abaqus的材料参数

- 格式:doc

- 大小:79.50 KB

- 文档页数:7

《Abaqus金属材料参数应力应变曲线分析》在工程应用中,对于金属材料的性能参数进行准确的评估和分析是至关重要的。

Abaqus作为一款优秀的有限元分析软件,提供了丰富的金属材料参数模型,可以帮助工程师们更好地理解金属材料的应力应变特性。

本文将围绕着Abaqus中的金属材料参数和应力应变曲线展开全面评估和分析,希望通过深入的研究,为读者们带来一些新的启发和认识。

1.金属材料参数在Abaqus中,金属材料参数主要包括杨氏模量、泊松比、屈服应力、屈服准则等。

其中,杨氏模量是衡量金属材料弹性性能的重要参数,泊松比则反映了材料在拉伸或压缩过程中的纵向应变和横向应变之间的关系。

屈服应力是材料开始发生塑性变形的临界应力值,不同材料的屈服应力也会有所差异。

Abaqus还提供了多种屈服准则,如von Mises屈服准则、Tresca屈服准则等,工程师可以根据具体情况选择合适的屈服准则来模拟材料的塑性行为。

2.应力应变曲线金属材料的应力应变曲线是描述材料在受力过程中应力和应变变化关系的重要曲线。

在Abaqus中,通过定义材料的本构模型和参数,可以较为准确地模拟出金属材料的应力应变曲线。

一般来说,金属材料的应力应变曲线包括弹性阶段、屈服阶段、硬化阶段和断裂阶段等。

通过对这些阶段的分析,可以更深入地了解材料在受力过程中的性能表现和特点。

3.分析和理解通过对Abaqus中金属材料参数和应力应变曲线的分析,我们可以更好地认识金属材料的力学性能和塑性行为。

在工程实践中,准确地获取和定义材料的参数,对于模拟材料的力学行为和结构的性能至关重要。

通过对应力应变曲线的深入分析,可以帮助工程师们更合理地设计和优化工程结构,提高材料的利用率和性能。

在个人看来,Abaqus作为一款强大的有限元分析软件,其对金属材料参数和应力应变曲线的模拟和分析功能十分强大。

通过合理地使用Abaqus中提供的金属材料参数模型,可以更准确地描述材料的力学性能,为工程实践提供更可靠的理论基础。

abaqus常用材料参数

Abaqus是一个用于分析非线性物理系统的高性能软件套件,可用于准确模拟成型过程、强度与疲劳性能以及热-应力分离等复杂工程系统。

它可以精确模拟各种材料性能,并且需要利用适当的材料参数。

因此,为了使Abaqus软件套件可用于工程设计,让我们来看看如何设置Abaqus中常用的材料参数。

首先,需要设置材料参数,主要有静弹性、泊松比、杨氏模量以及弹性模量等参数,具体而言,静弹性参数决定了材料在有限变形或者微弱变形条件下的弹性反应;泊松比参数是表示材料在加载时在极限变形状态下的膨胀比率;杨氏模量表示材料的刚性程度;弹性模量参数主要表示材料的密度及抗弯刚度。

其次,在设置材料参数时,需要根据实际情况设置参数的大小,一般是根据材料的性能或者根据实验测试结果得到的。

同时,还可以根据Abaqus软件提供的参考值来设置。

再次,当材料参数设置完成之后,还需要利用Abaqus软件来进行多次仿真,以确认设置的参数是否合适,而且仿真结果也要尽可能与实验结果一致。

最后,Abaqus软件也提供了一个可视化的功能,它可以显示模型的变形状态和应力、应变分布情况,从而使用户可以根据变形状态及应力、应变得出精确的结论,确保建模是准确的。

总之,Abaqus软件提供了一系列用于分析不同工程系统的强大功能,使用Abaqus时,需要设置正确的材料参数,并且要通过多次

仿真来调整参数,以确保模型的精确性,最终可以得到满意的仿真结果。

abaqus 金属材料参数应力应变曲线标题:深度解析Abaqus中金属材料参数及其应力应变曲线目录:1. 介绍2. Abaqus中的金属材料参数3. 应力应变曲线的基本概念4. Abaqus中的应力应变曲线模拟5. 个人观点和理解1. 介绍在工程领域,Abaqus是一个被广泛应用的有限元软件,用于进行结构和材料的性能分析。

其中,金属材料参数和应力应变曲线是Abaqus模拟中至关重要的部分。

本文将首先深入探讨Abaqus中金属材料参数的设定,然后介绍应力应变曲线的基本概念,并探讨在Abaqus中如何模拟这一曲线。

将共享个人对这一主题的观点和理解。

2. Abaqus中的金属材料参数在Abaqus中,金属材料参数是描述材料行为的重要组成部分。

这些参数包括屈服强度、杨氏模量、泊松比、屈服准则等。

其中,屈服强度是材料在拉伸载荷下首次发生塑性变形的抵抗能力,杨氏模量表示材料的刚度,泊松比表示材料在拉伸和压缩加载时的变形情况,屈服准则则是描述了材料开始变形的条件。

在设定金属材料参数时,首先需要考虑材料的特性和实际应用场景。

通过实验数据和材料测试,可以获取金属材料的各项参数,并在Abaqus软件中进行设定。

这些参数的准确性和合理性将直接影响模拟结果的准确性。

3. 应力应变曲线的基本概念应力应变曲线是描述材料在加载过程中应变与应力的关系的曲线。

通常包括弹性阶段、屈服阶段、硬化阶段和断裂阶段。

弹性阶段是指材料在受到一定载荷后恢复到原始形状的阶段,即应变与应力成线性关系;屈服阶段是指材料在受到一定载荷后开始发生塑性变形的阶段,应力逐渐达到最大值;硬化阶段是指材料在屈服后应变继续增加的阶段;断裂阶段是指材料在达到一定应变后发生破裂的阶段。

