客户验厂资料(翻译版)

- 格式:doc

- 大小:246.00 KB

- 文档页数:13

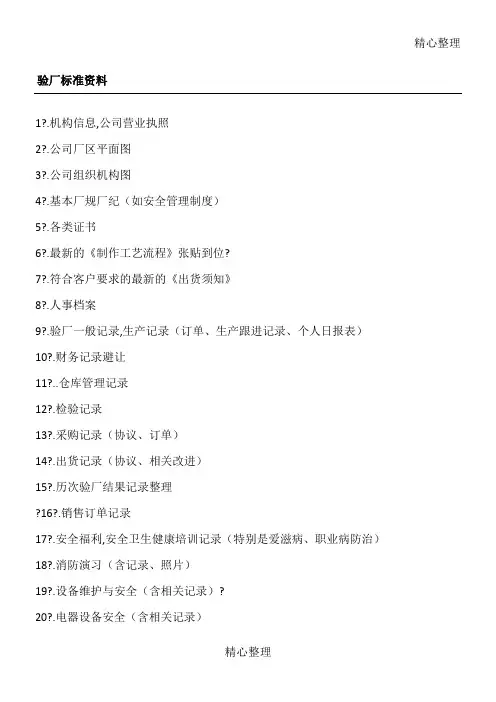

精心整理验厂标准资料1?.机构信息,公司营业执照2?.公司厂区平面图3?.公司组织机构图4?.5?.6?.7?.8?.9?.10?.11?..12?.13?.14?.15?.?16?.销售订单记录17?.安全福利,安全卫生健康培训记录(特别是爱滋病、职业病防治)18?.消防演习(含记录、照片)19?.设备维护与安全(含相关记录)?20?.电器设备安全(含相关记录)21?.安全生产检查记录22?.宿舍住宿人员名单?23?.住厂人员暂住证复印件、办理记录24?.吸烟室、洗脸池25?.厂房建筑结构安全合格证明26?.27?.28?.29?.30?.31?.32?.33?.34?.35?.36?.37?.38?.39?EHS委员会(组织结构、人员组成、章程、工作程序、例会记录)?40?.特殊设备许可证明41.?MSDS(含张贴到现场)化学品安全说明书42?.危险物库存清单/废弃物库存清单43?.耳塞配备、眼镜配备44?.工作服、工作鞋(含管理办法制订、发放记录)45?.各处厕所及浴室的标识、数量、位置图示46?.垃圾桶和垃圾点的分布图示?47?.配备垃圾桶,确保垃圾分类48?.工作卡的配齐与管理49?.50?.51?.52?.53?.54?.55?.56?.57?.58?.59?.60?.61?.62?.环境卫生管理办法、卫生区划分示意图63?.工会/工会代表选举程序(强调人权)64?.工会职责65?.工会组织会议记录66?.工会会员名单?67?.工会活动记录68?.合理化建议(建议渠道、建议箱)69?.其他:检查当天到厂人员的统计70?.厂外仓库71?.检查当天安全保卫工作布置(准备访客证、通知传递信息)72?.73?.74?.75?.。

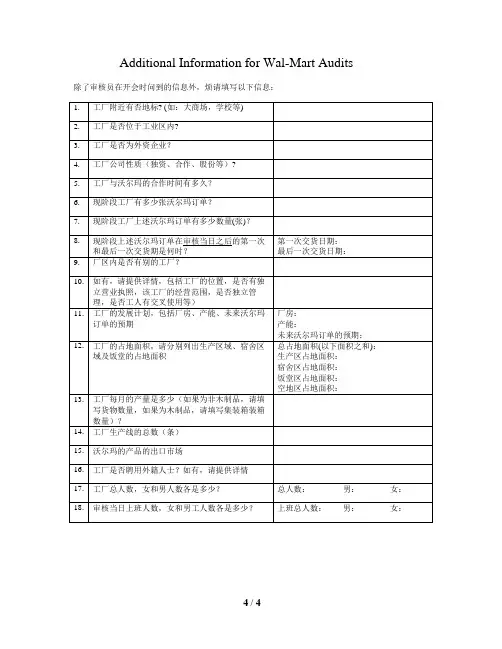

Additional Information for Wal-Mart Audits 除了审核员在开会时问到的信息外,烦请填写以下信息:请提供相应分包商的以下信息,如果有多家分包商,请各填一张每家分包商的信息。

•分包商名称:(中文)(英文)•分包商地址:(中文)(英文)•分包商的联系人姓名:•分包商的电话号码,传真号码和邮件地址:•被分包的产品:•被分包的生产工艺:o如果是产品分包,是否有原材料,半成品等分包给分包商加工:•是否有包含沃尔玛标签,标识等是否会被发送至分包商处:•在分包商处或者其生产产品上是否可以识别出沃尔玛产品品牌:•企业与分包商合作时间:•分包商生产沃尔玛产品时间:•被分包产品的品牌名称:•现阶段分包商生产被分包的产品的百分比:o企业分包给分包商现有订单张数和相应的总数量:o企业分包给分包商的产品相对审核当日的上次、下次、最后一次交货日期:•现阶段分包商生产的沃尔玛的品牌名称和部门号码:•分包信息的来源:请提供以下文件和记录:1.关于受过工伤的员工重返工作岗位时评估其是否能胜任原来的工作岗位的书面程序。

2.厂内排水系统的平面图。

3.废气排放源清单。

4.消耗臭氧层的物质(ODS)的物质清单。

5.用水量政策和相关的统计记录。

6.能源的监测和能源消耗记录。

7.导致温室效应的气体(GHG)排放源盘查清册。

8.减少碳排放计划。

9.土地使用许可证或厂房产权资格证。

10.环境方针政策。

11.关于环境的法律法规和其他要求识别与获取程序,和相关法律法规清单。

12.有资质人员负责处理环境方面的事务。

13.环境应急响应计划和演习记录。

14.所有员工的环境知识方面培训记录。

15.环境管理体系的管理者代表。

16.环境,健康和安全委员会。

17.关于环境,健康和安全方面的劳动保护用品的培训记录。

18.废弃物处理的培训记录。

19.关于化学品安全、标记、标识、物质安全资料表(MSDS)的意识,化学品泄漏的紧急处理程序的培训教材和培训记录。

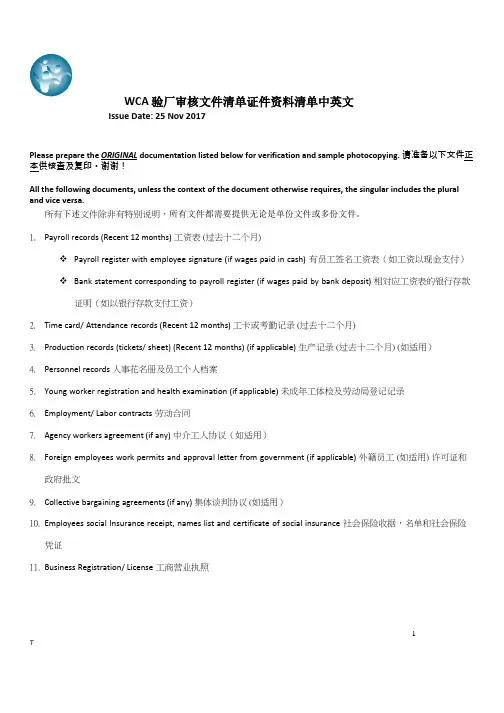

WCA 验厂审核文件清单证件资料清单中英文Issue Date: 25 Nov 20171TPlease prepare the ORIGINAL documentation listed below for verification and sample photocopying. 请准备以下文件正All the following documents, unless the context of the document otherwise requires, the singular includes the plural and vice versa.所有下述文件除非有特别说明,所有文件都需要提供无论是单份文件或多份文件。

