一篇关于FPGA的英文文献及翻译

- 格式:doc

- 大小:340.00 KB

- 文档页数:14

关于基于FPGA的波形发生器论文翻译的译文FPGA 技术介绍概述场域可程式化闸阵列(FPGA) 技术正持续发展,而全世界FPGA 市场的产值,则预估可从2005 年的19 亿美金提升到2010 年的27 亿 5 千万美金。

FPGA 是在1984 年由Xilinx 公司所发明,从简单的胶合逻辑(Glue logic) 晶片,演变为可取代客制的特定应用积体电路(ASIC) 与处理器,适用于讯号处理与控制应用。

为何FPGA 技术如此成功?此篇文章将介绍FPGA,并说明数项让FPGA 如此独特的优点。

何谓FPGA?最笼统来说,FPGAs 即为可再程式化的晶片。

透过预先建立的逻辑区块与可程式化路由资源,不需更改面包板或焊锡部分,即可设定这些晶片以建置客制硬体功能。

使用者可于软体中开发数位运算系统(Computing task) 并将之编译为组态档案或位元流(Bitstream),可包含元件接线的相关资讯。

此外,FPGA 完全为可重设性质,当使用者重新编译不同的电路设定时,可立刻拥有不同的特性。

在过去,工程师必须深入了解数位硬体设计,才能够使用FPGA 技术。

然而,高阶设计工具的新技术可针对图形化程式区或 C 程式码,转换为数位硬体电路,即变更了FPGA 程式设计的规则。

FPGA 整合了ASIC 与处理器架构系统的最佳部分,使FPGA 晶片可应用于所有产业。

FPGA 具有硬体时脉的速度与可靠性,且其仅需少量即可进行作业;可降低客制化ASIC 设计的费用。

可重新程式设计的晶片,具有与软体相同的弹性,却不受限于处理核心的数量。

与处理器不同的是,FPGA 为实际的平行架构,因此不同的处理作业并不需要占用相同资源。

每个独立的处理作业均将指派至专属的晶片区块,不需影响其他逻辑区块即可自动产生功能。

因此,当新增其他处理作业时,应用某部分的效能亦不会受到影响。

FPGA 技术的5 大优点效能–透过硬体的平行机制,FPGA 可突破依序执行(Sequential execution) 的固定运算,并于每时脉循环完成更多作业,以超越数位讯号处理器(DSP) 的计算功能。

