安全技术说明书-SandvikMining

- 格式:pdf

- 大小:157.51 KB

- 文档页数:6

1.1: 产品标识产品名称山特维克长效发动机油产品代码SANDVIK OE15W40-C1.2: 物质或混合物相关的确定的用途和禁止使用建议推荐用途润滑剂限制用途没有识别出建议为不适合的应用。

化学品及企业标识1.3: 安全技术说明书供应商详情生产企业 / 供应商山特维克矿山工程机械贸易(上海)有限公司地址上海市嘉定工业区兴荣路1200号8幢电子邮件地址********************1.4: 应急电话号码应急电话号码在化学急救事故发生时(泄漏,火灾,暴露或事故),拨打我们的服务提供商英国国家化学急救中心(NCEC ):欧洲: +44 1865 407 333巴西: +55 11 3197 5891美国: +1 202 464 2554墨西哥: +52 55 5004 8763非洲: +27 21 300 2732澳大利亚: +61 2 8014 4558新西兰: +64 9 929 1483中国 (大陆): + 86 532 8388 9090中国 (大陆以外): +86 512 8090 3042工作时间24小时/天,7天/周D V I K OE 15W 40-C /C H N /M E T R I C © 山特维克矿山2017,瑞典和其他国家的山特维克拥有这个注册商标及其全部知识产权。

安全技术说明书山特维克高性能油品长效发动机油SANDVIK OE15W40-C根据法规(EC )第1907/2006(REACH )号第31条,修订的附录II 。

发布日期:2017年6月20日内部代码:SDS-SANDVIK OE15W40-C/CHN/METRIC3: 成分/组成信息2.2: 标签要素EUH208: 含有成分 磺酸钙. 可能产生致敏反应。

EUH210: 安全技术说明书方便索取。

3.1: 混合物一般信息高度精炼的矿物油和添加剂构成的配制品成分名称标识号码浓度 *REACH 登记号注意事项二烷基二硫代磷酸锌EINECS: 283-392-81,00 - <2,50%01-2119493626-26* 除气体外,所有组分的浓度均为重量百分比。

T echnical Specification 7-6105-C 2014-12-18Sandvik DL411-7Production Drills1/4© 2014 S a n d v i k M i n i n g a n d C o n s t r u c t i onThe San dvik DL411-7 is an electro-hydraulic lon g-hole drilling rig for large-scale production drilling in underground mines.The rig has been design ed for vertical an d in clin ed plane rings and fans, parallel long production holes as well as long single holes. The 360° rotation and parallel coverage, together with wide tilt an gle ran ges forwards an d backwards, make the boom suitable to various drilling applications.Instrumentation and data drilling with various auto-mation option s allow maximum performan ce with superior drilling accuracy. Proven CAN-based tech-nology on board allows the operator to set the unit for any rock conditions. It also makes the upgrade of automation level easy, an d has a fault fin din g sys-tem, which reduces downtime.The machin e is based on a proven carrier for high mobility. Tramming is done from the operator's plat-form, and drilling from a remote position next to the machine.Carrier NC7N Boom ZR30Drilling module LFRC1600Rock drill HL710Hole diameter 64-102 mm Hole length Up to 54 m Control system TPC LH Cornering 3400 mmT otal weight21 000 kg(depending on options)2/4Coverage areaMAXIMUM DRIFT SIZEMINIMUM DRIFT SIZEDrilling Module HWW pH R LF16043245324514502100LF16053550355017502100LF16063855385520502100Included 100mm clearance on each sideAll dimensions in mm Rock DrillHL710Percussion power 19.5 kW Percussion pressure Max. 190 bar Percussion rate 42-52 Hz Rotation speedMax. 180 rpm Rotation torque (OMT250)Max. 1335 Nm Hole size64 - 102 mm Recommended drill steel 38-51 mm rods 64 mm tubes Shank adapter T38, T45, T51Weight 245 kg Length1035 mm Profile height286 mmShank lubrication deviceAir /oil mist, SLUShank lubrication compressor CT10, 1m³/min (7 bar)Air consumption 200 - 300 l/min Oil consumption 250 - 550 g/h #Power extractorHL710Technical Specification 2_1750Boom typeZR30Parallel coverage 3000mm Weight2 800kg Roll-over angle360°BoomTechnical Specification 4_1810LFRC160x x=4’ / 5’ /6’Capacity 29+1 rods/tubes Feed force 31kNFeed extensionLF1604: 1000mm LF1605: 1100mm LF1606: 1400mm Rod retainerPito 16Cuttings collectorCC1016Readiness for double tools Rods/T ubesStinger extensionLF1604: 1500mm LF1605/6: 1700mm#Sequence control Automatic rod/tube changing #Front stingerRequired for downholes Technical Specification 3_1557#Visual angle indicators Spirit levels#TMS DDSDrilling direction, depth and speed #Fan automation 360° fan drilling(Incl. one hole data drilling)#One hole data drillingAutomated single hole drillingInstrumentation optionsTechnical Specification 5_9202# Additional options features/components * Alternative options features/components3/4Machine dimensionsFEED L LF1604 3 000LF1605 3 300LF16063 600All dimensions in mmPowerpackHPP755 (55kW)Percussion pump 100cc variable displacement Rotation pump45cc variable displacement Boom movements pump28cc variable displacement Filtration size20 microns (pressure)10 microns (return)Oil tank volume 270 liters T ank filling Electric pump *T ank filling Manual pumpOil coolerWater cooled.Cooling capacity 1x45kW*Oil coolerAir cooled. Cooling capacity 2x30kWN/A with water hose reel*Biodegradable oils Shell Naturelle HFE46/HFE68#Vacuum pump for hydraulic oilHydraulic systemT ype TPC LHPower control Adjustable full powerAdjustable collaring power Anti-jamming control Adjustable anti-jamming pressureRotation control Adjustable rotation speed Flushing control Water flushing flow and pressure controlDrilling control panelPortable with cable remote control panel, 20m cableControl systemTechnical Specification 5_1300#Pressure cleaning system with reel5-15 bar#High pressure cleaning system with reelMax. 180 bar Cleaning system#Greasing unit with reel,pump and nozzleManual#Automatic greasing systemCarrier, boom and cassetteGreasing systems and optionsT otal input power 80 kW Main switchMSE 10Standard voltages 380-690 VAC *Optional voltage 1000 VACStarting method Star delta starter 380 VAC-690 VAC Soft starter 480 VAC, 575 VAC (USC)Direct on Line (DOL) 1000 VAC Voltage fluctuation ±10%Cable reelTCR3E with spooling system Cable reel control Control at operator station Batteries2x12V , 145Ah *Sealed AGM batteries 2x12V , 50Ah#Electric cable rubber or PUR Depending on voltage (see spec 5-4100)#Ground fault and overcurrent protection VYK #Auxiliary outlet 1 x 230V , 16A #Remote control for reel(s)At rear end #Three phase network outlet voltage readiness 380-690VAC only#Battery jump start FlushingWater flushing flow and pressure control. Air-mist flushing, optionWater pump WBP3Water pump capacity 215 l/min Water pump inlet pressure 2-7 bar Flushing water pressure Max. 20 bar*Optional compressorCT16 (11kW , 1.6m 3/min) orCT28 (18.5kW , 2.8m 3/min)External air connection IP5 air cleaner #Air mist flushing packages External water/air connection#End of the hole flushing1x60l air receivers, requires CT16 compressor#Water hose reel + hose THR2.5E +38mm (1½”), 65 metersFlushing system and options#Hand held fire extinguisher 1 pcs #Manual fire suppression system 6 nozzles #Automatic fire suppression system 6 nozzles #FS1000above 0°CFire suppression system and optionsTech. Spec. 5-9800# Additional options features/components * Alternative options features/components4/4Sandvik Mining and Construction OyP .O Box 100. FIN-33311 T ampere, Finland T el. +358 205 44 121, Fax +358 205 44 Sandvik Mining and Construction reserves the right to change this specification without further notice.© 2014 S a n d v i k M i n i n g a n d C o n s t r u c t i o nTramming dimensionsT ramming speedHorizontal: 15 km/h 14% = 1:7 = 8° 6,5km/h Gradeability / Inclination Max. 15° / 5°#Reduced tramming speed3rd gear lockoutT rammingSafety canopyFOPS (ISO 3449)Sound pressure level according to EN791Operator station: 102 dB(A)Emitted: 127 dB(A)SeatErgonomic, adjustableFor tramming including seat belt Reversing alarm Standard#Reversing cameraOn machine rear and side Operator’s stationFront lights(combined working and driving) 4 x 35W HID (24V) Rear working lights 2 x 35W HID (24V) Rear driving lights2 x 35W HID (24V) Parking Rear brake/park lights 2 x Red LEDPortable working lights 2 x 35W HID (24V) Positioning lights2 x Laser type Stair and service lights LED#Amber flashing lightFlashing (24V)Lights and options#RegionalAUS, USC, EUR *Harsh water packagesBasicSee spec sheet 5-9100PackagesCarrierNC7NCarrier type Wheel mounted, frame steering Frame steering ± 40°Rear oscillation ± 10°Ground clearance 320 mmDiesel engineMB OM904LA, 110kW , Tier 3Exhaust catalyser+muffler StandardT ransmission Hydrodynamic, Spicer T20 000Axles SpicerT yres 12.00-20/20RL*T yres12.00-20/28PR ECR *Optional tyresFoam filled tyresService Brakes, park and emergency SAHR type, fail safe wet disc brakes Fuel tank 140 litersHydraulic jacksFront frame stabilizer TJ60 (rear)Hand throttle Standard #Fast filling systemComplete #Wheel chocks and holders2 piecesCarrier#Spare rock drill #Spare wheel assembly Standard or foam filled #Special tools for rock drill #DocumentationExtra manualsExtra items# Additional options features/components * Alternative options features/components。

