多功能液压实验台设计

- 格式:doc

- 大小:402.50 KB

- 文档页数:40

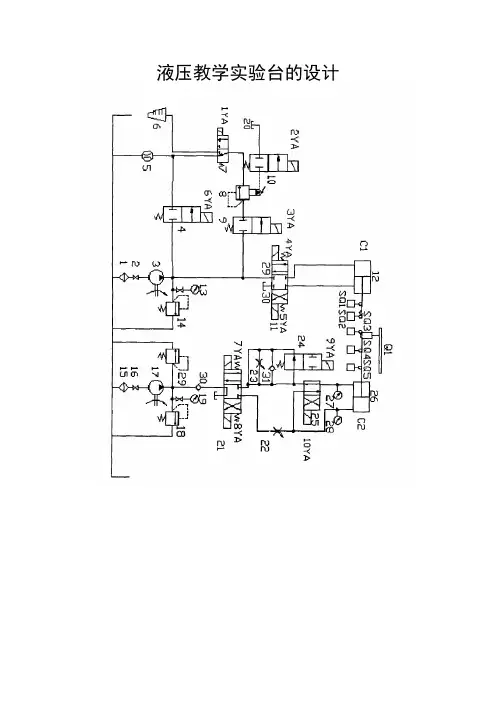

液压教学实验台的设计第二章液压教学实验台的回路分析2.1回路分析2.1.1液压调压回路分析液压调压回路的基本功能主要体现在,液压调定和液压限制系统在最高,工作压力时的功能体现,常见的主要指调压回路在工作过程中,不同阶段出现多级压力变换。

通常指的是溢流阀来控制这一功能。

图2.1.1是基本的液压调压回路实现图。

其中在设计改变节流阀,如图中2指的是开口调节液压缸的速度,如图中1指的是溢流阀开启溢流,可以让试验台在工作稳定溢流阀的压力,可以起到调定压力的作用,如图中3,指的是液压试验台可由阀远程调压控制。

图2.1.1液压调压回路分析2.1.2液压减压回路分析液压试验台常见的减压回路最基本的功能,主要体现在于使用系统低于压力调定值,可以实现稳定工作压力的,通常是机床的工作夹紧和机床导轨润滑及液压的控制油路,需要减压回路。

常见的液压减压回路如图表2.1.2所示,当减压回路在执行过程中低压的支路可以起到上串接定值减压的功能,如图表中下方的2所示。

当液压回路中的单向阀可以对图表3起到主油路压力减压的作用。

如图表4可以起到防止液压缸的压力受其干扰。

图2.1.2液压调压回路分析2.1.3节流调速回路分析液压节流阀可以起到串联在液压泵和液压缸之间的油路回路,通常可以控制液压缸油路流量达到调速的目的,如图2.1.3当液压泵对油液起到溢流阀回油箱的作用,常见的是回路油节起到调速回路能够正常的实现。

图2.2.3节流调速回路分析2.1.4行程阀和速度转换回路分析通常液压速度接换回路可以起到液压元件速度的切换,当液压行程阀在切换速度的不同事,回路可以起到快速-慢速的换接。

行程阀一般可以起到液压回路速度快和慢换接的方法,通常速度在行程阀实现时起到换接回路,如图 2.1.4,当液压缸活塞快速到达位置时,其活塞杆中的上挡可以压下行程阀如图中1,当行程阀关闭时,而液压缸右腔油液必须通过节流阀如图表2可以流回油箱,使得活塞运转到慢速。

当液压活塞压力经单向阀如图表3中,可以开启进入液压缸右腔,使得活塞快速向左返回。

一种多功能液压试验台控制系统设计摘要:本文介绍了一种多功能液压试验台控制系统设计,液压控制模块的设计采用了模块化设计方式,可以缩短产品设计开发周期减少开发成本。

液压系统采用LUDV负载反馈控制技术能实现对不同负载压力的多个执行元件同时系统流量自动按比例分配。

关键词:液压试验台;控制系统;负载反馈;模块化设计中图分类号:TP271 文献标识码:A 文章编号:1006-4311(2015)09-0051-030 引言随着液压元件制造技术的飞速发展,液压系统的测试技术已经发展成为多门学科的集成技术,主要包括:液压技术、计算机辅助控制技术、传感器技术、仪器仪表技术、测试技术以及为电子技术等五个技术。

