SLEEVE BLIND BOXDUCT WORK BY OTHERSSUSPENOED CEILING BY OTHERSTONE PANELWATERPROOFING BY OTHERSINTERIOR FINISH BY OTHERSBACK OF TRANSOM EXTRUSIONEXTERNAL VERTICAL FEATURE FINBACK OF MULLIONALUMINIUM DEAD LOAD BLOCK。

1玻璃2镀锌钢角码3室外铝型材表面处理4室内铝型材表面处理5型材6铝板7铝背板8室外铝板表面处理9点式玻璃不锈钢接驳螺栓10全玻幕墙和不锈钢部件11旋转门12门五金件13五金开启窗(多点锁系统)14螺栓/螺丝15保温棉16防火棉17181.铝型材19立柱(公料)20立柱(母料)21顶部横梁22横梁(开启期部份)23中挺横梁24底部(窗台)横梁25开启扇26室内铝罩板27铝百叶片28百叶窗铝框29铝副框30铝扣盖31以密封胶填充的铝水槽结构件32铝角33装饰条铝框34铝框35开启扇铝副框36铝扣盖建LEGEND OF MAERIALS37横向装饰条38横向装饰条托架39铝压条40内部装饰铝套41铝芯套42432.钢结构44由外墙承建商负责的钢结构45由工程师指定的焊缝46由总承建商负责的钢结构47矩形管48493.金属板材50指定颜色的铝板51不锈钢防鸟网52防烟涂料/板53铝盖54支撑防火材料用镀锌片55防水铝板56石材支撑铝槽57镀锌钢板58铝角59铝板支撑角铝60指定颜色的铝槽61风管连接套62634.托架64铝托架(含锯齿形定位垫片) 65热浸镀锌钢托架66预埋镀锌铁板/角码67铝制挂托架68铝套69铝角码70调节螺丝71供调节用长螺孔72限制板块移动的铝块73固定镀锌钢折板74755.紧固件(螺栓,螺母,垫圈)76不锈钢螺栓77不锈钢螺母78不锈钢垫圈79不锈钢弹簧垫圈80不锈钢自锁螺母81不锈钢自攻螺丝82不锈钢机器螺丝83不锈钢调整螺栓84多点锁85锁箱(手柄可拆卸)86不锈钢铆钉87清洁/维修铰索扣88射钉89后补锚栓90916.表面处理92氟碳喷涂处理93粉喷处理94涂漆钢结构95热镀锌钢结构96977.玻璃98中空玻璃(结构胶必须能承担设计风压) 99单层玻璃100夹胶玻璃1013M防爆膜1021038.密封胶104双组份结构密封胶105耐候胶106双面胶条107框架拼接密封胶108泡沫棒109单组份结构密封胶110密封胶密封111密气密封胶1121139.砖石结构114混凝土楼板/梁115混凝土反梁116楼板结构顶点11711810.填充材料119聚氯丁圆头胶条120聚氯丁耐候胶条121聚氯丁耐候雨披水胶条122硅酮玻璃/石材垫块123水汽隔断124与硅酮胶相容的橡胶垫块125可膨胀三元乙丙挤压型批水板12612711.绝缘材料128隔热材料129防火材料130隔热断桥(PA66)13113212.其它133泄水孔134等压孔135楼板建筑顶点136由外墙承包商负责的防水涂料137绝缘片138相应结构及湿度变形而预先采取的措施139由总承建商负责的结构140高强度塑胶/尼龙垫片(套)141卷帘护箱142通风管道由其它承包商承建143吊顶由其它承包商承建144石材145由其它承包商负责的防水层146由其它承包商负责的室内装饰147横梁后边线148外部竖向装饰条149立柱后边线150支撑铝板建筑材料符号表LEGEND OF MAERIALS(Glass)- LocalGMS bracket to kerfExtrusions Finishes ExteriorExtrusions Finishes InteriorAluminium ExtrusionAluminium PanelAluminium Back panExterior Aluminium panel finishStainless Steel Flush Bolt for point fixing glass Glass Wall and S/S ComponentsRevolving DoorDoor IronmongeryHardware - Operable Vents multipoint lockBolt/screwInsulationFirestopALUMINIUM EXTRUSIONMALE MULLIONFEMALE MULLIONHEAD EXTRUSIONTRANSOM WITH VENT SASHINTERMEDIATE TRANSOMSILL TRANSOMOPERABLE VENDALUMINIUM INTERIOR TRIMALUMINIUM LOUVRE BLADEALUMINIUM LOUVRE FRAMEALUMINIUM GLAZING ADAPTERALUMINIUM COVER DEADALUMINIUM STRUCTLRAL GUTTER SLEEVE SET IN SEALANT ALUMINIUM ANGLEALUMINIUM FEATURE FIN FRAMEALUMINIUM BOX SECTIONALUMINIUM CPERABLE VENT STOPALUMINIUM CLIP-ON COVERALUMINIUM HORIZONTAL PEATURE CAPPING HORIZONTAL FEATURE FIN BRACKETALUMINIUM PRESSUREALUMINIUM INTERIOR TRIM SLEEVEALUMINIUM STRUCTLRAL SLEEVESTEELWORKSECONDARY STEEL BY FACADE CONTRACTORWELDING AS NOMINATED BY ENGINEERSTEEL BY MAIN CONTRACTORSTEEL BOX SECTIONSHEET METALFORMED ALUMINIUM SHEET TO SELECTED COLOUR STAINLESS STEEL BIRDWIRE MESHSMOKE SEAL/FLASHINGALUMINIUM FORMED CAPPINGFIRE INSULATION SUPPORT BRACKET (GALANIZED STEEL ALUMINIUM FLASHINGPRESSED ALUMINIUM STONE SUPPORT CHANNEL FORMED GSM SHEETPRESSING ALUMINIUM ANGLEALUMINIUM CAPPING SUPPORTPRESSED ALUMINIUM CHANNEL TO SELECTED COLOUR DUCT CONNECTING SLEEVEBRACKETALUMINIUM BRACKET (W/SERRATED WASHER) GALVANISED STEEL BRACKETCAST-IN GALVANISED STEEL PLATE/ANGLE ALUMINIUM HOOK-ON BRACKETALUMINIUM SLEEVEALUMINIUM ANGLE BRACKETADJUSTMENT SCREWSLOTTED HOLES FOR ADJUSTMENTANTI-UPLIFT BRACKETFORMED STEEL CHANNEL/ANGLEFIXING(BOLTS,NUTS,WASHERS)STAINLESS STEEL BOLTSTAINLESS STEEL NUTSTAINLESS STEEL WASHERSTAINLESS STEEL SPRING WASHERSTAINLESS STEEL SELF-LOCKING NUTSTAINLESS STEEL SELF-TAPPING SCREWSTAINLESS STEEL MACHINE SCREWSTAINLESS STEEL JACKING BOLTMULTI-POINT LOCKING DEVICELOCK BOX W/REMOVABLE HANDELSTAINLESS STEEL POP RIVETCLEANING/MAINTENANCE GONDOLA LANYARO RESTRAINTSHOT PINMASONARY ANCHORFINISHPVF2 FINISHPOWER COAT FINISHPAINTED STEELHOT DIPPED GALVANISED STEELGLASSDOUBLE GLAZED UNIT (STRUCTURAL SEALANT MUST TAKE DESIGN WIND LOADMONOLITHIC GLASSLAMINATED GLASS3M FILMSEALANTSTWO-PART STRUCTURAL SEALANTWEATHER SEAL SEALANTDOUBLED SIDED TAPEFRAME JOINT SEALANTSEALANT BACKER RODONE-PART STRUCTURAL SEALANTSILICONE SEALEDAIR SEALMASONRYCONCRETE SLAB/BEAMCONCRETE UPSTANDTOP OF SLABGASKETNEOPRENE BULB GASKETNEOPRENE WEATHER SEAL GASKETNEOPRENE RAIN-SCREEN FLAPSILICONE GLASS/STONE SETTING BLOCKAIR & WATER BAFFLESILICONE COMPATIBLE HARD DUROMETER RUBBER SHIM EXTRUDED EPDM EXPANDABLE FLASHINGINSULATIONTHERMAL INSULATIONFIRE INSULATOINTHERMAL BREAK(PA66)MISCELLANEOUSWEEPHOLEPRESSURE EQUALIZATION HOLETOP OF FINISHED FLOORWATERPROOFING BY FACADE CONTRACTORISOLATION SHIM/TAPEPROVISION FOR BUILDING & THERMAL MOVEMENT STRUCTURE BY MAIN CONTRACTORHIGH IMPACT PLASTIC/NYLON SHIM OR SLEEVE BLIND BOXDUCT WORK BY OTHERSSUSPENOED CEILING BY OTHERSTONE PANELWATERPROOFING BY OTHERSINTERIOR FINISH BY OTHERSBACK OF TRANSOM EXTRUSIONEXTERNAL VERTICAL FEATURE FINBACK OF MULLIONALUMINIUM DEAD LOAD BLOCK。

