TL226(用于汽车内饰件材料的油漆材料要求)

- 格式:pdf

- 大小:3.56 MB

- 文档页数:10

汽车内饰件油漆涂层标准1 范围本标准适用于所有车型内饰件喷漆的技术要求。

用于内饰件的喷漆,例如:仪表板、门护板,杂物,头枕,扶手等装饰和防护目的。

本企业标准由范围、引用标准、技术要求、试验方法、产品出厂验收等部分组成。

2 规范性引用文件下列文件中的条款通过本标准的引用而成为本标准的条款。

凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据本标准达成协议的各方研究是否可使用这些文件的最新版本。

凡是不注日期的引用文件,其最新版本适用于本标准。

GB 250 评定变色用灰色样卡GB 251 评定沾色用灰色样卡GB 2828-2003 组批检查计数抽样程序及抽样表GB 2829-2002 周期检查计数抽样程序及抽样表GB/T 3920-97 纺织品色牢度试验(耐摩擦色牢度)GB 6739-1996 漆膜硬度铅笔测定法Q/SQR.04.025-2004 涂层附着力试验方法-划格法Q/SQR.04.057-2003 CAC-商标标记Q/SQR.04.058-2004 汽车零部件标记要求Q/SQR.04.065-2005 漆膜耐水试验方法Q/SQR.04.095-2004 塑料、织物氙弧灯连续照射试验Q/SQR.04.112-2003 产品包装标志要求Q/SQR.04.400-2005 涂层耐冲击试验方法DIN 50014 气候及技术引用标准气候3 术语内饰喷漆件:车身内部起装饰和防护作用的油漆件。

4 材料4.1材料和组成4.1.1 喷漆体按图纸或说明,或按照相应零部件标准要求;4.1.2 涂层体系漆基按图纸或说明;5 技术要求5.1 预处理在试验前,要放在正常气候条件下(空气温度为23℃,允许偏差在±1,空气湿度为50%和允许偏差在±3)24小时,做预处理。

5.2 外观喷漆件表面均匀,不允许有针孔、裂纹、流挂、条纹、叠层等缺陷。

喷漆表面的颜色和光泽必须与样品或色板一致。

作伙伴可通过相关采购部门提取本标准。

3.2 基本要求有关首次交付和相关更改的审批程序,执行标准为VW 011 55。

有关有害物避用,执行标准为VW 911 01。

一次全面性的试验需要8个零件。

所使用的涂层,不得含有铬或铅化合物。

3.3 基本工料按图纸。

3.4 保护形式/外观参考表格1。

图纸里如无特别标示,颜色分别为黑色。

3.5 预处理如使用空气干燥式涂敷系统,以及/或者涂装系统在工作温度超过60℃时便中止烘烤作业,则部件应在试验前接受24小时以及60℃的预处理过程。

然后,试样应按照DIN 50014中的要求冷却至室温(18℃至28℃)。

3.6 涂层厚度请参阅表格2。

接合缝以及涂敷面的层厚是有限制的,具体的限制参数需在相关图纸内注明。

表23.7 粘合力和脆性用符合DIN EN ISO 2409的涂层网格进行检验。

要求:参数0至1。

3.8 涂层石击强度试验用DIN 55996-1中的方法B进行检验,目测判断试验结果。

要求:小于或等于参数2。

3.9 其他特性参阅表格3。

4. 参考文献PV 1210TL 766TL 774TL 521 07TL 521 46VW 011 55VW 137 50VW 911 01VDA 621-412DIN 50014DIN 50017DIN 50021DIN 55996-1DIN EN 228DIN EN 590DIN EN ISO 2409 DIN EN ISO 4628-1DIN EN ISO 4628-8 车身和附件;耐腐蚀试验制动液;工料要求乙二醇基冷却添加剂;工料要求起动机油SAE 15W-40;润滑剂要求耐温性较高的中央液压油;要求一般性机动车外购件;首次交付和变更的许可金属件表面保护;保护形式,缩写符号,要求机动车环保标准,机动车部件,工料和工作介质;有害物禁用涂装技术测试;机动车涂装的耐化学腐蚀性预处理标准气候以及/或者检验;规定气候以及相关的技术应用;冷凝水试验气候用不同氯化钠溶液进行盐雾试验涂装材料;涂层石击强度试验;第一部分:多冲击试验机动车燃油;无铅汽油,最低要求和试验方法机动车燃油;柴油,最低要求和试验方法色漆和清漆,涂层网格试验色漆和清漆- 漆膜降解的评定- 缺陷量值、大小以及外观均匀改变程度的规定- 第1部分:一般说明和名称与符号系统。

ICS 87.010G 50团体标准T/CNCIA 01008-2018汽车塑料内饰件涂料Automobile plastic interior parts paint2018-09-01发布2018-12-01实施中国涂料工业协会发布T/CNCIA 01008-2018前言本标准依据GB/T 1.1-2009给出的规则起草。

