关于力的外文文献翻译、中英文翻译、外文翻译

- 格式:doc

- 大小:65.79 KB

- 文档页数:10

附录A 外文翻译译文:非牛顿流体电学:综述3.在非牛顿流体电泳在第二节讨论了关于电渗流带电表面,如果我们通过想象改变参考系统,带电表面的流体应该是静止的,然后将带电面以速度大小相等但与以前面讨论的亥姆霍兹Smoluchowski的速度方向相反移动。

这种情况下有效地代表了电泳具有很薄的EDL的粒子在一个无限大的非运动牛顿流体范围[17,18,26,34] 。

显然,先前讨论电渗的亥姆霍兹Smoluchowski速度当然也可适用于分析在无限大非牛顿流体域具有薄EDL颗粒的电泳速度,仅仅与它的符号相反,并改变了充电通道壁与带电粒子的潜力。

事实上,支付给非牛顿液体粒子电泳最早的关注可以追溯到30年前Somlyody [ 68 ]提起的一项有关采用非牛顿液体以提供优越的阈值特性的电泳显示器的专利。

在1985年, Vidybida和Serikov [ 69 ]提出关于球形颗粒的非牛顿电泳研究第一个理论解决方案。

他们展示了一个粒子在非牛顿净电泳运动流体可通过以交替的电场来诱导一个有趣的且违反直觉的效果。

最近才被Hsu课题组填补这方面20年的研究空白。

在2003年,Lee[70]等人通过一个球形腔的低zeta电位假设封闭andweak施加电场分析了电泳刚性球形颗粒在非牛顿的Carreau流体的运动。

他们特别重视电泳球形粒子位于中心的空腔特征。

之后,该分析被扩展来研究电泳位于内侧的球面的任意位置的球形颗粒的腔体[71] 。

除了单个粒子电泳外, Hsu[72]等人假设粒子分散潜力在卡罗流体zeta进行了集中的电泳调查分析,并分析了由Lee[73]完成的其它任意潜力。

为了研究在边界上非牛顿流体电泳的影响,Lee[74]等人分析了电泳球状粒子在卡罗体液从带电荷到不带电荷的平面表面,发现平面表面的存在增强了剪切变稀效果,对电泳迁移率产生影响。

类似的分析后来由Hsu等 [75]进行了扩展。

为了更紧密地模拟真实的应用环境,Hsu等人[76]分析了球形粒子的电泳由一个圆柱形的微细界卡罗流体低zeta电位到弱外加电场的条件。

英文文献资料(一)Clusters and the New Economics of CompetitionMichael E. Porter(Harvard university)Why Clusters Are Critical to CompetitionModern competition depends on productivity, not on access to inputs or the scale of individual enterprises.Productivity rests on how companies compete,not on the particular fields they compete panies can be highly productive in any industry–shoes, agriculture, or semiconductors – if they employ sophisticated methods, use advanced technology,and offer unique products and services. All industries can employ advanced technology; all industries can be knowledge intensive.The sophistication with which companies compete in a particular location, however, is strongly influenced by the quality of the local business environment.1 Companies cannot employ advanced logistical techniques, for example, without a high quality transportation infrastructure. Nor can companies effectively compete on sophisticated service without well-educated employees. Businesses cannot operate efficiently under onerous regulatory red tape or under a court system that fails to resolve disputes quickly and fairly. Some aspects of the business environment, such as the legal system, for example, or corporate tax rates, affect all industries. In advanced economies, however, the more decisive aspects of the business environment are often cluster specific; these constitute some of the most important microeconomic foundations for competition.Clusters affect competition in three broad ways:first, by increasing the productivity of companies based in the area; second, by driving the direction and pace of innovation, which underpins future productivity growth; and third, by stimulating the formation of new businesses, which expands and strengthens the cluster itself. A cluster allows each member to benefit as if it had greater scale or as if it had joined with others formally – without requiring it to sacrifice its flexibility.Clusters and Productivity. Being part of a cluster allows companies to operate more productively in sourcing inputs; accessing information, technology,and needed institutions; coordinating with related companies; and measuring and motivating improvement.Better Access to Employees and Suppliers. Companies in vibrant clusters can tap into an existing pool of specialized and experienced employees, thereby lowering their search and transaction costs in recruiting. Because a cluster signals opportunity and reduces the risk of relocation for employees, it can also be easier to attract talented people from other locations, a decisive advantage in some industries.A well-developed cluster also provides an efficient means of obtaining other important inputs.Such a cluster offers a deep and specialized supplier base. Sourcing locally instead of from distant suppliers lowers transaction costs. It minimizes the need for inventory, eliminates importing costs and delays, and –because local reputation is important –lowers the risk that suppliers will overprice or renege on commitments. Proximity improves communications and makes it easier for suppliers to provide ancillary or support services such as installation and debugging. Other things being equal, then, local outsourcing is a better solution than distantoutsourcing, especially for advanced and specialized inputs involving embedded technology, information, and service content.Formal alliances with distant suppliers can mitigate some of the disadvantages of distant outsourcing. But all formal alliances involve their own complex bargaining and governance problems and can inhibit a company’s flexibility. The close, informal relationships possible among companies in a cluster are often a superior Arrangement.In many cases, clusters are also a better alternative to vertical pared with in-house units, outside specialists are often more cost effective and responsive, not only in component production but also in services such as training. Although extensive vertical integration may have once been the norm, a fast-changing environment can render vertical integration inefficient, ineffective, and inflexible.Even when some inputs are best sourced from a distance, clusters offer advantages. Suppliers trying to penetrate a large, concentrated market will price more aggressively, knowing that as they do so they can realize efficiencies in marketing and in service.Working against a cluster’s advantages in assembling resources is the possibility that competition will render them more expensive and scarce. But companies do have the alternative of outsourcing many inputs from other locations, which tends to limit potential cost penalties. More important, clusters increase not only the demand for specialized inputs but also their supply.Access to Specialized Information. Extensive market, technical, and competitive information accumulates within a cluster, and members have preferred access to it. In addition, personal relationships and community ties foster trust and facilitate the flow of information. These conditions make information more transferable.Complementarities. A host of linkages among cluster members results in a whole greater than the sum of its parts. In a typical tourism cluster, for example, the quality of a visitor’s experience depends not only on the appeal of the primary attraction but also on the quality and efficiency of complementary businesses such as hotels, restaurants, shopping outlets, and transportation facilities. Because members of the cluster are mutually dependent, good performance by one can boost the success of the others.Complementarities come in many forms. The most obvious is when products complement one another in meeting customers’ needs, as the tourism example illustrates. Another form is the coordination of activities across companies to optimize their collective productivity. In wood products, for instance, the efficiency of sawmills depends on a reliable supply of high-quality timber and the ability to put all the timber to use – in furniture (highest quality), pallets and boxes (lower quality), or wood chips (lowest quality). In the early 1990s, Portuguese sawmills suffered from poor timber quality because local landowners did not invest in timber management. Hence most timber was processed for use in pallets and boxes, a lower-value use that limited the price paid to landowners. Substantial improvement in productivity was possible, but only if several parts of the cluster changed simultaneously.Logging operations, for example, had to modify cutting and sorting procedures, while sawmills had to develop the capacity to process wood in more sophisticated ways. Coordination to develop standard wood classifications and measures was an important enabling step. Geographically dispersed companies are less likely to recognize and capture such linkages.Other complementarities arise in marketing. A cluster frequently enhances the reputation of a location in a particular field, making it more likely that buyers will turn to a vendor based there.Italy’s strong reputation for fashion and design, for example, benefits companies involved in leather goods, footwear, apparel, and accessories. Beyond reputation, cluster members often profit from a variety of joint marketing mechanisms, such as company referrals, trade fairs, trade magazines, and marketing delegations.Finally, complementarities can make buying from a cluster more attractive for customers. Visiting buyers can see many vendors in a single trip. They also may perceive their buying risk to be lower because one location provides alternative suppliers. That allows them to multisource or to switch vendors if the need arises. Hong Kong thrives as a source of fashion apparel in part for this reason.Access to Institutions and Public Goods. Investments made by government or other public institutions– such as public spending for specialized infrastructure or educational programs – can enhance a company’s productivity. The ability to recruit employees trained at local programs, for example, lowers the cost of internal training. Other quasi-public goods, such as the cluster’s information and technology pools and its reputation, arise as natural by-products of competition.It is not just governments that create public goods that enhance productivity in the private sector. Investments by companies –in training programs, infrastructure, quality centers, testing laboratories, and so on – also contribute to increased productivity. Such private investments are often made collectively because cluster participants recognize the potential for collective benefits.Better Motivation and Measurement. Local rivalry is highly motivating. Peer pressure amplifies competitive pressure within a cluster,even among noncompeting or indirectly competing companies. Pride and the desire to look good in the local community spur executives to attempt to outdo one another.Clusters also often make it easier to measure and compare performances because local rivals share general circumstances – for example, labor costs and local market access – and they perform similar activities. Companies within clusters typically have intimate knowledge of their suppliers’ costs. Managers are able to compare costs and employees’performance with other local companies. Additionally, financial institutions can accumulate knowledge about the cluster that can be used to monitor performance.Clusters and Innovation. In addition to enhancing productivity, clusters play a vital role in a company’s ongoing ability to innovate. Some of the same characteristics that enhance current productivity have an even more dramatic effect on innovation and productivity growth.Because sophisticated buyers are often part of a cluster, companies inside clusters usually have a better window on the market than isolated competitors do. Computer companies based in Silicon Valley and Austin, Texas, for example, plug into customer needs and trends with a speed difficult to match by companies located elsewhere. The ongoing relationships with other entities within the cluster also help companies to learn early about evolving technology, component and machinery availability, service and marketing concepts, and so on. Such learning is facilitated by the ease of making site visits and frequent face-to-face contact.Clusters do more than make opportunities for innovation more visible. They also provide the capacity and the flexibility to act rapidly. A company within a cluster often can source what it needs to implement innovations more quickly. Local suppliers and partners can and do get closely involved in the innovation process, thus ensuring a better match with customers’ requirements.Companies within a cluster can experiment at lower cost and can delay large commitments until they are more assured that a given innovation will pan out. In contrast, a company relying ondistant suppliers faces greater challenges in every activity it coordinates with other organizations –in contracting, for example, or securing delivery or obtaining associated technical and service support. Innovation can be even harder in vertically integrated companies, especially in those that face difficult trade-offs if the innovation erodes the value of in-house assets or if current products or processes must be maintained while new ones are developed.Reinforcing the other advantages for innovation is the sheer pressure – competitive pressure, peer pressure, constant comparison – that occurs in a cluster. Executives vie with one another to set their companies apart. For all these reasons, clusters can remain centers of innovation for decades.Clusters and New Business Formation.It is not surprising, then, that many new companies grow up within an existing cluster rather than at isolated locations. New suppliers, for example, proliferate within a cluster because a concentrated customer base lowers their risks and makes it easier for them to spot market opportunities. Moreover, because developed clusters comprise related industries that normally draw on common or very similar inputs, suppliers enjoy expanded opportunities.Clusters are conducive to new business formation for a variety of reasons. Individuals working within a cluster can more easily perceive gaps in products or services around which they can build businesses. Beyond that, barriers to entry are lower than elsewhere. Needed assets, skills, inputs, and staff are often readily available at the cluster location, waiting to be assembled into a new enterprise.Local financial institutions and investors, already familiar with the cluster, may require a lower risk premium on capital. In addition, the cluster often presents a significant local market, and an entrepreneur may benefit from established relationships. All of these factors reduce the perceived risks of entry – and of exit, should the enterprise fail.The formation of new businesses within a cluster is part of a positive feedback loop. An expanded cluster amplifies all the benefits I have described – it increases the collective pool of competitive resources, which benefits a ll the cluster’s members. The net result is that companies in the cluster advance relative to rivals at other locations.英文文献中文翻译(二)来源:哈佛商业评论Vol.76第6期 1998年作者:迈克·E. 波特出版时间:1998簇群与新竞争经济学(美)迈克·E. 波特为什么簇群对竞争至关重要?现代竞争取决于生产力, 而非取决于投入或单个企业的规模。