建筑外文翻译外文文献英文文献混凝土强度和现代建筑材料以下是为大家整理的建筑外文翻译外文文献英文文献混凝土强度和现代建筑材料的相关范文,本文关键词为建筑,外文,翻译,文献,英文,混凝土,强度,现代,建筑材料,,您可以从右上方搜索框检索更多相关文章,如果您觉得有用,请继续关注我们并推荐给您的好友,您可以在英语学习中查看更多范文。

外文出处:buildingandenvironment12(20XX)186-191附件1:外文资料翻译译文混凝土强度和现代建筑材料文章摘要:钢筋混凝土可以用在框架结构上,常常用在预制构件并主要用在工业建筑相同结构建筑物上,混凝土也可以用在壳式建筑施工中,其表面同时也成为结构的组成部分。

现代建筑材料:大多数较大的建筑物都是由钢结构,钢筋混凝土以及预应力混凝土构成。

关键词:混凝土强度;现代建筑材料;高层建筑;框架结构在许多结构中,混凝土同时受到不同方向各种应力的作用.例如在梁中大部分混凝土同时承受压力和剪力,再楼板和基础中,混凝土同时承受两个相互垂直方向的压力外加剪力的作用.根据材料力学学习中已知的方法,无论怎样复杂的复合应力状态,都可化为三个相互垂直的主应力,它们作用在材料适当定向的单元立方体上.三个主应力中的任意一个或者全部既可是拉应力,也可是压应力.如果其中一个主应力为零,则为双轴应力状态。

如果有两个主应力为零,则为单轴应力状态,或为简单压缩或为简单拉伸。

在多数情况下,根据简单的试验,如圆柱体强度f'c和抗拉强度f't,只能够确定材料在单轴应力作用下的性能。

为了预测混凝土在双轴应力或三轴应力作用下的结构强度,在通过试验仅仅知道f'c或f'c与f't的情况下,需要通过计算确定混凝土在上述复合应力状态下的强度。

尽管人们连续不断地进行了大量的研究,但仍然没有得出有关混凝土在复合应力作用下的强度的通用理论。

经过修正的各种强度理论,如最大拉应力理论、莫尔-库仑理论和八面体应力理论(以上理论都在材料力学课本中讨论过)应用于混凝土,取得了不同程度的进展。

forced concrete structure reinforced with anoverviewReinSince the reform and opening up, with the national economy's rapid and sustained development of a reinforced concrete structure built, reinforced with the development of technology has been great. Therefore, to promote the use of advanced technology reinforced connecting to improve project quality and speed up the pace of construction, improve labor productivity, reduce costs, and is of great significance.Reinforced steel bars connecting technologies can be divided into two broad categories linking welding machinery and steel. There are six types of welding steel welding methods, and some apply to the prefabricated plant, and some apply to the construction site, some of both apply. There are three types of machinery commonly used reinforcement linking method primarily applicable to the construction site. Ways has its own characteristics and different application, and in the continuous development and improvement. In actual production, should be based on specific conditions of work, working environment and technical requirements, the choice of suitable methods to achieve the best overall efficiency.1、steel mechanical link1.1 radial squeeze linkWill be a steel sleeve in two sets to the highly-reinforced Department with superhigh pressure hydraulic equipment (squeeze tongs) along steel sleeve radial squeeze steel casing, in squeezing out tongs squeeze pressure role of a steel sleeve plasticity deformation closely integrated with reinforced through reinforced steel sleeve and Wang Liang's Position will be two solid steel bars linkedCharacteristic: Connect intensity to be high, performance reliable, can bear high stress draw and pigeonhole the load and tired load repeatedly.Easy and simple to handle, construction fast, save energy and material, comprehensive economy profitable, this method has been already a large amount of application in the project.Applicable scope : Suitable for Ⅱ, Ⅲ, Ⅳgrade reinforcing bar (including welding bad reinfor cing bar ) with ribbing of Ф 18- 50mm, connection between the same diameter or different diameters reinforcing bar .1.2must squeeze linkExtruders used in the covers, reinforced axis along the cold metal sleeve squeeze dedicated to insert sleeve Lane two hot rolling steel drums into a highly integrated mechanical linking methods.Characteristic: Easy to operate and joining fast and not having flame homework , can construct for 24 hours , save a large number of reinforcing bars and energy. Applicable scope : Suitable for , set up according to first and second class antidetonation requirement -proof armored concrete structure ФⅡ, Ⅲgrade reinforcing bar with ribbing of hot rolling of 20- 32mm join and construct live.1.3 cone thread connectingUsing cone thread to bear pulled, pressed both effort and self-locking nature, undergo good principles will be reinforced by linking into cone-processing thread at the moment the value of integration into the joints connecting steel bars.Characteristic: Simple , all right preparatory cut of the craft , connecting fast, concentricity is good, have pattern person who restrain from advantage reinforcing bar carbon content.Applicable scope : Suitable for the concrete structure of the industry , civil buil ding and general structures, reinforcing bar diameter is for Фfor the the 16- 40mm one Ⅱ, Ⅲgrade verticality, it is the oblique to or reinforcing bars horizontal join construct live.conclusionsThese are now commonly used to connect steel synthesis methods, which links technology in the United States, Britain, Japan and other countries are widely used. There are different ways to connect their different characteristics and scope of the actual construction of production depending on the specific project choose a suitable method of connecting to achieve both energy conservation and saving time limit for a project ends.钢筋混凝土构造中钢筋连接综述改革开放以来,伴随国民经济旳迅速、持久发展,多种钢筋混凝土建筑构造大量建造,钢筋连接技术得到很大旳发展。

