水转印学习工艺(1)

- 格式:ppt

- 大小:7.40 MB

- 文档页数:29

水转印工艺

水转印工艺,也称为水漂技术、水印技术,是一种将图案转移到物体表面的印刷工艺。

水转印工艺主要用于将不同材质的平面或曲面物体上的图案转移到目标物体上,以达到装饰、美化或标记的目的。

水转印工艺的步骤通常包括以下几个主要环节:

1. 准备工作:选择要转印的图案和目标物体,确保目标物体表面平整且无杂质。

2. 喷涂底漆:将目标物体喷涂上底漆,以增加图案的附着力和稳定性。

3. 准备水转印膜:将要转印的图案印在特制的水转印膜上,并浸泡在容器中的水中。

4. 涂布活化剂:在目标物体表面均匀涂布水转印活化剂,以使水转印膜的墨水在水中得到激活。

5. 转印过程:将已经激活的水转印膜放置在水中,然后将目标物体缓慢地浸入水中,使水转印膜与目标物体的表面接触。

随着目标物体的浸入水中,水中的压力将使水转印膜上的图案逐渐转移到目标物体的表面上。

6. 清洗和固化:浸泡一段时间后,将目标物体从水中取出,并用清水冲洗,以去除多余的水转印膜和墨水。

然后,在干燥的

条件下,用烤箱或其他方法固化转印图案,以增加其耐久性和稳定性。

水转印工艺具有图案多样、色彩鲜艳、适用范围广等优点,广泛应用于汽车零部件、家电、家具、玩具、装饰品等领域。

水转印的工艺

水转印,又称为水漂印,是一种将图案转移到物体表面的印刷工艺。

其工艺步骤如下:

1. 准备工作:将需要印刷的物体表面清洗干净,确保无油污、灰尘等杂质。

2. 准备印花膜:选择合适的印花膜,贴在水槽的表面。

印花膜上贴有制作图案。

3. 准备水槽:将水槽中注入适量的清水,并加入水漂液。

根据不同的印花膜,水漂液的配比以及浸泡时间也会有所不同。

4. 涂敷活化液:在印花膜上均匀涂敷活化液,待干燥,以激活印花膜表面的图案。

5. 将物体浸入水槽:将需要印刷的物体慢慢浸入水槽,确保整个物体的表面都接触到水。

6. 转移图案:经过一定的时间,待印花膜表面的图案开始融化,用水涟漪的方式将图案转移到物体表面。

之后,将物体从水中取出,用清水冲洗。

7. 后处理:待物体表面的水转印图案干燥后,可以进行喷涂保护漆等处理,以保持图案的持久性和外观。

需要注意的是,水转印工艺对环境的要求较高,需要一定的专业设备和经验操作。

并且,水转印的效果受到多种因素的影响,包括水温、水质、印花膜质量等等。

因此,对于初学者来说,建议在专业人员的指导下进行操作。

复杂的工艺品怎么水转印

复杂的工艺品在水转印时需要进行以下步骤:

1. 选取合适的水转印纸:因为工艺品通常都是复杂形状的,需要选择纸张适应性好的水转印纸。

2. 切割水转印纸:将水转印纸根据工艺品形状进行切割。

3. 准备水盆和水:准备一桶水,水温控制在25左右,水深度为8cm左右。

同时也要准备一个大一些的水盆,用来辅助大型工艺品的转印。

4. 准备转印液:将转印纸放入水中浸泡10~20秒,转印涂料会自行从底面转移到转印纸的表面。

5. 将转印纸贴在工艺品的表面:将浸泡了转印液的转印纸放在工艺品表面,捏紧以确保纸张漫布在表面上。

6. 用刮板辅助转印:用刮板轻轻地向内刮动,将纸张完全贴紧在工艺品表面。

尤其是对于复杂形状的工艺品来说,刮板是必不可少的帮手。

7. 将工艺品升上水面:将工艺品缓慢地升起来,将其放置在水上。

8. 将工艺品进行烘干:将工艺品在阴凉处进行自然晾干,干燥后进行适当的处理即可。

需要注意的是,在进行水转印的过程中,要保证水的温度稳定,避免水质受到污染。

另外,对于较为复杂的工艺品,在进行水转印前,需要特别注意制造工艺是否稳定。

水转印技术水转印技术是一种特殊的转移印刷新技术,经处理后成品膜质稳定,图纹清晰逼真、色泽清新艳丽、附着力强。

该技术可多色套印不规则部位。

水转印分为水标转印和水披覆转印,水标转印主要是完成文字和写真图案的转印,通过水分解使文字和写真图案转移到待印物品上,图案及文字可由客户自行提供。

水披覆转印倾向于在整个产品表面进行完整转印,披覆转印技术(Cubic Transfer)使用一种容易溶解于水中的水性薄膜来承载图文,由于水披覆薄膜张力极佳,很容易缠绕于产品表面形成图文层,产品表面就像喷漆一样得到截然不同的外观,可将彩色图纹披覆在任何形状之工件上,为生产商解决立体产品印刷的问题。

