贴片发光二极管 3528正白5-6LM SMD TOP LED 灯珠中英文参数资料

- 格式:pdf

- 大小:1.37 MB

- 文档页数:8

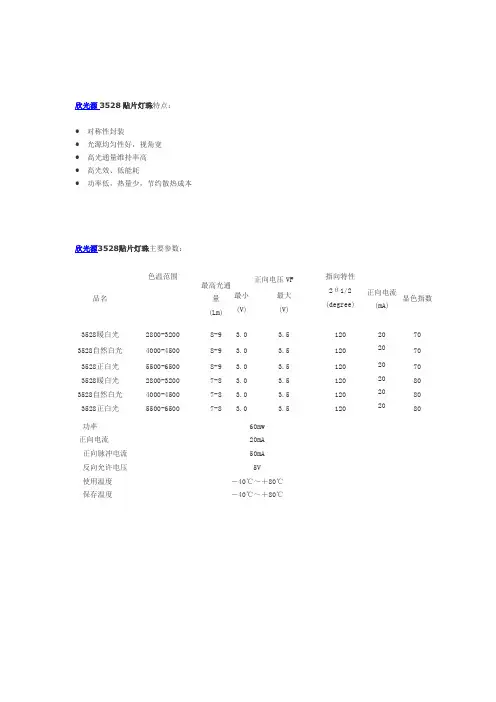

欣光源3528贴片灯珠特点:

●对称性封装

●光源均匀性好,视角宽

●高光通量维持率高

●高光效、低能耗

●功率低,热量少,节约散热成本欣光源3528贴片灯珠主要参数:

品名色温范围

最高光通

量

(Lm)

正向电压VF指向特性

2θ1/2

(degree)

正向电流

(mA)

显色指数

最小

(V)

最大

(V)

3528暖白光2800-32008-9 3.0 3.51202070 3528自然白光4000-45008-9 3.0 3.51202070 3528正白光5500-65008-9 3.0 3.51202070 3528暖白光2800-32007-8 3.0 3.51202080 3528自然白光4000-45007-8 3.0 3.51202080 3528正白光5500-65007-8 3.0 3.51202080功率60mw

正向电流20mA

正向脉冲电流50mA

反向允许电压5V

使用温度-40℃~+80℃

保存温度-40℃~+80℃

欣光源3528贴片LED结构图:

欣光源3528贴片LED成品图片:

欣光源3528贴片灯珠应用产品:

LED硬灯条,LED软灯条。

本文来自欣光源官网: 如有版权问题请联系作者。

(完整版)3528灯带规格书3528软灯条规格书1.规格:1、采用高亮度SMD3528 LED灯珠, FPC板,每三个或六个LED 为一段。

2、每条的标准长度为5M,每条灯珠数量分别有60PCS/M LED 灯珠,120PCS/M LED灯珠3、发光颜色:白/暖白颜色可供选择4、工作电压:DC12V/DC24v5、防水型SMD灯条:套管(IP65)、滴胶(IP65)、套管滴胶IP68)用途:1、SMD贴片软灯带适用于酒店,超薄灯箱,KTV娱乐场所等室内装饰。

2、用于广告招牌等精品装饰领域。

3、度假装饰照明灯,显示及展览。

4、商场专柜,珠宝,首饰台及名贵钟表柜台。

2.产品参数3528灯条白60LED 120°12V 4.8W 5米/卷型号不防水表面滴胶防水硅胶套管防水套管灌胶防水尺寸(MM)L5000*W10*H2 L5000*W10*H4 L5000*W11*H4 L5000*W12*H6 主要材料FPC柔性线路板FPC柔性线路线+环氧树脂FPC柔性线路板+硅胶套管FPC柔性线路板+套管+环氧树脂防水等级IP20 IP65 IP66 IP68透光率100% 85%-90% 90%-95% 80%-85%使用温度/湿度-20Co--50Co/50RH -10Co--60Co/60RH-20Co--60Co/80RH-20Co--60Co/100RH使用范围室内室内外,可淋水室内外,可淋水或浸泡室内外,可长时间浸泡水里色温暖白:2800-3500K,正白:6000-6500K,RGB 3.线路图及安装图4.产品安装注意事项(1)LED产品对静电很敏感,安装使用过程中请注意防止静电,防止因静电造成LED击穿从而导致死灯不亮,请勿用锐器去按压LED 表面,(2)不可将灯条直接插入110V-220V使用,否则会烧坏灯条,灯条需使用单独电源,电源功率可根据使用灯条的总功率及灯条连接的长度而定。

(3)产品安装时折弯和要避免刚好在LED或其他元器件的位置以免造成元器件脱落面损坏产品。

LED贴⽚常见灯珠规格型号和参数LED贴⽚常见灯珠规格型号和参数 0603、0805、1210、3528、5050都是指LED灯带上常使⽤的发光元器件----LED的尺⼨⼤⼩(英制/公制)叫法,例如0603指的是长度为0.06英⼨,宽度为0.03英⼨。

但是要注意3528和5050单位是公制。

下⾯是这些规格的详细介绍: 0603:换算为公制是1608,即表⽰LED元件的长度是1.6mm,宽度是0.8mm。

⾏业简称1608,英制叫法是0603. 0805:换算为公制是2012,即表⽰LED元件的长度是2.0mm,宽度是1.2mm.⾏业简称2112,英制叫法是0805. 1210:换算为公制是3528,即表⽰LED元件的长度是3.5mm,宽度是2.8mm。

⾏业简称3528,英制叫法是1210. 3528:这是公制叫法,即表⽰LED元件的长度是3.5mm,宽度是2.8mm。

⾏业简称3528. 5050:这是公制叫法,即表⽰LED元件的长度是5.0mm,宽度是5.0mm。

⾏业简称5050. ⽬前⼤多数⼚商⽣产的贴⽚型灯条采⽤的都以3528和5050以及3535和5630的居多,也有很多把3528和5050和3535等贴⽚led⽤在汽车照明上的。

