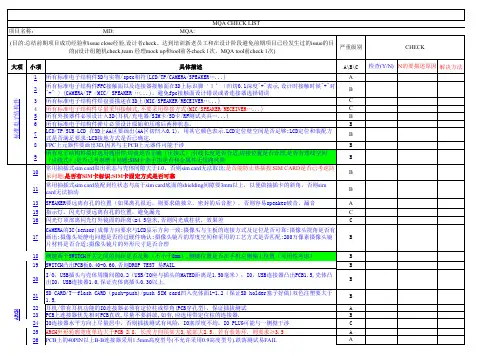

手机结构设计检查表

- 格式:doc

- 大小:293.50 KB

- 文档页数:16

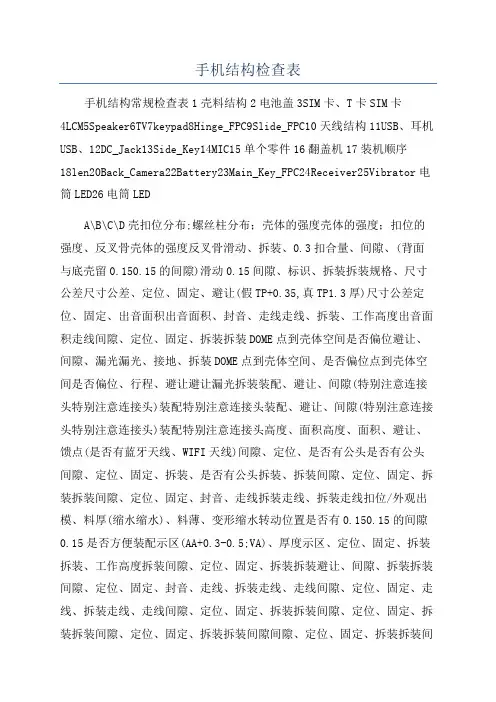

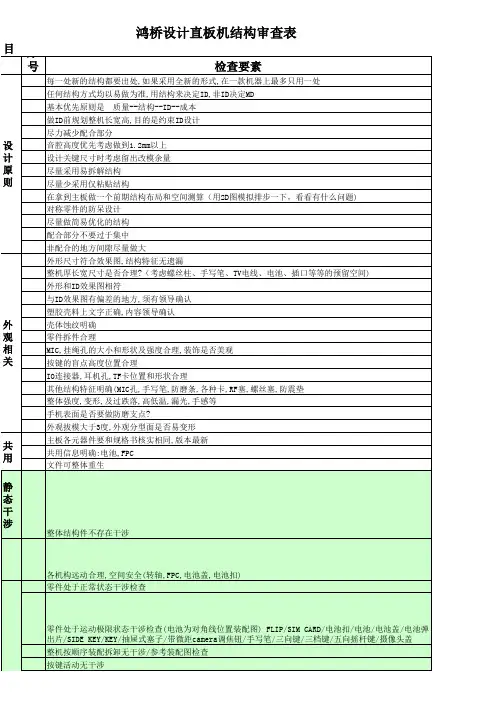

手机结构检查表手机结构常规检查表1壳料结构2电池盖3SIM卡、T卡SIM卡4LCM5Speaker6TV7keypad8Hinge_FPC9Slide_FPC10天线结构11USB、耳机USB、12DC_Jack13Side_Key14MIC15单个零件16翻盖机17装机顺序18len20Back_Camera22Battery23Main_Key_FPC24Receiver25Vibrator电筒LED26电筒LEDA\B\C\D壳扣位分布;螺丝柱分布;壳体的强度壳体的强度;扣位的强度、反叉骨壳体的强度反叉骨滑动、拆装、0.3扣合量、间隙、(背面与底壳留0.150.15的间隙)滑动0.15间隙、标识、拆装拆装规格、尺寸公差尺寸公差、定位、固定、避让(假TP+0.35,真TP1.3厚)尺寸公差定位、固定、出音面积出音面积、封音、走线走线、拆装、工作高度出音面积走线间隙、定位、固定、拆装拆装DOME点到壳体空间是否偏位避让、间隙、漏光漏光、接地、拆装DOME点到壳体空间、是否偏位点到壳体空间是否偏位、行程、避让避让漏光拆装装配、避让、间隙(特别注意连接头特别注意连接头)装配