该多功能液压测试试验台主要用于对掘进机液压系统液压元件进行检测和分析。

试验台液压系统对测试元件提供高压液压油,主要针对旧液压元件进行检测时元件内部容易有脏物污染系统,专门开发了液压系统清洗装置;该系统可将系统主要液压元件都集成到同一试验台上进行综合性能测试,也可以分别测试液压泵、液压阀和液压缸的性能参数。

1 液压系统的模块化设计多功能液压测试试验台的基于目前煤矿井下用一种掘进机液压系统的需求而开发的,要求对掘进机液压系统和液压元件进行功能和特性试验。

而整个试验台液压系统有许多基本回路组成,而这些系统回路在测试不同液压元件时是回路是相同的,因此在该试验台液压系统设计时将这些基本回路或作用相同的几个回路设计成液压模块部件,再根据试验台的使用要求把这些液压模块进行合理的组合。

模块化产品的构成模式主要是用一个简单地公式来表达的:新产品(系统)=通用模块(不变部分)+专用模块(变动部分)。

采用模块化思想开发非标设备,可以实现产品在小批量生产时尽可能选用通用模块减少产品的设计开发成本,模块化设计能实现产品的多样化和效益最大。

该试验台液压系统可以划分为四个模块:油液存储及处理模块,压力源产生模块,液压阀控制模块,油路测试输出模块。

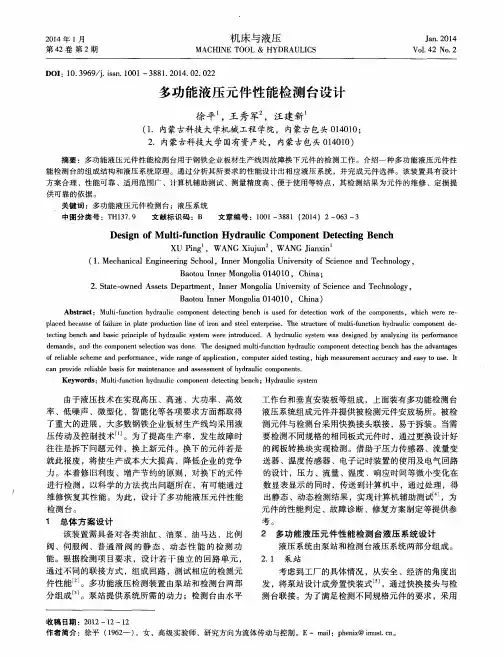

图1多功能液压元件综合实验台原理1.油箱2.液位液温计3.过滤器4.电接点温度表5.空滤器6.泵-电机组7.液压软管8.冷却器9.单向阀10.电磁溢流阀11,16.电液换向阀12.减压阀13.高压球阀14.涡轮流量计15.单向节流阀17.测压接头18.外接液压设备19.测试压力表20.溢流阀21.节流阀22.蓄能器Ⅰ.板式阀测试底板Ⅱ.测试接管20211817B A X ⅠⅡTYP 13148151112162210919675142多功能液压元件综合实验台的设计吴杰(广州博派白源液压设备有限公司,广州510475液压技术在现代工业机械中发挥越来越重要的作用。

为解决种类繁多的液压元件的不同测试要求,满足对液压实验台检测元件多样性的需求,设计了一种具有综合检测能力、压力与流量范围宽、油路变换方便、检测精度高的液压综合实验台,该实验台符合国家规定的试验条件与测试精度,占地小且节省资金。

1测试项目该实验台可实现的测试对象:(1DN6-DN25各种板式压力阀、方向阀、流量控制阀、叠加阀;(2DN32以下的各种管式液压阀;(3DN16、DN25插装阀;(4各种液压油缸及液压马达。

