MBF(多孔平衡型)-选型说明书

- 格式:pdf

- 大小:508.64 KB

- 文档页数:16

上海沈泉泵阀制造有限公司■产品概述PF(FS)型,其泵体泵盖,叶轮及其输送介质接触的零件均采用聚偏氟乙烯或增强聚丙烯模压加工或注塑加工而成。

聚偏氟乙烯塑料具有机械强度高(见附表I),耐腐蚀性能好(见附Ⅱ)是国际上应用较广的工程塑料之一。

PF(FS)型化工泵能满足输送-50℃-80℃温度条件下的多种浓度硫酸、盐酸、硝酸、 醋酸、磷酸、铬酸、草酸、氢氟酸和碱液、有机溶剂、氧化剂等化学介质、是化工、氯碱、 化肥、染料、试剂、农药、制药、电镀、环保等工业部门输送不含颗粒的腐蚀性介质的节 能型泵。

■产品结构PF(FS)型系列化工泵为直联式结构,由泵体及托架与电机法兰联接,托架支承泵体,叶轮通过轴与电机直联。

该系列泵的特点:结构简单紧凑、零件少、性能好。

泵的旋转方向, 自吸入口向电机方向看为顺时针方向旋转,泵出口垂直向上。

泵的密封,选用聚四氟乙烯(F4)波纹管,外装式耐腐蚀机械密封。

■型号意义■性能曲线图强耐腐蚀化工离心泵■性能参数表转速2900r/min转速1450r/min 吸上高度型号流量 m3/h扬程m 效率 配用电机kw 流量 m3/h扬程m效率n配用电机 KWm2 15 40 PF(FS)25-20-1201.5 20 41 1.16.5 15 51 PF(FS)32-25-125 5 20 50 1.510 15 50 5 3.75 39 PF(FS)40-32-125 7.5 20 55 2.2 3.75 5 40 1.1 31628 58 8 7 50 20 26 61 10 6.5 54 PF(FS)50-40-14525 24 63 312.5 6 55 1.551534 44 7.5 8.5 50 25 32 57 12.5 8 60 PF(FS)65-50-16030 30 59 5.515 7.5 60 2.253036 50 15 9 55 50 32 67 25 8 69 PF(FS)80-65-16060 28 65 7.530 7.2 68 3S6036 70 30 9.2 67 100 32 78 50 8 75 PF(FS)100-80-160120287511606.87145■产品装配1·将托架与电机法兰连接,拧紧螺栓。

GBF耐腐蚀离心泵概述:聚全氟乙丙烯(F46)具有非常优良的耐蚀和耐热性能,除熔金属锂、钾、钠、三氟化氯、高温下的三氟化氧、高流速的液氟外,它几乎可以抵搞所有化学介质(包括浓硝酸和王水)。

我单位选用该材料生产的GBF耐腐蚀离心泵。

配和国内优秀水力模型和采用IS型离心泵之性能参数,在一般立式泵的基础上进行巧妙组合设计而成。

GBF型衬氟管道离心泵具有特强的耐腐蚀性能,可替代316L不锈钢、钛合金等贵金属,而且高效节能、噪音低、性能可靠等优点。

GBF耐腐蚀离心泵适用于-85℃~+200℃温度的条件下,长期输送任意浓度的酸、碱液、氧化剂及其它腐蚀性液体。

广泛用于石油、化工、冶金、电力、造纸、烟气脱硫、除尘、食品制药和合成纤维等部门。

GBF耐腐蚀离心泵特点:1、GBF型衬氟管道离心泵为立式结构,进出口口径相同,且位于同一中心线上,如加上防护罩则可置于户外使用。

2、GBF型衬氟管道离心泵叶轮直接安在电机轴承配置合理,轴向尺寸短,结构紧凑。

泵与电机轴承配置合理,能有效地平衡泵运转产生的径向和轴向负荷,从而保证了泵的运行平稳,振动噪音很低。

3、GBF型衬氟管道离心泵轴封采用普通型和耐颗粒型的机械密封或机械密封组合,耐磨耐腐,能有效地增长机械密封的使用寿命。

4、GBF型衬氟管道离心泵可根据使用要求即流量和扬程的需要采用泵的串、并联运行方式。

销售部电话:021-61557676/61557678 400-6656-887 图文传真:021-56777153网 址:www.sqmade.com 电子邮箱:sales@sqmade.comGBF耐腐蚀离心泵性能参数表:型 号流 量扬 程转 速功率m3/h m r/min KWGBF25-12542029000.75/1.1 GBF25-125A 3.62029000.55/0.75 GBF25-1604322900 1.5/2.2 GBF25-160A 3.7322900 1.1/1.5 GBF40-125 6.3202900 1.1/1.5 GBF40-125A 5.61629000.75/1.1 GBF40-160 6.3322900 2.2/3 GBF40-160A 5.9282900 2.2 GBF40-200 6.35029004/5.5 GBF40-200A 5.94429004 GBF50-12512.5202900 1.5/2.2 GBF50-125A11162900 1.1/1.5 GBF50-16012.53229003/4 GBF50-160A11.7282900 2.2/3 GBF50-20012.5502900 5.5/7.5 GBF50-200A11.74429004/5.5 GBF65-125252029003/4 GBF65-125A22.3162900 2.2/3 GBF65-160253229004/5.5 GBF65-160A23.42829004/5.5 GBF65-200255029007.5/11 GBF65-200A23.54429007.5/11 GBF80-12550202900 5.5/7.5 GBF耐腐蚀离心泵型号:GBF80-125A451629004/5.5 GBF80-160503229007.5/11 GBF80-160A46.72829007.5/11 GBF80-2005050290015/18.5 GBF80-200A4744290011/15 GBF100-12510020290011/15 GBF100-125A891629007.5/11 GBF100-16010032290015/18.5 GBF100-160A93.528290011/15 GBF100-20010050290022/30 GBF100-200A93.544290018.5/22 GBF125-12516020290015/18.5 GBF125-125A14316290011/15 GBF125-16016032290022/30 GBF125-160A150********.5/22 GBF150-12516020290015/18.5 GBF150-125A150********/15 GBF150-16016032290022/30 GBF150-160A150********.5/22衬氟管道泵安装说明:1、安装前应检查机组坚固件有无松动现象,泵体流道有无异物堵塞,以免水泵运行时损坏叶轮和泵体。

BMF系统的组装和操作中文说明书上海乐泽环境工程有限公司2013-11目录一.BMF系统的组装 (2)二.装填砂子 (5)三.开始运行 (6)四.BMF过滤系统的运行描述 (6)五.BMF过滤系统的维护及保养 (7)六.故障检查与排除 (8)一.BMF系统的组装1. 安装地面的检查:地面要求平整,平整度要求小于0.5cm/m2;水泥地面要求承重大于4t/m2。

不同的设备的地面承重要求,请参考设备的基础图。

2. 排列BMF单元:将BMF单元按照图纸排列,对于一组的单元,要求进口在同一方向。

3. 连接快速接头:BMF过滤系统的连接都是通过快速接头或法兰实现的。

快速接头在保持连接密封的同时可以提供一定的柔性。

安装请参照以下次序:3.1 将卡箍拿开,将卡箍内部的密封圈套在连接件的一边。

3.2 将需要连接件的两边平口对齐,然后将密封圈移到可以将两连接件对齐平口的中央,并确认已将对齐的平口缝隙完全罩住;罩上卡箍,旋紧螺栓,连接完成。

按照同样的方式紧固所有卡箍。

3.3 若设备为法兰连接,请将法兰垫片放入两片法兰间,用适当的螺栓进行连接。

4. 安装阀门:BMF过滤单元采用 4x4x4 英寸气动隔膜三通阀门或蝶阀,BMF过滤器的接口连接方式详见表1.。

这些阀门是安装在BMF的进水口和出水口,安装时请参照系统的安装图。

注意:安装气动隔膜三通阀时,阀门的最短端与BMF连接,阀体上的箭头朝向BMF。

若有不同安装方式,详见安装图纸或联系上海乐泽。

表1.BMF过滤器装管口表5. 安装总管:按照图纸安装好总管,注意总管的开口方向。

5.1 其中:进水总管有四个螺纹接口,顶部2寸或1寸的内螺纹接口用于安装排气阀;1寸或3/4寸内螺纹接口用于连接控制水(系统用压缩空气则不需要);1/2寸外螺纹接口是用于安装压力表;1/4寸内螺纹接口用于安装高压采样点HIGH。