「力量」英文怎么说?strengthpowerforce中文意思与用法!看例句搞懂「力量」的英文要怎么说?最常见的英文单字有strength / power / force,这三个英文单字的中文意思,都有「力量、力」的意思,所以这三个英文单字也算是易混淆字。

本篇文章也会教学strength / power / force 这三个英文单字的含义,以及它们的中文意思到底差在哪。

如果你还不知道 strength / power / force 这三个英文单字在表达「力量」时,到底有什么差异,那就赶快来看这篇英文教学吧!「力量」的英文怎么说?strength / power / force 中文意思差在哪?下面分别会教学 strength / power / force 这三个英文易混淆字的中文意思差异。

内容目录1.strength 力量strength 的中文意思可以表达为体力或是精神力,可以指将某个行为化为可能的能力,也可以指肉体、精神、物理性的方面的力量。

strength 的形容词形式为 strong,中文意思有很多,可以表达为强壮的、强烈的。

strong 形容人时,表达这个人很强壮。

例: Tom is so strong. 汤姆好壮。

Strong 形容物品时,通常表示该物很浓烈、强烈的意思。

例: Strong drinks 强烈的酒。

例: Strong coffee 浓烈的咖啡。

strength 最常表达的意思为生理或精神上的力量,例如精神力或是气力。

例:She didn’t have the strength to walk any further. 她已经没有力气再往前走了。

例: People do not lack strength, they lack will. 人不缺乏力量,他们缺乏意志。

2.power 力量power 中文意思解释为「力量」,常用的地方很多,例如权势、肉体的力量、政治的力量…等等。

外文文献及翻译1. 文献:"The Effects of Exercise on Mental Health"翻译:运动对心理健康的影响Abstract: This article explores the effects of exercise on mental health. The author discusses various studies that have been conducted on this topic, and presents evidence to support the claim that exercise can have positive impacts on mental well-being. The article also examines the mechanisms through which exercise affects mental health, such as the release of endorphins and the reduction of stress hormones. Overall, the author concludes that exercise is an effective strategy for improving mental health and recommends incorporating physical activity into daily routines.摘要:本文探讨了运动对心理健康的影响。

作者讨论了在这个主题上进行的各种研究,并提出证据支持运动对心理健康有积极影响的观点。

该文章还探讨了运动如何影响心理健康的机制,如内啡肽的释放和压力激素的减少。

总的来说,作者得出结论,运动是改善心理健康的有效策略,并建议将体育活动纳入日常生活。

2. 文献: "The Benefits of Bilingualism"翻译:双语能力的好处Abstract: This paper examines the benefits of bilingualism. The author presents research findings that demonstrate the cognitiveadvantages of being bilingual, such as enhanced problem-solving skills and improved attention control. The article also explores the social and cultural benefits of bilingualism, such as increased cultural awareness and the ability to communicate with people from different backgrounds. Additionally, the author discusses the positive effects of bilingualism on mental health, highlighting its role in delaying the onset of cognitive decline and in providing a buffer against age-related memory loss. Overall, the author concludes that bilingualism offers a range of advantages and recommends promoting bilingual education and language learning. 摘要:本文研究了双语能力的好处。

电力系统继电保护论文中英文资料Relay protection development present situation[Abstract ]reviewed our country electrical power system relay protection technological devil orpiment process,has outlined the microcomputer relay protection technology achievement, pro posed the future relay protection technological development tendency will be: Computerizes, n networked,protects, the control,the survey,the data communication integration and the artificial I intellectualization.[Key word ]relay protection present situation development,relay protections future development1 relay protection development present situationThe electrical power system rapid development to the relay protection proposed unceasingly t he new request,the electronic technology,computer technology and the communication rapid development unceasingly has poured into the new vigor for the relay protection technology de velopment,therefore,the relay protection technology is advantageous, has completed the deve lopment 4 historical stage in more than 40 years time。