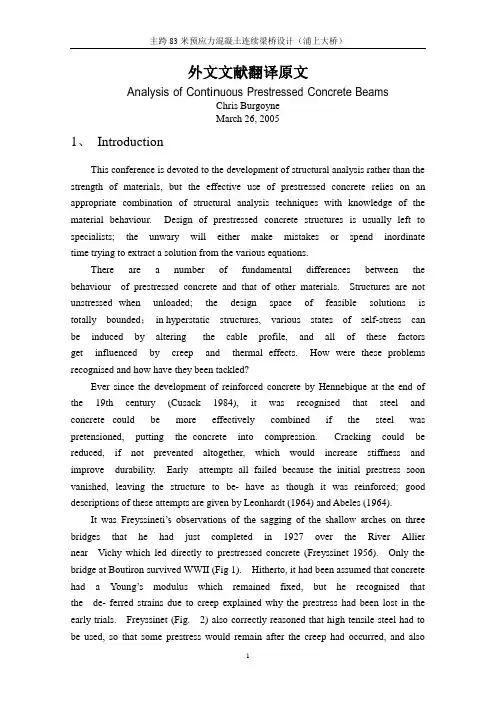

外文文献翻译原文Analysis of Con tin uous Prestressed Concrete BeamsChris BurgoyneMarch 26, 20051、IntroductionThis conference is devoted to the development of structural analysis rather than the strength of materials, but the effective use of prestressed concrete relies on an appropriate combination of structural analysis techniques with knowledge of the material behaviour. Design of prestressed concrete structures is usually left to specialists; the unwary will either make mistakes or spend inordinate time trying to extract a solution from the various equations.There are a number of fundamental differences between the behaviour of prestressed concrete and that of other materials. Structures are not unstressed when unloaded; the design space of feasible solutions is totally bounded;in hyperstatic structures, various states of self-stress can be induced by altering the cable profile, and all of these factors get influenced by creep and thermal effects. How were these problems recognised and how have they been tackled?Ever since the development of reinforced concrete by Hennebique at the end of the 19th century (Cusack 1984), it was recognised that steel and concrete could be more effectively combined if the steel was pretensioned, putting the concrete into compression. Cracking could be reduced, if not prevented altogether, which would increase stiffness and improve durability. Early attempts all failed because the initial prestress soon vanished, leaving the structure to be- have as though it was reinforced; good descriptions of these attempts are given by Leonhardt (1964) and Abeles (1964).It was Freyssineti’s observations of the sagging of the shallow arches on three bridges that he had just completed in 1927 over the River Allier near Vichy which led directly to prestressed concrete (Freyssinet 1956). Only the bridge at Boutiron survived WWII (Fig 1). Hitherto, it had been assumed that concrete had a Young’s modulus which remained fixed, but he recognised that the de- ferred strains due to creep explained why the prestress had been lost in the early trials. Freyssinet (Fig. 2) also correctly reasoned that high tensile steel had to be used, so that some prestress would remain after the creep had occurred, and alsothat high quality concrete should be used, since this minimised the total amount of creep. The history of Freyssineti’s early prestressed concrete work is written elsewhereFigure1:Boutiron Bridge,Vic h yFigure 2: Eugen FreyssinetAt about the same time work was underway on creep at the BRE laboratory in England ((Glanville 1930) and (1933)). It is debatable which man should be given credit for the discovery of creep but Freyssinet clearly gets the credit for successfully using the knowledge to prestress concrete.There are still problems associated with understanding how prestressed concrete works, partly because there is more than one way of thinking about it. These different philosophies are to some extent contradictory, and certainly confusing to the young engineer. It is also reflected, to a certain extent, in the various codes of practice.Permissible stress design philosophy sees prestressed concrete as a way of avoiding cracking by eliminating tensile stresses; the objective is for sufficient compression to remain after creep losses. Untensionedreinforcement, which attracts prestress due to creep, is anathema. This philosophy derives directly from Freyssinet’s logic and is primarily a working stress concept.Ultimate strength philosophy sees prestressing as a way of utilising high tensile steel as reinforcement. High strength steels have high elastic strain capacity, which could not be utilised when used as reinforcement; if the steel is pretensioned, much of that strain capacity is taken out before bonding the steel to the concrete. Structures designed this way are normally designed to be in compression everywhere under permanent loads, but allowed to crack under high live load. The idea derives directly from the work of Dischinger (1936) and his work on the bridge at Aue in 1939 (Schonberg and Fichter 1939), as well as that of Finsterwalder (1939). It is primarily an ultimate load concept. The idea of partial prestressing derives from these ideas.The Load-Balancing philosophy, introduced by T.Y. Lin, uses prestressing to counter the effect of the permanent loads (Lin 1963). The sag of the cables causes an upward force on the beam, which counteracts the load on the beam. Clearly, only one load can be balanced, but if this is taken as the total dead weight, then under that load the beam will perceive only the net axial prestress and will have no tendency to creep up or down.These three philosophies all have their champions, and heated debates take place between them as to which is the most fundamental.2、Section designFrom the outset it was recognised that prestressed concrete has to be checked at both the working load and the ultimate load. For steel structures, and those made from reinforced concrete, there is a fairly direct relationship between the load capacity under an allowable stress design, and that at the ultimate load under an ultimate strength design. Older codes were based on permissible stresses at the working load; new codes use moment capacities at the ultimate load. Different load factors are used in the two codes, but a structure which passes one code is likely to be acceptable under the other.For prestressed concrete, those ideas do not hold, since the structure is highly stressed, even when unloaded. A small increase of load can cause some stress limits to be breached, while a large increase in load might be needed to cross other limits. The designer has considerable freedom to vary both the working load and ultimate load capacities independently; both need to be checked.A designer normally has to check the tensile and compressive stresses, in both the top and bottom fibre of the section, for every load case. The critical sections are normally, but not always, the mid-span and the sections over piers but other sections may become critical ,when the cable profile has to be determined.The stresses at any position are made up of three components, one of which normally has a different sign from the other two; consistency of sign convention is essential.If P is the prestressing force and e its eccentricity, A and Z are the area of the cross-section and its elastic section modulus, while M is the applied moment, then where ft and fc are the permissible stresses in tension and compression.c e t f ZM Z P A P f ≤-+≤Thus, for any combination of P and M , the designer already has four in- equalities to deal with.The prestressing force differs over time, due to creep losses, and a designer isusually faced with at least three combinations of prestressing force and moment;• the applied moment at the time the prestress is first applied, before creep losses occur,• the maximum applied moment after creep losses, and• the minimum applied moment after creep losses.Figure 4: Gustave MagnelOther combinations may be needed in more complex cases. There are at least twelve inequalities that have