对于管道为系统进水支管,采样在系统进水总管上时,此接口无。

5.2 出水总管有三个螺纹接口,2寸或1寸的内螺纹接口装一个手动阀用于排空。

ABOUTCOMPANY关于成峰上海成峰流体设备有限公司(原上海成峰泵业制造有限公司)是一家集科研、生产、销售及服务于一体的大型股份制企业。

公司自创建以来,始终致力于技术和管理的完善与创新,已形成以泵类产品为核心,多元化发展的产品格局,广泛应用于城镇建设、水利电力、矿山冶金、石油化工、暖通空调、环境保护及治理、消防设施、农田排灌及自动化控制等领域。

公司技术力量雄厚,生产检测设备先进,产品质量稳定可靠,各项技术性能均达标。

生产的泵类产品均经过质量监督检验中心检测:消防泵、稳压缓冲消防泵、柴油机消防泵组经过国家消防检验中心检测;控制柜通过CCC认证;水箱、(箱式)无负压给水设备通过上海市卫生局检测;WQ系列污水污物潜水电泵,CFWR、CFLR系列热水离心泵获得全国工业产品生产许可证。

水泵的设计、开发、生产制造和服务通过质量管理体系认证。

先后被评为中国讲诚信守合同重质量典范企业、全国用户产品质量满意售后服务满意十佳企业、全国(产品)国家监督检查质量稳定合格企业及AAA级资信企业。

公司秉承“顾客至上,质量第一”的原则,坚持以市场为导向,紧紧围绕市场需求这一中心环节开展企业的一切经营活动。

目前公司在全国各省、市设立了七十多个销售网点,且均配有专业的售后服务团队,配合灵活的营销策略,运用公司庞大的营销网络队伍把握全国泵行业市场脉搏,凭借员工的齐心协力,使公司产品在市场竞争中取得主动,销售业绩逐年成倍增长。