了解应力应变曲线对于工程设计和材料选择至关重要,可以帮助工程师预测材料的性能和工件的耐久性,并为后续的仿真分析提供基础。

4. Abaqus中的应力应变曲线模拟在Abaqus中,模拟材料的应力应变曲线是一项复杂而又重要的任务。

c50混凝土abaqus参数C50混凝土Abaqus参数一、引言C50混凝土是一种常用的建筑材料,具有较高的强度和耐久性。

在使用C50混凝土进行结构分析时,可以使用ABAQUS软件来模拟其力学性能。

本文将介绍C50混凝土在ABAQUS中的参数设定和模拟方法。

二、C50混凝土的力学性能C50混凝土是指标号为C50的混凝土,其抗压强度为50MPa。

除了抗压强度外,C50混凝土还具有一系列力学性能,如抗拉强度、弹性模量、剪切强度等。

在ABAQUS中,我们可以通过设置一些参数来模拟C50混凝土的这些力学性能。

三、材料模型选择在ABAQUS中,我们可以选择不同的材料模型来模拟C50混凝土的力学行为。

常用的材料模型有弹性模型、各向同性塑性模型、本构模型等。

对于C50混凝土,通常采用本构模型来模拟其非线性行为。

ABAQUS中的本构模型包括弹塑性本构模型、本构弹塑性模型等,具体选择哪种模型需要根据具体问题和实验数据来决定。

四、材料参数设定在使用ABAQUS模拟C50混凝土之前,需要设置一些材料参数。

这些参数包括抗压强度、抗拉强度、弹性模量、泊松比、剪切强度等。

这些参数的设定需要参考实验数据或标准规范,确保模拟结果的准确性和可靠性。

五、加载方式设定在进行C50混凝土的力学性能模拟时,需要设定加载方式。

常见的加载方式有静态加载、动态加载等。

对于静态加载,可以设定加载速率和加载路径。

对于动态加载,可以设定加载频率和加载振幅等。

根据具体问题的要求,选择合适的加载方式和参数。

六、边界条件设定在进行C50混凝土的力学性能模拟时,需要设定边界条件。

边界条件包括约束条件和加载条件。

约束条件用于限制模型的位移和旋转,加载条件用于施加外部载荷。

根据具体问题的要求,设定合适的边界条件,确保模拟结果的准确性。

七、模拟结果分析在完成C50混凝土的力学性能模拟后,可以对模拟结果进行分析。

分析可以包括应力分布、应变分布、位移响应等。

通过分析模拟结果,可以评估C50混凝土的力学性能和结构的安全性,为实际工程提供参考依据。

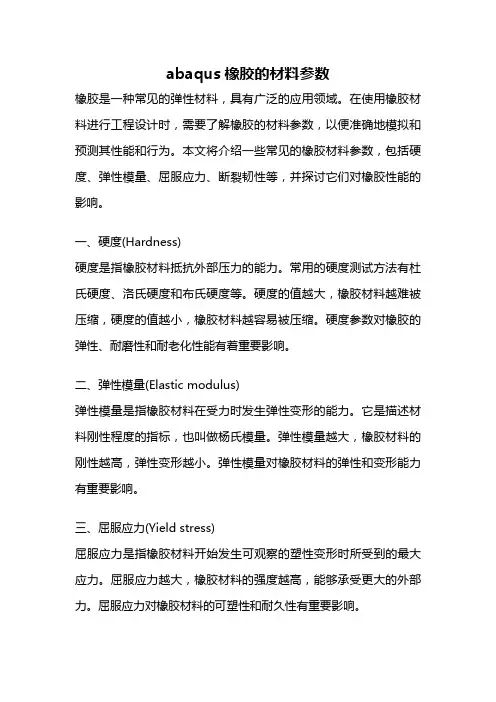

abaqus橡胶的材料参数橡胶是一种常见的弹性材料,具有广泛的应用领域。

在使用橡胶材料进行工程设计时,需要了解橡胶的材料参数,以便准确地模拟和预测其性能和行为。

本文将介绍一些常见的橡胶材料参数,包括硬度、弹性模量、屈服应力、断裂韧性等,并探讨它们对橡胶性能的影响。

一、硬度(Hardness)硬度是指橡胶材料抵抗外部压力的能力。

常用的硬度测试方法有杜氏硬度、洛氏硬度和布氏硬度等。

硬度的值越大,橡胶材料越难被压缩,硬度的值越小,橡胶材料越容易被压缩。

硬度参数对橡胶的弹性、耐磨性和耐老化性能有着重要影响。

二、弹性模量(Elastic modulus)弹性模量是指橡胶材料在受力时发生弹性变形的能力。

它是描述材料刚性程度的指标,也叫做杨氏模量。

弹性模量越大,橡胶材料的刚性越高,弹性变形越小。

弹性模量对橡胶材料的弹性和变形能力有重要影响。

三、屈服应力(Yield stress)屈服应力是指橡胶材料开始发生可观察的塑性变形时所受到的最大应力。

屈服应力越大,橡胶材料的强度越高,能够承受更大的外部力。

屈服应力对橡胶材料的可塑性和耐久性有重要影响。

四、断裂韧性(Fracture toughness)断裂韧性是指橡胶材料在断裂前能够吸收的能量。

它反映了材料抵抗断裂的能力。

断裂韧性越高,橡胶材料的耐冲击性和耐磨性越好。

断裂韧性对橡胶材料的使用寿命和可靠性有重要影响。

除了以上几个常见的橡胶材料参数外,还有一些其他的参数也对橡胶的性能和行为产生影响。

例如,温度对橡胶的弹性模量和硬度有显著影响。

随着温度的升高,橡胶材料的弹性模量和硬度会下降。

此外,橡胶的化学成分和配方也会对其性能产生重要影响。

不同种类的橡胶具有不同的化学成分和配方,因此其性能也有所差异。

橡胶的材料参数对其性能和行为有着重要的影响。

通过了解橡胶的硬度、弹性模量、屈服应力、断裂韧性等参数,可以更好地预测和控制橡胶的性能,从而满足工程设计的要求。

未来的研究可以进一步探索橡胶材料参数与其他因素的关系,以提高橡胶的性能和应用范围。

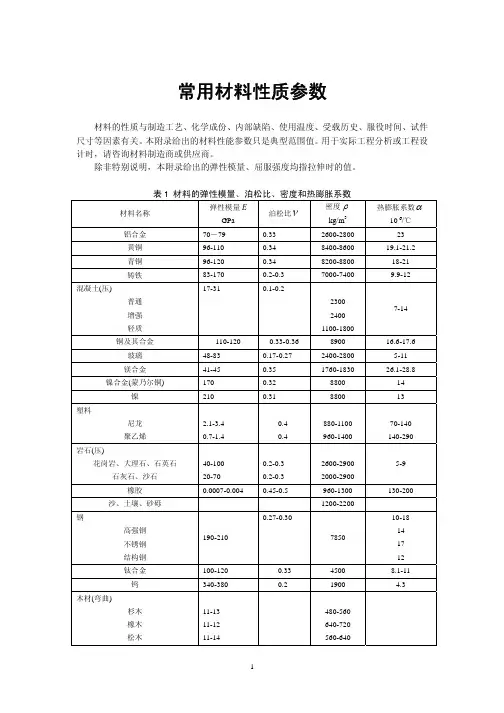

常用材料性质参数材料的性质与制造工艺、化学成份、内部缺陷、使用温度、受载历史、服役时间、试件尺寸等因素有关。

本附录给出的材料性能参数只是典型范围值。

用于实际工程分析或工程设计时,请咨询材料制造商或供应商。

除非特别说明,本附录给出的弹性模量、屈服强度均指拉伸时的值。

表1 材料的弹性模量、泊松比、密度和热膨胀系数材料名称弹性模量EGPa泊松比ν密度ρkg/m3热膨胀系数α10-6/℃铝合金 70-79 0.33 2600-2800 23 黄铜96-110 0.34 8400-8600 19.1-21.2 青铜96-120 0.34 8200-8800 18-21 铸铁83-170 0.2-0.3 7000-7400 9.9-12混凝土(压)普通增强轻质17-31 0.1-0.2230024001100-18007-14铜及其合金110-120 0.33-0.36 8900 16.6-17.6 玻璃48-83 0.17-0.272400-2800 5-11 镁合金41-45 0.35 1760-183026.1-28.8镍合金(蒙乃尔铜) 170 0.32 8800 14 镍210 0.31 8800 13 塑料尼龙聚乙烯2.1-3.40.7-1.40.40.4880-1100960-140070-140140-290岩石(压)花岗岩、大理石、石英石石灰石、沙石40-10020-700.2-0.30.2-0.32600-29002000-29005-9橡胶0.0007-0.004 0.45-0.5 960-1300 130-200 沙、土壤、砂砾1200-2200 钢高强钢不锈钢结构钢190-2100.27-0.30785010-18141712钛合金100-120 0.334500 8.1-11 钨340-380 0.2 1900 4.3 木材(弯曲)杉木橡木松木11-1311-1211-14480-560640-720560-640表2 材料的力学性能材料名称/牌号屈服强度sσMPa抗拉强度bσMPa伸长率5δ%备注铝合金LY12 35-500274100-5504121-4519 硬铝黄铜70-550 200-620 4-60 青铜82-690 200-830 5-60铸铁(拉伸) HT150HT250 120-290 69-4801502500-1铸铁(压缩) 340-1400混凝土(压缩) 10-70铜及其合金55-760 230-830 4-50玻璃平板玻璃玻璃纤维30-1000707000-20000镁合金80-280 140-340 2-20 镍合金(蒙乃尔铜) 170-1100 450-1200 2-50 镍100-620 310-760 2-50 塑料尼龙聚乙烯40-807-2820-10015-300岩石(压缩)花岗岩、大理石、石英石石灰石、沙石50-280 20-200橡胶1-7 7-20 100-800 普通碳素钢Q215 Q235 Q255 Q275 215235255275335~450375~500410~550490~63026~3121~2619~2415~20旧牌号A2旧牌号A3旧牌号A4旧牌号A5优质碳素钢25 35 45 55 2753153553804505306006452320161325号钢35号钢45号钢55号钢低合金钢15MnV 16Mn 390345530510182115锰钒16锰合金钢20Cr 40Cr 54078583598010920铬40铬30CrMnSi 88510801030铬锰硅铸钢ZG200-400 ZG270-500 2002704005002518钢线280-1000 550-1400 5-40钛合金760-1000 900-1200 10 钨 1400-40000-4 木材(弯曲)杉木橡木松木30-5030-4030-5040-7030-5040-70。

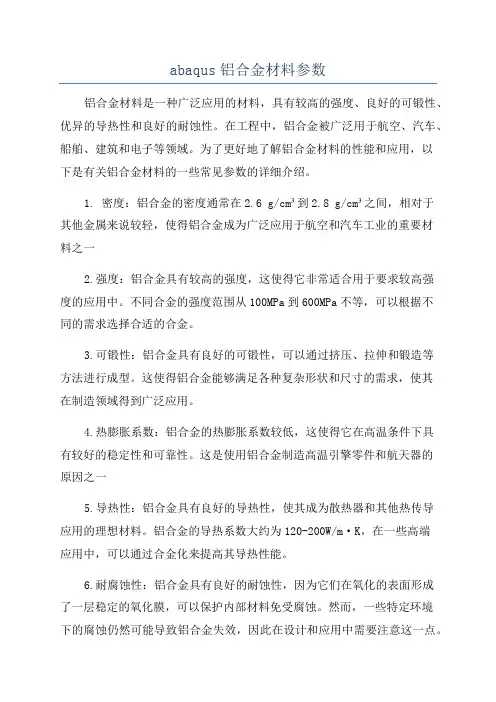

abaqus铝合金材料参数铝合金材料是一种广泛应用的材料,具有较高的强度、良好的可锻性、优异的导热性和良好的耐蚀性。

在工程中,铝合金被广泛用于航空、汽车、船舶、建筑和电子等领域。

为了更好地了解铝合金材料的性能和应用,以下是有关铝合金材料的一些常见参数的详细介绍。

1. 密度:铝合金的密度通常在2.6 g/cm³到2.8 g/cm³之间,相对于其他金属来说较轻,使得铝合金成为广泛应用于航空和汽车工业的重要材料之一2.强度:铝合金具有较高的强度,这使得它非常适合用于要求较高强度的应用中。

不同合金的强度范围从100MPa到600MPa不等,可以根据不同的需求选择合适的合金。

3.可锻性:铝合金具有良好的可锻性,可以通过挤压、拉伸和锻造等方法进行成型。

这使得铝合金能够满足各种复杂形状和尺寸的需求,使其在制造领域得到广泛应用。

4.热膨胀系数:铝合金的热膨胀系数较低,这使得它在高温条件下具有较好的稳定性和可靠性。

这是使用铝合金制造高温引擎零件和航天器的原因之一5.导热性:铝合金具有良好的导热性,使其成为散热器和其他热传导应用的理想材料。

铝合金的导热系数大约为120-200W/m·K,在一些高端应用中,可以通过合金化来提高其导热性能。

6.耐腐蚀性:铝合金具有良好的耐蚀性,因为它们在氧化的表面形成了一层稳定的氧化膜,可以保护内部材料免受腐蚀。

然而,一些特定环境下的腐蚀仍然可能导致铝合金失效,因此在设计和应用中需要注意这一点。

综上所述,铝合金具有较低的密度、良好的强度、可塑性和导热性,具有良好的耐蚀性,使其成为各种工业和制造应用的理想材料之一、在选择合适的铝合金材料时,需要根据具体应用的需求来考虑上述参数,并结合其他要素,如成本、加工性能和环境要求等进行综合评估。