本标准由中国涂料工业协会提出。

本标准由中国涂料工业协会标准化委员会归口。

本标准起草单位:艾仕得涂料系统(上海)有限公司,苏州吉人高新材料股份有限公司,漳州鑫展望化工有限公司,中山大桥化工集团有限公司,中国涂料工业协会。

本标准主要起草人:朱旭平,闫福成,徐泽孝,何明峰,杨小青,李力,齐祥昭。

汽车塑料内饰件涂料1范围本标准规定了汽车内饰件涂料产品(包括溶剂型和水性涂料)的术语和定义、分类、要求、试验方法、检验规则以及标志、包装和贮存。

本标准适用于溶剂型和水性加热固化型汽车塑料内饰件件涂料。

各类产品包含并不仅限于单组分、双组份产品。

各类涂料按用途可涵盖用于原厂乘用车内饰塑料件涂装的底漆,色漆以及清漆等涂料。

2规范性引用文件下列文件对于本文件的应用是必不可少的。

凡是注日期的引用文件,仅所注日期的版本适用于本文件。

凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T 1725 色漆、清漆和塑料不挥发物含量的测定GB/T 1728—1979 漆膜、腻子膜干燥时间测定法GB/T 1733 漆膜耐水性测定法GB/T 1740 漆膜耐湿热性测定法GB/T 3186 色漆、清漆和色漆与清漆用原材料取样GB/T 6753.3 涂料贮存稳定性试验方法GB/T 8170 数值修约规则与极限数值的表示和判定GB/T 9278 涂料试样状态调节和试验的温湿度GB/T 9286 色漆和清漆漆膜的划格试验GB/T 13452.2 色漆和清漆漆膜厚度的测定GB/T 13491 涂料产品包装通则GB 24409 汽车涂料中有害物质限量ISO 6504—3:1998 Methods of test for Paints-Part D11: Determination of contrast ratio (opacity) of light-coloured paints at a fixed spreading rate (涂料测试方法-D11部分:以固定的涂布率测定浅色涂料的对比度)SAE J1756 Fogging Characteristics of Interior Automotive Materials (Gravimetric or Photometric)(汽车内饰件的雾化特性(重量法或光度法))SAE J2412 Accelerated Exposure of Automotive Interior Trim Components Using a Controlled Irradiance Xenon-Arc Apparatus(汽车内饰件氙灯加速老化测试方法)VDA 270 Determination of the odour characteristics of trim materials in motor vehicles(汽车内饰材料气味特性的测定)3术语和定义下列术语和定义适用于本文件。