特别注意连接头装配、避让、间隙(特别注意连接头特别注意连接头)装配特别注意连接头高度、面积高度、面积、避让、馈点(是否有蓝牙天线、WIFI天线)间隙、定位、是否有公头是否有公头间隙、定位、固定、拆装、是否有公头拆装、拆装间隙、定位、固定、拆装拆装间隙、定位、固定、封音、走线拆装走线、拆装走线扣位/外观出模、料厚(缩水缩水)、料薄、变形缩水转动位置是否有0.150.15的间隙0.15是否方便装配示区(AA+0.3-0.5;VA)、厚度示区、定位、固定、拆装拆装、工作高度拆装间隙、定位、固定、拆装拆装避让、间隙、拆装拆装间隙、定位、固定、封音、走线、拆装走线、走线间隙、定位、固定、走线、拆装走线、走线间隙、定位、固定、拆装拆装间隙、定位、固定、拆装拆装间隙、定位、固定、拆装拆装间隙间隙、定位、固定、拆装拆装间隙、定位、固定、拆装拆装间隙、定位、固定(机板扣机板扣)、支撑、拆装机板扣拆装(铝片、锌合金、钢片)接地、厚度、加工形状接地、接地螺丝、螺母的大小、长度、热熔沉台大小、位置、强度厚度、宽度、避让间隙、面积宽度、避让间隙宽度全局多遍多遍检查(干涉位置抓图片)多遍19Front_Camera示区、定位、固定、拆装拆装、工作高度拆装21Cam_flah_light示区、定位、固定、拆装拆装27跑马灯28Hingelide(滑轨)29lide(滑轨)30Pen31PCB32五金33螺丝柱35吊绳孔36辅料37干涉34软胶、装饰件间隙、定位、固定、防呆软胶、注意黑粗体或加红色为重要检查内容,其他细节内容参考设计规范!。