更多的贴⽚led详细规格,或者产品规格书等请咨询统佳的客服⼈员索取。

3528 20mA 3.0-3.6v 0.06w3014 30mA 3.2-3.6v 0.1w4014 30mA 3.2-3.6v 0.1w5050 60mA 3.2-3.6v 0.18w5630 150mA 3.2-3.6v 0.5w⼤功率 350ma 3.2-3.6v 1W、3528(0.06W)、3629(0.2-0.3W)、5050(0.2-0.5W)、5630(0.2-0.5W)、3014、3020(0.06W)⾸先LED光源分为⼩功率LED光源(直插式,SMD贴⽚器件)⼤功率LED光源⼀。

3528蓝光规格书3528 BLUE SPECIFICATION 产品型号 Model NO.:HT-K3528BC版次 REV NO.:V01版文件编号Document NO.:YT-DG201303日期 DATE :2013.3.041.外形尺寸D imensions单位(Units):毫米(mm)2.光电特性Electrical / Optical characteristics1/10周期, 0.1 msec脉宽IFP Conditions : 1/10 Duty Cycle, 0.1 msec Pulse Width.½ Rja = Heat resistance from Dice to Ambient temperature (Ta) Rjs = Heat resistance from Dice to Solder temperature of Cathode Side (Ts) (3) 原始光电参数Initial Electrical/Optical Characteristics (TA=25ºC)(4)发光强度范围Luminous Intensity Ranking (TA=25ºC)允许误差± 10%Luminous Intensity Measurement allowance is ± 10%.(5)颜色范围Color Ranking (TA=25ºC)允许误差± 0.01Color Coordinates Measurement allowance is ± 0.01.3.包装PACKAGING(1)LEDS在装带之后纸箱包装. The LEDs are packed in cardboard boxes after taping.(2)装带规格Taping Specifications (单位:毫米Units:mm)(3)卷轴尺寸Reel Dimension装带数量2000个/卷2000Pcs/Reel(3) 最小包装标签注明以下:产品名称.批号.光电范围.数量.The label on the minimum packing unit shows ; Part Number, Lot Number, Ranking, Quantity.(4)请注意防水防潮Keep away from wate r, moisture in order to protect the LEDs.(5) 须采取适当防护措施,以防包装箱跌落或受到强力撞击造成对产品的损伤.The LEDS may be damaged if the boxes are dropped or receive a strong impact against them. so precautions must be taken to prevent any damage.4.可靠性RELIABILITY5.注意事项Cautions(1) 焊接条件Soldering Conditions本产品最多只可回焊两次,且在首次回焊后须冷却至室温之后方可进行第二次回焊.Number of reflow process shall be less than 2 times and cooling process to normal temperature is required between first and Second soldering process. 推荐焊接条件(Recommended soldering conditions)有铅回焊(Lead Solder ) 无铅回焊(Lead-Free Solder)推荐焊盘式样(Recommended Soldering Pattern ) 单位:毫米( Units:mm)(2)静电 Static Electricity触摸LED 时,推荐使用防静电手腕带或防静电手套.It is recommended that a wrist band or an anti-electrostatic glove be used when handling the LEDs. 所有装置、设备、机器均应接地.All devices, equipment and machinery must be properly grounded.静电损坏的LED 会显示出异常特征:正向电压变低或在低电流时死灯.标准: I F =0.5mA 时, V F > 2.0VDamaged LEDs will show some unusual characteristics such as the forward voltage becomes lower, or the LEDs do not light at the low current. Criteria : (V F > 2.0V at I F =0.5mA)(3)防潮包装Moisture Proof Package使用防潮包装It is recommended that moisture proof package be used .(4)储藏Storage打开包装袋之前,LED在温度为30°C或更低湿度70%RH以下,可保存一年.Before opening the package ,The LEDs should be kept at 30°C or less and 70%RH or less. The LEDs should be used within a year.(5)打开包装之后,应在24hrs 内焊接完毕.After opening the package, The LEDs should be soldered within 24 hours (1days) after opening the package. If unused LEDs remain, they should be stored in moisture proof packages, such as sealed containers with packages of moisture absorbent material (silica gel).下列情况发生时,须要在焊接前重新烘烤60 ± 5°C,24小时以上。

