最实用的MSA测量系统分析自动表格

- 格式:xlsx

- 大小:124.60 KB

- 文档页数:3

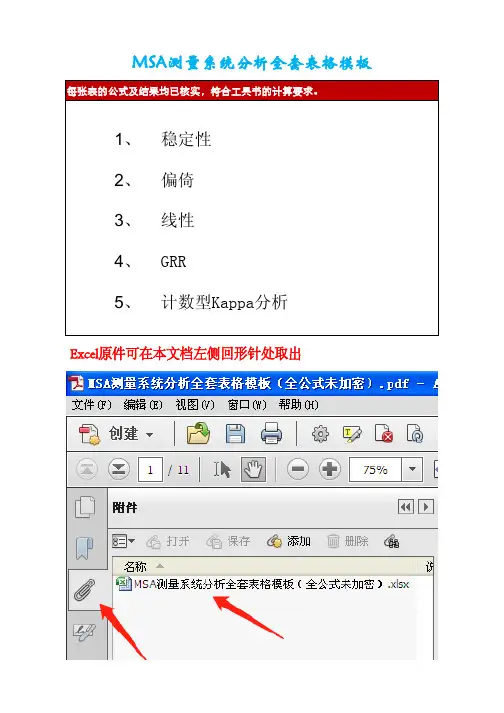

1、2、3、4、5、线性GRR计数型Kappa分析MSA测量系统分析全套表格模板稳定性偏倚Excel原件可在本文档左侧回形针处取出再现性Kappa=(Po-Pe)/(1-Pe)A*参考 交叉表A01总计Po:0.95Pe:0.51B*参考 交叉表B01总计Po:0.97Pe:0.51C*参考 交叉表C01总计Po:0.96Pe:0.5130期望的数量26.4636.5463数量38487期望的数量数量60363一致性好6666Kappa 一致性好判定误发期望的数量638728 4.76%可接受2.30%可接受 4.76%可接受3.45%可接受可接受5.75%可接受01参考总计62063871501C0.90有效性判定重复性检查总数匹配数漏发A A B 评价人评价人%B 93.33%可接受判 定判定0.9383.33%2530 3.17%36.5450.4687数量638715090.00%可接受0.92A C 一致性好150期望的数量B 期望的数量36.9651.0488数量6387150期望的数量26.0435.9662数量38588期望的数量6387数量60248.7284150数量6387150期望的数量35.28数量28284总计01Kappa 判 定A*B 0.89一致性好C 3027A*C 0.93一致性好参考B*C 参考总计可接受期望的数量27.7238.280.90一致性好数量615Page 11 of 11。