测试项目:(1压力阀:调压范围、压力稳定性、内泄漏及压力损失等;(2方向阀:滑阀机能、换向机能、压力损失及内泄漏等;(3流量阀:流量调节大小及稳定性等,压力损失及内泄漏;(4单向阀:内泄漏、压力损失、最小控制压力、开启压力及耐压试验等;(5液压油缸及液压马达:最低启动压力、内泄漏及耐压试验。

2实验台组成实验台由三大部分组成,即液压泵站、实验操作台和电气控制系统,在总体布置上,充分考虑到使用方便及空间布置紧凑。

液压泵站即液压源,用来将液压油提供给实验台,系统采用一台变量柱塞泵供油,泵站安装有蓄能器,用于吸收系统油液脉动,提供均匀稳定的压力油。

根据实际需要,设计系统最高工作压力为31.5MPa ,为了使泵站维修方便和主操作平台大小适中、操作方便,将液压泵、电机、蓄能器等外置。

开发与利用,对旧式液压实验台重新开发与利用有一定的推广应用价值。

1.3液压实验台的特点[3](1)采用透明有机玻璃外壳,可以观察到液压传动装置的内部构造和工作流程。

(2)防漏快插结构使得实验回路的组装简便、快捷,清洁、干净。

红色的液压油和银白色底版使得元件的内部结构鲜明直观。

(3)通过透明的油管和红色液压油可以清晰的观察到液压油在液压元件中的整个流动过程。

(4)独立的元件模块,方便的安装方式,可以随意的组合各实验模块,搭建各种不同的实验回路。

(5)液压元件的最大承受压力为1Mpa,,额定工作压力为0.8Mpa,是安全的低压实验系统。

(6)采用PLC 编程控制模块,实现可编程程序控制器(PLC)智能控制。

使得机、电、液控制有机结合起来,优化控制方案。

(7)配有虚拟仿真软件。

1.4本课题主要研究的内容[4](1)在了解液压实验台结构的基础上,根据液压实验台的功能要求,给出液压实验台的整体设计方案,及各部分功能划分。

(2)根据用户的主要功能需求,对各功能的实现方法作了详细的研究。

(3)详细分析系统的输入输出,完成液压实验台的硬件的选取。

此外,完成了液压实验台的电气控制图及PLC 控制电气图。

(4)对液压实验台的液压控制回路进行设计,可以使用户更加方便的了解实验台的运行状况,并且设计液压传动实验台控制面板及整体结构。

2 液压实验台系统原理与CAT 系统总体设计方案2.1液压实验台系统原理改进前的液压实验台系统(局部)原理如图2-1 所示。

图2-1 教学实验台(局部)液压系统原理图实验时需要根据实验步骤分别测量不同压力接点处的压力,通过流量计的流量以及负载变化时液压缸活塞杆的运动速度。

如测定定量叶片泵工作特性时,通过调节节流阀(3)的开口度,控制系统压力达到某一设定值,然后分别测量某一开口稳定后的流量,作为泵的不同负载时对应的输出流量;又如在测试先导式溢流阀(5)的启闭特性时,需按给定的压力值调节溢流阀(2)的调压手轮使系统逐渐升压,然后分别测出不同压力下被试溢流阀的溢流量。

YST-20KW液压综合试验台的设计摘要介绍了一种液压综合试验台的系统设计、工作原理及主要技术指标。

它综合了液压泵、液压阀和液压缸专用试验台的性能,达到了一机多用的目的,该试验台具有测试可靠、制造容易、维护方便、成本低廉等特点。

关键词:试验台; 测试参数; 液压泵; 液压阀; 液压缸YST-20KW hydraulic design of a comprehensive test-bed AbstractThe system design,operating principle and main technical in dex-es of a composite hydraulic test bench is described.It com bined the performance of dedicated test benches for hydraulic pump,hydraulic valves and hydraulic cylinders and achieved the pur-pose of multiple functions in one bench.The test bench features reliable test,easy construction,sim ple maintenance and low cost.System.Keywords:Test bench Measured parameter Hydraulic pump Hydraulic valve Hydraulic cylinder.前言21世纪是一个高度自动化的社会,随着科技的发展和人类的新需要,大型智型行走机器人将应运而生。