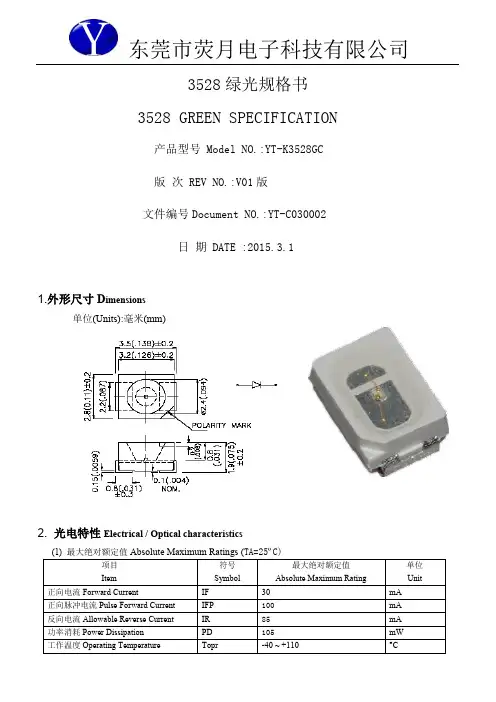

东莞市荧月电子科技有限公司3528绿光规格书3528 GREEN SPECIFICATION产品型号 Model NO.:YT-K3528GC版次 REV NO.:V01版文件编号Document NO.:YT-C030002日期 DATE :2015.3.11.外形尺寸D imensions单位(Units):毫米(mm)2.光电特性Electrical / Optical characteristics1/10周期, 0.1 msec脉宽IFP Conditions : 1/10 Duty Cycle, 0.1 msec Pulse Width.Rjs = Heat resistance from Dice to Solder temperature of Cathode Side (Ts) (3) 原始光电参数Initial Electrical/Optical Characteristics (TA=25ºC) Array(4)发光强度范围Luminous Intensity Ranking (TA=25ºC)允许误差± 10%Luminous Intensity Measurement allowance is ± 10%.(5)颜色范围Color Ranking (TA=25ºC)允许误差± 0.01Color Coordinates Measurement allowance is ± 0.01.3. 包装PACKAGING(1)LEDS 在装带之后纸箱包装. The LEDs are packed in cardboard boxes after taping.(2)装带规格Taping Specifications (单位:毫米Units:mm )(3)卷轴尺寸 Reel Dimension装带数量2000个/卷2000Pcs/Reel(3) 最小包装标签注明以下:产品名称.批号.光电范围.数量.The label on the minimum packing unit shows ; Part Number, Lot Number, Ranking, Quantity.(4)请注意防水防潮Keep away from wate r, moisture in order to protect the LEDs.(5) 须采取适当防护措施,以防包装箱跌落或受到强力撞击造成对产品的损伤.The LEDS may be damaged if the boxes are dropped or receive a strong impact against them. so precautions must be taken to prevent any damage.4.可靠性RELIABILITY*) U.S.L.:Upper Standard Level **) L.S.L.:Lower Standard Level5.注意事项Cautions(1) 焊接条件Soldering Conditions本产品最多只可回焊两次,且在首次回焊后须冷却至室温之后方可进行第二次回焊.Number of reflow process shall be less than 2 times and cooling process to normal temperature is required between first and Second soldering process. 推荐焊接条件(Recommended soldering conditions)推荐焊盘式样(Recommended Soldering Pattern ) 单位:毫米( Units:mm )(2)静电 Static Electricity触摸LED 时,推荐使用防静电手腕带或防静电手套.It is recommended that a wrist band or an anti-electrostatic glove be used when handling the LEDs.所有装置、设备、机器均应接地.All devices, equipment and machinery must be properly grounded.静电损坏的LED会显示出异常特征:正向电压变低或在低电流时死灯.标准: I F=0.5mA时, V F > 2.0VDamaged LEDs will show some unusual characteristics such as the forward voltage becomes lower, or the LEDs do not light at the low current. Criteria : (V F > 2.0V at I F=0.5mA)(3)防潮包装Moisture Proof Package使用防潮包装It is recommended that moisture proof package be used .(4)储藏Storage打开包装袋之前,LED在温度为30°C或更低湿度70%RH以下,可保存一年.Before opening the package ,The LEDs should be kept at 30°C or less and 70%RH or less. The LEDs should be used within a year.(5)打开包装之后,应在24hrs 内焊接完毕.After opening the package, The LEDs should be soldered within 24 hours (1days) after opening the package. If unused LEDs remain, they should be stored in moisture proof packages, such as sealed containers with packages of moisture absorbent material (silica gel).下列情况发生时,须要在焊接前重新烘烤60 ± 5°C,24小时以上。

常用 led 灯带 5种规格术语解释通闪电子经常会接到客户需求 LED 灯带的询价电话,但由于对 LED 灯带的规格术语不熟悉,常常需要给客户解释半天才能让客户了解。

针对这一现象, 下面就把 LED 灯带常用的 5种规格术语进行一下解释和分享, 同时也供采购朋友们参考:一、 LED 尺寸大小 :0603、 0805、 1210、 5050是指 LED 灯带上使用的发光元件 ----LED 的尺寸大小(英制 /公制 ,下面是这些规格的详细介绍:0603:换算为公制是 1005,即表示 LED 元件的长度是 1.0mm ,宽度是 0.5mm 。

行业简称 1005,英制叫法是 0603.0805:换算为公制是 2125, 即表示 LED 元件的长度是 2.0mm , 宽度是 1.25mm. 行业简称 2125, 英制叫法是 0805.1210:换算为公制是 3528,即表示 LED 元件的长度是 3.5mm ,宽度是 2.8mm 。

行业简称 3528,英制叫法是 1210.5050:这是公制叫法,即表示 LED 元件的长度是 5.0mm ,宽度是 5.0mm 。

行业简称 5050. 二、 LED 灯数 :15灯、 30灯、 60灯是指 LED 灯带每米长度上焊接了多少颗 LED 元件, 一般来说 1210规格灯带是每米 60颗 LED , 5050规格灯带是每米 30颗 LED ,特殊的有每米 60颗 LED 。

不同 LED 数量的 LED 灯带价格是不同的,这也是区分 LED 灯带价格的一个重要因素。

三、色温:是指将一标准黑体加热,温度升高到一定程度时颜色开始由深红 - 浅红 - 橙黄 - 白 - 蓝, 逐渐改变, 某光源与黑体的颜色相同时, 我们将黑体当时的绝对温度称为该光源之色温。

一般来说色温不作为考核 LED 灯带的一个指标,只是国外很多客户因为使用环境的关系, 会做一个特别的要求。

光源色温不同,光色也不同:•色温在 3300K 以下,光色偏红给以温暖的感觉;有稳重的气氛,温暖的感觉 . ,通称暖色温。

中之光电科技有限公司ZT3528W0S1-****(0.06W)规格书3.5 mm SMD Hyper White Top LED 3.5 mm 贴片超亮白色发光二极管Features 特征• Package Size :3.5 (L) ×2.8(W) × 1.2 (T) mm封装尺寸: 3.5 (长) ×2.8 (宽) ×1.2 (厚) mm •Silicone Packed 采用硅胶封装•Super long lifetime超长寿命 •Anti UV 防紫外线•White colors are available in(1800K-15000K) 可供白光(1800K-15000K) •High CRI products 高显色性产品 •Wide viewing angle (2θ1/2=120°) 宽角度 (2θ1/2=120°)Applications •产品应用•Indoor lighting : Fluorescent lamp, tube •室内照明:日光灯管、灯条•Commercial illumination and displays : •商业照明显示:广告字、广告灯箱 Advertising words, light box•LCD Backlighting •LCD 背光源•Decorative lighting : light strip •装饰照明:柔性灯条•Automotive interior auxiliary lighting •Other illumination and displays •其它照明和显示类OOTop View 顶视Side View 侧视OOBin Range of Forward Voltage电压等级代码(at I F = 20 mA, T a = 25 O C )Part No. Description产品型号说明Color Bin Limit色度代码;(at I F = 20 mA, T a = 25 O C )Color Bin色坐标常用BIN区(Common Bin)可选BIN区(Optional Bin)Typical Electro-Optical Characteristics Curves 典型光-电特性曲线图Solder Pad一、PRECAUTONS IN USE LED/使用LED注意事项;LED Soldering condition/ LED焊接条件;1:烙铁焊接:烙铁最高30W尖端温度不超过300℃;焊接时不超过3秒;Manual soldering:iron Maximum 30W,iron bit temperature can not over 300 degree;soldering time should not be more than 3 seconds;Cleanout/清洗;当用化学品清洗LED胶体时须特别小心,因为有些化学品对胶体表面有损伤并引起褪色如三氯乙烯、丙酮,可用乙醇擦拭浸渍,时间在常温下不超过2分钟。