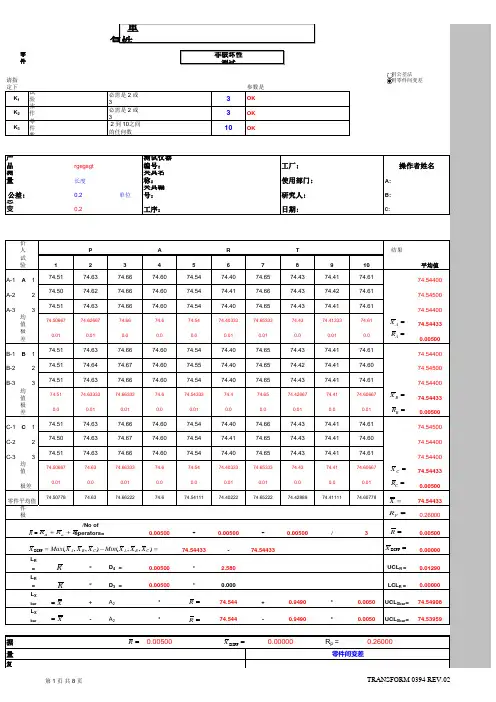

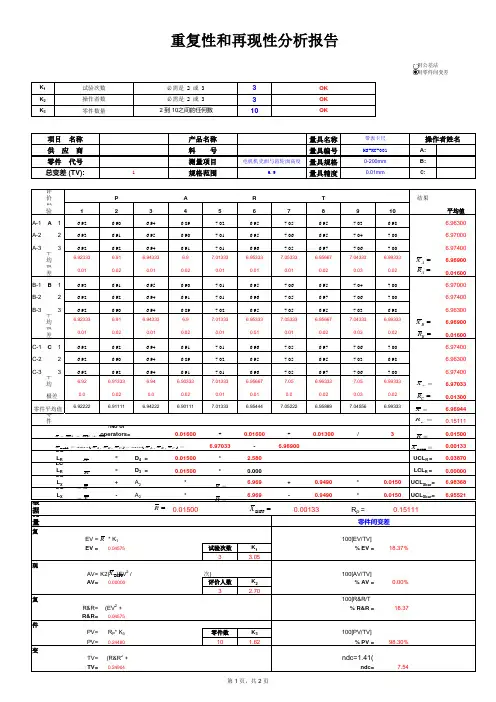

请指定下列参数以完成表格参数是试验次数必需是 2 或 33OK 操作者数必需是 2 或 33OK 零件数量2 到 10之间的任何数10OK'01 PSW '01 PSW '01 PSW'!A21'01 PSW'!A54'01 PSW'!H54产品名称/编号:rgegsgt 测试仪器编号:工厂:测量特性:长度夹具名称: 使用部门:A:0.2单位夹具编号: 研究人:B:总变差 (TV):0.2工序:日期:C:评价人P ART结果试验 #12345678910平均值A-1A174.5174.6374.6674.6074.5474.4074.6574.4374.4174.6174.54400A-2274.5074.6274.6674.6074.5474.4174.6674.4374.4274.6174.54500A-3374.5174.6374.6674.6074.5474.4074.6574.4374.4174.6174.54400平均值74.5066774.6266774.6674.674.5474.4033374.6533374.4374.4133374.6174.54433极差0.010.010.00.00.00.010.010.00.010.00.00500B-1B174.5174.6374.6674.6074.5474.4074.6574.4374.4174.6174.54400B-2274.5174.6474.6774.6074.5574.4074.6574.4274.4174.6074.54500B-3374.5174.6374.6674.6074.5474.4074.6574.4374.4174.6174.54400平均值74.5174.6333374.6633374.674.5433374.474.6574.4266774.4174.6066774.54433极差0.00.010.010.00.010.00.00.010.00.010.00500C-1C174.5174.6374.6674.6074.5474.4074.6674.4374.4174.6174.54500C-2274.5074.6374.6774.6074.5474.4174.6574.4374.4174.6074.54400C-3374.5174.6374.6674.6074.5474.4074.6574.4374.4174.6174.54400平均值74.5066774.6374.6633374.674.5474.4033374.6533374.4374.4174.6066774.544330.010.00.010.00.00.010.010.00.00.010.0050074.5077874.6374.6622274.674.5411174.4022274.6522274.4288974.4111174.6077874.54433零件极差0.26000 /No of operators=0.00500+0.00500+0.00500/30.0050074.54433-74.544330.00000UCL R =*D 4 =0.00500* 2.580UCL R =0.01290LCL R =*D 3 =0.00500*0.000LCL R =0.00000UCL Xbar +A 2*74.544+0.9490*0.0050UCL Xbar =74.54908UCL Xbar-A 2*74.544-0.9490*0.0050UCL Xbar =74.53959根据数据表:0.005000.00000R P =0.26000测量设备分析零件间变差重复性 - 设备变差 (EV)EV = * K 1% EV = 100[EV/TV]操作者姓名公差:K 1K 2K 3零件平均值极差用公差法用零件间变差RR=R =p R =A X =A R =B X =B R =C X =C R R =D IFF X =R =D IFF X =X X==R X==R =-=),,(),,(D IF F C B A C B A X X X Min X X X Max X CB A R R R ++=R。

实用文档某知名工厂最实用的MSA测量系统分析自动表格完整版完整版(一)随着经济的不断发展,各行各业的工厂都逐渐走向自动化和数字化的时代,以提升生产效率和品质、降低成本和人力开支等方面的优势。

在这个过程中,MSA测量系统分析自动表格被众多工厂所采用,它不仅提供了良好的数据收集和处理功能,而且更为出色的是,整合了各种测量设备数据,将数据进行统一的分析和处理,是工厂生产中使用最为广泛和有效的测量系统。