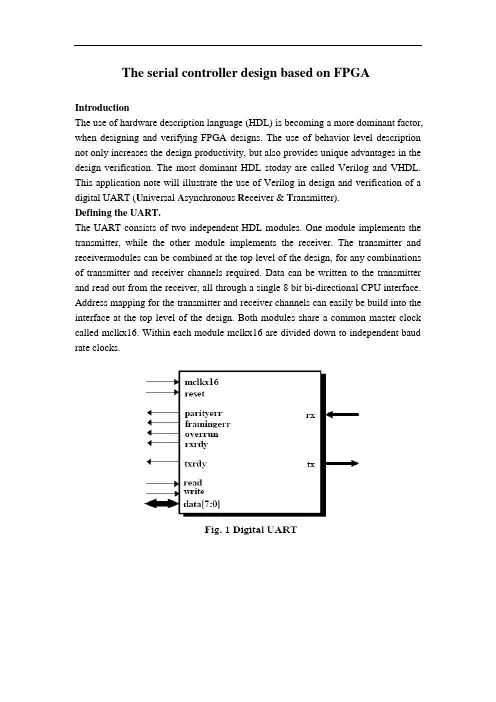

High Level Programming for Real TimeFPGA Based Image ProcessingD Crookes, K Benkrid, A Bouridane, K Alotaibi and A BenkridSchool of Computer Science, The Queen‟s University of Belfast, Belfast BT7 1NN, UK ABSTRACTReconfigurable hardware in the form of Field Programmable Gate Arrays (FPGAs) has been proposed as a way of obtaining high performance for computationally intensive DSP applications such us Image Processing (IP), even under real time requirements. The inherent reprogrammability of FPGAs gives them some of the flexibility of software while keeping the performance advantages of an application specific solution.However, a major disadvantage of FPGAs is their low level programming model. To bridge the gap between these two levels, we present a high level software environment for FPGA-based image processing, which aims to hide hardware details as much as possible from the user. Our approach is to provide a very high level Image Processing Coprocessor (IPC) with a core instruction set based on the operations of Image Algebra. The environment includes a generator which generates optimised architectures for specific user-defined operations.1. INTRODUCTIONImage Processing application developers require high performance systems for computationally intensive Image Processing (IP) applications, often under real time requirements. In addition, developing an IP application tends to be experimental and interactive. This means the developer must be able to modify, tune or replace algorithms rapidly and conveniently.Because of the local nature of many low level IP operations (e.g. neighbourhood operations), one way of obtaining high performance in image processing has been to use parallel computing [1]. However, multiprocessor IP systems have generally speaking not yet fulfilled their promise. This is partly a matter of cost, lack of stability and software support for parallel machines; it is also a matter of communications overheads particularly if sequences of images are being captured and distributed across the processors in real time.A second way of obtaining high performance in IP applications is to use Digital Signal Processing (DSP) processors [2,3]. DSP processors provide a performance improve-ment over standard microprocessors while still maintaining a high level programming model. However, because of the software based control, DSP processors have still difficulty in coping with real time video processing.At the opposite end of the spectrum lie the dedicated hardware solutions. Application Specific Integrated Circuits (ASICs) offer a fully customised solution to a particular algorithm [4]. However, this solution suffers from a lack of flexibility, plus the high manufacturing cost and the relatively lengthy development cycle.Reconfigurable hardware solutions in the form of FPGAs [5] offer high performance, with the ability to be electrically reprogrammed dynamically to perform other algorithms. Though the first FPGAs were only capable of modest integration levels and were thus usedmainly for glue logic and system control, the latest devices [6] have crossed the Million gate barrier hence making it possible to implement an entire System On a Chip. Moreover, the introduction of the latest IC fabrication techniques has increased the maximum speed at which FPGAs can run. Design‟s performance exceeding 150MHz are no longer outside the realm of possibilities in the new FPGA parts, hence allowing FPGAs to address high bandwidth applications such as video processing.A range of commercial FPGA based custom computing systems includes: the Splash-2 system [7]; the G-800 system [8] and VCC‟s HOTWorks HOTI & HOTII development [9]. Though this solution seems to enjoy the advantages of both the dedicated solution and the software based one, many people are still reluctant to move toward this new technology because of the low level programming model offered by FPGAs. Although behavioural synthesis tools have made enormous progress [10, 11], structural design techniques (including careful floorplanning) often still result in circuits that are substantially smaller and faster than those developed using only behavioural synthesis tools [12].In order to bridge the gap between these two levels, this paper presents a high level software environment for an FPGA-based Image Processing machine, which aims to hide the hardware details from the user. The environment generates optimised architectures for specific user-defined operations, in the form of a low level netlist. Our system uses Prolog as the basic notation for describing and composing the basic building blocks. Our current implementation of the IPC is based on the Xilinx 4000 FPGA series [13].The paper first outlines the programming environment at the user level (the programming model). This includes facilities for defining low level Image Processing algorithms based on the operators of Image Algebra [14], without any reference to hardware details. Next, the design of the basic building blocks necessary for implementing the IPC instruction set are presented. Then, we describe the runtime execution environment.2. THE USER’S PROGRAMMING MODELAt its most basic level, the programming model for our image processing machine is a host processor (typically a PC programmed in C++) and an FPGA-based Image Processing Coprocessor (IPC) which carries out complete image operations (such as convolution, erosion etc.) as a single coprocessor instruction. The instruction set of the IPC provides a core of instructions based on the operators of Image Algebra. The instruction set is also extensible in the sense that new compound instructions can be defined by the user, in terms of the primitive operations in the core instruction set. (Adding a new primitive instruction is a task for an architecture designer).The coprocessor core instruction setMany IP neighbourhood operations can be described by a template (a static window with user defined weights) and one of a set of Image Algebra operators. Indeed, simple neighbourhood operations can be split in two stages:∙ A …local‟ operato r applied between an image pixel and the corresponding window coefficient.∙ A …global‟ operator applied to the set of intermediate results of the local operation, to reduce this set to a single result pixel.The set of local operators contains …Add‟ (…+‟) and …multiplication‟ (…*‟), whereas the global operator contains …Accumulation‟ (…∑‟), …Maximum‟ (…Max‟) and …Minimum‟ (…Min‟). With these local and global operators, the following neighbourhood operations can be built:For instance, a simple Laplace operation would be performed by doing convolution (i.e. Local Operation = …∑‟ and Global operation= …*‟) with the following template:The programmer interface to this instruction set is via a C++ class. First, the programmer creates the required instruction object (and its FPGA configuration), and subsequently applies it to an actual image. Creating an instruction object is generally in two phases: firstly build an object describing the operation, and then generate the configuration, in a file. For neighbourhood operations, these are carried out by two C++ object constructors:image_operator (template & operator details)image_instruction (operator object, filename)For instructions with a single template operator, these can be conveniently combined in a single constructor:Neighbourhood_instruction (template, operators, filename)The details required when building a new image operator object include:∙The dimension of the image (e.g. 256 ⨯ 256)∙The pixels size (e.g. 16 bits).∙The size of the window (e.g. 3⨯3).∙The weights of the neighbourhood window.∙The target position within the window, for aligning it with the image pixels (e.g. 1,1).