Corporate Standard TL 226Ausgabe 2018-04 Klass.-Nr.: 50241Schlagwörter: Lacquer, varnishing, interior decoration, tampon printing, cubic print process, silkscreen, hotstamping, IMD coating, IML coating, PVD lacquered, metal lacquered, glass lacquered Lackierungen auf Werkstoffen der Fahrzeug-InnenausstattungCoatings on Materials of vehicle interiorRequirements(Translated Version)Previous editionsTL 226: 1981-02, 1986-12, 1995-01, 1995-10, 1998-11, 2003-11, 2006-04, 2013-08, 2016-10 ChangesThe following changes have been made to the TL 226:2016-10::–Section 3.1 "Basic requirements" some information specified in table 1–Section 3.4 "Painting process": processing guidelines specified in detail–Section 3.6 "Lacquer systems": Requirements for optics in table 2 revised–Section 3.7 "Finished part properties": Some requirements in table 3 adjusted–Section 4.2 "Abrasion behaviour": Notes on the visual evaluation of painted surfaces and image3 for reference evaluation on a lacquered sample plate added–Section 4.4 "cross section" added–Section 5 "Minimum requirements for supplier series monitoring": Serial monitoring tests adjusted in table 5–Further editorial changes1ScopeThis TL applies to lacquered, Tampon printed, Screen printed, heat-seal embossed, IMD (In-mold Decoration)-coated, IML (in-mold-labeling)-coated, laminated in cubic-print Coated metallic and non-metallic materials, which are Vehicle interior.Norm vor Anwendung auf Aktualität prüfen.Seite 1 von 13Die elektronisch erzeugte Norm ist authentisch und gilt ohne Unterschrift.Fachverantwortung NormungGQL-P/3 Kenny Strehlow Tel.: +49 5361 9-76941GQL-P/3 Eckart Herrmann Tel.: +49 5361 9-42116 K-ILI/5 Ute Hager-Süß K-ILIGQL-P Denis Eschwey Tel.: +49 5361 9-49035 Uwe WiesnerAlle Rechte vorbehalten. Weitergabe oder Vervielfältigung ohne vorherige Zustimmung einer Normenabteilung des Volkswagen Konzerns nicht gestattet.© Volkswagen Aktiengesellschaft VWNORM-2016-12Seite 2TL 226: 2018-042 2.1 Designation Plastic coatingExamples of drawing entries:2k-decorative paint According to TL 226, S (30 ± 5) µm OrO r Or2k-decorative haptic paint According to TL 226, S (35 ± 5) µmEffect paint According to TL 226, s total construction (65 ± 10) µm Layer structure: 1. Primer (15 ± 3) µm2.Base coat(35 ± 4) µm3.Clear coat (15 ± 3) µmEffect paint using an IMD-method according to TL 226, S (15 ± 5) µmWith s = dry layer thickness, k = components2.2 Metal CoatingExample of drawing entry:Powder topcoat According to TL 226, layer structure according to TL 2563RequirementsIf the following requirements for certain components or parts of parts are to be limited or not applied, this must be coordinated with the responsible departments and indicated in the drawing accordingly..3.1Basic requirementsApproval of first delivery and change according to VW01155.Emission behaviour according to VW 50180.Avoidance of hazardous substance according to VW91101.Flammability according to TL 1010New products must be used for the base material.The properties of the finished part and the required technological characteristic data must not be impaired by the paintwork.For all parts to be ship, the information given in table 1 shall be provided by the supplier..Seite 3TL 226: 2018-04 Table 1-Supplier informationGeneral SupplierContact person, tel./e-mail Part numberPart designationBlankl(Also be specified for IMD/IML components)Plastic parts Manufacturer, locationBasic material (plastic type, manufacturer, manufacturer name)Number of cavities in the tool, surface of the cavity (degree of polish, grain etc.)Mass temperatureTool temperaturefor development parts:Stand Blank (spray date, optimizations made)Painting Painting operation and plant (type, design, air conditioning), location Paint DateCoating structure(Paint system, paint manufacturer, layer thicknesses)Hue/Color IndicatorPretreatment(Cleaning: e.g. ionized air; Activation: e.g flame treatment)Photo with arrangement of the parts in the framefor development parts:Stand painting process (optimizations made)Mixing ratios of the componentsProcess Management(Continuous/discontinuous; Curing: UV/thermal)IMD, IML IMD/IML Component manufacturing plant, location(For IML components: manufacturing plant and place of preform) Date of manufactureLayer structure of the IMD-/IML coating(foil manufacturer, carrier film, coating thickness, paint system) Color / Styling / color codeCuring: UV/Thermal3.2Appearance and tactile propertiesParts must have a uniform appearance on the entire surface and conform to the drawing requirements, as well as the release pattern for color, gloss, and haptics..Pores, cracks, painters, dust inclusions, spots of incidence, blowholes, bubbles, flow lines and other defects which impair the prescribed appearance are not permissible.Documentation regarding color and gloss is carried out in the first sample test report according to VW 50190.Seite 4TL 226: 2018-043.3Open-air weatheringOpen-air weathering according to VW 50185. Complaints from this test procedure oblige the supplier to discontinue the complaints and to improve the surface..3.4Painting ProcessThe coating process must be coordinated between the paint shop, the paint manufacturer and the injection molder. The system supplier confirms this in the initial sample test report, i.e. it bears the responsibility to fill the aforementioned requirements.Responsibility is divided as followings:–The paint manufacturer informs about the fulfilment of TL requirements, provides its processing guidelines and gives application technical support.