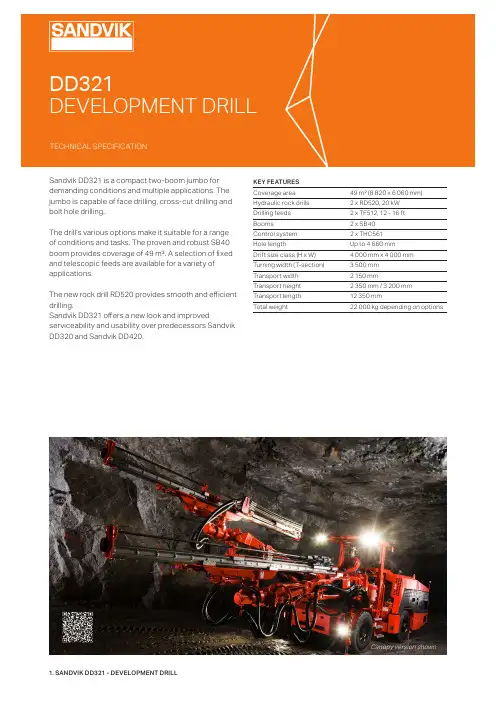

KEY FEATURES Coverage area 49 m² (8 820 x 6 060 mm)Hydraulic rock drills 2 x RD520, 20 kW Drilling feeds 2 x TF512, 12 - 16 ft Booms 2 x SB40Control system 2 x THC561Hole lengthUp to 4 660 mm Drift size class (H x W) 4 000 mm x 4 000 mm Turning width (T-section) 3 500 mm Transport width 2 150 mmTransport height 2 350 mm / 3 200 mm Transport length 12 350 mmTotal weight22 000 kg depending on optionsSandvik DD321 is a compact two-boom jumbo for demanding conditions and multiple applications. The jumbo is capable of face drilling, cross-cut drilling and bolt hole drilling.The drill’s various options make it suitable for a range of conditions and tasks. The proven and robust SB40 boom provides coverage of 49 m². A selection of fixed and telescopic feeds are available for a variety of applications.The new rock drill RD520 provides smooth and efficient drilling.Sandvik DD321 offers a new look and improvedserviceability and usability over predecessors Sandvik DD320 and Sandvik DD420.BOOM Type of boom SB40 (TS2-231)Parallel coverage 44.5 m²Parallelism Automatic hydraulic Boom extension 1 050 mm Feed extension 1 350 mm Boom weight, net 2 100 kg Roll-over angle 358°HYDRAULIC SYSTEM Powerpack2 x HPP555 (55 kW)Filtration (pressure / return)20 µ / 10 µOil tank volume 270 liters (drilling)Oil tank filling pump ElectricCooler for hydraulic oilOW30 oil-to-water (2 x 30 kW)HYDRAULIC ROCK DRILL Type of rock drill RD520 (TS2-235)Percussion power 20 kW Percussion pressure Max. 220 bar Percussion rate 74 Hz Stabilizer HydraulicRotation speed Max. 270 rpm (with OMS80)Rotation torque 400 Nm (with OMS80)Hole size (drifting)43 - 64 mm Hole size (cut hole)76 - 127 mm Recommended rod T38 - R32 - H35T38 - R35 - R39Shank adapter (male)T38Weight 225 kg Length 1 010 mm Profile height 90 mmAIR AND WATER SYSTEM Flushing of holes By water Water booster pump WBP2Water pump capacity 100 l/min Water pump inlet pressure 2 bar (Min.)Flushing water pressure 10 - 15 bar Shank lubrication device SLU2 (air / oil mist) Air compressorCTN10, 1 m³/min (7 bar)Rock drill oil consumption 180 - 250 g/h Rock dril air consumption 250 - 350 l/minDRILLING CONTROL SYSTEM Type of control system THC561 (TS2-362)Operating principle Hydraulic control Manual boom controlDirect control Fully proportional Hydraulic parallelism Drilling control Feed / percussion control Flushing controlAutomatic cycleStop and return automatics ELECTRIC SYSTEM Standard voltage 380 - 690 V (± 10%)Total installed power 135 kW Main switch gear MSE 20IP classification Specification TS2-132Starting method Star delta 380 V - 690 V Soft starter 575 VAutomatic cable reel TCR3E with spooling system Cable reel control Operator station and remote control at rear machine Batteries2 x 12 V, 145 AhFront and rear lights(combined working and driving)10 x 50 W LED (4 200 lm, 6 000 K)Parking rear brake / park lights 2 x Red LED Stair ans service light LED (24 V)DRILLING FEED Type of feed TF500-12’Standard TF500-14’Optional TF500-16’Optional Feed force Max. 25 kN Max. 25 kN Max. 25 kN Total length 5 270 mm 5 880 mm 6 490 mm Hole length 3 440 mm 4 050 mm 4 660 mm Rod length 3 700 mm 4 305 mm 4 915 mm Net weight 500 kg530 kg560 kgOPERATOR’S SAFETY CABIN Cabin certification FOPS / ROPS (ISO 3449 / 3471)Type of cabinStandard height Unit height in tramming 2 950 mmOperation Standing drilling, seated tramming Operator’s seat For trammingAdjustable with seat belt Sound pressure level according to EN 16228Operator station: 80 dB(A)Air conditioning StandardWindowsSafety laminated, with wiper Stainless steel windows frames Front screen protection grillStandardCARRIERType of carrier NC7 (frame-steered)Carrier articulation± 40°Rear axle oscillation± 10°Ground clearance320 mmDiesel engine Cummins QSB 4.5, 124 kW Stage IIIA Exhaust catalyzer StandardTransmission Hydrodynamic, Spicer T20 000 Axles SpicerTires12.00-20Service brakes SAHR type, fail save wet disc brakes Parking andemergency brakesSAHR type, fail save wet disc brakesTramming speed 16 km/h (Horizontal) 6 km/h (14%=1:7=8°)Gradeability / sideways tilt Max. 15° / 5° (according to EN 16228-2)Rod rack on carrier side For 10 - 16 ft rods