焊接工艺规程-中英文

- 格式:pdf

- 大小:372.62 KB

- 文档页数:4

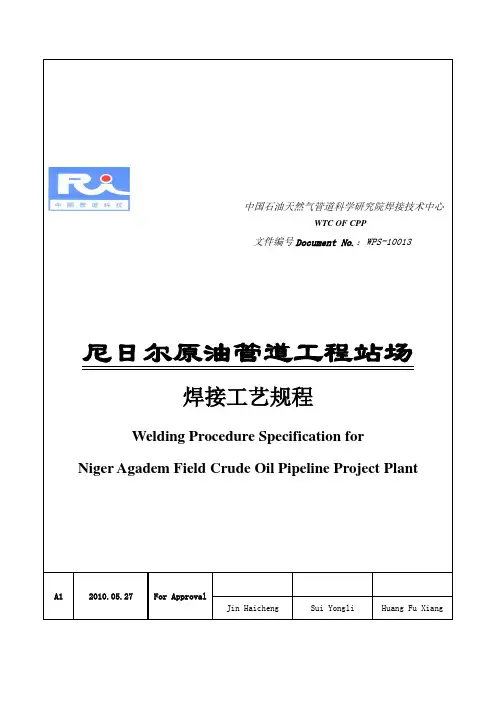

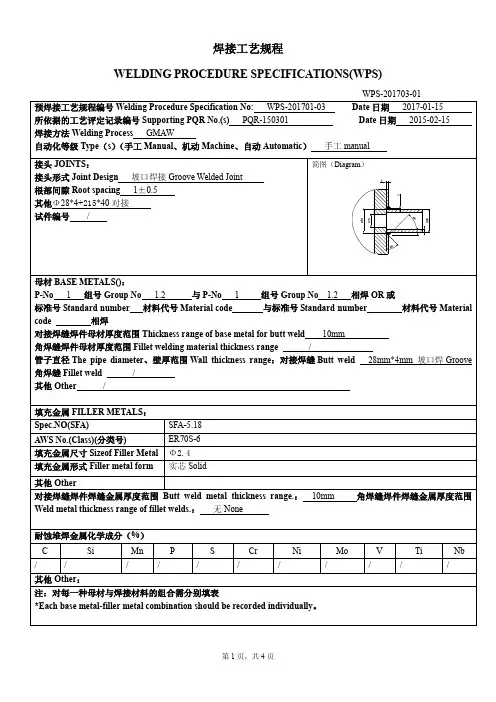

中国石油天然气管道科学研究院焊接技术中心WTC OF CPP文件编号Document No.:WPS-10013尼日尔原油管道工程站场焊接工艺规程Welding Procedure Specification forNiger Agadem Field Crude Oil Pipeline Project PlantA1 2010.05.27 For ApprovalJin Haicheng Sui Yongli Huang Fu XiangCNPC NIGER PETROLEUM .S.A.Niger Agadem Field Crude Oil Pipeline ProjectPage 1 of 15尼日尔原油管道工程焊接工艺规程列表LIST of WPS序号 ITEM工艺规程编号 WPS NO.评定编号 PQR NO.焊接工艺 PROCEDURE适用管径 Diameter适用壁厚 WALL THICKNESS填充材料CONSUMABLE MATERIALS 适用钢管 Suit pipeline页码 PAGE根焊 ROOT 填充/盖面 FILL/CAP 1 WPS-NREZC-S001 PQR-10044 SMAW+FCAW ≥323.9 4.8-19.1 GB/T 8110 ER50-6 AWS A 5.29 E71T8-K6 L360与L360 L360与16Mn 2 2 WPS-NREZC-S002 PQR-10045 GTAW+SMAW ≥168 4.8-19.1 GB/T 8110 ER50-6 GB/T 5117 E5015 L360与L360 L360与16Mn 4 3 WPS-NREZC- S003 PQR-10046 GTAW+SMAW ≥168 4.8-19.1 GB/T 8110 ER50-6 GB/T 5117 E4315 L245与L245 L245与20 6 4 WPS-NREZC-S004 PQR-10047 GTAW <168 4.8-19.1 GB/T 8110 ER50-6 GB/T 8110 ER50-6 L245与L245 L245与20 8 5 WPS-NREZC-S005 PQR-10048 GTAW <168 <4.8 GB/T 8110 ER50-6 GB/T 8110 ER50-6 L245与L245 L245与20 10 6 WPS-NREZC-S006 PQR-10049 GTAW Unlimited Unlimited GB/T 8110 ER50-6 GB/T 8110 ER50-6 L360与16Mn 12WPS-NREZC-S007PQR-10050GTAWUnlimitedUnlimitedGB/T 8110 ER50-6GB/T 8110 ER50-6L245与2014适用工程Project applied:尼日尔原油管道工程站场Niger Agadem Field Crude Oil Pipeline Project Plant编制单位Drafter Company:中国石油天然气管道科学研究院焊接技术中心WTC OF CPP焊接工艺Welding Process:GTAW(Root)+ FCAW(Fill、Cap)执行标准Reference Standard:SY/T 4103-2006焊接工艺指导书编号WPS No.:WPS-NREZC-S001评定编号PQR No: PQR–10044适用钢管Base MetalItem 材料1 material 1 材料2 material 2材质Type L360 L360 16Mn管径Diameter ≥323.9 ≥323.9壁厚Wall thickness 4.8-19.1 4.8-19.1适用填充材料F ill Material焊道Bead 根焊 Root 填充/盖面 Fill/Cap规范号AWS or GB Spec. GB/T 8110 AWS A 5.29类别Classification ER50-6 E71T8-K6推荐厂商Manmufacture Jin TaiJG-56 LINCOLN INNERSHIELD NR207+尺寸Size Ф2.0mm/Ф2.4mm Φ2.0 mm接头型式Joint Design:(图1 fig1、图2 fig2)接头型式Joint type:对接butt joint 坡口型式groove type:V型V type坡口角度groove angle:see fig1、fig2 钝边root face:1.0±0.4mm背垫backup:N/A 对口间隙root gap:2.5-3.5mm错边Misalignment:≤2.0mm 余高reinforcement:0-1.6 mm盖面焊缝宽Cap bead width:坡口上口每侧增宽Groove each side more than 0.5mm-2.0mm30±2.5°0-1.6mm1.0±0.4mm0.5-2.0mm母材1母材2母材 2母材 1母材 2母材 1T 0-1.6mm1.0±0.4mm15°-45°30°±2.5°Δt≥2.5mm图 1 接头型式joint design 图2 接头型式joint design注:可根据填充情况在立焊部位增加立填焊Stripper pass is adopted in the vertical position.