曲面披覆亦能在产品表面加上不同纹路,如皮纹、木纹、花纹、翡翠纹及云石纹等,同时亦可避色一般板面印花中常现的虚位。

广泛应用于ABS、PP、PE、木材、玻璃、陶瓷、碳纤、有涂层金属表面等。

一.水转印技术目前,大多数印刷方式都是针对平面或近似平面承印物的装饰印刷,如薄膜凹印、纸张胶印等;丝网印刷的承印物较多,可以印刷一些不规则的曲面,如塑料瓶;移印的适应性比丝网印刷又有进步,但涉及范围太窄。

这些印刷方式的共同点是利用承印物的柔性,将印版上的图文通过压力转印到承印物表面。

转印技术属于间接印刷,图文的转印不是通过直接在承印物表面印刷得到的,所以,可进行转印的承印物形状和材料种类非常多,如水转印技术就是利用水的压力作用将图文披覆在物体表面上,进行转移印刷的工艺技术。

水转印技术分类根据水转印的实现特征,可以分为水披覆转印和水标转印。

1.水披覆转印所谓水披覆转印,是指对物体的全部表面进行装饰,将工件的本来面目遮盖,能够对整个物体表面(立体)进行图案印刷,这是它的优点;但缺点也很明显,即柔性的图文载体完全与承印物接触时难免发生拉伸变形,所以,实际上转印到物体表面的图文难以达到逼真程度。

