Smc压缩空气过滤器

- 格式:pdf

- 大小:2.16 MB

- 文档页数:36

SMC三联件是什么,安装三联件起什么作用?SMC三联件是什么,安装三联件起什么作用?SMC三联件包括空气减压阀、过滤器、油雾器三大件。

其中减压阀可对气源进行稳压,使气源处于恒定状态,可减小因气源气压突变时对阀门或气动执行器等硬件的损伤;过滤器用于对气源的清洁,可过滤压缩空气中的水份,避开水份随气体进入气动执行器缸体;油雾器可对机体运动部件进行润滑,可以对不便利加润滑油的部件进行润滑,大大延长机体的使用寿命。

1、本过滤器排水有压差排水与手动排水二种方式。

手动排水时当水位达到滤芯下方水平之前必需排出。

2、压力调整时,在转动旋钮前请先拉起再旋转,压下旋转钮为定位。

旋转钮向右为调高出口压力,向左旋转为调低出口压力。

调整压力时应渐渐均匀地调至所需压力值,不应一步调整到位。

3、给油器的使用方法:给油器使用JIS K2213输机油(ISO Vg32或同级用油)。

加油量请不要超过杯子八分满。

数字0为油量最小,9为油量最大。

自9—0位置不能旋转,须顺时针旋转。

SMC三联件是由过滤器、减压阀和油雾器三部分构成,过滤器重要负责过滤压缩空气中的杂质,减压阀重要负责掌控系统压力,油雾器负责后端元件的给油润滑,正确次序是过滤器—减压阀—油雾器。

过滤器起到过滤作用,减压阀起到调压作用,油雾器喷油从而起到润滑下线元件的作用。

一、SMC三联件安装步骤:1、安装时请注意清洗连接管道及接头,避开脏物带入气路,要注意气体流动方向与本体上箭头所指方向是否一致,注意接管及接头牙型是否正确。

2、先将过滤器、调压阀(调压过滤器)给油器固定,将固定支架的凸槽与本体上凹糟匹配,再用固定片及螺丝锁紧即可。

3、单独使用调压阀、调压过滤器时的固定,旋转固定环使之锁紧附带的专用固定片即可。

二、SMC三联件有什么好处:1、气源压力保持在正常范围内;压缩空气含有杂质和水分,时间长了,杂质会在气阀室里面越积越多,会磨损里面的V型圈和O型圈,导致气动隔膜泵不工作。

SMC过滤器滤芯型号选型和主要用途SMC过滤器滤芯型号选型和主要用途SMC过滤器前后采样,采样头上有高效滤纸,显然,SMC过滤器前后采样点高效滤纸的污染程度会不同。

试验中,每经过段发尘试验,测量不发尘状态下SMC过滤器前后采样点高效滤纸的通光量,通过比较滤纸通光量的差别,用规定计算方法得出所谓过滤效率。

终的比色效率是试验全过程各阶段效率值依发尘量的加权平均值。

终止试验的条件与计重法条件相似:约定的终阻力值,或效率明显下降时。

比色法用于测量效率较高的般通风用SMC过滤器,空调系统中的大部分SMC过滤器属于这种SMC过滤器。

比色法曾是国外通行的试验方法,这种方法逐渐被计数法所取代。

SMC过滤器可以得到人们的喜爱,或者它有其自身的优势,除了它的三维偏心原理设计之外,在有效实现理想的密封表面空间运动轨迹方面,还具有吸引人们注意力的特点:1.开启力矩不小,非常敏捷,在使用过程中可以节省能源和资源;采用三维偏心度为SMC过滤器,具有耐高温,耐腐蚀,耐磨损的特点。

同时,由于其严格的计算,发现封闭环及其蝶板基本上没有磨损,因此其使用寿命不会降低。

2.SMC过滤器的结构看起来非常简单而不松动,重量改变了概念的沉重,达到了重量轻的特性,即使在安装和拆卸时也非常容易,可以轻松维护,减轻了相对负担。

3.由于采用了不锈钢闭环,因为它具有一定的弹性,所以无论在高温下还是在低温的情况下,它都具有与蝶板相同的特性,即密封性极好。

4.使用寿命长还有其他原因。

气动断开蝶阀的封闭表面,以便采用堆焊非常硬的合金材料和其他成分的钴基,可以加强密封表面,从而减少磨损程度,在很大程度上延长其使用寿命。

5.它操作起来不简单,不费力,不能对介质的高度施加压力,而且具有可靠的封闭性,此外,由于其独特的结构,因此其开关只需要转动90度即可茎可以完成。

SMC过滤器商业繁荣提供了优越的发展环境当前我国社会快速发展,经济快速发展,商业繁荣发展,社会各界健康快速发展,国家政策的支持,相关法律和执法机构的公正执法,为SMC过滤器行业的发展提供了优越的优势。