资料表明,液压技术作为能量传递或做功环节是其中必不可少的一部分。

故无论现在还是将来,液压技术在国民经济中都占有重要的一席之地,发挥着无法替代的作用。

液压元件将向高性能、高质量、高可靠性、系统套方向发展;向低能耗、低噪声、低振动、无泄漏以及污染控制、应用水基介质等适应环保要求方向发展;开发高集成化高功率密度、智能化、机电一体化以及轻小型微型液压元件;积极采用新工艺、新材料和电子、传感等高新技术液压综合试验台是对液压系统的部件、附件进行耐压试验、性能测试、泄漏检验的关键设备,对提高产品性能质量起着重要作用。

矿用多功能试验台设计摘要:针对矿山机械中的液压泵、液压马达、液压阀和液压缸等产品的检验需要,研制了矿用多功能试验台。

本文介绍了试验台液压系统组成及其工作原理,并根据试验对象的不同,确定了合理的信息采集与控制方案,并应用LabWindows/CVI开发了试验台的虚拟测试系统,提高了试验的可操作性和检测精度。

关键词:多功能试验台;工控机;PLC控制;LabWindows/CVI煤矿机械根据其功能,大致分为煤矿的开采、支护和运输设备三大类。

液压系统作为煤矿机械的主要传动系统,其系统性能取决于液压泵、液压马达、液压阀和液压缸等液压元件的质量,将直接影响矿山机械的使用性能。

而传统的矿用液压试验平台,检测手段落后,不能精确检测液压元件的性能,并且功能单一,致使试验设备资源的不能充分利用。

为了完善液压元件检测手段,提高试验台的试验适用范围,项目组严格按照国家规定的液压元件的试验标准,参考机电液一体化技术,综合运用计算机和PLC控制理论,研制了矿用多功能试验台,为液压产品质量提供了可靠的科学依据,对煤矿的安全高效生产具有重要意义。

1.试验台液压系统本试验台液压系统,由液压泵马达试验液压系统和液压阀缸试验液压系统两个子系统组成,整体实现了对液压泵、液压马达、多路换向阀、压力控制阀、流量控制阀、液压缸等液压元件的试验。

1.1.液压泵马达试验液压系统图1 液压泵马达试验液压系统1、16、24、25、32、33、34、35、36-截止阀;2、37-真空表;3、38、51-电动机;4、39、52-联轴器;5-双联叶片泵;6、7、41、54-精滤油器;8、9-电磁卸荷阀;10、11、44-单向阀;12-低压比例溢流阀;13-整流阀组;14、15、42、48、57-压力表;17、45、55-高压比例溢流阀;18、26、49-流量计;19、27、50-流量传感器;20-冷却器;21-液位计;22、29、31-温度传感器;23-电加热器;28、30、43、47、56-压力传感器;40-比例变量泵;46、58-电磁换向阀;53-定量泵液压泵马达试验液压系统原理图如图1所示,液压泵马达试验台大体由补油系统、可变压力供油系统、液压泵和马达试验系统组成,可以完成对液压泵和液压马达的效率、超速、噪声等试验。

浅议多功能液压教学实验台的设计【摘要】本篇文章主要对多功能液压教学实验台的设计进行讨论。

在介绍了研究的背景和意义,为后续内容的展开作铺垫。

在分别从设计原则、结构设计、功能设计、安全性设计和性能评价等方面进行了详细阐述,系统地介绍了多功能液压教学实验台的设计要点。

在对文章进行了总结分析,概括了设计中的亮点和不足之处,并展望了未来的发展方向。

多功能液压教学实验台作为教学实验设备,具有重要的教学和实践价值,设计合理的实验台将有助于提高学生学习效率和实践能力,为液压教学领域的发展做出积极贡献。

【关键词】多功能液压教学实验台,设计,液压,教学,实验台,引言,背景介绍,研究意义,设计原则,结构设计,功能设计,安全性设计,性能评价,总结分析,展望未来1. 引言1.1 背景介绍面对传统的液压教学实验台存在的一些问题,比如功能单一、操作复杂、安全性不足等,设计一种多功能液压教学实验台已成为当今液压教学领域的热点研究之一。

