(完整版)锂电池英文生产流程

- 格式:doc

- 大小:56.01 KB

- 文档页数:5

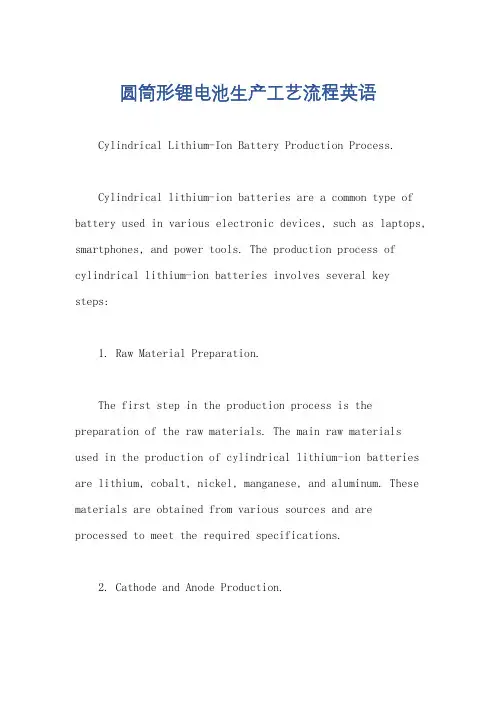

圆筒形锂电池生产工艺流程英语Cylindrical Lithium-Ion Battery Production Process.Cylindrical lithium-ion batteries are a common type of battery used in various electronic devices, such as laptops, smartphones, and power tools. The production process of cylindrical lithium-ion batteries involves several key steps:1. Raw Material Preparation.The first step in the production process is the preparation of the raw materials. The main raw materials used in the production of cylindrical lithium-ion batteries are lithium, cobalt, nickel, manganese, and aluminum. These materials are obtained from various sources and are processed to meet the required specifications.2. Cathode and Anode Production.The cathode and anode are the two electrodes of a lithium-ion battery. The cathode is typically made of a lithium-metal oxide compound, such as lithium cobalt oxide (LiCoO2) or lithium nickel manganese cobalt oxide (NMC). The anode is typically made of a carbon-based material, such as graphite or silicon.The cathode and anode materials are synthesized through a series of chemical processes. The cathode material is typically synthesized by mixing lithium salts with metal salts and then heating the mixture at high temperatures. The anode material is typically synthesized by mixing carbon precursors with a binder and then heating the mixture at high temperatures.3. Electrode Coating.Once the cathode and anode materials have been synthesized, they are coated onto metal current collectors. The current collectors are typically made of aluminum or copper. The cathode material is coated onto the positive current collector, and the anode material is coated ontothe negative current collector.The electrode coating process is typically carried out using a slurry method. The cathode or anode material is mixed with a solvent and a binder to form a slurry. The slurry is then coated onto the current collector using a doctor blade or a slot die coater.4. Electrode Drying and Calendering.After the electrodes have been coated, they are dried to remove the solvent. The electrodes are then calendered to improve their density and electrical conductivity. Calendering is a process in which the electrodes are passed through a series of rollers under pressure.5. Cell Assembly.The next step in the production process is the cell assembly. The cell assembly process involves stacking the electrodes together with a separator between them. The separator is a porous material that prevents the electrodesfrom making contact with each other and causing a short circuit.The electrodes and separator are typically stacked together in a winding machine. The winding machine rolls the electrodes and separator into a cylindrical shape.6. Cell Formation.Once the cells have been assembled, they are subjected to a formation process. The formation process involves charging and discharging the cells several times under controlled conditions. The formation process helps to stabilize the electrochemical reactions within the cells and improve their performance.7. Cell Testing.After the cells have been formed, they are tested to ensure that they meet the required specifications. The cells are tested for capacity, voltage, and internal resistance. The cells that do not meet the specificationsare rejected.8. Cell Packaging.The final step in the production process is the cell packaging. The cells are typically packaged in a metal can or a plastic pouch. The packaging protects the cells from the environment and prevents them from being damaged.The cylindrical lithium-ion battery production process is a complex and multi-step process. The quality of the batteries depends on the quality of the raw materials, the precision of the manufacturing processes, and the quality control procedures.。