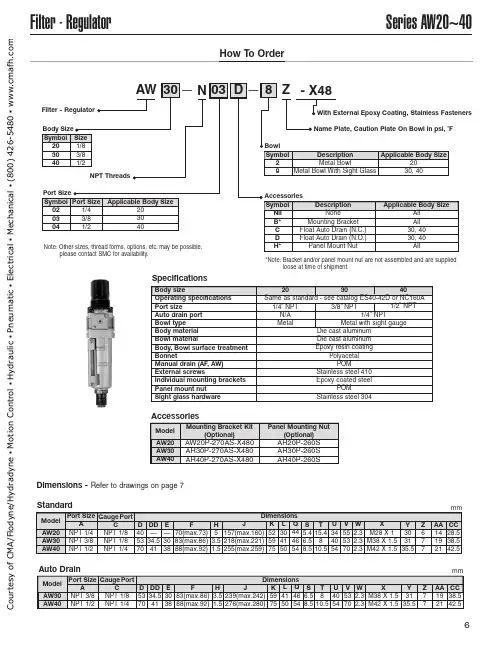

Series AW20~40Filter -RegulatorHow To OrderAW 30N 03D8Z -X48——Filter -Regulator Note:Other sizes,thread forms,options,etc.may be possible,please contact SMC for availability.With External Epoxy Coating,Stainless Fasteners Name Plate,Caution Plate On Bowl in psi,˚FNPT ThreadsBody SizeSymbol 203040Size 1/83/81/2Port SizeSymbol 020304Port Size 1/43/81/2Applicable Body Size203040SpecificationsBody sizeOperating specifications Port sizeAuto drain port Bowl type Body material Bowl materialBody,Bowl surface treatment BonnetManual drain (AF ,AW)External screwsIndividual mounting brackets Panel mount nutSight glass hardware203040Same as standard -see catalog ES40-42D or NC160A1/4”NPT N/A Metal 1/4”NPT Metal with sight gaugeDie cast aluminum Die cast aluminum Epoxy resin coatingPolyacetal POMStainless steel 410Epoxy coated steelPOMStainless steel 3043/8”NPT1/2”NPT BowlSymbol 28DescriptionMetal BowlMetal Bowl With Sight GlassApplicable Body Size 2030,40Accessories Symbol Nil B*C D H*Description None Mounting Bracket Float Auto Drain (N.C.)Float Auto Drain (N.O.)Panel Mount NutApplicable Body SizeAll All 30,4030,40AllAW30AW40A NPT 3/8NPT 1/2Dimensions Model Port Size C NPT 1/8NPT 1/4Gauge PortD 5370DD 34.541E 3038F 83(max.86)88(max.92)H3.51.5J 239(max.242)276(max.280)K 5975L 4150Q 4654S 6.58.5U 4054T 810.5V 5370W 2.32.3X M38X 1.5M42X 1.5Y 3135.5Z 77AA 1921CC 38.542.5AW20AW30AW40A NPT 1/4NPT 3/8NPT 1/2Dimensions Model Port Size C NPT 1/8NPT 1/8NPT 1/4Gauge PortD405370DD —34.541E —3038F 70(max.73)83(max.86)88(max.92)H 53.51.5J 157(max.160)218(max.221)255(max.259)K 525975L 304150Q 444654S 5.46.58.5U 344054T 15.4810.5AW20AW30AW40Mounting Bracket Kit(Optional)AW20P-270AS-X480AR30P-270AS-X480AR40P-270AS-X480Model V 555370W 2.32.32.3X M28X 1M38X 1.5M42X 1.5Y 303135.5Z 677AA 141921CC 28.538.542.5Panel Mounting Nut(Optional)AR20P-260S AR30P-260S AR40P-260SAuto DrainStandardAccessoriesDimensions -Refer to drawings on page 7mmmm *Note:Bracket and/or panel mount nut are not assembled and are suppliedloose at time of shipment.C o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o mSeries AW20~40Filter -RegulatorStandard(ManualDrain)2-Bracket and (Optional )With AutoDrain2-Bracket and (Optional)Bowl Detail EE(AW20)Note:Sight glass not applicable to AW20.C o u r t e s y o f C M A /F l o d y n e /H y d r a d y n e ▪ M o t i o n C o n t r o l ▪ H y d r a u l i c ▪ P n e u m a t i c ▪ E l e c t r i c a l ▪ M e c h a n i c a l ▪ (800) 426-5480 ▪ w w w .c m a f h .c o m。