–The paint shop furnishes informs about the underground (plastic type and trade name), earliest checks the requirements (also for pre-production parts), confirms compliance with the processing guidelines (e.g. drying time, temperature, humidity) of the Manufacturer and calls for application technical assistance.–The injection molder keeps the processing guidelines from the raw material. The substrate/blank must be able to paint in a process-safe. No damage to the raw material may be caused by the injection molding process, so that the varnishing ability is not adversely affected.3.5ConditioningAll samples delivered for inspection must be preconditioned by the supplier as follows:7 days at room temperature with a narrow air temperature range (18 °c to 28 °c) or 48 h at 60 °c. After every environmental/ heat aging process listed in Table 3, No. 4.1, 4.2, 5.1, 5.2, 5.3, 5.4. The parts must be conditioned 1 h at 18 °C to 28 °C. The visual evaluation, as well as the tests as per table 3, consec.no.2 and table 3, consec.no.3 are then performed..For those aging processes carried out in climatic chambers and heat chambers, the component being tested must be positioned in as-installed position, to the extent possible.3.6Paint systemsSee Table 2.Seite 5TL 226: 2018-04 Table 2 – Paint systemsPaint systemsRequirements forAppearance Symbols TactilepropertiesAcoustics Dry layer ThicknessS in µm2K-decorative paintAccording to the article or data of the digital record according to theVW 50190 (Color, Gloss)Lasermarking,tamponprinting, hotstamping(must be recordedin the drawingsNote)According torelease/Drawing entry[haptics:Subjectiverequirement ofsoftness (tactilesensation)]According torelease/Drawing entry(acoustics:improvementregardingsqueaking,squeak andother noisescompared tothe unpaintedcomponent)According torelease/Drawing entry(for multi-layerconstruction, the totaland single-layerthicknesses must bespecified on thedrawing)2K-decorative soft-touchpaint2K-soft touch paintEffect paint (e.g.metallics, Black HighGloss)Effect paint using IMDmethod, IML method,,cubic Print methodPVD coatedNOTE: For matte painting systems, scar-resistant systems must always be used.3.7Fished-part propertiesSee Table 3.Table 3 –Fished-part propertiesNr.Property Requirement1 Appearance and tactile properties in the delivery state Parts must be on the entire surface of aHave a uniform appearance and correspond to thedrawing requirements as well as the release patternfor haptics, gloss and color.Pores, cracks, lacquered runners and otherdefects which impair the prescribed appearanceare not permissible.Documentation regarding colour and gloss is in thefirst sample test report according to VW 50190.2 Adhesion2.1Cross-cut testas per DIN EN ISO 2409with subsequent, sudden tear-off the adhesivetape (Tape: Tesa 4657 a))Cross-cut test characteristic value ≤ 1Seite 6TL 226: 2018-04Nr.Property Requirement2.2Cross-cut test (St.Andrew’s cross)With subsequent, sudden tear-off of the adhesivetape (Tape: Tesa 4657 a))The cross-cut test (St.Andrew’s cross) must be performedwhen, for geometrical reasons, no cross-cut test can beperformed on the component.The test is performed with a cutting blade (e.g. cutterEdding Cutter M9 a)) with a sharp blade perpendicular tothe surface. Before gluing the adhesive tape, clean thecutting surface with a brush.Test characteristic value ≤ Note 2 (See Section 4.4)3 Scratch resistanceTest with Erichsen hardness test pencil Type 318 a)or Type 318 S a) with a 10 N load and a Bosch testtip (Ø 0,75 mm)A tear-off (material removal) of the paint is not Allowed.An impression caused by the load on the substrate is permissible.4 Temperature and climate change resistance4.1Heat resistance in the heat cabinet (a forced-air oven)–Components in the indirect irradiation area of the sun (e.g. decorative panels in the vertical area ofthe instrument panel): storage time 240 h, storagetemperature (90 ± 2) °c–Components in the transition area of the sun (e.g.ventilation nozzles, Steering wheels): Storage time500 H, storage temperature (105 ± 2) °c–Components in the direct irradiation area of the sun(e.g. defrost channel, upper Panel instrument panel):storage time 500 H, storage temperature (120 ± 2) °c Color Evaluation:Authenticity note of the grey scale ≥ 4 as per DIN EN 20105-A02.No change in appearance and haptics (e.g. cracking, blisters, colour handling, surface formation, delamination, softening, deformation) compared to the delivery condition.The requirements for adhesion and scratch resistance in accordance with table 3, No. 2 and Table 3, No. 3 must be met..4.2Climate change test8 Cycles as per PV 12005 Weather resistance and aging resistance5.1Condensation atmosphere with constant humidityas per DIN EN ISO 6270-2 CH, test duration 240 h No visible change from the delivery state.The requirements for adhesion and scratch resistance in accordance with table 3, No. 2 and Table 3, No. 3 must be met..Seite 7TL 226: 2018-04Nr. PropertyRequirement5.2Light fastnessTesting as per PV 1303Number of exposure periods as per drawing note (Fornotes on the classification based on as-installed position, see section 4.1) Color Evaluation:Authenticity note of the grey scale ≥ 4 as per DIN EN 20105-A02.No change in appearance and haptics (e.g. cracking, blisters, colour handling, surfaceformation, delamination, softening, deformation) compared to the delivery condition.The requirements for adhesion and scratch resistance in accordance with table 3, No. 2 and Table 3, No. 