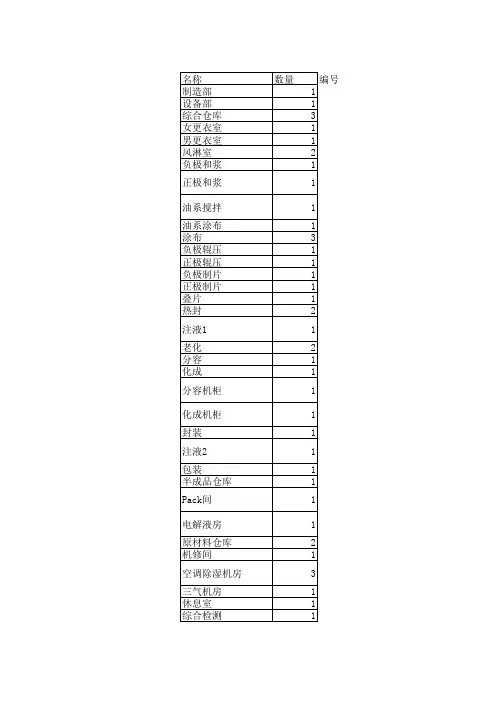

锂电车间工序名称翻译锂电生产车间工序名称英文翻译正极搅拌 Cathode mixing负极搅拌 Anode mixing涂布车间 coating workshop正极涂布 Cathode coating负极涂布 Anode Coating辊压车间 Roll workshop正极辊压 Cathode roll负极辊压 anode roll成品仓库 Finished product warehouse 激光点焊室 laser welding room烘烤室 Baking Room化成室 Kasei Room分容室 Sub-capacity Room生产部 Production Department品质部 Quality Department技术研发部 technology room试验室 Laboratory装配车间 Assembly shop注液室 injecting electrolyte room封口室 sealing room培训室 Training room采购部 Purchasing Department设备管理部 equipment department高压危险 High-voltage danger节约用水 economize for water节药用电economize for electricity卫生间 toilet男更衣室change room for men女更衣室change room for women正极点焊 Cathode Welding负极点焊 Anode Welding正极贴胶Cathode Sticking Tape负极压极耳Anode Tab Pressing正极压极耳Cathode Tab Pressing负极压极耳Anode Tab Pressing正极压极耳Cathode Tab Pressing正极折极耳 Cathode Folding负极折极耳 Anode Folding负极刷粉Anode Cleaning正极刷粉 Cathode Cleaning备胶 Preparing Tape卷绕 Winding冷压 Cold Pressing平压测短路 Short T esting分切 Slitting冲压成型Press for Forming剪极耳 Tab Cutting裁极耳 Tab Shearing断切隔膜 Separator Cutting贴PET膜 PET Sticking切边 Side Cutting热压 Hot Pressing检验合格区 Qualified Area断切 Cutting顶侧封 T op--side Sealing极耳测测短路Tap Short Circuit Testing 贴保护膜 Film Sticking 套PET膜 PET-Wrapping扩口 Opening装篮 Installing注液 Injecting Electrolyte静置 Standb真空封装 Vaccum Sealing二次封装 Second Sealing切边 Side Cutting切极耳 Tab Cutting点焊 Welding贴顶侧封胶Sticking Top Tape 折边 Folding烫边 Smothing备料 Material Prepairing压边 Side Pressing极耳放置区 Tab Area拉力测试 Power Testing首件The First Prduct首检 The First Ispection自动切边 Auto Cutting擦边 Sidewipe刮边 Scraping Film贴双面胶 Sticking Double-Tape 检外观 Appearance Inspection 测电阻 Impedance Check测电压 Valtage Check卡厚 Measure Thickness卡宽 Measure Width喷码 Spouting测内阻 Resistance Check撕膜 Separator Tearing卡长 Measure Length包胶 Sticking Tape备胶 Prepairing Tape套热缩管 Tube Setting复检工位 Recheck标准工位 Standard Operate半自动卷绕 Half-auto Winding电芯全检 Full Check压芯 Cell Pressing包底胶Sticking Bottom Tape包上胶Sticking Top Tape上隔圈Separator Ring Installing入壳、测短路 Short Testing点负极盖板Welding Anode Board 点正极盖板Welding Cathode Board 离芯 Cell Disjoining。

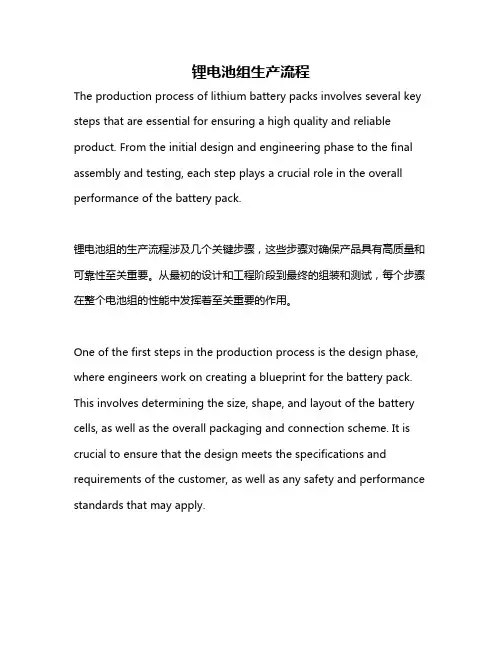

锂电池组生产流程The production process of lithium battery packs involves several key steps that are essential for ensuring a high quality and reliable product. From the initial design and engineering phase to the final assembly and testing, each step plays a crucial role in the overall performance of the battery pack.锂电池组的生产流程涉及几个关键步骤,这些步骤对确保产品具有高质量和可靠性至关重要。

从最初的设计和工程阶段到最终的组装和测试,每个步骤在整个电池组的性能中发挥着至关重要的作用。

One of the first steps in the production process is the design phase, where engineers work on creating a blueprint for the battery pack. This involves determining the size, shape, and layout of the battery cells, as well as the overall packaging and connection scheme. It is crucial to ensure that the design meets the specifications and requirements of the customer, as well as any safety and performance standards that may apply.生产过程中的第一步是设计阶段,工程师们在这个阶段致力于为电池组创建蓝图。