∙The …local‟ and …global‟ operations.Later, to apply an instruction to an actual image, the apply method of the instruction object is used:Result = instruction_object.apply (input image)This will reconfigure the FPGA (if necessary), download the input pixel data and store the result pixels in the RAM of the IPC as they are generated.The following example shows how a programmer would create and perform a 3 by 3 Laplace operation. The image is 256 by 256; the pixel size is 16 bits.2.1 Extending the Model for Compound OperationsIn practical image processing applications, many algorithms comprise more than a single operation. Such compound operations can be broken into a number of primitive core instructions.Instruction Pipelining: A number of basic image operations can be put together in series. A typical example of two neighbourhood operations in series is the …Open‟ operation. To do an …Open‟ operation, an …Erode‟ neighbourhood operation is first performed, and the resulting image is fed into a …Dilate‟ neighbourhood operation as shown in Figure 1.Figure 1 ‘Open’ complex operationThis operation is described as follows in our high level environment:Task parallel: A number of basic image operations can be put together in parallel.For example, the Sobel edge detection algorithm can be performed (approximately) by adding the absolute results of two separate convolutions. Assuming that the FPGA has enough computing resources available, the best solution is to implement the operations in parallel using separate regions of the FPGA chip.Figure 2 Sobel complex operationThe following is an example of the code, based on our high level instruction set, to define and use a Sobel edge detection instruction. The user defines two neighbourhood operators(horizontal and vertical Sobel), and builds the image instruction by summing the absolute results from the two neighbourhood operations.The generation phase will automatically insert the appropriate delays to synchronise the two parallel operations.3. ARCHITECTURES FROM OPERATIONSWhen a new Image_instruction object(e.g. Neighbourhood_instruction) is created (by new), the corresponding FPGA configuration will be generated dynamically. In this section, we will present the structure of the FPGA configurations necessary to implement the high level instruction set for the neighbourhood operations described above. As a key example, the structure of a general 2-D convolver will be presented. Other neighbourhood operations are essentially variations of this, with different local and global operators sub-blocks.A general 2D convolverAs mentioned earlier, any neighbourhood image operation involves passing a 2-D window over an image, and carrying out a calculation at each window position.To allow each pixel to be supplied only once to the FPGA, internal line delays are required. These synchronise the supply of input values to the processing elements, ensuringthat all the pixel values involved in a particular neighbourhood operation are processed at the same instant[15, 16]. Assuming a vertical scan of the image, Figure 3 shows the architecture of a generic 2-D convolver with a P by Q template. Each Processing Element (PE) performs the necessary Multiply/Accumulate operation.Figure 3 Architecture of a generic 2-D, P by Q convolution operation Architecture of a Processing ElementBefore deriving the architecture of a Processing Element, we first have to decide which type of arithmetic to be used- either bit parallel or bit serial processing.While parallel designs process all data bits simultaneously, bit serial ones process input data one bit at a time. The required hardware for a parallel implementation is typically …n‟ times the equivalent serial implementation (for an n-bit word). On the other hand, the bit serial approach requires …n… clock cycles to process an n-bit word while the equivalent parallel one needs only one clock cycle. However, bit serial architectures operates at a higher clock frequency due to their smaller combinatorial delays. Also, the resulting layout in a serial implementation is more regular than a parallel one, because of the reduced number of interconnections needed between PEs (i.e. less routing stress). This regularity feature means that FPGA architectures generated from a high level specification can have more predictable layout and performance. Moreover, a serial architecture is not tied to a particular processing word length. It is relatively straightforward to move from one word length to another withvery little extra hardware (if any). For these reasons, we decided to implement the IPC hardware architectures using serial arithmetic.Note, secondly, that the need to pipeline the bit serial Maximum and Minimum operations common in Image Algebra suggests we should process data Most Significant Bit first (MSBF). Following on from this choice, because of problems in doing addition MSBF in 2‟s complement, there are certain advantages in using an alternative number representation to 2‟s complement. For the p urposes of the work described in this paper, we have chosen to use a redundant number representation in the form of a radix-2 Signed Digit Number system (SDNR) [17]. Because of the inherent carry-free property of SDNR add/subtract operations, the corresponding architectures can be clocked at high speed. There are of course several alternative representations which could have been chosen, each with their own advantages. However, the work presented in this paper is based on the following design choices:∙Bit serial arithmetic∙Most Significant Bit First processing∙Radix-2 Signed Digit Number Representation (SDNR) rather than 2‟s complement.Because image data may have to be occasionally processed on the host processor, the basic storage format for image data i s still, however, 2‟s complement. Therefore, processing elements first convert their incoming image data to SDNR. This also reduces the chip area required for the line buffers (in which data is held in 2‟s complement). A final unit to convert a SDNR resu lt into 2‟s complement will be needed before any results can be returned to the host system. With these considerations, a more detailed design of a general Processing Element (in terms of a local and a global operation) is given in Figure 4.Figure 4 Architecture of a standard Processing ElementDesign of the Basic Building BlocksIn what follows, we will present the physical implementation of the five basic building blocks stated in section 2 (the adder, multiplier, accumulator and maximum/ minimum units). These basic components were carefully designed in order to fit together with as little wastage as possible.The ‘multiplier’ unitThe multiplier unit used is based on a hybrid serial-parallel multiplier outlined in [18]. It multiplies a serial SDNR input with a two‟s complement parallel coefficient B=b N b N-1…b1 as shown in Figure 5. The multiplier has a modular, scaleable design, and comprises four distinct basic building components [19]: Type A, Type B, Type C and Type D. An N bit coefficient multiplier is constructed by:Type A → Type B→ (N-3)*TypeC → Type DThe coefficient word length may be varied by varying the number of type C units. On the Xilinx 4000 FPGA, Type A, B and C units occupy one CLB, and a Type D unit occupies 2 CLBs. Thus an N bit coefficient multiplier is 1 CLB wide and N+1 CLBs high. The online delay of the multiplier is 3.In+In-Figure 5 Design of an N bit hybrid serial-parallel multiplierThe ‘accumulation’ g lobal operation unitThe accumulation unit is the global operation used in the case of a convolution. It adds two SDNR operands serially and outputs the result in SDNR format as shown in Figure 6. The accumulation unit is based on a serial online adder presented in [20]. It occupies 3 CLBs laid out vertically in order to fit with the multiplier unit in a convolver design.Figure 6Block diagram and floorplan of an accumulation unitThe ‘Addition’ local operation unitThis unit is used in additive/maximum and additive/minimum operations. It takes a single SDNR input value and adds it to the corresponding window template coefficient. The coefficient is stored in 2‟s complement format into a RAM addressed by a counter whose period is the pixel word length. To keep the design compact, we have implemented the counter using Linear Feedback Shift Registers (LFSRs). The coefficient bits are preloaded into the appropriate RAM cells according to the counter output sequence. The input SDNR operand is added to the coefficient in bit serial MSBF.