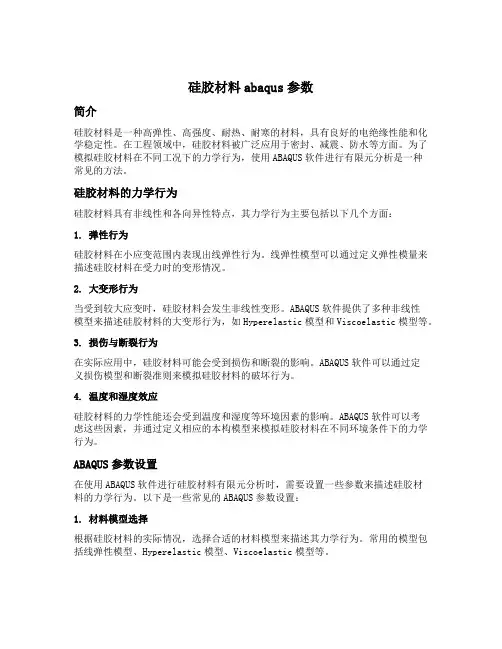

硅胶材料abaqus参数简介硅胶材料是一种高弹性、高强度、耐热、耐寒的材料,具有良好的电绝缘性能和化学稳定性。

在工程领域中,硅胶材料被广泛应用于密封、减震、防水等方面。

为了模拟硅胶材料在不同工况下的力学行为,使用ABAQUS软件进行有限元分析是一种常见的方法。

硅胶材料的力学行为硅胶材料具有非线性和各向异性特点,其力学行为主要包括以下几个方面:1. 弹性行为硅胶材料在小应变范围内表现出线弹性行为。

线弹性模型可以通过定义弹性模量来描述硅胶材料在受力时的变形情况。

2. 大变形行为当受到较大应变时,硅胶材料会发生非线性变形。

ABAQUS软件提供了多种非线性模型来描述硅胶材料的大变形行为,如Hyperelastic模型和Viscoelastic模型等。

3. 损伤与断裂行为在实际应用中,硅胶材料可能会受到损伤和断裂的影响。

ABAQUS软件可以通过定义损伤模型和断裂准则来模拟硅胶材料的破坏行为。

4. 温度和湿度效应硅胶材料的力学性能还会受到温度和湿度等环境因素的影响。

ABAQUS软件可以考虑这些因素,并通过定义相应的本构模型来模拟硅胶材料在不同环境条件下的力学行为。

ABAQUS参数设置在使用ABAQUS软件进行硅胶材料有限元分析时,需要设置一些参数来描述硅胶材料的力学行为。

以下是一些常见的ABAQUS参数设置:1. 材料模型选择根据硅胶材料的实际情况,选择合适的材料模型来描述其力学行为。

常用的模型包括线弹性模型、Hyperelastic模型、Viscoelastic模型等。

2. 材料参数定义根据选定的材料模型,需要定义相应的材料参数。

这些参数可以通过实验测试或者文献资料获取。

3. 边界条件设置在有限元分析中,需要给定合适的边界条件来模拟实际工况。

边界条件包括约束条件、加载方式等。

4. 网格划分为了准确地模拟硅胶材料的力学行为,需要对模型进行合理的网格划分。

网格划分应该考虑到硅胶材料的几何形状和力学特性。

5. 求解器选择ABAQUS软件提供了多种求解器来求解有限元分析问题。

Department of EngineeringUniversity of Cambridge? ? Engineering Department? ? computing helpABAQUS Materials Input5. ABAQUS - MaterialsQ5.1 : How do I find what material properties are needed for a particular analysis ?Read the relevant section in Chapter 6 : Analysis Procedures User's manual Vol. I . This gives an overview about the analysis and has more information about the material properties.Read also the following sections in Chapter 17 : Materials Introduction of the ABAQUS User's manual.Section - Material Library : OverviewSection - Material Data DefinitionSection - Combining Material PropertiesSection lists the material model combination tables. Several models are available to define the mechanical behaviour elastic, plastic .Some material options require the presence of other material options. Some exclude the use of the other material options. For example *DEFORMATION PLASTICITY completely defines the material's mechanicalbehaviour and should not be used with *ELASTIC.Once you have all the relevant keywords to define the material properties consult the keyword Manual for each of the keywords. This will explain what data is required for each of the keyword.Q5.2 : What material properties need to be specified in a thermal-electrical analysis ?Referring to Section of the ABAQUS User's manual you will require the heat transfer properties as well as the electrical properties. These are listed below :Heat Transfer properties*CONDUCTIVITY*LATENT HEAT*SPECIFIC HEAT*HEAT GENERATIONElectrical properties*DIELECTRIC*ELECTRICAL CONDUCTIVITY*JOULE HEAT FRACTION*PIEZOELECTRICThis forms the complete set of properties. If Piezoelectric elements are not used then *PIEZOELECTRIC and *DIELECTRIC properties will not be required.If only the steady state heat transfer response is of interest then *SPECIFIC HEAT properties are not required. Similarly if there are no phase changes involved then *LATENT HEAT is not required.*JOULE HEAT FRACTION is used to specify the fraction of electrical energy that will be released as heat.Example problem - thermal-electrical modelling of an automotive fuse illustrates the thermal-electrical analysis.ABAQUS allows for redundant material properties to be specified. It will simply ignore the material properties not required for the current analysis.Typical example of material properties :*MATERIAL, NAME ZINC*CONDUCTIVITY0.1121, 20.00.1103, 100.0*ELECTRICAL CONDUCTIVITY16.75E3, 20.012.92E3, 100.0*JOULE HEAT FRACTION1.0*DENSITY7.14E-6*SPECIFIC HEAT389.0Q5.3 : What material properties need to be specified in an analysis using temperature- displacement elements ?Referring to Section of the ABAQUS User's manual you will require the heat transfer properties as well as the mechanical properties. These are listed below :Mechanical properties*ELASTICAdditional properties which may be required : example plasticHeat Transfer properties*CONDUCTIVITY*LATENT HEAT*SPECIFIC HEAT*HEAT GENERATIONQ5.4 : What material properties need to be specified in an analysis using piezoelectric elements?Referring to Section of the ABAQUS User's manual you will require the electrical properties. These are listed below :Electrical properties*DIELECTRIC*ELECTRICAL CONDUCTIVITY*JOULE HEAT FRACTION*PIEZOELECTRICQ5.5 : What material properties need to be specified in modeling concrete with reinforcements?Use the concrete model available with rebar to model the reinforcements.Section of the ABAQUS Example's manual gives an example of the collapse analysis of a concrete slab subjected to a central point load.The data file for that example is collapse example.The complete set of ABAQUS input files can be obtained by using the following command :abaqus fetch j collapseconcslab**CONCRETE3000., 0. abs. value of compressive stress, abs. value of plastic strain.5500., 0.0015 " "*FAILURE RATIOS1.16, 0.0836This is used to define the shape of the failure surface see section of the ABAQUS USER's manual Vol. II .The first parameter is the ratio of the ultimate biaxial compression stress, to the uniaxial compressive stress. Default is 1.16.The second parameter is the absolute value of the ratio of uniaxial tensile stress at failure to the uniaxial compressive stress at failure. Default is 0.09.Tension Stiffening*TENSION STIFFENING1., 0.0., 2.E-3First parameter is the fraction of remaining stress to stress at cracking. The second parameter is the absolute value of the direct strain minus the direct strain at cracking.This defines the retained tensile stress normal to the crack as a function of the deformation in the direction of the normal to the crack.Shear Retention*SHEAR RETENTIONNot used for this example.Reinforcement modelling*REBAR is used to model the reinforcement.*REBAR,ELEMENT SHELL,MATERIAL SLABMT,GEOMETRY ISOPARAMETRIC,NAME YY SLAB, 0.014875, 1., -0.435, 4*REBAR,ELEMENT SHELL,MATERIAL SLABMT,GEOMETRY ISOPARAMETRIC,NAME XX SLAB, 0.014875, 1., -0.435, 1Here SLAB is the element name or name of the element set that containsthese rebars. The geometry is ISOPARAMETRIC. Other choice is SKEW. ELEMENT can be BEAM, SHELL, AXISHELL or CONTINUUM type. The following are the other parameters specified :cross-sectional area of the rebar.spacing of the rebars in the plane of the shellposition of the rebar. Distance from the reference surface. Here the mid-surface is the reference surface and the minus sign indicates that the distance is measured in the opposite direction to the direction of positive normal. The positive normal is defined by the right hand rule as the nodes are considered in an anti-clockwise sequence.edge number to which rebars are similar.Alternate Method o modelling REBAR ReinforcementsAlternatively REBAR can be modelled as follows :*NODE........**501, 0.0, 0.15, -0.02541, 1.5, 0.15, -0.02601, 0.0, 0.15, -0.07641, 1.5, 0.15, -0.07701, 0.0, 0.60, -0.02741, 1.5, 0.60, -0.02 801, 0.0, 0.60, -0.07 841, 1.5, 0.60, -0.07 ........***NGEN, NSET BAR10TF701, 741, 2*NGEN, NSET BAR10TB801, 841, 2......***ELEMENT, TYPE B31701, 701, 703801, 801, 803*ELGEN, ELSET BAR10TF701, 20, 2, 1, 1, 1, 1*ELGEN, ELSET BAR10TB801, 20, 2, 1, 1, 1, 1......*MATERIAL, NAME BAR8**** 8 mm dia bar***ELASTIC, TYPE ISO197.E6, 0.3*PLASTIC354.E3, 0.364.E3, 0.0018****......*BEAM SECTION, SECTION CIRC, MATERIAL BAR10, ELSET BAR10TF 0.005*BEAM SECTION, SECTION CIRC, MATERIAL BAR10, ELSET BAR10TB 0.005...*******ELSET, ELSET TOP, GENERATE5, 80, 5*****EMBEDDED ELEMENT,HOST ELSET TOPBAR10TF,BAR10TB**Q5.6 : What material properties need to be specified in using the deformation plasticity model ?See section of the users' manual Vol. II . See also section of the users' manual Vol. III , keyword section.For example :*DEFORMATION PLASTICITY1.E3, 0.3,2., 3, 0.396Here the data line contains the Young's modulus, Poissons ratio, Yield stress, Exponent, Yield offset respectively. If it is necessary to define the dependence of these parameters on temperature then the 6th parameter will be the temperature. Then repeat the dataline for different temperatures as required.| Computing Help |[Finite Elements] | [Engineering Packages]Cambridge University Engineering DeptInformation provided by Arul M Britto amb2 Last updated: 28 September 2010。

硅胶材料abaqus参数

(实用版)

目录

1.硅胶材料的概述

2.ABAQUS 软件的简介

3.硅胶材料的 ABAQUS 参数

4.ABAQUS 参数对硅胶材料性能的影响

5.结论

正文

一、硅胶材料的概述

硅胶材料是一种由硅、氧、氢等元素组成的有机硅化合物,具有优异的耐高、低温、耐候性、憎水、电气绝缘性、生理惰性等特点。

在国防军工、医疗卫生、工农业生产及人们的日常生活中获得了广泛应用。

二、ABAQUS 软件的简介

ABAQUS 是一种国际知名的大型通用有限元分析软件,广泛应用于各种工程领域,如航空航天、汽车制造、能源、建筑等。

该软件可进行线性或非线性结构分析、热传导分析、热膨胀分析、动力学分析等。

三、硅胶材料的 ABAQUS 参数

在 ABAQUS 中,硅胶材料的参数主要包括以下几点:

1.材料类型:硅胶材料通常分为热硫化硅橡胶(HTV)和室温硫化硅橡胶(RTV)两大类。

2.材料属性:包括弹性模量、泊松比、密度、热膨胀系数等。

3.边界条件:包括施加的载荷、约束条件等。

4.加载方式:包括静态加载和动态加载。

四、ABAQUS 参数对硅胶材料性能的影响

ABAQUS 参数的设置对硅胶材料的性能分析具有重要影响。

例如,不同的材料类型和属性设置会影响硅胶材料的力学性能、热传导性能等;不同的边界条件和加载方式会影响硅胶材料的应力、应变、位移等分析结果。

五、结论

本文对硅胶材料的 ABAQUS 参数进行了简要介绍,并探讨了参数设置对硅胶材料性能分析的影响。

【文章】abaqus材料阻尼比参数含义1. 引言在工程领域中,材料的阻尼比是一个非常重要的参数,它对结构的振动特性和动态响应有着重要影响。

在使用abaqus软件进行结构分析和仿真时,对材料的阻尼比参数进行准确理解和设定是至关重要的。

本文将从深度和广度两个方面全面评估abaqus材料阻尼比参数的含义,并根据此进行撰写有价值的文章。

2. abaqus材料阻尼比参数含义的深度探讨abaqus中的材料阻尼比参数指的是在结构振动分析中描述材料内部耗散能力的一个重要参数。

阻尼比越大,表示材料的能量耗散能力越强,振动衰减的速度越快。

在abaqus中,阻尼比参数通常用来描述材料在动态载荷作用下的振动特性,是与材料的内部结构和分子运动状态密切相关的一个参数。

3. abaqus材料阻尼比参数含义的广度探讨阻尼比参数在abaqus中有着广泛的应用,涉及到多个领域和行业。

在工程结构分析中,正确理解和设置材料阻尼比参数可以更准确地预测结构的动态响应和振动特性。

在地震工程中,材料阻尼比参数的设定对结构的抗震性能有着重要的影响。

在航空航天领域,材料阻尼比参数也是飞行器动力学分析和设计中不可或缺的重要参数。

4. 回顾与总结通过深度和广度的探讨,我们对abaqus材料阻尼比参数的含义有了更为全面和深入的理解。

在结构分析和仿真中,正确理解和设置材料阻尼比参数对于准确预测结构的振动特性和动态响应至关重要。

我们也认识到材料阻尼比参数在工程领域中有着广泛的应用,涉及到多个行业和领域的工程实践和研究。

深入理解abaqus材料阻尼比参数的含义对于提高工程设计和分析的准确性和可靠性具有重要意义。

5. 个人观点与理解作为一个工程师,我深知材料阻尼比参数的重要性。

在结构分析和设计中,我经常需要对abaqus中的材料阻尼比参数进行设置和调整。

通过学习和使用,我认识到正确理解并准确设置材料阻尼比参数对于工程实践具有重要意义。

我也意识到材料阻尼比参数的含义和作用并不局限于结构领域,而是涉及到更广泛的工程应用和研究领域。

abaqus的材料参数Department of Engineering University of Cambridge > Engineering Department > computing helpABAQUS Materials Input1. 5. ABAQUS - Materials2. Q5.1 : How do I find what material properties are needed for a particular analysis ?Read the relevant section in Chapter 6 : Analysis Procedures (User's manual Vol. I). This gives an overview about the analysis and has more information about the material properties.Read also the following sections in Chapter 17 : Materials Introduction of the ABAQUS User's manual.Section 17.1.1 - Material Library : OverviewSection 17.1.2 - Material Data DefinitionSection 17.1.3 - Combining Material PropertiesSection 17.1.3 lists the material model combination tables. Several models are available to define the mechanical behaviour (elastic, plastic).Some material options require the presence of other material options. Some exclude the use of the other material options. For example *DEFORMATION PLASTICITY completely defines the material's mechanical behaviour and should not be used with *ELASTIC.Once you have all the relevant keywords to define the material properties consult the keyword Manual for each of the keywords. This will explain what data is required for each of the keyword.3. Q5.2 : What material properties need to be specified in a thermal-electrical analysis ?Referring to Section 17.1.3 of the ABAQUS User's manual you will require the heat transfer properties as well as the electrical properties. These are listed below :Heat Transfer properties*CONDUCTIVITY*LATENT HEAT*SPECIFIC HEAT*HEAT GENERATIONElectrical properties*DIELECTRIC*ELECTRICAL CONDUCTIVITY*JOULE HEAT FRACTION*PIEZOELECTRICThis forms the complete set of properties. If Piezoelectric elements are not used then*PIEZOELECTRIC and *DIELECTRIC properties will not be required.If only the steady state heat transfer response is of interest then *SPECIFIC HEAT properties are not required. Similarly if there are no phase changes involved then *LATENT HEAT is not required.*JOULE HEAT FRACTION is used to specify the fraction of electrical energy that will be released as heat.Example problem 5.2.1 - thermal-electrical modelling of an automotive fuse illustrates the thermal-electrical analysis. ABAQUS allows for redundant material properties to be specified. It will simply ignore the material properties not required for the current analysis.Typical example of material properties :*MATERIAL, NAME=ZINC*CONDUCTIVITY0.1121, 20.00.1103, 100.0*ELECTRICAL CONDUCTIVITY16.75E3, 20.012.92E3, 100.0*JOULE HEAT FRACTION1.0*DENSITY7.14E-6*SPECIFIC HEAT389.04. Q5.3 : What material properties need to be specified in an analysis using temperature- displacement elements ?Referring to Section 17.1.3 of the ABAQUS User's manual you will require the heat transfer properties as well as the mechanical properties. These are listed below :Mechanical properties*ELASTICAdditional properties which may be required : example plastic Heat Transfer properties*CONDUCTIVITY*LATENT HEAT*SPECIFIC HEAT*HEAT GENERATION5. Q5.4 : What material properties need to be specified in an analysis using piezoelectric elements?Referring to Section 9.1.3 of the ABAQUS User's manual you will require the electrical properties. These are listed below : Electrical properties*DIELECTRIC*ELECTRICAL CONDUCTIVITY*JOULE HEAT FRACTION*PIEZOELECTRIC6. Q5.5 : What material properties need to be specified in modeling concrete with reinforcements?Use the concrete model available with rebar to model the reinforcements.Section 1.1.5 of the ABAQUS Example's manual gives an example of the collapse analysis of a concrete slab subjected to a central point load.The data file for that example is collapse example.The complete set of ABAQUS input files can be obtained by using the following command :abaqus fetch j=collapseconcslab**CONCRETE3000., 0. abs. value of compressive stress, abs. value of plastic strain. 5500., 0.0015 " "*FAILURE RATIOS1.16, 0.0836This is used to define the shape of the failure surface (see section 11.5.1 of the ABAQUSUSER's manual Vol. II).The first parameter is the ratio of the ultimate biaxial compression stress, to the uniaxial compressive stress. Default is 1.16. The second parameter is the absolute value of the ratio of uniaxial tensile stress at failure to the uniaxial compressive stress at failure. Default is 0.09.7. Tension Stiffening*TENSION STIFFENING1., 0.0., 2.E-3First parameter is the fraction of remaining stress to stress at cracking. The second parameter is the absolute value of the direct strain minus the direct strain at cracking.This defines the retained tensile stress normal to the crack as a function of the deformation in the direction of the normal to the crack.8. Shear Retention*SHEAR RETENTIONNot used for this example.9. Reinforcement modelling*REBAR is used to model the reinforcement.*REBAR,ELEMENT=SHELL,MATERIAL=SLABMT,GEOMETRY=ISOPARAMETRIC,NAME=YYSLAB, 0.014875, 1., -0.435, 4*REBAR,ELEMENT=SHELL,MATERIAL=SLABMT,GEOMETRY=ISOPARAMETRIC,NAME=XXSLAB, 0.014875, 1., -0.435, 1Here SLAB is the element name or name of the element set that contains these rebars. The geometry is ISOPARAMETRIC. Other choice is SKEW. ELEMENT can be BEAM, SHELL, AXISHELL or CONTINUUM type. The following are the other parameters specified :cross-sectional area of the rebar.spacing of the rebars in the plane of the shellposition of the rebar. Distance from the reference surface. Here the mid-surface is the reference surface and the minus sign indicates that the distance is measured in theopposite direction to the direction of positive normal. The positive normal is defined by the right hand rule as the nodes are considered in an anti-clockwise sequence.edge number to which rebars are similar.10. Alternate Method o modelling REBAR ReinforcementsAlternatively REBAR can be modelled as follows :*NODE........**-------------------END NODES FOR REBAR BEAM ELEMENTS501, 0.0, 0.15, -0.02541, 1.5, 0.15, -0.02601, 0.0, 0.15, -0.07641, 1.5, 0.15, -0.07701, 0.0, 0.60, -0.02741, 1.5, 0.60, -0.02801, 0.0, 0.60, -0.07841, 1.5, 0.60, -0.07........**---------------------GENERATE INTERMEDIATE NODES*NGEN, NSET=BAR10TF701, 741, 2*NGEN, NSET=BAR10TB801, 841, 2......**--------------------GENERATE THE BEAM ELEMENTS*ELEMENT, TYPE=B31701, 701, 703801, 801, 803*ELGEN, ELSET=BAR10TF701, 20, 2, 1, 1, 1, 1*ELGEN, ELSET=BAR10TB801, 20, 2, 1, 1, 1, 1......**---------------------DEFINE THE MATERIAL PROPERTIES*MATERIAL, NAME=BAR8**** 8 mm dia bar***ELASTIC, TYPE=ISO197.E6, 0.3*PLASTIC354.E3, 0.364.E3, 0.0018****---------------------DEFINE THE SECTION PROPERTIES......*BEAM SECTION, SECTION=CIRC, MATERIAL=BAR10, ELSET=BAR10TF0.005*BEAM SECTION, SECTION=CIRC, MATERIAL=BAR10, ELSET=BAR10TB0.005...**--------------------DEFINE AN ELEMENT SET WHICH CONTAINS**--------------------THE ELEMENTS THROUGH WHICH THE REBAR**--------------------ELEMENTS PASSES.....*ELSET, ELSET=TOP, GENERATE5, 80, 5****--------------------*EMBEDDED ELEMENT,HOST ELSET=TOPBAR10TF,BAR10TB**11. Q5.6 : What material properties need to be specified in using the deformation plasticity model ?See section 11.2.11 of the users' manual (Vol. II). See also section 23.4.7 of the users' manual (Vol. III), keyword section.For example :*DEFORMATION PLASTICITY1.E3, 0.3,2., 3, 0.396Here the data line contains the Young's modulus, Poissons ratio, Yield stress, Exponent, Yield offset respectively. If it is necessary to define the dependence of these parameters on temperature then the 6th parameter will be the temperature. Then repeat the dataline for different temperatures as required.| Computing Help |[Finite Elements] | [Engineering Packages]Cambridge University Engineering DeptInformation provided by Arul M Britto (amb2)Last updated: 28 September 2010。