成峰为客户所提供的一切高新优质产品及完善的售后服务,均是为了换取客户对我公司的信任与支持,为创国内行业先导公司与一流企业而不懈努力!Shanghai Chengfeng Fluid Equipment Co., Ltd. ( Shanghai Chengfeng Pumps Manufacturing Co., Ltd.) is a large-scale shareholding enterpriseintegrating scientific research, production, sales and service. Since the founding the Company has been dedicating in perfection and innovationof technology and management. It has formed a product pattern centering on pump products and supplemented by a diverse development. Itsproducts are widely used in urban construction, water conservancy and power generation, mines and metallurgy industry, petrochemical, heatingventilation and air conditioning, environmental protection and management, fire control equipment, agricultural fields draining and irrigation aswell as automation control fields.The Company has strong technical power, advanced testing equipment as well as stable and reliable product quality. All technical performancesare compliant with standards. All pump products manufactured are tested in the quality supervision and testing center. Fire control pumps,pressure regulated buffer fire control pumps and diesel fire control pumps are tested by the National Fire Control Center. Control cabinets havepassed CCC certification. Water tanks and (box-type) non-negative pressure water supply equipment have passed the testing by Shanghai HealthBureau. WQ series sewage and waste submersible pumps as well as CFWR and CFLR series hot water centrifugal pumps have acquired stateindustrial products production permit. Our designing, development, production and service have passed quality management system certification.Our company has been successively awarded the titles of China Model Enterprise for Credibility, Honoring Contract and Quality, National Top 10Quality and After-service Satisfactory Enterprise, State-wide (Product) Enterprise of Steady and Sound Quality in National Supervision and Inspectionas well as AAA Grade Credibility Enterprise.The Company adheres to the principles of "Customers Foremost and Quality Paramount", guides itself with market and carries out all businessactivities closely based on the needs of the market. At present, the Company has more than 70 sales network points in provinces and cities in China,and has a professional after-service team. We comprehend the pump industry and market in China with our flexible marketing strategy and hugemarketing network teams. With the joint efforts of our staff, the Company's products has gained a proactive role in market competition, and its salesachievement keep growing in folds year on year.All quality and new products and perfect after-service that Chengfeng provides are for gaining customers' trust and support, and for our consistentendeavor to build a leading company and top enterprise in China.QDL型泵性能曲线图 性能参数表49-59Performance curve diagram Performance parameter tablestructure and techniques in overseas countries and possesses high technology content. It's featured by high efficiency, wide range of performance, etc, which better satisfies the requirements of the users. This series is the most complete in specification and most extensive in flowing rate and head of its kind in China. In addition, in terms of the structure, this series adopts the upright and sectional type, which ensuresthe design point is20m3design point is72(m/h)centrifugal pumpinlet is100(mm)进水段Inlet section中段Middle section叶轮定位套Locating sleeve of the impeller叶轮Impeller平衡鼓Balancing drum平衡套Balancing set密封 Sealing机械密封Mechanical seal(填料)(Filler)出水段Outlet section填料体Filler填料轴套Filler shaft housing挡水套Water retaining cover轴承体Bearing body推力球轴承ball thrust bearing轴承盖Bearing cover硬质合金碳化硅Hard alloy carborundum油浸石棉绳Oil immersed asbestos cord电机支架Bracket of the motor联轴器Shaft joint滑动轴承体Sliding bearing body水冷式滑动轴承Water coolingsliding bearing下轴套Lower shaft housing卡环Snap ring卡环套Snap ring set导叶导流槽Guide vane andguiding gutter末导流槽Ending guidinggutter灌水回水管Watering and waterreturn pipeline填料压盖Filler gland pocket轴Axle电机Electric motorDL型泵性能曲线表和外形尺寸图及安装尺寸表0.620η(m)H(m)1413121110Pa(Kw)0.50.40.3(NPSH)r642H-Q(%)7060504030Pa-Q(NPSH)r-Q3(m/h)108642(l/s)32.521.510.540DL6-12n=1450r/min一级泵性能H进口出口H1H2hL进出口法兰尺寸图4-φdB bBbn-φd1DD1DNInlet/outlet flange diagramOutletInletη-Q27 26 252423 22 21 20 19 18 1716151413121110987654321123456789101112131415161718192021222324252627HT200HT200HT200HT200HT20045HT200HT200HT200橡胶HT200466310HT200HT200HT200HT200ZCu10Pn-12Crl34545HT200HT200Q235-AFHT20045Y、Y2序号No.名称Name材料Materials序号No.名称Name材料Materials结构简图及材料 Arrangement drawing and materials440351003302904-φ181********-18φ150110404-18φ外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flangeL h H2B b4-φd D D1DN N-φd1D D1DN N-φd140DL6-1223456789101114504.96.27.44.96.27.44.96.27.44.96.27.44.96.27.44.96.27.44.96.27.44.96.27.44.96.27.44.96.27.41.361.722.061.361.722.061.361.722.061.361.722.061.361.722.061.361.722.061.361.722.061.361.722.061.361.722.061.361.722.0624.823.621.637.235.432.449.647.243.262595474.470.864.886.882.675.299.294.486.4111.6106.297.6124118108136.4129.81200.830.921.031.251.381.551.671.842.072.082.32.582.52.763.12.913.223.623.333.684.143.754.144.654.174.65.154.595.065.661.52.23445.55.57.57.57.537403937403937403937403937403937403937403937403937403937403933.23.633.23.633.23.633.23.633.23.633.23.633.23.633.23.633.23.633.23.689596510251090115012851345144515051565250310370430490550610670730790147164181198215232249266283300DL型泵性能参数表 DL type pump performance parameter table型号Type级数Grade流量F l o w i n g r a t e3(m/h) (L/S)扬程(m)Head转速Rotation speed(r/min)功率P N(KW)ower轴功率A xle power电机功率M otor power效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W(kg)eight高 度H eightH H1DL型泵性能曲线表和外形尺寸图及安装尺寸表DL型泵性能曲线表和外形尺寸图及安装尺寸表H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBb n-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet1.140η(m)1513119Pa(Kw)0.90.70.5(NPSH)r 642(%)9080706050Pa-Q η-Q一级泵性能H(m) n=1450r/min H-Q3(m /h)20161284(l/s)6543210(NPSH)r-Q50DL12-12.5H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBb n-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet65DL30-16×1340η(m)一级泵性能H(m)2018161412Pa(Kw)21(NPSH)r-Q(NPSH)r 642Pa-Q H-Qη-Q(%)9080706050 n=1450r/min (m3/h)403224168(l/s)121086420440351003603004-φ18160125504-18φ160125504-18φ外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table 型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度 H eight HH1外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度 H eight HH14-φ234-18φ4-18φ520501104003501801456516012550145050DL12-12.52345678910912.618912.618912.618912.618912.618912.618912.618912.618912.6182.53.552.53.552.53.552.53.552.53.552.53.552.53.552.53.552.53.5527252240.537.53354504467.562.55581756694.587.57710810088121.5112.5991351251101.411.561.862.112.342.782.813.123.723.523.94.654.224.685.574.935.466.515.636.247.446.34728.37747.89.3475558475558475558475558475558475558475558475558475558 2.62.73.22.62.73.22.62.73.22.62.73.22.62.73.22.62.73.22.62.73.22.62.73.22.62.73.23345.55.57.57.511112032322653213493914194485263454305156006857708559401025955104011451305139015151600177518601450234567891018303518303518303518303518303518303518303518303518303558.39.758.39.758.39.758.39.758.39.758.39.758.39.758.39.758.39.737322955.54843.574645892.58072.51119687129.5112101.5148128116166.5144130.51851601453.244.224.64.866.336.96.488.449.28.110.5511.59.7212.613.811.314.716.112.916.818.414.618.920.716.321235.57.511151518.5222230566260566260566260566260566260566260566260566260566260 2.42.832.42.832.42.832.42.832.42.832.42.832.42.832.42.832.42.8311551299149316421746187020142118228733844254665075485896210661170299351435498537617664703824DL型泵性能曲线表和外形尺寸图及安装尺寸表DL型泵性能曲线表和外形尺寸图及安装尺寸表外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table 外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度H eight HH1H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBb n-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet80DL50-20×125644832161284040η(m)一级泵性能(NPSH)r-Q(NPSH)r 642H-Q(%)9080706050 n=1450r/min 3(m /h)80(l/s)242016H(m)30Pa-QQη-7201510Pa(Kw)5314-φ268-18φ8-18φ560601504504002001608020016080型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度 H eight HH14-φ268-18φ8-18φ2001608060060150470410220180100H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBbn-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet100DL72-30×1n=1450r/min 5060708090(%)η-QH-QPa-Q 246(NPSH)r (NPSH)r-Q071421283542(l/s)02856841121403(m /h)7911Pa(Kw)1020304050H(m)一级泵性能(m)η401314501450234567891080DL50-2042249659272777785193798711544075196317438559671079119113031328148516571834194621032240235225502.22.52.82.22.52.82.22.52.82.22.52.82.22.52.82.22.52.82.22.52.82.22.52.82.22.52.86070666070666070666070666070666070666070666070666070661115223030374545556.287.849.129.4211.813.712.615.718.215.719.622.818.923.627.421.927.531.925.131.436.528.336.341.131.539.245.743.2403464.86051.386.48068.410810085.5129.6120102.6151.2140119.7172.8160136.8194.4180153.921620017191418.191418.191418.191418.191418.191418.191418.191418.191418.132.45065.232.45065.232.45065.232.45065.232.45065.232.45065.232.45065.232.45065.232.45065.2100DL72-3023456754729054729054729054729054729054729015202515202515202515202515202515202564.56051.696.79077.4129120103.2161.2150129193.5180154.8225.7210180.615.919.2021.723.928.832.631.838.443.539.84854.447.857.665.455.867.376.259.861.558.359.861.558.359.861.558.359.861.558.359.861.558.359.861.558.32.93.54.42.93.54.42.93.54.42.93.54.42.93.54.42.93.54.42230455575901501169118862096229124664355606858109351060594743984116614301625DL型泵性能曲线表和外形尺寸图及安装尺寸表DL型泵性能曲线表和外形尺寸图及安装尺寸表外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table 外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度H eight HH1H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBb n-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet100DL108-30×1一级泵性能(m)η n=1450r/min 5060708090(%)η-QH-QPa-Q246(NPSH)r (NPSH)r-Q071421283542(l/s)02856841121403(m /h)111315Pa(Kw)1020304050H(m)H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBb n-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet125DL125-30×1η(m)一级泵性能H(m)5040302010Pa(Kw)171513(NPSH)r-Q(NPSH)r 642Pa-QH-Qη-Q(%)9080706050n=1450r/min 3(m /h)160128966432(l/s)484032241680114-φ268-18φ8-18φ20016080220180100640601505204504-φ268-18φ8-18φ22018010025021012564060150520450型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度H eight HH114502345671450234567100DL108-3091108135911081359110813591108135911081359110813522.53037.522.53037.522.53037.522.53037.522.53037.522.53037.565.36050.997.99076.3130.5120101.7163.1150127.1195.8180152.6228.421017820.424.427.230.736.640.940.948.754.551.160.968.161.373.181.771.685.395.370.172.768.970.172.768.970.172.768.970.172.768.970.172.768.970.172.768.92.83.44.22.83.44.22.83.44.22.83.44.22.83.44.22.83.44.2703870110012601500168043556068581093510601566176119712166234126163045557590110125DL125-3093.8125156.393.8125156.393.8125156.393.8125156.393.8125156.393.8125156.32634.743.42634.743.42634.743.42634.743.42634.743.42634.743.465.36050.997.99076.3130.5120101.7163.1150127.1195.8180152.6228.421017823.327.630.93541.546.346.755.361.858.369.177.27082.992.781.7096.70108.13755759011013272.174.270.372.174.270.372.174.270.372.174.270.372.174.270.372.174.270.32.22.83.22.22.83.22.22.83.22.22.83.22.22.83.22.22.83.216111846204122162491275643556068581093510607058201037123017301972DL型泵性能曲线表和外形尺寸图及安装尺寸表DL型泵性能曲线表和外形尺寸图及安装尺寸表外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table 外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter tableH进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBbn-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet150DL144-25×18090(%)η-QH-Q Pa-Q246(NPSH)r (NPSH)r-Q131517Pa(Kw)20253035H(m)一级泵性能(m)η(m3/h)1801441087236(l/s)5445362718906011n=1450r/min 70H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBb n-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet150DL160-25×11740η(m)一级泵性能H(m)3025201510Pa(Kw)151311(NPSH)r-Q(NPSH)r 642Pa-Q H-Qη-Q(%)9080706050 n=1450r/min 3(m /h)2001601208040(l/s)60504030201004-φ268-φ238-φ1860055145510450285240150250210125型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度 H eight HH1型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度 H eight HH14-φ268-φ238-φ186005514551045028524015025021012514502345678910150DL144-2510814418010814418010814418010814418010814418010814418010814418010814418010814418030405030405030405030405030405030405030405030405030405055.45041.483.17562.1110.810082.8138.5125103.5166.1150124.1193.8175144.8221.5200165.5249.2225186.2276.9250206.922.425.628.533.638.342.844.851.15756.163.971.367.376.785.578.589.599.889.7102.2114100.9115128.3112.1127.8142.5304575909011013216016072.97771.572.97771.572.97771.572.97771.572.97771.572.97771.572.97771.572.97771.572.97771.5 2.12.72.82.12.72.82.12.72.82.12.72.82.12.72.82.12.72.82.12.72.82.12.72.82.12.72.815801780206522452375265529253055318548261274287210021132126213921522583838103313481543157616451730188014502345678910150DL160-2512016020012016020012016020012016020012016020012016020012016020012016020012016020033.344.455.633.344.455.633.344.455.633.344.455.633.344.455.633.344.455.633.344.455.633.344.455.633.344.455.65350447975661061008813312511015915013218617515421220017623922519826625022024.128.732.836.14349.248.157.365.760.171.782.182.28698.584.210011596.2115132108129148119.814316437557590110132132160185757673757673757673757673757673757673757673757673757673 3.13.53.83.13.53.83.13.53.83.13.53.83.13.53.83.13.53.83.13.53.83.13.53.83.13.53.8162518662066229725982798292930593190512642772902103211621292142215527049281134131017661937200821592230DL型泵性能曲线表和外形尺寸图及安装尺寸表DL型泵性能曲线表和外形尺寸图及安装尺寸表外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table 外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度H eight HH1H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBbn-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet200DL230-25×118 n=1450r/min 60708090(%)η-QH-QPa-Q246(NPSH)r (NPSH)r-Q202224Pa(Kw)20253035H(m)一级泵性能(m)η3(m /h)28022416811256(l/s)847056422814016H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBb n-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet200DL250-30×1n=1450r/min 60708090(%)η-QH-QPa-Q246(NPSH)r (NPSH)r-Q253035Pa(Kw)1020304050H(m)一级泵性能(m)η3(m /h)32025619212864(l/s)9680644832160204-φ3612-φ238-φ23700652255604903402952002852401504-φ3612-φ238-φ2370065560490340295200285240150255型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度H eight HH1200DL230-251450200DL250-30145034.539.343.851.75965.768.978.687.686.298.3109.5103.4117.9131.42345645.551.957.968.377.986.891.1103.8115.7113.8129.8144.7136.6155.8173.62041223426672810295365379693910821225134714802097226024763 3.7 4.43 3.7 4.43 3.7 4.43 3.7 4.43 3.7 4.474.8 79 73.374.8 79 73.374.879 73.374.8 79 73.374.8 79 73.37590110160200187.5250312.5187.5250312.5187.5250312.5187.5250312.5187.5250312.552.169.486.852.169.486.852.169.486.852.169.486.852.169.486.866.56049.799.79074.5132.912099.3166.2150124.2199.418014923456172.5230287.5172.5230287.5172.5230287.5172.5230287.5172.5230287.547.963.979.947.963.979.947.963.979.947.963.979.947.963.979.955.45041.483.17562.1110.710082.7138.4125103.4166.1150124.1557511013216075.88074.275.88074.275.88074.275.88074.275.88074.23.13.53.83.13.53.83.13.53.83.13.53.83.13.53.819712184252728102953653796939108212258471063131214101886DL型泵性能曲线表和外形尺寸图及安装尺寸表DL型泵性能曲线表和外形尺寸图及安装尺寸表外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table 外型尺寸 Appearance size进口法兰Inlet flange出口法兰Outlet flange LhH2Bb4-φdDD1DNN-φd1DD1DNN-φd1DL型泵性能参数表 DL type pump performance parameter table型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度H eight HH1型号Type级数Grade流量F l o w i n g r a t e3(m /h)(L/S)扬程(m)Head 转速Rotation speed (r/min)功率P N(KW) ower 轴功率A xle power 电机功率M otor power 效率%Efficiency汽蚀余量(NPSH)r(m)Cavitationallowance重量W (kg)eight 高 度H eight HH1H进口出口H 1H 2hL进出口法兰尺寸图4-φdB bBbn-φd1DD 1 D N Inlet/outlet flange diagramOutletInlet20η(m)一级泵性能H(m)35302520Pa(Kw)3530(NPSH)r-Q(NPSH)r 642Pa-QH-Q η-Q(%)908070 n=1450r/min 253(m /h)40032024016080(l/s)12010080604020060200DL300-25×14-φdB bBb 200DL300-30×1H进口出口H 1H 2hL进出口法兰尺寸图n-φd1DD 1 D N Inlet/outlet flange diagramOutletInletη(m)一级泵性能H(m)5040302010Pa(Kw)403530(NPSH)r-Q(NPSH)r 642Pa-QH-Qη-Q(%)90807060n=1450r/min 25(l/s)1201008060402000801602403204003(m /h)4-φ3612-23φ8-23φ700655604903402952002852401502554-φ3612-23φ8-23φ70065560490340295200285240150255145023456145023456200DL300-30200DL300-251340185223302543286066882698411421300205625242712287030283.2 3.64.53.2 3.64.53.2 3.64.53.2 3.64.53.2 3.64.575.1 80 73.375.1 80 73.375.180 73.375.1 80 73.375.1 80 73.37511013216020045.451.356.168.176.984.190.8102.5112.1113.5128.2140.2136.2153.8168.255.45040.183.27560.2110.910080.3138.6125100.3166.3150120.462.583.3104.262.583.3104.262.583.3104.262.583.3104.262.583.3104.222530037522530037522530037522530037522530037522530037522530037522530037522530037522530037562.583.3104.262.583.3104.262.583.3104.262.583.3104.262.583.3104.25461.568.680.992.3102.9107.9123.1137.2134.9153.8171.5161.9184.6205.766.56049.799.79074.5132.912099.3166.2150124.2199.41801499013216020025075.88074.275.88074.275.88074.275.88074.275.88074.23.4 3.74.53.4 3.74.53.4 3.74.53.4 3.74.53.4 3.74.5210625242712287032586688269841142130017302230246027402920。