锂电工艺流程英语Lithium-ion batteries, commonly referred to as Li-ion batteries, have revolutionized the energy storage industry, powering our portable electronics, electric vehicles, and even grid-scale energy storage systems. The manufacturing process of these batteries involves several complex steps, each requiring precision and expertise. In this comprehensive guide, we'll explore the English terminology and steps involved in the Lithium-ion battery manufacturing process.**1. Material Preparation**The first step in the Lithium-ion battery manufacturing process is the preparation of raw materials. This involves selecting high-quality cathode and anode active materials, as well as suitable electrolytes and separators. The cathode and anode materials are typically composed of lithium compounds and carbon-based materials, respectively. **2. Electrode Fabrication**Once the raw materials are prepared, the next step is to fabricate the electrodes. This involves mixing theactive materials with binders and conductive additives, and then coating them onto a metal current collector. The most common metal current collectors are aluminum for the cathode and copper for the anode.**3. Electrode Drying and Cutting**After coating, the electrodes undergo a drying process to remove any moisture. Once dry, they are cut into the desired shape and size, ready for the next step in the manufacturing process.**4. Cell Assembly**Cell assembly is a crucial step, where the electrodes, electrolyte, and separator are combined to form the battery cell. The separator, typically made of porous polypropylene or polyethylene, is placed between the cathode and anode to prevent direct contact and thus, short-circuiting. The electrolyte, which is a liquid or solid material, is then added to facilitate the movement of ions between the electrodes.**5. Welding and Sealing**After assembly, the cell is sealed and welded to ensure its structural integrity and prevent leakage of the electrolyte. This step is crucial for ensuring the safety and performance of the battery.**6. Formation and Testing**The formed battery cell is then subjected to a formation process, which involves charging and discharging the cell to activate it. Following formation, the cell is tested to ensure its performance meets specifications. This testing may include capacity testing, internal resistance testing, and cycling tests.**7. Packaging and Final Testing**Once the individual cells are tested and approved, they are packaged into the final battery pack. This packaging may include additional safety features such as thermal cut-off devices and fuses. The final battery pack is then tested again to ensure it meets the required performance and safety standards.**8. Quality Control and Shipping**Quality control is an ongoing process throughout the manufacturing process. However, a final inspection is conducted before the batteries are shipped to customers. This inspection ensures that each battery meets therequired specifications and is safe for use.In conclusion, the Lithium-ion battery manufacturing process is a complex and meticulous procedure, requiring precision and expertise. Understanding the terminology and steps involved in this process is crucial for ensuring the safety, performance, and reliability of the final product. As the demand for Lithium-ion batteries continues to grow, so does the importance of understanding and improving their manufacturing processes.**锂电池生产工艺流程详解**锂电池,特别是锂离子电池(Li-ion),已彻底改变了储能行业,为便携式电子设备、电动汽车甚至电网级储能系统提供了动力。

锂离子电池组pack得生产工艺流程下载提示:该文档是本店铺精心编制而成的,希望大家下载后,能够帮助大家解决实际问题。

文档下载后可定制修改,请根据实际需要进行调整和使用,谢谢!本店铺为大家提供各种类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by this editor. I hope that after you download it, it can help you solve practical problems. The document can be customized and modified after downloading, please adjust and use it according to actual needs, thank you! In addition, this shop provides you with various types of practical materials, such as educational essays, diary appreciation, sentence excerpts, ancient poems, classic articles, topic composition, work summary, word parsing, copy excerpts, other materials and so on, want to know different data formats and writing methods, please pay attention!一、原材料准备阶段。

1.1 采购正极材料。

锂电工艺流程英语Lithium battery manufacturing processLithium batteries are widely used in electronic devices, electric vehicles, and renewable energy storage systems due to their high energy density and long cycle life. The manufacturing process of lithium batteries involves a series of complex steps, each of which is essential for producing high-quality batteries. In this article, we will discuss the general process of producing lithium batteries and the key technologies involved.1. Electrode preparationThe first step in the production of lithium batteries is the preparation of electrodes. This involves the coating of a conductive substrate with an active material, which is usually a lithium compound such as lithium cobalt oxide (LiCoO2) for the positive electrode and graphite for thenegative electrode. The active material is mixed with a binder and solvent to form a slurry, which is then coated onto the substrate using a coating machine. The coated electrodes are then dried and calendared to improve their density and adhesion.2. Cell assemblyOnce the electrodes are prepared, they are assembled into a cell along with a separator and electrolyte. The separator is a thin membrane that prevents the electrodes from coming into direct contact with each other while allowing the transport of lithium ions. The electrolyte is a solution of lithium salts in a solvent, which serves as the medium for the transport of lithium ions between the electrodes. The assembled cell is then sealed in a metal casing to form a hermetically sealed unit.3. FormationAfter assembly, the cells undergo a formation process, which involves the initial charging and discharging of the cells to activate the electrodes and stabilize the electrolyte. This process is essential for achieving the desired performance and cycle life of the batteries. The formation process is typically carried out in a controlled environment with precise temperature and humidity conditions.4. Aging and testingOnce the formation process is complete, the cells undergo aging to allow for the gradual stabilization of their performance. During this period, the cells are subjected to various tests to assess their capacity, energy efficiency, and cycle life. Any cells that do not meet the specified performance criteria are rejected, while those that pass the tests are selected for further processing.5. Module and pack assemblyThe selected cells are then assembled into modules, which are groups of cells connected in series and parallel to achieve the desired voltage and capacity. The modules are then assembled into packs, which are the final products that are used in various applications such as electric vehicles and energy storage systems. The pack assembly involves the integration of battery management systems, thermal management systems, and safety features to ensure the reliable and safe operation of the batteries.6. Quality control and inspectionThroughout the manufacturing process, strict quality control measures are implemented to ensure the consistent performance and safety of the batteries. This involves the inspection of raw materials, in-process monitoring, and final product testing to identify and rectify any defects or abnormalities. The quality control measures are crucial formeeting the stringent reliability and safety requirements of lithium batteries.Key technologies in lithium battery manufacturingThe production of lithium batteries involves several key technologies that are essential for achieving high-performance and reliable batteries. These technologies include:1. Electrode coatingThe electrode coating process is a critical step in the manufacturing of lithium batteries, as it directly affects the performance and cycle life of the batteries. Advanced coating technologies such as slot die and doctor blade coating are used to achieve precise and uniform coating of the electrodes, leading to improved energy density and cycle life.2. Solvent recoveryThe solvent used in the electrode coating process needs to be recovered and recycled to minimize waste and reduce environmental impact. Solvent recovery technologies such as distillation and membrane separation are employed to recover the solvent from the slurry and reuse it in the manufacturing process.3. Electrode drying and calendaringThe drying and calendaring of the coated electrodes are essential for improving their density and adhesion, which in turn affects the performance and cycle life of the batteries. Advanced drying and calendaring technologies such as infrared heating and roll pressing are used to achieve uniform and controlled drying and calendaring of the electrodes.4. Cell assembly and sealingThe cell assembly and sealing process is crucial for preventing the leakage of electrolyte and ensuring the long-term stability of the batteries. Advanced sealingtechnologies such as laser welding and ultrasonic welding are employed to achieve hermetic sealing of the cells, leading to improved safety and reliability.5. Battery management systemsThe integration of battery management systems (BMS) inthe pack assembly process is essential for monitoring and controlling the operation of the batteries. Advanced BMS technologies with features such as cell balancing, state-of-charge estimation, and thermal management are used to ensure the safe and efficient operation of lithium batteries.6. Safety testing and certificationSafety testing and certification are essential for ensuring the reliable and safe operation of lithium batteries. Advanced testing technologies such as abuse testing, thermal runaway testing, and crush testing are employed to assess the safety performance of the batteries and obtain certification from regulatory authorities.ConclusionThe manufacturing process of lithium batteries involves a series of complex steps, each of which is essential for producing high-quality batteries. Advanced technologies such as electrode coating, solvent recovery, cell assembly, and battery management systems are employed to achieve high-performance and reliable batteries. Strict quality control measures and safety testing are essential for meeting the stringent reliability and safety requirements of lithium batteries. As the demand for lithium batteries continues to grow, the development of advanced manufacturing technologies will play a crucial role in meeting the increasing performance and safety requirements of lithium batteries.。