+-+-Figure 7. Block diagram and floorplan of an …Addition‟ local operation unitOut-Out+The adder unit occupies 3 CLBs. The whole addition unit occupies 9 CLBs laid out in a 3x3 array. The online delay of this unit is 3 clock cycles.The Maximum/Minimum unitThe Maximum unit selects the maximum of two SDNR inputs presented to its input serially, most significant bit first. Figure 10 shows the transition diagram of the finite state machine performing the maximum …O‟ of two SDNRs …X‟ and ‟Y‟. The physical impl ementation of this machine occupies an area of 13 CLBs laid out in 3 CLBs wide by 5 high. Note that this will allow this unit to fit the addition local operation in an Additive/Maximumneighbourhood operation. The online delay of this unit is 3, compatible with the online delay of the accumulation global operation.*(O=X)*(O=Y)X +X --+Figure 8. State diagram and floorplan of a Maximum unitThe minimum of two SDNRs can be determined in a similar manner knowing that Min(X,Y)=- Max(-X,-Y).5. THE COMPLETE ENVIRONMENTThe complete system is given in Figure 11. For internal working purposes, we have developed our own intermediate high level hardware description notation called HIDE4k [21]. This is Prolog-based [22], and enables highly scaleable and parameterised component descriptions to be written.In the front end, the user programs in a high level software environment (typically C++) or can interact with a Dialog-based graphical interface, specifying the IP operation to be carried out on the FPGA in terms of Local and Global operators, window template coefficients etc. The user can also specify:The desired operating speed of the circuit.∙The input pixel bit-length.∙Whether he or she wants to use our floorplanner to place the circuit or leave this task to the FPGA vendor‟s Placement and Routing tools.The system provides the option of two output circuit description formats: EDIF netlist (the normal), and VHDL at RTL level.Behind the scenes, when the user gives all the parameters needed for the specific IP operation, the intermediate HIDE code is generated. Depending on the choice of the output netlist format, the HIDE code will go through either the EDIF generator tool to generate an EDIF netlist, or the VHDL generator tool to generate a VHDL netlist. In the latter case, the resulting VHDL netlist needs to be synthesised into an EDIF netlist by a VHDL synthesiser tool. Finally, the resulting EDIF netlist will go through the FPGA vendor‟s specific tools to generate the configuration bitstream file. The whole process is invisible to the user, thus making the FPGA completely hidden from the user‟s point of view. Note that the resulting configuration is stored in a library, so it will not be regenerated if exactly the same operation happens to be defined again.Complete and efficient configurations have been produced from our high level instruction set for all the Image Algebra operations and for a variety of complex operations including…Sobel‟, …Open‟ and …Close‟. They have been successfully simulat ed using the Xilinx Foundation Project Manager CAD tools.Figure 10 presents the resulting layout for a Sobel edge detection operation on XC4036EX-2 for 256x256 input image of 8-bits pixels. An EDIF configuration file, with all the placement information, has been generated automatically by our tools from the high level description in 2.1. Note that the generator optimises the design, and uses just a single shared line buffer area for the two (task parallel) neighbourhood operations. The resulting EDIF file is fed to Xilinx PAR tools to generate the FPGA configuration bitstream. The circuit occupies 475 CLBs. Timing simulation shows that the circuit can run at a speed of 75MHz which leads to a theoretical frame rate of 143 frames per second.Figure 10 Physical configuration of Sobel operation on XC4036EX-2 Figure 11 presents the resulting layout for an 'Open' operation on XC4036EX-2 for 256x256 input image of 8-bits pixels. As previously, EDIF configuration file with all the placement information has been generated, automatically by our tools from the correspondinghigh level description presented in section 2.1. The resulting EDIF file is then fed to Xilinx PAR tools to generate the FPGA configuration bitstream. The circuit occupies 962 CLBs. Timing simulation shows that the circuit can run at a speed of 75MHz which leads to a theoretical frame rate of 133 frames per second.Figure 11 Physical configuration of Open operation on XC4036EX-26. CONCLUSIONSIn this paper, we have presented the design of an FPGA-based Image Processing Coprocessor (IPC) along with its high level programming environment. The coprocessor instruction set is based on a core level containing the operations of Image Algebra. Architectures for user-defined compound operations can be added to the system. Possibly the most significant aspect of this work is that it opens the way to image processing application developers toexploit the high performance capability of a direct hardware solution, while programming in an application-oriented model. Figures presented for actual architectures show that real time video processing rates can be achieved when staring from a high level design.The work presented in this paper is based specifically on Radix-2 SDNR, bit serial MSBF processing. In other situations, alternative number representations may be more appropriate. Sets of alternative representations are being added to the environment, including a full bit parallel implementation of the IPC [23]. This will give the user a choice when trying to satisfy competing constraints.Although our basic approach is not tied to a particular FPGA, we have implemented our system on XC4000 FPGA series. However, the special facilities provided by the new Xilinx VIRTEX family (e.g. large on-chip synchronous memory, built in Delay Locked Loops etc.) make it a very suitable target architecture for this type of application. Upgrading our system to operate on this new series of FPGA chips is underway.REFERENCES[1] Webber, H C (ed.), …Image processing and transputers‟, IOS Press, 1992.[2] Rajan, K, Sangunni, K S and Ramakrishna, J, …Dual-DSP systems for signal and image-processing‟, Microprocessing & Microsystems, Vol 17, No 9, pp 556-560, 1993.[3] Akiyama, T, Aono, H, Aoki, K, et al,…MPEG2 video codec using Image compressionDSP‟, IEEE Transactions on Consumer Electronics, Vol 40, No 3, pp 466-472, 1994. [4] L.A. Christopher, W.T. Mayweather and S.S. Perlman, …VLSI median filter for impulsenoi se elimination in composite or component TV signals‟, IEEE Transactions on Consumer Electronics, Vol 34, no. 1, pp. 263-267, 1988.[5] J. Rose and A. Sangiovanni-Vincentelli, …Architecture of Field Programmable GateArrays‟, Proceedings of the IEEE Volume 81, No7, pp 1013-1029, 1993.[6] /products/virtex/ss_vir.htm[6] Arnold, J M, Buell, D A and Davis, E G, …Splash-2‟, Proceedings of the 4th AnnualACM Symposium on Parallel Algorithms and Architectures, ACM Press, pp 316-324, June 1992.[7] Gigaops Ltd., The G-800 System, 2374 Eunice St. Berkeley, CA 94708.[8] Chan, S C, Ngai, H O and Ho, K L, …A programmable image processing system usingFPGAs‟, International Journal of Electronics, Vol 75, No 4, pp 725-730, 1993.[9] /[10] /news/pubs/snug/snug99_papers/Jaffer_Final.pdf[11] FPL99.[12] Hutchings.[13] Xilinx 4000.[14] Ritter G X, Wilson J N and Davidson J L, …Image Algebra: an overview‟, ComputerVision, Graphics and Image Processing, No 49, pp 297-331, 1990.[15] Shoup, R G, …Parameterised Convolution Filtering in an FPGA‟, More FPGAs, WMoore and W Luk (editors), Abington, EE&CS Books, pp 274, 1994.[16] Kamp, W, Kunemund, H, Soldner and Hofer, H, …Programmable 2D linear filter forvideo applications‟, IEEE Journal of Solid State Circuits, pp 735-740, 1990.[17] Avizienis A, …Signed Digit Number Representation for Fast Parallel Arithmetic”, IRETransactions on Electronic Computer, Vol. 10, pp 389-400, 1961.[18] Moran, J, Rios, I and Mene ses, J, …Signed Digit Arithmetic on FPGAs‟, More FPGAs, WMoore and W Luk (editors), Abington, EE&CS Books, pp 250, 1994.[19] Donachy, P, …Design and implementation of a high level image processing machineusing reconfigurable hardware‟, PhD Thesis, Depar tment of Computer Science, The Queen‟s University of Belfast, 1996.[20] Duprat, J, Herreros, Y and Muller, J, …Some results about on-line computation offunction‟, 9th Symposium on Computer Arithmetic, Santa Monica, September 1989. [21]D Crookes, K Alota ibi, A Bouridane, P Donachy and A Benkrid, 1998, …An Environmentfor Generating FPGA Architectures for Image Algebra-based Algorithms‟, ICIP98, Vol.3, pp. 990-994.[22]Clocksin W F and Melish C S, 1994, …Programming in Prolog‟, Springer-Verlag.。