水披覆转印技术(Cubic Transfer)使用一种容易溶解于水中的水性薄膜来承载图文。

水转印原理及工艺流程水转印,又称水转印印花、水浸印花、水浸膜技术,是一种将图案或图案的装饰效果转移到产品表面的印刷工艺。

它可以在各种材料上实现高质量、高分辨率的图案印刷效果,广泛应用于汽车、家具、电子产品等领域。

水转印的原理是通过水的表面张力和压力将印花材料上的图案或纹理转移到产品表面。

首先,将设计好的图案印在特制的印花材料上,这种材料通常由水溶性树脂、颜料和粘度调节剂组成。

然后,将印花材料放入浸水槽中,使其均匀浸湿。

接下来,在印花材料的表面放置产品,确保产品与印花材料表面紧密接触。

通过施加压力,将印花材料上的图案转移到产品表面。

最后,产品经过干燥和固化处理,使图案牢固地附着在产品表面。

水转印的工艺流程可以分为以下几个步骤:1. 准备工作:确定需要印花的产品和印花图案,选择合适的印花材料,并准备好浸水槽和其他所需设备。

2. 图案处理:将设计好的图案印在印花材料上,这可以通过传统的印刷技术或数码印花技术实现。

确保图案的质量和分辨率,可以使用专业软件进行图像处理和调整。

3. 浸水处理:将印花材料放入浸水槽中,使其均匀浸湿。

可以根据具体需求调整水的温度和浸水时间,以获得最佳的印花效果。

4. 转印过程:将印花材料的表面放置在产品上,并施加适当的压力,使印花材料上的图案转移到产品表面。

确保产品与印花材料紧密接触,避免气泡和图案失真。

5. 干燥和固化:将转印完成的产品放置在通风良好的地方进行干燥和固化处理。

可以使用烘干设备加快干燥速度,并使用紫外光固化设备固化印花材料,以提高印花图案的耐久性和耐用性。

水转印作为一种新兴的装饰技术,具有广阔的应用前景。

它不仅可以实现各种图案和纹理的印刷,还可以在复杂的产品表面进行印花,如弧面、凹凸表面等。

通过不断创新和改进,水转印技术将会在未来的世界中发挥更加重要的作用。

陶瓷加工中的水转印工艺和控制在陶瓷制造中,一种常见的工艺是水转印。

水转印是一种用水印花膜将图案印在瓷器表面的工艺,具有简单、高效、美观、耐用等特点,因此广受欢迎。

本文将详细介绍水转印工艺及其控制。

一、水转印工艺1.准备工作水转印的第一步是准备工作。

首先,需要挑选适用于瓷器的水转印膜,这些膜可以有不同的颜色、图案和纹路。

然后,需要把瓷器清洗干净,确保瓷器表面光滑。

最后,需要准备好水转印机和流水线。

2.制作水转印膜水转印的第二步是制作水转印膜。

水转印膜是在PTS机上通过多层叠加热敏丝印刷,制成具有图案或文字的透明薄膜。

PTS还可以制作特殊的效果膜,如弯曲膜、3D膜等,以提高瓷器的美观度。

然后将水转印膜印刷到瓷器上。

3.水转印水转印的第三步是将水转印膜粘贴在瓷器表面上。

首先,将水转印膜浸泡在清水中,使其变得柔软。

然后将瓷器浸入水中,使水转印膜粘贴在瓷器表面上。

最后,将瓷器放入烘箱中干燥。

二、水转印的控制1.瓷器表面处理在水转印之前,需要对瓷器表面进行处理,以确保瓷器表面光滑,没有坑洞、气泡和残渍。

这项工作是制造高品质瓷器的关键步骤之一。

2.水转印膜的挑选水转印膜的选择应根据瓷器的材质和形状,以及设计师的要求。

不同的膜具有不同的图案和颜色,可以满足不同的需求。

3.水的温度控制水转印过程中,水的温度是非常重要的。

如果水太热,会导致瓷器变形或者膜的变形,从而影响印刷效果。

如果水太冷,则会影响膜的自粘性。

一般来说,水的温度应在25-30摄氏度,瓷器应完全浸入水中。

4.时间控制水转印的时间也需要控制。

如果时间太短,膜可能无法充分附着在瓷器表面上,导致撕裂或出现空气孔。

如果时间太长,则会导致膜失去自粘性,无法粘贴在瓷器表面上。

一般来说,水转印时间应为10-15秒左右。

5.烘干瓷器在水转印完成后需要进行烘干。

烘干温度和时间也需要控制。

如果烘干温度太高或时间太长,会影响瓷器的质量和耐久性。

一般来说,瓷器的烘干温度应在60-80摄氏度,时间应在15-20分钟。

水转印技术工艺介绍(Introduction of water transfer printingtechnology)Water transfer printing technology, most are based on a plane or planar substrate such as decorative printing, film gravure, offset printing paper; screen printing substrate more, can print some irregular surfaces, such as plastic bottles; adaptability than screen printed printing and progress, but the scope is too narrow. The common point of these printing methods is to utilize the flexibility of the substrate to transfer the images on the plate to the substrate by pressure. Transfer technology belongs to indirect printing, graphic printing not by so directly on the substrate surface, printing, very much can transfer the substrate shape and type of materials, such as pressure water transfer printing technology is the use of water to add coating on the surface of an object, the transfer printing technology.Water transfer printing technology classificationAccording to the characteristics of water transfer, can be divided into drape water transfer and water transfer.1. water drape transfer printingThe so-called drape water transfer, refers to the decoration of all the surface of the object, the workpiece should be able to cover the whole surface (stereo) for pattern printing, this is its advantages; but the disadvantages are also obvious, that is by flexibility of the carrier in full contact with the substrate inevitably occur when tensile deformation, so. Infact, the transfer to the surface of the object image to achieve fidelity.For the transfer of water transfer paper printing ink color is mostly by decorative color and simple repetitive pattern, no fine print sensitive film; water transfer film is composed mostly of flexible water soluble film manufacturing, transfer film for three-dimensional transfer is difficult for small text and the level of image transfer replication.2. water transferWater transfer is the transfer paper on graphic transfer to process the substrate surface, it is like the heat transfer process, just rely on hydraulic pressure transfer, water transfer printing technology is a recently popular graphic information, it can transfer a small area on the substrate surface, similar to shift printing printing but the investment effect, low cost, operation process is relatively simple, very popular with users. Water transfer process without activator, avoid organic solvent pollution, has obvious advantages in the production of handicrafts and decorations.Water transfer materialWater transfer printing material refers to the surface of the substrate processing can transfer the overall picture printing film, the base material can be plastic film, or water transfer paper. This printing film as the image carrier, it appears to be a great progress in printing technology, because there are a lot of products is difficult to direct printing, and with thiscarrier, people can use mature printing technology to print the first graphic will be printed on the carrier, then the image transferred to the substrate. If you have a high degree of heavy, strange shape, or small items, you can use the transfer process. For the single water transfer process, its adaptability is very wide, almost can not transfer products, used to transfer material of water transfer with water bestrow transfer film and water transfer paper.(1) water drape transfer filmSimilar to the production process of heat transfer membranes, the water transfer printing film is made by using an intaglio printing machine and a traditional printing process, and is printed on the surface of the water-soluble polyvinyl alcohol film. The substrate of water transfer printing film has a high rate of extensibility and is easily attached to the surface of the object easily. This is also the main reason why it is suitable for transferring on the surface of the whole object. But it is also obvious that the flexibility is great, that is, in the process of printing and transfer, the surface of the film is easy to deform. The second is the transfer process. If the processing is not good, the film may break. In order to avoid this shortcoming, we often put the water transfer coating printing film on the graphic design, with no specific shape, deformation does not affect the ornamental repeated patterns. Water transfer printing film can obtain high elongation in gravure printing, the cost can be reduced, with precise automatic tension control system of gravure printing machine, one can print 4 to 8 colors, overprint accuracy. Gravure printing water transfer film using water transfer printing ink,and compared with traditional ink, water transfer printing ink water resistance is good, dry way is volatile drying.(2) water transfer paperThe substrate water transfer paper is a special paper, soluble in water, from the aspect of structure, and drape water transfer film is not much difference, but the production process is very different. Water transfer paper is on the surface of the substrate by screen printing or offset printing to manufacture a transfer pattern, as shown in figure 1.Screen printing water transfer printing ink is a kind of special water resistant ink, and offset water transfer printing ink can be replaced by general offset printing ink, use special water transfer offset printing ink better. It is difficult to make water transfer paper by screen printing, but the ink layer is very thick;Offset printing, printing water transfer paper graphics and text to achieve higher resolution.Water transfer paper printing ink jet printer, is now the most popular method of making and using the printer and computer more easily according to their own preferences personalized photo, so popular. The production process of water bestrow transfer film and water transfer paper as shown in figure 2.Water transfer printing process1. water drape process(1) film activationThe drape water transfer film on the surface of the tile to transfer water, graphic layer up, keep the water in the water tank cleaning, and in a neutral state, with the activator in the graphic surface evenly spraying, the graphic layer activation, easy separation and carrier film. Activator is a kind of organic mixed solvent based on aromatic hydrocarbons. It can dissolve and destroy polyvinyl alcohol rapidly, but it will not damage the picture and text layer, make the picture and text be free. The principle of film activation is shown in figure 3.