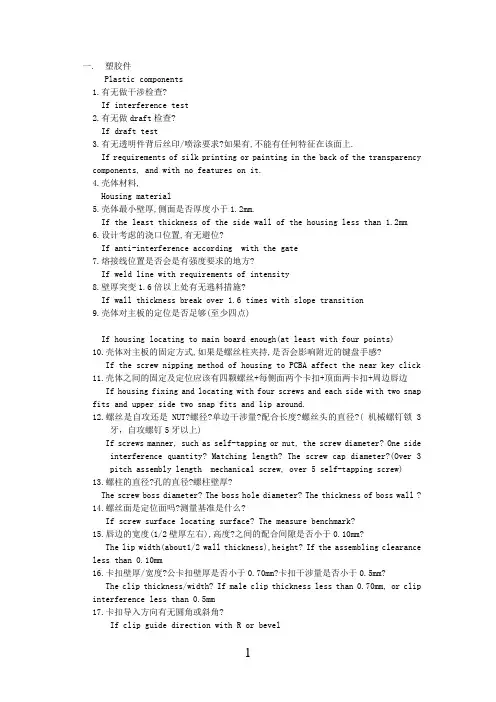

一. 塑胶件Plastic components1.有无做干涉检查?If interference test2.有无做draft检查?If draft test3.有无透明件背后丝印/喷涂要求?如果有,不能有任何特征在该面上.If requirements of silk printing or painting in the back of the transparency components, and with no features on it.4.壳体材料,Housing material5.壳体最小壁厚,侧面是否厚度小于1.2mm.If the least thickness of the side wall of the housing less than 1.2mm6.设计考虑的浇口位置,有无避位?If anti-interference according with the gate7.熔接线位置是否会是有强度要求的地方?If weld line with requirements of intensity8.壁厚突变1.6倍以上处有无逃料措施?If wall thickness break over 1.6 times with slope transition9.壳体对主板的定位是否足够(至少四点)If housing locating to main board enough(at least with four points)10.壳体对主板的固定方式,如果是螺丝柱夹持,是否会影响附近的键盘手感?If the screw nipping method of housing to PCBA affect the near key click11.壳体之间的固定及定位应该有四颗螺丝+每侧面两个卡扣+顶面两卡扣+周边唇边If housing fixing and locating with four screws and each side with two snap fits and upper side two snap fits and lip around.12.螺丝是自攻还是NUT?螺径?单边干涉量?配合长度?螺丝头的直径?( 机械螺钉锁3牙,自攻螺钉5牙以上)If screws manner, such as self-tapping or nut, the screw diameter? One side interference quantity? Matching length? The screw cap diameter?(Over 3 pitch assembly length mechanical screw, over 5 self-tapping screw)13.螺柱的直径?孔的直径?螺柱壁厚?The screw boss diameter? The boss hole diameter? The thickness of boss wall ?14.螺丝面是定位面吗?测量基准是什么?If screw surface locating surface? The measure benchmark?15.唇边的宽度(1/2壁厚左右),高度?之间的配合间隙是否小于0.10mm?The lip width(about1/2 wall thickness),height? If the assembling clearance less than 0.10mm16.卡扣壁厚/宽度?公卡扣壁厚是否小于0.70mm?卡扣干涉量是否小于0.5mm?The clip thickness/width? If male clip thickness less than 0.70mm, or clip interference less than 0.5mm17.卡扣导入方向有无圆角或斜角?If clip guide direction with R or bevel18.卡扣斜销行位不得少于5mm.在此范围内有无其他影响行位运动的特征?The clip slide pin not less than 5mm,within which if affect slide move 19.LCD周围有无定位/固定的特征rib?If locating or fixing features around LCD20.SPEAKER/RECEIVER/VIBRATOR周边有无定位/固定特征?If locating or fixing features around SPEAKER/RECEIVER/VIBRATOR?21.LENS周边有无对LEN浇口/定位柱/定位脚等的避位?If anti-interference to gate/locating pole/locating foot around LENS 22.对电铸件斜边有无避位?If anti-interference to the electroform components bevel edge23.键盘周边有无定位柱?加强RIB?If locating pole or reinforced rib24.转轴处壁厚是否小于1.2mm?If thickness at the hinge less than 1.2mm?25.转轴处根部有无圆角?多少?If root at the hinge with R? and what is the R?26.唇边与卡扣的配合是否是反卡结构?是否还有空间增加反卡?If the match between lip and clip counter-clip structure? If more space to add counter-clip?27.外置天线处是否有防掰出反卡?If outside antenna with anti-breaking off counter-clip28.电池仓面是否设计了入网标签及其他标签的位置?深度?If battery store surface with PTC label or other label, and what is depth?29.外面拔模角度是否小于2度?If pulling angle less than 2 degree30.热熔柱直径大于0.8mm时是否考虑了防缩水的结构?(空心柱)If protection to avoid shrinkage under melting pole diameter over 0.8mm(hollow pole)?31.超声波焊接材料的匹配性是否与供应商沟通过?If discuss with the supplier about the assembling quality of the ultrasonic weld material32.超声波能量带的设计是否合理(三角形,0.4*0.4)?有无防溢胶设计?If ultrasonic energy belt design (triangle, 0.4*0.4) reasonable? If with anti-spilling glue design?33.螺柱/卡扣处是否会缩水?If shrinkage at the screw boss and the snap34.有无厚度小于0.5mm的大面(大于400平方mm)?If big side(over 400 square mm) with thickness less than 0.5mm35.筋条厚度与壁厚的比例是否小于0.75:1?If the scale of thickness of the rib and the wall less than 0.75:136.铁料是否厚度/直径小于0.40mm?模具是否有尖角?If metal thickness/diameter less than 0.40mm. If mould with sharp angle?37.壳体喷涂区域的考虑,外棱边是否有圆角(大于1mm)以防掉漆?