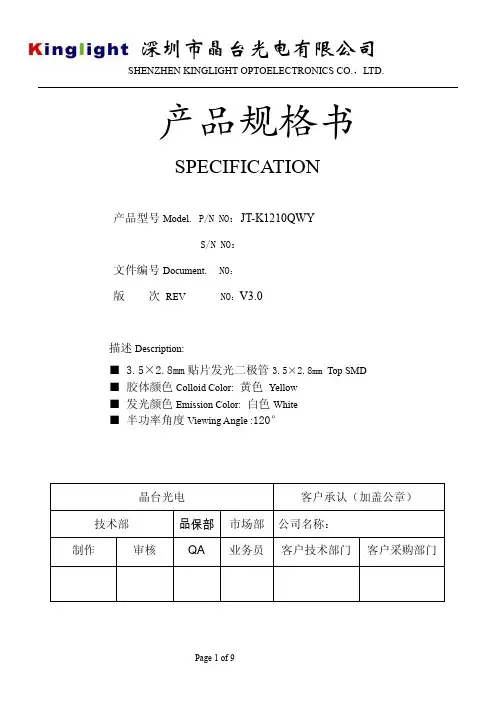

产品规格书 SPECIFICATION产品型号Model . P/N NO :JT-K1210QWY S/N NO : 文件编号Document . NO : 版 次 REV NO :V3.0描述Description:■ 3.5×2.8mm 贴片发光二极管3.5×2.8mm Top SMD ■ 胶体颜色Colloid Color: 黄色 Yellow ■ 发光颜色Emission Color: 白色White ■ 半功率角度Viewing Angle :120°1.外形尺寸D imensions单位(Units):毫米(mm)123528单晶焊盘图注意:所有尺寸单位为mm ,如无特殊说明误差范围为±0.1mm All dimensions area in mm tolerance is ±0.1mm unless otherwise noted.2.光电特性Electrical / Optical characteristics1/10周期, 0.1 msec脉宽IFP Conditions : 1/10 Duty Cycle, 0.1 msec Pulse Width.(2)样品光电参数Initial Electrical/Optical Characteristics (TA=25±5ºC)(3) 色区(BCD)标志区是出货区域,红色曲线是黑体轨迹线(4)色温标准分档(5)光通量标准分档0.5 LM/档(6)电压标准分档0.1V/档色座标(IF=20mA,Ta=25℃)正向电压允许误差± 0.05V Tolerance of measurement of Vf is ±0.05 V..光通量允许误差±0.2lm Luminous Intensity Measurement allowance is ±0.2lm 色温误差范围±100k Colour Temperature Measurement allowance is ±100k 显色指数允许误差±1 Color Rendering Index Measurement allowance is ± 1.3特性曲线Characteristic curve相对亮度与波长之间的关系4.可靠性RELIABILITY5.注意事项Cautions(1) 焊接条件Soldering Conditions本产品最多只可回焊两次,且在首次回焊后须冷却至室温之后方可进行第二次回焊.Number of reflow process shall be less than 2 times and cooling process to normal temperature is required between first and Second soldering process. 推荐焊接条件(Recommended soldering conditions)有铅回焊(Lead Solder )无铅回焊(Lead-Free Solder)(2)静电 Static Electricity触摸LED 时,推荐使用防静电手腕带或防静电手套.It is recommended that a wrist band or an anti-electrostatic glove be used when handling the LEDs. 所有装置、设备、机器均应接地.All devices, equipment and machinery must be properly grounded.静电损坏的LED 会显示出异常特征:正向电压变低或在低电流时死灯.标准: I F =0.5mA 时, V F > 2.0VDamaged LEDs will show some unusual characteristics such as the forward voltage becomes lower, or the LEDs do not light at the low current. Criteria : (V F > 2.0V at I F =0.5mA) (3)防潮包装Moisture Proof Package 使用防潮包装It is recommended that moisture proof package be used . (4)储藏Storage打开包装袋之前,LED 在温度为30°C 或更低湿度70%RH 以下,可保存一年. Before opening the package ,The LEDs should be kept at 30°C or less and 70%RH or less. The LEDs should be used within a year.(5)打开包装之后,应在24hrs 内焊接完毕.After opening the package, The LEDs should be soldered within 24 hours (1days) after opening the package.(6)使用注意事项Cautions:6.1.在开包装之前,请先检查包装袋有无漏气,如果有漏气现象,请退回我司重新烘烤除湿包装后再使用。

