第九章合成橡胶SyntheticRubber

- 格式:ppt

- 大小:7.49 MB

- 文档页数:54

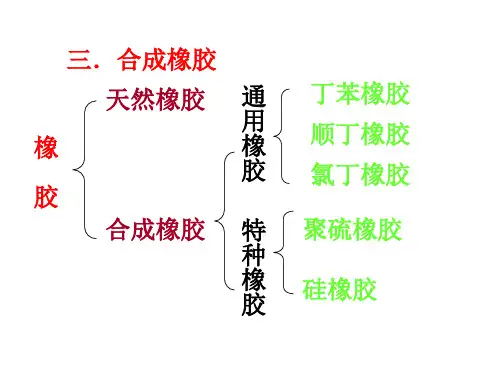

合成橡胶分类默认分类橡胶分为天然橡胶和合成橡胶。

天然橡胶主要来源于三叶橡胶树,当这种橡胶树的表皮被割开时,就会流出乳白色的汁液,称为胶乳,胶乳经凝聚、洗涤、成型、干燥即得天然橡胶。

合成橡胶是由人工合成方法而制得的,采用不同的原料(单体)可以合成出不同种类的橡胶。

合成橡胶的分类:一、丁苯橡胶SBR丁苯橡胶是丁二烯和苯乙烯经共聚合制得的橡胶。

英文缩写是SBR。

是产量最大的通用合成橡胶,有乳聚丁苯橡胶、溶聚丁苯橡胶。

世界丁苯橡胶生产能力中约87%使用乳液聚合法,通常所说的丁苯橡胶主要是指乳聚丁苯橡胶。

乳聚丁苯橡胶又包括高温乳液聚合的热丁苯与低温乳液聚合的冷丁苯。

前者于1942年工业化,目前仍有少量生产,主要用于水泥、粘合剂、口香糖、以及某些织物包覆与模塑制品及机械制品。

通常所说的丁苯橡胶主要是指低温乳液聚合法生产的丁苯橡胶,1947年工业化,它有较高的耐磨性和很高的抗张强度,良好的加工性能,以及其它综合性能,是目前产量最大、用途最广的合成橡胶品种。

溶聚丁苯橡胶(SSBR)是丁二烯与苯乙烯在烃类溶剂中,在丁基锂催化剂存在下聚合制得。

80年代后期生产的第二代溶聚丁苯橡胶滚动阻力优于乳聚丁苯橡胶和天然橡胶,抗湿滑性优于顺丁橡胶,耐磨性也好,可以满足轮胎高速、安全、节能、舒适的要求,用其制造轮胎比乳聚丁苯橡胶节油3%~5%。

丁苯生胶是浅黄褐色弹性固体,密度随苯乙烯含量的增加而变大,耐油性差,但介电性能较好;生胶抗拉强度只有20-35千克力/厘米2,加入炭黑补强后,抗拉强度可达250-280千克力/厘米2;其黏合性﹑弹性和形变发热量均不如天然橡胶,但耐磨性﹑耐自然老化性﹑耐水性﹑气密性等却优于天然橡胶,因此是一种综合性能较好的橡胶。

丁苯橡胶是橡胶工业的骨干产品,它是合成橡胶第一大品种,综合性能良好,价格低,在多数场合可代替天然橡胶使用,主要用于轮胎工业,汽车部件、胶管、胶带、胶鞋、电线电缆以及其它橡胶制品。

二、顺丁橡胶\\聚丁二烯橡胶(BR)丁二烯在聚合时由于条件不同可产生不同类型的聚合物。

1绪论Q1.总结高分子材料(塑料和橡胶)在发展过程中的标志性事件:(1)最早被应用的塑料(2)第一种人工合成树脂(3)是谁最早提出了高分子的概念(4)HDPE和PP的合成方法是谁发明的(5)是什么发现导致了近现代意义橡胶工业的诞生?1.(1)19世纪中叶,以天然纤维素为原料,经硝酸硝化樟脑丸增塑,制得了赛璐珞塑料,被用来制作台球。

(2)1907年比利时人雷奥·比克兰德应用苯酚和甲醛制备了第一种人工合成树脂—酚醛树脂(PF),俗称电木。

(3)1920年,德国化学家Dr.Herman.Staudinger首先提出了高分子的概念(4)1953年,德国K.Ziegler以TiCl4-Al(C2H5)3做引发剂,在60~90℃,0.2~1.5MPa条件下,合成了HDPE;1954年,意大利G.Natta以TiCl3-AlEt3做引发剂,合成了等规聚丙烯。