日本SMC过滤器正确安装及往意事项SMC过滤器是一种紧要的过滤设备,被广泛应用于生产流程中,用于去除水、气体、油脂及其它颗粒物等杂质,以保证生产过程和产品的质量和稳定性。

正确安装和维护SMC过滤器对于其正常运转和延长寿命尤为紧要。

本文将说明正确安装及维护SMC过滤器的步骤和注意事项。

一、安装准备在安装SMC过滤器之前,需要准备以下工具:1. 扳手,用于拆卸管道部分和固定拧紧过滤器安装部分。

2. 螺丝刀,用于拆卸配件。

3. 文件或砂纸,用于清理管道或安装部分的表面。

4. 尺子或量角器,用于测量管道部分的直径。

5. 聚四氟乙烯带,用于包裹在接头上以防止漏水。

6. 清洁布,用于擦拭过滤器。

二、安装步骤1. 清洗过滤器拆卸包装后,需要将SMC过滤器清洗干净,以去除表面的杂质和污垢。

2. 测量管道直径测量需要安装SMC过滤器的管道部分的直径,以便选择合适尺寸的过滤器。

3. 选择安装位置选择井避开过滤器受到不必要的振动和弯曲力。

同时,也要保证过滤器便利运维、察看和维护和修理。

4. 准备连接管道连接管道之前,必需先清洁管道表面,保证连接紧密。

接头之间可包裹聚四氟乙烯带,以防止漏水。

5. 安装过滤器将过滤器的连接接头与管道的连接处对接,并用扳手拧紧。

过滤器两端的连接接头角度不应超过10度,否则可能影响正常工作。

三、注意事项1. 选择合适连接方式选择连接方式时,应依据管道的直径和过滤器的型号提示选择,以保证连接坚固,有效防止管道漏水。

2. 防止接头过紧假如连接紧密,可能导致过滤器无法正常运转,甚至损坏过滤器。

3. 保证过滤器清洁在安装SMC过滤器后,需要定期对过滤器进行清洗,以保证过滤器工作效果。

4. 合理维护好的维护能够有效延长SMC过滤器的寿命,加添其使用效果。

总之,安装SMC过滤器是一个特别简单的过程,只要正确遵从上述步骤和注意事项即可。

同时,需要定期检查和维护SMC过滤器,以保证其正常运转和提高其使用寿命。

CompressedAir FiltrationCompressed Air Filtration Filters | Coalescers | Absorbers | Elements | Mist EliminatorsIn any compressed air net distribution it is a must to install one or more filters. As a result, an improved air quality is achieved, which benefits your complete compressed Using only a single filter could result in saturation of the reduced air quality or end upprematurely replacing your elements.TECHNOLOGY YOU CAN TRUSTA V A I LAB I L I T Y S E R VI C E AB IL I T Y R E L I A B I L I T YP A R T N ER SH IPS I MP L I C I T YUser BenefitsBoost quality and productivity • Purify the compressed air by eliminating oil/dust contaminants • Higher final product quality• Increase your overall productivity Save costs• Prolong the life span of your operation process (machine/equipment...)• Reduce potential downtime• Annual service intervals to ensure optimal operations Easy operation and installation Compatible with any compressor technology• Can be installed quickly and into an existing network• Optional pressure drop device (indicator/gauge) to advise on the cartridge replacement• Cartridge replacement done in no time• No electrical supply neededRisks You AvoidImpurities in the compressed air can cause:• Damage to the distribution lines, increasing the leakage risk • A considerable increase in maintenance costs• A reduction in the efficiency and life span of the pneumatic devices • Deterioration of the final product quality• Limitations to the reliability of the production process and all its components• Decrease of the overall profitabilityQuincy Filters Keep Your Air Distribution Network In Optimal Shape!2Important GuidelinesWhen selecting purification equipment for your compressed air system, these are some useful guidelines to consider:1. Depending on the application, each point of use in the system may require a different compressed air quality.2. Ensure that the purification equipment which is being chosen will provide the required air purity in accordance with the classi-fications from the ISO 8573-1:2010 table.3. When comparing filters to one another, make sure they have been tested in accordance with the standards of ISO 8573 and ISO 12500 series.4. Whenever you compare different filtration solutions, it is crucial to keep in mind that the filter performance is highly dependent on the inlet conditions.5. When taking into account the operational cost of oil coalescence filters, only compare the initial saturated wet pressure loss. The reason for this is that dry pressure loss is not representative forperformance in a normally wet compressed air system.36. For dust filters on the other hand, one can expect the pressure drop to rise over time. A low starting pressure drop does not mean it will remain as such throughout the filter element’s lifetime.7. Consider the total cost of ownership for purification equipment (purchase, operational and maintenance costs).Your local sales representative can help you to select the optimal purifcation equipment for your compressed air system.Compressed Air According to ISO 8573-1:2010Depending on the customer’s application, a certain air purity is required. These purity requirements have been categorized in air purity classes. The