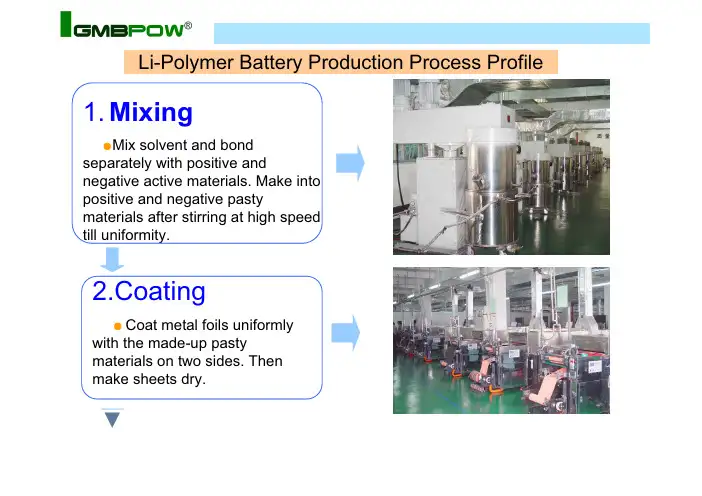

Li-Polymer Battery Production Process Profile1. MixingMix solvent and bond separately with positive and negative active materials. Make into positive and negative pasty materials after stirring at high speed till uniformity.2.CoatingCoat metal foils uniformly with the made-up pasty materials on two sides. Then make sheets dry.3.CuttingCut a roll of positive and negative sheet into smaller sheets according to battery specification and punching requests.4.PressingPress the above positive and negative sheets till they become flat.5.PunchingPunch sheets into electrodes according to battery specification.6.Re-pressingRe-press electrodes till they become flat and stout.7.WeightingStrictly choose the same weight cathodes and anodes to match according to battery design of capacity and layers. anodecathode8.StackingSeparate the cathodes and anodes completely by stacking separator into “s” according to battery specification and capacity. one corner of stacking workshop9. Short TestA cell is formed after stacking. Test its insulation performance.10.Welding tabWeld Al & Ni tabs to lead out anode & cathode terminals. cathode welding anode welding11.Short testTest a cell’s insulation performance after tabs is welded, trimmed and pasted adhesive tape.12.SealingSeal the mouth and left side after putting the naked cell into punched Al compound packing film. sealing mouth sealing left side13.Short testTest a cell’s insulation performance after it is sealed.14. vacuum dryDry the battery waiting for filling with vacuum to drain out wet gas completely in order to make sure the battery’s quality.15.FillingFill electrolyte into battery by filling mouth, which should be finished in a dry glove box. Relative humidity is controlled below 1%RH. one corner of filling workshop16.SealingSeal the filling mouth after filling, which should be finished in a dry glove box.17.InspectionInspect battery impedance and the weight of electrolyte to see if they meet the design requests. weight of electrolyte Inspection impedance Inspection18.FormationCharge and discharge the fresh battery for one or several times, which is watched and recorded its performance by a computer at all times.one corner of formation workshop19.vacuumingThe battery will produce gas after charging. Abstract gas from the battery till vacuum. one corner of vacuuming workshop20.SealingSeal right side of the battery to make sure its airtight performance.21.FoldingCut the redundant Al compound packing film of left & right sides and fold automatically at the same time with an automatic folding machine.22.Capacity sortingSort batteries according to their capacity with highprecision sorting equipments, which is watched and recorded their performances by computers at all times. one corner of sorting workshop23.AgingStore the batteries in batches in warehouse after inspecting their impedance, voltage, capacity and size. The room temperature is 10~45 and the humidity is 65 20%. The aging time is 30 days. The batteries is re-inspected regularly every 8 days during aging.one corner of aging warehouse24.AssemblyAssemble according to customers requests after aging. (The assembly styles can be different to meet the customer’s requests). The operator must inspect every batch battery's voltage, impedance and so on before assembly.one corner of assembly workshopvoltage inspectionimpedance inspection25. Outgoing inspectionInspect the battery performances according to GB/T18287-2000. The battery can’t leave the factory until OQC consider it qualified after sampling inspection according to GB/T2828.1impedance inspectionvoltage inspectionconstant temperature & humidity testshock testcapacity & charging/discharging inspectionconstant temperature cycle test26.PackingPackage consists of an inner plastic tray and an outer carton. Enlace cartons to fasten with strapping strips on stack board. Finally coat clear plastic film on these cartons to moisture-proof. This is to make sure safe transportation and to meet the regulations of GB191-1990 PackagingPictorial Marking for Handling of Goods.Thank you for watching。