Wah Wang Data SheetFor 3528 Single Chip Green Color Top LEDPart No: WW- GNA30TS-CAddress :Unit 03B, 18th Floor, Nanyang Plaza,No.57 Hung To Road, Kwun Tong,Kowloon, Hong KongTel :852-2512 9939 (10 line)2398 Fax :852-2344 Web Site :S.D.N. or D.N. No. :SN100350Customer Name :Mectronic s.r.l.Sample Approval Signature :Date :Wah Wang Data SheetTechnical Datasheet3528 is thermal management characteristic is betterthan other LED Solutions. By package SMD designand good thermal emission material.According to these advantages, it enables to apply various lighting applications and design solution, automotive lighting, and large size LCD backlight etc.Application• Mobile phone flash• Automotive interior / exteriorlighting• Automotive signal lighting• Automotive forward lighting• General Torch• Architectural lighting• LCD TV / Monitor Backlight• Projector light source• Traffic signals• Task lighting• Decorative / Pathway lighting• Remote / Solar poweredlighting• Household appliancesFeatures1. PLCC LED dimensions: 3.5(L) x2.8(W) x 1.9(H) mmintensity2.HighwideangleviewExtremely3.packagetape4.Anti-electrostatic5. Reliable and stablePart No. WW-GNA30TS-C Emitting Color GreenAbsolute Maximum Ratings at Ta=25℃Unit Parameter MAX.Peak Forward Current50 mA(1/10 Duty Cycle, 0.1ms Pulse Width)Continuous Forward Current 20 mAReverse Voltage 5 V℃5℃Operating Temperature Range -25 to +8℃100℃Storage Temperature Range -40 to +℃ 3 SecondsLead Soldering Temperature 260 forElectrical Optical Characteristics at Ta=25℃TestConditionMin.Typ.Max.UnitParameter SymbolLuminous Intensity Iv 600 800 --- mcd I F = 20mA (Note 8)Wavelength λ515 --- 525 nm I F = 20mAViewing Angle 2θ1/2 --- 120 --- Deg I F = 20mAForward Voltage V F 2.8 ---3.6 V I F = 20mAµA V R = 5VReverse Current I R --- ---10Notes:1.All dimensions are in millimeter. Tolerance is ±0.25mm(.01”) unless others otherwise noted.2. WW maintains a tolerance of ±10% on flux and power measurements.T ±5% tester tolerance and λd ±1nm4.A tolerance of ±0.1V on forward voltage measurements5.View Angle maintains a tolerance of ±20°6.Specifications are subject to change without notice.7.These products are sensitive to static electricity; high standard of care must be fully taken when handlingthem. Particularly if an over-voltage that exceeds the Absolute maximum Rating of these products wereapplied, the overflow energy will cause damage to and possibly result in destruction of these products.Buyer shall take absolute secure countermeasures against static electricity and surge when handlingthese products.8.Luminous intensity is measured with a light sensor and filter combination that approximates the CIE eye-response curve.θ1/2 is the off-axis angle at which the luminous intensity is half the axial luminous intensity.9.It use many parameters that correspond to the CIE 1931 2°X,Y, and Z are CIE1931 2°values of Red, Green and Blue content of the measurement.* Caution1. Please do not drive at Peak Forward Current more than 5 sec.Reliability:1) Test Items and Results No. Test ItemStandard Test MethodTest ConditionsNoteNumber of DamagedIf=20mA 1 Steady State Operating LifeTa=25℃ 1000hrs 0/22 JEITA ED-47012 Low TemperatureStorage 200 202 Ta=-40℃ 1000hrs 0/22 JEITA ED-47013 High TemperatureStorage 200 201 Ta=100℃ 1000hrs 0/22 JEITA ED-4701Ta=60℃ 4Temperature Humidity Storage100 103 RH=90% 1000hrs 0/22JEITA ED-47010℃ ~ +100℃5 Thermal Shock300 307 5min~ 15sec ~ 5min 10 cycles 0/22H :+100℃ 30min.Temperature Cycle∫ : +25℃ 5min. 6JEITA ED-4701100 105 L :-40℃ 30min 100 cycles 0/22JEITA ED-47017 Solder Heat 300 301Tsld=260℃, 10sec(Max.)2 times 0/22Failed ConditionsItemSymbolTest ConditionMinMaxForward Voltage Vf If =20mA -- U.S.L*)×1.1Reverse Current Ir Vr =5V -- U.S.L*)×2.0 Luminous Intensity Iv If =20mA L.S.L**)×0.7 --*U.S.L.:Upper Standard Level ** L.S.L.:Lower Standard LevelTypical Characteristics Typical Electrical/Optical Characteristic Curves℃(25Dimensions for TapeDimensions for ReelNotes:1.All dimensions are in mm, tolerance is±2.0mm unless otherwise noted.2.Specifications are subject to change without notice.PRECAUTION IN USE StorageRecommended storage environmentTemperature: 5o C ~ 30o C (41o F ~ 86o F) Humidity: 60% RH Max.Use within 7 days after opening of sealed vapor/ESD barrier bags. If the moisture absorbent material (silica gel) has faded away or the LEDs have exceeded the storage time, baking treatment should be performed using the following conditions. Baking treatment : 60±5℃ for 24 hours. Fold the opened bag firmly and keep in dry environment.SolderingA. Reflow ProcessReflow SolderingLead Solder Lead – free SolderPre-heat120~150℃ 180~200℃ Pre-heat time 120sec. Max. 120sec. Max.Peak temperature240℃ Max. 260℃ Max. Soldering time 10sec. Max. 10sec. Max. Condition refer to refer toTemperature-Temperature- profile 1 profile 2After reflow soldering rapid cooling should be avoided.[Temperature-profile (Surface of circuit board)] Use the conditions shown to the under figure.<1 : Lead Solder > <2 : Lead-free Solder >M M ax .ax .M ax.ax.B. Manual Soldering ProcessHand SolderingTemperature350℃ Max. Soldering time 3sec. Max. (one time only)a. For prototype builds or small series production runs it is possible to place and solder the LED by hand.b. Dispense thermal conductive glue or grease on the substrates and follow its curing specifications. Gently press LED housing to closely connect LED and substrate.c. It is recommended to hand solder the leads with a solder tip temperature of 280°C for less than 3 second, at a time with a soldering iron of less than 25W. Solder at intervals of two seconds or more.d. Take caution and be aware that damaged products are often a result of improper handsoldering technique.Cleaning :The conditions of cleaning after soldering:An alcohol-based solvent such as lsopropyl Alcohol(IPA) is recommended. Temperature Time:<50℃*30sec,or <30℃*3minUltra sonic cleaning:<15W/bath; Bath volume:1liter max. Curing:100 max,<3minCautions of Pick and Place:It should be avoided to load stress on the resin during high temperature. Avoid rubbing or scraping the resin by any object.Electric-static may cause damage to the component. Please confirm that the equipment is grounding well. Using an ionizer fan is recommended.Cautions of Design and Applications:It should be done to connect with a current-limiting serial resistor. Avoid to drive reverse voltage over the specifications on LED when ON/OFF. Any application should refer to the specifications of absolute maximum ratings.The dimensions of the recommended soldering pattern may mot meet every user. Please confirm and study first before designing the soldering pattern in order to obtain the best performance of soldering.Do not contact with any component on the assembly board.Static Electricity:These products are so sensitive to static electricity charge so all equipment and machinery must be properly grounded and it is recommended to use a wristband or anti-electrostatic glove when handing the SMD LED.Particularly if any over-current and over-voltage which exceed the AbsoluteMaximum Ratings of LED applied, the more energy may cause damage or possibly result in electrical destruction of the Products.A protection design should be installed in the LED driving circuit, which does not exceed the max. rating for surge current during on/off switching.A tip if soldering iron is requested to be grounded .An ionizer should be installed when risk of static generation is high.If the countermeasures mentioned above are implemented, LED can work well.Users are required to check those countermeasures when problems occur by static electricity chargeOther:Damaged SMD LED will show unusual characteristics such as leak current remarkably low current. Increase, turn-on voltage becomes lower and the SMD LED get unlighted at low current.In automatic mounting of the SMD LEDs on printed circuit boards, any bending and pulling forces or shock against the SMD LEDs shall be kept min. to prevent them from expanding or electrical failures and mechanical damages of the devices. Illustration & ApplicationThe SMD LED taping is much smaller than leaded components, thus enable smaller size, applications, etc. higher packing density, reduced storage space and finally smaller equipment board to be obtained. Besides, lightweight makes them ideal for miniatureThe products described in this brochure are intended only for standard applications or general electronic equipment such as :1. Telecommunication: indicator and backlight in telephone and fax.2. Automotive: backlight in dashboard and switch.3. LCD: Flat backlight for LCD, switch and symbol.Notes for designing:Care must be taken to provide the current limiting resistor in the circuit so as to drive the Wah Wang LEDs within the rated figures. Also, caution should be taken not to overload Wah Wang LEDs with instantaneous voltage at the turning ON and OFF of the circuit.When using the pulse drive care must be taken to keep the average current within the rated figures. Also, the circuit should be designed so as be subjected to reverse voltage when turning off the Wah Wang LEDs.Storage:In order to avoid the absorption of moisture,it is recommended to solder Wah Wang LEDs as soon as possible after unpacking the sealed envelope.If the envelope is still packed, to store it in the environment as following:(1) Temperature: 5℃ -30℃ (41°F ) Humidity: RH 60% Max.(2) After this bag is opened, devices that will be applied to infrared reflow, vapor-phase reflow, or equivalent soldering process must be:a. Completed within 24hours.b. Stored at less than 30% RH.(3)Devices require baking before mounting, if: (2) a or (2)b is not met.(4) If baking is required, devices must be baked under below conditions: 12 hours at 60℃ ± 3℃。