附录外文文献原文:The commonly used sources of power in hydraulic systems are pumps and accumulators .Similarly,accumulator connected to atmosphere will dischange oil at atmosphere pressure until it empty. only when connected to a system having resistance to flow can pressure be developed.Three types of pumps find use in fluid-power systems:rotary,reciprocating or piston-type, and 3,centrifugal pumps.Simple hydraulic system may use but one type of pump . The trend is to use pumps with the most satisfactory characteristics for the specific tasks involved . In matching the characteristics of the pump to the requirements of the hydraulic system , it is not unusual to find two types of pumps in series . For example , a centrifugal pump may be to supercharge a reciprocating pump , or a rotary pump may be used to supply pressurized oil for the contronls associated with a reversing variabledisplacement pumps . Most power systems require positive displacement pumps . At high pressure , reciprocating pumps are often preferred to rotary pumps .1、Rotary pumpsThese are built in many differnt designs and extremely popular in modern fluid power system . The most common rotay-pump designs used today are spurgear , internal gear ,generated rotor , sliding vane ,and screew pumps . Ehch type has advantages that make it most suitable for a given application .2、Gear pumpsGear pumps are the simplest type of fixed displacement hydraulic pump available . This type consists of two external gear , generally spur gear , within a closed-fitting housing . One of the gear is driven directly by the pump drive shaft . It ,in turn , then drives the second gear . Some designs utilize helical gears ,but the spur gear design predominates . Gear pumps operate on a very simple principle . As the gear teeth unmesh , the volume at the inlet port A expands , a partial vacuum on the suction side of the pump will be formed . Fluid from an external reservoir or tank is forced by atmospheric pressure into the pumpinlet . The continuous action of the fluid being carried from the inlet to the discharge side one of the pump forces the fluid into the system .3、Vane pumpsThe vane pump consists of a housing that is eccentric or offset with respect to the drive shaft axis . In some models this inside surface consists of a cam ring that can be rotated to shift the relationship between rotor are rectangular and extend radially from a center radius to the outside diameter of the rotor and from end to end . A rectangular vane that is essentially the same size as the slot is inserted in the slot and is free to slide in and out .As the rotor turns , the vanes thrust outward , and the vane tips track the inner surface of the housing , riding on a thin film of fluid . Two port or end plates that engage the end face of the ring provide axial retention .Centrifugal force generally contributes to outward thrust of the vane . As they ride along the eccentric housing surface , the vane move in and out of the rotor slots . The vane divide the area between the rotor and casing into a series of chambers .The sides of each chamber are formed by two adjacent vanes ,the port or end plates , the pump casing and the rotor . These chambers change in change in volume depending on their respective position about the shaft .As each chamber approaches the inlet port , its vanes move outward and its volume expands , causing fluid to flow into the expanded chamber . Fluid is then carried within the chamber around to the dischange port . As the chamber approaches the discharge port , its vanes are pushed inward ,the volume is reduced , and the fluid is forced out the discharge port .Vane pump speed is limited by vane peripheral speed . High peripheral speed will cause cavitation in suction cavity . which results in pump damage and reduced flow .An imbalance of the vanes can cause the oil film between the vane tips and the cam ring to break down , resulting in metal-to-metal contact and subsequent increased wear and slipage . One metheod applied to eliminate high vane thrust loading is a dual-vane construction .4、Piston-type pumpAll piston pumps operate by allowing oil to flow into a pumping cavity as a piston retreats and then forcing the oil out into another chamber as the piston advances . Design differences among pumps lie primarily in the methods of separating inlet from outlet oil .5、In-line piston pumpThe siplest typeof axial piston pump is the swash plate in-line design .The cylinder are connected though piston shoes and a retracting ring , so that the shoes beat anainst an angled swash plate . As the block turns ,the piston shoes follow the swash plate ,causing the piston to reciprocate . The ports are arranged in the valve plate so that the pistons pass the inlet port as they are being pulled out and pass the outlet port as they are being forcing back in .The angle of the swash plate controls the delibery . Where the swash plate is fixed , the pump is of the constant-displacement type . In the variable-displacement , inline piston pump , the swash plate is moumted on a pivoted yoke . As the swash plate angle is increased , the cylinder stroke is increase , resulting in a greater flow . A pressure compensator control can position the yoke automatically to maintain a constant output pressure .6、BENT-axis piston pumpAs the shaft roates , distance between any one piston and the valving surface changes continually . Each piston moves away from the valving surface during one half of the revolution and toward the valving surface during the other half . The inlet chamber is in line as the pistons move away , and the outletr chamber is in line as the pistons move closer , thus drawing liquiring in during one half of the inlet chamber as the pistons are moving away from the pintle . Thereforce , during rotation , pistons draw liquid into the cylinder bores as they pass the inlet side of the pinntle and force that liquid out of the bores as they pass the outlet side of the pintle . The displacement of this pump varies with the offset angle , the maximum angle being 30 degree ,the minimum zero . Fixed displacement models are usually avaiable with 23 degree angle .In the variable displacement construction a yoke with an external control is used to change the angle . With some contronls , the yoke can be moved over center to reverse the direction of flow from the pump .7、Pump/system interactionPressure-compensated variavle delivery pumps do not require a relief valve in the high pressure line . The pressure compensation feature eliminates the need for the relief valve .In nearly all working systems ,however , at least one is used on just-in-case basis . The use of a pressure compensator , while avoiding dependence on a relief valve , brings on its own problems .The actuator -spring-spool arrangement in the compensator is a dynamic , damped-mass-spring arrangement .However , when the system calls for a chang in axhievetheir maxmum volume as they reach the inlet port , the maximum volume of fluid will ve moved .If the relationship between housing and rotor is changed such that the chambers achieve their minimum of zero volume as they reach the inlet port , the pump delivery will be reduced to zero .Vane pump speed is limited by vane peripheral speed . High peripheral speed will cause cavitation in suction cavity , which results in pump damage and reduced flow . An imbalance of the vanes can cause the oil film between the cane tips and the cam ring to break down , resulting in metal-to-metal contact and subsequent increased wear and slipage . One method applied to eliminate high vane thrust loading is a dual-vane construction . In the dual-vane construction , tow independent vanes are located in each totor slot chmbered edges along the sides and top of each vane from a channel that essentially balances the hydraulic pressure on the top and bottom of each pair of vanes .Centrifugal force cause the vane to follow the contour of the cam-shaped ring .There is just sufficient seal between the vanes and ring without destroying the thin oil film .外文文献中文翻译:常用的液压系统的动力源是泵和蓄能器。

轮胎压力监测中英文资料外文翻译文献This paper discusses the use of surface acoustic wave (SAW) XXX SAW sensors。

tire pressure XXX during every phase of driving。

The authors present their prototypes for measuring tire pressure。

the SAW sensors used。

and the XXX test rides.ning tires XXX human life while operating a road XXX Nowadays。

car manufacturers try to save space and weight by not including a XXX。

this can lead to XXX and the need for a tire change is still XXX punctures。

it is essential to measure tire XXX 20 grams。

causing high dynamic load。

A few years ago。

XXX。

These devices use an one port SAW delay line XXX devices that do not require a power supply or XXX。

XXX.In this paper。

we discuss XXX discuss the XXX。

XXX driving。

ensuring the safety of drivers and passengers on the road.Passive SAW pressure sensors operate as either a one-port delay line with XXX。

减速器论文中英文对照资料外文翻译文献What is a Gearbox?A XXX.1.The n of a Gearbox1) The gearbox ces the speed while increasing the output torque。

The torque output。

is the motor output multiplied by the n。

but it should not exceed the XXX.2) The gearbox also ces the inertia of the load。

which decreases by the square of the n。

Most motors have an inertia value that can be XXX.2.Types of GearboxesCommon gearboxes include bevel gear cers (including parallel-axis bevel gear cers。

worm gear cers。

and cone gear cers)。

ary gear cers。

cycloid cers。

worm gear cers。

XXX.mon Gearboxes1) The main feature of the worm gear cer is its reverse self-locking n。