遮蔽夹具的精度?If outside edge with R(over 1mm) to avoid paint falling about the housingspray area, the precision of the shielding jig?38.双色喷涂的工艺缝尺寸是否满足W0.7mm*H0.5mm?If the size of the double color spraying technique slot match the 0.7mm*0.5mm39.塑料材料的颜色色板是否得到?If the plastic color panel available40.喷涂材料与塑材是否匹配?有无油漆厂的确认?颜色色板是否拿到?If spray material match the plastic, if the conformation of the paint plant,if the color panel available41.喷涂/丝印的测试标准及要求是否已经发给供应商?If the spray /silk print test standard and requirement sent to suppliers42. 吊绳孔:方便吊绳,强度可靠,应承受10公斤的拉力If the hang up line hole convenient for hang up line, intensity reliableenough to endure pulling force of 10 kg四, 电池 Batteries外置式电池 Outside battery1.电芯类型?Li-ion/Li-ion Polymer? 最大出厂厚度?Battery core types? Li-ion/Li-ion Polymer? Thickness?2.底壳底面厚度?侧面厚度?材料?What is the housing rear underside thickness? The side face thickness? Materials?3.面壳厚度?材料?What is the cover housing thickness? The materials?4.超声能量带的设计?溢胶措施有无?If ultrasonic energy belt and spilling plastic measures or not5.保护电路空间是否和封装厂确认?If conformation with encapsulation plants about the protection of circuit space6.电池呼吸空间是否考虑?(要留0.20mm的厚度空间)If battery breathing space or not? (0.20mm thickness space)7.内部是否预留粘胶空间(不小于0.15mm供两层双面胶)If double adhesive tape space inside or not (not less than 0.15mm for two layerdouble adhesive tape)8.底壳外表面是否留出标签的地方及厚度?If housing rear exterior side with label place, and the thickness?9.推开电池按钮时,电池能否自动弹出来?If battery flip out automatically when pushing out the battery button10.电池外壳周边是否因为分形线的位置而很锋利?(从截面看)If the battery cover is sharp due to the location of part line11.电池接触片要低于壳体0.3mm,目前设计是多少?The battery touching piece should be 0.3mm lower under the housing, What is the present design?12.电池安装方向是否合适?是否和电池连接器SPEC一致?If battery installation direction correct and in line with battery connector?13.电池按钮材料?能否耐2000次测试?The material of battery button? If battery button submitted to 2000 times test14.按钮如果依靠弹簧或弹片传力,有无借用零件?有无设计参考?要考虑手感.If with the help of components when passing force on spring or metal sheet, If design reference or not , take click into consideration.内置式电池BatteryIn-built batttery1.电芯类型?Li-ion/Li-ion Polymer?最大出厂厚度?Battery core types? Li-ion/Li-ion Polymer? The thickness?2.Li-ion Ploymer封装是否有底壳?厚度?If Li-ion Polymer encapsulation with bottom shell, and the thickness?3.壳体材料?侧边厚度?The housing material? Side face thickness?4.包装纸厚度?标签位置?The package paper thickness? The label location?5.电池接触片要低于壳体0.3mm(NEC标准),目前设计是多少?The battery touching piece should be 0.3mm lower under the housing, What is the present design?6.封装与电池盖的距离是否小于0.10mm?If the distance between battery and battery cover less than 0.10mm7.有无考虑呼吸空间?If breathing space or not ?8.定位及固定方式?The locating and fixing method ?9.安装方向?拆装空间?The installation direction and the disassembling space?10.接触电部位有无固定电池的特征?If battery fixing features at the electricity touching part?11.电池盖固定方式?The battery cover fixing method?12.电池盖材料?厚度?The battery cover material and the thickness?13.电池盖装配方向?拆装方式?卡扣数量?位置?The battery cover installation direction and disassembling method and the quantity of the clips and the location?14.电池盖有无按钮?If button with battery cover15.按钮行程是否正确?顶面是否有圆角以利电池盖滑出?If button travel correct? And if R with the top side as to battery cover sliding out easily?16.按钮材料?能否耐2000次测试?The button material? If pass 2000 times tests17.按钮如果依靠弹簧或弹片传力,有无借用零件?有无设计参考?要考虑手感If with the help of components when passing force on spring or metal sheet,If design reference or not , take click into consideration.