purity classes are defined in the ISO 8573-1 standard, edition 2010.This table defines 7 purity classes ranging from 0 up to 6 following the rule: the lowr the class, the higher the air quality.Model Grades 1800-10,500A Solution for Every Air QualityReference condition: pressure 7 bar (102 PSI). Maximum operating temperature of 122°F, only for QAF series.Minimum operating temperature of -4°F4Model Grades 6-1500Filter Range OverviewThe quality of air required throughout a typical compressed airsystem varies. Offering an extensive filter range, Quincy Compressor can always match your precise requirements, ensuring that all types of contamination are avoided and costs are reduced to an absolute minimum.QMF Filter RangeMicronic coalescing filters for general purposeprotection, removing solid particles, liquid water and oil aerosol.Total Mass Efficiency: 99 %QPF Filter RangeParticulate filters for dust protection. Removes solid particles, dust, liquid and oil aerosol.Count Efficiency: 99.8% at MPPS (MPPS = 0.1 micron)QCF Filter RangeHigh-efficiency coalescing filters, removing solid particles, liquid water and oil aerosol.Total Mass Efficiency: 99.9 %QAF Filter RangeActivated carbon filter for removal of oil vapour and hydrocarbon odors.1000 Hour Lifetime* Inlet oil concentration = 40 mg/m3** MPPS = Most Penetrating Particle Size of 0.01 µm5High Temperatures1 Micron Dust Filters, 450°F, 150 PSIG• Designed specifically for Heat Reactivated Desiccant Air Dryers • Nomex outer layer is provided for high-temperature operation • Push-to-fit design used on threaded filters for easy filter element replacement•Multiwrap element construction provides optimum performanceAluminum Housing Threaded NPT Connctions 15 to 650 CFM, Series HTDT• Features a high-temperature dust filter with heavy-duty bowl • Ribbed bowl facilitates removal when changing elements NOTE: Alloy filters shipped loose will have a special high-temperature black powder coat paint.ModelsHTDT 15 & 30Models HTDT 65–650Specifications & Engineering Datasponding to the working pressure.6Mechanical Moisture Separators6 to 1500 CFM, 232 PSIG, Series QWSQuincy Mechanical Moisture Separators are designed to removebulk liquids and large volumes of water. They are typically installeddownstream of after coolers, air receivers, refrigerated air dryers andat strategic points of use throughout the compressed air distributionsystem. The design employs an internal spinner to create a centrifugalaction that effectively removes large quantities of water.• Aluminum housings (1⁄4” to 3 NPT) to prevent corrosion• Low pressure drop: < 1 PSIG• CRN approvedSpecifications & Engineering Data7Stainless Steel FiltersCoalescer — AbsorberQuincy’s line of 316 grade Stainless Steel filters for pressure requirements of 750 PSIG through 5000 PSIG feature:• Three pressure ranges (750 PSIG, 1,500 PSIG, 5,000 PSIG)• Heavy-duty, Stainless Steel tie rod design for 1500 PSIG and 5000 PSIG750 PSIG/250°F 60 to 2000 SCFM (1/2” to 2” NPT)• SSCT standard coalescer • SPCT polishing coalescer • SACT activated carbon1500 PSIG/250°F 65 to 2050 SCFM (1/2” to 2” NPT)• ESCT standard coalescer • EPCT polishing coalescer • EACT activated carbon5000 PSIG/250°F 28 to 775 SCFM (1/2” to 11/2” NPT)• VSCT standard coalescer • VPCT polishing coalescer • VACT activated carbonHigh-PressureAluminum FiltersCoalescer — AbsorberQuincy’s aluminum alloy, 750 PSIG high-pressure filter lineup offers an economic alternative to the high cost of stainless steel. There are two levels of coalescing and an activated carbon absorber. Ideally suited for the PET bottle blowing industry, the coalescers remove various levels of liquid aerosols and the activated carbon absorber removes vapor and odors.• High-temperature capacity (250°F.)