which can achieve a large n。

The input and output shafts are not on the same axis or in the same plane。

However。

it generally has a large volume。

low n efficiency。

and low n.2) XXX and power。

It has a small size and high n。

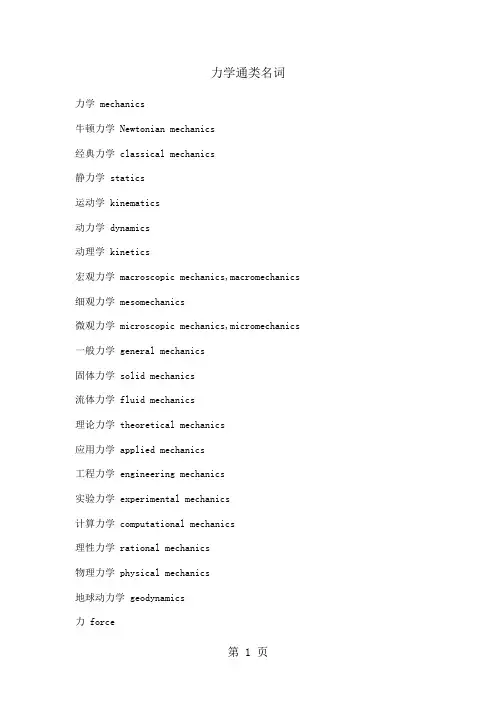

力学通类名词力学 mechanics牛顿力学 Newtonian mechanics经典力学 classical mechanics静力学 statics运动学 kinematics动力学 dynamics动理学 kinetics宏观力学 macroscopic mechanics,macromechanics 细观力学 mesomechanics微观力学 microscopic mechanics,micromechanics 一般力学 general mechanics固体力学 solid mechanics流体力学 fluid mechanics理论力学 theoretical mechanics应用力学 applied mechanics工程力学 engineering mechanics实验力学 experimental mechanics计算力学 computational mechanics理性力学 rational mechanics物理力学 physical mechanics地球动力学 geodynamics力 force作用点 point of action作用线 line of action力系 system of forces力系的简化 reduction of force system 等效力系 equivalent force system刚体 rigid body力的可传性 transmissibility of force 平行四边形定则 parallelogram rule力三角形 force triangle力多边形 force polygon零力系 null-force system平衡 equilibrium力的平衡 equilibrium of forces平衡条件 equilibrium condition平衡位置 equilibrium position平衡态 equilibrium state分析力学 analytical mechanics拉格朗日乘子 Lagrange multiplier拉格朗日[量] Lagrangian拉格朗日括号 Lagrange bracket循环坐标 cyclic coordinate循环积分 cyclic integral哈密顿[量] Hamiltonian哈密顿函数 Hamiltonian function正则方程 canonical equation正则摄动 canonical perturbation正则变换 canonical transformation正则变量 canonical variable哈密顿原理 Hamilton principle作用量积分 action integral哈密顿--雅可比方程 Hamilton-Jacobi equation 作用--角度变量 action-angle variables阿佩尔方程 Appell equation劳斯方程 Routh equation拉格朗日函数 Lagrangian function诺特定理 Noether theorem泊松括号 poisson bracket边界积分法 boundary integral method并矢 dyad运动稳定性 stability of motion轨道稳定性 orbital stability李雅普诺夫函数 Lyapunov function渐近稳定性 asymptotic stability结构稳定性 structural stability久期不稳定性 secular instability弗洛凯定理 Floquet theorem倾覆力矩 capsizing moment自由振动 free vibration固有振动 natural vibration暂态 transient state环境振动 ambient vibration反共振 anti-resonance衰减 attenuation库仑阻尼 Coulomb damping同相分量 in-phase component非同相分量 out-of-phase component超调量 overshoot参量[激励]振动 parametric vibration模糊振动 fuzzy vibration临界转速 critical speed of rotation阻尼器 damper半峰宽度 half-peak width集总参量系统 lumped parameter system相平面法 phase plane method相轨迹 phase trajectory等倾线法 isocline method跳跃现象 jump phenomenon负阻尼 negative damping达芬方程 Duffing equation希尔方程 Hill equationKBM方法 KBM method, Krylov-Bogoliu-bov-Mitropol'skii method 马蒂厄方程 Mathieu equation平均法 averaging method组合音调 combination tone解谐 detuning耗散函数 dissipative function硬激励 hard excitation硬弹簧 hard spring, hardening spring谐波平衡法 harmonic balance method久期项 secular term自激振动 self-excited vibration分界线 separatrix亚谐波 subharmonic软弹簧 soft spring ,softening spring软激励 soft excitation邓克利公式 Dunkerley formula瑞利定理 Rayleigh theorem分布参量系统 distributed parameter system 优势频率 dominant frequency模态分析 modal analysis固有模态 natural mode of vibration同步 synchronization超谐波 ultraharmonic范德波尔方程 van der pol equation频谱 frequency spectrum基频 fundamental frequencyWKB方法 WKB method, Wentzel-Kramers-Brillouin method 缓冲器 buffer风激振动 aeolian vibration嗡鸣 buzz倒谱 cepstrum颤动 chatter蛇行 hunting阻抗匹配 impedance matching机械导纳 mechanical admittance机械效率 mechanical efficiency机械阻抗 mechanical impedance随机振动 stochastic vibration, random vibration隔振 vibration isolation减振 vibration reduction应力过冲 stress overshoot喘振 surge摆振 shimmy起伏运动 phugoid motion起伏振荡 phugoid oscillation驰振 galloping陀螺动力学 gyrodynamics陀螺摆 gyropendulum陀螺平台 gyroplatform陀螺力矩 gyroscoopic torque陀螺稳定器 gyrostabilizer陀螺体 gyrostat惯性导航 inertial guidance姿态角 attitude angle方位角 azimuthal angle舒勒周期 Schuler period机器人动力学 robot dynamics多体系统 multibody system多刚体系统 multi-rigid-body system机动性 maneuverability凯恩方法 Kane method转子[系统]动力学 rotor dynamics转子[一支承一基础]系统 rotor-support-foundation system 静平衡 static balancing动平衡 dynamic balancing静不平衡 static unbalance动不平衡 dynamic unbalance现场平衡 field balancing不平衡 unbalance不平衡量 unbalance互耦力 cross force挠性转子 flexible rotor分频进动 fractional frequency precession半频进动 half frequency precession油膜振荡 oil whip转子临界转速 rotor critical speed自动定心 self-alignment亚临界转速 subcritical speed涡动 whirl连续过程 continuous process碰撞截面 collision cross section通用气体常数 conventional gas constant 燃烧不稳定性 combustion instability稀释度 dilution完全离解 complete dissociation火焰传播 flame propagation组份 constituent碰撞反应速率 collision reaction rate 燃烧理论 combustion theory浓度梯度 concentration gradient阴极腐蚀 cathodic corrosion火焰速度 flame speed火焰驻定 flame stabilization火焰结构 flame structure着火 ignition湍流火焰 turbulent flame层流火焰 laminar flame燃烧带 burning zone渗流 flow in porous media, seepage达西定律 Darcy law赫尔-肖流 Hele-Shaw flow毛[细]管流 capillary flow过滤 filtration爪进 fingering不互溶驱替 immiscible displacement不互溶流体 immiscible fluid互溶驱替 miscible displacement互溶流体 miscible fluid迁移率 mobility流度比 mobility ratio渗透率 permeability孔隙度 porosity多孔介质 porous medium比面 specific surface迂曲度 tortuosity空隙 void空隙分数 void fraction注水 water flooding可湿性 wettability地球物理流体动力学 geophysical fluid dynamics 物理海洋学 physical oceanography大气环流 atmospheric circulation海洋环流 ocean circulation海洋流 ocean current旋转流 rotating flow平流 advection埃克曼流 Ekman flow埃克曼边界层 Ekman boundary layer大气边界层 atmospheric boundary layer大气-海洋相互作用 atmosphere-ocean interaction 埃克曼数 Ekman number罗斯贝数 Rossby unmber罗斯贝波 Rossby wave斜压性 baroclinicity正压性 barotropy内磨擦 internal friction海洋波 ocean wave盐度 salinity环境流体力学 environmental fluid mechanics斯托克斯流 Stokes flow羽流 plume理查森数 Richardson number污染源 pollutant source污染物扩散 pollutant diffusion噪声 noise噪声级 noise level噪声污染 noise pollution排放物 effulent工业流体力学 industrical fluid mechanics流控技术 fluidics轴向流 axial flow并向流 co-current flow对向流 counter current flow横向流 cross flow螺旋流 spiral flow旋拧流 swirling flow滞后流 after flow混合层 mixing layer抖振 buffeting风压 wind pressure附壁效应 wall attachment effect, Coanda effect简约频率 reduced frequency爆炸力学 mechanics of explosion终点弹道学 terminal ballistics动态超高压技术 dynamic ultrahigh pressure technique 流体弹塑性体 hydro-elastoplastic medium热塑不稳定性 thermoplastic instability空中爆炸 explosion in air地下爆炸 underground explosion水下爆炸 underwater explosion电爆炸 discharge-induced explosion激光爆炸 laser-induced explosion核爆炸 nuclear explosion点爆炸 point-source explosion殉爆 sympathatic detonation强爆炸 intense explosion粒子束爆炸 explosion by beam radiation 聚爆 implosion起爆 initiation of explosion爆破 blasting霍普金森杆 