3 must be met..5.3Hydrolysis aging72 h at (90 ± 2) °C and (95 ± 3) % relative humidity in the climatic chamber(The formation of water droplets on the component must be prevented by suitable positioning in the climatic chamber)5.4 Sunlight Simulation240 h as per DIN 75220–D–IN1–T 5.5Corrosion behaviour(Only for painted metallic materials) 96 h neutral salt spray test(NSS) as perDIN EN ISO 9227– No Bubbles–No base metal corrosion6 Resistance to chemicals and behavior on exposure to abrasion 6.1Abrasion behavior: Testing as per PV 3906 b)A polyether urethane foam must be used as a backing between the cylindrical rubbing stud and the nettle fabric (see Section4.2).6.1.1 2 000 double strokes dry (for components in high-loadRange: e.g. steering wheel, controls, buttons, switch-handle)Painted surface: ≤ note 2 as per PV 3906 Changes shall only be indicated if they cannot be removed with a cloth moistened with distilled water. Friction Fabric:Bleeding of the frictional tissue according to the authenticity note of the grey scale ≥ 4 as per DIN EN 20105-A036.1.2 100 double strokes dryPainted Surface: Note 1 according to PV 3906. Changes shall only be indicated if they cannot be removed with a cloth moistened with distilled water. Friction Fabric:Bleeding of the frictional tissue according to the authenticity note of the grey scale ≥ 4 as per DIN EN 20105-A03 6.1.3 100 double strokes wet (distilled water)6.1.4 10 double strokes with 0.5 volume percent tenside,e.g. Pril ® a)6.1.5 10 double strokes with ammoniac, alcoholic cleaningsolution, e.g. Ajax® glass cleaner a) 6.1.6 10 double strokes with cleaning gasoline(Boiling range 80 °c to 100 °c)6.1.7 10 double strokes with alcohol[Ethanol 99%, denatured with 1% methyl ethyl ketone, for analysis (e.g.)]6.1.8 10 double strokes with synthetic welding solution A[Volume component φ (acetic acid) = 0.75% in water]6.1.9 10 double strokes with synthetic welding solution B[Ammonia mass share w (NH3) = 0.036% and sodiumchloride w (nacl) = 0.5% in water [approach: 1 g NH3-lo-Sung (25%, for example) with distilled water to 690.72 g (in Praxi: 691 g) and add 3.47 g NaCl]]Seite 8TL 226: 2018-04Nr. Property Requirement6.2Drop testWith the aid of a pipette, droplets of 0.1 ml are applied to the surface and dried 30 minutes after 10 minutes of reaction time at 60 °c. The surface should be assessed 24 hours after the impact. Formulation of the media see table 3, No 6.1.6.2.1 Surfactant SolutionNo visible change from the delivery state. Changes shall only be indicated if they cannot be removed with a moistened cloth by distilled water.6.2.2 Supply Grant, alcoholic washing solution 6.2.3 Cleaning gasoline 6.2.4 Alcohol6.2.5 Synthetic welding Solution A 6.2.6 Synthetic Welding Solution B 6.3Cream resistance as per PV 3964No change in appearance and haptics (e.g. crow's feet,Swelling, cracking, softening, stickiness) compared to the delivery condition. A slight gloss increase is permissible.Color assessment for Matt Coating systems: The authenticity note of the grey scale ≥ 4 according to DIN en 20105-A02.The requirements for adhesion and scratch resistance in accordance with table 3, No. 2 and Table 3, No. 3 must be met..7Scrub resistance (micro-scratch resistance) of high-gloss surfaces b) as per PV 3987–Requirement A (high abrasion resistance): relative gloss change ≤ 15% –Requirement B (mean abrasion resistance): relative gloss change ≤ 40% –The determination of the requirement is based on the component position/surface (see section 4.3) and in consultation between the responsible departments and the relevant materials engineering.a) Tesa 4657 Is the manufacturer's name of the product, manufactured by Tesa SE.Edding Cutter M9 Is the manufacturer's name of the product, manufactured by Edding AG.Erichsen-Härteprüfstab Typ 318 or Type 318 S Are the manufacturer's designations of the product, manufactured by Erichen GmbH & Co. KG.Pril® Is the manufacturer's name of the product, manufactured by Henkel AG & Co. kgaa.Ajax-Scheibenreiniger® Is the manufacturer's name of the product, manufactured by Colgate-Palmolive Company.D This information is intended only to inform the users of this works standard and does not imply any recognition of theaforementioned products by the Volkswagen Group. Equivalent products may be used if they are demonstrably to produce the same results.b) If due to the component geometry it is not possible to carry out the test, the test must be carried out on a flat plate that has beenpainted by the production process..Seite 9 TL 226: 2018-044 4.1 Notes on testing LightfastnessThe number of exposure periods to be included in testing can be found in the engineering drawing. Table 4 provides an overview of the component areas and the accociated number of exposure periods..Table 4Components Number of periodsHat shelves, linings in open trunks, upper part of the dashboard panel (e. g. Air distributorbehind the windshield)10Steering wheel, Interior rearview mirror 6 Dashboard (e.g. decorative materials), center console, seat backrest, head restraints 5Door panels, direct irradiation area (e.g. parapet) 5Door panels, area with indirect irradiation (e. g. Door decorative materials in the lower doorpanel area)3Pillar trims exposed to direct irradiation 5Pillar trims exposed to indirect irradiation 3Seats, lower area (e. g painted seat adjustment buttons) 3Steering column shrouds 3Molded headliner (e. g button for interior light) 2 Concealed components (button for opening the trunk lid/tailgates) 24.2Abrasion behaviorA