作为一种实用文档,MSA测量系统分析自动表格完整版在工厂中的应用是非常普遍的,这主要得益于它集成了多种测量设备的测量数据分析和管理,以及数据的处理和分析功能。

工厂中的各种设备都可以通过该系统实现自动化的数据分析,比如常见的坐标测量机、光学测量仪、硬度计、其他型号的工具和仪器等。

这样的话,就可以避免由于多种工具和测量对象所造成的数据的混乱,使得数据变得更加清晰、准确和有效。

此外,MSA测量系统分析自动表格完整版还提供了一些重要的指标,比如可重复性和可复现性等,它们可以帮助工厂进行最优的品质控制和流程监控,确保产品质量和稳定性。

同时,该系统还可以得出经济性分析结果,比如成本和收益等方面的数据,有助于工厂进行成本和效益分析、生产计划等方面的管理。

在工厂具体应用中,MSA测量系统分析自动表格完整版还为工厂提供了快速响应和处理的能力。

工厂在监控和控制过程中可以即时获取各种测量数据,使用该系统进行实时的数据分析和处理,以此来节省时间和提高效率,为生产提供更优秀的成果。

总的来说,MSA测量系统分析自动表格完整版在工厂应用中是非常实用和得心应手的一种工具,它综合了各种测量设备的数据分析和管理,并提供了可自定义分析的功能,使工厂在生产过程中更加伺得心应手、高效且准确。