目录1 概述............................................................................... - 3 -1.1 什么是MST?................................................................................... - 3 -1.2 B120B的主要特点 ............................................................................. - 3 -2 组网及应用 ......................................................................... -3 -2.1 传统话音业务的接入.......................................................................... - 3 -2.2 数据及其它业务的接入与混传................................................................. - 4 -2.3 灵活可变的单路接入.......................................................................... - 4 -2.4 512×512的全数字交叉......................................................................... - 4 -2.5 E1通道保护功能 .............................................................................. - 5 -2.6 与MST-B120/MST-A15的结合使用 .............................................................. - 6 -3 技术指标 ........................................................................... - 6 -3.1 E1接口规范................................................................................... - 6 -3.2 局端电话接口卡(MBFXO)/用户端电话接口卡(MBFXS)规范...................................... - 6 -3.3 热线电话接口卡(MBPRA)规范.................................................................. - 7 -3.4 磁石电话接口卡(MBMAG)规范.................................................................. - 7 -3.5 EM2/4线接口卡(MBEM2/4)规范................................................................. - 7 -3.6 64K同向接口卡(MB64K)规范................................................................... - 7 -3.7 V.24接口卡(MBV24)规范 ...................................................................... - 7 -3.8 V.35接口卡(MBV35)规范 ...................................................................... - 7 -3.9 以太网接口卡(MB10Base-T)规范 .............................................................. - 7 -3.10 基带传输卡(MB2B)规范 ...................................................................... - 8 -3.11 DSL小卡(MBDSL)规范......................................................................... - 8 -3.12 网管接口规范................................................................................ - 8 -3.13 机箱尺寸、重量 ............................................................................. - 8 -3.14 功耗......................................................................................... - 8 -4 设备组成 ........................................................................... - 8 -4.1 主机说明 ..................................................................................... - 8 -4.2 单元盘说明................................................................................... - 9 -4.3 后面板说明.................................................................................. - 12 -5 用户接口卡 .........................................................................- 13 -5.1 局端电话接口卡(MBFXO) ..................................................................... - 13 -5.2 用户端电话接口卡(MBFXS)................................................................... - 13 -5.3 热线电话接口卡(MBPRA) ..................................................................... - 13 -5.4 磁石电话接口卡(MBMAG) ..................................................................... - 13 -5.5 EM2/4线接口卡(MBEM2/4) .................................................................... - 14 -5.6 64K同向接口卡(MB64K)....................................................................... - 15 -5.7 V.24接口卡(MBV24).......................................................................... - 15 -5.8 V.35接口卡(MBV35).......................................................................... - 16 -5.9 以太网接口卡(MB10Base-T).................................................................. - 17 -5.10 基带传输卡(MB2B).......................................................................... - 17 -5.11 MBDSL接口卡(MBDSL)........................................................................ - 18 -6 安装...............................................................................- 18 -6.1 包装方式 .................................................................................... - 18 -6.2 安装所需工具................................................................................ - 18 -6.3 机械安装 .................................................................................... - 18 -6.4 电气安装 .................................................................................... - 18 -7 开关设置 ...........................................................................- 21 -7.1 时钟开关设置................................................................................ - 21 -7.2 网络号、节点号(站号)开关设置 ............................................................. - 22 -8 网管设置 ...........................................................................- 22 -9 B120B设备传输故障汇总...............................................................- 23 -10 设备识别 ..........................................................................- 24 -10.1 零器件识别................................................................................. - 24 -10.2 板卡识别................................................................................... - 25 -1概述1.1什么是MST?MST(Multi-Service Terminal)综合业务复用设备是使用专用集成电路芯片研制生产的多业务接口设备。