1. Payroll records (Recent 12 months) 工资表 (过去十二个月)Payroll register with employee signature (if wages paid in cash) 有员工签名工资表(如工资以现金支付)Bank statement corresponding to payroll register (if wages paid by bank deposit) 相对应工资表的银行存款证明(如以银行存款支付工资)2. Time card/ Attendance records (Recent 12 months) 工卡或考勤记录 (过去十二个月)3. Production records (tickets/ sheet) (Recent 12 months) (if applicable) 生产记录 (过去十二个月) (如适用)4. Personnel records 人事花名册及员工个人档案5. Young worker registration and health examination (if applicable) 未成年工体检及劳动局登记记录6. Employment/ Labor contracts 劳动合同7. Agency workers agreement (if any) 中介工人协议(如适用)8. Foreign employees work permits and approval letter from government (if applicable) 外籍员工 (如适用) 许可证和政府批文9. Collective bargaining agreements (if any) 集体谈判协议 (如适用)10. Employees social Insurance receipt, names list and certificate of social insurance 社会保险收据,名单和社会保险凭证11. Business Registration/ License 工商营业执照WCA 验厂审核文件清单证件资料清单中英文Issue Date: 25 Nov 20172T12. Fire safety inspection / certificates and building / construction permits for facility / dormitory buildings 消防检查报告或合格证明及建筑/施工许可证13. Fire drill records 消防演习记录、急救演习/紧急疏散计划14. Facility regulation or employee handbook, in regard to the following areas: 厂规或员工手册, 包括以下几个方面:Recruitment policy 招聘政策Disciplinary procedure 纪律处分程序15. Local minimum wage standard (if any) and/ or Government Labor Law notice (if any) 政府有关当地最低工资规定文件/政府的劳动法的通知 (如适用)16. Special appliance certificates such as certificate for elevator, boiler 特种设备认证证书如电梯,锅炉17. Permits for special appliance operations such as lift operator, electrician, and boiler 特种工人上岗证(如:电梯工锅炉工上岗证, 电工, 锅炉许可证等)18. Canteen or eating facilities hygiene certificate, cook/ kitchen staff health certificates 厨房卫生许可证, 厨工卫生许可证19. Facility building layout/ evacuation plan 厂房平面图20. Special waivers from local government regarding working hours arrangement (if applicable) 从当地政府就工作時間的特殊批文 (如适用)21. Health & Safety program and training records 健康与安全计划及培训记录22. Work-related accidents/ injury records 工伤事故记录及工伤记录等23. Environmental certificates (if applicable) 环保证书(如适用)24. Any written policy or process that governs company and employee business practices. e.g. business integrity & anti- corruption, fair competition (optional if Business Practice module is applicable in the assessment) and dataWCA 验厂审核文件清单证件资料清单中英文Issue Date: 25 Nov 20173Tprotection (optional if Business Practice module is applicable in the assessment) including (but not limited) to thefollowing: 任何书面政策或程序去规范公司和员工的商业道德规范。

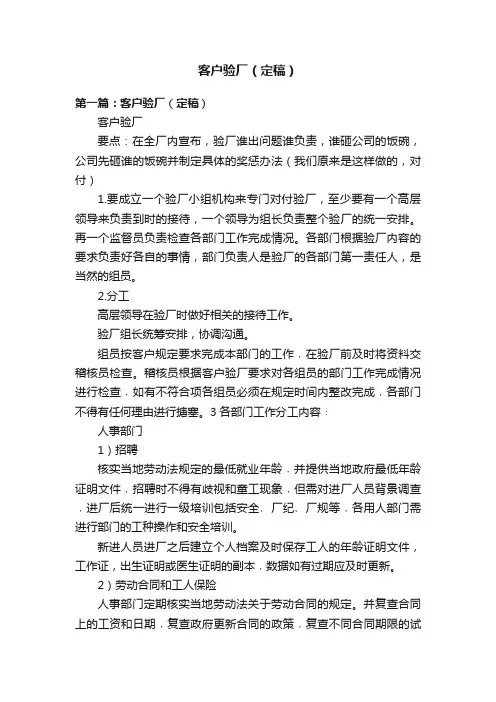

客户验厂(定稿)第一篇:客户验厂(定稿)客户验厂要点:在全厂内宣布,验厂谁出问题谁负责,谁砸公司的饭碗,公司先砸谁的饭碗并制定具体的奖惩办法(我们原来是这样做的,对付)1.要成立一个验厂小组机构来专门对付验厂,至少要有一个高层领导来负责到时的接待,一个领导为组长负责整个验厂的统一安排。

再一个监督员负责检查各部门工作完成情况。

各部门根据验厂内容的要求负责好各自的事情,部门负责人是验厂的各部门第一责任人,是当然的组员。

2.分工高层领导在验厂时做好相关的接待工作。

验厂组长统筹安排,协调沟通。

组员按客户规定要求完成本部门的工作﹐在验厂前及时将资料交稽核员检查。

稽核员根据客户验厂要求对各组员的部门工作完成情况进行检查﹐如有不符合项各组员必须在规定时间内整改完成﹐各部门不得有任何理由进行搪塞。

3各部门工作分工内容﹕人事部门1)招聘核实当地劳动法规定的最低就业年龄﹐并提供当地政府最低年龄证明文件﹐招聘时不得有歧视和童工现象﹐但需对进厂人员背景调查﹐进厂后统一进行一级培训包括安全﹑厂纪﹑厂规等﹐各用人部门需进行部门的工种操作和安全培训。

新进人员进厂之后建立个人档案及时保存工人的年龄证明文件,工作证,出生证明或医生证明的副本﹐数据如有过期应及时更新。

2)劳动合同和工人保险人事部门定期核实当地劳动法关于劳动合同的规定。

并复查合同上的工资和日期﹐复查政府更新合同的政策﹐复查不同合同期限的试用期﹐如合同期满须及时到劳动部门重新办理劳动合同。

定期办理医疗﹑工伤﹑养老﹑生育﹑失业保险﹐符合劳动部门的规定并提供劳动部门有关规定的批文。

3)工时﹑工资﹑考勤人事部门提供当地政府最低工资批文﹐合同当中也应满足政府批文要求。

工时﹑工资和考勤记录应符合客户验厂和劳动法的要求﹐对考勤表﹑工卡每月定期检查﹐不得有打卡错误或不打卡现象﹐如有不符合时应及时纠正﹐工时﹑工资﹑考勤表应和财务﹑生产部门的数据相符合﹐如有不符合现象﹐各部门重新核查﹐各部门统计员要积极的配合人事部门工作。