这是一种有效提升工厂生产效率和质量的的必备工具。

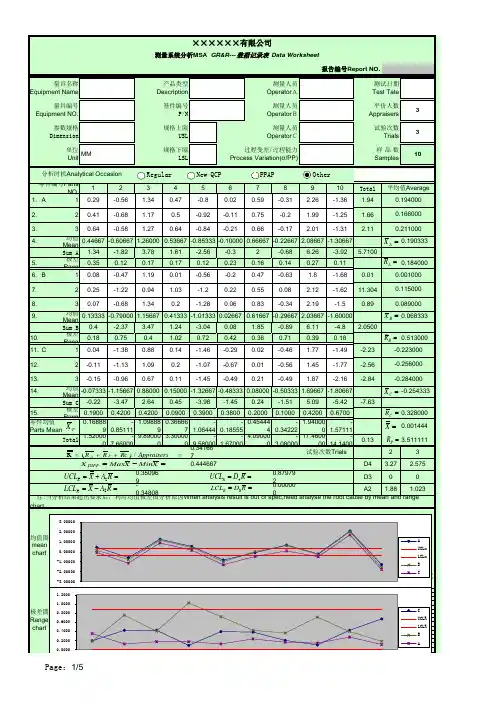

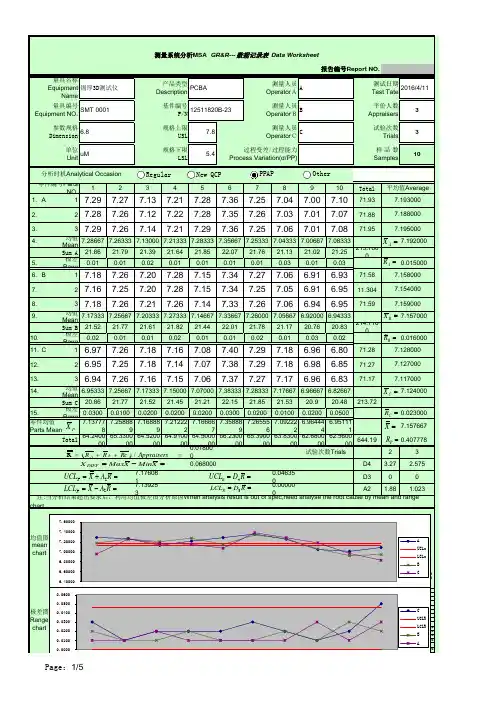

331012345678910Total 1.A 10.29-0.56 1.340.47-0.80.020.59-0.31 2.26-1.36 1.942.20.41-0.681.170.5-0.92-0.110.75-0.21.99-1.251.663.30.64-0.58 1.270.64-0.84-0.210.66-0.17 2.01-1.31 2.114.均值Mean0.44667-0.60667 1.260000.53667-0.85333-0.100000.66667-0.22667 2.08667-1.306670.190333Sum A 1.34-1.82 3.78 1.61-2.56-0.32-0.68 6.26-3.92 5.71005. 极差Rang0.350.120.170.170.120.230.160.140.270.110.1840006.B 10.08-0.47 1.190.01-0.56-0.20.47-0.63 1.8-1.680.017.20.25-1.220.941.03-1.20.220.550.082.12-1.6211.3048.30.07-0.68 1.340.2-1.280.060.83-0.34 2.19-1.50.899.均值Mean0.13333-0.79000 1.156670.41333-1.013330.026670.61667-0.29667 2.03667-1.600000.068333Sum B0.4-2.37 3.47 1.24-3.040.08 1.85-0.89 6.11-4.8 2.050010. 极差Rang0.180.750.4 1.020.720.420.360.710.390.180.51300011.C 10.04-1.380.880.14-1.46-0.290.02-0.46 1.77-1.49-2.2312.2-0.11-1.131.090.2-1.07-0.670.01-0.56 1.45-1.77-2.5613.3-0.15-0.960.670.11-1.45-0.490.21-0.491.87-2.16-2.8414.均值Mean-0.07333-1.156670.880000.15000-1.32667-0.483330.08000-0.50333 1.69667-1.80667-0.254333Sum C -0.22-3.47 2.640.45-3.98-1.450.24-1.515.09-5.42-7.6315. 极差Rang0.19000.42000.42000.09000.39000.38000.20000.10000.42000.67000.3280000.168889-0.851111.0988890.366667-1.06444-0.185550.454444-0.34222 1.940000-1.571110.0014441.520000-7.660009.890000 3.300000-9.58000-1.67000 4.090000-3.0800017.460000-14.14000.13 3.5111110.34166723D4 3.27 2.5750.3509690.879792D300-0.348080.00000A2 1.88 1.02312345678910UCLx0.35100.35100.35100.35100.35100.35100.35100.35100.35100.3510LCLx-0.3481-0.3481-0.3481-0.3481-0.3481-0.3481-0.3481-0.3481-0.3481-0.3481UCL R 0.87980.87980.87980.87980.87980.87980.87980.87980.87980.8798LCL R0.00000.00000.00000.00000.00000.00000.00000.00000.00000.0000公差:6σpp变差PV PV 1.104596PV TVTV#DIV/0!TV基于公差base%#DIV/0!