polyether urethane foam (foam as per DIN EN ISO 12947-1, table “Requirements for properties of polyether urethane foam”) must be used as the backing between the cylindrical rubbing stud and nettle fabric (undyed nettle fabric as per DIN ENISO 105-X12 (see figure 1 and figure2 ).Figure 1-Nettle fabric and foam Figure2- Nettle fabric fined on the rubbingstud, including foam backingSeite 10TL 226: 2018-04–The visual evaluation of the painted surface is made as per PV 3906 (section "evaluation") according to the following notes (reference evaluation on a lacquered sample plate see Figure 3):– Note 1 = No visible change, e.g. No friction marks– Note 2 = Slight change, e.g. weakly identifiable friction marks – Note 3 = Significant change, such as color change, surface injury –Note 4 = Strong change, e.g. visibility of the basic materialFigure 3 – Reference evaluation on a lacquered sample plate4.3Abrasion resistance of high-gloss surfacesClassification of request areas: – Requirement A:–Components that have a high-gloss surface, are located in the directly visible area or with in direct reach of the occupants, and are exposed to high loads: e.g. steering wheel trim panel, center console, navigation system/ air-conditioning system trim panel, large-surface decorative components/ decorative trims of the dashboard. – Functional components: e.g. switches, infotainment system, door handle –Requirement B:– Components that have a high-gloss surface, are located in the indirectly visible area orwithin indirect reach of the occupants, and are exposed to less severe loads: e.g., decorative components in the area of the door side panel, windshield decorative insertIMD/IML surfaces in combined high-gloss/matte design are considered high-gloss if at least 75% of the surface is high-gloss.The requirement for the respective component is specified in consultation between theappropriate Materials Engineering department and other appropriate departments.Seite 11TL 226: 2018-044.4 Cross SectionAfter jerky pulling off of the adhesive tape, the assessment of the liability value is made according to the following notes (schematic representation of the cross section values see Figure 4):– Note 1 = No deposition or removal of the coating– Note 2 = Low oversight removal of the coating on the cuts up to 0.5 mm on each side – Note 3 = Removing the coating on the cuts larger than 0.5 mm on one or more sides –Note 4 = Large-scale removal of the coatingFigure 4 – Cross section parameters5 Minimum requirements for supplier series monitoringIn order to ensure the tested and approved quality of the components in the current series, the supplier must carry out and document the series-accompanying tests according to table 5 onthe lacquered parts.Seite 12TL 226: 2018-04Table 5-Serial monitoring testsTesting as per TL 226 Property For each production shift, per colorQuarterly per componentand colorTabelle 3, lfd. Nr. 1 Color, Gloss × × Tabelle 1Thickness × × Tabelle 3, lfd. Nr. 2 a) Paint adhesion × × Tabelle 3, lfd. Nr. 3 Scratch resistance × × Tabelle 3, lfd. Nr. 5.3 Hydrolysis Aging b) – × Tabelle 3, lfd. Nr. 6.3Cream resistance–×Additionally for UV and high-gloss coatings Tabelle 3, lfd. Nr. 7Scrub resistance c)–×a) Testing of adhesion of each production shift per color can be performed without pre-conditioning..b) For monitoring conformity of production, performance of hydrolysis aging is also possible in the desiccator with temperature andhumidity monitoring..c) If the test cannot be performed due to the component geometry, the test must be performed on a flat plate which has been paintedin advance using the same process as n production..6 Other applicable documentsThe following documents quoted in the standard are required for the application of this standard: PV 1200Vehicle Parts; Testing of Resistance to Environmental Cycle Test (+80/-40) °CPV 1303 Non-Metallic Materials; Xenon Arc Light Aging of Vehicle Interior ComponentsPV 3906 Non-Metallic Planar Materials; Testing of Abrasion BehaviorPV 3964 Surfaces in the Passenger Compartment; Testing of Cream Resistance PV 3987 Scrub Resistance (Micro-Scratch Resistance) of High-Gloss Surfaces in the Vehicle InteriorTL 1010 Materials for Vehicle Interiors; Burning Behavior; Material Requirements VW 01155 Vehicle Parts; Approval of First Supply and Changes VW 50180 Components in the Vehicle Interior; Emission Behavior VW 50185 Vehicle Parts; Resistance to Open-Air WeatheringVW 50190 Interior Trim Components; Metrological Evaluation of Color and Gloss Level; Visual Evaluation of Chrome SurfacesEnvironmental Standard for Vehicles; Vehicle Parts, Materials, Operating Fluids; Avoidance of Hazardous Substances DIN 75220 Ageing of automotive components in solar simulation unitsDIN EN 20105-A02 Textiles - Tests for color fastness - Part A02: Grey scale for assessing change in colorTextiles - Tests for color fastness - Part A03: Grey scale for assessing stainingVW 91101 DIN EN 20105-A03Seite 13TL 226: 2018-04Textiles - Tests for color fastness - Part X12: Color fastness to rubbingTextiles - Determination of the abrasion resistance of fabrics by the Martindale method - Part 1: Martindale abrasion testing apparatus DIN EN ISO 2409 Paints and varnishes - Cross-cut testDIN EN ISO 6270-2Paints and varnishes - Determination of resistance to humidity - Part 2: Procedure for exposing test specimens in condensation-water atmosphereCorrosion tests in artificial atmospheres - Salt spray testsDIN EN ISO 105-X12 DIN EN ISO 12947-1 DIN EN ISO 9227。