to be satisfied at any cross-section, but since an I-section can be defined by six variables, and two are needed to define the prestress, the problem is over-specified and it is not immediately obvious which conditions are superfluous. In the hands of inexperienced engineers, the design process can be very long-winded. However, it is possible to separate out the design of the cross-section from the design of the prestress. By considering pairs of stress limits on the same fibre, but for different load cases, the effects of the prestress can be eliminated, leaving expressions of the form:rangestress e Perm issibl Range Mom entZ These inequalities, which can be evaluated exhaustively with little difficulty, allow the minimum size of the cross-section to be determined.Once a suitable cross-section has been found, the prestress can be designed using a construction due to Magnel (Fig.4). The stress limits can all be rearranged into the form:()M fZ PA Z e ++-≤1 By plotting these on a diagram of eccentricity versus the reciprocal of the prestressing force, a series of bound lines will be formed. Provided the inequalities (2) are satisfied, these bound lines will always leave a zone showing all feasible combinations of P and e. The most economical design, using the minimum prestress, usually lies on the right hand side of the diagram, where the design is limited by the permissible tensile stresses.Plotting the eccentricity on the vertical axis allows direct comparison with the crosssection, as shown in Fig. 5. Inequalities (3) make no reference to the physical dimensions of the structure, but these practical cover limits can be shown as wellA good designer knows how changes to the design and the loadings alter the Magnel diagram. Changing both the maximum andminimum bending moments, but keeping the range the same, raises and lowers the feasible region. If the moments become more sagging the feasible region gets lower in the beam.In general, as spans increase, the dead load moments increase in proportion to the live load. A stage will be reached where the economic point (A on Fig.5) moves outside the physical limits of the beam; Guyon (1951a) denoted the limiting condition as the critical span. Shorter spans will be governed by tensile stresses in the two extreme fibres, while longer spans will be governed by the limiting eccentricity and tensile stresses in the bottom fibre. However, it does not take a large increase in moment ,at which point compressive stresses will govern in the bottom fibre under maximum moment.Only when much longer spans are required, and the feasible region moves as far down as possible, does the structure become governed by compressive stresses in both fibres.3、Continuous beamsThe design of statically determinate beams is relatively straightforward; the engineer can work on the basis of the design of individual cross-sections, as outlined above. A number of complications arise when the structure is indeterminate which means that the designer has to consider, not only a critical section,but also the behaviour of the beam as a whole. These are due to the interaction of a number of factors, such as Creep, Temperature effects and Construction Sequence effects. It is the development of these ideas whichforms the core of this paper. The problems of continuity were addressed at a conference in London (Andrew and Witt 1951). The basic principles, and nomenclature, were already in use, but to modern eyes concentration on hand analysis techniques was unusual, and one of the principle concerns seems to have been the difficulty of estimating losses of prestressing force.3.1 Secondary MomentsA prestressing cable in a beam causes the structure to deflect. Unlike the statically determinate beam, where this motion is unrestrained, the movement causes a redistribution of the support reactions which in turn induces additional moments. These are often termed Secondary Moments, but they are not always small, or Parasitic Moments, but they are not always bad.Freyssinet’s bridge across the Marne at Luzancy, started in 1941 but not completed until 1946, is often thought of as a simply supported beam, but it was actually built as a two-hinged arch (Harris 1986), with support reactions adjusted by means of flat jacks and wedges which were later grouted-in (Fig.6). The same principles were applied in the later and larger beams built over the same river.Magnel built the first indeterminate beam bridge at Sclayn, in Belgium (Fig.7) in 1946. The cables are virtually straight, but he adjusted the deck profile so that the cables were close to the soffit near mid-span. Even with straight cables the sagging secondary momentsare large; about 50% of the hogging moment at the central support caused by dead and live load.The secondary moments cannot be found until the profile is known but the cablecannot be designed until the secondary moments are known. Guyon (1951b) introduced the concept of the concordant profile, which is a profile that causes no secondary moments; es and ep thus coincide. Any line of thrust is itself a concordant profile.The designer is then faced with a slightly simpler problem; a cable profile has to be chosen which not only satisfies the eccentricity limits (3) but is also concordant. That in itself is not a trivial operation, but is helped by the fact that the bending moment diagram that results from any load applied to a beam will itself be a concordant profile for a cable of constant force. Such loads are termed notional loads to distinguish them from the real loads on the structure. Superposition can be used to progressively build up a set of notional loads whose bending moment diagram gives the desired concordant profile.3.2 Temperature effectsTemperature variations apply to all structures but the effect on prestressed concrete beams can be more pronounced than in other structures. The temperature profile through the depth of a beam (Emerson 1973) can be split into three components for the purposes of calculation (Hambly 1991). The first causes a longitudinal expansion, which is normally released by the articulation of the structure; the second causes curvature which leads to deflection in all beams and reactant moments in continuous beams, while the third causes a set of self-equilibrating set of stresses across the cross-section.The reactant moments can be calculated and allowed-for, but it is the self- equilibrating stresses that cause the main problems for prestressed concrete beams. These beams normally have high thermal mass which means that daily temperature variations do not penetrate to the core of the structure. The result is a very non-uniform temperature distribution across the depth which in turn leads to significant self-equilibrating stresses. If the core of the structure is warm, while the surface is cool, such as at night, then quite large tensile stresses can be developed on the top and bottom surfaces. However, they only penetrate a very short distance into the concrete and the potential crack width is very small. It can be very expensive to overcome the tensile stress by changing the section or the prestress。