基于零件变差%#DIV/0!基于过程变差%#DIV/0!基于过程能力%#DIV/0!公式A Formulandc 5.0936924公式B FormulaX^2/nkr 0.0001878 3.167450088.362122291.88836694.647300Source DF SS MS F P Source DF SS MS F PParts 988.361939.81799492.291420.00000988.361939.81799245.610.000002 3.16726 1.5836379.406050.000002 3.16726 1.5836339.6170.00000180.358980.019940.433720.9741160 2.758930.0459878 3.117920.03997Total 8994.647118994.64711Source VarComp Stdev %Contribu %TV %Toleranc Source VarComp Stdev %Contribut %TV%Tolerance 0.098110.313228.27%28.75%#DIV/0!0.091430.302377.76%27.86%#DIV/0!0.045980.21443 3.87%19.68%#DIV/0!0.039970.19993 3.39%18.42%#DIV/0!0.052120.22830 4.39%20.96%#DIV/0!0.051460.22684 4.37%20.90%#DIV/0!0.052120.22830 4.39%20.96%#DIV/0!0.051460.22684 4.37%20.90%#DIV/0!0.000000.000000.00%0.00%#DIV/0!1.08867 1.0433991.73%95.78%#DIV/0! 1.08645 1.0423392.24%96.04%#DIV/0!Reproducibility Reproducibility Operator Operator Operators*Part 极差图Range chartSUMSQ(sum(men-part))/r sumSQ(all)n=part k=men ANOVA Table With Operator*Part Interaction ANOVA Table Without Operator*Part InteractionParts Operators Gauge R&R With Operator*Part Interaction Gauge R&R Without Operator*Part InteractionTotal Gauge R&R Total Gauge R&R Repeatability Repeatability Operators Operators*Part Repeatability Repeatability Total Part - To - Part Part - To - Part 注:当分析结果超出要求后,利用均值极差图分析原因When analysis result is out of spec,need analyse the root cause by mean and range chart 。