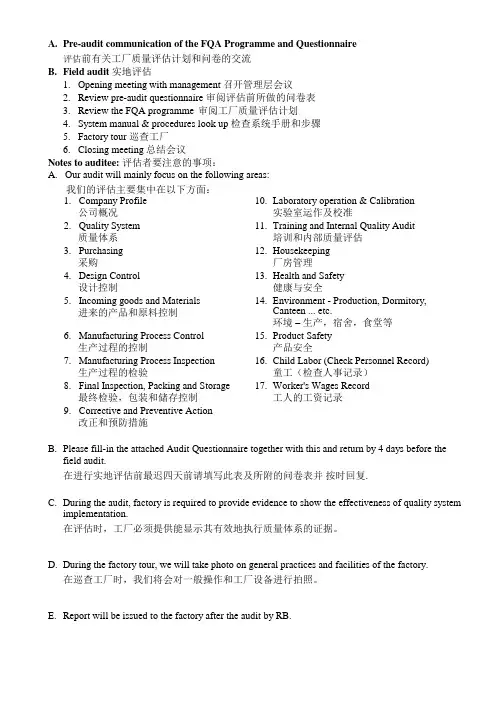

A.Pre-audit communication of the FQA Programme and Questionnaire评估前有关工厂质量评估计划和问卷的交流B.Field audit 实地评估1.Opening meeting with management 召开管理层会议2.Review pre-audit questionnaire 审阅评估前所做的问卷表3.Review the FQA programme 审阅工厂质量评估计划4.System manual & procedures look up 检查系统手册和步骤5.Factory tour 巡查工厂6.Closing meeting 总结会议Notes to auditee: 评估者要注意的事项:A. Our audit will mainly focus on the following areas:我们的评估主要集中在以下方面:pany Profile公司概况boratory operation & Calibration实验室运作及校准2.Quality System质量体系11.Training and Internal Quality Audit培训和内部质量评估3.Purchasing采购12.Housekeeping厂房管理4.Design Control设计控制13.Health and Safety健康与安全5.Incoming goods and Materials进来的产品和原料控制14.Environment - Production, Dormitory,Canteen ... etc.环境–生产,宿舍,食堂等6.Manufacturing Process Control生产过程的控制15.Product Safety产品安全7.Manufacturing Process Inspection生产过程的检验16.Child Labor (Check Personnel Record)童工(检查人事记录)8.Final Inspection, Packing and Storage最终检验,包装和储存控制17.Worker's Wages Record工人的工资记录9.Corrective and Preventive Action改正和预防措施B.Please fill-in the attached Audit Questionnaire together with this and return by 4 days before thefield audit.在进行实地评估前最迟四天前请填写此表及所附的问卷表并按时回复.C.During the audit, factory is required to provide evidence to show the effectiveness of quality systemimplementation.在评估时,工厂必须提供能显示其有效地执行质量体系的证据。

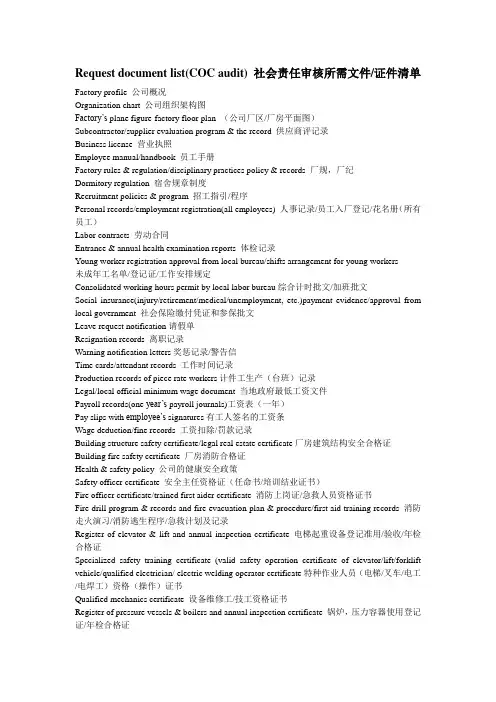

Request document list(COC audit) 社会责任审核所需文件/证件清单Factory profile 公司概况Organization chart 公司组织架构图Factory’s plane figure-factory floor plan (公司厂区/厂房平面图)Subcontractor/supplier evaluation program & the record 供应商评记录Business license 营业执照Employee manual/handbook 员工手册Factory rules & regulation/disciplinary practices policy & records 厂规,厂纪Dormitory regulation 宿舍规章制度Recruitment policies & program 招工指引/程序Personal records/employment registration(all employees) 人事记录/员工入厂登记/花名册(所有员工)Labor contracts 劳动合同Entrance & annual health examination reports 体检记录Young worker registration approval from local bureau/shifts arrangement for young workers未成年工名单/登记证/工作安排规定Consolidated working hours permit by local labor bureau综合计时批文/加班批文Social insurance(injury/retirement/medical/unemployment, etc.)payment evidence/approval from local government 社会保险缴付凭证和参保批文Leave request notification请假单Resignation records 离职记录Warning notification letters奖惩记录/警告信Time cards/attendant records 工作时间记录Production records of piece rate workers计件工生产(台班)记录Legal/local official minimum wage document 当地政府最低工资文件Payroll records(one year’s payroll journals)工资表(一年)Pay slips with employee’s signatures有工人签名的工资条Wage deduction/fine records 工资扣除/罚款记录Building structure safety certificate/legal real estate certificate厂房建筑结构安全合格证Building fire safety certificate 厂房消防合格证Health & safety policy 公司的健康安全政策Safety officer certificate 安全主任资格证(任命书/培训结业证书)Fire officer certificate/trained first aider certificate 消防上岗证/急救人员资格证书Fire drill program & records and fire evacuation plan & procedure/first aid training records 消防走火演习/消防逃生程序/急救计划及记录Register of elevator & lift and annual inspection certificate 电梯起重设备登记准用/验收/年检合格证Specialized safety training certificate (valid safety operation certificate of elevator/lift/forklift vehicle/qualified electrician/ electric welding operator certificate特种作业人员(电梯/叉车/电工/电焊工)资格(操作)证书Qualified mechanics certificate 设备维修工/技工资格证书Register of pressure vessels & boilers and annual inspection certificate 锅炉,压力容器使用登记证/年检合格证Approval certificate of chemical warehouse/register & storage records/ MSDS(material safety data sheet) of dangerous chemicals 化学危险品仓许可/(储存物控记录)/安全防范应急措施/无聊安全数据表Environment protection quality monitoring & test report车间有毒有害作业环保监测报告Environment assessment report on factory projects/permit certificate of waste emission/waste monitoring & test records 排污许可/环保检测报告Legal hygiene certificate of kitchen/canteen & health certificates of kitchen/ canteen workers。

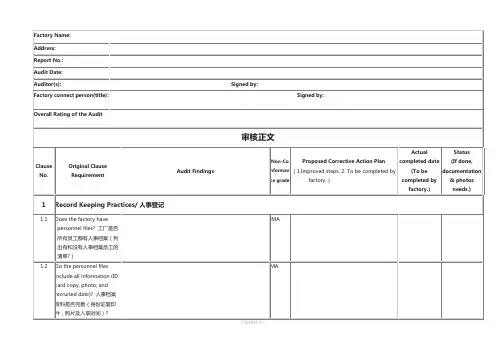

Remark:

1.If one critical violation was found, (such as slave labor, forced labor, child labor, physical abuse to the workers, etc.) this

factory should be out, the overall rating of the audit should be at risk.