焊接环境Welding Environment 焊前准备Welding preparation温度Temperature :≥5℃湿度Humidity :≤90%RH风速Wind Speed :钨极氩弧焊GTAW <2m/s自保护药芯焊丝电弧焊FCAW <8m/s焊接位置Pipe Position :5G 、6G对口方式Type of lin-up :外对口器或定位焊 E xternal Clamp orPosition weld预热及层间温度Pre-heating & Interpass Temp焊接设备equipment for welding预热温度Pre-heating Temp :无N/A 层间温度Interpass Temp :50-200℃根焊Root :下降外特性直流电源dropping characteristic DCPower Source填充/盖面Fill & Cap :具有平外特性的直流焊接电源+相应送丝机Constant-voltage DC Power Source + wire-feeder 保护气体Gas钨极Tungsten Electrode保护气体Gas :100% Argon (Root ) Ar 气体纯度argon gas purity :≥99.96%钨极类型Type :钍钨极或铈钨极Ce or Th 钨极尺寸Size :D=(2.0~3.2)mm技术措施Technique measure焊接方向welding direction :根焊上向,其它下向root uphill,other downhill (5G 、6G )焊工数量Number of welder :2名焊工2 welders 焊丝烘干Wire drying :不要求 N/A根焊结束与热焊开焊之间的最大时间间隔Max-time lapse between completion of root and start hot pass :≤10min.焊后热处理Postweld Heat Treatment :不要求 N/A焊接工艺参数Welding process parameter焊道Bead工艺Process填充金属Fillermetals 尺寸Size (mm) 极性Polarity电流Current(A) 电压Volt (V) 焊接速度Travel speed (cm/min) Argon fluid speed(L/min) Tungsten electrode length Air spout diameterArgonarc length (mm) Root GTAW ER50-6 2.4 DCEN 70-120 10-16 5-10 7-12 6-9 8-10 2-4 Fill FCAW E71T8-K6 2.0 DCEN 180-260 18-21 15-26 / / / CapFCAWE71T8-K62.0DCEN180-26018-2115-23////注:DCEN —表示焊条(焊丝)接电源负端DCEN means that electrode or wire negatively connected.施工措施Construction Measure焊缝坡口清理bevel cleaning : 焊前必须按照施工规范将坡口内外两侧各10mm范围内的铁锈清理干净。

焊接工艺流程译成英文(中英文版)Welding Process Flow: A Comprehensive Translation焊接工艺流程:全面翻译The welding process flow encompasses a series of intricate steps that ensure the fusion of metal parts. It begins with the careful preparation of materials and equipment, followed by the execution of specific welding techniques, and concludes with rigorous inspections to guarantee the integrity of the weld.焊接工艺流程包括一系列确保金属部件融合的复杂步骤。

它从材料与设备的精心准备开始,接着执行特定的焊接技术,并以严格的检查来确保焊接的完整性。

Preparation phase involves cleaning the metal surfaces to remove dirt, oil, and rust, which could compromise the quality of the weld. This is followed by selecting the appropriate welding consumables such as electrodes, filler metals, and shielding gases.准备阶段涉及清洁金属表面,去除可能影响焊接质量的污垢、油污和锈迹。

接下来是选择合适的焊接耗材,如电极、填充金属和屏蔽气体。

In the execution phase, various welding methods such asArc Welding, MIG/MAG Welding, TIG Welding, and Flux-cored Arc Welding are employed based on the material type and thickness. Each method has its unique set of parameters that must be meticulously controlled to achieve optimal results.在执行阶段,根据材料类型和厚度,采用各种焊接方法,如电弧焊、MIG/MAG焊、TIG焊和药芯电弧焊。