通过更加智能、便捷、安全的设计,多功能液压教学实验台可以更好地满足学生的学习需求,提高实验效率,促进液压技术的传播和应用。

本文将对多功能液压教学实验台的设计进行探讨和分析,旨在为液压技术教学提供更加现代化、实用化的工具,推动液压技术教学的不断发展和完善。

部分到此结束。

1.2 研究意义液压技术在现代工程中被广泛应用,液压系统的设计和应用已经成为工程教育中不可或缺的一部分。

而多功能液压教学实验台则是液压教学中必不可少的重要工具。

通过对多功能液压教学实验台的设计和研究,可以提高学生对液压系统原理和应用的理解,培养学生的实际操作能力和创新意识,进一步提升液压专业人才的素质和竞争力。

多功能液压教学实验台的设计意义重大,不仅可以帮助学生理论学习和实践操作相结合,还可以为学生提供一个真实的实验环境,增加他们解决实际问题的能力。

通过多功能液压教学实验台的设计和使用,学生可以更好地理解液压系统的结构和工作原理,掌握液压系统的调试和维护技能,为将来从事相关工作奠定坚实的基础。

液压试验台设计方案书:液压试验台一、液压试验台用途、基本性能、作业环境。

本液压试验台用于减速器冷却器装置的耐压试验。

试验台要求除被试件装夹、接头联接、开机、关机为手动控制外,其余均为自动控制。

本试验__装在减速器车间,环境温度为室温。

二、试验台设计功能:被测冷却器是为减速器箱体内润滑油降温的冷却系统,为保证冷却器中冷却水在工作工况下不发生泄漏或渗漏现象,特设计测试冷却器压力试验系统。

试验系统流程及功能如下:流程:为被测冷却器充液——升压——保压——泄压——排液功能要求:在人工安装好被测件后,首先将冷却器充满工作介质,充满后冷却器管路中不允许有空气存在;充液完成后系统自动转换为升压;压力达到试验压力后自动转到保压模式工作,保压时间为20~30min,在此阶段中要对保压起始压力和终点压力进行数据采集并对记录数据存储;保压结束后自动泄压;泄压结束后用风压将液排尽(风源由减速器车间提供),打压过程结束,可以拆下被测冷却器。

三、被测冷却器介绍:被测冷却器为管形冷却器,冷却水入口和出口连接在安装面板上——均为内螺纹联接,工作时安装面板固定在减速器箱体上,冷却器工作部分被浸泡在减速器润滑油中,通过流动的冷却水吸收热量来控制润滑油的温度。

该类冷却器冷却水管路通径为φ16mm,展开长最长为1000mm。

四、系统具体要求 1. 工作介质:自然水或乳化液;2. 试验压力:6~12Mpa (可手工调节);3. 试验工位数量:6;4. 各工位要求并联联接,统一操作,但保压必须单路控制且单路采点记录;5. 各工位出口和回液口均为软管联接,具体接头结构见附图;6. 因液压回路不可避免的系统渗漏,故要求系统有专门的“系统标零”和“补偿”功能:高压工作介质出口封死的情况下、在规定试验时间内,检测出系统压力降,在记录系统中存储该数据。

此数据在试验过程中可自动“补偿”被测冷却器的检测数据,使测试结果更加真实。

另外,该项功能可以不定期的进行工作——更新“坐标点”。

浅议多功能液压教学实验台的设计【摘要】本文主要讨论了多功能液压教学实验台的设计。

在介绍了研究背景和研究意义。

在详细讨论了设计原则、结构设计、液压系统设计、控制系统设计和安全保障设计。

通过对以上几个方面的设计,可以确保教学实验台具有多功能性和高效性。

在总结了本文的研究成果,并展望了未来的发展方向。

多功能液压教学实验台的设计对于提高教学效果和培养学生的实践能力具有重要意义,值得进一步深入研究和应用。

【关键词】液压教学实验台,多功能,设计,液压系统,控制系统,安全保障,研究背景,研究意义,设计原则,结构设计,总结成果,展望未来1. 引言1.1 研究背景过去,液压传动技术一直是工程教育中的重要内容,但是传统的教学实验设备往往功能单一、性能有限,无法满足现代工程教育的需求。