(2) water drape transfer processWill need water transfer items along the contour gradually close to the water transfer film, graphic layer will be under the pressure of the water slowly transferred to the product surface, adhesion due to adhesion of ink and printing materials or special coating inherent. Transfer process, the substrate and water coated film laminating speed to maintain uniform, avoid film wrinkles and make graphic unsightly. In principle, we should ensure proper stretching of the picture and text, and avoid overlap as much as possible. In particular, the overlap and excessive overlap can make people feel confused. The more complex the product, the higher the demand for *.Water temperature is an important parameter affecting the quality of transfer, the water temperature is too low, may cause the dissolution of substrate film, water temperature is toohigh, and easy to cause damage to graphics and text, causing deformation of text. The automatic water temperature control device can be used to control the water temperature in a stable range. The mass of the workpiece for the shape is relatively simple, unified, and water transfer equipment special instead of manual operation, such as a cylindrical workpiece, which can be fixed on the rotating shaft, on the surface of the films to rotate to make the graphic layer transfer, drape water transfer process as shown in figure 4.After the transfer of printing and painting, but also for the following steps.Tidy upRemove the workpiece from the tank, remove the remaining film, and then rinse off the floating layer which is not attached to the surface of the product. Pay attention to the water pressure can not be too large, otherwise it is easy to transfer the graphic damage.DryingRemove the moisture on the surface of the product, in order to transfer the ink layer thoroughly drying; in order to increase the adhesion fastness, you can use the hair dryer to dry, or you can put the product in the drying box drying. Plastic products drying temperature can not be too high, generally at 50~60 degrees C, the temperature is too high, easy to substrate deformation; metal, glass, ceramics and other materials drying temperature can be appropriately improved.Spraying protective paintIn order to enhance the environmental resistance of graphics and text, spray paint on the surface. Spray paint can be used solvent light oil, spray after natural drying or heating drying; also can use UV light oil, ultraviolet curing drying. In contrast, UV curing is more adaptive to environmental protection requirements.Light oil solvent type and supporting mixed hardening agent, such as water transfer in Dongguan Changan general equipment sales for spraying light oil, is a kind of polyurethane resin for light oil binders, with PU hardener; coating thickness can be controlled by adding diluent improving light oil viscosity; attention can not be dried in an oven. For different printing materials, spraying light oil is divided into three types, that is suitable for plastic materials light oil, flexible materials for light oil and suitable for metal, glass and other non absorbent material light oil.2. water transfer process(1) environmental factorsCleaning the substrate surface is a necessary condition for high quality printing, which is the same for any printing process. To ensure that the substrate is completely bare state transfer; in addition, a clean and tidy working environment conducive to transfer ink layer tightly attached on the surface of the substrate, the transfer effect of floating dust can mosteasily in the air.(2) the activation of water transfer paperWater transfer paper can be divided into water transfer paper and stripping dissolved water transfer paper, water transfer paper can peel graphic after activation and substrate can achieve separation, transfer; dissolved water transfer paper activated substrate dissolved in water, and in the free state to achieve transfer.The activation of water transfer paper activation and drape water transfer film is different, it is immersed in water transfer paper, the graphic and separated from the substrate, without special solvent, as shown in figure 5,The process is simpler.The specific process is to first transfer the graphic water transfer paper into the required specifications, put into a clean sink, soak for about 20 seconds, so that the mask and substrate separation, ready for transfer.Water transfer process as shown in figure 6,Take out the water transfer paper gently close to the substrate surface, with squeegee pressure map technology, so that the water squeezed out, keep the graphic tile in the specified position, natural drying. The stripping water transfer paper, natural drying and then placed inside the oven drying, in order to improve the fastness graphic, drying temperature at 100degrees celsius. Because the stripping water transfer paper by surface has a layer of protective varnish, no longer spray protection. But there is no water soluble transfer paper graphic surface protective layer, natural drying need to spray varnish treatment, spraying UV light oil curing machine for curing. When spraying varnish, we must pay attention to prevent dust falling on the surface, otherwise, the appearance of the product will be greatly affected. The coating thickness is controlled by adjusting the viscosity of the varnish and the amount of paint sprayed. Excessive spraying results in a decrease in uniformity. For the larger transfer area of the substrate, using screen printing for glazing, you can get a thicker coating, but also very effective protection measures.Application of water transfer printing1. printing materialsWater transfer technology can be used to decorate most of the articles in daily life, such as plastic, metal, glass, ceramics, wooden flat and molded body. According to the need for coating before transfer, you can print materials are divided into the following two categories.(1) material that is easy to transferThe printing properties of some materials in plastics, such as polystyrene (PS), ABS, organic glass, polycarbonate (PC), polyvinyl chloride (PVC) material, without coating can transfer printing transfer principle and similarity principle.