(完整版)锂电池英文生产流程Mixing(配料)Mix solvent and bound separately with positive and negative active materials. Make into positive and negative pasty materials after stirring at high speed till uniformity.Coating(涂布)Now, we are in coating line. We use back reverse coating. This is the slurry-mixing tank. The anode(Cathode)slurry is introduced to the coating header by pneumaticity from the mixing tank. The slurry is coated uniformly on the copper foil, then the solvent is evaporated in this oven. (下面的依据情况而定)There are four temperature zones, they are independently controlled. Zone one sets at 55 degree C, zone two sets at 65 degree C, zone three sets at 80 degree C, zone four sets at 60 degree C. The speed of coating is 4 meters per minute.You see the slurry is dried. The electrode is wound to be a big roll and put into the oven. The time is more than 2 hours and temperature is set at 60 degree C.Throughout the coating, we use micrometer to measure the electrode thickness per about 15 minutes. We do this in order to keep the best consistency of the electrode.Vocabulary:coating line 涂布车间back reverse coating 辊涂coating header 涂布机头Al/copper foil 铝/铜箔degree C 摄氏度temperature zones 温区wind to be a(big)roll 收卷evenly/uniformly 均匀oven 烘箱evaporate 蒸发electrode 极片CuttingCut a roll of positive and negative sheet into smaller sheets according to battery specification and punching request.PressingPress the above positive and negative sheets till they become flat.PunchingPunching sheets into electrodes according to battery specification,ElectrodeAfter coating we compress the electrode with this cylindering machine at about 7meters per minute. Before compress we clean the electrode with vacuum and brush to eliminate any particles. Then the compressed electrode is wound to a big roll. We use micrometer to measure the compressed electrode thickness every 10 minutes. After compressing we cut the web into large pieces. We tape the cathode edge to prevent any possible internal short. The large electrode with edge taped is slit into smaller pieces. This is ultrasonic process that aluminum tabs are welded onto cathodes using ultrasonic weld machine. We tape the weld section to prevent any possible internal short. And finally, we clean the finished electrodes with vacuum and brush.Vocabulary:cylindering 柱形辊压vacuum 真空particle 颗粒wound 旋紧卷绕micrometer 千分尺internal short 内部短路slit 分切ultrasonic 超声波weld 焊接Anode makingIn anode making process, we cut the material into certain length strips. At the mean time, we put a small piece of insulation tape to the tab in order to prevent any possible internal short. Then the prepared nickel tab is riveted on anode and pat plain.We also tape the rivet section to prevent any possible internal short. And finally, we clean the finished electrodes with vacuum and brush.Jelly rollThis is Jelly roll, a manual winding process. In the course of Jelly roll, firstly, we place the separator in between central pins, press the foot switch to turn central pins about 120 degrees. Secondly, place the anode to the edge of central pins, and turn central pins about 180 degrees. Lastly, place the cathode to the edge of central pins. During the winding process, we apply tension by pressing the electrodes and the separator. We put the termination tape at the end.After Jelly roll, we check the short circuit, then form the Jelly roll by pressing, so that it is easier to insert the Jelly roll into the can.Control points:1. When winding to the end of the anode, covering the anode completely by the separator.2. In the whole process, it is the most important points to ensure the best alignment among the cathode, the anode and the separator for the Jelly roll. The separator has to cover the anode and the cathode, and the anode has to cover the cathode completely. These points are mainly checked before short checking.Vocabulary:Jelly roll 卷绕Manual 手工的Separator 隔膜纸central pin 卷针foot switch 脚踏开关anode 负极片cathode 正极片termination tape 尾端胶纸short circuit 短路alignment 整齐Taping & insertingPut the tape on the two side of J/R, T o prevent J/R being hurt in the insertion process.Put a piece of tape between cathode tab and J/R .Because anode electrode is wider than cathode electrode.Put the bottom tape.Insert the finished J/R into the can manually and then short circuit check by multi-meter.Spot welding Ni tab to cap.Ultrasonic welding the Al tab to cap using ultrasonic weld.We have the second spot welding to ensure the best contact between the tab and cap.Apply top insulator, to prevent Ni tab contacting with can.Final