TranslationThe Micro-architecture of FPGA BasedSoft ProcessorsPeter Yiannacouras, Jonathan Rose, and J. Gregory Steffan Department of Electrical and Computer EngineeringUniversity of Toronto 10 King’s College RoadToronto, CanadaABSTRACTAs more embedded systems are built using FPGA platforms, there is an increasing need to support processors in FPGA. One option is the soft processor, a programmable instruction processor implemented in the reconfigurable logic of the FPGA. Commercial soft processors have been widely deployed, and hence we are motivated to understand their micro-architecture. We must re-evaluate micro-architecture in the soft processor context because an FPGA platform is significantly different than an ASIC platformor, example, the relative speed of memory and logic is quite different in the two platforms, as is the area cost. In this paper we present an infrastructure for rapidly generating RTL models of soft processors, as well as a methodology for measuring their area, performance, and power. Using our automatically-generated soft processors we explore the micro-architecture trade-off space including: (1) hardware vs software multiplication support; (ii) shifter implementations; and (iii) pipeline depth, organization, and forwarding. For example, we find that a 3-stage pipeline has better wall-clock-time performance than deeper pipelines, despite lower clock frequency. We also compare our designs to Altera's NiosII commercial soft processor variations and find that our automatically generated designs span the design space while remaining very competitive.General TermsKeywords Soft processor, FPGA, exploration, micro-architecture, RTL generation, application specific tradeoff, nios, embedded processor, pipeline, ASIP。