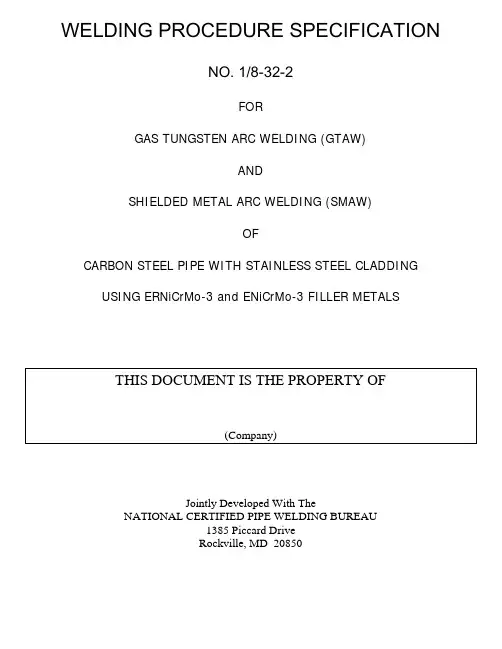

WELDING PROCEDURE SPECIFICATIONNO. 1/8-32-2FORGAS TUNGSTEN ARC WELDING (GTAW)ANDSHIELDED METAL ARC WELDING (SMAW)OFCARBON STEEL PIPE WITH STAINLESS STEEL CLADDING USING ERNiCrMo-3 and ENiCrMo-3 FILLER METALSTHIS DOCUMENT IS THE PROPERTY OF_______________________________(Company)Jointly Developed With TheNATIONAL CERTIFIED PIPE WELDING BUREAU1385 Piccard DriveRockville, MD 20850This Welding Procedure Specification (WPS) and supporting Procedure Qualification record(s) (PQR) are the property of the National Certified Pipe Welding Bureau. They are issued for adoption by members only and are to be returned to the Bureau upon termination of membershipANSI American National Standards InstituteASME American Society of Mechanical EngineersAWS American Welding Society, Inc.REPRODUCTION AND USE OF THIS WPS AND SUPPORTING PQR(S) BY OTHER THANMEMBERS OF THE BUREAU IS UNAUTHORIZED© 2005-Copyrighted in the United States and Canada by the National Certified Pipe Welding BureauJointly Developed with theNational Certified Pipe Welding Bureau1385 Piccard DriveRockville, MD 20850-4340Welding Procedure Specification (WPS)Joint Designs for Joining Internally Clad Piping by WeldingPreferred Weld End Preparation and Fit-upOpen Root Adding ERNoCrMo-3 Filler MetalClass 3 Consumable Insert meeting ERNoCrMo-3 analysisSecondary Weld End Preparation and Fit-up3/32 to 1/8”P-8 Step 3: Build up root faces using GTAWS tep 4: Weld Root PassReduced Section Tensile Tests X Rectangular Turned Full Section Specimen Width/Dia (in.) Thickness (in) Area (sq in.) Ultimate load (lb.) Ultimate Stress (psi) Failure Location1 0.525 0.5499 0.289 23,560 81,500 Base Metal, Ductile2 0.524 0.5350 0.280 23,182 82,800 Base Metal, DuctileBend Tests Transverse Face and Root x Side Longitudinal Face and Root Type Results Type ResultsSide Acceptable Side AcceptableSide Acceptable Side AcceptablePipe Welding BureauChairman, Technical Committee。

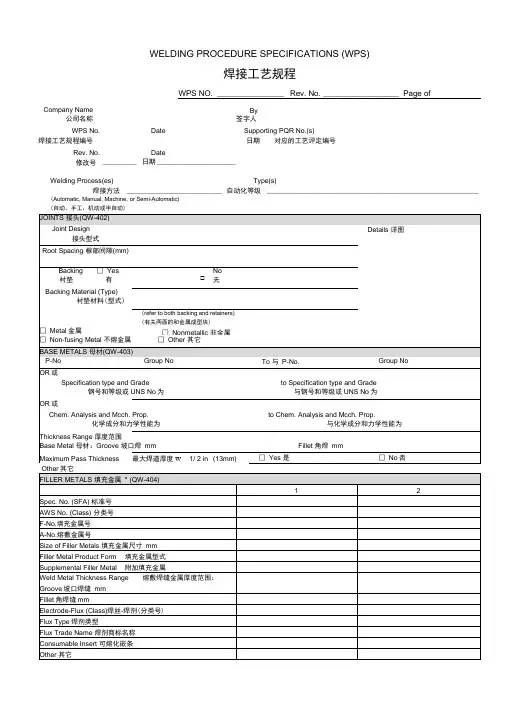

WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _______________ Rev. No. _________________ Page ofBy 签字人DateSupporting PQR No.(s) 日期 对应的工艺评定编号Date__________ 日期 _______________________ Welding Process(es) Type(s) 焊接方法 ____________________________ 自动化等级 ______________________________________________________________(Automatic, Manual, Machine, or Semi-Automatic) (自动、手工、机动或半自动)Company Name公司名称 WPS No.焊接工艺规程编号Rev. No.修改号*Each base metal-filler metal combination should be recorded individually.WELDING PROCEDURE SPECIFICATIONS (WPS)焊接工艺规程WPS NO. _________________ Rev. No. ___________________ Page ofPulsing Current 脉冲电流Heat Input ( Max.)热输入(最大)Tungsten Electrode Size and Type ( Pure Tungsten,2Thoriated etc.)钨极尺寸和型号(纯钨,2%钍钨极等) Mode of Metal Transfer for GTAW (FCAW) ( Spray Arc, Short Circuiting Arc, et 熔滴过渡型式(射流或短路)Electrode Wire Feed Speed Rang 送丝速度范围 ______________________________________________________________________________________Other 其它TECHNIQUE 焊接技术(QW-410)Stri ng or Weave Bead 直进焊或摆动焊 ______________________________________________________________________________________ Orifice or Gas Cup Size 嘴孔或喷嘴尺寸 mmInitial and Interpass Cleaning打底焊道和中间焊道的清理方法(Brushing, Grinding, etc.)( 刷理或打磨等等) ______________________Method of Back Gouging背面清根方法Oscillati on 横摆方法 ________________________________________________________________________________________________________ Con tact Tube to Work Dista nee 导电嘴至工件距离 ____________________________________________________________________________ Multiple or Single Pass 多道焊或单道焊 (Per Side)( 每侧) _________________________________________________________________ Multiple or Single Electrodes 多丝焊或单丝焊Travel Speed 焊接速度(Range)(范围) _________________________________________________________________________________Peening 锤击Use of thermal processes 使用热工艺 _______________________________________________________________________________________ Other 其它对于每一母材-填充金属的组合均需分别填表Date 日期。