Material Name and Condition. Density Yng's Poisslb/in^3 Modul Ratio Strs S msi ksi k acrylic lucite 0.0430 0.43 0.400 6.0 1 aluminum pure 99.996 annealed 0.0970 10.00 0.330 1.8 aluminum pure 99.45-o condition 0.0980 10.00 0.330 4.0 1 aluminum pure-h12 sheet 0.0980 10.00 0.330 12.0 1 aluminum pure-h16 sheet 0.0980 10.00 0.330 16.0 1 aluminum 1060-o sheet 0.0980 10.00 0.330 4.0 1 aluminum 1060-h12 sheet 0.0980 10.00 0.330 11.0 1 aluminum 1060-h18 sheet 0.0980 10.00 0.330 18.0 1 aluminum 1100-o sheet 0.0980 10.00 0.330 5.0 1 aluminum 1100-h14 sheet 0.0980 10.00 0.330 17.0 1 aluminum 1100-h18 sheet 0.0980 10.00 0.330 26.0 2 aluminum 2011-t3 bar 0.1020 10.20 0.330 43.0 5 aluminum 2011-t8 bar 0.1020 10.20 0.330 45.0 5 aluminum 2014-o bar 0.1010 10.60 0.330 14.0 2 aluminum 2014-t6 sheet 0.1010 10.60 0.330 68.0 7 aluminum 2014-t651 0.1010 10.60 0.330 63.5 6 aluminum 2017-o bar 0.1010 10.50 0.330 10.0 2 aluminum 2017-t4 bar 0.1010 10.50 0.330 40.0 6 aluminum 2021-o sheet 0.1030 10.70 0.330 10.0 2 aluminum 2021-t31 sheet 0.1030 10.70 0.330 40.0 6 aluminum 2021-t81 plate 0.1030 10.70 0.330 63.0 7 aluminum 2021-t8151 0.1030 10.70 0.330 66.6 7 aluminum 2024-o sheet 0.1000 10.60 0.330 11.0 2 aluminum 2024-t3 sheet 0.1000 10.60 0.330 51.0 6 aluminum 2024-t4 sheet 0.1000 10.60 0.330 47.0 6 aluminum 2024-t851 plate 0.1000 10.60 0.330 68.0 7 aluminum 2025-t6 plate 0.1010 10.40 0.330 37.0 5 aluminum 2219-o sheet 0.1020 10.60 0.330 11.0 2 aluminum 2219-t31 sheet 0.1020 10.60 0.330 45.0 5 aluminum 2219-t62 sheet 0.1020 10.60 0.330 39.0 5 aluminum 2219-t851 sheet 0.1020 10.60 0.330 51.0 6 aluminum 2219-t851 0.1020 10.60 0.330 53.8 6 aluminum 2618-t6 sheet 0.1000 10.50 0.330 56.0 6 aluminum 3003-o sheet 0.0990 10.00 0.330 6.0 1 aluminum 3003-h12 sheet 0.0990 10.00 0.330 18.0 1 aluminum 3003-h14 0.0990 10.00 0.330 21.1 2 aluminum 3003-h18 sheet 0.0990 10.00 0.330 27.0 2 aluminum 3004-o sheet 0.0980 10.00 0.330 10.0 2 aluminum 3004-h32 sheet 0.0980 10.00 0.330 25.0 3 aluminum 3004-h34 sheet 0.0980 10.00 0.330 29.0 3 aluminum 3004-h38 sheet 0.0980 10.00 0.330 36.0 4 aluminum 4032-t6 0.0970 11.40 0.330 46.0 5 aluminum 5050-o sheet 0.0970 10.00 0.330 8.0 2 aluminum 5050-h32 sheet 0.0970 10.00 0.330 21.0 2aluminum 5050-h38 sheet 0.0970 10.00 0.330 29.0 3 aluminum 5052-o sheet 0.0970 10.20 0.330 13.0 2 aluminum 5052-o 0.0970 10.20 0.330 12.0 2 aluminum 5052-h34 sheet 0.0970 10.20 0.330 31.0 3 aluminum 5052-h38 sheet 0.0970 10.20 0.330 38.0 4 aluminum 5083-o sheet 0.0960 10.30 0.330 22.0 4 aluminum 5083-o 0.0960 10.30 0.330 20.4 4 aluminum 5083-h12 sheet 0.0960 10.30 0.330 44.0 5 aluminum 5083-h32 sheet 0.0960 10.30 0.330 38.0 5 aluminum 5083-h34 sheet 0.0960 10.30 0.330 45.0 5 aluminum 5083-h321 0.0960 10.30 0.330 34.1 4 aluminum 5086-o sheet 0.0960 10.30 0.330 19.0 4 aluminum 5086-o 0.0960 10.30 0.330 17.0 3 aluminum 5086-h32 plate 0.0960 10.30 0.330 30.0 4 aluminum 5086-h34 sheet 0.0960 10.30 0.330 38.0 5 aluminum 5086-h34 plate 0.0960 10.30 0.330 38.0 5 aluminum 5154-o sheet 0.0960 10.20 0.330 16.0 3 aluminum 5154-h32 sheet 0.0960 10.20 0.330 31.0 4 aluminum 5154-h34 sheet 0.0960 10.20 0.330 38.0 4 aluminum 5154-h38 sheet 0.0960 10.20 0.330 43.0 4 aluminum 5454-o sheet 0.0970 10.20 0.330 16.0 3 aluminum 5454-o 0.0970 10.20 0.330 16.7 3 aluminum 5454-h32 sheet 0.0970 10.20 0.330 32.0 4 aluminum 5454-h32 0.0970 10.20 0.330 28.9 4 aluminum 5454-h34 sheet 0.0970 10.20 0.330 40.0 4 aluminum 5454-h32 plate 0.0970 10.20 0.330 38.0 4 aluminum 5456-o sheet 0.0960 10.30 0.330 25.0 4 aluminum 5456-o 0.0960 10.30 0.330 23.2 4 aluminum 5456-h24 sheet 0.0960 10.30 0.330 41.0 5 aluminum 5456-h321 sheet 0.0960 10.30 0.330 37.0 5 aluminum 5456-h321 plate 0.0960 10.30 0.330 34.0 5 aluminum 6061-o sheet 0.0980 10.00 0.330 8.0 1 aluminum 6061-t6 sheet thick 0.0980 10.00 0.330 41.0 4 aluminum 6061-t6 sheet thin 0.0980 10.00 0.330 43.0 4 aluminum 6061-t6 0.0980 10.00 0.330 42.2 4 aluminum 6061-t651 plate 0.0980 10.00 0.330 39.0 4 aluminum 6063-o sheet 0.0980 10.00 0.330 7.0 1 aluminum 6063-t4 sheet 0.0980 10.00 0.330 13.0 2 aluminum 6063-t6 sheet 0.0980 10.00 0.330 31.0 3 aluminum 6063-t6 0.0980 10.00 0.330 31.0 3 aluminum 6063-t832 sheet 0.0980 10.00 0.330 39.0 4 aluminum 6066-o sheet 0.0980 10.00 0.330 12.0 2 aluminum 6066-t4 sheet 0.0980 10.00 0.330 30.0 5 aluminum 6066-t6 sheet 0.0980 10.00 0.330 51.0 5 aluminum x7005-o sheet 0.1010 10.30 0.330 12.0 2 aluminum x7005-t6 sheet 0.1010 10.30 0.330 46.0 5aluminum 7039-o sheet 0.1010 10.10 0.330 15.0 3 aluminum 7039-t6 sheet 0.1010 10.10 0.330 55.0 6 aluminum 7039-t61 plate 0.1010 10.10 0.330 48.0 5 aluminum 7049-t73 die forgings 0.1020 10.20 0.330 61.0 7 aluminum 7049-t73511 extrusions 0.1020 10.20 0.330 62.0 7 aluminum 7049-t75511 extrusions 0.1020 10.20 0.330 69.0 7 aluminum 7050-t73652 hand forging 0.1010 10.30 0.330 60.0 7 aluminum 7050-t736 die forgings 0.1010 10.30 0.330 60.0 7 aluminum 7075-o sheet 0.1010 10.30 0.330 15.0 3 aluminum 7075-t6 sheet 0.1010 10.30 0.330 76.0 8 aluminum 7075-t651 plate 0.1010 10.40 0.330 76.0 8 aluminum 7075-t73 sheet 0.1010 10.30 0.330 63.0 7 aluminum 7076-t61 0.1020 9.70 0.330 60.0 7 aluminum 7079-o sheet 0.0990 10.40 0.330 15.0 3 aluminum 7079-t6 sheet 0.0990 10.40 0.330 70.0 7 aluminum 7079-t651 plate 0.0990 10.40 0.330 77.0 8 aluminum 7178-o sheet 0.1020 10.40 0.330 15.0 3 aluminum 7178-t6 sheet 0.1020 10.40 0.330 75.0 8 aluminum 7178-t76 plate 0.1020 10.20 0.330 72.0 8 aluminum 7178-t651 plate 0.1020 10.40 0.330 84.0 9 aluminum wrought 1060 o 0.0980 10.00 0.330 4.0 1 aluminum wrought 1060 h14 0.0980 10.00 0.330 13.0 1 aluminum wrought 1060 h18 0.0980 10.00 0.330 18.0 1 aluminum wrought 1100 o 0.0980 10.00 0.330 5.0 1 aluminum wrought 1100 h14 0.0980 10.00 0.330 17.0 1 aluminum wrought 1100 h18 0.0980 10.00 0.330 22.0 2 aluminum wrought 1350 o 0.0980 10.00 0.330 4.0 1 aluminum wrought 1350 h19 0.0980 10.00 0.330 24.0 2 aluminum wrought 2011 t3 0.1090 10.20 0.330 43.0 5 aluminum wrought 2011 t8 0.1090 10.20 0.330 45.0 5 aluminum wrought 2014 o 0.1010 10.60 0.330 14.0 2 aluminum wrought 2014 t6 0.1010 10.60 0.330 68.0 7 aluminum wrought 2017 o 0.1010 10.50 0.330 10.0 2 aluminum wrought 2017 t4 0.1010 10.50 0.330 40.0 6 aluminum wrought 2024 o 0.1010 10.60 0.330 11.0 2 aluminum wrought 2024 t3 0.1010 10.60 0.330 50.0 7 aluminum wrought 2024 t4 or t351 0.1010 10.60 0.330 47.0 6 aluminum wrought 2024 t361 0.1010 10.60 0.330 57.0 7 aluminum wrought 2036 t4 0.1000 10.30 0.330 28.0 4 aluminum wrought 2219 o 0.1030 10.60 0.330 11.0 2 aluminum wrought 2219 t31 or t351 0.1030 10.60 0.330 36.0 5 aluminum wrought 2219 t81 or t851 0.1030 10.60 0.330 51.0 6 aluminum wrought 3003 o 0.0990 10.00 0.330 6.0 1 aluminum wrought 3003 h12 0.0990 10.00 0.330 18.0 1 aluminum wrought 3003 h14 0.0990 10.00 0.330 21.0 2 aluminum wrought 3003 h18 0.0990 10.00 0.330 27.0 2aluminum wrought 3004 h32 0.0980 10.00 0.330 25.0 3 aluminum wrought 3004 h34 0.0980 10.00 0.330 29.0 3 aluminum wrought 3004 h38 0.0980 10.00 0.330 36.0 4 aluminum wrought 3105 o 0.0980 10.00 0.330 8.0 1 aluminum wrought 3105 h14 0.0980 10.00 0.330 22.0 2 aluminum wrought 3105 h18 0.0980 10.00 0.330 28.0 3 aluminum wrought 3105 h25 0.0980 10.00 0.330 23.0 2 aluminum wrought 4032 t6 0.0970 11.40 0.330 46.0 5 aluminum wrought 5005 o 0.0980 10.00 0.330 6.0 1 aluminum wrought 5005 h14 0.0980 10.00 0.330 22.0 2 aluminum wrought 5005 h18 0.0980 10.00 0.330 28.0 2 aluminum wrought 5005 h38 0.0980 10.00 0.330 27.0 2 aluminum wrought 5050 o 0.0970 10.00 0.330 8.0 2 aluminum wrought 5050 h34 0.0970 10.00 0.330 24.0 2 aluminum wrought 5050 h38 0.0970 10.00 0.330 29.0 3 aluminum wrought 5052 o 0.0970 10.20 0.330 13.0 2 aluminum wrought 5052 h34 0.0970 10.20 0.330 31.0 3 aluminum wrought 5052 h38 0.0970 10.20 0.330 37.0 4 aluminum wrought 5083 o 0.0960 10.30 0.330 21.0 4 aluminum wrought 5083 h321 or h116 0.0960 10.30 0.330 33.0 4 aluminum wrought 5086 0 0.0960 10.30 0.330 17.0 3 aluminum wrought 5086 h32 or h116 0.0960 10.30 0.330 30.0 4 aluminum wrought 5154 o 0.0960 10.20 0.330 17.0 3 aluminum wrought 5154 h34 0.0960 10.20 0.330 33.0 4 aluminum wrought 5154 h38 0.0960 10.20 0.330 39.0 4 aluminum wrought 5252 h25 0.0960 10.00 0.330 25.0 3 aluminum wrought 5454 o 0.0970 10.20 0.330 17.0 3 aluminum wrought 5454 h32 0.0970 10.20 0.330 30.0 4 aluminum wrought 5454 h34 0.0970 10.20 0.330 35.0 4 aluminum wrought 5456 o 0.0960 10.30 0.330 23.0 4 aluminum wrought 5456 h24 0.0960 10.30 0.330 41.0 5 aluminum wrought 5456 h34 0.0960 10.30 0.330 37.0 5 aluminum wrought 5657 h25 0.0970 10.00 0.330 20.0 2 aluminum wrought 5657 h38 or h28 0.0970 10.00 0.330 24.0 2 aluminum wrought 6061 o 0.0980 10.00 0.330 8.0 1 aluminum wrought 6061 t451 0.0980 10.00 0.330 21.0 3 aluminum wrought 6061 t651 0.0980 10.00 0.330 40.0 4 aluminum wrought 6063 o 0.0970 10.00 0.330 7.0 1 aluminum wrought 6063 t4 0.0970 10.00 0.330 13.0 2 aluminum wrought 6063 t6 0.0970 10.00 0.330 31.0 3 aluminum wrought 6066 o 0.0980 10.00 0.330 12.0 2 aluminum wrought 6066 t4 0.0980 10.00 0.330 30.0 5 aluminum wrought 6066 t6 0.0980 10.00 0.330 52.0 5 aluminum wrought 6101 t6 0.0970 10.00 0.330 28.0 3 aluminum wrought 7001 o 0.1030 10.30 0.330 22.0 3 aluminum wrought 7001 t6 0.1030 10.30 0.330 91.0 9aluminum wrought 7075 t6 or t651 0.1010 10.30 0.330 73.0 8 aluminum wrought 7075 t73 0.1010 10.30 0.330 63.0 7 aluminum wrought 7178 o 0.1020 10.40 0.330 15.0 3 aluminum wrought 7178 t6 or t651 0.1020 10.40 0.330 78.0 8 aluminum wrought 7178 t76 or t7651 0.1020 10.40 0.330 73.0 8 beryllium s-65 0.0670 42.00 0.029 30.0 4 beryllium s-200f 0.0670 42.00 0.029 35.0 4 beryllium 1319 0.0670 42.00 0.029 35.0 5 beryllium 1162 0.0670 42.00 0.029 25.0 3 beryllium qmv 0.0670 42.00 0.029 30.0 5 beryllium-copper 10 dead soft 0.3190 20.00 0.310 20.0 3 beryllium-copper 10 planished 0.3190 20.00 0.310 25.0 3 beryllium-copper 10 h temper 0.3190 20.00 0.310 55.0 7 beryllium-copper 10 at temper 0.3190 20.00 0.310 80.0 10 beryllium-copper 10 ht temper 0.3190 20.00 0.310 100.0 11 beryllium-copper 10 htr temper 0.3190 20.00 0.310 110.0 12 beryllium-copper 10 htc temper 0.3190 20.00 0.310 50.0 7 beryllium-copper 25 dead soft 0.3020 19.00 0.310 28.0 6 beryllium-copper 25 planished 0.3020 19.00 0.310 30.0 6 beryllium-copper 25 1/4 h temper 0.3020 19.00 0.310 60.0 7 beryllium-copper 25 1/2 h temper 0.3020 19.00 0.310 75.0 8 beryllium-copper 25 h temper 0.3020 19.00 0.310 90.0 10 beryllium-copper 25 at temper 0.3020 19.00 0.310 140.0 16 beryllium-copper 25 1/4 ht temper 0.3020 19.00 0.310 150.0 17 beryllium-copper 25 1/2 ht temper 0.3020 19.00 0.310 160.0 18 beryllium-copper 25 ht temper 0.3020 19.00 0.310 165.0 19 brass cartridge cu.7 zn.3 1/2 hard 0.3080 16.00 0.330 52.0 6 brass cartridge cu.7 zn.3 1/4 hard 0.3080 16.00 0.330 40.0 5 brass cartridge cu.7 zn.3 annealed 0.3080 16.00 0.330 19.0 5 bronze commercial cu.9 zn.1 1/2 hard 0.3180 17.00 0.330 45.0 5 bronze commercial cu.9 zn.1 annealed 0.3180 17.00 0.330 12.0 3 copper cold rolled 0.3220 17.00 0.330 45.0 5 copper hot rolled 0.3230 17.00 0.330 10.0 3 copper oxygen free (99.92) annealed 0.3210 17.00 0.330 10.0 3 gold pure (99.9) annealed 0.6980 12.00 0.420 1.0 1 gold pure (99.9) cold rolled 0.6980 12.00 0.420 30.0 3 inconel x annealed 0.3000 31.00 0.330 50.0 11 inconel x hot rolled 0.3000 31.00 0.330 120.0 18 iron gray cast 0.2600 13.00 0.300 32.0 3 iron ingot (99.9+) annealed 0.2840 30.10 0.290 19.0 3 iron ingot (99.9+) hot rolled 0.2840 30.10 0.290 19.0 3 iron wrought hat rolled 0.2780 29.00 0.290 30.0 4 lead pure 0.4100 2.00 0.420 1.9 magnesium az31b-h24 0.0640 6.50 0.350 22.0 3 magnesium hk31b-h24 0.0650 6.40 0.350 29.0 3 magnesium wrought az31b 3-al 1-zn h24 sheet 0.016/0.249 0.0643 6.50 0.330 32.0 4magnesium wrought az31b 3-al 1-zn h24 sheet 0.250/0.374 0.0643 6.50 0.330 magnesium wrought az31b 3-al 1-zn h24 sheet 0.375/0.500 0.0643 6.50 0.330 27.0 3 magnesium wrought az31b 3-al 1-zn h24 sheet 0.501/1.000 0.0643 6.50 0.330 24.0 3 magnesium wrought az31b 3-al 1-zn h24 sheet 1.001/2.000 0.0643 6.50 0.330 23.0 3 magnesium wrought az31b 3-al 1-zn h24 sheet 2.001/3.000 0.0643 6.50 0.330 21.0 3 magnesium wrought az31b 3-al 1-zn h26 sheet 0.250/0.374 0.0643 6.50 0.330 30.0 4 magnesium wrought az31b 3-al 1-zn h26 sheet 0.375/0.438 0.0643 6.50 0.330 28.0 4 magnesium wrought az31b 3-al 1-zn h26 sheet 0.439/0.500 0.0643 6.50 0.330 28.0 4 magnesium wrought az31b 3-al 1-zn h26 sheet 0.501/0.750 0.0643 6.50 0.330 28.0 4 magnesium wrought az31b 3-al 1-zn h26 sheet 0.751/1.000 0.0643 6.50 0.330 26.0 3 magnesium wrought az31b 3-al 1-zn h26 sheet 1.001/1.500 0.0643 6.50 0.330 25.0 3 magnesium wrought az31b 3-al 1-zn h26 sheet 1.501/2.000 0.0643 6.50 0.330 24.0 3 magnesium wrought az31b 3-al 1-zn o sheet 0.016/0.060 0.0643 6.50 0.330 22.0 3 magnesium wrought az31b 3-al 1-zn o sheet 0.061/0.249 0.0643 6.50 0.330 23.0 3 magnesium wrought az31b 3-al 1-zn o sheet 0.250/0.500 0.0643 6.50 0.330 22.0 3 magnesium wrought az31b 3-al 1-zn o sheet 0.501/2.000 0.0643 6.50 0.330 22.0 3 magnesium wrought az31b 3-al 1-zn o sheet 2.001/3.000 0.0643 6.50 0.330 21.0 3 magnesium wrought hk31a 3.2-th 0.7-zr h24 sheet 0.016/0.125 0.0647 6.50 0.330 30.0 3 magnesium wrought hk31a 3.2-th 0.7-zr h24 sheet 0.126/0.250 0.0647 6.50 0.330 30.0 3 magnesium wrought hk31a 3.2-th 0.7-zr h24 sheet 0.251/1.000 0.0647 6.50 0.330 31.0 3 magnesium wrought hk31a 3.2-th 0.7-zr h24 sheet 1.001/3.000 0.0647 6.50 0.330 29.0 3 magnesium wrought hk31a 3.2-th 0.7-zr o sheet 0.016/0.250 0.0647 6.50 0.330 20.0 3 magnesium wrought hk31a 3.2-th 0.7-zr o sheet 0.251/0.500 0.0647 6.50 0.330 19.0 3 magnesium wrought hk31a 3.2-th 0.7-zr o sheet 0.501/1.000 0.0647 6.50 0.330 18.0 3 magnesium wrought hk31a 3.2-th 0.7-zr o sheet 1.001/3.000 0.0647 6.50 0.330 17.0 3 magnesium wrought hm21a 2.0-th 0.8-mn t8 sheet 0.016/0.250 0.0643 6.50 0.330 28.0 3 magnesium wrought hm21a 2.0-th 0.8-mn t8 sheet 0.251/0.500 0.0643 6.50 0.330 30.0 3 magnesium wrought hm21a 2.0-th 0.8-mn t8 sheet 0.501/1.000 0.0643 6.50 0.330 28.0 3 magnesium wrought hm21a 2.0-th 0.8-mn t8 sheet 1.001/2.000 0.0643 6.50 0.330 25.0 3 magnesium wrought hm21a 2.0-th 0.8-mn t8 sheet 2.001/3.000 0.0643 6.50 0.330 26.0 3 magnesium wrought hm21a 2.0-th 0.8-mn t81 sheet 0.125/0.312 0.0643 6.50 0.330 30.0 3 magnesium wrought az31b 3.0-al 1.0-zn temper-f