1概述GENERALBLF 系列粉体蝶阀是川沪阀门开发的专用粉体/颗粒物料的工业产品。

阀体采用轻巧的高压铸铝合金制成,蝶板是内衬有钢芯的耐磨高分子材料,与耐磨橡胶密封圈形成的软性密封使其非常适合各种粉体/颗粒物料的应用场合,特别是对于磨损性强的物料。

在需要重力落料或气力输送的粉体/颗粒物料处理系统中.BLF 蝴蝶阀常常被安装在料斗、筒仓、螺旋输送机出口以及气送管路上。

BLF 双法兰蝴蝶阀带有2个相同的法兰面,而BLF 单法兰蝴蝶阀部配有一个伸出的连接环用以安装软套管。

根据应用要求,可以单独选配驱动手柄或者气缸驱动套件。

工业化的设计加上特殊复合材料的使用,使BLF 蝴蝶阀具有结构紧凑轻巧、蝶板耐磨、密封寿命长、安装维护简便等特点,是一种成本一效益极高的粉体阀。

BLF series butterfly valve is CHUANHU automatic control valves developed specifically for powder/granule material for industrial products. The valve body adopts lightweight high-pressure cast aluminum alloy, the butterfly plate is lined with cored steel wear-resistant polymeric material, and the rubber sealing ring formed of soft sealing make it very suitable for all kinds of powder / particle materials applications, especially for resistance to abrasion of materials. In need of gravity blanking or pneumatic conveying of powder / particle material handling system, BLF butterfly valves are mounted on the hopper, silo, screw conveyor outlet and a pneumatic duct. BLF double flanged butterfly valve with the same 2 flange, and BLF single flange butterfly valve equipped with an extended ring for Installation of flexible sleeve. According to the application requirements, can be separately selected drive handle or a cylinder drive kit. Industrial design and special composite materials using BLF, the butterfly valve has the advantages of compact structure, lightweight wear-resistant sealing butterfly plate, long service life, easy installation and maintenance and other characteristics, is a cost-effective high powder valve标准规格 STANDARD SPECIFICATION公称通径 Body size DN50~4000 公称压力 Body ratings PN 0.25, 0.6 MPa 尺寸标准 Dimension standard 国标 GB阀体材质 Body material 铝合金 Aluminium alloy 阀座材质 Seat material 本体密封 W控制方式 Control开关型、调节型Switch type, Adjust type电动执行器形式 Electric actuator form普通型、防爆型、智能一体化Standard type, Explosion-proof type, Intelligent integration 电源电压 Power supply voltage380V/220V/110V 交流电源或24V/110V 直流电源 380V/220V/110V AC or 24V/110V DC2主要外形及连接法兰尺寸 MAIN OUTLINE AND CONNECTING FLANGE SIZE● BL1F 单法兰粉体蝶阀型号TYPE φAφBφCφDEFGφHφH孔径*数量 φP外凹槽直径*数量φRSTUVZKGBLlF100 95 180 220 105 250 115 35 22*19 14*4 20*4 220 40 80 M12 50 M10 4 BLlF150 150 200 228 163 290 115 35 22*19 14*4 20*4 228 40 80 M12 50 Ml0 5 BLIF200 200 250 278 213 340 115 35 22*19 14*4 20*4 278 40 80 M12 50 Ml0 6,5 BLIF250 250 300 328 263 390 115 35 22*19 14*8 20*8 328 40 80 M12 50 M10 7 5 BLIF300 300 350 378 313 440 115 35 22*19 14*8 20*16 378 40 80 M12 50 Ml0 9 BLIF350 350 400 440 363 530 123 50 28*25 14*8 20*8 440 40 80 M12 50 Ml0 16 BLIF4004004705304135801235028*2514*820*165304080M1250Ml020.5● BL2F 双法兰粉体蝶阀型号TYPE φAφBφCφDEFGφHφH 孔径*数量φP外凹槽直径*数量φRSTUVZKGBL2F100 95 180 220 250 77 35 22*19 14*4 220*4 220 80 M12 50 Ml0 4 BL2F150 150 200 228 290 77 35 22*19 14*4 20*4 228 80 M12 50 M10 5 BL2F200 200 250 278 340 77 35 22X19 14*4 20*4 278 80 M12 50 Ml0 6 5 BL2F250 250 300 328 390 77 35 22*19 14*8 20*8 328 80 M12 50 Ml0 7 5电动执行机构说明书ELECTRIC ACTUATOR INSTRUCTIONS概述Summary“CHV”系列电动执行器用于控制0~270°。