3528贴片LED灯珠参数介绍

3528贴片LED灯珠参数介绍:

3528贴片LED灯珠主要用在:室内照明、商业照明、工业照明领域。

如LED照明产品,LED装饰产品,LED背光产品、灯饰照明、背光源显示(LCD,广告牌)、汽车灯等。

工作电流:IF=(20mA)

3528白光电压3.0-3.4V 发光强度2200-2800(mcd) 光通量6500mlm 角度120°

3528红光电压 1.8-2.4V 发光强度 600-900 (mcd) 光通量2200mlm 角度120°

3528蓝光电压 3.0-3.4V 发光强度 300-500 (mcd) 光通量1000mlm 角度120°

3528黄光电压 1.8-2.4V 发光强度 500-800 (mcd) 光通量2000mlm 角度120°

3528绿光电压3.0-3.4V 发光强度1000-1200(mcd) 光通量3000mlm 角度120°

光衰小:LED工作后,20mA正常连续点亮,亮度会逐渐增加至1500小时左右,亮度增加12%;10000小时,光衰低于25%。

贴片最大可通过电流为500mA,只可以是瞬间,时间不超过2秒,正常15mA,20mA点亮不影响光衰

SMD LED经严格分光分色、亮度均匀一致

高亮度,色区集中,大角度,低热阻,超低光衰工艺,超长寿命。

型号:LZ-3528*蓝,纯绿,黄,红 TOP LED 产品符合ROHS 标准■ 应用■尺寸规格备注:所有尺寸规格误差都在±0.1mm.除非有另作说明..■ 最大绝对值等级(Ta = 25℃)■典型的电光学参数( IF=20mA and Ta = 25℃)■备注1.光强误差: ±15%2.主波长误差: ±1.0nm3.电压误差: ±0.1V■典型的光电参数图表(Ta=25°C Unless Otherwise Noted)伏安特性曲线 相对功率和电流曲线关系相对功率和温度曲线关系 相对功率和波长曲线关系温度电流变化曲线 辐射角度■ 可靠性焊接温度:焊接Radiation Angle0% Maximum Forward Current vs.Ambient Temperature50%Relative Luminous Intensity vs. WavelengthRadiation Angle0% Maximum Forward Current vs.Ambient Temperature 90°60°Relative Luminous Intensity vs. Ambient Temperature90°30°0%50%100%70°80°60°Ta(°C)Radiation Angle0%Maximum Forward Current vs.Ambient Temperature 90°60°50%90°30°0%50%100%40°30°70°80°60°50°Relative Luminous Intensity vs. Forward CurrentForward Current vs. Forward VoltageTa(°C)Ta(°C)回流焊接■包装说明书:■卷带说明书尺寸规格如下:mm 备注:1)此包装只适合用于MYGD2)正常的包装数量: 2,000pcs/reel。