英⽂焊接⼯艺规程English中国⽯油天然⽓管道科学研究院焊接技术中⼼WTC OF CPP⽂件编号Document No.:WPS-10013尼⽇尔原油管道⼯程站场焊接⼯艺规程Welding Procedure Specification forNiger Agadem Field Crude Oil Pipeline Project PlantA1 2010.05.27 For ApprovalJin Haicheng Sui Yongli Huang Fu XiangCNPC NIGER PETROLEUM .S.A.Niger Agadem Field Crude Oil Pipeline ProjectPage 1 of 15尼⽇尔原油管道⼯程焊接⼯艺规程列表LIST of WPS序号 ITEM⼯艺规程编号 WPS NO.评定编号 PQR NO.焊接⼯艺 PROCEDURE适⽤管径 Diameter适⽤壁厚 WALL THICKNESS填充材料CONSUMABLE MATERIALS 适⽤钢管 Suit pipeline页码 PAGE根焊 ROOT 填充/盖⾯ FILL/CAP 1 WPS-NREZC-S001 PQR-10044 SMAW+FCAW ≥323.9 4.8-19.1 GB/T 8110 ER50-6 AWS A 5.29 E71T8-K6 L360与L360 L360与16Mn 2 2 WPS-NREZC-S002 PQR-10045 GTAW+SMAW ≥168 4.8-19.1 GB/T 8110 ER50-6 GB/T 5117 E5015 L360与L360 L360与16Mn 4 3 WPS-NREZC- S003 PQR-10046 GTAW+SMAW ≥168 4.8-19.1 GB/T 8110 ER50-6 GB/T 5117 E4315 L245与L245 L245与20 6 4 WPS-NREZC-S004 PQR-10047 GTAW <168 4.8-19.1 GB/T 8110 ER50-6 GB/T 8110 ER50-6 L245与L245 L245与20 8 5 WPS-NREZC-S005 PQR-10048 GTAW <168 <4.8 GB/T 8110 ER50-6 GB/T 8110 ER50-6 L245与L245 L245与20 10 6 WPS-NREZC-S006 PQR-10049 GTAW Unlimited Unlimited GB/T 8110 ER50-6 GB/T 8110 ER50-6 L360与16Mn 12WPS-NREZC-S007PQR-10050GTAWUnlimitedUnlimitedGB/T 8110 ER50-6GB/T 8110 ER50-6L245与2014适⽤⼯程Project applied:尼⽇尔原油管道⼯程站场Niger Agadem Field Crude Oil Pipeline Project Plant 编制单位Drafter Company:中国⽯油天然⽓管道科学研究院焊接技术中⼼WTC OF CPP焊接⼯艺Welding Process:GTAW(Root)+ FCAW(Fill、Cap)执⾏标准Reference Standard:SY/T 4103-2006焊接⼯艺指导书编号WPS No.:WPS-NREZC-S001评定编号PQR No: PQR–10044适⽤钢管Base MetalItem 材料1 material 1 材料2 material 2材质Type L360 L360 16Mn管径Diameter ≥323.9 ≥323.9壁厚Wall thickness 4.8-19.1 4.8-19.1适⽤填充材料F ill Material焊道Bead 根焊 Root 填充/盖⾯ Fill/Cap规范号AWS or GB Spec. GB/T 8110 AWS A 5.29类别Classification ER50-6 E71T8-K6推荐⼚商Manmufacture Jin TaiJG-56 LINCOLN INNERSHIELD NR207+尺⼨Size Ф2.0mm/Ф2.4mm Φ2.0 mm接头型式Joint Design:(图1 fig1、图2 fig2)接头型式Joint type:对接butt joint 坡⼝型式groove type:V型V type坡⼝⾓度groove angle:see fig1、fig2 钝边root face:1.0±0.4mm背垫backup:N/A 对⼝间隙root gap:2.5-3.5mm错边Misalignment:≤2.0mm 余⾼reinforcement:0-1.6 mm盖⾯焊缝宽Cap bead width:坡⼝上⼝每侧增宽Groove each side more than 0.5mm-2.0mm30±2.5°0-1.6mm1.0±0.4mm0.5-2.0mm母材1母材2母材 2母材 1母材 2母材 1T 0-1.6mm1.0±0.4mm15°-45°30°±2.5°Δt≥2.5mm图 1 接头型式joint design 图2 接头型式joint design注:可根据填充情况在⽴焊部位增加⽴填焊Stripper pass is adopted in the vertical position.焊接环境Welding Environment 焊前准备Welding preparation温度Temperature :≥5℃湿度Humidity :≤90%RH风速Wind Speed :钨极氩弧焊GTAW <2m/s⾃保护药芯焊丝电弧焊FCAW <8m/s焊接位置Pipe Position :5G 、6G对⼝⽅式Type of lin-up :外对⼝器或定位焊 E xternal Clamp orPosition weld预热及层间温度Pre-heating & Interpass Temp焊接设备equipment for welding预热温度Pre-heating Temp :⽆N/A 层间温度Interpass Temp :50-200℃根焊Root :下降外特性直流电源dropping characteristic DCPower Source填充/盖⾯Fill & Cap :具有平外特性的直流焊接电源+相应送丝机Constant-voltage DC Power Source + wire-feeder 保护⽓体Gas钨极Tungsten Electrode保护⽓体Gas :100% Argon (Root ) Ar ⽓体纯度argon gas purity :≥99.96%钨极类型Type :钍钨极或铈钨极Ce or Th 钨极尺⼨Size :D=(2.0~3.2)mm技术措施Technique measure焊接⽅向welding direction :根焊上向,其它下向root uphill,other downhill (5G 、6G )焊⼯数量Number of welder :2名焊⼯2 welders 焊丝烘⼲Wire drying :不要求 N/A根焊结束与热焊开焊之间的最⼤时间间隔Max-time lapse between completion of root and start hot pass :≤10min.焊后热处理Postweld Heat Treatment :不要求 N/A焊接⼯艺参数Welding process parameter焊道Bead⼯艺Process填充⾦属Fillermetals 尺⼨Size (mm) 极性Polarity电流Current(A) 电压Volt (V) 焊接速度Travel speed (cm/min) Argon fluid speed(L/min) Tungsten electrode length Air spout diameterArgonarc length (mm) Root GTAW ER50-6 2.4 DCEN 70-120 10-16 5-10 7-12 6-9 8-10 2-4 Fill FCAW E71T8-K6 2.0 DCEN 180-260 18-21 15-26 / / / CapFCAWE71T8-K62.0DCEN180-26018-2115-23////注:DCEN —表⽰焊条(焊丝)接电源负端DCEN means that electrode or wire negatively connected.施⼯措施Construction Measure焊缝坡⼝清理bevel cleaning : 焊前必须按照施⼯规范将坡⼝内外两侧各10mm范围内的铁锈清理⼲净。