J/R insertion by the centrifuge.Cap positioning by hand. Then check the cap in the suitable position, or the defects is put into red bin ,Finally , short circuit check again to ensure that there be no internal short J/R flowing to next line.Vocabulary:J/R 极芯tape 胶纸electrode 极片multi-meter 万用表Spot welding 点焊Ni tab 极耳Ultrasonic weld 超焊Insulator 隔圈centrifuge machine 甩壳机defect 次品red bin 红盒Laser weldingThis is the Laser welding room! The first process is welding for the aluminum cap, specially connect the rivet with the weld plate to prevent the cell impedance excursion.The second process is the Laser seam welding. In the process, it must ensure the intensity and airproof characters of the weld.After the cell is welded, we would perform the leak checking, the short circuit checking and the weighing checking.Vocabulary:Laser welding room 激光焊接车间Cap 盖板Rivet 铆钉Plate 镍片impedance excursion 内阻漂移intensity 强度leak checking 检漏short circuit checking 测短路weighing checking 称重Oven drying electrolyte filling and storingThis is the process of cells oven drying at 80℃ for more than 12 hours under vacuum. After oven drying, the cells are transferred to the process of electrolyte filling through this channel. The electrolyte filling performs in dry room. The electrolyte is injected in two times so that it can be filled easily and sufficiently. When filling, vacuum first, then inject electrolyte. After that, we repeat vacuum and vent to room pressure several times. Finally the cell is put off at room pressure, then weigh the cell in order to check the amount of electrolyte. After weighing, we seal with tape onto the filling port to prevent the cells absorbing water during storing.We store the filled cells for 24 hours at room temperature so that the electrolyte can be saturated sufficiently by the anodes and cathodes.Vocabulary:oven drying 烘烤vacuum 真空electrolyte filling 注液electrolyte 电解液room pressure 大气压filling port 注液孔storing 陈化saturated 浸润anode 正极cathode 负极Pre-charge and ball sealAt first, we place a piece of absorb cotton above the filling port to absorb the excess electrolyte. This is the first process.The second process is performing a pre-charge at 0.1C rate for 390 minutes.After the pre-charge, we take a voltage checking to the cell at once. If the voltage is lower than the standard, it needs to be re-charged.The fourth process is the ball seal. we must complete this process in 15 minutes.First, put the steel ball in the right place. Then, give pressure to it so that the steel ball can fill the filling port.In the whole process, we must make sure that the temperature and humidity are in the regular range.Finally, the process is cleaning to eliminate the electrolyte on the cell surface with acetone solvent.Vocabulary:filling port 注液孔electrolyte 电解液pre-charge 预先充电ball seal 封口voltage checking 量电压regular range 合格范围eliminate 消除acetone solvent 丙酮溶剂Aging and FormationThis is the aging room. We age cells at 35~40 Degree C for 7 days. The temperature is controlled by two heating instruments which are set at 38 Degree C. Then we transfer cells to the testing workshop. First, we check the voltage of cells with multi-meters. According to voltage, we divide the cells into acceptables and defects. Formation is done at 1.0 Capacity rate for 140 minutes to 4.2 Voltage. After that, check thickness and impedance. At last, we transfer the acceptables to the storehouse.Vocabulary:aging room 老化房heating instrument 加热器testing workshop 检测车间acceptables 良品defects 次品formation 化成thickness 尺寸,厚度impedance 内阻storehouse 仓库标识牌内容(中文) 英文1 正极球磨Cathode Ball Mill Mixing2 负极球磨Anode Ball Mill Mixing3 正极混浆Cathode Slurry Mixing4 负极混浆Anode Slurry Mixing5 正极涂布Cathode Coating6 负极涂布Anode Coating7 极片烘烤Electrode Drying 8 正极压片Cathode Compress9 负极压片Anode Compress 10 正极分大片Cathode Cutting11 正极分小片Cathode Slitting 12 负极分大片Anode Cutting13 负极分小片Anode Slitting 14 切镍带Anode Tab Cutting15 极耳铆接Anode Riveting 16 极耳贴胶纸Anode Tab Taping17 大片贴胶纸Cathode Edge Taping 18 刷片Electrode Brushing19 极耳超焊#1 Cathode Tab Welding #1装配车间英语极片烘烤Electrode Drying Area裁隔膜纸Separator Cutting 壳体贴膜Out-film Apply超焊铝镍带Cathode Tab Welding贴内壁胶纸Inner Insulation Taping卷绕Jelly Roll Winding检验#1 Checking Station#1整形Jelly Roll Forming贴侧面胶纸J/R Side Taping贴上端胶纸J/R Top Taping贴底部胶纸J/R Bottom Taping装壳Jelly Roll Insertion点焊负极Anode Tab Welding剪正极耳Cathode Tab Cutting 超焊正极耳#2 Cathode Tab Welding #2二次点焊Spot Welding 套隔圈Insulator Insertion甩壳Final J/R Insertion卡盖板Cap Installation检验#2 Checking Station #2点焊盖板Cap Pre—Welding激光焊接Laser Seam welding 整形Forming检验漏气Leak Checking短路测试Hi—pot称重分档Weighing Sorting。