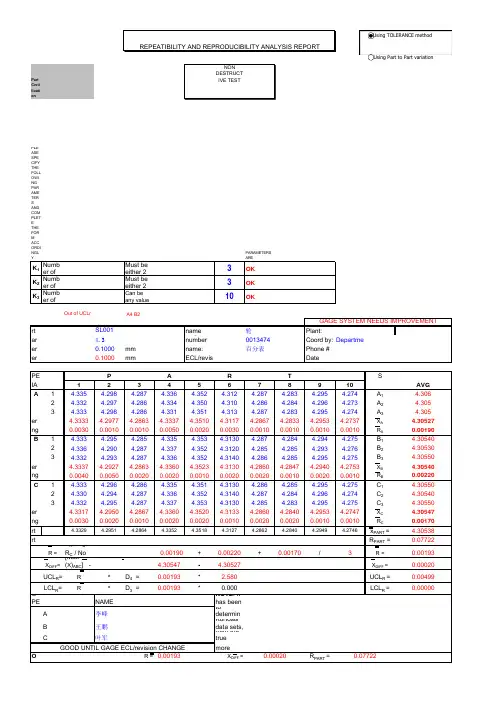

Part Certi ficati onDESTRUCT IVE TESTPLE ASE SPE CIFY THE FOLL OWI NG PAR AME TER S AND COM PLET E THE FOR M ACC ORDI NGL YPARAMETERS AREK 1Numb er of Must be either 23OK K 2Numb er of Must be either 23OK K 3Numb er of Can be any value10OKOut of UCLrA4 B2'01PSW''01PSW'!A6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENT Pa rt Part name 凸轮轴链轮Plant:Ch ar 4.3Gage number 0013474Coord by:QCDepartme Tol er 0.1000mmGage name:百分表Phone #Tol er 0.1000mmGage ECL/revisDateO PE P A R T RESULTSTR IA 12345678910AVG A 1 4.335 4.298 4.287 4.336 4.352 4.312 4.287 4.283 4.295 4.274A 1 4.3062 4.332 4.297 4.286 4.334 4.350 4.310 4.286 4.284 4.296 4.273A 2 4.30534.333 4.298 4.286 4.331 4.351 4.313 4.287 4.283 4.295 4.274A 34.305Av er 4.3333 4.2977 4.2863 4.3337 4.3510 4.3117 4.2867 4.2833 4.2953 4.2737X A 4.30527Ra ng 0.00300.00100.00100.00500.00200.00300.00100.00100.00100.0010R A0.00190B 1 4.333 4.295 4.285 4.335 4.353 4.3130 4.287 4.284 4.294 4.275B 1 4.305402 4.336 4.290 4.287 4.337 4.352 4.3120 4.285 4.285 4.293 4.276B 2 4.3053034.332 4.293 4.287 4.336 4.352 4.3140 4.286 4.285 4.295 4.275B 34.30550Av er 4.3337 4.2927 4.2863 4.3360 4.3523 4.3130 4.2860 4.2847 4.2940 4.2753X B 4.30540Ra ng 0.00400.00500.00200.00200.00100.00200.00200.00100.00200.0010R B0.00220C 1 4.333 4.296 4.286 4.335 4.351 4.3130 4.286 4.285 4.295 4.275C 1 4.305502 4.330 4.294 4.287 4.336 4.352 4.3140 4.287 4.284 4.296 4.274C 2 4.3054034.332 4.295 4.287 4.337 4.353 4.3130 4.285 4.283 4.295 4.275C 34.30550Av er 4.3317 4.2950 4.2867 4.3360 4.3520 4.3133 4.2860 4.2840 4.2953 4.2747X C 4.30547Ra ng 0.00300.00200.00100.00200.00200.00100.00200.00200.00100.0010R C0.00170Pa rt 4.33294.29514.28644.33524.35184.31274.28624.28404.29494.2746x PART = 4.30538Pa rtR PART =0.07722R =R A + R B +R C / No0.00190+0.00220+0.00170/3R =0.00193X DIFF =[Max(X )ABC ] - 4.30547- 4.30527X DIFF =0.00020UCL R =R *D 4 =0.00193* 2.580UCL R =0.00499LCL R =R*D 3 =0.00193*0.000LCL R =0.00000OPENAMENOTE : It has been A 李峰todetermin B 王鹏Kurtosis data sets,C 叶军from the true GOOD UNTIL GAGE ECL/revision CHANGEneed moreFR OR =0.00193X DIFF =0.00020R PART =0.07722SL001Part Certi ficati on DESTRUCT IVE TESTPLE ASE SPE CIFY THE FOLL OWI NG PAR AME TER S AND COM PLET E THE FOR M ACC ORDINGL Y PARAMETERS AREK1Number ofMust beeither 23OKK2Number ofMust beeither 23OKK3Number ofCan beany value10OK Out of UCLr A4 B2'01 PSW''01PSW'!A6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENTPa rt Partname凸轮轴链轮Plant:Char 4.3Gagenumber0013474Coord by:QCDepartmeToler0.1000mm Gagename:百分表Phone #Toler0.1000mm GageECL/revis DateSL001 MePart Certi ficati onDESTRUCT IVE TESTPLE ASE SPE CIFY THE FOLL OWI NG PAR AME TER S AND COM PLET E THE FOR M ACC ORDI NGL YPARAMETERS AREK 1Numb er of Must be either 23OK K 2Numb er of Must be either 23OK K 3Number of Can be any value10OKOut of UCLrA4 B2'01PSW''01PSW'!A6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENT Pa rt Part name 凸轮轴链轮Plant:Ch ar 4.3Gage number 0013474Coord by:QCDepartme Tol er 0.1000mmGage name:百分表Phone #Tol er0.1000mmGage ECL/revisDateSL001Part Certi ficati on DESTRUCT IVE TESTPLE ASE SPE CIFY THE FOLL OWI NG PAR AME TER S AND COM PLET E THE FOR M ACC ORDINGL Y PARAMETERS AREK1Number ofMust beeither 23OKK2Number ofMust beeither 23OKK3Number ofCan beany value10OK Out of UCLr A4 B2'01 PSW''01PSW'!A6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENTPa rt Partname凸轮轴链轮Plant:Char 4.3Gagenumber0013474Coord by:QCDepartmeToler0.1000mm Gagename:百分表Phone #Toler0.1000mm GageECL/revis DateSL001Part Certi ficati onDESTRUCT IVE TESTPLE ASE SPE CIFY THE FOLL OWI NG PAR AMETER S AND COM PLET E THE FOR M ACC ORDI NGL YPARAMETERS AREK 1Numb er of Must be either 23OK K 2Numb er of Must be either 23OK K 3Numb er of Can be any value10OKOut of UCLrA4 B2'01PSW''01PSW'!A6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENT Pa rt Part name 凸轮轴链轮Plant:Ch ar 4.3Gage number 0013474Coord by:QCDepartme Tol er 0.1000mmGage name:百分表Phone #Tol er0.1000mmGage ECL/revisDateSL001。