(2) materials that need coatingNon - absorbent materials such as glass, metal and ceramics, as well as non - polar materials, such as polyethylene and polypropylene, need to be coated with special coatings to carry out water transfer. The coating is a kind of paint with good adhesion to the transfer material. It can be processed by screen printing, spray coating and roller coating. From the perspective of printing, coating technology to solve the problem of surface decoration for many not printed materials, many transfer process is now popular, such as heat transfer, hot melt transfer, ceramic decal, pressure-sensitive transfer, are needed in the surface of the substrate by coating processing.2. water transfer printing products(1) telecommunications productsToday, people are becoming more and more interested in the personalized decoration of mobile phones. In addition to their quality, the unique appearance of mobile phone manufacturers is also the focus of competition.Generally speaking, the shell of mobile phone is made of plastic injection, and adding various pigments in the ingredient is a more traditional way of decoration, but this method has higher cost and is not easy to change. In the rapidly changing information society, people's aesthetic taste is very difficult to grasp the inconstant in policy. Using this method is obviously difficult to meet the trend of human pursuit offashion, and water transfer printing technology can make mobile phone shell decoration more personality, colorful.(2) decoration industryThe characteristics of water transfer printing technology is the most easy to implement personalized, which in itself is love change and individuality young, so many young people in the application of technology transfer on the occasion, such as leisure teahouse, hall and indoor window can be water transfer for decoration, and the regular water transfer process change of decorative patterns, in order to obtain fresh feeling; in the furniture industry, painting once occupied the important position, the rise of the water transfer process in recent years, changed the furniture decorative pattern is single, drab, serious environmental pollution at present.(3) arts and craftsThis is a rely on appearance to conquer the world of consumers, to win customers immutable and frozen face is futile. Performance of water transfer technology in surface finishing of crafts is an investment should not choose one of too big. Water transfer printing is difficult to say what special advantages, but can not help but admit that it will many of the last century's 70s antique into the new generation intwenty-first Century, to get people's favor. Examples in this regard, the clock on the wall beyond count, such as table frame, roof chandelier.Obviously, water transfer technology is available in a new wayto achieve specific substrate surface decoration, and decoration graphic novel, high quality. But for now, the process of water transfer process * basically stay in the tedious work manual, also can not complete the precise positioning of the polychromatic, mechanical process is relatively slow. These problems limit the further development of water transfer technology.Brief introduction of water transfer printing processWith the improvement of product packaging and decoration requirements, the application of water transfer printing has been developed and used more and more widely. The principle of indirect printing and perfect printing effect to solve the problem of surface decoration of many products, mainly used to transfer all kinds of ceramic, glass paper etc..- transfer objects widely1. printing of ceramic decal. Can be used in ceramic tableware, ceramic water and other daily-use ceramics pattern making, can be used for ceramic tiles made of decorative tiles, waistline, ceramics and other building decoration.2. decorative glass. Water can be used for glass, glass bottles, all kinds of ads mugs, glass containers and decorative glass.3. helmet decals printed. Widely used in motorcycle helmet, helmet and other surface pattern design.4. sporting goods decals. Such as tennis rackets, fishing rodon the surface of trademark and logo; metal fittings decals, such as making a bicycle and motorcycle fitting patterns and text; making toys models surface decals, printed carpentry colored paper; fashionable tattoo stickers; the other is difficult to directly print the decal.Two 、 water transfer printing processThe production of water transfer paper, paper pattern, drying, soaking, paste products1. water transfer decal. Computer processing according to the pattern of the output film printing, and then in the water transfer printing paper (specially good paper without treatment) on the pattern of all kinds of printing, and printing cover oil at the end of the paper on the printed pattern. Another method is to use a color laser printer to print the pattern directly onto the water transfer base paper and then transfer it to water.2. flower soaking. The printed paper into the water, soaking 30 s removed from the water, so it can slip can be. Note that the soaking time should not be too long, otherwise it will dissolve the glue on the surface of the paper.3. patterns posted. The first will be posted in surface processing, and then soaked paper posted to it, then the excess water scraping, drying.4. drying. Articles such as metals, ceramics, and glass are placed in the oven and baked at 140 for 20 min; the plastic isbaked 60 min at a temperature of 70 degrees; candles, helmets, or tempered glass are not baked.5. finished goods. Spray a layer of transparent lacquer on the surface of the baked goods. After 12h drying, the flower surface and the decorations are permanently joined together. If you don't do this process, you can, but the fastness is poor.In a word, the printing company can develop special business according to the special need of water transfer according to its own business need.Color Pattern CoatingKnown as environmentally friendly technology, is also the latest in a highly efficient printing, probably related to his printing ink from the process. Water transfer using the water pressure and the activator to peel layer dissolved water transfer vector film transfer, basic process is as follows: a) film printing: the polymer film printed on different patterns; two) primer spray: many materials must be coated with a layer of adhesive, such as metal and ceramic, if transfer to a different pattern, must use a different color, such as the use of wood basic brown coffee color yellow, white for stone grains; three) extension of the film: let the film flat on the water, and the membrane extends smoothly; four) activation: a special solvent (activator) the transfer film pattern activate ink state; five) transfer: the use of pressure to activated pattern printed on the printed material; six) washing: will be printed on the workpiece residual impurities of water wash; seven) drying: drying the workpiece to be printed, depending on thematerial temperature The primality and melting point; eight) spray paint: spray the transparent protective paint protection is printed surface; nine) drying: spray paint surface drying.Water transfer printing technology has two kinds, one is called water transfer technology, the other is a drape water transfer technology transfer, the former mainly completes the text and pictorial pattern, the latter tendency to transfer the whole surface of the product. Cubic Transfer uses an aqueous film that is easily dissolved in water to carry pictures and text. Because of the excellent tension of the water film, it is easy to wrap on the surface of the product to form a picture and text layer, and the surface of the product is like a spray paint to get a different appearance. Drape printing technology can be used to drape colored patterns on any type of workpiece and solve the problem of printing three-dimensional products for manufacturers. Surface coating surface also in the product with different lines, such as striae, wood, jade and marble pattern, but also avoid color printing often is the general board of the virtual. In the printing process, the surface of the product and its integrity can be avoided because the product surface does not need to contact the printed film.。