• Multiwrap element construction for optimum performance and long life• Synthetic lubricant and mineral oil compatibility• Large sump and quiet zone to prevent re-entrainment • Push-to-fit design for easy filter element replacement• Modular design allows for easy installation of multiple filters and saves energy750 PSIG/250°F 150 to 3000 SCFM (1/2” to 2” NPT)• HSCT standard coalescer • HPCT polishing coalescer • HACT activated carbon750 PSIG - Specifications & Engineering Data8corresponding to the working pressure.corresponding to the working pressure.9High-Pressure1500 & 5000 PSIG - Specifications & Engineering Data10corresponding to the working pressure.corresponding to the working pressure.11Models E_T 65-2050V_T 28-775Models H_T 94 & 147Models S_T 60–2000ModelsH_T 265–1882Unique Double Element Design1,500 cfm through 15,000 cfm models utilize a space-saving double element design (see Figure 2). Using a double nesting technique, the Quincy Mist Eliminator offers high efficiency separation in a low profile package. By nesting an element inside an element, total surface area is greater than conventional single element designs. Due to reduced overall height, the Quincy Mist Eliminator can be installed in locations where conventional single element designs cannot. For example, a 10,000 cfm Quincy Mist Eliminator low profile design is only 118 inches tall. Compare this to other single element designs that are 210 inches tall. That’s a reduction of over 7 feet in overall height! Imagine the savings in time and convenience when you change the element or service the unit.All Quincy Mist Eliminator tanks are ASME coded and stamped. Standard equipment includes a calibrated differential pressure gauge and enamel paint. No Loss Demand Drains are optional. Pressure relief valves are not included but may be required by local codes.Mist EliminatorHigh Efficiency Heavy-Duty Coalescing FilterLong Life and Low Pressure DropThe Quincy Mist Eliminator is a heavy-duty coalescing type filter engineered to efficiently remove oil, particulate, and water from compressed air. By using a combination of impaction, interception and Brownian Movement, the Quincy Mist Eliminator achieves100% efficiency in removing particles 3 micron and larger, 99.8% of 0.1 micron and larger and 99.5% of 0.01 micron and larger. Typical pressure drop is less than 1 psig. Average element life in continuous service is 10 years. A 10-year element life can be achieved in relatively clean environments.• Lower pressure drop compared to conventional coalescing and particulate filters (average 1 psig versus 6 psig). Higher pressure drops require the compressor to operate at an elevated pressure, therefore requiring more power. Every 2 psig reduction in pres-sure saves approximately 1% air compressor power based on 100 psig operating pressure. Quincy Mist Eliminator could easily save in excess of $1,500 per year in air compressor electrical energy (based on 8,000 hours per year operation, $0.07 per Kw hour, 100 hp compressor and a 93% motor efficiency).• Large tank volume captures and retains inadvertent lubricant discharge caused by compressor separation system malfunction, which protects downstream equipment.• Average element life of 10 years versus 6 months for conventional coalescing and particulate filter elements reduces maintenance and waste disposal.12Mist EliminatorSpecifications & Engineering DataNotes: Larger Sizes Available, Consult Factory * Does Not Include Rigging.13Quincy Helps Y ou Do More. For Less.Combining nearly 100 years of expertise with unrivaled quality and performance, Quincy Compressor is the headquarters for your air filtration needs. Innovative filtration solutions are engineered to provide the best quality air and meet today’s increasing quality demands. Backed by the Air Quality Performance Guarantee, Quincy Compressor offers a full line-up of superior quality filtration solutions to meet the high quality requirements of your specific application. Exceed your expectations by providing your system with Quincy Compressor filters. Compressed Air FiltersQuincy Compressor Air Quality Performance Guarantee• Quincy Compressor offers a performance guarantee on its Air Treatment Filtration line. Quincy’s Filters are guaranteed to perform to the currently published specifications as found in filtration documentation available at /literature_ library.html.