and two shank adaptersFuel tank140 litersCarrier stabilization 2 x Vertical (front) 2 x Vertical (rear)Centralized greasing points Specification (TS2-463)Hand held fire extinguisher 1 x 7.7 or 9 kg (type ABC) Tramming alarm Standard Knowledge Box™Connectivity solution (TS2-535) Colour scheme SandvikDocumentation 1 x Operator’s manual1 x Maintenance manual1 x T echnical manual (in English only)1 x Parts manual (in English only)2 x T oolman USB keyOPTIONAL FEATURES AND PACKAGESElectric system*Optional voltage*Electric cableGround fault and overcurrentprotectionElectric current draw reducer unitAuxiliary outletBattery jump startDewatering pump outletreadinessAmber flashing lightIndicator light for boom move-ment prevention switch statusCable plug holder1 000 V (50 or 60 Hz) withDirect-On-Line starterSpecification TS2-121VYK1 x 110 V or 1 x 230 V, 16 AOptionSite voltage 380 - 690 V (Max. 8 kW)LED (24 V)2 x on both sides(green or red depending status),1 x indicator inside cabinFor 1000V electric systemAir and water systemAir mist flushing kitFlushing flow control*End of hole air flushingWater hose reel with water hoseCompressed air outletIP5 air cleaner and flow control2 boomsIncluding CT28 air compressorTHR2.5E with 38 mm (1 ½”), 65 mQuick couplingCleaning systemLP system with reelHP system with reelUp to 15 bar (TS2-343)Up to 180 bar (TS2-343)Greasing systemsManual systemAutomatic systemGreasing unit with pump, reel andnozzle (TS2-463)Carrier and booms (TS2-463)Operator’s safety cabin /canopy*Safety canopy*Stainless steel cabinCabin heatingCabin audio systemBoot washerFOPS (ISO 3449)FOPS (ISO 3449)During tramming and drillingCD player / radio / MP3 and loud-speakers and 12V outletAt cabin entranceFire suppression systemSpare hand held fire extinguisherManual or automatic systemAutomatic system1 x 7.7 or 9 kg (type ABC)Ansul, 6 nozzles (TS2-460)Sandvik Eclipse™ (TS2-461)CarrierReduced tramming speed*Diesel engine*Foam filled tiresFast filling and evacuationsystemWheel chocks and holdersTramming camerasRod rack and shank holderSpeedometer3 rd gear lockoutB4.5, 129 kW, Tier 4F, Stage V4 pcsWiggins (complete)2 SetsRear and sideOn carrier sideFor NC7 carrierExtra itemsSpare rock drillSpare wheel assemblySpecial tools for rock drillWarranty extensionDocumentationiSURE®Package: Country specificoptions*Package: Harsh waterRD520, RDX512.00-20 or foam filled tireComplete tool setField tool setOne year (excl. Kazakhstan)Extra paper, CATbase, Link onemanualsiSURE II Plus annual license(Advanced drill and blast designincluding round reports)iSURE III Premium annual license(MWD including Pull out analyses)LAM, USC, AUS packageBasic or advanced (Spec. TS2-049)*) Replaces standard featureOPTIONAL FEATURES AND PACKAGESRock drill*Type of rock drill RDX5 (OMS80) instead of RD520 Drilling feed*Feed length*Telescopic feed Rod retainer Two rods system 14’, 16’TFX6/12, TFX8/14TRR1 incl. safety wire,add 35 mm length of the feedTRS included TRR1 with safety wire.Boom*Type of boom SB40NV instead of SB40 Hydraulic system*Oil tank filling pump Vaccum pump ManualFor hydraulic systemDrilling control systemConstant speed drilling Reaming mode switch InstrumentationAccess detector and protector Replaces feed / percussion control Selection switch between standard / reaming hole drillingTMS+ D2 for TFX-feedTMS+ DDSS2 for TF-feedTCAD+ with iSURE I Basic(Drill plan design)Mandatory in Europe (TS2-211)TF512TF514TF516TFX6/12TFX8/14Overall lengthmm12 35012 55013 00011 90011 900Drilling feed Radius (R)T-cross (C)TF500–12’ 6 300 mm 3 700 mm TF500–14’ 6 450 mm 3 850 mmTF500–16’ 6 600 mm 4 000 mm TFX6/12 6 250 mm 3 600 mm TFX8/146 250 mm3 600 mmT S 2-126:11/E N G /M E T R I C © S a n d v i k M i n i n g a n d R o c k S o l u t i o n s 2022 S A N D V I K i s a r e g i s t e r e d t r a d e m a r k o w n e d b y S a n d v i k I n t e l l e c t u a l P r o p e r t y A B i n S w e d e n a n d o t h e r c o u n t r i e s .Sandvik Mining and Rock Solutions reserves the right to make changes to the information on this data sheet without prior notification to users. Please contact a Sandvik representative for clarification on specifications and options.ROCKTECHNOLOGY.SANDVIK。