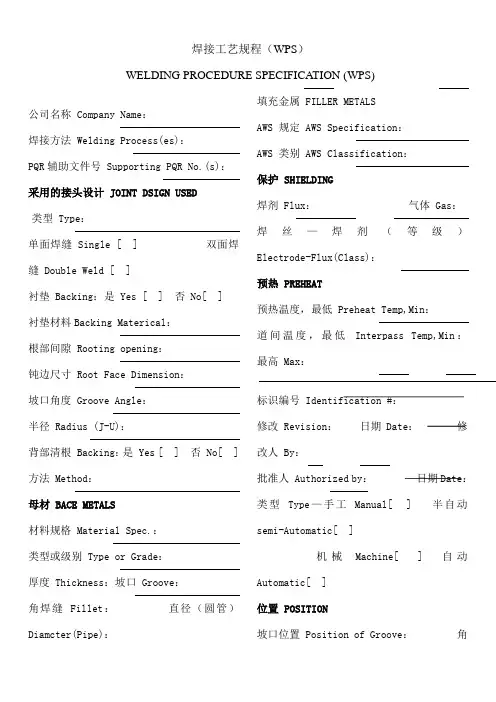

焊接工艺规程(WPS)WELDING PROCEDURE SPECIFICATION (WPS)公司名称 Company Name:焊接方法 Welding Process(es):PQR辅助文件号 Supporting PQR No.(s):采用的接头设计 JOINT DSIGN USED类型 Type:单面焊缝 Single [ ] 双面焊缝 Double Weld [ ]衬垫 Backing:是 Yes [ ] 否 No[ ] 衬垫材料Backing Materical:根部间隙 Rooting opening:钝边尺寸 Root Face Dimension:坡口角度 Groove Angle:半径 Radius (J-U):背部清根 Backing:是 Yes [ ] 否 No[ ]方法 Method:母材 BACE METALS材料规格 Material Spec.:类型或级别 Type or Grade:厚度 Thickness:坡口 Groove:角焊缝 Fillet:直径(圆管)Diamcter(Pipe):填充金属 FILLER METALSAWS 规定 AWS Specification:AWS 类别 AWS Classification:保护 SHIELDING焊剂 Flux:气体 Gas:焊丝—焊剂(等级)Electrode-Flux(Class):预热 PREHEAT预热温度,最低 Preheat Temp,Min:道间温度,最低Interpass Temp,Min:最高 Max:标识编号 Identification #:修改 Revision:日期Date:修改人 By:批准人 Authorized by:日期Date:类型Type—手工Manual[ ] 半自动semi-Automatic[ ]机械Machine[ ] 自动Automatic[ ]位置 POSITION坡口位置 Position of Groove:角焊缝 Fillet:立焊方向Vertical Progression:上行Up[ ] 下行 Down[ ]电特性 ELECTRICAL CHARACTERISTICS过渡形式(GMAW) Transfer Mode(GMAW) 短路 Short-Circuting:[ ] 熔滴Globular:[ ]喷射 Spray:[ ]电流 Current:交流 AC:[ ] 直流反接 GCEP:[ ]脉冲 Pulsed:[ ] 直流正接 DCEN:[ ]钨极(GTAW) Tungsten Electrode尺寸 Size:类型 Type:技术 TECHNIQUE直线或横向摆动喊道Stringer or Weave Bead:多道或单道(每边) Multi-pass or Single Pass(per side):焊丝数 Numbei of Electrodes:焊丝间隔Electrode Spacing 纵向Longitudinal:横向Lateral:角度 Angle:导电咀到工件距离 Contact Tube to Work Distance:锤击 Peening:道间清理 Interpass Cleaning:焊后热处理 POSTWELD HEAT TREATMENT温度 Temp.:时间 Time :。