如何设计一款功能丰富、性能稳定的多功能液压教学实验台成为了当下一个亟待解决的问题。

只有通过对多功能液压教学实验台的设计与研究,才能更好地适应工程专业学生的培养需求,提高教学质量和效果。

基于以上背景,本文将从设计原则、结构设计、液压系统设计、控制系统设计和安全保障设计等方面对多功能液压教学实验台进行深入研究和探讨,旨在为液压技术教学提供更好的支持和帮助。

1.2 研究意义多的调整内容、格式等。

感谢配合!多功能液压教学实验台在工程教育中具有重要的意义。

通过设计与制作多功能液压教学实验台,可以帮助学生更好地理解液压传动原理和液压系统的工作原理,提高学生的实践能力和创新意识。

多功能液压教学实验台可以帮助学生培养动手能力和解决问题的能力,增强学生实际操作能力和团队协作能力。

多功能液压教学实验台还可以为教师提供一个更加灵活多样的教学工具,让教学更加生动有趣,激发学生学习的兴趣和潜力。

研究与设计多功能液压教学实验台对于提高工程教育质量,培养学生的综合能力和创新精神,具有重要的现实意义和深远影响。

2. 正文2.1 设计原则设计原则是多功能液压教学实验台设计中至关重要的一环。

基于 WINCC及 PLC的多功能液压阀综合试验台的设计及实现摘要:设计了一种多功能液压试验台,介绍了其工作原理、系统组成及主要技术参数。

结合企业产品设计研发需要,试验台能满足液压阀、液压缸等多项测试。

通过对试验台数据测试和数据采集系统的集成设计,设计开发了适合该试验台的数据分析软件。

关键词:多功能液压阀;WinCC;S7-1200;一、前言根据中华人民共和国国家标准GB 25974.3-2010《煤矿用液压支架第3部分:液压控制系统及阀》。

用于对液压阀(液控单向阀类、安全阀类、换向阀类)进行强度及寿命试验。

传统的强度以及寿命试验多半是多个试验台单独作业测试,测试过程繁琐,且占用空间太大。

为此,需要设计一套整合三种系列的综合性能试验台,以完成如下功能:a.所需要的参数可以根据需要设定和修改;b.自动记录试验相关数据:包括寿命试验设定的压力、动作次数、阀类型、编号、操作人员等;c.自动记录试验相关数据还包括试验过程中的压力测定数据、每次动作的时间;d.可以完成测定压力数据的历史实时曲线显示、查询以及打印功能;e.每间隔一定次数(可根据需要任意设定),进行被实验阀的完好性判定;f.被实验阀完成寿命测试后,形成完整的数据试验报表,允许测试人员查询、打印或者以EXCEL表格形式导出.二、试验台系统组成多功能综合性能试验台由五部分组成:液压供油系统、液压控制系统、电气控制系统、数据采集检测以及计算机监控系统。

其中液压供油系统放置于液压测试台附近,被测阀件、液压控制系统、电气控制系统以及计算机监控系统均整合在液压测试台内,构成完整的一体化操作测试平台。

图1为液压系统原理图,三种类型的阀共用多个液压回路及传感器,通过对不同液压阀的切换和连锁控制,实现对液控单向阀类、安全阀类、换向阀类的强度或者寿命测试试验。

图1:液压阀多功能综合试验台液压原理图三、测控系统设计图2:测控系统结构图多功能液压阀综合性能试验台采用网络化结构,其中计算机采用研华公司生产的IPC610L工业控制计算机,通过PROFINET工业以太网,实现对各种控制参数和指令的下达,并且实时采集现场的各类数据;显示各液压系统元件的动作状态、测试时间、各测量点实时压力数值和曲线;此外进行阀性能判定、试验报表的处理、OPC数据的管理、后台数据库的处理;历史数据曲线的显示查询以及打印、关键数据的导出等。