Technical Specification 07271-2 2007-05-01Sandvik DX700700D XAPPLICATIONSandvik DX700 is a hydraulic, self-propelled, self-contained, crawler based surface drilling rig equipped with a cabin (F.O.P.S. and R.O.P.S.) and rod handling system. It drills vertical, inclined or horizontal holes with a diameter of 64 - 115 mm (2 ½" - 4 ½") utilizing 38, 45 or 51 mm (1 ½", 1 ¾" or 2") extension rods. DX700 is equipped with HL 710, hydraulic top ham-mer rock drill. With high rotation torque, sufficient flushing and sophisticated ergonomic drilling control system the rig is well suited also in very fractured rock conditions. The rock drill and articulated boom are mounted on the turnable superstructure giving a drill-ing coverage of 17,6 m 2 (optionally 26,4 m 2).The powerpack of DX700 consists of a Caterpillar diesel engine and a gearbox, which divides the power for hydraulic pumps and flushing air compressor. The powerpack is mounted crosswise at the rear end of the superstructure to keep counterweight on the op-posite side of the boom and feed regardless of the drilling direction. DX700 has an ergonomic cabin to increase operator's safety and visibility. The cabin is certified for R.O.P.S. (ISO-3471 Roll-Over Protection Structure) and F.O.P.S. (ISO-3449 Falling Object Protection Struc-ture). Windows are laminated for added safety. The noise level in the cabin is less than 80 dB(A). To keep dust at a minimum, the cabin is fitted with efficient filters for incoming fresh air. Adjustable seat, good visibility, adequate lighting and an optimum working temperature are among the many features ensuring a good operating environment. Drilling functions are proportionally controlled by one hydraulic joystick. Several routine functions e.g. antijamming are exe-cuted automatically. There are fewer levers to make it easy to use. Driving, rear jack and winch control can be done outside the cabin from the optional remote control box.Typical applications for DX700 are road cutting, pipe-line drilling and foundation drilling, as well as produc-tion drilling in medium size quarries. Therefore DX700 is most often used by construction contractors, mines and quarries, and also included in the equipment fleet of rental houses as well.DRILLING DIMENSIONS90º30ºOptional 90º1m1mTRANSPORT DIMENSIONS259077003210700© 2007 Sandvik Mining and Construction Sandvik Mining and Construction OySandvik Mining and Construction reserves the right to change this specification without further notice.STANDARD COMPONENTS1. Rock drillHL 710, hydraulic 2. Chain feed CF 145H3. Rod handler RH 714 incl. 1 set of jaws4. Boom DB 800H, articulated5.CarrierTrack mounted, turnable su-perstructure6. Powerpack Diesel driven, hydraulic pumpsand on-board compressor7. Hydraulic system Load sensing and open center 8. Control system THC 700 Rock Pilot 9. Movable drill steel support 10. Operator's cabin F.O.P.S. and R.O.P.S. 11. Dust collection sys-temDC 800 H, hydraulic12. Working lights 9 pcs 13. Gauge set For accumulator pressurechecking14. Reversing alarm15. ManualsService and spare parts manuals: 2 x paper copy2 x CD-ROM (Toolman)16. EU-safety devicesTRANSPORT DIMENSIONSWeight (without options) 14 800 kgWidth 2.5 m Height 3.6 m / 3.2 m Total length 7.2 m / 10.7 mTHE JAWS FOR DRILL STEELSDrill steeltype Drill steel diameter Recommended hole diameter 1.Extension rods38 mm 1 ½" 64 - 70 mm 2 ½" - 2 ¾" 2. MF-rod 38 mm 1 ½" 64 - 70 mm 2 ½" - 2 ¾" 3.Extension rods45 mm 1 ¾" 76 - 89 mm 3" - 3 ½" 4. MF-rod 45 mm 1 ¾" 76 - 89 mm 3" - 3 ½" 5. MF-rod 51 mm 2"89 - 115 mm 3 ½" - 4 ½" 6.Extension rods51 mm 2”89 - 115 mm 3" - 3 ½"Note- not with 10' MF-rods- with hose reel only 10' or 12' rods - 51 mm (2") extension rods only 5 + 1-if several jaws selected please specify jaws assembledSELECTION OF OPTIONS1. Turnable superstructure 180º2. Air conditioning3. Rod greasing system4. P&Q electric vertical angle indicator (± 6 deg.)5. Electric angle indicator TIM 2302 with aiming unit6. Measuring system TIM 2303 with aiming unit7. Laser based measuring system TIM 23058. Power extractor9. Electric filling pump for refuelling10. Remote control box; for rear ground support, drivingand oscillation11.Remote control box + hydraulic winch with cabletightness automatics (replaces and includes previous option)12. Hydraulic rear ground support 13. Three-bar grouser plates 14. Guides for grousers15. Fuel operated heater for cabin, hydr. oil and engine 16. Flushing control automatics 17. Shut down of suction for water holes 18. Sanrock Mini H hydraulic bit grinder 19.Readyness for Power extractor20. Towing hook21. Primary separator PE 5022. Horizontal drilling kit (includes hose reel) 23. Hose reel (not with 14' rods) 24. Radio with CD player 25. Central lubrication system 26. Kit for alternative steels 27. Water injection system with tank28. Water injection system w/o tank 29. Zero Dust system30.Biogradeable hydraulic oil, Shell naturelle HFE 46 orHFE 68 (synthetic ester) 31. Extra manuals 32. First service kit for DX700² 33. Special tools for HL 710, field kitID 150 734 8834.Special tools for HL 710, complete ID 150 730 7835. Antifreeze for air lines 36. Vacuum cleaner for cabin。