两人因此获得了诺贝尔奖。

(5)1839年美国人Goodyear发明了橡胶的硫化,1826年英国人汉考克发明了双辊开炼机,这两项发明使橡胶的应用得到了突破性的进展,奠定了现代橡胶加工业的基础。

Q2.树脂、通用塑料、工程塑料的定义。

化工辞典中的树脂定义: 为半固态、固态或假固态的不定型有机物质, 一般是高分子物质, 透明或不透明。

无固定熔点, 有软化点和熔融范围, 在应力作用下有流动趋向。

受热、变软并渐渐熔化, 熔化时发粘, 不导电, 大多不溶于水, 可溶于有机溶剂如乙醇、乙醚等, 根据来源可分成天然树脂、合成树脂、人造树脂, 根据受热后的饿性能变化可分成热定型树脂、热固性树脂, 此外还可根据溶解度分成水溶性树脂、醇溶性树脂、油溶性树脂。

通用塑料: 按塑料的使用范围和用途分类, 具有产量大、用途广、价格低、性能一般的特点, 主要用于非结构材料。

常见的有聚乙烯(PE)、聚丙烯(PP)、聚氯乙烯(PVC)、聚苯乙烯(PS)。

工程塑料:具有较高的力学性能, 能够经受较宽的温度变化范围和较苛刻的环境条件, 并在此条件下长时间使用的塑料, 可作为结构材料。

合成橡胶硅胶聚合物English Answer:Synthetic Rubber.Synthetic rubber is a man-made material that is designed to have the same properties as natural rubber. It is produced through a chemical process that involves the polymerization of various monomers. Synthetic rubber is used in a wide range of applications, including tires, hoses, belts, and gaskets.There are many different types of synthetic rubber, each with its own unique properties. Some of the most common types include:Styrene-butadiene rubber (SBR): SBR is the most widely used type of synthetic rubber. It is a copolymer of styrene and butadiene. SBR is known for its good abrasion resistance and low cost.Polybutadiene rubber (BR): BR is a homopolymer of butadiene. It is known for its high resilience and lowrolling resistance. BR is used in a variety of applications, including tires and hoses.Neoprene rubber (CR): CR is a copolymer of chloroprene and butadiene. It is known for its good resistance to oil and chemicals. CR is used in a variety of applications, including hoses, gaskets, and seals.Nitrile rubber (NBR): NBR is a copolymer ofacrylonitrile and butadiene. It is known for its good resistance to oil and heat. NBR is used in a variety of applications, including hoses, gaskets, and seals.Polyurethane rubber (PUR): PUR is a type of synthetic rubber that is made from the reaction of a diisocyanate and a polyol. PUR is known for its high strength and abrasion resistance. PUR is used in a variety of applications, including tires, hoses, and belts.Silicone Polymers.Silicone polymers are a type of synthetic polymer thatis made from the silicone element. Silicone polymers are known for their high stability, flexibility, and resistance to heat and chemicals. They are used in a wide range of applications, including medical devices, electronics, and cookware.There are many different types of silicone polymers, each with its own unique properties. Some of the most common types include:Polydimethylsiloxane (PDMS): PDMS is the most widely used type of silicone polymer. It is a clear, colorless liquid that is known for its high stability and flexibility. PDMS is used in a variety of applications, includingmedical devices, electronics, and cookware.Polymethylphenylsiloxane (PMPS): PMPS is a type of silicone polymer that is known for its high strength and resistance to heat. PMPS is used in a variety ofapplications, including electrical insulation and high-temperature gaskets.Polyvinylmethylsiloxane (PVMS): PVMS is a type of silicone polymer that is known for its high transparency and low refractive index. PVMS is used in a variety of applications, including optical lenses and coatings.Polyethylsiloxane (PES): PES is a type of silicone polymer that is known for its high resistance to radiation and chemicals. PES is used in a variety of applications, including aerospace and nuclear engineering.Comparison of Synthetic Rubber and Silicone Polymers.Synthetic rubber and silicone polymers are two types of synthetic materials that are often used for similar applications. However, there are some key differences between these two materials.Composition: Synthetic rubber is made from the polymerization of various monomers, while silicone polymersare made from the silicone element.Properties: Synthetic rubber is known for its good abrasion resistance, low cost, and flexibility. Silicone polymers are known for their high stability, flexibility, and resistance to heat and chemicals.Applications: Synthetic rubber is used in a wide range of applications, including tires, hoses, belts, and gaskets. Silicone polymers are used in a wide range of applications, including medical devices, electronics, and cookware.Conclusion.Synthetic rubber and silicone polymers are twoimportant types of synthetic materials that are used in a wide range of applications. These materials have different properties and compositions, so it is important to choose the right material for the specific application.Chinese Answer:合成橡胶。