extrusion 0.0643 6.50 0.330 28.0 3 magnesium wrought az61a 6.5-al 1.0-zn temper-f extrusion 0.0650 6.50 0.330 33.0 4 magnesium wrought az80a 8.5-al 0.5-zn temper-f extrusion 0.0650 6.50 0.330 36.0 4 magnesium wrought az80a 8.5-al 0.5-zn temper-t5 extrusion 0.0650 6.50 0.330 40.0 5 magnesium wrought hm31a 3.25-th 1.2-mn temper-t5 extrusion 0.0653 6.50 0.330 39.0 4 magnesium wrought zk60a 5.5znh 0.45-zr temper-f extrusion 0.0661 6.50 0.330 40.0 4 magnesium wrought zk60a 5.5znh 0.45-zr temper-t5 extrusion 0.0661 6.50 0.330 44.0 5 magnesium wrought az31b 3.0-al 1.0-zn temper-f tubing 0.0643 6.50 0.330 24.0 3 magnesium wrought az61a 6.5-al 1.0-zn temper-f tubing 0.0650 6.50 0.330 24.0 4 magnesium wrought zk60a 5.5znh 0.45-zr temper-f tubing 0.0661 6.50 0.330 34.0 4 magnesium wrought zk60a 5.5znh 0.45-zr temper-t5 tubing 0.0661 6.50 0.330 40.0 5 magnesium wrought az31b 3.0-al 1.0-zn temper-f forging 0.0643 6.50 0.330 28.0 3 magnesium wrought az61a 6.5-al 1.0-zn temper-f forging 0.0650 6.50 0.330 26.0 4 magnesium wrought az80a 8.5-al 0.5-zn temper-f forging 0.0650 6.50 0.330 31.0 4 magnesium wrought az80a 8.5-al 0.5-zn temper-t5 forging 0.0650 6.50 0.330 34.0 5 magnesium wrought az80a 8.5-al 0.5-zn temper-t6 forging 0.0650 6.50 0.330 36.0 5magnesium wrought hm21a 2.0-th 0.8-mn temper-t5 forging 0.0643 6.50 0.330 magnesium wrought zk60a 5.5znh 0.45-zr temper-t5 forging 0.0661 6.50 0.330 30.0 4 magnesium wrought zk60a 5.5znh 0.45-zr temper-t6 forging 0.0661 6.50 0.330 39.0 4 magnesium cast am100a 10.0-al 0.3-zn temper-f 0.0654 6.50 0.330 12.0 2 magnesium cast am100a 10.0-al 0.3-zn temper-t4 0.0654 6.50 0.330 13.0 4 magnesium cast am100a 10.0-al 0.3-zn temper-t6 0.0654 6.50 0.330 16.0 4 magnesium cast am100a 10.0-al 0.3-zn temper-t61 0.0654 6.50 0.330 22.0 4 magnesium cast az63a 60.0-al 3.0-zn temper-f 0.0663 6.50 0.330 14.0 2 magnesium cast az63a 60.0-al 3.0-zn temper-t4 0.0663 6.50 0.330 14.0 4 magnesium cast az63a 60.0-al 3.0-zn temper-t5 0.0663 6.50 0.330 15.0 2 magnesium cast az63a 60.0-al 3.0-zn temper-t6 0.0663 6.50 0.330 19.0 4 magnesium cast az81a 7.5-al 0.7-zn temper-t4 0.0650 6.50 0.330 12.0 4 magnesium cast az91a 8.7-al 0.7-zn temper-f 0.0654 6.50 0.330 14.0 2 magnesium cast az91a 8.7-al 0.7-zn temper-t4 0.0654 6.50 0.330 13.0 4 magnesium cast az91a 8.7-al 0.7-zn temper-t6 0.0654 6.50 0.330 19.0 4 magnesium cast az92a 9.0-al 2.0-zn temper-f 0.0657 6.50 0.330 14.0 2 magnesium cast az92a 9.0-al 2.0-zn temper-t4 0.0657 6.50 0.330 14.0 4 magnesium cast az92a 9.0-al 2.0-zn temper-t5 0.0657 6.50 0.330 17.0 2 magnesium cast az92a 9.0-al 2.0-zn temper-t6 0.0657 6.50 0.330 22.0 4 magnesium cast ez33a 2.5-re 3.2-zn temper-t5 0.0660 6.50 0.330 16.0 2 magnesium cast hk31a 3.2-th 0.3-zn temper-t6 0.0646 6.50 0.330 15.0 3 magnesium cast hz32a 3.2-th 2.1-zn temper-t5 0.0660 6.50 0.330 15.0 2 magnesium cast k1a 0.7-zr temper-f 0.0629 6.50 0.330 8.0 2 magnesium cast qe22a 2.5-ag 2.2-re 0.7-zr temper-t6 0.0654 6.50 0.330 28.0 3 magnesium cast qh21a 2.5-ag 1-re 1.1-th 0.7-zr temper-t6 0.0657 6.50 0.330 30.0 4 magnesium cast ze41a 4.2-zn 1.25-re 0.7-zr temper-t5 0.0657 6.50 0.330 20.0 3 magnesium cast ze63a 5.75-zn 2.6-re 0.7-zr temper-t6 0.0672 6.50 0.330 28.0 4 magnesium cast ze62a 5.7-zn 1.8-th 0.75-zr temper-t5 0.0669 6.50 0.330 25.0 4 magnesium cast zk51a 4.6-zn 0.75-zr temper-t5 0.0654 6.50 0.330 24.0 4 magnesium cast zk61a 60.0-zn 0.8-zr temper-t6 0.0660 6.50 0.330 28.0 4 molybdenium drawn 14 min. 0.3680 42.00 0.320 60.0 21 monel sand cast ni.63 cu.32 si.012 0.3120 19.00 0.330 35.0 8 monel wrought ni.67 cu.30 annealed 0.3190 26.00 0.360 35.0 7 monel wrought ni.67 cu.30 cold drawn 0.3190 26.00 0.360 80.0 10 monel wrought ni.67 cu.30 cold rolled hard 0.3190 26.00 0.360 100.0 11 monel wrought ni.67 cu.30 hot rolled 0.3190 26.00 0.360 50.0 9 nickel silver cu.65 zn.2 ni.15 1/2 hard 0.3140 18.00 0.310 62.0 7 nickel silver cu.65 zn.2 ni.15 annealed 0.3140 18.00 0.310 19.0 5 nickel silver cu.65 zn.2 ni.15 full hard 0.3140 18.00 0.310 75.0 8 nickel wrought (99.0) annealed 0.3210 30.00 0.310 20.0 7 nickel wrought (99.0) cold drawn 0.3210 30.00 0.310 70.0 9 nickel wrought (99.0) cold rolled hard 0.3210 30.00 0.310 95.0 10 nickel wrought (99.0) hot rolled 0.3210 30.00 0.310 25.0 7 palladium commercial (99.5) annealed 0.4320 17.00 0.390 5.0 3 palladium commercial (99.5) cold rolled 0.4310 17.00 0.390 32.0 4 platinum pure (99.99) annealed 0.7220 21.00 0.390 10.0 2 platinum pure (99.99) cold rolled 0.7720 21.00 0.390 27.0 3plutonium alpha 0.6970 14.00 0.190 plutonium delta 0.5710 6.00 0.290 16.0 2 polycarbonate 0.0430 0.34 0.380 8.0 1 polyethylene type iii 0.0440 0.15 0.450 1.8 silver pure (99.9) annealed 0.3790 11.00 0.370 12.0 2 silver pure (99.9) cold rolled 0.3790 11.00 0.370 38.0 4 steel wrought stainless 201 sheet annealed 0.2800 28.60 0.290 55.0 11 steel wrought stainless 201 sheet 10% cr 0.2800 28.60 0.290 90.0 13 steel wrought stainless 201 sheet 40% cr 0.2800 28.60 0.290 165.0 19 steel wrought stainless 202 sheet annealed 0.2800 28.60 0.290 50.0 10 steel wrought stainless 202 sheet 10% cr 0.2800 28.60 0.290 98.0 12 steel wrought stainless 202 sheet 40% cr 0.2800 28.60 0.290 155.0 18 steel wrought stainless 203 ez 1 in. bar annealed 0.2840 28.60 0.290 45.0 8 steel wrought stainless 203 ez 1 in. bar cd 0.2840 28.60 0.290 80.0 11 steel wrought stainless 203 ez 1 in. bar full hard 0.2840 28.60 0.290 140.0 17 steel wrought stainless 301 sheet annealed 0.2860 29.00 0.290 40.0 12 steel wrought stainless 301 sheet 10% cr 0.2860 28.00 0.290 88.0 15 steel wrought stainless 301 sheet 40% cr 0.2860 28.00 0.290 170.0 19 steel wrought stainless 301 sheet 60% cr 0.2860 27.00 0.290 230.0 23 steel wrought stainless 302 sheet annealed 0.2870 27.90 0.290 40.0 9 steel wrought stainless 302 sheet 10% cr 0.2870 27.90 0.290 92.0 10 steel wrought stainless 302 sheet 40% cr 0.2870 27.90 0.290 132.0 15 steel wrought stainless 302b plate anealed 0.2870 27.90 0.290 40.0 9 steel wrought stainless 303 1 in. bar annealed 0.2900 28.00 0.290 37.0 9 steel wrought stainless 303 1 in. bar 10% cr 0.2900 28.00 0.290 45.0 10 steel wrought stainless 303 1 in. bar 40% cr 0.2900 28.00 0.290 80.0 17 steel wrought stainless 303 se 1 in. bar annealed 0.2860 28.00 0.290 35.0 9 steel wrought stainless 303 se 1 in. bar half hard 0.2860 28.00 0.290 105.0 13 steel wrought stainless 303 se 1 in. bar full hard 0.2860 28.00 0.290 137.0 17 steel wrought stainless 304 bar annealed 0.2900 28.10 0.290 34.0 8 steel wrought stainless 304 bar 10% cr 0.2900 28.10 0.290 70.0 9 steel wrought stainless 304 bar 40% cr 0.2900 28.10 0.290 135.0 14 steel wrought stainless 304l bar annealed 0.2860 28.00 0.290 32.0 8 steel wrought stainless 304l bar 10% cr 0.2860 28.00 0.290 73.0 10 steel wrought stainless 304l bar 40% cr 0.2860 28.00 0.290 137.0 15 steel wrought stainless 305 sheet annealed 0.2860 28.00 0.290 33.0 8 steel wrought stainless 305 sheet 10% cr 0.2860 28.00 0.290 70.0 9 steel wrought stainless 305 sheet 40% cr 0.2860 28.00 0.290 130.0 14 steel wrought stainless 308 sheet annealed 0.2900 28.00 0.290 33.0 8 steel wrought stainless 308 sheet 10% cr 0.2900 28.00 0.290 64.0 9 steel wrought stainless 308 sheet 40% cr 0.2900 28.00 0.290 128.0 15 steel wrought stainless 309 sheet annealed 0.2900 29.00 0.290 37.0 8 steel wrought stainless 309 sheet 10% cr 0.2900 29.00 0.290 57.0 8 steel wrought stainless 309 sheet 40% cr 0.2900 29.00 0.290 124.0 13 steel wrought stainless 310 sheet annealed 0.2870 28.20 0.290 45.0 8 steel wrought stainless 310 sheet 10% cr 0.2870 28.20 0.290 67.0 10 steel wrought stainless 310 sheet 40% cr 0.2870 28.20 0.290 138.0 15steel wrought stainless 316 sheet annealed 0.2870 28.10 0.290 38.0 8 steel wrought stainless 316 sheet 10% cr 0.2870 28.10 0.290 70.0 9 steel wrought stainless 316 sheet 40% cr 0.2870 28.10 0.290 128.0 14 steel wrought stainless 316l sheet annealed 0.2840 28.00 0.290 37.0 7 steel wrought stainless 316l sheet half hard 0.2840 28.00 0.290 90.0 12 steel wrought stainless 316l sheet full hard 0.2840 28.00 0.290 127.0 16 steel wrought stainless 317 1 in. bar annealed 0.2900 28.00 0.290 38.0 8 steel wrought stainless 317 1 in. bar 10% cr 0.2900 28.00 0.290 57.0 10 steel wrought stainless 317 1 in. bar 40% cr 0.2900 28.00 0.290 134.0 14 steel wrought stainless 321 sheet annealed 0.2850 28.00 0.290 32.0 9 steel wrought stainless 321 sheet 10% cr 0.2850 28.00 0.290 70.0 10 steel wrought stainless 321 sheet 40% cr 0.2850 28.00 0.290 133.0 15 steel wrought stainless 347 sheet annealed 0.2860 28.20 0.290 40.0 9 steel wrought stainless 347 sheet 10% cr 0.2860 28.20 0.290 77.0 10 steel wrought stainless 347 sheet 40% cr 0.2860 28.20 0.290 138.0 15 steel wrought stainless 348 bar 0.2900 28.20 0.290 37.0 9 steel wrought stainless 19-9dl sheet annealed 0.2870 29.50 0.290 67.0 11 steel wrought stainless 19-9dl sheet hr+sr at 1200f 0.2870 29.50 0.290 103.0 12 steel wrought stainless 21-6-9 sheet annealed 0.2830 29.40 0.290 68.0 11 steel wrought stainless 21-6-9 sheet cr 0.2830 29.40 0.290 130.0 14 steel wrought stainless 21-6-9 sheet 60 %cr 0.2830 29.40 0.290 182.0 20 steel wrought stainless 22-13-5 sheet annealed 0.2850 28.00 0.290 86.0 12 steel wrought stainless 22-13-5 sheet 60% cr 0.2850 28.00 0.290 199.0 21 steel wrought stainless 18-2mn 0.25 in bar annealed 0.2850 28.00 0.290 65.0 12 steel wrought stainless 18-2mn 0.25 in bar 20% cr 0.2850 28.00 0.290 135.0 17 steel wrought stainless 18-2mn 0.25 in bar 60% cr 0.2850 28.00 0.290 224.0 26 steel wrought stainless 400 sheet anealed 0.2800 29.00 0.290 32.0 6 steel wrought stainless 405 sheet annealed 0.2800 29.00 0.290 47.0 6 steel wrought stainless 405 sheet ??% cr 0.2800 29.00 0.290 65.0 9 steel wrought stainless 405 sheet ??% cr 0.2800 29.00 0.290 125.0 13 steel wrought stainless 430 sheet annealed 0.2800 29.00 0.290 52.0 7 steel wrought stainless 430 sheet ??% cr 0.2800 29.00 0.290 65.0 9 steel wrought stainless 430 sheet ??% cr 0.2800 29.00 0.290 125.0 13 steel wrought stainless 442 sheet annealed 0.2800 29.00 0.290 52.0 8 steel wrought stainless 442 sheet ??% cr 0.2800 29.00 0.290 70.0 9 steel wrought stainless 442 sheet ??% cr 0.2800 29.00 0.290 100.0 11 steel wrought stainless 446 sheet annealed 0.2700 29.00 0.290 52.0 8 steel wrought stainless 446 sheet ??% cr 0.2700 29.00 0.290 70.0 9 steel wrought stainless 446 sheet ??% cr 0.2700 29.00 0.290 109.5 11 steel wrought stainless 18 sr sheet annealed 0.2700 29.00 0.290 65.0 8 steel wrought stainless 261 e-brite strip annealed 0.2770 29.00 0.290 46.0 6 steel wrought stainless 261 e-brite strip 20% cr 0.2770 29.00 0.290 88.0 9 steel wrought stainless 261 e-brite strip 60% cr 0.2770 29.00 0.290 116.0 12 steel wrought stainless 403 bar annealed 0.2780 29.70 0.290 45.0 7 steel wrought stainless 403 bar temper 1200f 0.2780 29.70 0.290 85.0 11 steel wrought stainless 403 bar temper 600f 0.2780 29.70 0.290 140.0 18steel wrought stainless 410 1 in. bar temper 1000f 0.2790 29.00 0.290 104.0 11 steel wrought stainless 410 1 in. bar temper 600f 0.2790 29.00 0.290 143.0 18 steel wrought stainless 410 1 in. bar temper 300f 0.2790 29.00 0.290 148.0 18 steel wrought stainless 414 bar anealed 0.2800 28.50 0.290 90.0 11 steel wrought stainless 414 bar temper 1200f 0.2800 28.50 0.290 105.0 12 steel wrought stainless 414 bar temper 800f 0.2800 28.50 0.290 150.0 20 steel wrought stainless 416 bar anealed 0.2780 29.00 0.290 35.0 6 steel wrought stainless 416 bar temper 1200f 0.2780 29.00 0.290 90.0 11 steel wrought stainless 416 bar temper 600f 0.2780 29.00 0.290 140.0 18 steel wrought stainless 420 1 in. bar anealed 0.2770 29.00 0.290 50.0 9 steel wrought stainless 420 1 in. bar temper 1400f 0.2770 29.00 0.290 70.0 11 steel wrought stainless 420 1 in. bar temper 400f 0.2770 29.00 0.290 215.0 25 steel wrought stainless 422 bar anealed 0.2810 29.80 0.290 74.0 9 steel wrought stainless 422 bar temper 1400f 0.2810 29.80 0.290 90.0 12 steel wrought stainless 422 bar temper 1200f 0.2810 29.80 0.290 125.0 14 steel wrought stainless 422 bar temper 800f 0.2810 29.80 0.290 168.0 23 steel wrought stainless 431 1 in. bar anealed 0.2800 29.00 0.290 95.0 12 steel wrought stainless 431 1 in. bar temper 1100f 0.2800 29.00 0.290 115.0 14 steel wrought stainless 431 1 in. bar temper 500f 0.2800 29.00 0.290 149.0 19 steel wrought stainless 440a bar anealed 0.2800 29.00 0.290 60.0 10 steel wrought stainless 440a bar temper 600f 0.2800 29.00 0.290 240.0 26 steel wrought stainless 440b bar anealed 0.2800 29.00 0.290 62.0 10 steel wrought stainless 440b bar temper 600f 0.2800 29.00 0.290 270.0 28 steel wrought stainless 440c bar anealed 0.2800 29.00 0.290 65.0 11 steel wrought stainless 440c bar temper 600f 0.2800 29.00 0.290 275.0 28 steel wrought stainless 440f bar temper 600f 0.2800 29.00 0.290 275.0 28 steel wrought stainless 12 mov sheet annealed 0.2790 29.00 0.290 65.0 10 steel wrought stainless 12 mov temper 900f 0.2790 29.00 0.290 195.0 24 steel wrought stainless 12 mov temper 700f 0.2790 29.00 0.290 188.0 23 steel wrought stainless greek ascolony bar tmpr 1000f 0.2840 29.00 0.290 137.0 16 steel wrought stainless greek ascolony bar tmpr 500f 0.2840 29.00 0.290 175.0 20 steel wrought stainless 17-14 cu-mo bar 1350f wq 0.2870 29.00 0.290 41.0 8 steel wrought stainless hmn bar annealed 0.2790 29.00 0.290 56.0 11 steel wrought stainless hmn bar age 1400f 0.2790 29.00 0.290 110.0 17 steel wrought stainless hmn bar age 1300f 0.2790 29.00 0.290 135.0 18 steel wrought stainless 17-7ph sheet annealed 0.2820 29.00 0.290 40.0 13 steel wrought stainless 17-7ph sheet th 1050 0.2760 29.00 0.290 185.0 20 steel wrought stainless 17-7ph sheet rh 950 0.2760 29.00 0.290 220.0 23 steel wrought stainless 17-7ph sheet ch 900 0.2770 29.50 0.290 260.0 26 steel wrought stainless ph 15-7 mo sheet annealed 0.2820 29.00 0.290 55.0 13 steel wrought stainless ph 15-7 mo sheet th 1050 0.2770 29.00 0.290 200.0 21 steel wrought stainless ph 15-7 mo sheet rh 950 0.2770 29.00 0.290 225.0 24 steel wrought stainless ph 15-7 mo sheet ch 900 0.2770 29.00 0.290 260.0 26 steel wrought stainless ph 14-8 mo sheet annealed 0.2830 28.30 0.290 55.0 12 steel wrought stainless ph 14-8 mo sheet srh 1050 0.2830 28.30 0.290 205.0 21 steel wrought stainless ph 14-8 mo sheet srh 950 0.2780 28.30 0.290 220.0 23。