KEY FEATURES Hydraulic rock drill Sandvik HLX5Drill feed Sandvik TF512BoomSandvik SB40Coverage area 40 m²Hole lengthUp to 4,660 mm Minimum drift size (H x W)3,000 mm x 3,000 mm Turning width (T-section)4,040 mm Transport width 1,980 mmTransport height 2,670 mm (lowered cabin)2,920 mm (high cabin)Transport length 12,370 mmTotal weight15,500 kgdepending on optionsSandvik DD311-40C is a single-boom electro-hydraulic jumbo for fast and accurate drilling in drifting and tunneling of 40 m² cross sections. The hydraulic controls enable accurate and efficient drilling performance.The HLX5 rock drill has proven to be efficient and powerful. Optimal coverage is achieved with the robust SB40 boom. The drilling performance can be improved with optional instrumentation.Sandvik DD311 is the successor of the well-known Sandvik DD310 and offers easier maintenance.BOOM TECHNICAL SPECIFICATION TS2-231Boom type Sandvik SB40Parallel coverage 44.5 m²Parallelism Automatic hydraulic Boom extension 1,050 mm Feed extension 1,350 mm Boom weight, net 2,100 kg Roll-over angle358°HYDRAULIC SYSTEM Powerpack HPP555 (55 kW)Percussion pump 100 cc (variable)Rotation pump 45 cc (gear)Filtration size 20 micron (pressure)10 micron (return)Oil tank volume 180 liters (drilling)55 liters (tramming)Tank filling Manual pumpOil coolerWater cooled.Cooling capacity 1 x 30 kW Tool set for hydraulic adjustmentSpec. sheet 2-9100HYDRAULIC ROCK DRILL TECHNICAL SPECIFICATION TS2-232Rock drillSandvik HLX5Percussion power 20 kW Percussion pressure Max. 220 bar Percussion rate 67 HzRotation speed Max. 250 rpm (with OMS80)Rotation torque 400 Nm (with OMS80)Hole size (drifting)43 - 64 mm Hole size (cut hole)76 - 127 mmRecommended rod T38 - Hex 35 - R32T38 - Hex 35 - Alpha 330T38 - Hex 35 -R35Shank adapter T38 (male)Weight 210 kg Length 955 mm Profile height87 mmShank lubrication device Air / oil mist, SLU-1Air consumption 250 - 350 l/min Oil consumption180 - 250 g/hInflating device for accumulator Spec. sheet 2-9110CONTROL SYSTEM TECHNICAL SPECIFICATION 5-1010TypeSandvik THC560, hydraulic Manual boom controlDirect control Fully proportional Hydraulic parallelism Drilling control Manual collaringFeed / percussion control Anti-jamming system Automatic cycleStop and return automaticsOptions• Sandvik SB40NV boom instead of Sandvik SB40.Options• TF feed lengths. TF510, TF514, TF516.• Telescopic feed. Sandvik TFX6/12, TFX8/14.• Rod retainer.TRR1 incl. safety wire, add 35 mm length of the feed.• Two rods system. TRS included TRR1 with safety wire.Options• Electric filling pump.• Biodegradable oils. Shell Naturelle HFE46 / HFE68.ELECTRIC SYSTEM Total input power 70 kW Main switch MSE 5IP classification Spec. sheet TS2-132Standard voltage 380 - 690 VAC (± 10%)Starting method Star delta, DOL or soft starter depending on voltage Automatic cable reelTCR1Cable reel control (in / out)Operator station and remote control at rear of unit Sealed AGM batteries 2 x 12 V, 95 AhFront working lights(combined working and driving)4 x 50 W LED (4,200 lm, 6,000 K)Front working lights(combined working and driving)4 x 50 W LED (4,200 lm, 6,000 K)Parking rear brake / park lights 2 x Red LEDOptions• Constant speed drilling• Instrumentation TCAD+ with iSURE I-II design and reporting.• iSure III Analysis (with TCAD+ option).FEED TECHNICAL SPECIFICATION 3-1400Feed type TF500-10’TF500-12’TF500-14’TF500-16’Feed force Max. 25 kN Max. 25 kN Max. 25 kN Max. 25 kN Total length 4,660 mm 5,270 mm 5,880 mm 6,490 mm Hole length 2,830 mm 3,440 mm 4,050 mm 4,660 mm Rod length 3,090 mm 3,700 mm 4,305 mm 4,915 mm Net weight470 kg500 kg530 kg560 kgFLUSHING SYSTEM FlushingWater Water pump type WBP1Water pump capacity 43 l/min Water pump inlet pressure 2 bar (Min.)Flushing water pressure 10 - 15 barAir compressorCTN10, 1 m³/min (7 bar)TRAMMING AND OPERATOR STATION Tramming speed 12 km/h (Horizontal)5 km/h (14%=1:7=8°)Gradeability / inclination Max. 15° / 5°Safety cabin FOPS / ROPS (ISO 3449)High cabin ROPS < 16,000 kg Low cabin ROPS < 18,000 kg OperationStanding drilling, seated tramming Sound pressure level according to EN 791Operator station: 80 dB(A)SeatErgonomic, adjustable for tram-ming including seat belt Air conditioning Filtration 100µReversing alarmOptions• Optional voltage. 1,000 VAC, 50 Hz.• Electric cable rubber or PUR. Spec sheet TS2-121.• Indicator lights for jacks up.• Optional outlet. 230 VAC outlet Max. 16 A.• Battery jump start.• Extra working lights. 2 x 50 W LED (4,200 lm, 6,000 K).• Amber strobe light. LED (24 VDC).Options• Air mist flushing. (Spec. 5-9501).• Water flushing with air cleaning of hole with 2 x 60L air receivers.• Water flushing with air cleaning of hole with CTN16.• Air mine connection with IP5 air cleaner.• Additional air for hole cleaning with air. 2 x 60L air receivers.• CT28 air compressor.• Water hose reel with water hose. 32 mm (1 ¼”), 80 meters.• Water hose with hooks. 32 mm (1 ¼”), 80 meters.Options• Lowered cabin, height 2,670 mm (seated operation).• T-back seat.• Cabin heating (webasto) during drilling and tramming.• CD player / radio / MP3 requires 12 VAC outlet.• Front screen protection bar.CARRIER Carrier Sandvik NC5Carrier type Wheel-mounted, frame steering Frame steering ± 40°Rear oscillation ± 10°Ground clearance 320 mmDiesel engine BF4M2011, 62 kW, Tier 2, Stage II Diesel engine control Electronic, EMR Exhaust catalyzer StandardTransmissionHydrostatic, automotive Axles Dana spicer 112 with extended differential breathers Tires12.00-20Service brakes Hydrostatic and positive braking Parking andemergency brakes Hydraulic oil immersed multiple disc brakes on both brakes Fuel tank80 litersHydraulic jacksTelescopic (front)Vertical (rear)Options• Diesel engine TCD2012, 74 kW, Tier 3, Stage IIIA.• Foam-filled tires.• Fast filling systems. Complete.• Wheel chocks and holder (2 pieces).•Manual hand pump for brake release.• Reversal rotation for cleaning.• LP cleaning system with reel. Max. 15 bar.• HP cleaning system with reel. Max. 180 bar.• Centralized greasing points. Boom and carrier.• Greasing unit with pump, reel and nozzle. Manual.• Automatic greasing system. Boom and carrier.• Handheld fire extinguisher. 1 or 2 pcs 9 kg Type ABC.• Manual fire suppression system. 6 nozzles (incl.1 x extinguisher).• Auto. fire suppression system. 6 nozzles (incl.1 x extinguisher).• Access detector system. (Spec. TS2-211).Packages• Regional packages. LAM, USC, AUS, EUR.• Harsh water packages. Basic or advanced (Spec. TS2-049). • Rotary drilling package (Spec. TS2-195).• Arctic package. Excl. 1,000 VAC and USC package (TS2-195).Extra items• Ground fault and overcurrent protection (VYK).• Spare rock drill.• Spare wheel assembly. Standard or foam-filled.• Special tools for rock drill.• Documentation. Extra manuals.TF510TF512TF514TF516TFX6/12TFX8/14Overall lengthmm11,82012,37012,57013,02011,90511,905Angle (A)Radius (R)T-cross (C)DD311-40C (TF510)mm 40°6,1683,920DD311-40C (TF512)mm 40°6,2904,040DD311-40C (TF514)mm 40°6,4254,170DD311-40C (TF516)mm 35°7,0004,800DD311-40C (TFX6/12)mm 40°6,2303,980DD311-40C (TFX8/14)mm40°6,2303,980T S 2-034:03/E N G /M E T R I C © S a n d v i k M i n i n g 2015 S A N D V I K i s a r e g i s t e r e d t r a d e m a r k o w n e d b y S a n d v i k I n t e l l e c t u a l P r o p e r t y A B i n S w e d e n a n d o t h e r c o u n t r i e s .Sandvik Mining reserves the right to make changes to the information on this data sheet without prior notification to users. Please contact a Sandvik representative for clarification on specifications and options.All dimensions in mm。