中文译文:建筑业的竞争及竞争策略美国的工程建筑公司几十年来一直控制着国际建筑市场,但近来世界上发生的事件改变了它的主导地位。

为了调查今后十年对工程建筑竞争产生影响的推动力及趋势,由建筑工业研究院的"2000年建筑特别工作组:发起一项称为“2000年建筑市场竞争分析”的研究项目。

该研究项目考察了一些影响竞争的因素,包括下列方面:企业能力塑造:采用纵向联合,横向发展的方法,提高企业的综合能力。

扩大市场领地,这种做法包括被海外的联合企业收购或被其合并,或是由美国公司收购外国公司。

筹措资金的选择方法:私有化作用,建筑权力转让项目,未来市场中工程筹资特征。

管理、组织及结构:未来的经营管理及组织方法、组织结构、组织技巧要有利于引导职员在世界竞争环境中发挥作用。

劳力特征:未来具有专业水平和技工水平的工程建筑工人的供求情况技术问题:技术将如何影响竞争,如何用来弥补劳力不足的缺陷。

研究目标及范围这一研究项目的目标是收集信息,使之为适应2000年及以后的工程建筑业在调整、制定策略方面的需要提供真知灼见,并制定出2000年工程建筑业的可能的发展计划。

这项研究回顾了工程建筑业的历史过程,审视了当前的发展趋势,以确定影响该工业未来的推动力,与该工业相关的有重塑企业能力,私有化及筹措资金方法的潜在作用以及经营管理、组织方法、公司结构方面的未来发展方向。