Hopkinson bar电炮 electric gun电磁炮 electromagnetic gun爆炸洞 explosion chamber轻气炮 light gas gun马赫反射 Mach reflection基浪 base surge成坑 cratering能量沉积 energy deposition爆心 explosion center爆炸当量 explosion equivalent火球 fire ball爆高 height of burst蘑菇云 mushroom侵彻 penetration规则反射 regular reflection崩落 spallation应变率史 strain rate history流变学 rheology聚合物减阻 drag reduction by polymers挤出[物]胀大 extrusion swell, die swell 无管虹吸 tubeless siphon剪胀效应 dilatancy effect孔压[误差]效应 hole-pressure[error]effect 剪切致稠 shear thickening剪切致稀 shear thinning触变性 thixotropy反触变性 anti-thixotropy超塑性 superplasticity粘弹塑性材料 viscoelasto-plastic material 滞弹性材料 anelastic material本构关系 constitutive relation麦克斯韦模型 Maxwell model沃伊特-开尔文模型 Voigt-Kelvin model宾厄姆模型 Bingham model奥伊洛特模型 Oldroyd model幂律模型 power law model应力松驰 stress relaxation应变史 strain history应力史 stress history记忆函数 memory function衰退记忆 fading memory应力增长 stress growing粘度函数 voscosity function相对粘度 relative viscosity复态粘度 complex viscosity拉伸粘度 elongational viscosity拉伸流动 elongational flow第一法向应力差 first normal-stress difference 第二法向应力差 second normal-stress difference 德博拉数 Deborah number魏森贝格数 Weissenberg number动态模量 dynamic modulus振荡剪切流 oscillatory shear flow宇宙气体动力学 cosmic gas dynamics等离[子]体动力学 plasma dynamics电离气体 ionized gas行星边界层 planetary boundary layer阿尔文波 Alfven wave泊肃叶-哈特曼流] Poiseuille-Hartman flow哈特曼数 Hartman number生物流变学 biorheology生物流体 biofluid生物屈服点 bioyield point生物屈服应力 bioyield stress电气体力学 electro-gas dynamics铁流体力学 ferro-hydrodynamics血液流变学 hemorheology, blood rheology血液动力学 hemodynamics磁流体力学 magneto fluid mechanics磁流体动力学 magnetohydrodynamics, MHD磁流体动力波 magnetohydrodynamic wave磁流体流 magnetohydrodynamic flow磁流体动力稳定性 magnetohydrodynamic stability 生物力学 biomechanics生物流体力学 biological fluid mechanics生物固体力学 biological solid mechanics宾厄姆塑性流 Bingham plastic flow开尔文体 Kelvin body沃伊特体 Voigt body可贴变形 applicable deformation可贴曲面 applicable surface边界润滑 boundary lubrication液膜润滑 fluid film lubrication向心收缩功 concentric work离心收缩功 eccentric work关节反作用力 joint reaction force微循环力学 microcyclic mechanics微纤维 microfibril渗透性 permeability生理横截面积 physiological cross-sectional area 农业生物力学 agrobiomechanics纤维度 fibrousness硬皮度 rustiness胶粘度 gumminess粘稠度 stickiness嫩度 tenderness渗透流 osmotic flow易位流 translocation flow蒸腾流 transpirational flow过滤阻力 filtration resistance压扁 wafering风雪流 snow-driving wind停滞堆积 accretion遇阻堆积 encroachment沙漠地面 desert floor流沙固定 fixation of shifting sand流动阈值 fluid threshold固体力学弹性力学 elasticity弹性理论 theory of elasticity均匀应力状态 homogeneous state of stress应力不变量 stress invariant应变不变量 strain invariant应变椭球 strain ellipsoid均匀应变状态 homogeneous state of strain应变协调方程 equation of strain compatibility拉梅常量 Lame constants各向同性弹性 isotropic elasticity旋转圆盘 rotating circular disk楔 wedge开尔文问题 Kelvin problem布西内斯克问题 Boussinesq problem艾里应力函数 Airy stress function克罗索夫--穆斯赫利什维利法 Kolosoff-Muskhelishvili method 基尔霍夫假设 Kirchhoff hypothesis板 Plate矩形板 Rectangular plate圆板 Circular plate环板 Annular plate波纹板 Corrugated plate加劲板 Stiffened plate,reinforced Plate中厚板 Plate of moderate thickness弯[曲]应力函数 Stress function of bending壳 Shell扁壳 Shallow shell旋转壳 Revolutionary shell球壳 Spherical shell[圆]柱壳 Cylindrical shell锥壳 Conical shell环壳 Toroidal shell封闭壳 Closed shell波纹壳 Corrugated shell扭[转]应力函数 Stress function of torsion 翘曲函数 Warping function半逆解法 semi-inverse method瑞利--里茨法 Rayleigh-Ritz method松弛法 Relaxation method莱维法 Levy method松弛 Relaxation量纲分析 Dimensional analysis自相似[性] self-similarity影响面 Influence surface接触应力 Contact stress赫兹理论 Hertz theory协调接触 Conforming contact滑动接触 Sliding contact滚动接触 Rolling contact压入 Indentation各向异性弹性 Anisotropic elasticity颗粒材料 Granular material散体力学 Mechanics of granular media热弹性 Thermoelasticity超弹性 Hyperelasticity粘弹性 Viscoelasticity对应原理 Correspondence principle褶皱 Wrinkle塑性全量理论 Total theory of plasticity 滑动 Sliding微滑 Microslip粗糙度 Roughness非线性弹性 Nonlinear elasticity大挠度 Large deflection突弹跳变 snap-through有限变形 Finite deformation格林应变 Green strain阿尔曼西应变 Almansi strain弹性动力学 Dynamic elasticity运动方程 Equation of motion准静态的 Quasi-static气动弹性 Aeroelasticity水弹性 Hydroelasticity颤振 Flutter弹性波 Elastic wave简单波 Simple wave柱面波 Cylindrical wave水平剪切波 Horizontal shear wave竖直剪切波 Vertical shear wave体波 body wave无旋波 Irrotational wave畸变波 Distortion wave膨胀波 Dilatation wave瑞利波 Rayleigh wave等容波 Equivoluminal wave勒夫波 Love wave界面波 Interfacial wave边缘效应 edge effect塑性力学 Plasticity可成形性 Formability金属成形 Metal forming耐撞性 Crashworthiness结构抗撞毁性 Structural crashworthiness 拉拔 Drawing破坏机构 Collapse mechanism回弹 Springback挤压 Extrusion冲压 Stamping穿透 Perforation层裂 Spalling塑性理论 Theory of plasticity安定[性]理论 Shake-down theory运动安定定理 kinematic shake-down theorem 静力安定定理 Static shake-down theorem率相关理论 rate dependent theorem载荷因子 load factor加载准则 Loading criterion加载函数 Loading function加载面 Loading surface塑性加载 Plastic loading塑性加载波 Plastic loading wave简单加载 Simple loading比例加载 Proportional loading卸载 Unloading卸载波 Unloading wave冲击载荷 Impulsive load阶跃载荷 step load脉冲载荷 pulse load极限载荷 limit load中性变载 nentral loading拉抻失稳 instability in tension加速度波 acceleration wave本构方程 constitutive equation完全解 complete solution名义应力 nominal stress过应力 over-stress真应力 true stress等效应力 equivalent stress流动应力 flow stress应力间断 stress discontinuity应力空间 stress space主应力空间 principal stress space静水应力状态 hydrostatic state of stress 对数应变 logarithmic strain工程应变 engineering strain等效应变 equivalent strain应变局部化 strain localization应变率 strain rate应变率敏感性 strain rate sensitivity应变空间 strain space有限应变 finite strain塑性应变增量 plastic strain increment累积塑性应变 accumulated plastic strain 永久变形 permanent deformation内变量 internal variable应变软化 strain-softening理想刚塑性材料 rigid-perfectly plastic Material 刚塑性材料 rigid-plastic material理想塑性材料 perfectl plastic material材料稳定性 stability of material应变偏张量 deviatoric tensor of strain应力偏张量 deviatori tensor of stress应变球张量 spherical tensor of strain应力球张量 spherical tensor of stress路径相关性 path-dependency线性强化 linear strain-hardening应变强化 strain-hardening随动强化 kinematic hardening各向同性强化 isotropic hardening强化模量 strain-hardening modulus幂强化 power hardening塑性极限弯矩 plastic limit bending Moment塑性极限扭矩 plastic limit torque弹塑性弯曲 elastic-plastic bending弹塑性交界面 elastic-plastic interface弹塑性扭转 elastic-plastic torsion粘塑性 Viscoplasticity非弹性 Inelasticity理想弹塑性材料 elastic-perfectly plastic Material极限分析 limit