(如果发现1个严重缺陷点,如狱工,童工,对工人体罚等),工厂将会被停用,本次验厂结果是此工厂存在很大风险。

)

2.If three to five (include) major violation were found, the overall rating of the audit should be Need Improvement.

(如果发现3~5个(含5个)主要缺陷点,本次验厂结果是此工厂需要改善。

3.If two or less major and six or less minor violation were found, the overall rating of the audit should be Acceptable, and

Need Improvement.

如果发现2个以下主要缺陷点和6个以下次要缺陷点,本次验厂结果是此工厂可接受使用但需要改善。

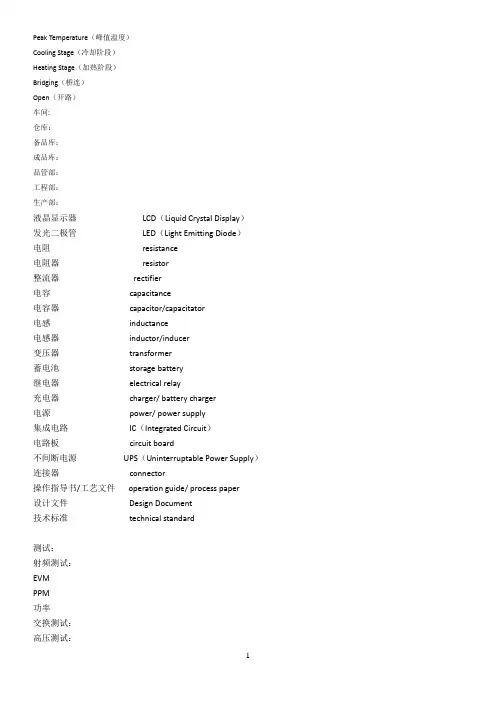

Peak Temperature(峰值温度)Cooling Stage(冷却阶段)Heating Stage(加热阶段)Bridging(桥连)Open(开路)车间:仓库:备品库:成品库:品管部:工程部:生产部:液晶显示器LCD(Liquid Crystal Display)发光二极管LED(Light Emitting Diode)电阻resistance电阻器resistor整流器rectifier电容capacitance电容器capacitor/capacitator电感inductance电感器inductor/inducer变压器transformer蓄电池storage battery继电器electrical relay充电器charger/ battery charger电源power/ power supply集成电路IC(Integrated Circuit)电路板circuit board不间断电源UPS(Uninterruptable Power Supply)连接器connector操作指导书/工艺文件operation guide/ process paper设计文件Design Document技术标准technical standard测试:射频测试:EVMPPM功率交换测试:高压测试:漏电流测试:接地电阻测试:QC(quality control)品质管理(员)SQC(Statistical Quality Control)统计品质管理TQC(Total Quality Control)全面品质管理AQL(Acceptable Quality Level)允许水准,可接受品质等级QA(Quality Audit)品质稽核QE(Quality Engineering)质量工程IQC(Incoming Quality Control)进料检验IPQC(In Process Quality Control)制程检验FQC(Final Quality Control)最终检验,线上检验OQC(Outgoing Quality Control)出货检验SIP(Standard Inspection Procedure)检验标准MQM(Modern Quality Management)(日本)现代品质管理体系(比ISO9001严格)QCC(Quality Control Circle)品管圈Check Sheet 核查表,审查表被欧盟禁止的有害物质Lead 铅PbCadmium 镉CdMercury 汞/水银HgHexavalent Chromium 六价铬Cr+6PBB(Polybrominated biphenyls)溴化联苯PBDE(Polybrominated biphenyl ether)溴化联苯醚WEEE―(Waste From Electrical And Electronic Equipment)欧盟《关于报废电子电器设备指令》(简称:WEEE指令)ROHS―(The Use Of Certain Hazardous Substances In Electrical And Electronic Equipment)欧盟《关于在电子电气设备中限制使用某些有害物质指令》(简称:ROHS指令)ISO(International Organization for Standardization)国际标准化组织Preheat Zone 预热区Soak Zone 吸收区Ramp to Reflow 升温区Reflow Zone 再流区Cooling Zone 冷却区Reflow Soldering 再流焊Wave Soldering 波峰焊SMT 表面组装技术SMC(Surface Mount Component)表面组装元器件SMD(Surface Mount Device)表面组装元器件SMA(Surface Mount Assembly)表面组装组件Shelf Life 贮存寿命Working Life工作寿命Lot No. 批号Net/Net Weight净重Exp. Date 有效期至Mfg. Date 制造日期BS Brain Storming 腦力激蕩QCC Quality Control Circle 品質圈PDCA Plan Do Check Action 計劃執行檢查總結DCC delivery control center 交貨管制中心Computer 電腦類產品Consumer electronics 消費性電子產品Communication 通訊類產品Engineering control system 工程管制系統Quality control system品質管制系統Manufacturing control system生產管制系統Management control system經營管制系統Classification整理(sorting, organization)-seiriRegulation整頓(arrangement, tidiness)-seitonCleanliness清掃(sweeping, purity)-seisoConservation清洁(cleaning, cleanliness)-seiktsuCulture教養(discipline)-shitsukeSave 節約Safety安全品質保證類FAI first article inspection 新品首件檢查FAA first article assurance 首件確認CP capability index 能力指數CPK capability process index 模具製程能力參數SSQA standardized supplier quality audit 合格供應商品質評估FMEA failure model effectiveness analysis 失效模式分析FQC運作類AQL Acceptable Quality Level 運作類允收品質水準S/S Sample size 抽樣檢驗樣本大小ACC Accept 允收REE Reject 拒收CR Critical 極嚴重的MAJ Major 主要的MIN Minor 輕微的Q/R/S Quality/Reliability/Service 品質/可靠度/服務P/N Part Number 料號L/N Lot Number 批號AOD Accept On Deviation 特采UAI Use As It 特采FPIR First Piece Inspection Report 首件檢查報告PPM Percent Per Million 百萬分之一制程統計品管專類SPC Statistical Process Control 統計製程管制SQC Statistical Quality Control 統計品質管制GRR Gauge Reproductiveness & Repeatability 量具之再制性及重測性判斷量可靠與否DIM Dimension 尺寸DIA Diameter 直徑N Number 樣品數其它品質術語類QIT Quality Improvement Team 品質改善小組ZD Zero Defect 零缺點QI Quality Improvement 品質改善QP Quality Policy 目標方針TQM Total Quality Management 全面品質管理RMA Return Material Audit 退料認可7QCTools 7 Quality Control Tools 品管七大手法通用之件類ECN Engineering Change Notice 工程變更通知(供應商)ECO Engineering Change Order 工程改動要求(客戶)PCN Process Change Notice 工序改動通知PMP Product Management Plan 生產管制計劃SIP Standard Inspection Procedure 製程檢驗標準程序SOP Standard Operation Procedure 製造作業規範IS Inspection Specification 成品檢驗規範BOM Bill Of Material 物料清單PS Package Specification 包裝規範SPEC Specification 規格DWG Drawing 圖面系統文件類ES Engineering Standard 工程標準CGOO China General PCE龍華廠文件IWS International Workman Standard 工藝標準ISO International Standard Organization 國際標準化組織GS General Specification 一般規格部類PMC Production & Material Control 生產和物料控制PCC Product control center 生產管制中心PPC Production Plan Control 生產計劃控制MC Material Control 物料控制DC Document Center 資料中心QE Quality Engineering 品質工程(部)QA Quality Assurance 品質保證(處)QC Quality Control 品質管制(課)PD Product Department 生產部LAB Laboratory 實驗室IE Industrial Engineering 工業工程R&D Research & Design 設計開發部生產類PCs Pieces 個(根,塊等)PRS Pairs 雙(對等)CTN Carton 卡通箱PAL Pallet/skid 棧板PO Purchasing Order 采購訂單MO Manufacture Order 生產單D/C Date Code 生產日期碼ID/C Identification Code (供應商)識別碼SWR Special Work Request 特殊工作需求L/N Lot Number 批號P/N Part Number 料號OEM Original Equipment Manufacture 原設備製造(來樣代工) ODM Original Design Manufacture 原設計制造(設計代工)PC Personal Computer 個人電腦CPU Central Processing Unit 中央處理器A.S.A.P As Soon As Possible 盡可能快的E-MAIL Electrical-Mail 電子郵件N/A Not Applicable 不適用QTY Quantity 數量I/O input/output 輸入/輸出NG Not Good 不行,不合格C=0 Critical=0 極嚴重不允許APP Approve 核準,認可,承認CHK Check 確認ASS'Y Assembly 裝配,組裝T/P True Position 真位度5WIH When, Where, Who, What, Why, How to6M Man, Machine, Material, Method, Measurement, Message4MTH Man, Material, Money, Method, Time, How 人力,物力,財務,技術,時間(資源) SQA Strategy Quality Assurance 策略品質保證DQA Design Quality Assurance 設計品質保證MQA Manufacture Quality Assurance 製造品質保證SSQA Sales and service Quality Assurance 銷售及服務品質保證LRR Lot Reject Rate 批退率SPS Switching power supply 電源箱DT Desk Top 臥式(機箱)MT Mini-Tower 立式(機箱)DVD Digital Video DiskVCD Video Compact DiskLCD Liquid Crystal DisplayCAD Computer Aided DesignCAM Computer Aided ManufacturingCAE Computer Aided EngineeringPCB Printed Circuit Board 印刷電路板CAR Correction Action Report 改善報告NG Not Good 不良WDR Weekly Delivery