研究范围包括选定一些公司,采访这些公司有专业特长的人员。

这些人员的专业涉及面很广,包括商业建筑,重工业建筑,公共事业设施建设,基础建设.轻工业建筑,电力,生产程序以及航天科学。

工程建筑业竞争特性工程建筑业的竞争特征由于下列原因在变动:80年代发生的事件,以及计划在90年代实施的项目,正在引导建筑业摆脱相互对立的局面,转向相互合作。

应该以积极的眼光看待新的公司进入国际工程建筑市场,因为它增加了全球合作的机遇。

合作关系会使所有的伙伴受益,这是因为美国公司可以在合作伙伴的国家找到机遇,同样,外国公司也会打入美国市场。

1玻璃2镀锌钢角码3室外铝型材表面处理4室内铝型材表面处理5型材6铝板7铝背板8室外铝板表面处理9点式玻璃不锈钢接驳螺栓10全玻幕墙和不锈钢部件11旋转门12门五金件13五金开启窗(多点锁系统)14螺栓/螺丝15保温棉16防火棉17181.铝型材19立柱(公料)20立柱(母料)21顶部横梁22横梁(开启期部份)23中挺横梁24底部(窗台)横梁25开启扇26室内铝罩板27铝百叶片28百叶窗铝框29铝副框30铝扣盖31以密封胶填充的铝水槽结构件32铝角33装饰条铝框34铝框35开启扇铝副框36铝扣盖建LEGEND OF MAERIALS37横向装饰条38横向装饰条托架39铝压条40内部装饰铝套41铝芯套42432.钢结构44由外墙承建商负责的钢结构45由工程师指定的焊缝46由总承建商负责的钢结构47矩形管48493.金属板材50指定颜色的铝板51不锈钢防鸟网52防烟涂料/板53铝盖54支撑防火材料用镀锌片55防水铝板56石材支撑铝槽57镀锌钢板58铝角59铝板支撑角铝60指定颜色的铝槽61风管连接套62634.托架64铝托架(含锯齿形定位垫片) 65热浸镀锌钢托架66预埋镀锌铁板/角码67铝制挂托架68铝套69铝角码70调节螺丝71供调节用长螺孔72限制板块移动的铝块73固定镀锌钢折板74755.紧固件(螺栓,螺母,垫圈)76不锈钢螺栓77不锈钢螺母78不锈钢垫圈79不锈钢弹簧垫圈80不锈钢自锁螺母81不锈钢自攻螺丝82不锈钢机器螺丝83不锈钢调整螺栓84多点锁85锁箱(手柄可拆卸)86不锈钢铆钉87清洁/维修铰索扣88射钉89后补锚栓90916.表面处理92氟碳喷涂处理93粉喷处理94涂漆钢结构95热镀锌钢结构96977.玻璃98中空玻璃(结构胶必须能承担设计风压) 99单层玻璃100夹胶玻璃1013M防爆膜1021038.密封胶104双组份结构密封胶105耐候胶106双面胶条107框架拼接密封胶108泡沫棒109单组份结构密封胶110密封胶密封111密气密封胶1121139.砖石结构114混凝土楼板/梁115混凝土反梁116楼板结构顶点11711810.填充材料119聚氯丁圆头胶条120聚氯丁耐候胶条121聚氯丁耐候雨披水胶条122硅酮玻璃/石材垫块123水汽隔断124与硅酮胶相容的橡胶垫块125可膨胀三元乙丙挤压型批水板12612711.绝缘材料128隔热材料129防火材料130隔热断桥(PA66)13113212.其它133泄水孔134等压孔135楼板建筑顶点136由外墙承包商负责的防水涂料137绝缘片138相应结构及湿度变形而预先采取的措施139由总承建商负责的结构140高强度塑胶/尼龙垫片(套)141卷帘护箱142通风管道由其它承包商承建143吊顶由其它承包商承建144石材145由其它承包商负责的防水层146由其它承包商负责的室内装饰147横梁后边线148外部竖向装饰条149立柱后边线150支撑铝板建筑材料符号表LEGEND OF MAERIALS(Glass)- LocalGMS bracket to kerfExtrusions Finishes ExteriorExtrusions Finishes InteriorAluminium ExtrusionAluminium PanelAluminium Back panExterior Aluminium panel finishStainless Steel Flush Bolt for point fixing glass Glass Wall and S/S ComponentsRevolving DoorDoor IronmongeryHardware - Operable Vents multipoint lockBolt/screwInsulationFirestopALUMINIUM EXTRUSIONMALE MULLIONFEMALE MULLIONHEAD EXTRUSIONTRANSOM WITH VENT SASHINTERMEDIATE TRANSOMSILL TRANSOMOPERABLE VENDALUMINIUM INTERIOR TRIMALUMINIUM LOUVRE BLADEALUMINIUM LOUVRE FRAMEALUMINIUM GLAZING ADAPTERALUMINIUM COVER DEADALUMINIUM STRUCTLRAL GUTTER SLEEVE SET IN SEALANT ALUMINIUM ANGLEALUMINIUM FEATURE FIN FRAMEALUMINIUM BOX SECTIONALUMINIUM CPERABLE VENT STOPALUMINIUM CLIP-ON COVERALUMINIUM HORIZONTAL PEATURE CAPPING HORIZONTAL FEATURE