• Under normal operating conditions, and when installed in an original installation, the Quincy QCF, QMF, and QPF filter elements meet or exceed air quality standards of ISO 8573. The Quincy filters are guaranteed to operate for 8,000 hours or 12 months, which-ever shall occur first, before reaching the recommended 6 PSIG pressure differential for filter replacement.• Quincy Compressor guarantees that the aforementioned filters will perform as stated above, or Quincy Compressor will either repair or replace the filter or element, at Quincy’s discretion. Quincy Compressor will not be responsible for removal, reinstallation and/or related costs.The Air Quality Performance Guarantee is in accordance and established based upon Air Quality-ISO 8573 standard for oil-free and contaminant-free compressed air applications. The Air Quality Performance Guarantee remains in effect for the below listed site so far as all installation and maintenance requirements set forth and in accordance with the warranty and policies and procedures handbook, under Section 1 General Information; Warranty Coverage Rules are maintained.1415Quality Comes in All Shapes and Sizes—But Just One Color.The Quincy PromiseQuincy Compressor and its partnering distributors promise to provide you with uncompromising reliability in all Quincy equipment. This makes your compressed air system one less thing that you need to worry about, allowing you to focus on your company’s productivity and profitability.The Quincy SolutionOperating at peak efficiency and providing quality product is a priority for many of our customers. Quincy Compressor in partnership with our global network of authorized distributors strives to be your provider for all of your compressed air system needs. From the air compressor to filtration to dryers and storage solutions, Quincy Compressor is your single-source provider for all of your compressed air system needs.Air CompressorsQuincy Compressor is a premier provider of many different types of air compressors designed for a variety of applications using different compression technologies.The Quincy QT is a Reciprocating Splash Lubricated compressor for tough everyday use. The Quincy QP is a reciprocating fully pressure lubricated compressor for a competitive advantage. The Quincy QR is a reciprocating compressor designed for the most demanding conditions. The Quincy QGS 5-30 HP is a heavy-duty belt drivenrotary compressor at a competitive price. The Quincy QSI provides an industrial-grade premium fixed-speed rotary screw air compressor.The Quincy QGV provides a premium variable-speed rotary screw air compressor designed to optimize your energy efficiency. Compressed Air TreatmentQuincy Compressor is your single-source provider of compressed air treatment products to complement your air compressor. Quincy provides refrigerated air dryers, desiccant air dryers, compressed air filtration from 5 to .01 micron, condensate drains, condensate management systems, storage solutions, and flow control valves. Quincy Compressor is truly a single-source provider for all of your compressed air needs.Genuine PartsGenuine Parts from Quincy Compressor keep your equipmentrunning like new. When servicing your Quincy compressor, insist on Genuine Quincy parts. Not only will you save time and money, but you will gain the peace-of-mind from using only the highest quality parts worthy of the Quincy name.System ControlsWhether you have one air compressor or many air compressors from many different manufacturers, Quincy Compressor provides you with a way to control and monitor all of the components in your compressed air system in a way that maximizes your energy efficiency and decreases your energy costs. Whether you need to control your system on site or from half way around the world,Quincy Compressor is your source for reliable, efficient controls.©2017 Quincy Compressor. All rights reserved. Printed in U.S.A.(QATF-005 10/19)701 N. Dobson Avenue | Bay Minette, AL 36507Phone 251.937.5900 | Fax 251.937.0872Email:*************************|。