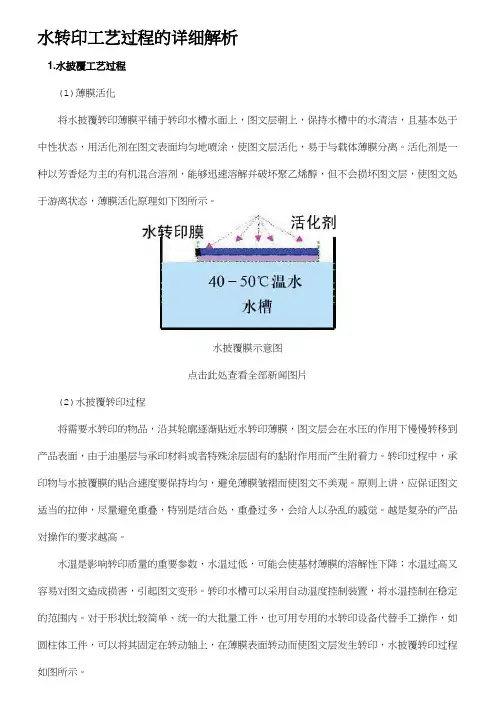

水转印工艺过程的详细解析1.水披覆工艺过程(1)薄膜活化将水披覆转印薄膜平铺于转印水槽水面上,图文层朝上,保持水槽中的水清洁,且基本处于中性状态,用活化剂在图文表面均匀地喷涂,使图文层活化,易于与载体薄膜分离。