分类号:Nr..50 24 1 2003年11月保密:保留所有权利。

未经大众汽车集团标准部门事先书面批准,不得传播或复制。

来源N O L I S :使用之前要检查标准的实用性允许成品件的性质或要求的工艺参娄涂漆时在允许的内受到影响涂层/涂漆和修理涂漆应在基质(基础)上或在第1层漆上粘牢。

修理涂漆应做标记。

对所有要做试验的零件,应由供货商提供下述参数:1 基础材料的数据(制造厂名称和VDA-标记)2 色调3 预处理a)净化,例如,用异丙醇b)表面活化,例如,通过燃烧c)其它表面处理,例如,磷酸锌处理4 漆层结构(所有参数的定义)例如,2K—软漆或Haptik(手感)漆,底漆XYZ,公司XYZ,配料XYZ底漆XYZ,公司XYZ,配料XYZMV10:X,混合比例应根据漆决定,用硬XYZ,公司XYZ,配料XYZ,油漆工,油漆工的Audietierung说明。

5 涂漆设备6 涂漆地点7 涂漆日期3.2 外观和手感零件应在整个面上具有均匀的外观并符合图纸要求的鉴定样品的手感、光亮度和颜色。

不允许有影响外观的气泡、裂纹、油漆流条。

颜色和光亮度规定在首件样品试验报告里(按VW 501 90)3.3 大气曝露(风化)大气曝露试验按VW 501 85标准规定进行。

由供货商负责满足试验要求和改善油漆结构。

3.4 涂漆过程(方法)涂漆过程(方法)应在油漆工和油漆制造厂之间商定。

双方确认的方法规定在首件样品试验报告里,也就是双方负责满足列举的要求。

这个要求如下述:-油漆制造厂通报满足TL-要求的情况,以供加工时使用和对使用技术提供帮助。

-油漆工应了解基质(塑料类型和商用名称),检验要求(对于试制零件;至少检验附着性),确认遵守油漆制造厂的加工准则和应用技术的辅助要求。

3.5 预处理所有为试验提供的样品应进行下述预处理:在18至28℃室温条件下,放置7天或在60℃时放置48h。

试验后,零件应至少调节30min,然后进行肉眼鉴定。

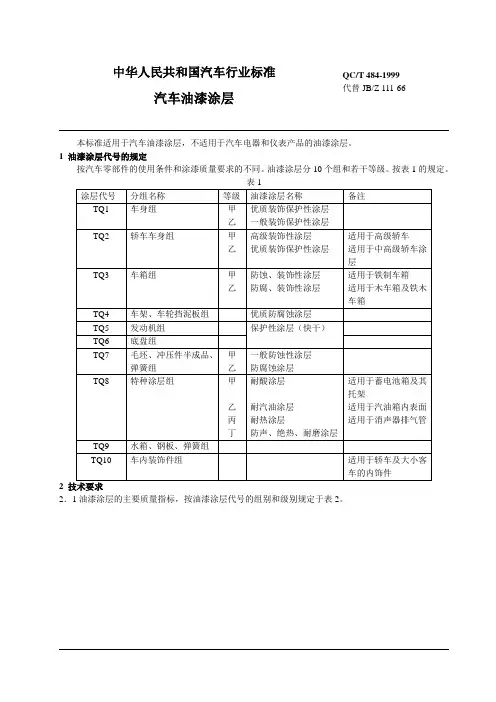

中华人民共和国汽车行业标准汽车油漆涂层本标准适用于汽车油漆涂层,不适用于汽车电器和仪表产品的油漆涂层。

1 油漆涂层代号的规定按汽车零部件的使用条件和涂漆质量要求的不同。

油漆涂层分10个组和若干等级。

按表1的规定。

表12 技术要求2.1油漆涂层的主要质量指标,按油漆涂层代号的组别和级别规定于表2。

QC/T 484-1999 代替JB/Z 111-662.2整车的漆膜应完整,不允许有露底(包括焊缝、封闭内腔)和碰伤的表面。

在总装的过程中,应加强对车身及覆盖件的油漆涂层的保护。

在总装后车架、底盘等应补漆。

2.3汽车零部件油漆涂层的颜色,本标准不做统一规定。

由各企业根据零部件的用途和用户的要求确定。

3 标注根据汽车各零部件的使用条件、涂层质量要求,选择油漆涂层的代号和等级。

例如:高级轿车车身装饰性涂层,在产品图纸上的标注如下:漆以TQ2甲QC/T484-1999。

4 检验4.1油漆涂层质量指标的检验方法,按下述规定:4.1.1漆膜外观:与标准版目测比较。

4.1.2漆膜光泽:按GB/T1764-1979《漆膜光泽度测定法》测定。

4.1.3漆膜厚度:按GB/T1764-1979《漆膜厚度测定发》测定。

4.1.4冲击强度:按GB/T764-1979《漆膜耐冲击测定法》测定。

4.1.5弹性:按GB/T1731-1979《漆膜柔韧性测定法》测定。

4.1.6硬度:按GB/T1730-1979《漆膜硬度测定发(摆杆法)测定》。

4.1.7耐碱性:采用以下两种检验方法测定:a)把涂漆的样板,浸入泥土80±2℃的碳酸氢钠水溶液中,经过是10min后,检查漆膜被溶解的状况;b)把涂漆的样板,浸在55±1℃含0.1 NaOH水溶液中,经过10min后,检查漆膜被溶解的情况。

4.1.9耐酸性:将0.1NH3SO4溶液,滴在被试样板上,在20℃下经过24h后观察漆膜变化情况4.1.10耐水性:将样板浸在50±1℃的恒温水浴中,观察漆膜变化情况,加温在50±1℃保持8h,然后停止加热,在保温的设备中自然冷却16h为一个周期。

附件A(标准化)国际材料数据系统(IMDS)中材料数据卡(MDB)的技术要求 A.1 目的 本附件定义了大众公司接受国际材料数据系统(IMDS)的材料数据卡(MDB)时应遵循的准则。

要遵守这里面的规则,就必须避免: —首次样件过程中出现干扰 —从供货厂来的材料数据卡,必须进行校对,否则它将被大众公司拒绝。

A.2 适用范围 该标准适用于连同汽车一起交货给用户的配件,制品和全部物质材料,这些数据是首次样品试验报告的组成部分,它们最晚在首次样品试验之前必须提供。

A.3 符号 红色正方形是用来代表总成(ZSB),次总成(次ZSB)或一个单件。

红色正方形代表一个总成,在总成下一级也只允许红色正方形出现,因为它代表了组成该总成的所有零件。

黄色的圆圈代表半成品。

半成品就是有待继续加工的在制品。

半成品可以在下一级结构树中上由半成品组合而成。

半成品符号主要是用于卷轴纺织品(地毯),规定厚度的钢板,玻璃丝垫,坯件等等。

两个绿色小圆圈是表示材料的符号。

材料可以在下一级通过材料或高纯物质来描述。

材料可以通过外貌来描述,它们在成品中以何种形式存在(例如时效硬化的粘合剂,焙烧的油漆)。

符号用于复合材料及单一材料。

兰色三角形表示高纯物质。

高纯物质并不必然是化学概念上纯的物质,它也可能是一种混合物。

对这种物质,没有必要再把其各种成分区分开来。

高纯物质理应只归类于单一材料。

高纯物质特殊情况: —保密高纯物质(见 A.4.9条) —未知材料(见 A.4.10条) A.4 规则 接到材料数据卡(MDB)时,如下各种情况必须检查:—VW-零件号—零件名称—结构树(体系)—零件范围的完整性—材料名称—商品名称—材料分类按 VDA 231-106—保密高纯材料—未知材料(Joker)的应用—按VDA 232-101 的规定严格禁止的高纯材料和有义务申报的高纯材料—用于样件提供的数据(图号、图纸状态、供货厂代码) A.4.1 零件号 在“信息接收”卡中,VW 零件号是根据标准VW 01098给出。

TL226 2006年4月主题词:油漆, 涂漆,施漆, 油漆作业,内饰配件,移印,擦子压强,热压印热封,IMD(内部装饰件),立体印刷变化与2003年11月版TL226相比,有以下变化:-表1修订- 2.1.1章,塑料材质涂层样件描述进行了修正- 3.8章“耐刮擦”进行了修正- 3.10.1章“热老化“修正- 3.15增加“耐乳霜”测试-参考标准进行更新-标准重组与上一版本相比有改变的地方已经用竖线标识。

之前版本:1981-02, 1986-12, 1995-01, 1995-10, 1998-11, 2003-111. 范围本标准适用于施漆工艺,移印,热封和IMD (内部装饰件) –涂层, 涂漆的金属和非金属材料立体印刷,即汽车室内使用。

2.描述2.1样件描述2.1.1塑料涂层双组分装饰涂料,按TL 226,S 15 to 30 μm双组分装饰触摸涂料,按TL 226,S 30 to 50 μm2.1.2金属涂层面漆粉末根据TL226, 涂层机构根据TL256.3 要求下面技术要求,如果对某种构件或一定范围内的构件在使用上受到限制或不宜使用,则在图纸上应有说明.3.1 基本技术要求首次供货和更改的批准根据VW01155避免有害物质按VW 911 01对于一次圆满试验,至少需要5件成品部件或总面积为0.5 m2的零件成品部件的性能、也就是所要求的技术参数,如果由于上漆而受到损害,一定要锁定在允许范围之内.涂层/油漆和潜在的修补油漆应该牢固的粘附与基层或原始漆层上。

修补漆区域应该标示出来。

供应商应该提供所有零件的以下信息:1.基面材料的说明(制造商名称和VDA(汽车工业联合会)标记)2.颜色3.预处理4.油漆结构a)清晰,例如用异丙醇b)表面活化,例如曝露与火焰c)其他表面处理,例如锌磷化5.油漆机构(所有参数定义)6.上漆位置7.上漆日期3.2 外观及触觉特性零件的整体表面应显现出一致的外观;应符合图纸要求并为触感特性,光泽,颜色释放样件。