FIN BRACKETALUMINIUM PRESSUREALUMINIUM INTERIOR TRIM SLEEVEALUMINIUM STRUCTLRAL SLEEVESTEELWORKSECONDARY STEEL BY FACADE CONTRACTORWELDING AS NOMINATED BY ENGINEERSTEEL BY MAIN CONTRACTORSTEEL BOX SECTIONSHEET METALFORMED ALUMINIUM SHEET TO SELECTED COLOUR STAINLESS STEEL BIRDWIRE MESHSMOKE SEAL/FLASHINGALUMINIUM FORMED CAPPINGFIRE INSULATION SUPPORT BRACKET (GALANIZED STEEL ALUMINIUM FLASHINGPRESSED ALUMINIUM STONE SUPPORT CHANNEL FORMED GSM SHEETPRESSING ALUMINIUM ANGLEALUMINIUM CAPPING SUPPORTPRESSED ALUMINIUM CHANNEL TO SELECTED COLOUR DUCT CONNECTING SLEEVEBRACKETALUMINIUM BRACKET (W/SERRATED WASHER) GALVANISED STEEL BRACKETCAST-IN GALVANISED STEEL PLATE/ANGLE ALUMINIUM HOOK-ON BRACKETALUMINIUM SLEEVEALUMINIUM ANGLE BRACKETADJUSTMENT SCREWSLOTTED HOLES FOR ADJUSTMENTANTI-UPLIFT BRACKETFORMED STEEL CHANNEL/ANGLEFIXING(BOLTS,NUTS,WASHERS)STAINLESS STEEL BOLTSTAINLESS STEEL NUTSTAINLESS STEEL WASHERSTAINLESS STEEL SPRING WASHERSTAINLESS STEEL SELF-LOCKING NUTSTAINLESS STEEL SELF-TAPPING SCREWSTAINLESS STEEL MACHINE SCREWSTAINLESS STEEL JACKING BOLTMULTI-POINT LOCKING DEVICELOCK BOX W/REMOVABLE HANDELSTAINLESS STEEL POP RIVETCLEANING/MAINTENANCE GONDOLA LANYARO RESTRAINTSHOT PINMASONARY ANCHORFINISHPVF2 FINISHPOWER COAT FINISHPAINTED STEELHOT DIPPED GALVANISED STEELGLASSDOUBLE GLAZED UNIT (STRUCTURAL SEALANT MUST TAKE DESIGN WIND LOADMONOLITHIC GLASSLAMINATED GLASS3M FILMSEALANTSTWO-PART STRUCTURAL SEALANTWEATHER SEAL SEALANTDOUBLED SIDED TAPEFRAME JOINT SEALANTSEALANT BACKER RODONE-PART STRUCTURAL SEALANTSILICONE SEALEDAIR SEALMASONRYCONCRETE SLAB/BEAMCONCRETE UPSTANDTOP OF SLABGASKETNEOPRENE BULB GASKETNEOPRENE WEATHER SEAL GASKETNEOPRENE RAIN-SCREEN FLAPSILICONE GLASS/STONE SETTING BLOCKAIR & WATER BAFFLESILICONE COMPATIBLE HARD DUROMETER RUBBER SHIM EXTRUDED EPDM EXPANDABLE FLASHINGINSULATIONTHERMAL INSULATIONFIRE INSULATOINTHERMAL BREAK(PA66)MISCELLANEOUSWEEPHOLEPRESSURE EQUALIZATION HOLETOP OF FINISHED FLOORWATERPROOFING BY FACADE CONTRACTORISOLATION SHIM/TAPEPROVISION FOR BUILDING & THERMAL MOVEMENT STRUCTURE BY MAIN CONTRACTORHIGH IMPACT PLASTIC/NYLON SHIM OR SLEEVE BLIND BOXDUCT WORK BY OTHERSSUSPENOED CEILING BY OTHERSTONE PANELWATERPROOFING BY OTHERSINTERIOR FINISH BY OTHERSBACK OF TRANSOM EXTRUSIONEXTERNAL VERTICAL FEATURE FINBACK OF MULLIONALUMINIUM DEAD LOAD BLOCK。