焊接工艺评定报告Weldi ng Procedure Qualificatio n Report焊接工艺评定报告编号: _____________________________PQR NO.:焊接工艺规程编号: _________________________________WPS NO.:结 论: 按NB/T47014-2011标准评定合格Con clusi On : accepted by assessi ng accordi ng to NB/T47014-2011批 准 人: ___________________________________Approved by:期: _____________________________The date of approval:xxxxxxxxxxx 有限公司版权说明:此文件内容属 XXXXXXXX有限公司所有,未经同意,不得使用、复制、转借发表评 定 项Assessme nt Items:目: ___________________________评 定Assessme ntDescripti on: own ership is subject toXXXX, use, copy and rent without approval from XXXX is prohibited.焊接工艺规程WPS焊接工艺评定报告PQR焊接工艺评定报告(续)焊缝外观检查记录表Appeara nee of the weld in specti on record formCompetent Check Assessment date焊工试验的焊接记录The welder test the weld ing records技术负责人:焊接检查员:施工班组: Technical director Welding inspector Construction team。

英文焊接工艺规程(总4页)--本页仅作为文档封面,使用时请直接删除即可----内页可以根据需求调整合适字体及大小--Welding Procedure Specification(Wps) Yes [X]Prequalified X Qualified By TestingOr Procedure Qualification Records(Pqr) Yes [ ]I dentification#R evision D ate B yC ompany Name A uthorized ByD ateW elding Process(Es) T ype- M anual [ ] S emi-A utomatic [ ] S upporting Pqr No.(S) M achine [ ] A utomatic [ ]Joint Design Used PositionT ype: P osition Of G roove F illet:S ingle [ ] D ouble Weld [ ]V ertical Progression: U p [ ] D own [ ]B acking: Yes [ ] No [ ]Backing Material: Electrical CharacteristicsR oot Opening: R oot Face DimensionG roove Angle: R adius(J-U) T ransfer M ode (Gmaw) S hort-C ircuiting[ ]B ack Gouging: Y es[ ] N o[ ] M ethod G lobular [ ] S pray [ ]C urrent: Ac[ ] Dcep[ ] Dcen [ ] Pulsed[ ]Base Metals O therM aterial Spec. T ungsten E lectrode(Gtaw)T ype Or Grade S ize:T hickness:Groove Fillet T ype:D iameter(Pipe)TechniqueFiller Metals S tringer Or W eave B ead:Aws S pecification M ulti-Pass Or S ingle P ass(Per Side)Aws C lassification N umder Of E lectrodesE lectrode S pacing L ongitudinalL ateralShielding A ngleF luxG asC ontact T ube To W orkD istanceC ompositionE lectrode-Flux(Class)F low Rate P eeningG as Cup Size I nterpass C leaning:Preheat Postweld Heat TreatmentP reheat T emp.,M in T emp.I nterpass T emp.,M in M ax T imeWelding ProcedureProcedure Qualification Record (PQR)#Test ResultsGUIDED BEND TESTVISUAL INSPECTIONAppearance Radiographic-Ultrasonic ExaminationUndercut RT report no: ResultPiping Porosity UT report no: ResultConvexity (FILLET WELD TEST RESULTS)Test Date Minimum Size Multiple Pass Maximum Size Single Pass Witnesses By Macroetch Macroetch1. 3. 1. 3.2. 2.All-weld-metal tension testOther tests Tensile strength ,psiYield point/strength,psiElongation in 2 in,%Laboratory test no.Welder’s name Clock no. stamp no.Test’s conducted by LaboratoryTest numberPerWe,the undersigned,certify that the statements in this record are correct and that the test welds were prepared,welded,and tested in accordance with the requirements of section 4 of AMSI/AWS ,( 86 ) structural welding code-steel. YearSignedByTitleDate。