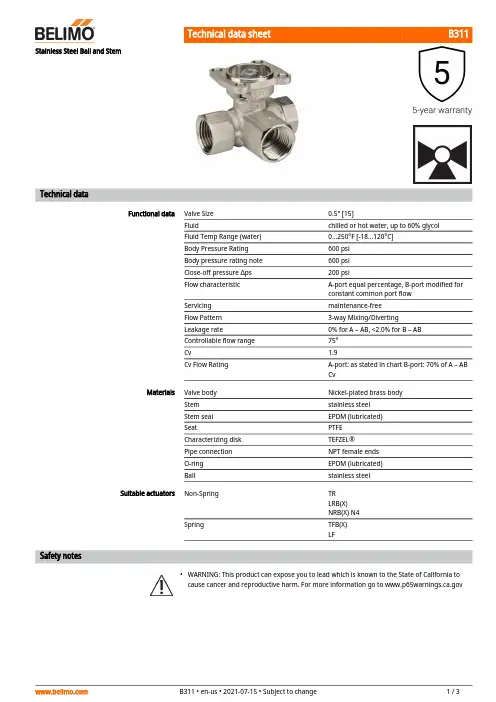

B311•Stainless Steel Ball and StemTechnical dataFunctional data Valve Size0.5" [15]Fluid chilled or hot water, up to 60% glycolFluid Temp Range (water)0...250°F [-18...120°C]Body Pressure Rating600 psiBody pressure rating note600 psiClose-off pressure ∆ps200 psiFlow characteristic A-port equal percentage, B-port modified forconstant common port flowServicing maintenance-freeFlow Pattern3-way Mixing/DivertingLeakage rate0% for A – AB, <2.0% for B – ABControllable flow range75°Cv 1.9Cv Flow Rating A-port: as stated in chart B-port: 70% of A – ABCvMaterials Valve body Nickel-plated brass bodyStem stainless steelStem seal EPDM (lubricated)Seat PTFECharacterizing disk TEFZEL®Pipe connection NPT female endsO-ring EPDM (lubricated)Ball stainless steelSuitable actuators Non-Spring TRLRB(X)NRB(X) N4Spring TFB(X)LFSafety notesWARNING: This product can expose you to lead which is known to the State of California tocause cancer and reproductive harm. For more information go to B311ApplicationProduct featuresThis valve is typically used in air handling units on heating or cooling coils, and fan coil unit heating or cooling coils. Some other common applications include Unit Ventilators, VAV box re-heat coils and bypass loops. This valve is suitable for use in a hydronic system with variable or constant flow.Flow/Mounting detailsDimensionsDimensional drawingsLRB, LRXType DN Weight [kg][kg]B311150.30AB C D E F H1H28.5" [216]2.4" [60] 5.2" [132] 4.6" [117] 1.3" [33]1.3" [33] 1.2" [30]1.1" [28]LRQB, LRQXAB C D E F H1H28.9" [226]2.4" [60]5.7" [146]5.2" [131]1.6" [40]1.6" [40]1.2" [30]1.3" [33]TRAB C D E F 3.7" [95]2.4" [60]4.8" [122]4.2" [107]1.3" [33]1.2" [31]B311TFRB, TFRXA B C D E F6.6" [167] 2.4" [60] 4.9" [124] 4.3" [110] 1.5" [39] 1.5" [39]LFA B C D E F7.9" [200] 2.4" [60] 5.7" [146] 5.1" [129] 1.8" [46] 1.8" [46]ARB N4, ARX N4A B C D E F11.4" [289] 2.4" [60]7.2" [184] 6.7" [169] 3.1" [80] 3.1" [80]LRB24-3-T On/Off, Floating Point, Non-Spring Return, 24VTechnical dataElectrical data Nominal voltage AC/DC 24 VNominal voltage frequency50/60 HzPower consumption in operation 1.5 WPower consumption in rest position0.2 WPower consumption for wire sizing 2 VATransformer sizing 2.5 VA (class 2 power source)Electrical Connection Screw terminal (for 26 to 14 GA wire)Overload Protection electronic thoughout 0...90° rotationFunctional data Direction of motion motor selectable with switch 0/1Manual override external push buttonAngle of rotation90°Angle of rotation note adjustable with mechanical stopRunning Time (Motor)90 sNoise level, motor35 dB(A)Position indication Mechanically, pluggableSafety data Degree of protection IEC/EN IP54Degree of protection NEMA/UL NEMA 1Enclosure UL Enclosure Type 1Agency Listing cULus acc. to UL60730-1A/-2-14, CAN/CSAE60730-1:02, CE acc. to 2014/30/EUListed to UL 2043 - suitable for use in airplenums per Section 300.22(C) of the NEC andSection 602 of the IMCQuality Standard ISO 9001Ambient temperature-22...122°F [-30...50°C]Storage temperature-40...176°F [-40...80°C]Ambient humidity Max. 95% RH, non-condensingServicing maintenance-freeWeight Weight 1.1 lb [0.50 kg]LRB24-3-TServicingAccessoriesElectrical accessoriesDescriptionTypeBattery backup system, for non-spring return models NSV24 US Battery, 12 V, 1.2 Ah (two required)NSV-BAT Auxiliary switch 1 x SPDT add-on S1A Auxiliary switch 2 x SPDT add-onS2AFeedback potentiometer 140 Ω add-on, grey P140A GR Feedback potentiometer 1 kΩ add-on, grey P1000A GR Feedback potentiometer 10 kΩ add-on, grey P10000A GR Feedback potentiometer 2.8 kΩ add-on, grey P2800A GR Feedback potentiometer 500 Ω add-on, grey P500A GR Feedback potentiometer 5 kΩ add-on, greyP5000A GRElectrical installationINSTALLATION NOTESProvide overload protection and disconnect as required.Actuators may be connected in parallel. Power consumption and input impedance must beobserved.Actuators may also be powered by DC 24 V.Actuators Hot wire must be connected to the control board common. Only connect common toneg. (-) leg of control circuits. Terminal models (-T) have no-feedback.Actuators are provided with a numbered screw terminal strip instead of a cable.Meets cULus requirements without the need of an electrical ground connection.Warning! Live electrical components!During installation, testing, servicing and troubleshooting of this product, it may be necessary to work with live electrical components. Have a qualified licensed electrician or other individual who has been properly trained in handling live electrical components perform these tasks. Failure to follow all electrical safety precautions when exposed to live electrical components could result in death or serious injury.Wiring diagrams On/OffFloating PointFloating Point - Triac SourceFloating Point - Triac SinkInstallation notesDimensions。

双壳体多级高压离心泵(滑动自润滑轴承首级双吸)安装、操作与维护手册(该封面无效,请使用专用封面)录安全防备措施 (2)1、概要 (2)2、拆箱与储存 (3)3、泵机组安装 (5)4、泵结构 (7)5、启动和停车 (8)6、维护 (9)7、泵装配 (10)8、拆卸 (12)9、故障原因及排除方法 (12)安全防备措施●使用产品前请仔细阅读安全预防措施以确保正确使用。

●该防备措施是为安全使用离心泵而制定,以避免对你和他人造成伤害。

为表明损害和危险的程度,根据错误使用泵而造成的不良后果,将防备措施划分为三个等级。

它们分别为“危险”、“警告”、“注意”。

该三项包含了安全操作的重要信息,务必遵守。

危险:表示即将导致死亡或对人体造成严重伤害。

警告:表示可能导致死亡或对人体造成严重伤害。

注意:表示可能导致对人体的伤害或仅仅是设备的损坏。

符号表示“危险”、“警告”或“注意”。

表示禁止的行为。

表示必须的行为或指令。

1、概要1.1介绍非常感谢您购买嘉利特荏原泵业有限公司的双壳体多级高压离心泵。

完全理解本说明书内容、正确的安装、服务人员的详细解说及良好的维护计划是保证泵正常有效运行的基本条件。

本说明书阐述了泵安装、运行、维护的正确方法及过程中需要警惕的地方。

任何时候对泵进行的操作都要按照本说明书的指示进行。

另外,请小心的将说明书保存在特定位置,以便任何时间使用、操作该产品的人都能查阅。

确保在使用泵前详细阅读说明书。

必要时将下列文件与说明书一同使用(1)外形图、剖面图(2)性能曲线(3)数据表(4)其他由本公司提供的图纸1.2安全使用为确保泵的安全使用,将这些必须遵守的防备措施列在说明书里。

下面列出部分任何时候必须绝对遵守的的防备措施。

1.3吊运1)泵机包装在板条箱中,标志着“此边向上”的板条箱应按标志方法装运。

注意板条箱上的木板上的总重的标志。

2)安装时的起吊:在任何情况下,不允许起吊绳挂在轴承体上。

3)一般情况下,各机组分开包装,否则包装箱体积太大。

HF -BLF-IIIBP型电液控制执行机构操作及维修手册九江市环球科技开发有限公司目录1 简介............................................................... 错误!未定义书签。

1.1、概述......................................................... 错误!未定义书签。

2 线形控制结构执行表 (5)3 控制描述........................................................... 错误!未定义书签。

3.1 液压控制系统:............................................... 错误!未定义书签。

1. 系统元件说明................................................... 错误!未定义书签。

2. 系统工作流程................................................... 错误!未定义书签。

3.2 PLC控制操作描述.............................................. 错误!未定义书签。

1. 阀位控制系统................................................... 错误!未定义书签。

2. 联锁控制系统................................................... 错误!未定义书签。

3.3 系统操作..................................................... 错误!未定义书签。

1. 该系统具有四种操作方式......................................... 错误!未定义书签。

GRUNDFOS数据手册CR, CRI, CRN50 Hz IEC立式多级泵1.产品概述 (3)典型应用 (3)泵送液体 (4)符合ErP指令 (4)2.性能范围 (5)3.产品范围 (6)4.应用 (8)5.特性和优点 (9)泵 (9)电机 (9)接线盒位置 (10)环境温度 (10)粘度 (10)6.结构 (11)CR 1s, 1, 3, 5, 10, 15, 20 (11)CRI 1s, 1, 3, 5, 10, 15, 20 (12)CRN 1s, 1, 3, 5, 10, 15, 20 (13)CR 32, 45, 64 (14)CRN 32, 45, 64 (15)CR 95, 125, 155, 185, 215, 255 (16)CRN 95, 125, 155, 185, 215, 255 (17)7.标识 (18)型号说明 (18)8.运行条件 (20)最大运行压力和最高液体温度 (20)轴封的运行范围 (22)最大入口压力 (23)9.选型 (24)泵的选择 (24)如何读懂曲线图 (28)性能曲线参考指南 (29)10.性能曲线与技术数据 (30)CR 1s (30)CRI, CRN 1s (32)CR 1 (34)CRI, CRN 1 (36)CR 3 (38)CRI, CRN 3 (40)CR 5 (42)CRI, CRN 5 (44)CR 10 (46)CRI, CRN 10 (48)CR 15 (50)CRI, CRN 15 (52)CR 20 (54)CRI, CRN 20 (56)CR 32 (58)CRN 32 (60)CR 45 (62)CRN 45 (64)CR 64 (66)CRN 64 (68)CR 95 (70)CRN 95 (72)CR 125 (74)CRN 125 (76)CR 155 (78)CRN 155 (80)CR 185 (82)CRN 185 (84)CR 215 (86)CRN 215 (88)CR 255 (90)CRN 255 (92)11.电机数据 (94)二极电机,用于CR,CRI,CRN,50 Hz (94)12.泵送液体列表 (95)13.配件 (97)管道连接 (97)LiqTec (107)传感器 (108)14.变型 (109)15.Grundfos Product Center (110)CR, CRI, CRN2目录1.产品概述本数据手册介绍格兰富CR、CRI 和CRN 泵。