Requirement 周出貨要求PPM Percent Per Million 百萬分之一TPM Total Production Maintenance 全面生產保養MRP Material Requirement Planning 物料需計劃OS Operation System 作業系統TBA To Be Assured 待定,定缺D/C Drawing ChangeP/P Plans & ProcedureEMI Electrical-Music Industry 電子音樂工業Electrical Magnetic Interference 電子干扰RFI Read Frequency Input 讀頻輸入MMC Maximum Material ConditionMMS Maximum Material SizeLMC Least Material ConditionLMS Least Material SizeLED lighting-emitting diode 發光二极管QBR Quarter Business RecordCIP Continuous improvement processFGI Forecasted Goal InventoryCNC Computerized numeral controllerB2C Business to customerB2B Business to businessAVL Approved vendor listPOP Procedure of packagingEOL End of lifeVDCS Vender defect correcting sheetPDCS Process defect correcting sheetGRN Goods receiving noteA/R Accounting receivableA/P Accounting payable三:專業詞匯通用類president董事長operator作業員position職務general manager總經理special assistant 特助deputy manager |'depjuti| =vice manager副理deputy supervisor =vice supervisor 副課長group leader組長line leader線長supervisor 課長responsible department負責單位Human Resources Department人力資源部Head count 人頭數production department生產部門planning department企劃部QC Section品管課stamping factory沖壓廠painting factory烤漆廠molding factory成型廠administration/general affairs dept./總務部production unit生產單位meeting minutes會議記錄distribution department分發單位subject主題conclusion結論decision items決議事項pre-fixed finishing date預定完成日Color management 顏色管理Visual management 目視管理production capacity生產力first count初盤first check初盤復櫂second count 復盤second check復盤復核quantity of physical inventorysecond count 復盤點數量physical inventory盤點數量physical count quantity帳面數量difference quantity差異量spare parts physical inventory list備品盤點清單cause analysis原因分析waste materials廢料description品名specification 規格model機種work order工令revision版次remark備注registration登記registration card登記卡to control管制application form for purchase請購單consume, consumption消耗to notify通知to fill in填寫to collect, to gather收集statistics統計cosmetic inspection standard 外觀檢驗規範computer case 電腦外殼(組件) personal computer enclosure 電腦機箱產品front plate前板rear plate后板chassis |'∫æsi| 基座bezel panel面板Hood 上蓋base pan 基座bezel 面板riser card 擴充卡flat cable 排線TOP driver cage 上磁架bottom driver cage 下磁架resin film 樹脂膜raw materials原料materials物料steel plate鋼板roll/coil material捲料spare parts =buffer備品plastic parts塑膠件sheet metal parts/stamping parts 沖件material check list物料檢查表finished product成品semi-finished product半成品good product/accepted goods/accepted parts/good parts良品defective product/non-good parts不良品disposed goods處理品warehouse/hub倉庫packing material包材basket蝴蝶竺plastic basket膠筐flow chart流程表單production tempo生產進度現狀lots of production生產批量manufacture procedure制程to revise, modify修訂to switch over to, switch—to,switching over切換engineering bottleneck, projectdifficulty工程瓶頸glove(s)手套glove(s) with exposed fingers割手套Band-Aid創可貼Industrial alcohol工業酒精broom掃把mop拖把vacuum cleaner吸塵器rag 抹布garbage container灰箕garbage can垃圾箱garbage bag垃圾袋liaison聯絡單rags抹布lamp holder燈架to mop the floor拖地to clean a table擦桌子air pipe 氣管delivery deadline交貨期die worker模工production, to produce生產equipment設備resistance電阻beacon警示燈coolant冷卻液crusher破碎機club car高爾夫球車plate電鍍power button電源按鍵reset button重置鍵forklift叉車Workshop traveler 天車trailer =long vehicle拖板車Hydraulic trolley手壓車hydraulic hand jack油壓板車casing = containerization裝箱velocity速度patent專利coordinate座標supply and demand供求career card履歷卡barricade隔板carton box紙箱to pull and stretch拉深work cell/work shop工作間sub-line支線bottleneck 瓶頸品質類qualified products, up-to-grade products良品defective products, not up-to-grade products不良品defective product box不良品箱poor processing 制程不良poor incoming part來件不良exposed metal/bare metal金屬裸露excessive defect過多的缺陷critical defect極嚴重缺陷major defect主要缺陷minor defect次要缺陷not up to standard不合規格cosmetic defect外觀不良lack of painting烤漆不到位slipped screw head/slippery slipped thread滑絲missing part漏件wrong part錯件oxidation氧化defective threading抽芽不良poor staking鉚合不良deficient purchase來料不良deficient manufacturing procedure 制程不良cosmetic inspection外觀檢查inner parts inspection內部檢查blister 氣泡angular offset 角度偏差dent 壓痕scratch 刮傷deformation 變形filings 鐵削defective label 不良標簽abrasion 磨損Breaking. (be)broken,(be)cracked 斷裂short射料不足nick缺口speck瑕疪shine亮班splay 銀紋gas mark焦痕delaminating起鱗speckle斑點mildewed =moldy = mouldy發霉deformation變形burr(金屬)flash(塑件)毛邊poor staking鉚合不良excessive gap間隙過大grease/oil stains油污inclusion雜質shrinking/shrinkage縮水mixed color雜色fold of packaging belt打包帶折皺painting make-up補漆discoloration羿色water spots水漬impurity 雜質Mismatch 錯位failure, trouble 故障deformation 變形rust 生銹peel 脫漆Shrink 縮水Contamination 臟污water spots 水漬Gap 間隙label error 標簽錯誤Missing label 漏貼rejection criteria 拒收標准Suspected rejects 可疑庇abrasion 損傷、磨損Texture surface 印花紋表面Streak 條紋stains 污點Blotch 斑點discoloration 脫色Inclusion 雜質slug mark 壓痕dirt grime 灰塵blush 毛邊薄膜sink 下凹Hickey 漏漆labels and logos 貼紙與商標Configuration labels 組合貼紙corrugated container 瓦擺紙箱Delaminating 脫層splattering 散點Gouge 銼孔puckering 折痕Quality Innovation Activity SystemISO 2859-1 Sampling PlansCritical: A Critical defect is a defect which, based on expert assessment and experience, can cause dangerous or unsafe situations for users, installers or maintenance people or people directly involved with the product as long as they follow the instructions mentioned in the technical documentation.Major: A defect, other than a Critical defect, that causes the product not to function as agreed or will presumably cause the product not to function as agreed in the foreseeable future, or reduces materially the usability of the product for its intended purpose.Deviations from agreed specifications are classified as Major. Some visual imperfections can be classified as Major defect too.Minor: A Minor defect is a defect not classified as Critical or Major. Small deviations from the agreed specifications, that are not likely to reduce materially the usability of the product for its intended purpose are classified as minor defect.。