analysis极限设计 limit design极限面 limit surface上限定理 upper bound theorem上屈服点 upper yield point下限定理 lower bound theorem下屈服点 lower yield point界限定理 bound theorem初始屈服面 initial yield surface后继屈服面 subsequent yield surface屈服面[的]外凸性 convexity of yield surface 截面形状因子 shape factor of cross-section 沙堆比拟 sand heap analogy屈服 Yield屈服条件 yield condition屈服准则 yield criterion屈服函数 yield function屈服面 yield surface塑性势 plastic potential能量吸收装置 energy absorbing device能量耗散率 energy absorbing device塑性动力学 dynamic plasticity塑性动力屈曲 dynamic plastic buckling塑性动力响应 dynamic plastic response塑性波 plastic wave运动容许场 kinematically admissible Field静力容许场 statically admissible Field流动法则 flow rule速度间断 velocity discontinuity滑移线 slip-lines滑移线场 slip-lines field移行塑性铰 travelling plastic hinge塑性增量理论 incremental theory of Plasticity米泽斯屈服准则 Mises yield criterion普朗特--罗伊斯关系 prandtl- Reuss relation特雷斯卡屈服准则 Tresca yield criterion洛德应力参数 Lode stress parameter莱维--米泽斯关系 Levy-Mises relation亨基应力方程 Hencky stress equation赫艾--韦斯特加德应力空间 Haigh-Westergaard stress space 洛德应变参数 Lode strain parameter德鲁克公设 Drucker postulate盖林格速度方程 Geiringer velocity Equation结构力学 structural mechanics结构分析 structural analysis结构动力学 structural dynamics拱 Arch三铰拱 three-hinged arch抛物线拱 parabolic arch圆拱 circular arch穹顶 Dome空间结构 space structure空间桁架 space truss雪载[荷] snow load风载[荷] wind load土压力 earth pressure地震载荷 earthquake loading弹簧支座 spring support支座位移 support displacement支座沉降 support settlement超静定次数 degree of indeterminacy 机动分析 kinematic analysis结点法 method of joints截面法 method of sections结点力 joint forces共轭位移 conjugate displacement影响线 influence line三弯矩方程 three-moment equation 单位虚力 unit virtual force刚度系数 stiffness coefficient柔度系数 flexibility coefficient 力矩分配 moment distribution力矩分配法 moment distribution method力矩再分配 moment redistribution分配系数 distribution factor矩阵位移法 matri displacement method单元刚度矩阵 element stiffness matrix单元应变矩阵 element strain matrix总体坐标 global coordinates贝蒂定理 Betti theorem高斯--若尔当消去法 Gauss-Jordan elimination Method 屈曲模态 buckling mode复合材料力学 mechanics of composites复合材料 composite material纤维复合材料 fibrous composite单向复合材料 unidirectional composite泡沫复合材料 foamed composite颗粒复合材料 particulate composite层板 Laminate夹层板 sandwich panel正交层板 cross-ply laminate斜交层板 angle-ply laminate层片 Ply多胞固体 cellular solid膨胀 Expansion压实 Debulk劣化 Degradation脱层 Delamination脱粘 Debond纤维应力 fiber stress层应力 ply stress层应变 ply strain层间应力 interlaminar stress比强度 specific strength强度折减系数 strength reduction factor 强度应力比 strength -stress ratio横向剪切模量 transverse shear modulus 横观各向同性 transverse isotropy正交各向异 Orthotropy剪滞分析 shear lag analysis短纤维 chopped fiber长纤维 continuous fiber纤维方向 fiber direction纤维断裂 fiber break纤维拔脱 fiber pull-out纤维增强 fiber reinforcement致密化 Densification最小重量设计 optimum weight design网格分析法 netting analysis混合律 rule of mixture失效准则 failure criterion蔡--吴失效准则 Tsai-W u failure criterion达格代尔模型 Dugdale model断裂力学 fracture mechanics概率断裂力学 probabilistic fracture Mechanics格里菲思理论 Griffith theory线弹性断裂力学 linear elastic fracture mechanics, LEFM 弹塑性断裂力学 elastic-plastic fracture mecha-nics, EPFM 断裂 Fracture脆性断裂 brittle fracture解理断裂 cleavage fracture蠕变断裂 creep fracture延性断裂 ductile fracture晶间断裂 inter-granular fracture准解理断裂 quasi-cleavage fracture穿晶断裂 trans-granular fracture裂纹 Crack裂缝 Flaw缺陷 Defect割缝 Slit微裂纹 Microcrack折裂 Kink椭圆裂纹 elliptical crack深埋裂纹 embedded crack[钱]币状裂纹 penny-shape crack预制裂纹 Precrack短裂纹 short crack表面裂纹 surface crack裂纹钝化 crack blunting裂纹分叉 crack branching裂纹闭合 crack closure裂纹前缘 crack front裂纹嘴 crack mouth裂纹张开角 crack opening angle,COA裂纹张开位移 crack opening displacement, COD裂纹阻力 crack resistance裂纹面 crack surface裂纹尖端 crack tip裂尖张角 crack tip opening angle, CTOA裂尖张开位移 crack tip opening displacement, CTOD 裂尖奇异场 crack tip singularity Field裂纹扩展速率 crack growth rate稳定裂纹扩展 stable crack growth定常裂纹扩展 steady crack growth亚临界裂纹扩展 subcritical crack growth裂纹[扩展]减速 crack retardation止裂 crack arrest止裂韧度 arrest toughness断裂类型 fracture mode滑开型 sliding mode张开型 opening mode撕开型 tearing mode复合型 mixed mode撕裂 Tearing撕裂模量 tearing modulus断裂准则 fracture criterionJ积分 J-integralJ阻力曲线 J-resistance curve断裂韧度 fracture toughness应力强度因子 stress intensity factorHRR场 Hutchinson-Rice-Rosengren Field守恒积分 conservation integral有效应力张量 effective stress tensor应变能密度 strain energy density能量释放率 energy release rate内聚区 cohesive zone塑性区 plastic zone张拉区 stretched zone热影响区 heat affected zone, HAZ延脆转变温度 brittle-ductile transition temperature 剪切带 shear band剪切唇 shear lip无损检测 non-destructive inspection双边缺口试件 double edge notched specimen, DEN specimen单边缺口试件 single edge notched specimen, SEN specimen三点弯曲试件 three point bending specimen, TPB specimen中心裂纹拉伸试件 center cracked tension specimen, CCT specimen 中心裂纹板试件 center cracked panel specimen, CCP specimen紧凑拉伸试件 compact tension specimen, CT specimen大范围屈服 large scale yielding小范围攻屈服 small scale yielding韦布尔分布 Weibull distribution帕里斯公式 paris formula空穴化 Cavitation应力腐蚀 stress corrosion概率风险判定 probabilistic risk assessment, PRA损伤力学 damage mechanics损伤 Damage连续介质损伤力学 continuum damage mechanics细观损伤力学 microscopic damage mechanics累积损伤 accumulated damage脆性损伤 brittle damage延性损伤 ductile damage宏观损伤 macroscopic damage细观损伤 microscopic damage微观损伤 microscopic damage损伤准则 damage criterion损伤演化方程 damage evolution equation 损伤软化 damage softening损伤强化 damage strengthening损伤张量 damage tensor损伤阈值 damage threshold损伤变量 damage variable损伤矢量 damage vector损伤区 damage zone疲劳 Fatigue低周疲劳 low cycle fatigue应力疲劳 stress fatigue随机疲劳 random fatigue蠕变疲劳 creep fatigue腐蚀疲劳 corrosion fatigue疲劳损伤 fatigue damage疲劳失效 fatigue failure疲劳断裂 fatigue fracture疲劳裂纹 fatigue crack疲劳寿命 fatigue life疲劳破坏 fatigue rupture疲劳强度 fatigue strength疲劳辉纹 fatigue striations疲劳阈值 fatigue threshold交变载荷 alternating load交变应力 alternating stress应力幅值 stress amplitude应变疲劳 strain fatigue应力循环 stress cycle应力比 stress ratio安全寿命 safe life过载效应 overloading effect循环硬化 cyclic hardening循环软化 cyclic softening环境效应 environmental effect裂纹片 crack gage裂纹扩展 crack growth, crack Propagation 裂纹萌生 crack initiation循环比 cycle ratio实验应力分析 experimental stress Analysis 工作[应变]片 active[strain] gage基底材料 backing material应力计 stress gage零[点]飘移 zero shift, zero drift应变测量 strain measurement应变计 strain gage应变指示器 strain indicator应变花 strain rosette应变灵敏度 strain sensitivity机械式应变仪 mechanical strain