目录一、 概述 (1)二、 技术规范 (1)三、 排量与压力关系 (2)四、 主要零部件结构说明 (2)五、 新泵的安装 (5)六、 对吸入系统的要求 (8)七、 动力端的准备工作 (8)八、 喷淋泵总成 (10)九、 液力端主要零部件的装配 (12)十、 动力端主要零部件的拆卸和装配 (15)十一、 润滑 (18)十二、 泵的安装起动和运转中的监视 (22)十三、 泵的维护保养 (23)十四、 钻井泵可能发生的故障和排出方法 (25)十五、 封存注意事项 (26)十六、 泵用润滑油和润滑脂 (26)十七、 3NB—1300F/1600F钻井泵随机专用工具清单 (27)十八、 3NB—1300F/1600F钻井泵随机备用件清单 (28)十九、 建议用户订购清单 (29)二十、 3NB—1300F/1600F钻井泵零件目录 (30)一、 概述3NB—1300F/1600F钻井泵是卧式三缸单作用活塞泵,由动力端和液力端两大部分组成。

具有结构先进、体积小、使用可靠、有较好的互换性、易于维护保养等优点。

该泵的易损件、轴承、密封件、技术参数等均与同规格的F泵相同。

主要结构由动力端和液力端两大部分组成。

动力端包括:机架总成、小齿轮轴总成、曲轴总成、十字头总成等;液力端包括:液缸、阀总成、缸套、活塞总成、吸入管路、排出管路等。

为了防止气塞和减少出口压力波动,在泵的吸入管路和泵出口一侧分别装有吸入空气包和排出空气包。

为了保证泵不超过额定的工作压力,在泵的出口的另一侧装有剪销安全阀。

为保证泵在高冲数时的上水性能,每台泵应安装灌注泵。

动力端齿轮、轴承、十字头采用飞溅润滑和强制润滑相结合,因而能足够保证具有良好的润滑条件。

液力端的缸套和活塞由喷淋泵供给水进行润滑、清洗、冷却。

随泵带有一套专用拆装工具,供日常维修之用。

只要认真搞好该泵的维护保养,3NB—1300F/1600F钻井泵是每个钻井工作者的极好伙伴,必将给你带来良好的经济效益。

THEMBF - 2型泵组装教程安装步骤1、开箱检验及管理(1)泵组开箱检验应有采购单位、建设单位(监理单位)参加,按照装箱清单进行下列项目检验,检验后应保存有各方签字的检验记录。

a、核对箱号、箱数并检查包装状况;b、核对机器的名称、型号、规格及数量;c、对交货设备进行外观质量检查;d、检查随机产品技术文件、备品备件及专用工具等是否齐全。

(2)泵组和各零部件若暂不安装,应采取适当的防护措施,妥善保管;防止损坏、锈蚀、老化、变形、错乱或丢失等现象。

若存放时间超过12个月,则泵的各零部件应涂以防锈油进行保存,正式安装时再将防锈油清洗掉,换上润滑油。

或者按供货商的储存要求保管。

(3)对与泵组配套的电气、仪表等精密仪器件,可由相关专业人员检查验收。

并按要求进行储存、保管。

2、安装前的技术准备(1)泵组正式安装前,应具备下列技术文件:a、设计文件,包括THEMBF - 2型泵安装平面布置图、THEMBF - 2型泵基础图及相关专业的施工图等;b、产品技术文件,包括THEMBF - 2型泵出厂合格证书、质量证明文件和质量检查记录、THEMBF - 2型泵试验报告、THEMBF - 2型泵总装配图、主要零部件图、易损件图及安装使用说明书等;c、应执行的相关技术标准和规范。

(2)安装前应编制安装技术文件。

3、施工现场条件、基础验收与处理(1)泵组安装前,现场应具备下列条件:a、土建工程已基本结束;基础具备安装条件,与泵组相关的地下工程已完成,场地平整,道路畅通;b、吊装设备具备使用条件;c、零部件、工具等的储存设施等可以使用。

(2)基础移交时,土建单位应提供基础质量合格证文件及测量记录。

基础上应明显标尺标高基准线、中心线,参照物坐标点和标高基准点。

重要泵组的基础应有沉降观测点。

(3)对基础进行外观检查,混凝土基础不得有裂纹、蜂窝、空洞、漏筋等缺陷。

(4)按照基础设计文件和泵组产品技术文件,对泵基础尺寸及位置进行复测检查,基础的允许偏差应符合标准规定要求。

MBF差压式流量计(多孔平衡型)High accuracyBroad range of applicationsProven technologyEasy to operateDesigned to match your applicationinstrumentation目 录1、概 述 (1)2、测量原理 (1)3、特 点 (2)4、技术参数 (3)5、产品分类 (3)6、安装尺寸图 (4)7、安装说明 (13)8、型号说明 (14)一、 概 述 Fischer&Porter 公司的MBF 系列多孔平衡流量计采用了国际最先进的对称多孔结构设计,是目前最先进的差压式流量计之一。

MBF 系列多孔平衡流量计除具有标准节流装置简单、可靠、安全、适用面广等优点之外,还具有精度高、直管段要求低、量程比宽、永久压损小等优点;同时还克服了标准节流装置的杂物滞留、堵塞和边缘易磨损、维护和检定成本高等缺点,具有广阔的发展前景。

二、测量原理 MBF 系列多孔平衡流量计遵循流体力学定律和伯努利方程,流量计流出系数、传感器多孔孔径位置、形状设计和开孔数量通过独特的研发数据演算,并对各种工况进行优化,使测量精度、重复性、量程比、永久压损等综合指标达到最佳,成为目前最先进的差压式流量计。

多孔整流器 标准孔板 多孔平衡节流件MBF 系列多孔平衡流量计结合了多孔整流器和标准孔板的测量原理,在节流板中心一个圆孔的基础上,对称分布数量不等的圆孔。

当介质流过圆孔时,流体被平衡调整,涡流被最小化,形成近似理想流体,通过取压装置和变送器,可获得稳定的差压信号,根据伯努利方程计算出流体的流量。

公式: Q=KY 式中: Q :介质流量(m3/h)K :仪表系数 Y :膨胀系数 △P:差压值(Pa)ρ:介质工况密度(Kg/m3)MBF 系列多孔平衡流量计实现了流场平衡,整流达到最佳的效果,充分满足流体力学定律对流体测量的要求,将死区效应降到最低。

节流件前后产生的涡流大大降低,显著提高了测量精度,无需很长的直管段整流,永久压力损失由于涡流减少降低到传统节流装置的约1/3,量程比扩展到10:1,杂物滞留现象基本消除,不易磨损大大提高了产品使用寿命。

三、特 点 3.1 测量精度高 MBF 系列多孔平衡流量计对称多孔设计,使流场达到平衡,能基本消除仅一个孔节流带来的死区效应,取压区域涡流大大降低,取压口拾取的差压信号信噪比大大提高;振动降低,稳定性提高,传感器检测精度大大提高,可达到0.5%精度。

3.2 直管段要求短 MBF 系列多孔平衡流量计对称多孔设计,能将流场快速整流成近似理想体,无需过多的直管段整流。

同其它类型的差压流量计相比,对前、后直管段的要求小,安装时前直管段要求为1-3D,后直管段要求为0.5-1D(如图)。

3.3 永久压损小MBF 系列多孔平衡流量计结构设计无死区效应,在相同的差压值情况下,能将标准孔板因死区涡流带来永久压力损失降低2-3倍,可以大量节省装置运行过程中的流体输送能源(如图)。