合成橡胶及其发展

合成橡胶(Synthetic Rubber)又称人造橡胶,是指以石油或天然气

等原料,经过精细的化学合成工艺制备而成的胶状物质。

它具有耐冲击、

耐老化、耐高低温、耐油污、重量轻、抗菌、弹性好等优点。

由于其综合

良好的物理和化学性质,可广泛应用于汽车、家具、船舶、家用电器、仪

器仪表、电子等行业。

合成橡胶的历史可以追溯到20世纪初,当时科学家对它们进行的研

究和发展还很有限。

在20世纪30年代,合成树脂的开发使得合成橡胶的

发展非常迅速,从而使得合成橡胶得以大量应用于工业中。

20世纪50年

代以来,随着现代化的发展和环境保护意识的增强,合成橡胶的发展也日

趋成熟。

特别是在航空、航天等高要求的领域,合成橡胶的应用更加普及。

合成橡胶的种类繁多,主要有丁苯橡胶(BR)、乙丙橡胶(EPR)、

氯丁橡胶(CR)和聚氨酯橡胶(PU)等。

1、丁苯橡胶(BR)是20世纪30年代最早发明的合成橡胶,也是目

前世界上应用最广泛的合成橡胶,可以用作屏蔽料、衬底、平板橡胶、摩

擦材料等。

其特点是耐油、耐酸碱、耐水和耐低温,但不耐高温。

2、乙丙橡胶(EPR)是20世纪50年代开始发明的合成橡胶,具有优

异的耐高温性能,可在-50°C~180°C的温度下正常使用,耐油、耐酸碱。

合成橡胶生产工艺合成橡胶(synthetic rubber)生产工艺包括以下几个主要步骤:原材料准备、反应制备、调质、混炼、成型和后处理。

下面将逐一介绍。

1. 原材料准备:合成橡胶的主要原材料包括有机物和无机物。

有机物一般为石油化工产品,如丁苯橡胶(BR)、丁基橡胶(BR)、丁腈橡胶(NBR)等。

无机物包括活性剂、促进剂、稳定剂等。

原材料需要经过严格的检验和准备,确保其质量和纯度。

2. 反应制备:合成橡胶的反应制备是指将有机物和无机物通过化学反应合成橡胶。

反应制备过程中需要将原材料加入反应釜中,控制反应条件如温度、压力和反应时间等。

反应完毕后,得到的反应物经过处理,去除杂质。

3. 调质:合成橡胶的调质步骤是为了提高橡胶的性能和使用寿命。

调质一般包括添加助剂和改变橡胶分子链结构等。

助剂是用来增加橡胶的强度、耐热性和耐寒性等。

改变分子链结构可以改变橡胶的硬度、弹性和耐磨性等。

4. 混炼:混炼是将调质后的合成橡胶与其他添加剂混合,形成橡胶混合胶料。

添加剂包括硫化剂、活性剂、稳定剂、增塑剂等。

混炼可以通过机械搅拌或者混炼机进行。

混炼的目的是均匀分散各种添加剂,使其与橡胶充分融合。

5. 成型:成型是将混炼好的橡胶胶料制成所需的形状,常见的成型方法有压延、挤出、注塑等。

成型过程中需要将胶料加热至一定温度,以使其流动性增加,并借助模具进行成型。

成型完成后,橡胶制品需要经过冷却和固化。

6. 后处理:合成橡胶制品在成型后需要进行后处理。

后处理包括去除模具和修整。

去除模具是指将橡胶制品从模具中取出。

修整是指修剪、打磨橡胶制品的边缘,并进行质量检验和包装。

总结:合成橡胶的生产工艺大致可以分为原材料准备、反应制备、调质、混炼、成型和后处理等几个步骤。

通过精确的操作和控制,可以制备出具有特定性能和用途的合成橡胶制品。

合成橡胶的生产工艺随着科技的不断进步也在不断改进,以提高生产效率和降低成本。

gummi 橡胶类型

Gummi橡胶是一种弹性材料,具有较高的弹性和耐久性,广泛用于各种领域,如汽车、电子、医疗、航空航天等。

根据不同的配方和用途,Gummi 橡胶可以分为多种类型,以下是一些常见的类型:

1. 天然橡胶(Natural Rubber):天然橡胶是从橡胶树中提取的,是最早使用的橡胶材料之一。

它具有优良的弹性和耐久性,但易受到温度和湿度的影响。

2. 合成橡胶(Synthetic Rubber):合成橡胶是由多种化学品在工厂中合成的,具有与天然橡胶相似的弹性和耐久性,但不受温度和湿度的影响。

常见的合成橡胶包括丁苯橡胶(Styrene Butadiene Rubber)、聚丁二烯橡胶(Polybutadiene Rubber)和丁基橡胶(Isoprene Rubber)等。

3. 硅橡胶(Silicone Rubber):硅橡胶是一种基于硅氧烷的弹性材料,具有优良的耐热性、耐氧化性和耐化学腐蚀性。

它广泛用于高温和化学环境下的应用。

4. 氟橡胶(Fluoroelastomer):氟橡胶是一种高度耐用的弹性材料,具有出色的耐油、耐化学品和耐高温性能。

它广泛用于石油、化工和航空航天等领域。

5. 丙烯酸酯橡胶(Acrylic Elastomer):丙烯酸酯橡胶是一种基于丙烯酸

酯的弹性材料,具有出色的耐油、耐化学品和耐低温性能。

它广泛用于汽车、石油和航空航天等领域。

以上是常见的Gummi橡胶类型,每种类型都有其独特的性能和应用范围。

在实际应用中,需要根据具体需求选择合适的类型。

Synthetic rubberA polymer that was critical to the war effort was "synthetic rubber", which was produced in a variety of forms. Synthetic rubbers are not plastics. Synthetic rubbers are elastic materials.The first synthetic rubber polymer was obtained by Lebedev in 1910. Practical synthetic rubber grew out of studies published in 1930written independently by American Wallace Carothers, Russian scientist Lebedev and the German scientist Hermann Staudinger. These studies led in 1931 to one of the first successful synthetic rubbers, known as "neoprene", which was developed at DuPont under the direction of E.K. Bolton. Neoprene is highly resistant to heat and chemicals such as oil and gasoline, and is used in fuel hoses and as an insulating material in machinery.In 1935, German chemists synthesized the first of a series of synthetic rubbers known as "Buna rubbers". These were "copolymers", meaning that their polymers were made up from not one but two monomers, in alternating sequence. One such Buna rubber, known as "GR-S" (Government Rubber Styrene), is a copolymer of butadiene and styrene, became the basis for U.S. synthetic rubber production during World War II.Worldwide natural rubber supplies were limited and by mid-1942 most of the rubber-producing regions were under Japanese control. Military trucks needed rubber for tires, and rubber was used in almost every other war machine. The U.S. government launched a major (and largely secret) effort to develop and refine synthetic rubber. A principal scientist involved with the effort was Edward Robbins.By 1944 a total of 50 factories were manufacturing it, pouring out a volume of the material twice that of the world's natural rubber production before the beginning of the war.After the war, natural rubber plantations no longer had a stranglehold on rubber supplies, particularly after chemists learned to synthesize isoprene. GR-S remains the primary synthetic rubber for the manufacture of tires.Synthetic rubber would also play an important part in the space race and nuclear arms race. Solid rockets used during World War II used nitrocellulose explosives for propellants, but it was impractical and dangerous to make such rockets very big.During the war, California Institute of Technology (Caltech) researchers came up with a new solid fuel, based on asphalt fuel mixed with an oxidizer, such as potassium or ammonium perchlorate, plus aluminium powder, which burns very hot. This new solid fuel burned more slowly and evenly than nitrocellulose explosives, and was much lessdangerous to store and use, though it tended to flow slowly out of the rocket in storage and the rockets using it had to be stockpiled nose down.After the war, the Caltech researchers began to investigate the use of synthetic rubbers instead of asphalt as the fuel in the mixture. By the mid-1950s, large missiles were being built using solid fuels based on synthetic rubber, mixed with ammonium perchlorate and high proportions of aluminium powder. Such solid fuels could be cast into large, uniform blocks that had no cracks or other defects that would cause nonuniform burning. Ultimately, all large military rockets and missiles would use synthetic rubber based solid fuels, and they would also play a significant part in the civilian space effort.译文:合成橡胶合成橡胶,是在战争中起着至关重要的被制作成各种用途的一种聚合物。