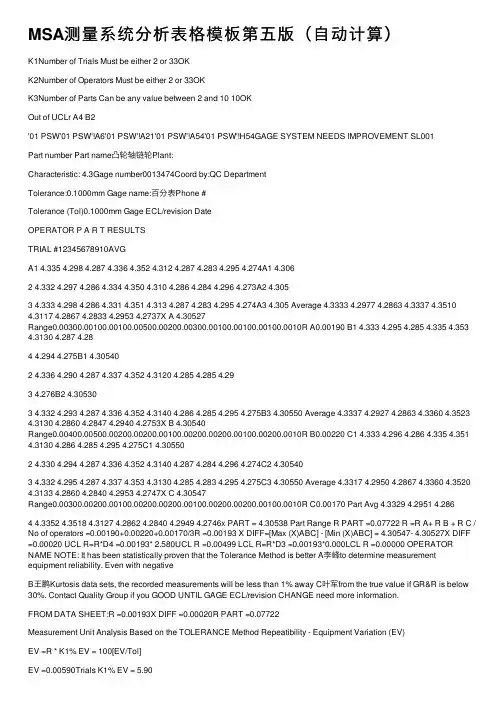

MSA测量系统分析表格模板第五版(⾃动计算)K1Number of Trials Must be either 2 or 33OKK2Number of Operators Must be either 2 or 33OKK3Number of Parts Can be any value between 2 and 10 10OKOut of UCLr A4 B2'01 PSW'01 PSW'!A6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENT SL001Part number Part name凸轮轴链轮Plant:Characteristic: 4.3Gage number0013474Coord by:QC DepartmentTolerance:0.1000mm Gage name:百分表Phone #Tolerance (Tol)0.1000mm Gage ECL/revision DateOPERATOR P A R T RESULTSTRIAL #12345678910AVGA1 4.335 4.298 4.287 4.336 4.352 4.312 4.287 4.283 4.295 4.274A1 4.3062 4.332 4.297 4.286 4.334 4.350 4.310 4.286 4.284 4.296 4.273A2 4.3053 4.333 4.298 4.286 4.331 4.351 4.313 4.287 4.283 4.295 4.274A3 4.305 Average 4.3333 4.2977 4.2863 4.3337 4.35104.3117 4.2867 4.2833 4.2953 4.2737X A 4.30527Range0.00300.00100.00100.00500.00200.00300.00100.00100.00100.0010R A0.00190 B1 4.333 4.295 4.285 4.335 4.353 4.3130 4.287 4.284 4.294 4.275B1 4.305402 4.336 4.290 4.287 4.337 4.352 4.3120 4.285 4.285 4.293 4.276B2 4.305303 4.332 4.293 4.287 4.336 4.352 4.3140 4.286 4.285 4.295 4.275B3 4.30550 Average 4.3337 4.2927 4.2863 4.3360 4.35234.3130 4.2860 4.2847 4.2940 4.2753X B 4.30540Range0.00400.00500.00200.00200.00100.00200.00200.00100.00200.0010R B0.00220 C1 4.333 4.296 4.286 4.335 4.351 4.3130 4.286 4.285 4.295 4.275C1 4.305502 4.330 4.294 4.287 4.336 4.352 4.3140 4.287 4.284 4.296 4.274C2 4.305403 4.332 4.295 4.287 4.337 4.353 4.3130 4.285 4.283 4.295 4.275C3 4.30550 Average 4.3317 4.2950 4.2867 4.3360 4.35204.3133 4.2860 4.2840 4.2953 4.2747X C 4.30547Range0.00300.00200.00100.00200.00200.00100.00200.00200.00100.0010R C0.00170 Part Avg 4.3329 4.2951 4.2864 4.3352 4.3518 4.3127 4.2862 4.2840 4.2949 4.2746x PART = 4.30538 Part Range R PART =0.07722 R =R A+ R B + R C / No of operators =0.00190+0.00220+0.00170/3R =0.00193 X DIFF=[Max (X)ABC] - [Min (X)ABC] = 4.30547- 4.30527X DIFF =0.00020 UCL R=R*D4 =0.00193* 2.580UCL R =0.00499 LCL R=R*D3 =0.00193*0.000LCL R =0.00000 OPERATOR NAME NOTE: It has been statistically proven that the Tolerance Method is better A李峰to determine measurement equipment reliability. Even with negativeB王鹏Kurtosis data sets, the recorded measurements will be less than 1% away C叶军from the true value if GR&R is below 30%. Contact Quality Group if you GOOD UNTIL GAGE ECL/revision CHANGE need more information.FROM DATA SHEET:R =0.00193X DIFF =0.00020R PART =0.07722Measurement Unit Analysis Based on the TOLERANCE Method Repeatibility - Equipment Variation (EV)EV =R * K1% EV = 100[EV/Tol]EV =0.00590Trials K1% EV = 5.903 3.05Reproducibility - Appraiser Variation (AV)AV= [ ( X DIFF * K2)2 - (EV2 / nr)](n parts, r trials)% AV = 100[AV/Tol]AV=0.00000Oper K2% AV =0.003 2.70Repeatibility & Reproducibility (R & R)% R&R = 100[R&R/Tol]R&R= (EV2 + AV2)% R&R = 5.90R&R=0.00590Part Variation (PV)PV=R PART * K3Parts K3% PV = 100[PV/Tol]PV=0.1251010 1.62% PV =125.10Total Variation (TV) 1.62TV= (R&R2 + PV2)#REF!GAGE IS REJECTEDTV=0.12524RANGES OUT OF UCLrK 1Number of Trials Must be either 2 or 33OK K 2Number of Operators Must be either 2 or 3 3OK K 3Number of PartsCan be any value between 2 and 1010OKOut of UCLrA4 B2'01 PSW '01 PSW'!A6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENTPart number Part name凸轮轴链轮Plant:Characteristic: 4.3Gage number 0013474Coord by:QC Department Tolerance:0.1000mmGage name:百分表Phone #Tolerance (Tol)0.1000mmGage ECL/revisionDateSL001。

测量系统分析(MSA)程序(IATF16949-2016/ISO9001-2015)1.0目的 :对所有量具、量测及试验设备实施统计分析, 藉以了解量具系统之准确度与精确度。