abaqus 金属材料参数应力应变曲线abaqus 金属材料参数应力应变曲线1. 引言金属材料的力学性质对于工程设计和材料研究至关重要。

在工程应用中,了解金属材料的力学行为可以帮助我们预测材料在加载条件下的性能和可靠性。

而abaqus作为一款常用的有限元分析软件,能够通过建立合适的材料模型,模拟材料的力学响应。

在abaqus中,金属材料参数的设定是非常重要的,其中最基本和常用的参数之一是应力应变曲线。

本文将深入探讨abaqus中金属材料参数的设置与应力应变曲线的关系,为读者提供有关abaqus金属材料参数应用的深入理解。

2. 金属材料参数的设置2.1 弹性模量与泊松比金属材料的弹性模量是一个关键参数,描述了材料在弹性阶段的应力-应变行为。

弹性模量可以通过材料的压缩试验或拉伸试验得到。

在abaqus中,可以通过输入杨氏模量和泊松比来定义材料的弹性行为。

对于弹性完全线性的材料,可以简单地输入杨氏模量和泊松比即可。

2.2 屈服强度与应变硬化模型金属材料在受到一定应力时会发生塑性变形,而塑性变形的起始点就是屈服强度。

在abaqus中,屈服强度可以通过输入屈服应力和屈服应变来定义。

一般来说,屈服应力可以通过材料的拉伸试验曲线得到。

而屈服应变可以通过使用应变硬化模型来描述。

应变硬化模型是用来描述金属材料在塑性变形过程中硬化的机理。

abaqus中提供了多种应变硬化模型,如线性硬化模型、赫希方程模型和拉曼方程模型等。

不同的模型适用于不同的材料和力学行为。

我们需要根据具体的材料性质和实验数据,选择最适合的应变硬化模型,并确定相应的参数。

3. 应力应变曲线的建立在abaqus中,通过建立材料模型和输入相应的材料参数,可以生成应力应变曲线。

在进行有限元分析时,abaqus会根据设定的材料参数,结合加载条件,自动生成材料的应力应变曲线。

通过abaqus生成的应力应变曲线可以帮助我们深入理解金属材料的力学行为。

通过观察应力应变曲线的特征,我们可以了解金属材料的强度、塑性、韧性等性能。

硅胶材料abaqus参数(最新版)目录一、硅胶材料的概述二、ABAQUS 软件的简介三、硅胶材料的 ABAQUS 参数设置四、硅胶材料的 ABAQUS 参数对模拟结果的影响五、结论正文一、硅胶材料的概述硅胶材料是一种由硅、氧、氢等元素组成的有机硅化合物,具有优异的耐高、低温、耐候性、憎水、电气绝缘性、生理惰性等特点。