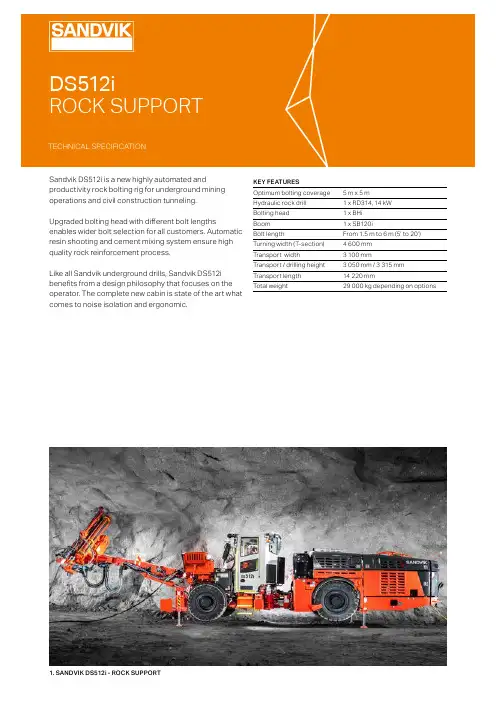

KEY FEATURESOptimum bolting coverage 5 m x 5 m Hydraulic rock drill 1 x RD314, 14 kW Bolting head 1 x BHi Boom 1 x SB120iBolt lengthFrom 1.5 m to 6 m (5’ to 20’)Turning width (T-section) 4 600 mm Transport width3 100 mmTransport / drilling height 3 050 mm / 3 315 mm Transport length 14 220 mmTotal weight29 000 kg depending on optionsSandvik DS512i is a new highly automated andproductivity rock bolting rig for underground mining operations and civil construction tunneling.Upgraded bolting head with different bolt lengthsenables wider bolt selection for all customers. Automatic resin shooting and cement mixing system ensure high quality rock reinforcement process.Like all Sandvik underground drills, Sandvik DS512i benefits from a design philosophy that focuses on the operator. The complete new cabin is state of the art what comes to noise isolation and ergonomic.HYDRAULIC SYSTEMPowerpack HPP355 (1 x 55 kW) Filtration size (pressure / return)20 µ / 10 µOil tank volume270 litersOil tank filling pump ElectricOil cooler (water actuated)OW30 oil-to-water (1 x 30 kW)AIR AND WATER SYSTEMFlushing of holes By WaterWater booster pump type WBP2Water pump capacity100 l/minWater pump inlet pressure 2 bar (Min.)Flushing water pressure10 - 15 barShank lubrication device SLU-1 (Air / oil mist)Air compressor CTN10 (1.0 m³/min at 7 bar) Oil consumption150 - 250 g/hAir consumption250 - 350 l/min Compressed air outlet Quick couplingDRILLING CONTROL SYSTEMControl system type SICADrilling control modes Intelligent Torque control / Feed percussion / manualUpgradeable automation levelsComprehensive diagnostic systemElectronic joystick controls15’’ full color touch screenCable kit for spare part programmingSafety lock for movement prevention 2 switches ELECTRICAL SYSTEMStandard voltage380 – 1 000 V (±10%)Total installed power70 - 80 kWMain switch gear MSE20IP classification Specification TS2-132Starting method Direct on line 380 V - 1 000 V Automatic cable reel TCR4CD with spooling systemCable reel controlOperator station and remotecontrol at rear machineFront lights6 x 50 W LED (24V)>125lx, 20 000 lm; 6 000 kRear lights2 x 50 W LED (24V) and2 x 17 W LED (24V) 8 000 lm; 6 000 k Parking rear brake / park lights2 x Red LEDStair and service lights LED (24 V)Electric quality monitoringVoltage, Amperage, Power, Pf Energy,Phase-sequenceMotor protectionIntelligent control with power maxi-mizationExtra low voltage supplyContinuous 80 A (27 VDC) with bat-tery back-up and managementOPERATOR’S SAFETY CABINSafety cabin certification FOPS / ROPS (ISO 3449 / 3471) OperationSeated trammingStanding and seated drillingSound pressure levelAccording to EN791, ISO4872, ISO1120.Operator station: 69 db(A)Vibration level According to EN791, ISO2631-1SeatFully adjustable seat(tramming and drilling)Optimized dust level control via air circulationAir conditioning EU6/7 filtering capacityCabin heating During tramming and drilling Electricity outlets1 x 24 V, 1 x 12 Vand CD player readinessStairs and indoors lights LEDAudio player CD / MP3 player with radioBoot washer At each cabin entranceSafety laminated acousticwindowsHYDRAULIC ROCK DRILLType of rock drill RD314 (TS2-137) Percussion power14 kWPercussion pressure Max. 160 barPercussion rate110 HzRotation speed Max. 520 rpm (with OMS100) Rotation torque340 Nm (with OMS100) Hole size (bolting)33 - 43 mmShank adapter45 mm / R32 female Weight122 kgLength571 mmBOLTING HEADType of bolting head BH (TS2-277)Bolting head feed KS140Bolt caroussel capacity 8 rock bolts with 150 x 150 mm maximum plate sizeBolt head length Max. 7 535 mm (BH60) Net weight Max. 2 174 kg (BH60)BOLTING BOOMType of boom SB120i (4-3320) Boom extension 1 900 mmBoom weight, net 3 000 kgRoll-over angle360°OPTIONAL FEATURES AND PACKAGESBolting head*Bolt carousel capacity10 rock bolts for square plate 120 mm12 rock bolts for square plate 100 mm16 rock bolts for square plate 85 mm Bolting option*Bolting alternatives Automatic resin