gage直角应变花 rectangular rosette引伸仪 Extensometer应变遥测 telemetering of strain横向灵敏系数 transverse gage factor横向灵敏度 transverse sensitivity焊接式应变计 weldable strain gage平衡电桥 balanced bridge粘贴式应变计 bonded strain gage粘贴箔式应变计 bonded foiled gage粘贴丝式应变计 bonded wire gage桥路平衡 bridge balancing电容应变计 capacitance strain gage补偿片 compensation technique补偿技术 compensation technique基准电桥 reference bridge电阻应变计 resistance strain gage温度自补偿应变计 self-temperature compensating gage 半导体应变计 semiconductor strain Gage集流器 slip ring应变放大镜 strain amplifier疲劳寿命计 fatigue life gage电感应变计 inductance [strain] gage光[测]力学 Photomechanics光弹性 Photoelasticity光塑性 Photoplasticity杨氏条纹 Young fringe双折射效应 birefrigent effect等位移线 contour of equal Displacement暗条纹 dark fringe条纹倍增 fringe multiplication干涉条纹 interference fringe等差线 Isochromatic等倾线 Isoclinic等和线 isopachic应力光学定律 stress- optic law主应力迹线 Isostatic亮条纹 light fringe光程差 optical path difference热光弹性 photo-thermo -elasticity光弹性贴片法 photoelastic coating Method 光弹性夹片法 photoelastic sandwich Method 动态光弹性 dynamic photo-elasticity空间滤波 spatial filtering空间频率 spatial frequency起偏镜 Polarizer反射式光弹性仪 reflection polariscope残余双折射效应 residual birefringent Effect应变条纹值 strain fringe value应变光学灵敏度 strain-optic sensitivity应力冻结效应 stress freezing effect应力条纹值 stress fringe value应力光图 stress-optic pattern暂时双折射效应 temporary birefringent Effect脉冲全息法 pulsed holography透射式光弹性仪 transmission polariscope实时全息干涉法 real-time holographic interferometry网格法 grid method全息光弹性法 holo-photoelasticity全息图 Hologram全息照相 Holograph全息干涉法 holographic interferometry全息云纹法 holographic moire technique全息术 Holography全场分析法 whole-field analysis散斑干涉法 speckle interferometry散斑 Speckle错位散斑干涉法 speckle-shearing interferometry, shearography 散斑图 Specklegram白光散斑法 white-light speckle method云纹干涉法 moire interferometry[叠栅]云纹 moire fringe[叠栅]云纹法 moire method云纹图 moire pattern离面云纹法 off-plane moire method参考栅 reference grating试件栅 specimen grating分析栅 analyzer grating面内云纹法 in-plane moire method脆性涂层法 brittle-coating method条带法 strip coating method坐标变换 transformation of Coordinates计算结构力学 computational structural mechanics 加权残量法 weighted residual method有限差分法 finite difference method有限[单]元法 finite element method配点法 point collocation里茨法 Ritz method广义变分原理 generalized variational Principle 最小二乘法 least square method胡[海昌]一鹫津原理 Hu-Washizu principle赫林格-赖斯纳原理 Hellinger-Reissner Principle 修正变分原理 modified variational Principle约束变分原理 constrained variational Principle 混合法 mixed method杂交法 hybrid method边界解法 boundary solution method有限条法 finite strip method半解析法 semi-analytical method协调元 conforming element非协调元 non-conforming element混合元 mixed element杂交元 hybrid element边界元 boundary element强迫边界条件 forced boundary condition 自然边界条件 natural boundary condition 离散化 Discretization离散系统 discrete system连续问题 continuous problem广义位移 generalized displacement广义载荷 generalized load广义应变 generalized strain广义应力 generalized stress界面变量 interface variable节点 node, nodal point[单]元 Element角节点 corner node边节点 mid-side node内节点 internal node无节点变量 nodeless variable杆元 bar element桁架杆元 truss element梁元 beam element二维元 two-dimensional element一维元 one-dimensional element三维元 three-dimensional element轴对称元 axisymmetric element板元 plate element壳元 shell element厚板元 thick plate element三角形元 triangular element四边形元 quadrilateral element四面体元 tetrahedral element曲线元 curved element二次元 quadratic element线性元 linear element三次元 cubic element四次元 quartic element等参[数]元 isoparametric element超参数元 super-parametric element亚参数元 sub-parametric element节点数可变元 variable-number-node element 拉格朗日元 Lagrange element拉格朗日族 Lagrange family巧凑边点元 serendipity element巧凑边点族 serendipity family无限元 infinite element单元分析 element analysis单元特性 element characteristics刚度矩阵 stiffness matrix几何矩阵 geometric matrix等效节点力 equivalent nodal force节点位移 nodal displacement节点载荷 nodal load位移矢量 displacement vector载荷矢量 load vector质量矩阵 mass matrix集总质量矩阵 lumped mass matrix相容质量矩阵 consistent mass matrix阻尼矩阵 damping matrix瑞利阻尼 Rayleigh damping刚度矩阵的组集 assembly of stiffness Matrices 载荷矢量的组集 consistent mass matrix质量矩阵的组集 assembly of mass matrices单元的组集 assembly of elements局部坐标系 local coordinate system局部坐标 local coordinate面积坐标 area coordinates体积坐标 volume coordinates曲线坐标 curvilinear coordinates静凝聚 static condensation合同变换 contragradient transformation 形状函数 shape function试探函数 trial function检验函数 test function权函数 weight function样条函数 spline function代用函数 substitute function降阶积分 reduced integration零能模式 zero-energy modeP收敛 p-convergenceH收敛 h-convergence掺混插值 blended interpolation等参数映射 isoparametric mapping双线性插值 bilinear interpolation小块检验 patch test非协调模式 incompatible mode节点号 node number单元号 element number带宽 band width带状矩阵 banded matrix变带状矩阵 profile matrix带宽最小化 minimization of band width波前法 frontal method子空间迭代法 subspace iteration method 行列式搜索法 determinant search method 逐步法 step-by-step method纽马克法 Newmark威尔逊法 Wilson拟牛顿法 quasi-Newton method牛顿-拉弗森法 Newton-Raphson method增量法 incremental method初应变 initial strain初应力 initial stress切线刚度矩阵 tangent stiffness matrix割线刚度矩阵 secant stiffness matrix模态叠加法 mode superposition method平衡迭代 equilibrium iteration子结构 Substructure子结构法 substructure technique超单元 super-element网格生成 mesh generation结构分析程序 structural analysis program 前处理 pre-processing后处理 post-processing网格细化 mesh refinement应力光顺 stress smoothing组合结构 composite structure流体力学流体动力学 fluid dynamics连续介质力学 mechanics of continuous media介质 medium流体质点 fluid particle无粘性流体 nonviscous fluid, inviscid fluid连续介质假设 continuous medium hypothesis流体运动学 fluid kinematics水静力学 hydrostatics液体静力学 hydrostatics支配方程 governing equation伯努利方程 Bernoulli equation伯努利定理 Bernonlli theorem毕奥-萨伐尔定律 Biot-Savart law欧拉方程 Euler equation亥姆霍兹定理 Helmholtz theorem开尔文定理 Kelvin theorem涡片 vortex sheet库塔-茹可夫斯基条件 Kutta-Zhoukowski condition 布拉休斯解 Blasius solution达朗贝尔佯廖 d'Alembert paradox雷诺数 Reynolds number施特鲁哈尔数 Strouhal number随体导数 material derivative不可压缩流体 incompressible fluid 质量守恒 conservation of mass动量守恒 conservation of momentum 能量守恒 conservation of energy 动量方程 momentum equation能量方程 energy equation控制体积 control volume液体静压 hydrostatic pressure涡量拟能 enstrophy压差 differential pressure流[动] flow流线 stream line流面 stream surface流管 stream tube迹线 path, path line流场 flow field流态 flow regime流动参量 flow parameter流量 flow rate, flow discharge涡旋 vortex涡量 vorticity。