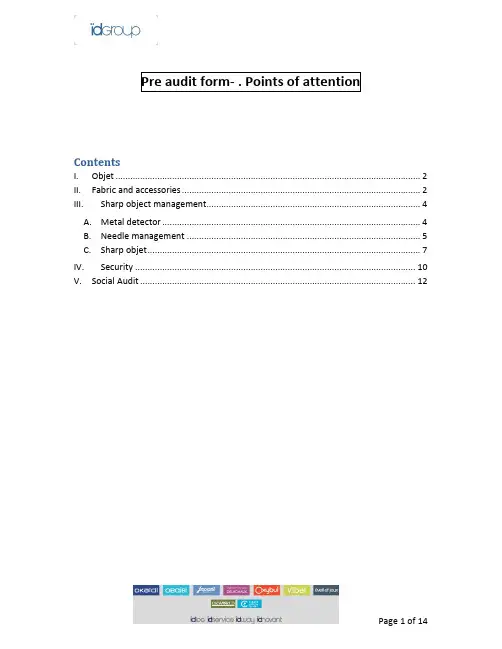

ContentsI. Objet (2)II. Fabric and accessories (2)III. Sharp object management (4)A. Metal detector (4)B. Needle management (5)C. Sharp objet (7)IV. Security (10)V. Social Audit (12)I. Objet此文件是为了再次强调一下,验厂时需要注意的事项,并不包括全部验厂内容,只作为强调之用。

The objet of this document is to help factory to understand the points of attention during a audit.This only review a few of the important points that the factory should pay attention to compel to IdGroup standard. Those are just main guidelines. This document is for reference only.II. Fabric and accessoriesFabric and accesoiries shouldn’t be directly on the floor.纱线和辅料不能直接放在地上,为避免弄脏,发霉和损坏。

This is to avoid stain, mold and make the fabric defective.Accessories card is advised and fabric control is required. (4points, or other) with records,所有辅料和原料,都要有明确的入库明细,如图,成分,颜色,数量,实物样等。

FACTORY SCOPING REPORT 工厂调查报告PLEASE NOTE THAT ALL SECTIONS INCLUDING PHOTOS (see page 4 for details) MUST BE COMPLETED. INCOMPLETE FORMS WILL NOT BE ACCEPTED.请注意:所有部分必须完成,包括图片在内(具体详情参见第四页)。

我们拒绝接受不完整的表格。

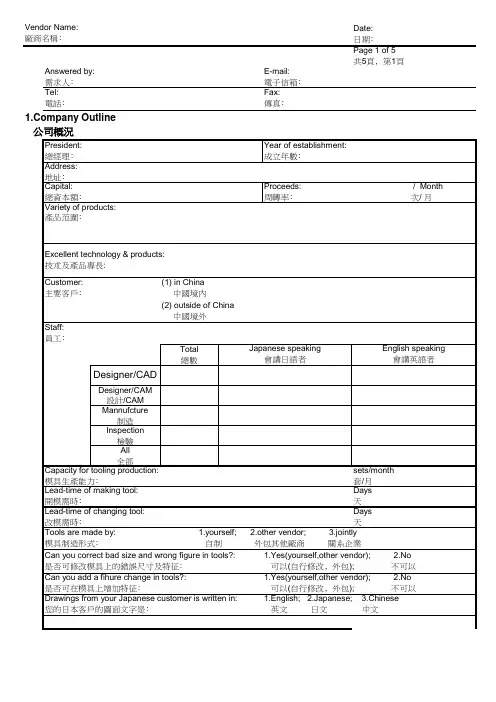

PARENT COMPANY PROFILE 总公司简介(Where this is the same as the factory, please fill in this section for factory 此表格同样适用于工厂,请填写此部分)Company 公司: Owner 所有者:Company Name and Address 公司名称及地址: Telephone : 852-2523-2068/86-139********Well Power Co., Ltd.Beaufort House, P.O. Box 438, Road Town, Tortola, British Virgin Island Fax:852-2854-0339/ (86 - 20) 82222901Correspondence Address in HK:Unit 606, 6th, Floor, Alliance Building 133 Connaught Road Central, HK E-mail:yen@ Web Site 网址:Year company founded 公司成立年份: Feb, 27th, 2001FACTORY PROFILE工厂简介(Please fill in for unit producing the goods 请填写此部分)Factory Name 工厂名称Company Name and Address 公司名称与地址: Telephone:Fax:E-mail:Web Site:Year factory founded 工厂成立年份 : Years at current site :Factory Hours 工厂时间Weekdays am to pm Sat / Sun am to pmShift pattern (if more than 1 shift) 轮班制(多于1班)AverageOT hours 平均加班时间Factory location 工厂位置 (nearest main town 距市中心最近) Travel time from nearest airport 距机场最近Transport method 运输方式(train 火车,car汽车 etc)COMPANY TURNOVER 公司营业额(Total company turnover over the last 5 years, starting from last year 从去年算起,公司过去五年的营业额总额)Last Year Year 2 Year 3 Year 4 Year 5 Turnover (Company)Turnover (Factory)FACTORY 工厂(Top 4 customers 4大客户– please complete for FACTORY )Customer % of yourbusinessHow longfor? 时间Products manufactured 产品Current markets当前市场1. TOMY (HK) LTD2.3.4.Please list any other productscategories produced 请列举产品目录中其他产品% of yourbusiness所占百分比What customers/markets have youproduced these items for? 为那些客户/市场生产这些产品How long? 多久FACTORY INFORMATION 工厂信息Number of employees 员工总数TOTAL 总数:Please indicate number ofemployees in each area.请分别说明各领域的员工数目Administrative 管理 - Factory 工厂 :Engineering 工程 :Maintenance 维修:Production 生产:Quality Assurance 质量保证 :Quality Control 质量控制 :Warehouse/Distribution 储存/分配:Other 其他 :Please indicate the types ofproduction carried out /equipment at the factory –please show quantity ofmachines.请说明工厂生产类型及设备类型,并说明机器数量。