锂电工艺英文介绍Lithium-ion battery technology is a type of rechargeable battery that utilizes lithium ions as the primary carrierof electric charge. This technology has gained significant attention and popularity due to its high energy density, long cycle life, and relatively low self-discharge rate. Lithium-ion batteries are commonly used in portable electronic devices such as smartphones, laptops, and tablets, as well as in electric vehicles and grid energy storage systems.The manufacturing process of lithium-ion batteries involves several key steps. The first step is to preparethe electrode materials, which typically consist of a cathode, anode, and separator. The cathode material is usually a lithium metal oxide, such as lithium cobalt oxide, lithium iron phosphate, or lithium manganese oxide. The anode material is typically made of graphite or othercarbon-based materials. The separator is a porous membrane that prevents the electrodes from coming into directcontact with each other.Once the electrode materials are prepared, they are assembled into a cell along with an electrolyte solution. The electrolyte is a lithium salt dissolved in a solvent, which allows lithium ions to move between the electrodes during charging and discharging. The cell is then sealed to prevent leakage of the electrolyte and to maintain a stable environment for the electrochemical reactions to occur.After the cells are assembled, they undergo a series of quality control tests to ensure their performance and safety. These tests include measuring the capacity, voltage, and internal resistance of the cells, as well as subjecting them to various environmental and abuse conditions toassess their durability and reliability.In addition to the cell manufacturing process, lithium-ion battery technology also involves the development of battery management systems (BMS) and charginginfrastructure. BMS are essential for monitoring the stateof charge, state of health, and state of safety of the battery, as well as for balancing the individual cellswithin a battery pack to ensure uniform performance. Charging infrastructure includes the design andimplementation of charging stations and protocols for fast and efficient recharging of lithium-ion batteries.Overall, the development and advancement of lithium-ion battery technology have revolutionized the way we use and store energy. With ongoing research and innovation, this technology continues to improve in terms of energy density, cost, and safety, paving the way for a more sustainable and electrified future.锂电池技术是一种利用锂离子作为主要电荷载体的可充电电池。