活化剂是一种以芳香烃为主的有机混合溶剂,能够迅速溶解并破坏聚乙烯醇,但不会损坏图文层,使图文处于游离状态,薄膜活化原理如下图所示。

水披覆膜示意图点击此处查看全部新闻图片(2)水披覆转印过程将需要水转印的物品,沿其轮廓逐渐贴近水转印薄膜,图文层会在水压的作用下慢慢转移到产品表面,由于油墨层与承印材料或者特殊涂层固有的黏附作用而产生附着力。

转印过程中,承印物与水披覆膜的贴合速度要保持均匀,避免薄膜皱褶而使图文不美观。

原则上讲,应保证图文适当的拉伸,尽量避免重叠,特别是结合处,重叠过多,会给人以杂乱的感觉。

越是复杂的产品对操作的要求越高。

水温是影响转印质量的重要参数,水温过低,可能会使基材薄膜的溶解性下降;水温过高又容易对图文造成损害,引起图文变形。

转印水槽可以采用自动温度控制装置,将水温控制在稳定的范围内。

对于形状比较简单、统一的大批量工件,也可用专用的水转印设备代替手工操作,如圆柱体工件,可以将其固定在转动轴上,在薄膜表面转动而使图文层发生转印,水披覆转印过程如图所示。

水披覆膜转印过程转印披覆图文后还要进行以下几步处理:①整理将工件从水槽中取出,除去残留的薄膜,再用清水洗去没有固着在产品表面的浮层。

注意水压不能太大,否则容易对转印的图文造成破坏。

②干燥除去产品表面的水分,以利于转印墨层的彻底干燥;为增加附着牢度,可用吹风机干燥,也可将产品放在烘干箱内干燥。

塑料产品干燥温度不能太高,大致在50~60℃,温度太高容易使承印物变形;金属、玻璃、陶瓷等材料的干燥温度可以适当提高。

③喷涂保护漆为增强图文层对环境的抵抗性,要在表面进行喷漆处理。

喷漆可以用溶剂型光油,喷完后进行自然干燥或加热干燥;也可用UV光油,采用紫外线固化干燥。

水转印工艺技术水转印工艺技术是一种应用于工业制造业的新型工艺技术,通过将特定图案或颜色转移至产品表面,使产品具有独特的装饰效果。

下面将介绍水转印工艺技术的原理、流程以及应用领域。

水转印工艺技术的原理是利用水的浸透性,将特殊溶解性颜料印刷在水表面形成定型膜,然后将产品迅速浸入水中,使膜上的颜料转移到产品表面,形成与产品表面完全贴合的图案或颜色。

这种技术不仅可以实现简单图案的转印,还可以实现多种颜色的渐变效果,使产品具有更丰富的装饰效果。

水转印工艺技术的流程主要包括:基材处理、图案印刷、涂膜、水浸膜转印、产品清洗和干燥等步骤。

首先,需要对产品进行表面处理,如研磨、清洁等,以确保图案能够贴合地在产品表面转印。

接下来,通过特殊的印刷设备将图案印刷在水表面形成定型膜,然后将产品迅速浸入水中,膜上的图案将转移到产品表面。

转印后,需要进行清洗和干燥等步骤以达到最终的效果。

水转印工艺技术在众多领域中有广泛的应用。

首先,在汽车制造业中,水转印工艺技术可以使汽车零部件的表面呈现出立体感和金属质感,并可以实现各种纹路和颜色的变化,提高产品的装饰效果。

其次,在电子产品制造业中,水转印工艺技术可以提供各种图案和颜色的选择,使产品更加个性化。

此外,水转印工艺技术还被广泛应用于家居装饰、日用品制造、玩具制造等领域,为产品增添艺术气息。

水转印工艺技术相较于传统的印刷工艺有很多优势。

首先,水转印工艺技术可以在任意形状的产品表面进行转印,而传统的印刷技术往往受到产品形状的限制。

其次,水转印工艺技术可以实现多种颜色的渐变效果,使产品具有更加丰富的装饰效果。

另外,水转印工艺技术的成本相对较低,生产效率较高,适用于大规模生产。

总之,水转印工艺技术是一种具有广泛应用前景的新型工艺技术。

通过水转印工艺,可以为产品提供独特的装饰效果,并且具有成本较低、生产效率较高的优势。

相信在未来的发展中,水转印工艺技术将得到更广泛的应用和推广。

工艺流程(一)概述水转印全称:仿真曲面披覆水转印,对承印物全部表面进行装饰,本来面目被遮盖,对整个承印物(立体)进行装饰印刷。

原理:将特殊处理的高分子薄膜,用阳印机印上图样,放在水槽中展平活化后利用水压原理将图样,均匀披覆在水印物表面,这种印刷工艺被称为印刷技术的一次革命,在国内研制推广和工业化生产只是近十年的事。