3528贴片灯珠具体规格参数如下:1. 【产品名称】:LED3528贴片2. 【电压】:3.0-3.2V3. 【电流】:20MA4. 【功率】:0.06W5. 【产品尺寸】:3.5*2.8*1.9MM6. 【芯片厂家】:三安7. 【亮度】:6-7LM 7-8LM 8-9LM8. 【色温】:2800-3200K 4000-4500K 6000-6500K 11000-13000K9. 【使用寿命】:>50,000个小时产品特征:发光角度大,广泛应用于日光灯、面板灯、球泡灯、吸顶灯、天花灯、背光、指示产品等主要材质:硬硅胶封装(进口日本信越=保证低光衰,防硫化)金线焊接(北京达博=纯金99.99%金线焊接)特点:体积小、角度大,亮度高、低电压驱动包装:真空包装2000/PCS/盘焊接方法:适应于所有的SMT贴片式焊接。

产品应用:手机按键灯、车载指示灯、仪器仪表指示灯、手机背光源、LED显示屏、MP3背光源、液晶显示屏,背光源、户外看板、背光源产品、电器产品指示、汽车仪表、影音设备、车载DVD、智能水表、电表。

MP3、MP4、MP5、蓝牙、特种照明、交通信号灯、室内照明、工业照明、广告语标示等LED3528白光贴片,3528白光贴片,3528白光贴片灯珠,3528白光灯珠,3528白光LED,SMD3528白光灯珠,SMD3528白光,3528白光LED,3528白光价格,深圳3528白光厂家,3528白光LED灯珠,LED3528白光贴片灯珠,3528白光发光二极管,发光二极管3528白光,发光二极管3528白光贴片灯珠,LED3528白光贴片厂家,LED3528白光厂家直销,LED3528白光价格优势,3528白光供应商,贴片3528白光灯珠。

第8页光源系列 LAMP Series闪射系列 FLASHING SERIES外形设计美观、烟尘式散热排气孔Beautiful and decent appearance design, Smoke-Dust cooling exhaust hole产品特性 PRODUCTS FEATURES灯体采用6063航空铝材,冷锻式一体成型,外形新颖,美观大方;独有烟尘式散热设计,通过散热排气孔能更快的带走热量,散热效率高;电源采用美国BCD方案设计,高精度智能控制电路,具有过载欠压等保护,使用更安全;进口一体化透镜,透光率高达93%,表面鳞面设计,更好的防止眩光;新型EMC超导热大功率灯珠,具有高光效,高显指,采用陶瓷支架,散热效果更好,将低光衰。

The lamp body is made of 6063 aviation aluminum with novel and beautiful appearance. Product Category: Cold Forging, Integrated molding.Cooling Design: Unique Smoke-Dust Type, it can take away heat faster through the vent holes, so the cooling efficiency is very high.Power source: Using BCD solution design from US with precision smart control circuit, overload & under voltage protection, keeps it more secure.Lens: Integrated lens imported from abroad, light transmission rate is as high as 93%, and the surface design uses Scaly surface, so it can prevent glare much better;New EMC Lamp beads: superconducting heat and high power, high luminance, and high color render index.Ceramic bracket: provides better heat dissipation and low light decay.应用范围商业重点照明、酒店重点照明、装饰照明、专卖店、咖啡厅、KTV、超市、写字楼、书房、面包店、书店、家居等场所。