smc过滤器SMC过滤器: 提高气体净化效率的关键装备引言SMC过滤器是一种用于气体净化的关键装备,具有广泛的应用领域。

在如今的工业和环境保护中,过滤技术的重要性越来越受到重视。

本文将介绍SMC过滤器的原理、结构、功能以及应用领域,以展示它在提高气体净化效率方面的重要作用。

一、原理SMC过滤器的工作原理基于物理过滤和化学吸附。

当气体通过过滤器时,其中的悬浮颗粒和污染物会被过滤层阻隔或吸附降解,使得气体中的杂质得以去除。

过滤器通常采用不同孔径大小的滤网和化学吸附材料组成,以处理不同大小和性质的污染物。

二、结构SMC过滤器通常由外壳、过滤层和连接件组成。

外壳是过滤器的保护层,起到支撑和固定过滤层的作用。

过滤层是关键部分,通常由纤维制成,具有不同的孔径大小,以过滤不同级别的颗粒和污染物。

连接件用于连接过滤器和管道系统,确保气体能够有效地通过过滤器。

三、功能1. 气体净化SMC过滤器的主要功能是净化气体,去除其中的悬浮颗粒和污染物。

这些颗粒和污染物可能是异物、粉尘、细菌、病毒等。

通过有效地过滤和吸附,SMC过滤器能够提高气体的纯净程度,保护环境和人体健康。

2. 空气净化除了工业应用,SMC过滤器还可以应用于室内空气净化。

在如今的城市生活中,空气质量日益恶化,PM2.5和其他污染物对人体健康造成了极大的威胁。

SMC过滤器能够有效去除空气中的污染物,提供健康的室内环境。

3. 安全保护一些特殊行业和环境需要对气体进行特殊处理,以确保安全。

SMC 过滤器可以应用于核工业、化工厂、医疗机构等领域,去除有害气体或有毒物质,保护工作人员和环境安全。

四、应用领域1. 工业领域在工业生产过程中,气体污染是一个常见问题。

SMC过滤器可以应用于空气压缩机、除尘设备、焊接设备等,去除其中的粉尘和污染物,保证工业生产的安全和高效。

2. 环境保护在环境保护领域,气体净化和空气净化是关键任务。

SMC过滤器可以应用于废气处理设备、垃圾焚烧厂、化学工厂等,去除其中的有害气体和污染物,减少对环境的影响。

SMC过滤减压阀工作原理SMC过滤减压阀工作原理是什么SMC过滤减压阀是压缩空气过滤器减压阀采纳滚动式膜片,而当输入端压力波动时,同时减压阀膜片自动作出调整,进而使压力平稳的输出,从而保证压力稳定。

下面就是过滤减压阀的特点及工作原理。

SMC过滤减压阀预处理的装置。

过滤阀是使用水力掌控阀及精密的易堵塞的机械产品所必需具备的过滤设备。

那么过滤阀是怎么安装的,需要注意些什么?一、安装步骤1、清洗过滤器壳体。

2、外壳进出口与过滤系统管路相连,连接时注意方向,确保滤芯为外侧进水、内侧出水状态。

3、将滤芯开口一端的塑料袋打开,检查O形圈是否完好、就位。

4、用合适的的湿润剂(例如水)湿润O形圈和滤芯座插孔。

5、手握滤芯靠近O形圈的一端,垂直将滤芯插口插入滤芯座插孔。

6、将全部的滤芯插好后,去掉滤芯包装袋,再扣上压板固定,然后将金属罩壳安装好。

7、然后打开外壳顶部的放气阀。

8、略微打开入口阀,使液体进入壳体,直到液体从壳体顶部的放气阀益出为止,此时关闭放气阀。

9、缓慢调整打开下游出口阀,直至打开。

10、缓慢调整打开入口阀,直至打开此时过滤器上下游之间的压力降为0.02Mpa(确定流量下的初始压降)。

二、安装注意事项1、安装之前肯定要在干净室范围内打开产品的塑料包装;2、在搬运的过程中双手要握住过滤器的外框;3、较大的过滤器安装的时候至少需要两个人;4、不能用手托过滤器中心的部位;5、不能碰触过滤器内部的材料;6、不能使用小刀划开过滤器的外包装;7、保护好过滤器的密封垫,避开与其他的物体发生碰撞。

一、什么是SMC过滤减压阀SMC过滤减压阀可依据输出压力精度的要求选配高精度的精密减压阀;而且压缩空气经过两级三段式过滤器去除压缩空气中的油、水、尘等杂质后,从而大大提高了减压阀膜片的使用寿命和调整压力的精密度;由于过滤元件使用寿命较长,所以在维护上可单独对过滤元件、减压元件进行修复,并且无需整体更换,节省成本。

二、过滤阀减压工作原理1、SMC过滤减压阀螺丝,调整弹簧受力并向下压膜片,使于此相连的阀芯和底盘向下移动,与此同时阀芯底盘上方形成通路,致使气源压力通过出口输出。

文件No.CM2*-OM0230Q气缸C*M2**-*ZC*M2**-*Z-XC85C*M2**-*Z-X446安全注意事项 P21. 产品规格P41-1. 规格2.设置方法・使用方法P42-1. 使用空气2-2. 设计注意事项2-3. 安装·设置2-4. 使用环境条件2-5. 速度控制2-6. 允许动能2-7. 方向控制2-8. 磁性开关3. 保养点检P173-1. 活塞杆密封圈的更换方法3-2.点检3-3. 消耗品4. 订制品(XC85,X446) P194-1. 食品机械用润滑脂规格4-2. PTFE润滑脂规格5. 气缸使用的基本回路 P206. 故障与对策 P217. 构造P23安全注意事项此处所示的注意事项是为了确保您能安全正确地使用本产品,预先防止对您和他人造成危害和伤害而制定的。

这些注意事项,按照危害和损伤的大小及紧急程度分为「注意」「警告」「危险」三个等级。

无论哪个等级都是与安全相关的重要内容,所以除了遵守国际规格(ISO/IEC)、日本工业规格(JIS)*1)以及其他安全法规*2)外,这些内容也请务必遵守。*1) ISO 4414: Pneumatic fluid power -- General rules relating to systemsISO 4413: Hydraulic fluid power -- General rules relating to systemsIEC 60204-1: Safety of machinery -- Electrical equipment of machines (Part 1: General requirements)ISO 10218-1992: Manipulating industrial robots-SafetyJIS B 8370: 空气压系统通则JIS B 8361: 油压系统通则JIS B 9960-1: 机械类的安全性-机械的电气装置(第1部:一般要求事项)JIS B 8433-1993: 工业用操控机器人-安全性等*2) 劳动安全卫生法等注意误操作时,有人员受伤的风险以及物品破损的风险。警告误操作时,有人员受到重大伤害甚至死亡的风险。