(二)水披覆转印工艺流程1.转印膜的印刷在高分子薄膜上用凹印的方法印上所需图文。

2.喷底漆按需要在承印物上喷上不同的颜色,如:小纹——常使用棕色、土黄色e纹——白色为主3.膜的延展把转印膜图文朝上,在水中平铺,待其展平。

4.膜的活化用活化剂在图文表面均匀喷化,使图文活化与基膜分离处于游离状态。

活化剂是一种有机混合溶剂,能迅速溶解基膜,不损坏图层。

5.转印将承印物贴近活化的薄膜,图文层会慢慢地转移到水印物上,注意水温,转印速度要均匀。

6.水洗将承印物取出,在专用清洗机上清洗残膜与浮层,注意调好水压。

7.烘干应在专用的烘干机上进行,温度、速度要可调可控。

8.喷化保护膜溶剂型光油要与硬化剂混合使用,不同承印物不同。

(三)水披覆转印花膜1.水披覆转印膜生产方式与热转印膜的生产过程相似,水披覆转印膜是用凹版印刷机采用传统印刷工艺,在水溶性聚乙烯醇薄膜表面印刷图纹而成。

凹版印刷机具有精确的张力自动控制系统,一次可以印刷出4~8种颜色,套印准确度高,凹印水批覆转印膜使用的仿真曲面水披覆转印油墨和传统油墨相比,耐水性好。

2.水披覆转印膜转移后的干燥干燥方式为挥发性干燥。

(四)水披覆转印膜的特点水披覆转印膜的荩材伸缩率非常高,很容易紧密地贴附于物体表面,这正满足它适合在整个物体表面进行转印的主要原因。

但伸缩性大的缺点也是显而易见的,即在印刷过程中,薄膜表面的图文容易变形,其次是转印过程巾,柔性的图文载体完全与承印物接触时难免发生拉伸变形。

所以,实际上转印到物体表面的图文难以达到逼真的程度。

为了避免这个缺点,我们经常把水披覆转印膜上的图文设计成小且有具体造型,变形后也不影响观赏的重复图案。

38网印工业S c r e e n P r i n t i n g I n 市场动态MARKET 玻璃、陶瓷、五金、木材、塑料、皮革、大理石等表面光滑的材料。

水转印在转印过程中不需要加压与加热,所以对于一些不耐高温、不能承受压力的超薄型材来说更是首选的佳品。

一、水转印的工艺(按用途可分为水披覆和水标贴两种)1、水披覆工艺过程(1)薄膜活化将水披覆转印薄膜平铺于转印水槽水面上,图文层朝上,保持水槽中的水清洁,且基本处于中性状态,用活化剂在图文表面均匀地喷涂,使图文层活化,易于与载体薄膜分离。

活化剂是一种以芳香烃为主的有机混合溶剂,能够迅速溶解并破坏聚乙烯醇,但不会损坏图文层,使图文处于游离状态。

(2)转印过程将需要水转印的物品,沿其轮廓逐渐贴近水转印薄膜,图文层会在水压的作用下慢慢转移到产品表面,由油墨层与承印材料或者特殊涂层固有的黏附作用而产生附着力。

转印过程中,承印物与水披覆膜的贴合速度要保持均匀,避免薄膜皱褶而使图文不美观。

原则上讲,应保证图文适当的拉伸,尽量避免重叠,特别是结合处,重叠过多,会给人以杂乱的感觉。

越是复杂的产品对操作的要求就越高。

水温是影响转印质量的重要参数,水温过低,可能会使基材薄膜的溶解性下降;水温过高又容易对科技在不断地进步,许多在人们以前想都不敢想的技术也应运而生了。

就拿印刷行业来说,现在已经不再是简单的纸上印刷了,很多不同于纸的材料和形状不规则的产品,也纷纷向印刷业提出了新课题,因此也就有了特印业。

顾名思义,所畏的特印业就是指不同材质、不同形状的多种特殊印刷工艺。

其中应用最广泛的当属丝印/移印了。

当然,烫金及热转印也是热门的工艺之一。

但是还有一种新的工艺正在兴起,那就是水转印了。

由于水转印的实用性很广,所以是一种很有潜力的工艺。

在此,就目前的应用范围、现状、市场潜力、发展趋势等做一一阐述。

因为水转印是通过特殊载体,以水为介质把图案转贴到承印物表面。

所以在制作工艺上和材料成本上会比普通的印刷成本要高些,制作程序也会更为复杂一点。