多功能液压实验台设计多功能液压实验台毕业设计论文摘要多功能液压实验台完全是根据各国对多功能液压实验台形式试验的标准设计制造的,该实验台能够实现常用液压元件的性能测试和液压传动基本实验回路实验。

本设计包括两部分:一是液压系统的功能原理设计(包括功能设计、组成元件设计和液压系统计算),二是液压系统的结构设计(主要是液压装置的设计)。

本实验台结构紧凑,节省空间;够实现完成给定的实验项目,实验操作简便,实验间切换方便灵活,各部件工作正常、稳定,无有泄漏现象;所有实验元件均为独立组件,可由学生自行设计、组装实验回路;系统的额定压力:6.3MPa;能够完成2种液压元件的性能测试,12个液压回路实验,即:液压泵的特性测试、溢流阀的特性测试;调压回路、减压回路、进油节流调速回路、采用行程阀的速度换接回路、调速阀串接的速度换接回路、调速阀并联的速度换接回路、采用顺序阀的顺序动作回路、采用压力继电器的顺序动作回路、采用三位换向阀的卸载回路、采用溢流阀的卸荷回路、用顺序阀的平衡回路、用液控单向阀的锁紧回路。

多功能液压实验台采用了行程阀和顺序阀实现快进与工进的换接,不仅简化了油路,而且使动作可靠,转换的位置精度也比较高。

由于工进速度比较低,采用布置灵活的电磁阀来实现两种工进速度的换接,可以得到足够的换接精度。

关键词:液压回路泵阀AbstractHydraulic multi-functional test-bed is in accordance with national test-bed for multi-function hydraulic form of the standard design and manufacture of test, the test commonly used to achieve the performance of hydraulic components and hydraulic test loop experiments the basic experiment. The design includes two parts: First, the principle of hydraulic system design (including functional design, component design and hydraulic system components), the second is the structural design of the hydraulic system (mainly the design of the hydraulic device).Compact structure of the test-bed to save space; enough to achieve the completion of the pilot project to set the experimental method is simple, convenient and flexible switch between experiments, the components of the work of a normal, stable, non-leakage phenomenon; all experimental components are independent components, can be students to design, assemble experimental circuit; system rated pressure: 6.3MPa; able to complete two kinds of performance testing of hydraulic components, hydraulic circuit 12 experiments,Namely: the characteristics of hydraulic pump testing, the characteristics of relief valve testing; regulator loop decompression loop speed control loop into the oil-savings, speed of adoption of trip-for-access valve circuit, the speed governor valve for next series loop speed control valve for the speed of parallel access circuit, the order of sequence valve action circuits, using the pressure of the order of the relay loop action, the use of three of the unloading valve circuit, the unloading relief valve of the circuit, with the order of circuit balance valve, pilot controlled check valve with the locking loop.Test-bed multi-function hydraulic valve using a trip valve and the order and work to achieve fast-forward into the next exchange, not only simplifies the circuit, but also action and reliable conversion of positional accuracy is high. As the work is relatively low speed, using a flexible arrangement of the solenoid valve to achieve the speed of the two-for-work into the next, can be sufficient accuracy for access.Key words:hydraulic circuit pump valve目录摘要 (I)Abstract (Ⅱ)目录 (III)1 液压技术概述 (1)1.1液压技术的应用和发展概况 (1)1.2液压传动的优缺点 (1)2液压系统方案设计 (3)2.1调压回路 (3)2.2减压回路 (3)2.3进油节流调速回路 (4)2.4采用行程阀的速度换接回路 (4)2.5调速阀串接的速度换接回路 (4)2.6调速阀并联的速度换接回路 (4)2.7 采用顺序阀的顺序动作回路 (5)2.8采用压力继电器的顺序动作回路 (5)2.9采用三位换向阀的卸载回路 (6)2.10采用溢流阀的卸载回路 (6)2.11用顺序阀的平衡回路 (7)2.12用液控单向阀的锁紧回路 (8)3 液压泵概述 (9)4 直动型溢流阀概述 (10)5 液压系统的参数计算 (11)5.1液压缸参数计算 (11)5.2液压泵的参数计算 (12)5.3电动机的选择 (12)6 液压元件的选择 (14)6.1液压阀的选择 (14)6.2油管的选择 (16)6.3油箱的确定 (16)6.4 液压阀配置形式的选择 (18)6.5泵-电机装置的选择 (19)结论 (20)致谢 (21)参考文献 (22)附录 (23)1 液压技术概述1.1液压技术的应用和发展概况液压与气压传动相对于机械传动来说是一门新兴技术。