FPGA Implementation of RS232 to Universalserial bus converter1 V.Vijaya, (PhD) M.Tech2 Rama Valupadasu (Ph D), M.Tech, 3.B.RamaRao Chunduri, PhD, M.TechAssoc. Professor. VCEW Asst.Professor, NIT, Warangal Professor, NIT, Warangalvsrtej@yahoo.co.in agnivesh91@yahoo.co.in cbrr@nitw.ac.in4. Ch.Kranthi Rekha, M.Tech,5. B.Sreedevi, M.Tech,Asst.Professor Assoc. Professor. VCEWLUC, Mantin, Malaysia vaagvijs_15@yahoo.co.inmadakranthirekha@yahoo.co.inAbstract— Universal Serial Bus (USB) is a new personal computer interconnection protocol, developed to make the connection of peripheral devices to a computer easier and more efficient. It reduces the cost for the end user, improves communication speed and supports simultaneous attachment of multiple devices (up to127)RS232, in another hand, was designed to single device connection, but is one of the most used communication protocols. An embedded converter from RS232 to USB is very interesting, since it would allow serial-based devices to experience USB advantages without major changes. This work describes the specification and development of such converter and it is also a useful guide for implementing other USB devices. The main blocks in the implementation are USB device, UART (RS232 protocol engine) and interface FIFO logic. The USB device block has to know how to detect and respond to events at a USB port and it has to provide a way for the device to store data to be sent and retrieve data that have been received UART consists of different blocks which handle the serial communication through RS232 protocol. There are a set of control registers to control the data transfer. The interface FIFO logic has FIFO to bridge the data rate differences between USB and RS232 protocols. Index Terms— First-In-First-Out, RS-232, Universal Asynchronous Receive Transmit, Universal Serial Bus.I.INTRODUCTIONThis paper describes the specification and implementation of a converter from RS232 to USB (Universal Serial Bus). Thisconverter is responsible for receiving data from a peripheraldevice’s serial interface and sending it to a computer’s USBinterface. In the same way, it must be able to send data from the PC’s USB interface to the device. The problems faced with the old standards stimulated the development of a newcommunication protocol, which should be easier to use,faster, and more efficient. RS232 is a definition for serial communication on a 1:1 base. RS232defines the interface layer, but not the application layer. To use RS232 in a specific situation, application specific software must be written on devices on both ends of the connecting RS232 cable. RS232 ports can be either accessed directly by an application, or via a device driver in the operating system. USB is a new personal computer interconnection standard developed by industry and telecommunication leaders, which implements the Plug and Play technology. It allows multiple devices connection (up to 127) ranges. The use of a the devices attachment to PCs. USB is a low cost, easing solution and supports transfer rates up to 12Mbs, comprehending the low-speed and mid-speed data converter from a serial interface to USB would free a serial communication port to other applications, allowing a device that uses a serial interface to communicate using an USB interface. USB on the other hand is a bus system which allows more than one peripheral to be connected to a host computer via one USB port. Hubs can be used in the USB chain to extend the cable length and allow for even more devices to connect to the same USB port. The standard not only describes the physical properties of the interface, but also the protocols to be used. Because of the complex USB protocol requirements, communication with USB ports on a computer is always performed via a device driver. This way, we are not limited to the availability of a serial port and we can experience the USB advantages. Using a converter allows us to have the device unchanged, making the converter responsible for treating the differences between the protocols. This work was based on protocol engine which can be managed by exchanging data with a PC across a serial interface. Most of the times, this communication is not done constantly, since it is necessary to have a serial port available just for it. This paper presents the converter implementation, focusing on the development process, which comprehends the device itself and the PC-side software that will communicate with it. This methodology can be extended to other devices. We first present some important USB standard concepts. Then, we define the system specification, divided on host and device requirements. After, we describe the hardware (UART) features and software design and implementation. Finally, we discuss about achieved results and future workII.PROBLEM DESCRIPTIONThe USB specification describes bus attributes, protocol definition, programming interface and other features required to design and build systems and peripherals compliant with the USB standard. We briefly explain features used in our project.2011 IEEE Symposium on Computers & InformaticsThe USB interface does not give this flexibility. When however an RS232 port is used via an USB to RS232 converter, this flexibility should be present in some way. Therefore to use an RS232 port via an USB port, a second device driver is necessary which emulates a RS232 UART, but communicates via USB. USB works as a Master/Slave bus, where the USB Host is the Master and the devices are the Slaves. The only system resources required by a USB system are the memory locations used by USB system software and the memory and/or I/O address space and IRQ line used by the USB host controller. USB devices can be functional (displays, mice, etc) or hubs, used to connect other devices in the bus. They can be implemented as low or high-speed devices. Low-speed devices are limited to a maximum 1.5 Mb/s rate. Each device has a number of individual registers - known as Endpoints which are indirectly accessed by the device drivers for data exchange. Each endpoint supports particular transfer characteristic has a unique address and direction. A special case is Endpoint 0, which is used for control operations and can do bi-directional transfers. It must be present in all devices. According to the device’s characteristics, other types of endpoints can be defined. USB Host verifies the attachment and detachment of new devices, initiating the enumeration process and managing all the following transactions. It is responsible to install device driver (based on information provided by device descriptors), to automatically reconfigure the system (hot attachment) and to collect statistics and status of each device. USB on the other hand is a bus system which allows more than one peripheral to be connected to a host computer via one USB port. Hubs can be used in the USB chain to extend the cable length and allow for even more devices to connect to the same USB port. The standard not only describes the physical properties of the interface, but also the protocols to be used. Because of the complex USB protocol requirements, communication with USB ports on a computer is always performed via a device driver. Device’s descriptors specify USB devices attributes and characteristics and describe device communication requirements (Endpoint Descriptors). The USB host uses this information to configure the device, to find its driver, and to access it. Devices with similar functions are grouped into classes [1, 2] in order to share common features and even use the same device drivers. Each class can define their own descriptors (class-specific descriptors), as for example, HID (Human Interface Device) Class Descriptors and Report Descriptors. The HID class consists of devices used by people to control computer systems. It defines a structure that describes a HID device, with specific communication requirements. According to the converter characteristics, it can be implemented as a HID device, using already developed HID drivers. A HID device’s descriptors must support an Interrupt IN endpoint and the firmware must also contain a report descriptor that defines the format for transmitted and received device data.A. RequestsThe USB protocol is based on requests sent by the host and processed by the USB devices. These requests can be directed to a device or a specific endpoint in it. Standard requests must be implemented by all devices and are used for configuring a device and controlling the state of its USB interface, among other features. Two HID-specific requests must be supported by the converter: Set Report and Get Report. These requests enable the device to receive and send generic device information to the host. Set Report request is the only way the host can send data to a HID device, once it does not have an Interrupt OUT endpointB. Communication FlowUSB is a shared bus and many devices might use it at the same time. The devices share the bandwidth using a protocol based on tokens and commanded by the host. USB communication is based on transferring data at regular intervals called frames. A frame is composed by one or more transactions that must be executed in a 1 ms time. USB data transfers are typically originated by a USB Device Driver when it needs to communicate with its device. It supplies a memory buffer used to store the data in transfers to or from the USB device. The USB Driver provides the interface between USB Device Driver and USB Host Controller, translating transfer requests into USB transactions, consistent with the bandwidth requirements and protocol structure. Some of these transfers consist of a large block of data, which need to be splitted into several transactions. The Host Controller generates the transaction based on the Transfer Descriptor, which describes the frame sharing among the several devices requests. When a transaction is sent to the bus, all devices see it. Each transaction begins with a packet that determines its type and the endpoint address. The USB driver controls this addressing scheme. Inside the device, the USB Device Layer comprehends the actual USB communication mechanism and transfer characteristics. USB Logical Device implements a collection of endpoints that comprise a given functional interface, which can be manipulated by its respective USB client.C. Transfer TypesThe USB specification defines four transfer types: Control, Interrupt, Isochronous and Bulk. Control transfers send requests and data relating to the device’s abilities and configuration. They can also be used to transfer blocks of information for any other purpose. Control transfers consist of a Setup stage, followed by a Data stage, which is composed of one or more Data transactions, and a Status stage. All data transactions in a Data Stage must be in the same direction (In or out). Interrupt transfers are typically used for devices that need to transfer data at regular period of time, and consequently must be polled periodically. The polling interval is defined in the Endpoint Descriptor. The data payloadfor this kind of transfer for low-speed devices is 8 bytes. Error correction is done in this kind of transfer. Two other transfer types are Isochronous and Bulk , which are used for devices thatneed a guaranteed transfer rate or for large blocks of data transfers. They are not used in this work.III. PROCEDURE/ALGORITHM A. System SpecificationTo develop a USB peripheral we need all the following: A host that supports USB. Driver software on the host to communicate with the peripheral. An application executing in the host that communicates with the peripheral device. A UART with a USB interface. Code implementation on the USB controller to carry Out the USB communication. Code implementation on the USB controller to carry out the peripheral functions. Hardware specific problem arises from handshaking to prevent buffer overflows at the receiver's side. RS232 applications can use two types of handshaking, either with control commands in the data stream, called software flow control, or with physical lines, called hardware flow control. Not all USB to RS232 converters provide these hardware flow control lines. It is not always easily identified if an application needs them. Some applications do not use hardware flow control at all, and those cheap USB to RS232 converters will work without problems. Other applications use hardware flow control, but infrequently. Only with large data bursts, or in situations where the CPU is busy performing other tasks, hardware flow control might kick in to prevent data loss. In those situations, communications may seem error free, but with sometimes bytes lost, or unspecified errors in the communications. In a UART& FIFO used to store sent and received data in the USB communication process. Two endpoints were defined for the converter, where the first one is Endpoint 0, used for control operations and the second one is an Interrupt IN Endpoint, defined for sending data to the host. This way, a converter from a serial interface to USB can be implemented as a HID device with the features mentioned above.Fig 2.RS232 to USB ConverterB. HOST REQUIREMENTSThe choice of the Operating System used by the host wasdone in 1999, based on the USB support it provides. Itshould provide the entire drivers infrastructure and supportthe protocol characteristics, as for example, Plug and Play. The host must be able to receive USB data using its device drivers and make them available to the applications that have done the request. It is essential that we have a driver in the host to process USB transfers, recognizing the device, receiving and sending data to a USB device.A. Device requirementsSome communication requirements, such as transmission speed, frequency and amount of data to be transferred, were essential in communication the process of defining the UART be used. Considering the speeds available for USB