使用加固纤维聚合物增强混凝土梁的延性作者:Nabil F. Grace, George Abel-Sayed, Wael F. Ragheb摘要:一种为加强结构延性的新型单轴柔软加强质地的聚合物(FRP)已在被研究,开发和生产(在结构测试的中心在劳伦斯技术大学)。

这种织物是两种碳纤维和一种玻璃纤维的混合物,而且经过设计它们在受拉屈服时应变值较低,从而体现出伪延性的性能。

通过对八根混凝土梁在弯曲荷载作用下的加固和检测对研制中的织物的效果和延性进行了研究。

用现在常用的单向碳纤维薄片、织物和板进行加固的相似梁也进行了检测,以便同用研制中的织物加固梁进行性能上的比较。

这种织物经过设计具有和加固梁中的钢筋同时屈服的潜力,从而和未加固梁一样,它也能得到屈服台阶。

相对于那些用现在常用的碳纤维加固体系进行加固的梁,这种研制中的织物加固的梁承受更高的屈服荷载,并且有更高的延性指标。

这种研制中的织物对加固机制体现出更大的贡献。

关键词:混凝土,延性,纤维加固,变形介绍外贴粘合纤维增强聚合物(FRP)片和条带近来已经被确定是一种对钢筋混凝土结构进行修复和加固的有效手段。

关于应用外贴粘合FRP板、薄片和织物对混凝土梁进行变形加固的钢筋混凝土梁的性能,一些试验研究调查已经进行过报告。

Saadatmanesh和Ehsani(1991)检测了应用玻璃纤维增强聚合物(GFRP)板进行变形加固的钢筋混凝土梁的性能。

Ritchie等人(1991)检测了应用GFRP,碳纤维增强聚合物(CFRP)和G/CFRP板进行变形加固的钢筋混凝土梁的性能。

Grace等人(1999)和Triantafillou(1992)研究了应用CFRP薄片进行变形加固的钢筋混凝土梁的性能。

Norris,Saadatmanesh和Ehsani(1997)研究了应用单向CFRP薄片和CFRP织物进行加固的混凝土梁的性能。

在所有的这些研究中,加固的梁比未加固的梁承受更高的极限荷载。

建筑材料英文Building Materials。

Building materials are the foundation of any construction project. They play a crucial role in determining the strength, durability, and aesthetic appeal of a building. In this document, we will explore the different types of building materials commonly used in construction and their English names.1. Concrete。

Concrete is a versatile building material that is made up of cement, water, and aggregates such as sand and gravel. It is widely used in the construction of foundations, walls, and floors. Concrete is known for its strength and durability, making it an ideal choice for various construction projects.2. Steel。

Steel is another essential building material that is used in the construction of structures such as beams, columns, and frames. It is known for its high tensile strength and resistance to corrosion, making it suitable for use in a wide range of construction applications.3. Brick。