五. 小镜片 Sub Lens1.镜片的工艺(IMD/IML/模切/注塑+硬化)The lens techniques (IMD/IML/die cutting/injection+hard coating)2.镜片的材料(PC/PMMA/GLASS)The lens materials(PC/PMMA/GLASS)3.镜片的厚度及最小厚度The lens thickness and the least thickness?4.IMD/IML/注塑镜片P/L,draft,radius?IMD/IML/injection lens P/L,draft, radius?5.固定方式及定位方式,最小粘接宽度是否大于1.5mm?The fixing and the locating methods ? and if the least adhesive width over1.5mm?6.窗口(VA&AA)位置是否正确If window(VA&AA) location correct7.冲击试验是否会有问题(100g钢球20cm高)If impact test ok(100g steel ball 20cm high)8.表面硬度是否足够(2H/3H…)If surface hardness enough(2H/3H…)9.镜片的耐摩擦测试(500g力50次,划伤宽度不大于100微米)The lens friction endurance test(50 times under force of 500g, scratchingmark width less than 100um)10.镜片本身及固定区域有无导致ESD问题的孔洞存在If ESD problems caused by holes in lens and fixed area?11.周边的电铸或金属件如何避免ESDHow to avoid ESD in electroform and metal parts?12.小镜片周边的金属是否会对天线有影响(开盖时)If metal near small lens affect the antenna(when cover lifting)13.镜片外面是否超出壳体面,应该降低0.05mm避免磨损.If lens outside parts beyond housing surface, and should be o.oo5mm loweras to avoid friction14.有无将测试标准发给供应商?If test standard sent to suppliers?六. 转轴Hinge1.转轴的直径The hinge diameter?2.转轴的扭力The hinge torque3.打开角度(SPEC)The opening angle4.有无预压角度(开盖预压为4-7度,建议5度;合盖预压为20度左右)If prepress angle(opening angle 4-7degreee, 5degree suggested; closingangle about 20degree)5.固定有无问题,有无轴向串动?If location ok, and axial move with hinge direction6.装拆有无空间问题?If space ok when (dis)assembling7.固定转轴的壁厚是多少,材料(推荐PC GE C1200HF或者三星HF1023IM)What is the fixed hinge wall thickness and material(PC GE C1200HF or Samsung 10231IM recommended)8.转轴配合处的尺寸及公差是否按照转轴SPEC?If the size and tolerance of the hinge assembling according to hinge SPEC 9.转轴与另一端的支撑是否同心?If the hinge and the crutch on the other end concentric?10.转轴处壳体是否有壁厚不均潜在缩水的可能性?If the hinge housing parts thickness unequal or shrinkage?11.与转轴对应的一端轴套与壳体的配合尺寸;The assembling size of housing and hinge cover opposite the hinge?12.壳体上有无设计转轴终了位置的止动缓冲垫?If stop cushion in the housing at the final state of hinge moving 七. 连接FLIP(SLIDE)/BASE的FPCThe FPC connecting the flip(slide) /base1 .FPC的材料,层数,总厚度The FPC material, layers and total thickness?2.PIN数,PIN宽PIN距PIN quantity, PIN width, and PIN distance3.最外面的线到FPC边的距离是多少(推荐0.3mm)The distance between most outside line and FPC edge ?(0.3mm suggested) 4.FPC内拐角处最小圆角要求大于1mm,且内拐角有0.20mm宽的布铜,防止折裂. The least corner R inside FPC should be over 1mm, and with copper of 0.20mm wide to avoid break5.有无屏蔽层和接地或者是刷银浆?If shielding cover, grounding or silver brushing?6.FPC与壳体的长度是否合适,有无MOCKUP 验证If the length of FPC and housing accurate, and with MOCKUP validation 7.壳体在FPC通过的地方是否有圆角?多少?推荐大于0.20mm.If R in the housing where FPC passes, and the degree ? over 0.20mm suggested 8.FPC与壳体间隙最小值?(推荐值为0.5mm)The least thickness between FPC and housing(0.5mm suggested)?9.FPC不在转轴内的部分是否有定位及固定措施?If location and fixing method in the FPC parts outside the hinge? 10.对应的连接器的固定方式The opposite connector fixing method11.FPC和连接器的焊接有无定位要求?定位孔?If locating requirement at the joint of FPC and the connector ? and the locating hole?12.补强板材料,厚度The strength added board material and the thickness?十四, 装配检查,assembling checkup1.翻盖打开角度The flip angle2.翻盖面和主机面的间隙The clearance between the flip surface and the housing surface 3.各配合零件的配合面处有无拔模If draft at the assembling surface of the assembling components 4.各配合零件之间的间隙是否合理.If the clearance of the assembling components reasonable5.所有零件的干涉检查,The interference test of all the components。