devices, it was clear that the converter could be implemented as a low speed device, where the communication speed varies from 10 to 100Kb/s. Considering the amount of data transferred and the transmission frequency, the converter was defined to use Interrupt transfers, a transfer type where considerable amounts of data must be transferred in pre defined amounts of time. The host is responsible for verifying if the device needs to transmit data from time to time. Interrupt transfers can be done in both directions, but needs to transmit data from time to time. Interrupt transfers can be done in both directions, but not at the same time. For the converter, they could be used to send and receive data from the PC. The Operating System provides HID drivers that allow us to use this transfer type. The maximum packet size for one transaction is 8 bytes for low speed devices. If we are sending larger amounts of data, they need to be splitted into many transactions, once USB is a shared bus. Another feature defined for the converter was the number of endpoints needed. As explained before, endpoints are buffersFig 1.RS232 to USB Interface DiagramIII HARDWARE DESCRIPTIONIt is a low-cost solution for low-speed applications with high I/O requirements. RS232 ports which are physically mounted in a computer are often powered by three power sources: +5 Volts for the UART logic, and -12 Volts and +12 Volts for the outputdrivers. USB however only provides a +5 Volt power source.Some USB to RS232converters use integrated DC /DC converters to create the appropriate voltage levels for the RS232 signals, implementations, the +5 Volt voltages is directly used to drive the output The UART has serial interface to the RS232 driver. The operation of UART is controlled by an external host processor. There is an 8-bit data interface to host along with read and write control signals. Clock is fed from external crystal. Thefamily is USB specification [1] compliant and supports one address and three data endpoints [5]. The choice of a UART with three endpoint was done in order to allow us to have, beyond the Interrupt IN, an Interrupt OUT endpoint for receiving data from the host (OUT). Its definition requires we have an odd endpoint number besides Endpoint 0. This configurationcould not be implemented at the time the project was being developed once the Operating System did not offer support for Interrupt OUT endpoints, which were defined in a later version of the specification. The instruction set has been optimized specifically for USB operations, USB controller provides one USB device address with three endpoints. The USB device address is assigned to the device and saved in the USB Device Address Register (7 bits) during the USB enumeration process. The USB controller communicates with the host using dedicated FIFO, one per endpoint. Each endpoint FIFO is implemented as 8 bytes of dedicated SRAM and the status and control of each of them can be done using its Mode Register and Count Register.IV. SOFTWARE DESIGN AND IMPLEMENTATIONThe development of the converter was divided in phases: Descriptors definition. Device detection and enumeration module (request treatment), Serial data exchange module, USB/serial modules interface be overlapped. USB data exchange module (request treatment). The phases definition does not imply that they cannot be overlapped.A .Descriptors definitionThe main structure to be data implemented consists of device descriptors, as defined by the USB specification [1] These descriptors store information about the device and the USB communication process, used by the host to identify the device and its characteristics. The Device Descriptor is the first descriptor the host reads on device attachment. It includes the basic information the host needs in order to retrieve further characteristics from the device. Its fields' values were defined according to the converter characteristics [7]. To implement a new device, some of these values must be re evaluated and changed if necessary. The converter was defined to use just one interface and two endpoints (Control and Interrupt IN). Interrupt OUT endpoints were defined just in a later version of HID specification. To solve this problem, data packets are sent to the UPS across Endpoint 0, using the SET REPORT request, and received through Endpoint 1, using Interrupt transfers. The data reception is done through Output Reports, which were defined as 16 8-bit fields, according to the largest command sent to the UPS. Sending data to the host is done through Input Reports, which were defined as 8, 8- bit fields. Report Descriptors define the size and uses for the data that implements the device’s functionality.B. Device Detection and EnumerationThe second phase consists of the implementation of the code that enables the host to detect and enumerate the device. The implementation of these routines was based on some example codes [8, 9, 10]. Inside the we must have the code to access the descriptors, to recognize and to respond to the request codes that the host sends when it enumerates the device.C. The process of sending and receiving dataThe process of sending data to the UPS is done through ControlTransfers using SET REPORT on Endpoint 0. The host sends a request to the USB device, indicating it wants to send data. Aninterrupt informs the device when new data have arrived onEndpoint 0 and the corresponding Interrupt Service Routinecopies it into a data buffer, which is used in the serial communication process.. The maximum packet size that isreceived from the host was defined according to the largestcommand that must be sent to the function must be changed toallow receiving an arbitrary number of bytes. These routines are called after the Host or the controller sends a packet to the bus.Endpoint 0 ISR receives. Using hardware flow control impliesthat more lines must be present between the sender and thereceiver, leading to a thicker and more expensive cable. Therefore, software flow control is a good alternative if it is notneeded to gain maximum performance in communications.Software flow control makes use of the data channel between thetwo devices which reduces the bandwidth. The reduce of bandwidth is in most cases however not so astonishing that it is areason to not use it. First, the computer sets its RTS line to signalthe device that some information is present. The device checks ifthere is room to receive the information and if so, it sets the CTS line to start the transfer. When using a null modem connection,this is somewhat different. There are two ways to handle thistype of handshaking in that situation. One is, where the RTS ofeach side is connected with the CTS side of the other. In that way, the communication protocol differs somewhat from theoriginal one. The RTS output of computer A signals computer B that A is capable of receiving information, rather than a requestfor sending information as in the original configuration. Thistype of communication can be performed with a null modemcable for full handshaking. Although using this cable is not completely compatible with the original way hardware flow control was designed, if software is properly designed for it it can achieve the highest possible speed because no overhead ispresent for requesting on the RTS line and answering on the CTSline. In the second situation of null modem communication withhardware flow control, the software side looks quite similar to the original use of the handshaking lines. The CTS and RTS linesof one device are connected directly to each other. This means,that the request to send query answers itself. As soon as the RTSoutput is set, the CTS input will detect a high logical value indicating that sending of information is allowed. This impliesthat information will always be sent as soon as sending isrequested by a device if no further checking is present. Toprevent this from happening, two other pins on the connector are used, the data set ready DSR and the data terminal ready DTR. These two lines indicate if the device attached is working properly and willing to accept data. When these lines are cross-connected (as in most null modem cables) flow control can be performed using these lines. A DTR output is set, if that computer accepts incoming characters.V.R ESULT A NALYSIS:Fig.4.Shows the Waveforms of RS232USBconverterFIG. 5. RTLSCHEMATICSFIG. 6.The Routed designVI. CONCLUSIONSAn embedded converter from RS232 to USB is designed in this project. VHDL will be used for implementing all these blocks. ModelSim Simulator tool will be used for functional simulation of the design. Reduces the cost for the end user, improves communication speed and supports simultaneous attachment of multiple devices (up to 127). USB protocol operates at 480 Mbps FPGA implementation of the design is done on Spartan 3E FPGA (XC3S500E). The design used 6% of the FPGA area and a maximum frequency of 130MHz is obtained.ACKNOWLEDGMENTWe are grateful to management Vaagdevi college of Engineering, Warangal, NIT Warangal, Linton University College, and Mantin for the facilities to provide to complete the project in time.REFERENCES1.Ana Luiza de Almeida Pereira Zuquim, Claudionor JosCNunes Coelho Jr, Antanio Ot6vio Fernández, Marcos PCgode Oliveira, AndrCa Iabrudi Tavares, “An EmbeddedConverter from RS232 to Universal Serial Bus”, IEEE2.Jan axelson, “USB Complete, Everything you need todevelop custom USB peripherals”, Penram Intl.Publishing(India), 19993.Universal Serial Bus Specification Revision 2.04.5.Charles H.Roth, Jr, “Digital Systems Design using VHDL”,PWS publishing company, 1996.6.ZainalabediNavabi,“VHDL Analysis and Modelling ofDigital Systems”, McGraw – Hill, Second Edition.7.8.9.Douglas L. Perry ,”VHDL”, Second Edition, McGraw-Hill,Inc, 199310..au/catalog/targus-usb-to-parallel-adapter-p-1160.html11. USB Complete: The Developer's Guide, 4th Edition12. USB Mass Storage: Designing and ProgrammingDevices and Embedded Hosts14. FPGAPrototyping by VHDL Examples: Xilinx Spartan-3Version. Pong P.ChuBibliographical notesV.Vijaya obtained her B.Tech Degree in Electronics & Communication Engg., from (JNTU) Jawaharlal Nehru Technological University College of Engg., Ananthapur, and M.Tech. Degree in Instrumentation and Control Systems, from JNTUK college of Engg Kakinada and Pursuing PhD from JNTUH, Hyderabad. V.Vijaya worked at APEL Radio Communication Systems, Hyderabad and presently, she is working as Associate Professor in the ECE Dept of Vaagdevi College of Engineering at Warangal. She has 10 years of Teaching Experience and 2 years of Industrial Experience. Attended 15 workshops/refresher courses/short term courses at various places. Member of Project Review Committee (UG/PG); CRC for (UG/PG).She is the project coordinator for UG/PG. Her area of interest are Image processing, Signal processing, VLSI, Mobile Communications, Wireless Communications. She is life member of ISTE, IETE.She is the member of IEEE. She has published no. of papers in national conferences and international conferences.V.Rama obtained her B.Tech in Electronics &Communication Engg., from JNTU, Kakinada, and M.Tech. from NIT, Warangal. Pursuing PhD from NIT, Warangal She is working as Asst Professor in the ECE Dept., at NIT, Warangal. Staff adviser of ECE Dept., Incharge for basic Electronics Lab. She involved inextracurricular activites at institute. She has 12 years of Teaching Experience. She organized no. of UGC workshops in NITW. Her area of research is Bio Medical Signal Processing. Her areas of interest are Image processing, Signal processing, Tele medicine. She is the member of IEEE. She has published no. of papers in national and international conferences.CH.Kranthi Rekha had received her B.E in Electronics and Communication Engineering from Madurai Kamaraj University in 2000 and Completed M.Tech from JNTUH, Hyderabad. Presently she is working as Lecturer in Linton university college, Mantin, Malaysia, She has more than 10 years of teaching experience. She is the Author of two Books (Digital communications and Digital Image processing). Organized student level technical symposium technocraft-’09. Attended 10 workshops/refresher courses/short term courses at various places. As a resource person to talk on Image processing. Member of Project Review Committee (UG/PG); CRC for (UG/PG). Her area of interest are Neural networks, Image processing, Signal processing, VLSI, Communications. She is life member of ISTE, IETE.She has published no. of papers in national conferences and international conferences.B.Sreedevi obtained her AMIE Degree in Electronics & Communication Engg., from Institution of Engineers, Calcutta, and M.Tech. Degree in Digital System Computer Electronics, from JNTUA college of Engg Ananthapur. She is working as Associate Professor in the ECE Dept of Vaagdevi College of Engineering at Warangal. She has 10 years of Teaching Experience. Attended 12 workshops/refresher courses/short term courses at various places. Member of Project Review Committee (UG/PG); CRC for (UG/PG). Her area of interest are Image processing, Signal processing, VLSI, Communications. She is life member of ISTE, IETE. She has published no. of papers in national conferences and international conferences.C.B.RamaRao obtained his B.Tech in Electronics & Communication Engg., from JNTU Kakinada, and M.Tech. from JNTU Kakinada, Ph.D from IIT, kharagpur. He is working as Professor in the ECE Dept., at NIT, Warangal. At present he is the Head of ECE Dept.,. He involved in various activities at institute. He acted as associate dean of academic affairs at NITW. He has 28 years of Teaching Experience. He organized no. of workshops at NITW. His area of research is in advanced digital signal processing. His areas of interest are Bio Medical Signal Processing, Image processing, Signal processing. He is the member of IEEE. He has published no. of papers in national and international conferences.。