shooting “In the hole” resin cartridges injection systemScreen handlerCement dust collectorBolt storageBolting head oiler GCR, WI, S, BCS, M, KARI systemSee spec. 8-610SSB90RSH dedicated boom Above the mixerOn right side, or front module Recommended with P-systemHydraulic systemVacuum pump for hydraulicsystemBy pass oil filterInstrumentationAccess detector, or protector Mandatory in Europe (TS2-211) Air and water system*Air compressor Compressed air outlet Water hose reel and hose CT28 (2.8 m³/min, at 7 bar)Quick couplingTHR2.5E with Ø38 mm (1 ½”), 65 mCleaning systemLP system with reelHP system with reel Bolting module continuous washing system Up to 15 barUp to 180 bar Remote controlledGreasing systemsManual system Automatic system Specification 5-2110Lincoln (complete)OPTIONAL FEATURES AND PACKAGESElectric system*Electric cablesGround fault and overcurrentprotectionDewatering pump outletMultivoltage basicMultivoltage proCurrent draw reducer unitRemote controlled spot lightsIndicator lights for jacksEarth continuity controlAmber flashing lightBattery jump startSpecification TS2-121VYK8 kW, Site voltage 380 - 690 V380 – 440 V, 690 V 50 or 60 Hz380 – 1 000 V, 50 or 60 Hz2 pcsUp and down1 wire pilot circuit with remote reset /disconnectLED (24 V)OptionalOperator’s safety cabinTiltable cabinCabin heatingTramming camera10° to improve operator’s comfortDuring tramming and drillingRear and sideFire suppression systemSpare hand held fire extinguisherManual or automatic systemFire suppression system1 x 7.7 or 9 kg (type ABC)Ansul, 6 nozzlesSandvik Eclipse™CarrierReduced tramming speed*Diesel engine*Foam filled tiresFast filling systemRod rackWheel chocks and holders3 rd gear lockoutQSB6.7, 205 kW, Tier4F, Stage IVQSB4.5, 122 kW, Tier4F, Stage IV4 pcsCompleteOn carrier side (4 rods)2 pcsExtra itemsSpare rock drillSpare wheel assemblySpecial tools for rock drillDocumentationWarranty extensionAutomation packageRD314Standard or foam filled tireField kit, complete setExtra, Catbase, Link one manualsOne year (excl. Kazakhstan)Silver, Gold*) replaces standard featureCARRIERType of carrier C400D (frame-steered)Carrier articulation± 35°Rear axle oscillation± 8°Ground clearance330 mmDiesel engine QSB4.5, 119 kW, Tier 3, Stage IIIA Transmission HydrostaticAxles Dana SpicerTires14.00–24 PR28Brakes SAHR type, fail-safe wet disc brakes Tramming speed 12 km/h (limited)Gradeability / sideways tilt Max.15° / 5°Fuel tank100 litersHydraulic jacks 2 x SJ500 (front) 2 x SJ600 (rear)Brake release Manual hand pump Wheel chocks and holders 2 SetsCentralized greasing points Specification 5-2110 Manual greasing system Specification 5-2110 Hand held fire extinguisher 1 x 7.7 or 9 kg (type ABC) Tramming alarm StandardToolboxes and first aid kitColour scheme SandvikDocumentation 2 x Operator’s manual2 x Maintenance manual2 x T echnical manual (in English only) 2 x Parts manual (in English only)2 x CD of manuals (PDF files)Bolting head Minimumoperating height and width (A;D)Optimum operating height (B)Maximumoperatingheight (C)Maximumwidth (E)BH15 2 9308 32010 26012 460BH18 3 1508 32010 26012 460BH22 3 6508 32010 26012 460BH24 3 9008 78010 72013 380BH27 4 1108 78010 72013 380BH30 4 4508 78010 72013 380BH40 5 6509 62011 56015 060BH50 6 65010 62012 56017 060BH607 62010 62012 56017 060Minimum operating height A Optimum operating height B Maximum operating height BT S 2-354:01/E N G /M E T R I C © S a n d v i kM i n i n g a n d R o c k T e c h n o l o g y 2019 S A N D V I K i s a r e g i s t e r e d t r ad e m a r k o w n e d b y S a n d v i k I n t e l l e c t u a l P r o p e r t y A B i n S w e d e n a n d o t h e r c o u n t r i e s .Sandvik Mining and Rock Technology reserves the right to make changes to the information on this data sheet without prior notification to users. Please contact a Sandvik representative for clarification on specifications and options.All dimensions in mm* Add 100 mm height with tilting optionAll dimensions in mmROCKTECHNOLOGY.SANDVIK。