工厂之客户验厂应对材料Corporation standardization office #QS8QHH-HHGX8Q8-GNHHJ8工厂之客户验厂应对材料员工生活1. 厂部是否规定你们一定要在厂里住或在外面住如果你想在厂里住或搬出外面住,厂里是否限制呢申请批不批准答:没有限制,随时都可以自由申请。

(工厂要求普通工人必须在厂内住宿)2. 厂方是否向你们收取住宿费,伙食费等其他费用收费标准如何答:收取一部分费用。

住宿费每人每月收20元;伙食费每餐收元。

也可以不在厂内住宿或食饭。

(每人每月的住宿费为30元,伙食费每餐元)3. 住宿条件是否好,厕所是否有人冲洗,是否有人打扫宿舍[下载自.管理资源吧] 答:住宿卫生条件好。

宿舍、厕所由我们同房人员轮流打扫卫生评比奖励制度,宿舍外的厂内厕所由厂部安排清洁工每天打扫、冲洗。

4. 厂部是否限制你们用水电是否要收水电费答:厂部为我们无限制提供水电,厂区内水电不收费,宿舍用水电按表计费(电费:[下载自.管理资源吧]度;水费:元立方米),同时,每人每月免费提供 3 立方米水,每月薪员工免电 5 度。

/5. 厂内及宿舍是否提供干净的饮水饭堂用水都很干净答:厂区、宿舍、饭堂提供的饮用水都很干净。

6. 宿舍大门是否有门锁宿舍内可不可以烧水煲饭答:大门没上锁,饭堂有饭菜供应,厂部规定宿舍不可以烧水煲饭。

7. 饭堂是否干净卫生,饭菜好不好吃答:干净卫生,好吃。

(工人对饭菜的抱怨很多)8. 厂方是否给你们提供娱乐条件答:有,如提供电视、影碟、卡拉OK、篮球、羽毛球、乒乓球等。

9. 你们宿舍的人是否同时下班怎么冲凉,答:是同时下班,有些出去玩,看电视,分批轮流冲凉,我们都很自学。

工厂管理纪律1. 你对厂方有哪些意见,哪些要改善答:没有什么意见,都感觉厂部对我们员工很好。

(工厂为改善待遇,全厂4000多人曾举行罢工)2. 如果你们做错了事情,上司或厂部将怎样处理你是否会罚款答:初犯教育,重犯警告,多次违反被开除,厂部不会罚款。

客户验厂需要准备的资料客户验厂准备资料一、质量管理基础1.1 受控的有效的,质量手册、程序文件、客户指定的或与品质相关的作业文件,ISO9001:2008的认证证书、复印件、各部门SOP、WI。

1.2公司的程序文件及相关表单,个人认为需进行大的修订及完善,(之前可能编写时间仓促,后期也没有时间修改)为了保证程序文件的质量,建议由质管办统一编写。

1.3质量方针、质量目标1.3.1 质量方针需在公司内部予以传达,建议在公司办公场所完善后,在较显眼区域做标语,可以将质量方针打印在一张小纸上,工卡大小的纸,让员工放在工卡里面。

1.3.2质量目标:合适的质量目标,可量化的,如客诉率、退货率、合格率、各部门的工作目标:各部门建立相应的工作目标,这个目标可按季度制定,逐步提升。

(品质部很重要)2.1公司组织架构图;品质部组织架构图;品质部职务说明书;品质部检验员考核记录;特殊(关键)品质监控点检验员上岗证;仪器校验员资格证,(需外部培训的,最好是计量院培训的)。

2.2任命一位质量代表2.3质量相关人员职务说明书,(各部门均需完善)。

2.4检验记录,合格品的检验记录,不合格品的检验记录,及不合格品后续的处理记录,(如判退货,放行等)。

免检物料清单,免检物料定义。

3.1内部审核程序,内审记录,(包括会议记录,纠正预防措施等)。

4.1纠正措施与预防措施程序。

4.2相应的纠正预防措施记录表,(可包括电子档的8D,相关改善前后的图片,改善过程的视频,改善沟通的会议记录),必要的培训记录等。

4.3定义异常关闭的条件。

(可在客诉处理流程中完善)5.1建立完善的“客户服务管理程序”6.2员工培训管理程序6.3 培训记录(签到表、培训教材、培训现场照片、视频等)6.4质量检验员考核表(可有理论试卷、实操)6.5电工证,特种车辆驾驶证,公司安防人员资格证(安全任证)二、设备与计量器具7.1建立“生产设备”管理规范,(包括采购、维修、保养、使用等流程的管理)7.2“生产设备清单”“重要生产设备履历表”,“耗材部件清单”“易损部件清单”,“设备紧急故障处理规范”7.3“检测设备与计量器具管理规范”7.4“检测设备和计量器具清单”7.5“生产设备保养记录表”“外校检测设备校准计划表”外校合格证书“内校计量器具计划表”“内校记录”“内校标签”8.1“生产设备生产能力参数清单”“新产品评审表”(包括物料情况,产能满足,检验标准齐全,检验能力等)新客户订单,客户意向性订单评审表8.2增加“SPC”、“CMK”、“GRR”“生产设备点检表”“检测设备点检表”8.3“生产设备与工具验收报告”8.4“工具装置清单”“工具标签”“工具验收报表”8.5“检测设备(仪器)清单”“产品出厂检验规范”(规范中注明各检验项目所需仪器工具)9.1“生产设备年度维修保养计划”9.2“生产设备年度维修记录表”(可包括与厂方联络的记录)9.3“仪器外校清单”,“外校计划表”“外校合格证”9.4“检定(校准)作业规范”(各种内校的计量器具)9.5“计量器具内校计划”(季度)9.6检定/校准记录表“9.7客户查看“检定/核准记录“10.1外培计量员,(建议深圳计量院),设置计量员,(专或兼职)10.2计量员资格证书10.3计量室温湿度计,温湿度记录表,三、过程控制与检验11.1“供应商管理程序”11.2“物资分类明细表”(物料品质重要性等级)11.3“合格供应商名录”11.4“供应商评审表”“供应商资质调查表”“质量协议”“环保协议”11.6“采购合同”12.1“来料检验规范”(如有免检物料,需定义)12.2“来料检验记录”13.1“关键工序质量控制点管理规范”或QC工程图13.2 QC工程图或控制计划13.3“关键工序质量控制作业指导书”14..1“采购管理程序”或包含采购过程的程序文件“生产过程管理程序”“成品检验规范”14.2同上15.1“不合格品管理程序”15.3 8D15.4“检验记录”四、技术文件16.1“产品设计开发管理程序”16.2产品有国家强制性标准,需提供证书16.3“产品设计开发管理程序”相关变更申请单,变更通知单,4M变更管理规范。