3528⽩灯规格书Top View LEDs67-21/X2C-BXXXXXXXXX/2T FeaturesP-LCC-2 package.Fluorescence TypeHigh Luminous IntensityHigh EfficiencyPb-free.The product itself will remain within RoHScompliant version.DescriptionsDue to the package design, 67-21 has wide viewing angle, low power consumption and white LEDs are devices which are materialized by combing BlueLEDs and special phosphors. This feature makesthe LED ideal for light guide application.ApplicationsGeneral lightingDecorative and Entertainment Lighting.Indicators.Illuminations.Switch lights.Device Selection GuideChipMaterialEmitted Color Resin ColorInGaNCool WhiteWarm WhiteWater ClearTop View LEDs67-21/X2C-BXXXXXXXXX/2T Product Number Explanation 67–21/X 2 C-B XX XX XX XX XX/2TBin Group of Forward VoltageBin Group of Max. Luminous IntensityBin Group of Min. Luminous IntensityMax. Color temperatureMin. Color temperatureBin Code of Color Rendering Index NotesTable of Color Rendering IndexSymbol DescriptionM CRI(min) : 60L CRI(min) : 70K CRI(min) : 80H CRI(min) : 90Example:67-21/L2C-B45560C2CB2/2TTop View LEDs67-21/X2C-BXXXXXXXXX/2T Mass Production listProduct CRImin.CCT(K)I V(mcd)MinI V(mcd)MaxΦ(lm)Typ.67-21/M2C-B50632C4CB2/2T605000K~6300K20002400 5.78 67-21/M2C-B50638BACB2/2T605000K~6300K16002000 4.86 67-21/M2C-B50634B6BB2/2T605000K~6300K12001600 3.93 67-21/L2C-B4556AC2CB2/2T704500K~5650K18002200 5.39 67-21/L2C-B45566B8BB2/2T704500K~5650K14001800 4.53 67-21/L2C-B45564B6BB2/2T704500K~5650K12001600 3.67 67-21/L2C-B28328BACB2/2T702850K~3250K16002000 4.62 67-21/L2C-B28326B8BB2/2T702850K~3250K14001800 3.88 67-21/L2C-B28322B4BB2/2T702850K~3250K10001400 3.14 Top View LEDs67-21/X2C-BXXXXXXXXX/2TPackage Dimensions2.7±0.2for reflow solding (propose)+PolarityNote : Tolerance unless mentioned is ±0.1mm;Unit = mmTop View LEDs67-21/X2C-BXXXXXXXXX/2T Absolute Maximum Ratings (Ta=25 )Parameter Symbol Rating UnitReverse Voltage V R5VForward Current I F30mA Peak Forward Current (Duty 1/10 @1KHz)I FP100mA Power Dissipation Pd110mW Electrostatic Discharge ESD1000VOperating Temperature Topr-40 ~ +85Storage Temperature Tstg-40 ~ +90Soldering Temperature Tsol Reflow Soldering:260for10sec.Hand Soldering:350for3sec.Electro-Optical Characteristics (Ta=25 )Parameter Symbol Min.Typ.Max.Unit Condition Viewing Angle2θ1/2-----120-----deg I F=20mA Reverse Current I R----------50 A V R=5VTop View LEDs67-21/X2C-BXXXXXXXXX/2T Bin Range of Luminous IntensityBin Code Min.Max.Unit Condition8A600800AB80010002B100012004B120014006B14001600mcd I F=20mA 8B16001800AC180020002C200022004C220024006C24002600Bin Range of Forward VoltageGroup Bin Code Min.Max.Unit Condition34 2.7 2.835 2.8 2.936 2.93373 3.138 3.1 3.2V I F=20mA GB239 3.2 3.340 3.3 3.441 3.4 3.542 3.5 3.643 3.6 3.7Notes:1. Tolerance of Luminous Intensity: ±11%2. Tolerance of Forward Voltage: ±0.05VTop View LEDs67-21/X2C-BXXXXXXXXX/2TBin Range of Chromaticity Coordinates I F =20mACCTBin CodeCIE_x CIE_y CCTBin CodeCIE_x CIE_y 0.31480.3444 0.4312 0.4234 0.3288 0.3569 0.4456 0.4287 0.3290 0.3451 0.4376 0.4116 W50.3160 0.3332 P50.4240 0.4065 0.3160 0.3332 0.4240 0.4065 0.3290 0.3451 0.4376 0.4116 0.3292 0.3313 0.4294 0.3943 6300K ~5650K W60.3175 0.3204 3250K ~3050KP60.4165 0.3890 0.32880.3569 0.4456 0.4287 0.3469 0.3717 0.4614 0.4333 0.3458 0.3592 0.4525 0.4162 V50.3290 0.3451 N50.4376 0.4116 0.3290 0.3451 0.4376 0.4116 0.3458 0.3592 0.4525 0.4162 0.3444 0.3442 0.4436 0.3991 5650K ~5000K V60.3292 0.3313 3050K ~2850KN60.42940.39430.34690.3717 0.3642 0.3829 0.3622 0.3716 U50.3458 0.3592 0.3458 0.3592 0.3622 0.3716 0.35940.35575000K ~4500KU60.3444 0.3442Note: Tolerance of Chromaticity Coordinates: ±0.01Top View LEDs67-21/X2C-BXXXXXXXXX/2T The C.I.E. 1931 Chromaticity DiagramTop View LEDs67-21/X2C-BXXXXXXXXX/2TTypical Electro-Optical Characteristics Curves10Forward Voltage V -(Volts)F10R e l a t i v e l u m i n o u s i n t e n s i t y (%)Ambient Temperature T (°C -601 10-20-400206040)a 100801001000Ambient TemperatureAmbient Temperature T (°C a)Forward Current Derating Curve10F o r w a r d C u r r e n t02030I (m A )5040F 0.70.80.91.01Ta=25°Wavelength λ(nm)100F o r w a r d C u r r e n t 1020I (m A )305040FSpectrum Distribution0.10.30.50.20.480°90°0.650°60°70°40°Radiation DiagramTa=25°Forward Current 1010I (mA)30°FRelative Luminous Intensity vs.Ta=25°f=1KHz Duty=1/10Forward Current Forward Current vs.Forward VoltageRelative Luminous Intensity vs.R e l a t i v e l u m i n o u s i n t e n s i t y (%)R e l a t i v e l u m i n o u s i n t e n s i t y (%)Top View LEDsLabel ExplanationCAT:Luminous Intensity Rank HUE: Chromaticity Coordinates REF:Forward Voltage Rank Reel DimensionsNote : Tolerance unless mentioned is ±0.1mm; Unit = mmTop View LEDs67-21/X2C-BXXXXXXXXX/2T Carrier Tape Dimensions: Loaded Quantity 2000pcs Per Reel.Top View LEDs67-21/X2C-BXXXXXXXXX/2T Reliability Test Items and ConditionsThe reliability of products shall be satisfied with items listed below.Confidence level 90%LTPD 10%No.Items Test ConditionTestHours/CyclesSampleSizeAc/Re1Reflow Soldering Temp. : 260 5Min. 5sec.6 Min.22 PCS.0/12Temperature Cycle H : +100 15min5 minL : -40 15min300 Cycles22 PCS.0/13Thermal Shock H : +100 5min10 secL : -10 5min300 Cycles22 PCS.0/14High TemperatureStorageTemp. : 100 1000 Hrs.22 PCS.0/15Low TemperatureStorageTemp. : -40 1000 Hrs.22 PCS.0/16DC Operating Life I F = 20 mA1000 Hrs.22 PCS.0/17High Temperature / HighHumidity85 / 85%RH1000 Hrs.22 PCS.0/1Top View LEDs67-21/X2C-BXXXXXXXXX/2T Precautions for Use1. Over-current-proofCustomer must apply resistors for protection; otherwise slight voltage shift will cause bigcurrent change (Burn out will happen).2. Storage2.1 Do not open moisture proof bag before the products are ready to use.2.2 Before opening the package: The LEDs should be kept at 30 or less and 90%RH or less. 2.3 After opening the package: The LED's floor life are 168 hours under 30 or less and 60%RH or less. If unused LEDs remain, it should be stored in moisture proof packages.2.4 If the moisture absorbent material (silica gel) has faded away or the LEDs have exceeded thestorage time, baking treatment should be performed using the following conditions.Baking treatment: 60±5 for 24 hours.3. Soldering Condition3.1 Pb-free solder temperature profile1~5 °C / Sec.3.2 Reflow soldering should not be done more than two times.3.3 When soldering, do not put stress on the LEDs during heating.3.4 After soldering, do not warp the circuit board.Top View LEDs67-21/X2C-BXXXXXXXXX/2T 4. Soldering IronEach terminal is to go to the tip of soldering iron temperature less than 350 for 3 seconds within once in less than the soldering iron capacity 25W. Leave two seconds and more intervals, and do soldering of each terminal. Be careful because the damage of the product is often started at the time of the hand solder.5. RepairingRepair should not be done after the LEDs have been soldered. When repairing is unavoidable, a double-head soldering iron should be used (as below figure). It should be confirmed beforehand。