翻译原文 (4)Photovoltaic (PV) Electric Systems (4)The Advantages of Mitsubishi Solar Panels (5)1光伏电力系统光伏电力系统利用太阳能电池吸收太阳光线,并将这种能量转化成电能。

这个系统让广大家庭通过一种清洁,可靠,平静的方式来产生电能,这样就可以补偿将来的部分电能支出,也减少了对输电网的依赖。

太阳能电池一般是由经改进的硅,或者其他能够吸收阳光并将之转化成电能的半导体材料制成。

太阳能电池是相当耐用的(1954年在美国安装的第一个光伏电力系统至今仍在运营)。

绝大多数的生厂商都担保自己的产品的电源输出至少维持20年。

但大多数的有关太阳能研究的专家认为一个光伏电力系统至少能维持25到30年。

1.1 太阳能电池的类型目前有单晶硅,多晶硅和薄膜三种基本形式的光伏组件。

这些类型的电池工作效率都很好但单晶硅电池效率最好。

薄膜技术的电池以成本低为特色,而且伴随着太阳能电池板的发展它的效率也在不断地提高。

越来越多的生厂商以及各种各样的电池型号在当今市场上出现。

一个太阳能技术的支持者可以帮你分析各个系统的利弊,如此你就可以得到为你所用数十年的最佳的系统设计方案。

1.2光伏电力系统如何运作光电板通常安装在建筑物顶部,通过逆变器来引到建筑物中。

逆变器将通过太阳能板产生的直流电转化成交流电,而在当今美国交流电是向建筑提供电动力的主要形式。

朝南方向的太阳能板能使能量的收集效果最大化,大部分都是与建筑物顶部成60度的位置安放太阳能电池。

有关太阳能电池发电的更多的信息,可以查询Cooler Planet’s的《太阳能电池如何工作》。

朝南方向的太阳能板能使能量的收集效果最大化,大部分都是与建筑物顶部成60度的位置安放太阳能电池。

1.3 太阳能电池板与光伏建筑一体化太阳能电池板是用于捕获太阳光的平面板,他们以阵列的形式安装在建筑物顶部或者柱子上。

他们是传统的用于获得太阳能的阵列形式。

The History of Crane1. OverviewThe first construction cranes were invented by the Ancient Greeks and were powered by men or beasts of burden, such as donkeys. These cranes were used for the construction of tall buildings. Larger cranes were later developed, employing the use of human treadwheels, permitting the lifting of heavier weights. In the High Middle Ages, harbor cranes were introducedto load and unload ships and assist with their construction – some were built into stone towers for extra strength and stability. The earliest cranes were constructed from wood, but cast iron and steel took over with the coming of the Industrial Revolution.For many centuries, power was supplied by the physical exertion of men or animals, although hoists in watermills and windmills could be driven by the harnessed natural power. The first 'mechanical' power was provided by steam engines, the earliest steam crane being introducedin the 18th or 19th century, with many remaining in use well into the late 20th century. Modern cranes usually use internal combustion engines or electric motors and hydraulic systems to provide a much greater lifting capability than was previously possible, although manual cranes are still utilized where the provision of power would be uneconomic.Cranes exist in an enormous variety of forms – each tailored to a specific use. Sizes range from the smallest jib cranes, used inside workshops, to the tallest tower cranes, used for constructing high buildings. For a while, mini - cranes are also used for constructing high buildings, in order to facilitate constructions by reaching tight spaces. Finally, we can find larger floating cranes, generally used to build oil rigs and salvage sunken ships. This article also covers lifting machines that do not strictly fit the above definition of a crane, but are generally known as cranes, such as stacker cranes and loader cranes.2. History(1)Ancient GreeceThe crane for lifting heavy loads was invented by the Ancient Greeks in the late 6th century BC. The archaeological record shows that no later than c.515 BC distinctive cuttings for both lifting tongs and lewis irons begin to appear on stone blocks of Greek temples. Since these holes point at the use of a lifting device, and since they are to be found either above the center of gravity of the block, or in pairs equidistant from a point over the center of gravity, they are regarded by archaeologists as the positive evidence required for the existence of the crane.The introduction of the winch and pulley hoist soon lead to a widespread replacement of ramps as the main means of vertical motion. For the next two hundred years, Greek building sites witnesseda sharp drop in the weights handled, as the new lifting technique made the use of several smaller stones more practical than of fewer larger ones. In contrast to the archaic period with its tendencyto ever-increasing block sizes, Greek temples of the classical age like the Parthenon invariably featured stone blocks weighing less than 15-20 tons. Also, the practice of erecting large monolithic columns was practically abandoned in favor of using several column drums.Although the exact circumstances of the shift from the ramp to the crane technology remain unclear, it has been argued that the volatile social and political conditions of Greece were moresuitable to the employment of small, professional construction teams than of large bodies of unskilled labor, making the crane more preferable to the Greek polis than the more labor-intensive ramp which had been the norm in the autocratic societies of Egypt or Assyria.The first unequivocal literary evidence for the existence of the compound pulley system appears in the Mechanical Problems (Mech. 18, 853a32-853b13) attributed to Aristotle (384-322 BC), but perhaps composed at a slightly later date. Around the same time, block sizes at Greek temples began to match their archaic predecessors again, indicating that the more sophisticated compound pulley must have found its way to Greek construction sites by then.Ancient RomeThe heyday of the crane in ancient times came during the Roman Empire, when construction activity soared and buildings reached enormous dimensions. The Romans adopted the Greek crane and developed it further. We are relatively well informed about their lifting techniques, thanks to rather lengthy accounts by the engineers Vitruvius (De Architectura 10.2, 1-10) and Heron of Alexandria (Mechanica 3.2-5). There are also two surviving reliefs of Roman treadwheel cranes, with the Haterii tombstone from the late first century AD being particularly detailed.The simplest Roman crane, the Trispastos, consisted of a single-beam jib, a winch, a rope, and a block containing three pulleys. Having thus a mechanical advantage of 3:1, it has been calculated that a single man working the winch could raise 150 kg (3 pulleys x 50 kg = 150), assuming that 50 kg represent the maximum effort a man can exert over a longer time period. Heavier crane types featured five pulleys (Pentaspastos) or, in case of the largest one, a set of three by five pulleys (Polyspastos) and came with two, three or four masts, depending on the maximum load. The Polyspastos, when worked by four men at both sides of the winch, could already lift 3000 kg (3 ropes x 5 pulleys x 4 men x 50 kg = 3000 kg). In case the winch was replaced by a treadwheel, the maximum load even doubled to 6000 kg at only half the crew, since the treadwheel possesses a much bigger mechanical advantage due to its larger diameter. This meant that, in comparison to the construction of the Egyptian Pyramids, where about 50 men were needed to move a 2.5 ton stone block up the ramp (50 kg per person), the lifting capability of the Roman Polyspastos proved to be 60 times higher (3000 kg per person).However, numerous extant Roman buildings which feature much heavier stone blocks than those handled by the Polyspastos indicate that the overall lifting capability of the Romans went far beyond that of any single crane. At the temple of Jupiter at Baalbek, for instance, the architrave blocks weigh up to 60 tons each, and one corner cornice block even over 100 tons, all of them raised to a height of about 19 m. In Rome, the capital block of Trajan's Column weighs 53.3 tons, which had to be lifted to a height of about 34 m (see construction of Trajan's Column).It is assumed that Roman engineers lifted these extraordinary weights by two measures (see picture below for comparable Renaissance technique): First, as suggested by Heron, a lifting tower was set up, whose four masts were arranged in the shape of a quadrangle with parallel sides, not unlike a siege tower, but with the column in the middle of the structure (Mechanica 3.5). Second, a multitude of capstans were placed on the ground around the tower, for, although having a lower leverage ratio than treadwheels, capstans could be set up in higher numbers and run by more men (and, moreover, by draught animals). This use of multiple capstans is also described by AmmianusMarcellinus (17.4.15) in connection with the lifting of the Lateranense obelisk in the Circus Maximus (ca. 357 AD). The maximum lifting capability of a single capstan can be established by the number of lewis iron holes bored into the monolith. In case of the Baalbek architrave blocks, which weigh between 55 and 60 tons, eight extant holes suggest an allowance of 7.5 ton per lewis iron, that is per capstan. Lifting such heavy weights in a concerted action required a great amount of coordination between the work groups applying the force to the capstans.Middle AgesDuring the High Middle Ages, the treadwheel crane was reintroduced on a large scale after the technology had fallen into disuse in western Europe with the demise of the Western Roman Empire. The earliest reference to a treadwheel (magna rota) reappears in archival literature in France about 1225, followed by an illuminated depiction in a manuscript of probably also French origin dating to 1240. In navigation, the earliest uses of harbor cranes are documented for Utrecht in 1244, Antwerp in 1263, Brugge in 1288 and Hamburg in 1291, while in England the treadwheel is not recorded before 1331.Generally, vertical transport could be done more safely and inexpensively by cranes than by customary methods. Typical areas of application were harbors, mines, and, in particular, building sites where the treadwheel crane played a pivotal role in the construction of the lofty Gothic cathedrals. Nevertheless, both archival and pictorial sources of the time suggest that newly introduced machines like treadwheels or wheelbarrows did not completely replace more labor-intensive methods like ladders, hods and handbarrows. Rather, old and new machinery continued to coexist on medieval construction sites and harbors.Apart from treadwheels, medieval depictions also show cranes to be powered manually by windlasses with radiating spokes, cranks and by the 15th century also by windlasses shaped like a ship's wheel. To smooth out irregularities of impulse and get over 'dead-spots' in the lifting process flywheels are known to be in use as early as 1123.The exact process by which the treadwheel crane was reintroduced is not recorded, although its return to construction sites has undoubtedly to be viewed in close connection with the simultaneous rise of Gothic architecture. The reappearance of the treadwheel crane may have resulted from a technological development of the windlass from which the treadwheel structurally and mechanically evolved. Alternatively, the medieval treadwheel may represent a deliberate reinvention of its Roman counterpart drawn from Vitruvius' De architectura which was available in many monastic libraries. Its reintroduction may have been inspired, as well, by the observation of the labor-saving qualities of the waterwheel with which early treadwheels shared many structural similarities.Structure and placementThe medieval treadwheel was a large wooden wheel turning around a central shaft with a treadway wide enough for two workers walking side by side. While the earlier 'compass-arm' wheel had spokes directly driven into the central shaft, the more advanced 'clasp-arm' type featured arms arranged as chords to the wheel rim, giving the possibility of using a thinner shaft and providing thus a greater mechanical advantage.Contrary to a popularly held belief, cranes on medieval building sites were neither placed on the extremely lightweight scaffolding used at the time nor on the thin walls of the Gothic churches which were incapable of supporting the weight of both hoisting machine and load. Rather, cranes were placed in the initial stages of construction on the ground, often within the building. When a new floor was completed, and massive tie beams of the roof connected the walls, the crane was dismantled and reassembled on the roof beams from where it was moved from bay to bay during construction of the vaults. Thus, the crane ‘grew’ and ‘wandered’ with the building with the result that today all extant construction cranes in England are found in church towers above the vaulting and below the roof, where they remained after building construction for bringing material for repairs aloft.Less frequently, medieval illuminations also show cranes mounted on the outside of walls with the stand of the machine secured to putlogs.Mechanics and operationIn contrast to modern cranes, medieval cranes and hoists - much like their counterparts in Greece and Rome - were primarily capable of a vertical lift, and not used to move loads for a considerable distance horizontally as well. Accordingly, lifting work was organized at the workplace in a different way than today. In building construction, for example, it is assumed that the crane lifted the stone blocks either from the bottom directly into place, or from a place opposite the centre of the wall from where it could deliver the blocks for two teams working at each end of the wall. Additionally, the crane master who usually gave orders at the treadwheel workers from outside the crane was able to manipulate the movement laterally by a small rope attached to the load. Slewing cranes which allowed a rotation of the load and were thus particularly suited for dockside work appeared as early as 1340. While ashlar blocks were directly lifted by sling, lewis or devil's clamp (German Teufelskralle), other objects were placed before in containers like pallets, baskets, wooden boxes or barrels.It is noteworthy that medieval cranes rarely featured ratchets or brakes to forestall the load from running backward. This curious absence is explained by the high friction force exercised by medieval treadwheels which normally prevented the wheel from accelerating beyond control. Harbor usageAccording to the "present state of knowledge" unknown in antiquity, stationary harbor cranes are considered a new development of the Middle Ages. The typical harbor crane was a pivoting structure equipped with double treadwheels. These cranes were placed docksides for the loading and unloading of cargo where they replaced or complemented older lifting methods like see-saws, winches and yards.Two different types of harbor cranes can be identified with a varying geographical distribution: While gantry cranes which pivoted on a central vertical axle were commonly found at the Flemish and Dutch coastside, German sea and inland harbors typically featured tower cranes where the windlass and treadwheels were situated in a solid tower with only jib arm and roof rotating. Interestingly, dockside cranes were not adopted in the Mediterranean region and the highly developed Italian ports where authorities continued to rely on the more labor-intensive method ofunloading goods by ramps beyond the Middle Ages.Unlike construction cranes where the work speed was determined by the relatively slow progressof the masons, harbor cranes usually featured double treadwheels to speed up loading. The two treadwheels whose diameter is estimated to be 4 m or larger were attached to each side of the axle and rotated together. Today, according to one survey, fifteen treadwheel harbor cranes from pre-industrial times are still extant throughout Europe.[28] Beside these stationary cranes, floating cranes which could be flexibly deployed in the whole port basin came into use by the 14th century.RenaissanceA lifting tower similar to that of the ancient Romans was used to great effect by the Renaissance architect Domenico Fontana in 1586 to relocate the 361 t heavy Vatican obelisk in Rome. From his report, it becomes obvious that the coordination of the lift between the various pulling teams required a considerable amount of concentration and discipline, since, if the force was not applied evenly, the excessive stress on the ropes would make them rupture.Early modern ageCranes were used domestically in the 17th and 18th century. The chimney or fireplace crane was used to swing pots and kettles over the fire and the height was adjusted by a trammel.4. Types of the cranesMobileMain article: Mobile craneThe most basic type of mobile crane consists of a truss or telescopic boom mounted on a mobile platform - be it on road, rail or water.FixedExchanging mobility for the ability to carry greater loads and reach greater heights due to increased stability, these types of cranes are characterized that they, or at least their main structure does not move during the period of use. However, many can still be assembled and disassembled.外文翻译起重机的历史1. 概况第一台具有机械结构的起重机是由古希腊人发明的,并且由人或者是牲畜比如驴,作为动力源。