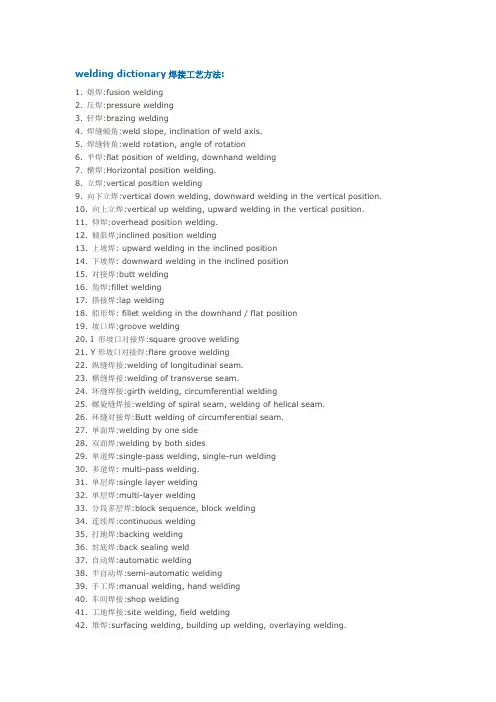

welding dictionary焊接工艺方法:1. 熔焊:fusion welding2. 压焊:pressure welding3. 钎焊:brazing welding4. 焊缝倾角:weld slope, inclination of weld axis.5. 焊缝转角:weld rotation, angle of rotation6. 平焊:flat position of welding, downhand welding7. 横焊:Horizontal position welding.8. 立焊:vertical position welding9. 向下立焊:vertical down welding, downward welding in the vertical position.10. 向上立焊:vertical up welding, upward welding in the vertical position.11. 仰焊:overhead position welding.12. 倾斜焊;inclined position welding13. 上坡焊: upward welding in the inclined position14. 下坡焊: downward welding in the inclined position15. 对接焊:butt welding16. 角焊:fillet welding17. 搭接焊:lap welding18. 船形焊: fillet welding in the downhand / flat position19. 坡口焊:groove welding20. I 形坡口对接焊:square groove welding21. Y形坡口对接焊:flare groove welding22. 纵缝焊接:welding of longitudinal seam.23. 横缝焊接:welding of transverse seam.24. 环缝焊接:girth welding, circumferential welding25. 螺旋缝焊接:welding of spiral seam, welding of helical seam.26. 环缝对接焊:Butt welding of circumferential seam.27. 单面焊:welding by one side28. 双面焊:welding by both sides29. 单道焊:single-pass welding, single-run welding30. 多道焊: multi-pass welding.31. 单层焊:single layer welding32. 单层焊:multi-layer welding33. 分段多层焊:block sequence, block welding34. 连续焊:continuous welding35. 打地焊:backing welding36. 封底焊:back sealing weld37. 自动焊:automatic welding38. 半自动焊:semi-automatic welding39. 手工焊:manual welding, hand welding40. 车间焊接:shop welding41. 工地焊接:site welding, field welding42. 堆焊:surfacing welding, building up welding, overlaying welding.43. 衬垫焊:welding with backing.44. 焊剂垫焊:welding with flux backing45. 电弧点焊:arc spot welding.46. 套环:ferrule47. 单面/双面串联点焊:direct/indirect serial spots welding.工艺参数1. 焊接工艺参数:welding parameter坡口, 焊缝1. 坡口: groove2. 坡口面角度: angle of bevel, bevel angle.3. 坡口角度: Included angle, groove angle.4. 坡口高度:groove depth5. 钝边:root face.6. 开坡口:beveling of the edge, chamfering.7. single-V/U groove (with root face)8. 焊缝区:weld metal zone9. 热影响区:heat-affected Zone (HAZ)10. 工艺/使用/热/焊接性:fabrication/service/thermal weldability.11. 碳弧气刨:carbon arc air gouging.12. 火焰气刨:flame gouging13. 等离子切割:plasma arc cutting(PAC)14. 激光切割: laser cutting (LC)15. 喷沙: sand blast16. 清渣:slag removal17. 清根: back chipping18. 碳/铬/镍当量:carbon/chromium/nickel equivalent.电弧焊1. 手工电弧焊:manual metal arc welding2. 直流电弧焊:direct current arc welding3. 交流电弧焊:alternating current arc welding4. 三相电弧焊:three phases current arc welding5. 熔化极电弧焊: arc welding with consumable electrode6. 金属极电弧焊:metal arc welding7. 碳弧焊:carbon arc welding8. 电弧堆焊:arc surfacing9. 自动堆焊:automatic surfacing10. 埋弧焊:submerged-arc welding (SAW)11. 自动埋弧焊:automatic submerged-arc welding (SAW)12. 半自动埋弧焊:semi-automatic submerged-arc welding (SAW)13. 气体保护焊:gas shielded arc welding14. 惰性气体保护焊:inert-gas arc welding15. 氩弧焊:argon arc welding16. 钨极惰性气体保护焊:tungsten inert-gas arc welding17. 活性气体保护焊:metal active gas arc welding18. Co2气体保护焊:carbon-dioxide arc welding.19. 电渣焊:electro-slag welding (ESW)20. 电阻焊:resistance welding (RW)21. 点焊:spot welding22. 摩擦焊:friction welding (FW)23. 爆炸焊: explosive welding (EW)24. 热切割: thermal cutting (TC)25. 气割: gas cutting26. 塑性/脆性:plastic/brittle焊接缺陷1. 焊接变形: welding deformation2. 焊接残余变形: welding residual deformation3. 加强筋:stiffener4. 引弧板:run-on tab, end tab5. 引出板:run-off tab, end tab6. 焊缝/弧坑/热影响区裂纹:weld metal/crater/ heat-affected Zone (HAZ) crack7. 未焊透:incomplete penetration, lack of penetration8. 未溶合:lack of fusion, incomplete fusion9. 夹杂物:inclusion10. 夹钨:tungsten inclusion11. 气孔:gas pore, blowhole12. 针尖状气孔:pinhole13. 密集气孔:porosity14. 条虫状气孔:wormhole15. 咬边:undercut16. 焊瘤:overlap17. 烧穿:burn through18. 白点:fish eye, flake19. 凹坑:pit20. 未焊满: incompletely filled groove21. 塌陷: excessive penetration22. 夹渣: slag inclusion焊接检验1. 试件/试样: test piece/specimen2. 直射/斜射/水浸超声探伤:straight/angle beam/immersed ultrasonic inspection3. 射线探伤:radiographic inspection4. 渗透探伤: penetrant inspection5. 荧光检验:fluorescent penetrant inspection6. 着色检验:dye penetrant inspection7. 磁粉探伤:magnetic particle examination8. 电磁发探伤:electromagnetic test9. 密封性检验:leak test10. 气密性检验: air tight test11. 破坏检验:destructive test12. 耐压检验:pressure test13. 水压试验:hydraulic test14. 气呀试验:pneumatic test15. 声发射:acoustic emersion16. 淬火:quenching17. 回火:tempering18. 退火:annealing19. 熔炼:smelting。