P1:多孔平衡流量计 P2:标准孔板3.4 测量范围宽 MBF 系列多孔平衡流量计突破标准节流装置的测量局限,可以根据流体特性进行灵活多变的结构设计。

配一个变送器时量程比达到10:1(传感器最高可达30:1),雷诺数拓宽为200~10000000,高流速度段节流特性更佳。

3.5 稳定性好MBF 系列多孔平衡流量计在下游形成的涡流小,从而信号稳定性好。

其它类型的节流装置在节流件后形成的涡流较长,产生高幅、低频波动信号,这些信号会对差压变送器的数值造成干扰。

3.6 可测量脏污介质MBF 系列多孔平衡流量计的平衡设计,减少了紊流剪切力和涡流的形成,从而大大降低了滞留死区的现象,保证脏污介质可以顺利通过多个孔,减小了流体孔被堵塞的机会。

3.7 双向流检测结构设计MBF 系列多孔平衡流量计可以进行气液两相、浆料、含少量固体颗粒介质的测量。

结构上采用双向直孔,左右完全对称,可方便的测量双向流(如图)。

节流件厚度突破了标准孔板的限制,比标准孔板结构更安全,使用寿命更长。

标准孔板 多孔平衡节流件3.8 节能型设计MBF 系列多孔平衡流量计是一种节能型差压式流量计,具体体现为:a、由于测量精度高,所以可做计量使用,从而节约了因计量不准确而造成的贸易结算损失;b、由于压力损失小,所以节约了介质在输送过程中的能量,从而大大节约了成本;c、直管段要求短,节省了工艺管道材料和施工费用;d、长期稳定性运行,无边缘磨损,延长了检定周期,节约了检定费用。

五、产品分类MBF多孔平衡流量计一般分为夹持式、法兰式、焊接式,用户可根据要求采用不同的连接方式。

MBF多孔平衡流量计安装、使用、维护方便简单、安全可靠,广泛应用在各种液体、气体、蒸汽气液混合介质、双向流介质的流量测量。

应用口径:夹持式:DN15-DN3000法兰式:DN15-DN600 焊接式:DN15-DN3000介质温度:取决于管道和法兰的材质和等级, 工作温度可达600℃介质压力:夹持式:≤42Mpa法兰式:≤26Mpa 焊接式:≤42Mpa 根据用户要求法兰标准:德 标:DIN2501 美 标:ANSI 日 标:JIS国 标:GB 化工部:HG特殊标准根据用户要求传感器材质: CS0Cr18Ni9 316 316L HBHC其它(具体材质详见订货数据表)四、技术参数 ● 型 号: MBF4000 ● 介质范围: 气 体 液 体 蒸 汽 其 它 ● 公称通径: DN15~3000 ● 连接方式: 夹持连接 法兰连接 焊接连接 其 它 ● 精 度: ±0.5% ● 重 复 性: ±0.2% ● 量 程 比:(配一个变送器时) 10:1(传感器最高可达30:1) ● 前后直管段要求: 前1-3DN,后0.5-1DN ● 雷诺数适用范围: 200~10000000 ● β值范围: 0.1-0.85 ● 介质温度范围: -200℃~+600℃ ● 介质压力范围: ≤42Mpa ● 材质范围: CS、0Cr18Ni9、316、316L、HB、HC 等 特殊材质根据用户要求 ● 法兰标准: 美标、德标、国标等 特殊标准根据用户要求 ● 防爆等级: 详见变送器参数 ● 防护等级: 详见变送器参数 ● 环境温度: 详见变送器参数六、安装尺寸图6.1 夹持式 ( 德标、化工部、国标 )法兰标准及压力等级DIN/HG20592/GB (Mpa) 口径 (DN)PN0.6PN1.0 PN1.6 PN2.5 PN4.0PN6.3 PN10.0 PN16.0 PN25.0 A A A A A A A A A 15 1/2” 3 3 3 3 3 3 5 5 5 20 3/4” 3 3 3 3 3 3 5 5 5 25 1” 3 3 3 3 3 3 5 5 5 32 1-1/4” 3 3 3 3 3 3 5 5 5 40 1-1/2” 3 3 3 3 3 3 5 5 5 50 2” 3 3 3 3 3 3 5 5 5 65 2-1/2” 3 3 3 3 3 3 5 5 5 80 3” 3 3 3 3 3 3 5 5 5 100 4” 3 3 3 3 3 3 5 5 5 125 5” 4 4 4 4 4 4 6 6 6 150 6” 4 4 4 4 4 4 6 6 6 200 8” 6 6 6 6 6 6 8 8 8 250 10” 6 6 6 6 6 6 8 8 8 300 12” 7 7 7 7 7 7 9 9 9 350 14” 9 9 9 9 9 9 11 11 11 400 16” 9 9 9 9 9 9 11 11 11 450 18” 12 12 12 12 12 12 14 14 14 500 20” 12 12 12 12 12 12 14 14 14 60024”161616161616181818注:1、其他未注尺寸根据法兰标准、压力等级、密封面形式等确定。

2、压力等级、口径超出表格所列部分请与公司技术部联系。

6.2 夹持式 ( 美标、化工部、国标 )法兰标准及压力等级ANSI/HG20615/GB (CL/Mpa)直径 (DN/ANSI) CL150/PN2.0 CL300/PN5.0CL600/PN11.0CL900/PN15.0CL1500/PN26.0 CL2500/PN42.0A A A A A A 15 1/2” 3 3 5 5 5 7 20 3/4” 3 3 5 5 5 7 251”3 3 5 5 5 7 32 1-1/4” 3 3 5 5 5 7 40 1-1/2” 3 3 5 5 5 7 502”3 3 5 5 5 7 65 2-1/2” 3 3 5 5 5 7 80 3” 3 3 5 5 5 7 100 4” 3 3 5 5 5 7 125 5”4 4 6 6 6 8 150 6” 4 4 6 6 6 8 200 8” 6 6 8 8 8 10 250 10” 6 6 8 8 8 10 300 12” 7 7 9 9 9 11 350 14” 9 9 11 11 11 13 400 16” 9 9 11 11 11 13 450 18” 12 12 14 14 14 16 500 20” 12 12 14 14 14 16 600 24”161618181820注:1、其他未注尺寸根据法兰标准、压力等级、密封面形式等确定。

2、压力等级、口径超出表格所列部分请与公司技术部联系。

6.3 管道法兰式管取压 ( 德标、化工部、国标 )法兰标准及压力等级DIN/HG20592/GB (Mpa)口径(DN)PN0.6PN1.0 PN1.6 PN2.5 PN4.0 PN6.3PN10.0 PN16.0PN25.0 L L L L L L L L L 15 1/2” 200 200 200 200 200 300 350 350 350 20 3/4” 200 200 200 200 200 300 350 350 350 25 1” 200 200 200 200 200 300 350 350 350 32 1-1/4” 200 200 200 200 200 300 350 350 350 40 1-1/2” 200 200 200 200 200 350 400 400 400 50 2” 200 200 200 200 200 350 400 400 400 65 2-1/2” 200 200 200 200 200 400 500 500 500 80 3” 200 200 200 200 200 400 500 500 500 100 4” 250 250 250 250 250 450 500 500 500 125 5” 250 250 250 250 250 500 550 550 600 150 6” 300 300 300 300 300 500 550 600 650 200 8” 350 350 350 350 350 500 600 650 700 250 10” 500 500 500 500 500 600 650 700 800 300 12” 600 600 600 600 600 650 700 800 900 350 14” 600 600 600 600 600 650 700 800 1000 400 16” 600 600 600 600 600 700 800 850 1000 450 18” 600 600 600 600 600 750 850 900 1100 500 20” 600 600 600 600 600 800 900 950 1200 60024”600600600600600900100011001400注:1、其他未注尺寸根据法兰标准、压力等级、密封面形式等确定。