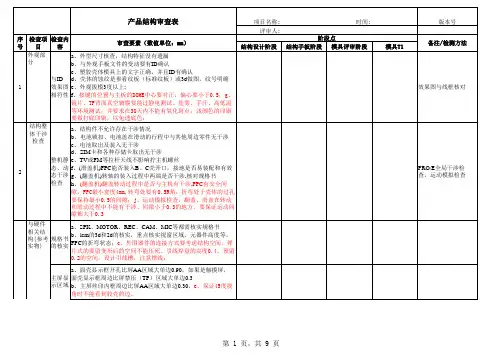

序号检查项目检查内容检查标准(数值单位:mm)结果(OK/NG)改善方法外观确定与ID效果图相符性a 外型尺寸依效果图b 盲点高度0.25,c 耐磨点高度0.4~0.5d 外表面无深凹槽或由客户要求e 外表面无利边利角由客户要求结构整体干涉检查静态干涉检查 a 零件与零件是否存在干涉情况整机动态干涉检查a 电池卡扣在滑动的行程中有无与其他周边零件干涉b 模拟翻盖于工作角度范围内旋转动全过程有无干涉情况且翻盖与主机最小间隙0.30c 模拟翻盖在工作角度内转动时FPC 与周边零件有无干涉情况d 电池取出及装入是否干涉周边零件与硬件相关的结构小屏显示区域 a 翻盖面壳显示框比小屏VA区域大0.30b 小屏印刷内框比小屏VA区域小0.30主屏显示区域a 翻盖底壳显示框周边比大屏VA区域大0.30b 主屏印刷内框周边比大屏VA区域小0.30LCD防尘a 大屏泡棉整圈完好,高度由0.50压缩至0.30b 大屏背胶整圈完好,宽度2.0以上,允许局部1.0,厚0.15厚0.10MMc 小屏泡棉整圈完好,高度由0.80(0.50)压缩至0.50(0.30)d 小屏背胶整圈完好,宽度2.0以上,允许局部1.0,厚0.15厚0.10MMe 背胶泡棉周边间隙:离定位胶位0.10,离视窗0.30离视窗0.20lcm定位及装配性能 a 平面两个方向定位间隙0.10定位间隙0.15b 高度方向有做勾或翻底定位骨位长至距PCB0.10处定位骨位长至距PCB0.05处SPK音量的结构保证a speaker音腔高度最少有0.8mmb speaker发声面胶壳厚度最少0.8mmspeaker音量的结构保证c 出声面积不小于speaker本身出声孔面积的三分之一10%——15%b 前音腔完全封闭,SPK围骨厚度0.70e 后音腔有足够空间摄像头部分 a 摄像头视角无阻碍,包括翻开150度后b 需做密封和防震产品结构审查表(Check List)231项目名称:项目名称:项目名称:项目名称:项目名称:项目名称:项目经理: 审查日期: 部门经理: 复查日期: 核准:。

4钢片接触馈点方式?5天线厂有否书面评审报告?1镜片的工艺,材料和厚度。

(大于0.8mm )2镜片备胶厚度,备胶面积是否足够。

(要求最小粘接宽度大于1.5mm )3窗口(VA&AA)位置是否正确 。

4镜片本身及固定区域有无导致ESD 问题的孔洞存在 。

5镜片是否低于壳面0.05-0.1mm 。

6镭射纸下方双面胶要避空,壳体要避开0.10mm 厚度空间。

1镜片的工艺,材料和厚度(大于0.5mm )。

2镜片备胶厚度,备胶面积是否足够。

(要求最小粘接宽度大于1.5mm )3摄像开口是否足够,要求比角度区域单边大0.5mm。

4镜片本身及固定区域有无导致ESD 问题的孔洞存在 。

5镜片是否低于壳面0.05-0.1mm 。

6电镀金属元素对天线有否影响。

1键盘表面工艺检查,字符设定符合软件要求2键面是否要求高出壳体,导航键是否要求高出3OK键或近似键如何防呆。

4键帽是否太薄或太厚,有否设计裙边?5“5”盲人键6按键外部和内部间隙检查7塑胶支架或钢片支架强度是否足够,厚度?8按键跌落是否容易脱落?9按键行程空间是否超过0.5mm ?(金属按键除外)。

10硅胶厚度?导电基直径、高度?11检查导电基与DOME是否对中。

高度间隙预留0-0.1之间。

12如果Dome设计偏心,怎样改善手感和键帽倾斜。

13LED数量及分布是否均匀,硅胶灯位有否避开、14透光、遮光怎样处理15怎样防止键的联动?16静电怎样预防?17考虑装配是否困难。

1表面工艺确认2键帽突出侧面0.5mm左右。

3考虑怎样防呆4怎样定位,装配是否困难?5裙边设计检查,跌落不能脱出。

6与壳体间隙多少?不能卡键或摇晃。

7导电基直径多大,导电基深度多少(一般要求0.3-0.5MM便于调整手感)8Dome是否对中,偏心如何控制手感?9静电怎样预防?1材料硬度?2装配是否方便 ,侧胶塞是否影响主板装入?3固定是否牢固?不允许150N内拉出或断裂。

4左右螺钉塞怎样防呆?5USB胶塞有没有扣手位或壳体避空位6胶塞表面符号位置、大小、深度?1装饰件是塑胶还是五金?2相似外形零件是否有防呆?3塑胶件一般定位方式:背胶、卡扣、热熔或复合组合。