使用LabVIEW FPGA模块开发可编程自动化控制器Building Programmable Automation Controllers with LabVIEW FPGA OverviewProgrammable Automation Controllers (PACs) are gaining acceptance within the industrial control market as the ideal solution for applications that require highly integrated analog and digital I/O, floating-point processing, and seamless connectivity to multiple processing nodes. National Instruments offers a variety of PAC solutions powered by one common software development environment, NI LabVIEW. With LabVIEW, you can build custom I/O interfaces for industrial applications using add-on software, such as the NI LabVIEW FPGA Module.With the LabVIEW FPGA Module and reconfigurable I/O (RIO) hardware, National Instruments delivers an intuitive, accessible solution for incorporating the flexibility and customizability of FPGA technology into industrial PAC systems. You can define the logic embedded in FPGA chips across the family of RIO hardware targets without knowing low-level hardware description languages (HDLs) or board-level hardware design details, as well as quickly define hardware for ultrahigh-speed control, customized timing and synchronization, low-level signal processing, and custom I/O with analog, digital, and counters within a single device. Youalso can integrate your custom NI RIO hardware with image acquisition and analysis, motion control, and industrial protocols, such as CAN and RS232, to rapidly prototype and implement a complete PAC system.Table of Contents1.Introduction2.NI RIO Hardware for PACs3.Building PACs with LabVIEW and the LabVIEW FPGA Module4.FPGA Development Flowing NI SoftMotion to Create Custom Motion Controllers6.Applications7.ConclusionIntroductionYou can use graphical programming in LabVIEW and the LabVIEW FPGA Module to configure the FPGA (field-programmable gate array) on NI RIO devices. RIO technology, the merging of LabVIEW graphical programming with FPGAs on NI RIO hardware, provides a flexible platform for creating sophisticated measurement and control systems that you could previously create only with custom-designed hardware.An FPGA is a chip that consists of many unconfigured logic gates. Unlike the fixed, vendor-defined functionality of an ASIC(application-specific integrated circuit) chip, you can configure and reconfigure the logic on FPGAs for your specific application. FPGAs are used in applications where either the cost of developing and fabricating an ASIC is prohibitive, or the hardware must be reconfigured after being placed into service. The flexible, software-programmable architecture of FPGAs offer benefits such as high-performance execution of custom algorithms, precise timing and synchronization, rapid decision making, and simultaneous execution of parallel tasks. Today, FPGAs appear in such devices as instruments, consumer electronics, automobiles, aircraft, copy machines, and application-specific computer hardware. While FPGAs are often used in industrial control products, FPGA functionality has not previously been made accessible to industrial control engineers. Defining FPGAs has historically required expertise using HDL programming or complex design tools used more by hardware design engineers than by control engineers.With the LabVIEW FPGA Module and NI RIO hardware, you now can use LabVIEW, a high-level graphical development environment designed specifically for measurement and control applications, to create PACs that have the customization, flexibility, and high-performance of FPGAs. Because the LabVIEW FPGA Module configures custom circuitry in hardware, your system can process and generate synchronized analog and digitalsignals rapidly and deterministically. Figure 1 illustrates many of the NI RIO devices that you can configure using the LabVIEW FPGA Module.Figure 1. LabVIEW FPGA VI Block Diagram and RIO Hardware Platforms NI RIO Hardware for PACsHistorically, programming FPGAs has been limited to engineers who have in-depth knowledge of VHDL or other low-level design tools, which require overcoming a very steep learning curve. With the LabVIEW FPGA Module, NI has opened FPGA technology to a broader set of engineers who can now define FPGA logic using LabVIEW graphical development. Measurement and control engineers can focus primarily on their test and control application, where their expertise lies, rather than the low-level semantics of transferring logic into the cells of the chip. The LabVIEW FPGA Module model works because of the tight integration between the LabVIEW FPGA Module and the commercial off-the-shelf (COTS) hardware architecture of the FPGA and surrounding I/O components.National Instruments PACs provide modular, off-the-shelf platforms for your industrial control applications. With the implementation of RIO technology on PCI, PXI, and Compact Vision System platforms and the introduction of RIO-based CompactRIO, engineers now have the benefits of a COTS platform with the high-performance, flexibility, and customizationbenefits of FPGAs at their disposal to build PACs. National Instruments PCI and PXI R Series plug-in devices provide analog and digital data acquisition and control for high-performance, user-configurable timing and synchronization, as well as onboard decision making on a single device. Using these off-the-shelf devices, you can extend your NI PXI or PCI industrial control system to include high-speed discrete and analog control, custom sensor interfaces, and precise timing and control.NI CompactRIO, a platform centered on RIO technology, provides a small, industrially rugged, modular PAC platform that gives you high-performance I/O and unprecedented flexibility in system timing. You can use NI CompactRIO to build an embedded system for applications such as in-vehicle data acquisition, mobile NVH testing, and embedded machine control systems. The rugged NI CompactRIO system is industrially rated and certified, and it is designed for greater than 50 g of shock at a temperature range of -40 to 70 °C.NI Compact Vision System is a rugged machine vision package that withstands the harsh environments common in robotics, automated test, and industrial inspection systems. NI CVS-145x devices offer unprecedented I/O capabilities and network connectivity for distributed machine vision applications.NI CVS-145x systems use IEEE 1394 (FireWire) technology, compatible with more than 40 cameras with a wide range of functionality,performance, and price. NI CVS-1455 and NI CVS-1456 devices contain configurable FPGAs so you can implement custom counters, timing, or motor control in your machine vision application.Building PACs with LabVIEW and the LabVIEW FPGA ModuleWith LabVIEW and the LabVIEW FPGA Module, you add significant flexibility and customization to your industrial control hardware. Because many PACs are already programmed using LabVIEW, programming FPGAs with LabVIEW is easy because it uses the same LabVIEW development environment. When you target the FPGA on an NI RIO device, LabVIEW displays only the functions that can be implemented in the FPGA, further easing the use of LabVIEW to program FPGAs. The LabVIEW FPGA Module Functions palette includes typical LabVIEW structures and functions, such as While Loops, For Loops, Case Structures, and Sequence Structures as well as a dedicated set of LabVIEW FPGA-specific functions for math, signal generation and analysis, linear and nonlinear control, comparison logic, array and cluster manipulation, occurrences, analog and digital I/O, and timing. You can use a combination of these functions to define logic and embed intelligence onto your NI RIO device.Figure 2 shows an FPGA application that implements a PID control algorithm on the NI RIO hardware and a host application on a Windows machine or an RT target that communicates with the NI RIO hardware. Thisapplication reads from analog input 0 (AI0), performs the PID calculation, and outputs the resulting data on analog output 0 (AO0). While the FPGA clock runs at 40 MHz the loop in this example runs much slower because each component takes longer than one-clock cycle to execute. Analog control loops can run on an FPGA at a rate of about 200 kHz. You can specify the clock rate at compile time. This example shows only one PID loop; however, creating additional functionality on the NI RIO device is merely a matter of adding another While Loop. Unlike traditional PC processors, FPGAs are parallel processors. Adding additional loops to your application does not affect the performance of your PID loop.Figure 2. PID Control Using an Embedded LabVIEW FPGA VI withCorresponding LabVIEW Host VI.FPGA Development FlowAfter you create the LabVIEW FPGA VI, you compile the code to run on the NI RIO hardware. Depending on the complexity of your code and the specifications of your development system, compile time for an FPGA VI can range from minutes to several hours. To maximize development productivity, with the R Series RIO devices you can use a bit-accurate emulation mode so you can verify the logic of your design before initiating the compile process. When you target the FPGA Device Emulator, LabVIEW accesses I/O from the device and executes the VI logic on the Windowsdevelopment computer. In this mode, you can use the same debugging tools available in LabVIEW for Windows, such as execution highlighting, probes, and breakpoints.Once the LabVIEW FPGA code is compiled, you create a LabVIEW host VI to integrate your NI RIO hardware into the rest of your PAC system. Figure 3 illustrates the development process for creating an FPGA application. The host VI uses controls and indicators on the FPGA VI front panel to transfer data between the FPGA on the RIO device and the host processing engine. These front panel objects are represented as data registers within the FPGA. The host computer can be either a PC or PXI controller running Windows or a PC, PXI controller, Compact Vision System, or CompactRIO controller running a real-time operating system (RTOS). In the above example, we exchange the set point, PID gains, loop rate, AI0, and AO0 data with the LabVIEW host VI.Figure 3. LabVIEW FPGA Development FlowThe NI RIO device driver includes a set of functions to develop a communication interface to the FPGA. The first step in building a host VI is to open a reference to the FPGA VI and RIO device. The Open FPGA VI Reference function, as seen in Figure 2, also downloads and runs the compiled FPGA code during execution. After opening the reference, you read and write to the control and indicator registers on the FPGA using theRead/Write Control function. Once you wire the FPGA reference into this function, you can simply select which controls and indicators you want to read and write to. You can enclose the FPGA Read/Write function within a While Loop to continuously read and write to the FPGA. Finally, the last function within the LabVIEW host VI in Figure 2 is the Close FPGA VI Reference function. The Close FPGA VI Reference function stops the FPGA VI and closes the reference to the device. Now you can download other compiled FPGA VIs to the device to change or modify its functionality.The LabVIEW host VI can also be used to perform floating-point calculations, data logging, networking, and any calculations that do not fit within the FPGA fabric. For added determinism and reliability, you can run your host application on an RTOS with the LabVIEW Real-Time Module. LabVIEW Real-Time systems provide deterministic processing engines for functions performed synchronously or asynchronously to the FPGA. For example, floating-point arithmetic, including FFTs, PID calculations, and custom control algorithms, are often performed in the LabVIEW Real-Time environment. Relevant data can be stored on a LabVIEW Real-Time system or transferred to a Windows host computer for off-line analysis, data logging, or user interface displays. The architecture for this configuration is shown in Figure 4. Each NI PAC platform that offers RIO hardware can run LabVIEW Real-Time VIs.Figure 4. Complete PAC Architecture Using LabVIEW FPGA, LabVIEW Real-Timeand Host PCWithin each R Series and CompactRIO device, there is flash memory available to store a compiled LabVIEW FPGA VI and run the application immediately upon power up of the device. In this configuration, as long as the FPGA has power, it runs the FPGA VI, even if the host computer crashes or is powered down. This is ideal for programming safety power down and power up sequences when unexpected events occur.Using NI SoftMotion to Create Custom Motion ControllersThe NI SoftMotion Development Module for LabVIEW provides VIs and functions to help you build custom motion controllers as part of NI PAC hardware platforms that can include NI RIO devices, DAQ devices, and Compact FieldPoint. NI SoftMotion provides all of the functions that typically reside on a motion controller DSP. With it, you can handle path planning, trajectory generation, and position and velocity loop control in the NI LabVIEW environment and then deploy the code on LabVIEW Real-Time or LabVIEW FPGA-based target hardware.NI SoftMotion includes functions for trajectory generator and spline engine and examples with complete source code for supervisory control, position, and velocity control loop using the PID algorithm. Supervisory control and the trajectory generator run on a LabVIEW Real-Time target and run at millisecond loop rates. The spline engine and the control loop can run either on a LabVIEW Real-Time target at millisecond loop rates or on a LabVIEW FPGA target at microsecond loop rates.ApplicationsBecause the LabVIEW FPGA Module can configure low-level hardware design of FPGAs and use the FPGAs within in a modular system, it is ideal for industrial control applications requiring custom hardware. These custom applications can include a custom mix of analog, digital, and counter/timer I/O, analog control up to 125 kHz, digital control up to 20 MHz, and interfacing to custom digital protocols for the following:•Batch control•Discrete control•Motion control•In-vehicle data acquisition•Machine condition monitoring•Rapid control prototyping (RCP)•Industrial control and acquisition•Distributed data acquisition and control•Mobile/portable noise, vibration, and harshness (NVH) analysisConclusionThe LabVIEW FPGA Module brings the flexibility, performance, and customization of FPGAs to PAC platforms. Using NI RIO devices and LabVIEW graphical programming, you can build flexible and custom hardware using the COTS hardware often required in industrial control applications. Because you are using LabVIEW, a programming language already used in many industrial control applications, to define your NI RIO hardware, there is no need to learn VHDL or other low-level hardware design tools to create custom hardware. Using the LabVIEW FPGA Module and NI RIO hardware as part of your NI PAC adds significant flexibility and functionality for applications requiring ultrahigh-speed control, interfaces to custom digital protocols, or a custom I/O mix of analog, digital, and counters.使用LabVIEW FPGA(现场可编程门阵列)模块开发可编程自动化控制器综述工业控制上的应用要求高度集成的模拟和数字输入输出、浮点运算和多重处理节点的无缝连接。