A W S D焊接工艺规程中英文对照集团文件版本号:(M928-T898-M248-WU2669-I2896-DQ586-M1988)焊接工艺规程(WPS)WELDING PROCEDURE SPECIFICATION (WPS)公司名称 Company Name:焊接方法 Welding Process(es):PQR辅助文件号 Supporting PQR No.(s):采用的接头设计 JOINT DSIGN USED类型 Type:单面焊缝 Single [ ] 双面焊缝 Double Weld [ ]衬垫 Backing:是 Yes [ ] 否 No[ ] 衬垫材料Backing Materical:根部间隙 Rooting opening:钝边尺寸 Root Face Dimension:坡口角度 Groove Angle:半径 Radius (J-U):背部清根 Backing:是 Yes [ ] 否No[ ]方法 Method:母材 BACE METALS材料规格 Material Spec.:类型或级别 Type or Grade:厚度 Thickness:坡口 Groove:角焊缝 Fillet:直径(圆管)Diamcter(Pipe):填充金属 FILLER METALSAWS 规定 AWS Specification:AWS 类别 AWS Classification:保护 SHIELDING焊剂 Flux:气体 Gas:焊丝—焊剂(等级) Electrode-Flux(Class):预热 PREHEAT预热温度,最低 Preheat Temp,Min:道间温度,最低 Interpass Temp,Min:最高 Max:标识编号 Identification #:修改 Revision:日期Date:修改人 By:批准人 Authorized by:日期Date:类型 Type—手工 Manual[ ] 半自动semi-Automatic[ ]机械 Machine[ ] 自动Automatic[ ]位置 POSITION坡口位置 Position of Groove:角焊缝 Fillet:立焊方向 Vertical Progression:上行Up[ ] 下行 Down[ ]电特性 ELECTRICAL CHARACTERISTICS过渡形式(GMAW) Transfer Mode(GMAW) 短路 Short-Circuting:[ ] 熔滴 Globular:[ ]喷射 Spray:[ ]电流 Current:交流 AC:[ ] 直流反接 GCEP:[ ]脉冲 Pulsed:[ ] 直流正接 DCEN:[ ]钨极(GTAW) Tungsten Electrode尺寸 Size:类型 Type:技术 TECHNIQUE 直线或横向摆动喊道 Stringer or Weave Bead:多道或单道(每边) Multi-pass or Single Pass(per side):焊丝数 Numbei of Electrodes:焊丝间隔 Electrode Spacing 纵向Longitudinal:横向Lateral:角度Angle:导电咀到工件距离 Contact Tube to Work Distance:锤击 Peening:道间清理 Interpass Cleaning:焊后热处理 POSTWELD HEAT TREATMENT温度 Temp.:时间 Time :。

中英文对照各种施工工艺大全1、钢结构工程Steel Project1.1钢结构焊接Welded Steel1.1.1工艺流程作业准备→电弧焊接(平焊、立焊、横焊、仰焊)→焊缝检查Process Ready to work→Arc Weld(Flat Welding、Stand Welding、Sidelong Welding 、Welding belief) →Weld inspection1.1.2钢结构电弧焊接:Arc Welding Steel:1.1.2.1平焊:选择合适的焊接工艺,焊条直径,焊接电流,焊接速度,焊接电弧长度等,通过焊接工艺验证;清理焊口:焊前检查坡口、组装间隙是否符合要求,定位焊是否牢固,焊缝周围不得有油污、锈物;烘焙焊条应符合规定温度与时间,从烘箱中取出的焊条,放在焊条保温桶内,随用随取;焊拉电源:根据焊件厚度、焊接层次、焊条型号、直径、焊工熟练程度等因素,选择适宜的焊接电流;引弧:角焊缝起落弧点应在焊缝端部,宜大于10㎜,不应随便打弧,打火引弧后应立即将焊条从焊缝区拉开,使焊条块结合与构件间保持2~4㎜间隙产生电弧。

对接焊缝及对接和角接组合焊缝,在焊缝两端设引弧板和引出板,必须在引弧板上引出后再焊到焊缝区,中途接头则应在焊缝接头前方15~20㎜处打火引弧,将焊件预热后再将焊条退回到焊缝起始处,把熔池填满到要求的厚度后,方可向前施焊;焊接速度:要求等速焊接,保证焊缝厚度、宽度均匀一致,从面罩内看熔池中铁水与熔渣保持等距离(2~3㎜)为宜;焊接电弧长度:根据焊条型号不同而确定,一般要求电弧长度稳定不变,酸性焊条一般为3~4㎜,碱性焊条一般为2~3㎜为宜;焊接角度:根据两焊件的厚度确定,焊接角度有两个方面,一是焊条与焊接前进方向的夹角为60~75°;二是焊条与焊接左右夹角有两种情况,当焊件厚度相等时,焊件与焊件夹角为45°;当焊件厚度不等时,焊条与较厚焊件一侧夹角应大于焊条与薄焊件一侧夹角;收弧:每条焊缝焊到末尾,应将弧坑填满后,往焊接方向相反的方向带弧,使弧坑甩在焊道貌岸然里边,以防弧坑咬肉。

焊接工艺规程WELDING PROCEDURE SPECIFICATION1. 目的和范围Purpose and Scope此规程规定了焊接的工人、材料和设备的需求,以保证焊接质量满足规范的要求。

This procedure prescribes requirement of welding workers, materials and equipment in order to ensure the welding quality satisfy regulated requirements.2. 职责Responsibility2.1 设计部门做成焊接工艺,并负责技术培训工作和重要项目的焊接工作。

The Design department shall constitute welding procedure, and be responsible for technical work training and important project welding work.2.2 质量控制部门负责监督,并在整个焊接过程中负责检查。

The QC department is responsible for monitoring and checking during the whole welding process.3. 步骤Procedure3.1 人员Personnel3.1.1焊接的材料管理员必须经过培训合格并获得前工作展开的资格证书。

The welding material keeper shall be trained to be qualified and get the qualification certificate prior to the commencement of work.3.1.2持证焊工应每半年重新核定,如果核定顺利通过,则其焊接资格证书继续有效。

如果焊机考试失败,该证书将被取消。