在国防军工、医疗卫生、工农业生产及人们的日常生活中获得了广泛应用。

二、ABAQUS 软件的简介ABAQUS 是一款国际知名的大型通用有限元分析软件,广泛应用于工程领域,包括线性结构静力学、非线性结构动力学、热传导分析、热膨胀分析、疲劳分析等。

三、硅胶材料的 ABAQUS 参数设置在 ABAQUS 中,硅胶材料的参数设置主要包括以下几个方面:1.材料属性:硅胶材料的弹性模量、泊松比、密度等物理属性需要根据实际材料的性能参数进行设置。

2.边界条件:根据实际问题,设置硅胶材料的边界条件,如固定边界、滑动边界、对称边界等。

3.加载条件:设置硅胶材料的加载条件,如均匀加载、脉冲加载、温度变化等。

4.求解设置:根据问题类型和计算需求,设置求解算法、求解类型、迭代次数等。

四、硅胶材料的 ABAQUS 参数对模拟结果的影响硅胶材料的 ABAQUS 参数设置对模拟结果具有重要影响。

例如,若材料属性设置不准确,可能导致模拟结果与实际现象相差较大;若边界条件设置不合理,可能导致计算不稳定或结果失真;若加载条件设置不合适,可能导致模拟过程无法进行或结果失去意义。

五、结论总之,在利用 ABAQUS 软件对硅胶材料进行模拟分析时,需要综合考虑材料的物理属性、边界条件、加载条件和求解设置等多个方面,以确保模拟结果的准确性和可靠性。

硅胶材料abaqus参数引言硅胶材料是一种具有广泛应用前景的高分子材料,其在各个领域中都有着重要的作用。

为了实现对硅胶材料的力学行为进行模拟和分析,A B AQ US是一款常用的有限元分析软件。

本文将介绍在AB AQ US中使用硅胶材料时的参数设定,帮助读者更好地理解和应用硅胶材料的模拟方法。

硅胶材料简介硅胶材料是由聚硅氧烷为主要链路的高分子有机物,具有优异的柔韧性、化学稳定性以及耐高温性能。

在实际工程中,硅胶材料常用于密封、防水、绝缘、减振等领域。

为了准确地模拟硅胶材料的行为,需要进行一系列参数的设定。

硅胶材料的A B A Q U S模型在A BA QU S中,使用本构模型来描述硅胶材料的力学行为。

以下是一些常用的参数及其含义:密度硅胶材料的密度决定了其质量与体积的比值。

在A BA QU S中,可以根据硅胶材料的实际密度来设置模型的密度参数。

弹性模量弹性模量是描述硅胶材料刚度的参数,可以反映其在受力时的变形特性。

在A BA QU S中,可以根据实验数据或者理论计算得出的硅胶材料的弹性模量来设置模型的参数。

泊松比泊松比是描述硅胶材料在受力时的纵横向变形关系的参数。

在A BA QU S 中,可以根据实验数据或者理论计算得出的硅胶材料的泊松比来设置模型的参数。

屈服强度屈服强度是一个材料在受力作用下开始变形的临界点。

在AB AQ US中,可以根据硅胶材料的实际屈服强度来设置模型的参数。

硬化模型硬化模型是描述硅胶材料应力应变关系的参数。

在AB AQ US中,可以选择合适的硬化模型来模拟硅胶材料的应力应变曲线。

硅胶材料在A B A Q U S中的应用在实际工程中,硅胶材料常常处于复杂的力学环境中,如受压、拉伸、剪切等。

为了准确地分析硅胶材料的力学性能,需要在AB AQ US中设置合适的加载条件和约束条件。

通过对硅胶材料施加不同的载荷和约束条件,可以获得其应力、应变、位移等力学行为的模拟结果。

结论通过本文的介绍,我们了解了在A BA QU S中使用硅胶材料时的参数设定方法。

Department of Engineering University of Cambridge > Engineering Department > computing helpABAQUS Materials Input1. 5. ABAQUS - Materials2. Q5.1 : How do I find what material properties are needed for a particular analysis ?Read the relevant section in Chapter 6 : Analysis Procedures (User's manual Vol. I). This gives an overview about the analysis and has more information about the material properties.Read also the following sections in Chapter 17 : Materials Introduction of the ABAQUS User's manual.▪Section 17.1.1 - Material Library : Overview▪Section 17.1.2 - Material Data Definition▪Section 17.1.3 - Combining Material PropertiesSection 17.1.3 lists the material model combination tables. Several models are available to define the mechanical behaviour (elastic, plastic).Some material options require the presence of other material options. Some exclude the use of the other material options. For example *DEFORMATION PLASTICITY completely defines the material's mechanical behaviour and should not be used with *ELASTIC.Once you have all the relevant keywords to define the material properties consult the keyword Manual for each of the keywords. This will explain what data is required for each of the keyword.3. Q5.2 : What material properties need to be specified in a thermal-electrical analysis ?Referring to Section 17.1.3 of the ABAQUS User's manual you will require the heat transfer properties as well as the electrical properties. These are listed below :▪Heat Transfer properties▪*CONDUCTIVITY▪*LATENT HEAT▪*SPECIFIC HEAT▪*HEAT GENERATION▪Electrical properties▪*DIELECTRIC▪*ELECTRICAL CONDUCTIVITY▪*JOULE HEAT FRACTION▪*PIEZOELECTRICThis forms the complete set of properties. If Piezoelectric elements are not used then*PIEZOELECTRIC and *DIELECTRIC properties will not be required.If only the steady state heat transfer response is of interest then *SPECIFIC HEAT properties are not required. Similarly if there are no phase changes involved then *LATENT HEAT is not required.*JOULE HEAT FRACTION is used to specify the fraction of electrical energy that will be released as heat.Example problem 5.2.1 - thermal-electrical modelling of an automotive fuse illustrates the thermal-electrical analysis.ABAQUS allows for redundant material properties to be specified. It will simply ignore the material properties not required for the current analysis.Typical example of material properties :*MATERIAL, NAME=ZINC*CONDUCTIVITY0.1121, 20.00.1103, 100.0*ELECTRICAL CONDUCTIVITY16.75E3, 20.012.92E3, 100.0*JOULE HEAT FRACTION1.0*DENSITY7.14E-6*SPECIFIC HEAT389.04. Q5.3 : What material properties need to be specified in an analysis using temperature- displacement elements ?Referring to Section 17.1.3 of the ABAQUS User's manual you will require the heat transfer properties as well as the mechanical properties. These are listed below :▪Mechanical properties▪*ELASTIC▪Additional properties which may be required : example plastic ▪Heat Transfer properties▪*CONDUCTIVITY▪*LATENT HEAT▪*SPECIFIC HEAT▪*HEAT GENERATION5. Q5.4 : What material properties need to be specified in an analysis using piezoelectric elements?Referring to Section 9.1.3 of the ABAQUS User's manual you will require the electrical properties. These are listed below :▪Electrical properties▪*DIELECTRIC▪*ELECTRICAL CONDUCTIVITY▪*JOULE HEAT FRACTION▪*PIEZOELECTRIC6. Q5.5 : What material properties need to be specified in modeling concrete with reinforcements?Use the concrete model available with rebar to model the reinforcements.Section 1.1.5 of the ABAQUS Example's manual gives an example of the collapse analysis of a concrete slab subjected to a central point load.The data file for that example is collapse example.The complete set of ABAQUS input files can be obtained by using the following command :abaqus fetch j=collapseconcslab**CONCRETE3000., 0. abs. value of compressive stress, abs. value of plastic strain. 5500., 0.0015 " "*FAILURE RATIOS1.16, 0.0836This is used to define the shape of the failure surface (see section 11.5.1 of the ABAQUSUSER's manual Vol. II).The first parameter is the ratio of the ultimate biaxial compression stress, to the uniaxial compressive stress. Default is 1.16.The second parameter is the absolute value of the ratio of uniaxial tensile stress at failure to the uniaxial compressive stress at failure. Default is 0.09.7. Tension Stiffening*TENSION STIFFENING1., 0.0., 2.E-3First parameter is the fraction of remaining stress to stress at cracking. The second parameter is the absolute value of the direct strain minus the direct strain at cracking.This defines the retained tensile stress normal to the crack as a function of the deformation in the direction of the normal to the crack.8. Shear Retention*SHEAR RETENTIONNot used for this example.9. Reinforcement modelling*REBAR is used to model the reinforcement.*REBAR,ELEMENT=SHELL,MATERIAL=SLABMT,GEOMETRY=ISOPARAMETRIC,NAME=YYSLAB, 0.014875, 1., -0.435, 4*REBAR,ELEMENT=SHELL,MATERIAL=SLABMT,GEOMETRY=ISOPARAMETRIC,NAME=XXSLAB, 0.014875, 1., -0.435, 1Here SLAB is the element name or name of the element set that contains these rebars. The geometry is ISOPARAMETRIC. Other choice is SKEW. ELEMENT can be BEAM, SHELL, AXISHELL or CONTINUUM type. The following are the other parameters specified :▪cross-sectional area of the rebar.▪spacing of the rebars in the plane of the shell▪position of the rebar. Distance from the reference surface. Here the mid-surface is the reference surface and the minus sign indicates that the distance is measured in theopposite direction to the direction of positive normal. The positive normal is defined by the right hand rule as the nodes are considered in an anti-clockwise sequence.▪edge number to which rebars are similar.10. Alternate Method o modelling REBAR ReinforcementsAlternatively REBAR can be modelled as follows :*NODE........**-------------------END NODES FOR REBAR BEAM ELEMENTS501, 0.0, 0.15, -0.02541, 1.5, 0.15, -0.02601, 0.0, 0.15, -0.07641, 1.5, 0.15, -0.07701, 0.0, 0.60, -0.02741, 1.5, 0.60, -0.02801, 0.0, 0.60, -0.07841, 1.5, 0.60, -0.07........**---------------------GENERATE INTERMEDIATE NODES*NGEN, NSET=BAR10TF701, 741, 2*NGEN, NSET=BAR10TB801, 841, 2......**--------------------GENERATE THE BEAM ELEMENTS*ELEMENT, TYPE=B31701, 701, 703801, 801, 803*ELGEN, ELSET=BAR10TF701, 20, 2, 1, 1, 1, 1*ELGEN, ELSET=BAR10TB801, 20, 2, 1, 1, 1, 1......**---------------------DEFINE THE MATERIAL PROPERTIES*MATERIAL, NAME=BAR8**** 8 mm dia bar***ELASTIC, TYPE=ISO197.E6, 0.3*PLASTIC354.E3, 0.364.E3, 0.0018****---------------------DEFINE THE SECTION PROPERTIES......*BEAM SECTION, SECTION=CIRC, MATERIAL=BAR10, ELSET=BAR10TF0.005*BEAM SECTION, SECTION=CIRC, MATERIAL=BAR10, ELSET=BAR10TB0.005...**--------------------DEFINE AN ELEMENT SET WHICH CONTAINS**--------------------THE ELEMENTS THROUGH WHICH THE REBAR**--------------------ELEMENTS PASSES.....*ELSET, ELSET=TOP, GENERATE5, 80, 5****--------------------*EMBEDDED ELEMENT,HOST ELSET=TOPBAR10TF,BAR10TB**11. Q5.6 : What material properties need to be specified in using the deformation plasticity model ?See section 11.2.11 of the users' manual (Vol. II). See also section 23.4.7 of the users' manual (Vol. III), keyword section.For example :*DEFORMATION PLASTICITY1.E3, 0.3,2., 3, 0.396Here the data line contains the Young's modulus, Poissons ratio, Yield stress, Exponent, Yield offset respectively. If it is necessary to define the dependence of these parameters on temperature then the 6th parameter will be the temperature. Then repeat the dataline for different temperatures as required.| Computing Help |[Finite Elements] | [Engineering Packages]© Cambridge University Engineering DeptInformation provided by Arul M Britto (amb2)Last updated: 28 September 2010。