2.0范围 :所有控制计划(Control Plan)中包含的/或客户要求的各种量测系统均适用之。

3.0定义 :3.1MSA:量测系统分析3.2量具:是指任何用来获得测量结果的装置。

经常是用在工厂现场的装置,包括通/止规(go/nogodevice)。

3.3量测系统:是对测量单元进行量化或对被测的特性进行评估,其所使用的仪器或量具、标准、操作、方法、夹具、软件、人员、环境和假设的集合;也就是说,用来获得测量结果的整个过程。

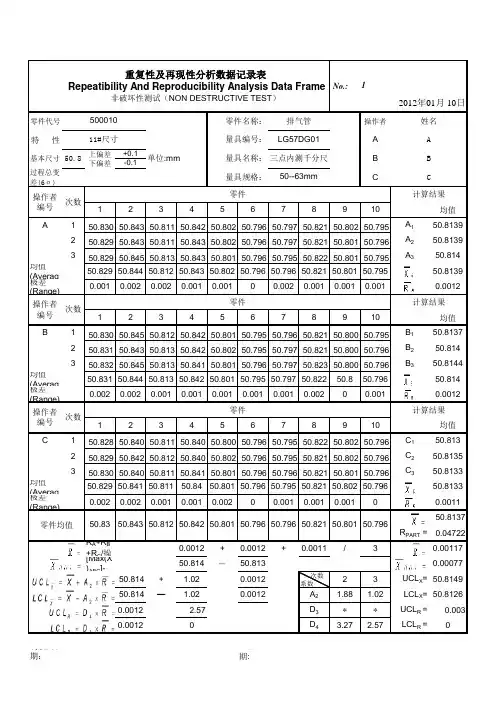

3.4量具重复性(EV):一个评价人多次使用一件测量仪器,对同一零件的某一特性进行多次测量下的变差。

3.5量具再现性(AV):由不同的评价人使用相同的量具,测量一个零件的一个特性的测量平均值的变差。

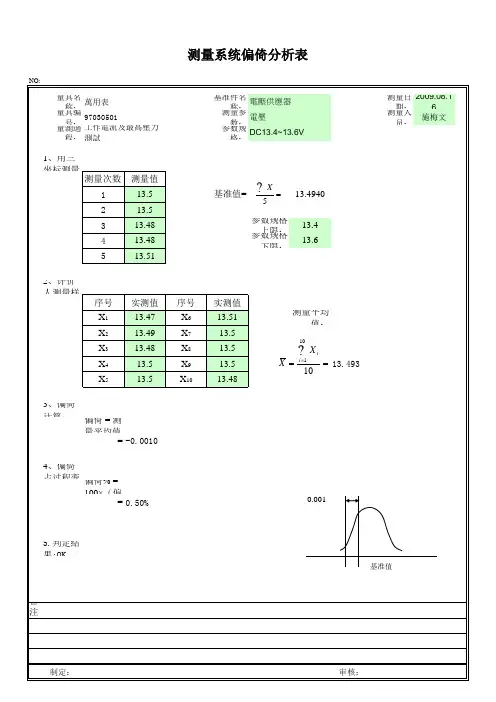

3.6偏性:同一人使用同一量具在管制计划规划地点与在实验室量测同一产品之相同特性所得平均值与真值之间的差异。

3.7稳定性:指同一量具于不同时间量测同一零件之相同特性所得之变异。

3.8线性:指量具在预期内之偏性表现。

4.0权责:4.1量测系统测试的排定、数据分析、仪器操作人员的选择:品保部4.2测试执行:各相关单位4.3MSA操作人员的培训:品保部5.0执行方法5.1QA工程师人员依公司PCP文件建立《xx年MSA实施计划表》或客户要求,并依据计划表之排程进行对仪器做量测系统分析。

5.2取样方法:5.2.1计量型取样:从代表整个工作范围的过程中随机抽取10件样品,但所抽取的10件样品其数值必须涵盖该产品的公差带。

5.2.2计数型取样:取50PCS样品,其中包含临近值,不良品与合格品。

5.2.3.需要2或3个测量者随机抽取对每个产品各测量取一定数量样品.5.3计数型:5.3.1被评价的零件的选定随机抽取50个零件,把零件编号,由研究小组给出该50个零件的标准,必须含合格,不合格,模糊品,条件允许的情况下最好各占1/3。