产品名称:SMC滤芯-新乡市克瑞斯过滤产品品牌:日本SMC适用介质:压缩空气等气体适用范围:石油,化工,电力,钢铁,船舶,喷涂,液压机械,汽车等行业工作原理滤芯是过滤器中重要组成部分,含有杂质的混合气体,通过滤芯时,将混合气体中的液体、油雾、固体颗粒、油蒸气、碳氢化合物、异味、细菌等滤除掉;一般性而言,除极少数滤芯具有再生性外,滤芯在使用一段时间后,需要更换;产品参数油雾分离芯0.3μm 超小油雾分离芯0.01μm微雾分离芯0.01μm滤芯型号流量NM3/min滤芯型号流量NM3/min滤芯型号流量NM3/minAM-EL150 0.3 AME-EL150 0.2 AMD-EL150 0.2 AM-EL250 0.75 AME-EL250 0.5 AMD-EL250 0.5 AM-EL350 1.5 AME-EL350 1.0 AMD-EL350 1.0 AM-EL450 2.2 AME-EL450 2.0 AMD-EL450 2.0 AM-EL550 3.5 AME-EL550 3.5 AMD-EL550 3.5 AM-EL650 6.0 AME-EL650 6.0 AMD-EL650 6.0 AM-EL850 12.0 AME-EL850 12.0 AMD-EL850 12.0主管路过滤芯3μm 除臭过滤芯0.01μm滤芯型号流量NM3/min 滤芯型号流量NM3/minAFF-EL2B 0.3 AMF-EL150 0.2 AFF-EL4B 0.75 AMF-EL250 0.5 AFF-EL8B 1.5 AMF-EL350 1.0 AFF-EL11B 2.2 AMF-EL450 2.0 AFF-EL22B 3.5 AMF-EL550 3.5 AFF-EL37B 6.0 AMF-EL650 6.0 AFF-EL75B 12.0 AMF-EL850 12.0以上资料由新乡市克瑞斯过滤技术有限公司提供参考!!。

压缩空气用SMC电子压力规参数设置操作SMC电子压力规是一种常见的用于测量和控制气体压力的设备,可以广泛应用于各种工业领域。

在使用SMC电子压力规时,参数设置是非常重要的操作步骤,下面将详细介绍如何进行参数设置。

首先,打开SMC电子压力规的电源开关,确保设备正常运行。

接下来,使用正确的连接线将SMC电子压力规与被测设备连接起来,并确保连接稳固。

然后,通过按压设备上的“Menu”按钮进入参数设置界面。

在参数设置界面中,可以看到各种可调节的参数选项,包括单位、显示分辨率、上下限警报等。

首先,通过按压上下键选择“Unit”选项,然后按压“Enter”键进行确认。

在“Unit”选项中,可以选择不同的压力单位,如psi、bar、MPa等。

根据实际需求选择合适的单位,并按压“Enter”键进行确认。

接下来,通过按压上下键选择“Resolution”选项,然后按压“Enter”键进行确认。

在“Resolution”选项中,可以选择不同的分辨率,包括高分辨率和低分辨率。

根据实际需求选择合适的分辨率,并按压“Enter”键进行确认。

然后,通过按压上下键选择“Upper Limit”选项,然后按压“Enter”键进行确认。

在“Upper Limit”选项中,可以设置压力的上限值。

根据实际需求设置合适的上限值,并按压“Enter”键进行确认。

接着,通过按压上下键选择“Lower Limit”选项,然后按压“Enter”键进行确认。

在“Lower Limit”选项中,可以设置压力的下限值。

根据实际需求设置合适的下限值,并按压“Enter”键进行确认。

最后,通过按压上下键选择“Alarm”选项,然后按压“Enter”键进行确认。

在“Alarm”选项中,可以设置压力上下限超过警报时的报警方式,包括声音报警和灯光报警。

根据实际需求设置合适的报警方式,并按压“Enter”键进行确认。

完成以上参数设置后,按压“Menu”按钮退出参数设置界面,设备将根据所设置的参数开始测量和控制压力。