作伙伴可通过相关采购部门提取本标准。

3.2 基本要求

有关首次交付和相关更改的审批程序,执行标准为VW 011 55。

有关有害物避用,执行标准为VW 911 01。

一次全面性的试验需要8个零件。

所使用的涂层,不得含有铬或铅化合物。

3.3 基本工料

按图纸。

3.4 保护形式/外观

参考表格1。

图纸里如无特别标示,颜色分别为黑色。

3.5 预处理

如使用空气干燥式涂敷系统,以及/或者涂装系统在工作温度超过60℃时便中止烘烤作业,则部件应在试验前接受24小时以及60℃的预处理过程。

然后,试样应按照DIN 50014中的要求冷却至室温(18℃至28℃)。

3.6 涂层厚度

请参阅表格2。

接合缝以及涂敷面的层厚是有限制的,具体的限制参数需在相关图纸内注明。

表2

3.7 粘合力和脆性

用符合DIN EN ISO 2409的涂层网格进行检验。

要求:参数0至1。

3.8 涂层石击强度试验

用DIN 55996-1中的方法B进行检验,目测判断试验结果。

要求:小于或等于参数2。

Q_JLYJ7110550A-2012汽车塑料内饰件油漆涂层技术要求Q/JLY J7110550A-2012汽车塑料内饰件油漆涂层技术要求<秘密级>编制:李丽娜校对:康平平审核:蔡孝审定:魏宪波标准化:伍永会批准:韦兴民浙江吉利汽车研究院有限公司二○一二年三月前言本标准替代了Q/JLY J711085-2009《汽车塑料内饰件油漆涂层技术要求》,本标准与Q/JLY J711085-2009的主要差异为:——修改了规范性引用文件的语言描述;——更改并增加了部分引用的标准及标准号,由修改前的“GB/T 1723-1993涂料粘度测定方法”修改为“Q/JLY J7110090A-2010涂料粘度测定方法”,“GB/T 6739-2006色漆和清漆铅笔法测定漆膜硬度”修改为“Q/JLY J711372-2009铅笔法测试油漆涂层硬度”,“GB/T 9274-1988色漆和清漆耐液体介质的测定”修改为“Q/JLY J711226-2009复合涂层耐酸碱性测定方法”和“Q/JLY J711253-2009 复合涂层耐汽油性测定方法”;增加了“GB 24409-2009汽车涂料中有害物质限量”、“GB 17930-2011车用汽油”和“Q/JLY J7110088A-2010涂料贮存稳定性试验方法”的引用;删除了“Q/JLY J711092-2008汽车塑料外饰件用底漆涂料标准”;——增加了“贮存稳定性”、“限用溶剂含量”和“重金属含量”三项原漆性能要求及相关试验方法;——更改了耐碱性、耐酸性和耐汽油性的试验方法;——对引用标准的标准号及名称做了更新。

本标准由浙江吉利汽车研究院有限公司提出。

本标准由浙江吉利汽车研究院有限公司整车试制部负责起草。

本标准起草人:李丽娜。

本标准于2012年3月31日发布,2012年4月16日实施。

本标准所替代的标准更替情况为:——Q/JLY J711085-2009(2009年4月20日首次发布)1 范围本标准规定了汽车塑料内饰件油漆涂层的技术要求和试验方法。

TL226 2006 年4月主题词:油漆, 涂漆,施漆, 油漆作业,内饰配件,移印,擦子压强,热压印热封,IMD(内部装饰件),立体印刷变化与2003 年11 月版TL226 相比,有以下变化:- 表1 修订- 2.1.1 章,塑料材质涂层样件描述进行了修正- 3.8 章“耐刮擦”进行了修正- 3.10.1 章“热老化“修正- 3.15 增加“耐乳霜”测试- 参考标准进行更新- 标准重组与上一版本相比有改变的地方已经用竖线标识。

之前版本:1981-02, 1986-12, 1995-01, 1995-10, 1998-11, 2003-111. 范围本标准适用于施漆工艺,移印,热封和IMD (内部装饰件)–涂层, 涂漆的金属和非金属材料立体印刷,即汽车室内使用。

2. 描述2.1 样件描述2.1.1 塑料涂层双组分装饰涂料,按TL 226, S 15 to 30 μm 双组分装饰触摸涂料,按TL 226, S 30 to 50 μm2.1.2 金属涂层面漆粉末根据TL226, 涂层机构根据TL256.3 要求下面技术要求,如果对某种构件或一定范围内的构件在使用上受到限制或不宜使用,则在图纸上应有说明.3.1 基本技术要求首次供货和更改的批准根据VW01155 避免有害物质按VW 911 01 对于一次圆满试验,至少需要5件成品部件或总面积为0.5 m2的零件成品部件的性能、也就是所要求的技术参数, 如果由于上漆而受到损害,一定要锁定在允许范围之内.涂层/油漆和潜在的修补油漆应该牢固的粘附与基层或原始漆层上。

修补漆区域应该标示出来。

供应商应该提供所有零件的以下信息:1. 基面材料的说明(制造商名称和VDA (汽车工业联合会)标记)2. 颜色3. 预处理4. 油漆结构a)清晰,例如用异丙醇b)表面活化,例如曝露与火焰c)其他表面处理,例如锌磷化5. 油漆机构(所有参数定义)6. 上漆位置7. 上漆日期3.2 外观及触觉特性零件的整体表面应显现出一致的外观;应符合图纸要求并为触感特性,光泽,颜色释放样件。