虽然从17世纪中叶叶帕斯卡提出静压传递原理、18世纪末英国制造出世界上第一台水压机算起,已有几百年的历史,但液压与气压传动在工业上被广泛采用和有较大幅度的发展确是20世纪中期以后的事情。

近代液压传动是由19世纪崛起并蓬勃彭破发展的石油工业推动起来的,最早实践成功的液压传动装置是舰艇上的炮塔转换器,其后才在机床上应用。

第二次世界大战其间,由于军事工业和装备迫切需要反应迅速、动作准确、输出功率大的液压传动装置及控制装置,促使液压技术迅速发展。

战后,液压技术很快转入民用工业,在机械、工程机械、冶金机械、塑料机械、农林机械、汽车、船舶等行业得到了大幅度的应用和发展。

20世纪60年代以后,随着原子能、空间技术、电子技术等方面的发展,液压技术向更广阔的领域渗透,发展成为包括传动、控制和检测在内的一门完整的自动化技术。

现今,采用液压传动的程度已成为衡量一个国家工业水平的重要标志之一。

如发达国家生产的95%的工程机械、90%的数控加工中心、95%以上的自动线都采用了液压传动。

随着液压机械自动化程度的不断提高,液压元件应用数量急剧增加,元件小型化、系统集成化是必然的发展趋势。

特别是近十年来,液压技术与传感技术、微电子技术密切结合,出现了许多诸如电液比例控制阀、数字阀、电液伺服液压缸等机(液)电一体化元器件,使液压技术在高压、高速、大功率、节能高效、低噪声、使用寿命长、高度集成化等方面取得了重大发展。

无疑,液压元件和液压系统的计算机辅助设计(CAD)、计算机辅助试验(CAT)和计算机实时控制也是当前液压技术的发展方向。

1.2液压传动的优缺点与机械传动和电力拖动系统相比,液压传动具有以下优点:1.液压元件的布置不受严格的空间位置限制,系统中各部分用管道连接,布局安装有很大的灵活性,能构成用其他方法难以组成的复杂系统。

2.可以在运行过程中实现大范围的无级调速,调速范围可达2000:1。

3.液压传动和液气联动传递运动均匀平稳,易于实现快速启动、制动和频繁的换向。

4.操作控制方便、省力,易于实现自动控制、中远程距离控制、过载保护。

与电气控制、电子控制相结合,易于实现自动工作循环和自动过载保护。

5.液压元件属机械工业基础件,标准化、系列化和通用化程度较高,有利于缩短机器的设计、制造周期和降低制造成本。

除此之外,液压传动突出的优点还有单位质量输出功率大。

因为液压传动的动力元件可采用很高的压力(一般可达32Mpa,个别场合更高),因此,在同等输出功率下具有体积小、质量小、运动惯性小、动态性能好的特点。

液压传动的缺点:1.在传动过程中,能量需经两次转换,传动效率偏低。

2.由于传动介质的可压缩性和泄漏等因素的影响,不能严格保证定比传动。

3.液压传动性能对温度比较敏感,不能在高温下工作,采用石油基液压油作传动介质时还需注意防火问题。