Mixing(配料)Mix solvent and bound separately with positive and negative active materials. Make into positive and negative pasty materials after stirring at high speed till uniformity.Coating(涂布)Now, we are in coating line. We use back reverse coating. This is the slurry-mixing tank. The anode(Cathode)slurry is introduced to the coating header by pneumaticity from the mixing tank. The slurry is coated uniformly on the copper foil, then the solvent is evaporated in this oven. (下面的依据情况而定)There are four temperature zones, they are independently controlled. Zone one sets at 55 degree C, zone two sets at 65 degree C, zone three sets at 80 degree C, zone four sets at 60 degree C. The speed of coating is 4 meters per minute.You see the slurry is dried. The electrode is wound to be a big roll and put into the oven. The time is more than 2 hours and temperature is set at 60 degree C.Throughout the coating, we use micrometer to measure the electrode thickness per about 15 minutes. We do this in order to keep the best consistency of the electrode.Vocabulary:coating line 涂布车间back reverse coating 辊涂coating header 涂布机头Al/copper foil 铝/铜箔degree C 摄氏度temperature zones 温区wind to be a(big)roll 收卷evenly/uniformly 均匀oven 烘箱evaporate 蒸发electrode 极片CuttingCut a roll of positive and negative sheet into smaller sheets according to battery specification and punching request.PressingPress the above positive and negative sheets till they become flat.PunchingPunching sheets into electrodes according to battery specification,ElectrodeAfter coating we compress the electrode with this cylindering machine at about 7meters per minute. Before compress we clean the electrode with vacuum and brush to eliminate any particles. Then the compressed electrode is wound to a big roll. We use micrometer to measure the compressed electrode thickness every 10 minutes. After compressing we cut the web into large pieces. We tape the cathode edge to prevent any possible internal short. The large electrode with edge taped is slit into smaller pieces. This is ultrasonic process that aluminum tabs are welded onto cathodes using ultrasonic weld machine. We tape the weld section to prevent any possible internal short. And finally, we clean the finished electrodes with vacuum and brush.Vocabulary:cylindering 柱形辊压vacuum 真空particle 颗粒wound 旋紧卷绕micrometer 千分尺internal short 内部短路slit 分切ultrasonic 超声波weld 焊接Anode makingIn anode making process, we cut the material into certain length strips. At the mean time, we put a small piece of insulation tape to the tab in order to prevent any possible internal short. Then the prepared nickel tab is riveted on anode and pat plain. We also tape the rivet section to prevent any possible internal short. And finally, we clean the finished electrodes with vacuum and brush.Jelly rollThis is Jelly roll, a manual winding process. In the course of Jelly roll, firstly, we place the separator in between central pins, press the foot switch to turn central pins about 120 degrees. Secondly, place the anode to the edge of central pins, and turn central pins about 180 degrees. Lastly, place the cathode to the edge of central pins. During the winding process, we apply tension by pressing the electrodes and the separator. We put the termination tape at the end.After Jelly roll, we check the short circuit, then form the Jelly roll by pressing, so that it is easier to insert the Jelly roll into the can.Control points:1. When winding to the end of the anode, covering the anode completely by the separator.2. In the whole process, it is the most important points to ensure the best alignment among the cathode, the anode and the separator for the Jelly roll. The separator has to cover the anode and the cathode, and the anode has to cover the cathode completely. These points are mainly checked before short checking.Vocabulary:Jelly roll 卷绕Manual 手工的Separator 隔膜纸central pin 卷针foot switch 脚踏开关anode 负极片cathode 正极片termination tape 尾端胶纸short circuit 短路alignment 整齐Taping & insertingPut the tape on the two side of J/R, To prevent J/R being hurt in the insertion process.Put a piece of tape between cathode tab and J/R .Because anode electrode is wider than cathode electrode.Put the bottom tape.Insert the finished J/R into the can manually and then short circuit check by multi-meter.Spot welding Ni tab to cap.Ultrasonic welding the Al tab to cap using ultrasonic weld.We have the second spot welding to ensure the best contact between the tab and cap.Apply top insulator, to prevent Ni tab contacting with can.Final J/R insertion by the centrifuge.Cap positioning by hand. Then check the cap in the suitable position, or the defects is put into red bin ,Finally , short circuit check again to ensure that there be no internal short J/R flowing to next line.Vocabulary:J/R 极芯tape 胶纸electrode 极片multi-meter 万用表Spot welding 点焊Ni tab 极耳Ultrasonic weld 超焊Insulator 隔圈centrifuge machine 甩壳机defect 次品red bin 红盒Laser weldingThis is the Laser welding room! The first process is welding for the aluminum cap, specially connect the rivet with the weld plate to prevent the cell impedance excursion.The second process is the Laser seam welding. In the process, it must ensure the intensity and airproof characters of the weld.After the cell is welded, we would perform the leak checking, the short circuit checking and the weighing checking.Vocabulary:Laser welding room 激光焊接车间Cap 盖板Rivet 铆钉Plate 镍片impedance excursion 内阻漂移intensity 强度leak checking 检漏short circuit checking 测短路weighing checking 称重Oven drying electrolyte filling and storingThis is the process of cells oven drying at 80℃ for more than 12 hours under vacuum. After oven drying, the cells are transferred to the process of electrolyte filling through this channel. The electrolyte filling performs in dry room. The electrolyte is injected in two times so that it can be filled easily and sufficiently. When filling, vacuum first, then inject electrolyte. After that, we repeat vacuum and vent to room pressure several times. Finally the cell is put off at room pressure, then weigh the cell in order to check the amount of electrolyte. After weighing, we seal with tape onto the filling port to prevent the cells absorbing water during storing.We store the filled cells for 24 hours at room temperature so that the electrolyte can be saturated sufficiently by the anodes and cathodes.Vocabulary:oven drying 烘烤vacuum 真空electrolyte filling 注液electrolyte 电解液room pressure 大气压filling port 注液孔storing 陈化saturated 浸润anode 正极cathode 负极Pre-charge and ball sealAt first, we place a piece of absorb cotton above the filling port to absorb the excess electrolyte. This is the first process.The second process is performing a pre-charge at 0.1C rate for 390 minutes.After the pre-charge, we take a voltage checking to the cell at once. If the voltage is lower than the standard, it needs to be re-charged.The fourth process is the ball seal. we must complete this process in 15 minutes.First, put the steel ball in the right place. Then, give pressure to it so that the steel ball can fill the filling port.In the whole process, we must make sure that the temperature and humidity are in the regular range.Finally, the process is cleaning to eliminate the electrolyte on the cell surface with acetone solvent.Vocabulary:filling port 注液孔electrolyte 电解液pre-charge 预先充电ball seal 封口voltage checking 量电压regular range 合格范围eliminate 消除acetone solvent 丙酮溶剂Aging and FormationThis is the aging room. We age cells at 35~40 Degree C for 7 days. The temperature is controlled by two heating instruments which are set at 38 Degree C. Then we transfer cells to the testing workshop. First, we check the voltage of cells with multi-meters. According to voltage, we divide the cells into acceptables and defects. Formation is done at 1.0 Capacity rate for 140 minutes to 4.2 Voltage. After that, check thickness and impedance. At last, we transfer the acceptables to the storehouse.Vocabulary:aging room 老化房heating instrument 加热器testing workshop 检测车间acceptables 良品defects 次品formation 化成thickness 尺寸,厚度impedance 内阻storehouse 仓库标识牌内容(中文) 英文1 正极球磨Cathode Ball Mill Mixing2 负极球磨Anode Ball Mill Mixing3 正极混浆Cathode Slurry Mixing4 负极混浆Anode Slurry Mixing5 正极涂布Cathode Coating6 负极涂布Anode Coating7 极片烘烤Electrode Drying 8 正极压片Cathode Compress9 负极压片Anode Compress 10 正极分大片Cathode Cutting11 正极分小片Cathode Slitting 12 负极分大片Anode Cutting13 负极分小片Anode Slitting 14 切镍带Anode Tab Cutting15 极耳铆接Anode Riveting 16 极耳贴胶纸Anode Tab Taping17 大片贴胶纸Cathode Edge Taping 18 刷片Electrode Brushing19 极耳超焊#1 Cathode Tab Welding #1装配车间英语极片烘烤Electrode Drying Area裁隔膜纸Separator Cutting壳体贴膜Out-film Apply超焊铝镍带Cathode Tab Welding贴内壁胶纸Inner Insulation Taping卷绕Jelly Roll Winding检验#1 Checking Station#1整形Jelly Roll Forming贴侧面胶纸J/R Side Taping贴上端胶纸J/R Top Taping贴底部胶纸J/R Bottom Taping装壳Jelly Roll Insertion点焊负极Anode Tab Welding剪正极耳Cathode Tab Cutting 超焊正极耳#2 Cathode Tab Welding #2二次点焊Spot Welding套隔圈Insulator Insertion甩壳Final J/R Insertion卡盖板Cap Installation检验#2 Checking Station #2点焊盖板Cap Pre—Welding激光焊接Laser Seam welding 整形Forming检验漏气Leak Checking短路测试Hi—pot称重分档Weighing Sorting。