第1章通用法律法规要求.标准1.1•宜家供应商应了解、接受IWAY的要求,并签署遵守IWAY的承诺书,以了解并接受IWAY的要求。

标准解释1.1•工厂应与宜家签署并保留一份遵守IWAY的承诺书.(采购合同附件ICC)•签署的承诺书要是最新版本.•承诺书中要描述工厂能够在何时达到IWAY的要求标准1.2•宜家的供应商必须向所有与宜家产品有关的下级供应商传达IWAY要求。

•宜家的供应商必须确保所有与宜家产品有关的下级供应商已签署了解并接受IWAY要求的文件。

下游供应商的定义:•处理工序例如纺织、染色、缝纫、切割、抛光、表面处理等等(可以称为转包商)。

•提供配件或原材料例如钢管、螺钉、布料、纱线、木材、化学品、金属线等等。

•IWAY要求不必传达给例如提供电力、燃料、办公用品等与生产没有直接关系的下游供应商或是提供生产设备例如机器或工具的供应商。

标准解释1.2:•工厂应识别并建立一份与宜家产品有关的完整的下游供应商清单•工厂应将现行最新有效版本(2005年7月)的IWAY标准传达给所有与宜家产品有关的供应商.•工厂应与所有和宜家产品有关的供应商签署并保留一份能证明他们收到、了解、接受有关IWAY要求的文件.标准1.3•宜家的供应商应向所有员工传达IWAY的要求。

宜家的要求必须以员工可理解的语言张贴于所有员工均可阅读的地点,如公告栏。

标准解释1.3:•供应商必须将IWAY标准张贴于所有员工均可阅读的地点,如公告栏、楼梯口、食堂、宿舍等。

•所张贴的IWAY标准应是中文最新的版本.•建议工厂把IWAY的要求作为新员工入职培训的内容之一标准1.4•宜家的供应商应指定一位或多位负责人员,并确定其职责和权限,以保证本文件中要求的有关环境、社会与工作条件以及木材采购要求的执行。

•负责人应具备足够的与其工作内容相关的能力和知识标准解释1.4:•工厂要建立一个有效的IWAY小组/委员会(要有组织架构图).•IWAY小组/委员会的成员有明确的职责及分工•工厂应保留一份对IWAY小组/委员会成员的职责及分工的书面文件•工厂应确保他们有足够的权力来实施IWAY工作.•IWAY小组/委员会成员的应有足够的知识和能力.标准1.5•宜家的供应商应至少每12个月进行一次IWAY内部审核。

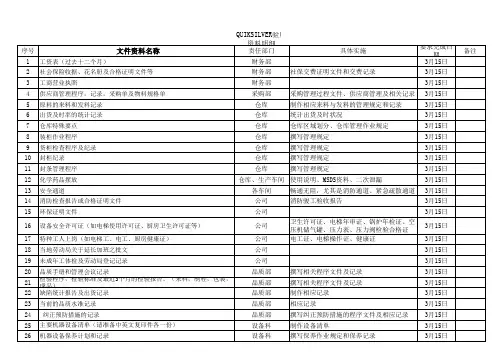

序号资料内容1质量手册、程序文件2管理评审、内部过程审核、内部体系审核资料整理,需收集整改证据3公司管理评审确定的改善项目和持续改进项目的完成情况跟踪4顾客抱怨汇总和分析,月抱怨次数、PPM、退货数量的统计和分析(PDCA闭环)(8D报告列出清单,需把分析后的结果纳入到PFMEA中,是否有永久措施需纳入到CP中的)针对顾客抱怨需定期对员工进行培训,需有培训记录5审核当天生产的产品的控制计划与检验指导书一致6产品审核计划与实施记录7检具管理现有检具清单,摆放:定置定位、清洁有序认可报告,需有纸质版,相关部门会签(项目开发部、工艺)作业指导书齐全,损坏需更换,检查员检查方法8样件管理(包含标准样件、极限样件、单工序样件)样件清单样件标识,需在有效期内样件存放,定置定位,清洁有序,样件认可报告,需有纸质版,顾客认可,相关部门会签(项目开发部、工艺)定期重新认可9过程检验现场检验指导书的存放,要求清洁有序、易于检索按检验指导书要求对生产过程进行首件、过程检查,巡检记录需及时,清晰,每月存档首件的检验标识、摆放哪些过程需进行SPC监控,需有数据收集记录,操作者和检查员需了解方法,每月进行测算CPK10不合格品的管理生产过程、成品、顾客处的不合格品处理,需有评审,按评审意见处置,评审和处置需有记录如返工返修需有再次检验的记录每天、每周、每月的不合格品统计分析,针对重大的缺陷需跨部门会议,制定措施,跟踪措施完成情况,必要时需提交PFMEA,更改CP11原材料检验指导书,检验记录、报告针对原材料不合格的反馈和处理,后续跟踪供应商审核,供应商质保协议、目标协议和监控12供方的PPAP资料13量检具的管理:量检具清单定期检定计划,检定报告,合格标签,在有效期内,MSA分析报告14APQP文件包(准备1-2套完整的APQP资料)15顾客要求的识别和落实16设计更改、工程更改的管理(满足顾客要求,并需对更改进行评审,对相关工作的完成情况进行跟踪,供方参与)变更履历17正式投产前项目移交工作流程案例18供方PPAP,供方首件、首批认可报告19技术文件的管理(图纸、技术标准、BOM、设变、APQP文件、控制计划等)20定期更新FMEA(收集顾客抱怨、过程不良等信息)21测量室平面布置图、测量室环境监控测量设备指导书测量设备每天使用前需点检,需有记录测量设备的维护保养计划,记录22公司KPI指标完成情况跟踪结果(针对未达标项和内部过程质量须有原因分析和整改措施,措施跟踪等)第 1 页,共 3 页23公司KPI:人员离职率、出勤率、特殊人员资格认定率统计,对未达标的要进行分析,制定措施,跟踪措施完成情况(PDCA闭环)24岗位描述(与生产和产品质量相关的岗位均需有)25员工激励文件、激励记录(合理化建议、采纳、奖励)26员工培训计划、记录和考核27员工素质矩阵图(需定期更新)需公示在生产现场,应考虑到缺勤时的顶岗计划28操作人员需开展具有针对性的培训,每年都需有一次计划性的培训,以保持员工的素质要求。

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: Some questions may not apply in whole or in part to your facility. In these cases, please do not leave the question blank. Instead, state “Not Applicable” (“N/A”) in the “Brief Description or Procedure” field. Please provide a brief explanation. Any changes need to reported to Ping, inc. immediately. 注意:一些问题可能没有全部应用或部分应用于你们工厂。

这些问题中,请不要留空,在“简要描述”中用“无应用”(“N/A”)填写。

请提供简要解释。

任何的修改需要立即告知PING。

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive

NOTE: We understand that all measures may not be appropriate for the factory because of the company’s size and structure. Ho wever, the company should strive。