KEY FEATURESNew generation world-class Automation & Connectivity System (ACS)Automatically adapts the crusher to varying feed condi-tions ensuring maximum 24/7 performanceHydroset™ system Provides safety and settingadjustment functionsMainframe is built as a unibody without moving parts For optimal strength and less components requiring maintenanceTop serviceability Lifting from above minimizesrisks, and allows for quicker andsafer maintenanceAdjustable eccentric throw To exactly balance capacity tothe process thus harmonizingthe crushing stagesConstant liner profile Maintains the feed opening andperformance during the entireservice life of the linersWide range of crushing chambers suited for all types of applications Choose from extra coarse crushing chambers with the largest intake to extremely fine crushing chambersMechanical dump valve for tramp iron protection Reduces pressure peaks and mechanical stress on the crusher, greatly improving reliabilityFull lubrication monitoring and control Real-time monitoring of the crusher lubrication system for increased uptime and reliabilitySandvik CH840i is a technologically advanced, high capacity mid-range cone crusher for secondary and tertiary crushing, designed for crushing applications in mines or large sized quarries.Each crusher has a hydraulically supported main shaft which is supported at both ends. With a robust design, adjustable eccentric throw, a constant intake opening, high performance can be achieved by proper selection of a Sandvik OEM crushing chamber. The CH840i brings you a revolution in intelligent crushing. Connected via the My Sandvik portal,it offer 24/7 access to data generated by your connected Sandvik crusher fleet. Now you can make decisions based on facts, and clearly see areas where you can improve uptime and productivity. My Sandvik also gives you access to manuals and ane-commerce platform for easily and efficiently buying and reordering wear and spare parts. It lets you track and trace parts online to make maintenance planning simpler.The CH840i comes with the new generation Automation and Connectivity System (ACS) as standard. The system continuously monitors and optimizes crusher performance and controls the complete lubrication system, increasing uptimeand reliability. It can automatically adjust crusher settings to compensate for crushing chamber wear, ensuring consistent product size. Hydroset™ and the advanced dump valve automatically provide overload protection to let tramp iron or other uncrushable material pass through.Bolted rather than welded top and bottom shell liners reduce maintenance time and are much safer. It’s 90% faster to change liners compared to welding. The improved over-pressure system with dedicated air channel inlets keeps dust out to increase reliability. The standard off-line filter unit keeps lubrication oil cleaner with 24/7 fine filtration, reducing wear on your internal crusher components and extending oil life by up to 5 times.GENERAL DESIGN CRITERIA Crusher type Cone crusher, hydraulically adjusted Application Minerals processingCrushing stage Secondary, tertiary, quaternary Max. feed size 250 mm CSS range 10-48 mm Nominal capacity*103-427 mtphAmbient temperature -20°C to +40°C(Contact Sandvik if outside range)Altitude of site≤ 2,000 m(Contact Sandvik if outside range)* Capacity and possible CSS is dependent on the crushing chamber, the eccentric throw, the crusher’s setting and the feed material’s bulk density, crushability, size analysis, moisture content, etc.GENERAL CRUSHER DATA Weight 20,278 kgMain frameTwo-part unibody structure without moving parts.Cast steel.Top shell Two-arm design Bottom shell Five-arm designTwo inspection hatches Feed hopper Rubber / steel lined steel hopper Two inspection doors Feed level sensor Vegapuls 67Main shaftSupported at both ends Top spider bearing and eccentric bearing Eccentric bushings (Throws – mm)• 28, 32, 36• 36, 40, 44• 44, 48, 52Eccentric speed327 rpm (50 Hz, SPC-belt)332 rpm (60 Hz, SPC-belt)331 rpm (60 Hz, 8V-belt)Max. motor power 330 kW DriveV-Belt or DirectSafety coupling Omega (for Direct drive option)Pinion shaft speed1,470 rpm (50 Hz, SPC-belt)1,494 rpm (60 Hz, SPC-belt) 1,491 rpm (60 Hz 8V-belt)SubframeWith rubber dampersMaintenance tool boxExtractor for eccentric bushing Extractor for bottom shell bushing Extractor for step bearingAdditional lifting and maintenance tools includedGENERAL INFORMATIONMOTOR CHARACTERISTICSManufacturer WEG Model W22/HGFType Three-phase, squirrel cage Weight 1,850–2,650 Kg Rated power330 kW Frequency 50/60 Hz Poles4Vibration resistanceMotor is supplied with special winding that is reinforced in order to support the vibration levels Insulation class F Protection classIP55MECHANICAL DUMP VALVE System descriptionMechanical spring loaded hydraulic valveSYSTEM CHARACTERISTICS Type Dust seal air pressure Air input Blower Air quality Filtered Air flow <70 m³/h Air pressure<10 kPa Weight (blower, hoses)25 kg Motor power 0.75 kWMotor speed 2,800 rpm (50Hz) 3,350 rpm (60Hz)Phases 3Insulation class F Protection classIP55CRUSHER DRIVE SYSTEMCRUSHER DUST EXCLUSIONCRUSHER TRAMP IRON PROTECTIONUPPER FEED HOPPERNo. of rubber liners 16Max. weight 8 kgMaterialSandvik WT6000 rubber Fastening methodBoltedCONE LINER No. of rubber liners 20Max. weight 9-10 kg / 4-5 kgMaterialManganese steel or Sandvik WT6000 rubber (option)Fastening method BoltedTOP SHELL SPIDER CAP Max. weight 198 kg MaterialCarbon steelFastening methodBolted seal with O-ringTOP SHELL ARM SHIELDS No. of shields 2Max. weight 84 kgMaterialManganese steel Fastening methodBoltedBOTTOM SHELL BODY LINERS No. of liners 10Max. weight 16-24 kg / 5-7 kgMaterialWear-resistant hardened steel or Sandvik WT6000 rubber (option)Fastening methodBoltedBOTTOM SHELL ARM LINERS No. of liners 5Max. weight 80–83 kg MaterialManganese steel Fastening method Bolted (welding*)CRUSHER WEAR PROTECTIONCRUSHING CHAMBERS Mantle alternatives A, B, FlexiFeed B Concave alternatives EC, C, MC, M, F Alloys for mantles and concaves M1, M2, M7, M9Mantle and concave backing materialPlastic free, metallic contactLifting tools for mantles and concavesAvailable as option *No main frame weldingMONITORING FUNCTIONS Main/secondary lubrication circuit dataOil temperature Oil flowOil pressureOil tank temperature Oil levelDifferential pressure across filter Pinion shaft lubrication circuit dataOil pressureDifferential pressure across filterOver-pressure air system Filter monitoring functions Offline filter statusOPERATIONAL FUNCTIONSOil heatersMain lubrication oil pump Pinion lubrication oil pump Over-pressure fan Air/oil coolers Offline filter functionsELECTRICAL HARDWARE Lubrication controlConnection modules tank Cable kit CABINET DIMENSIONS Lubrication control cabinet (LxHxD)1200x800x250 mmHYDROSET SYSTEM System designSingle reversible pump Oil tank reservoir capacity 85 liters Pump design Gear pump Pump capacity10.4 l/min @50 Hz 12.6 l/min @60 HzOil filter Filter type Spin-on Filtration grade 10 µm Filter materialGlass fiber No. of filters 1Pump motor Type Three-phase, squirrel cage Power 3 kW @50 Hz 3.6 kW @60 Hz Speed 1,500 rpm @50 Hz 1,800 rpm @60 Hz Poles4Insulation class F Protection classIP55GENERAL DATAOil tank reservoir capacitySupplies oil to the main lubrica-tion system, Pinion lubrication systems and to the Hydroset system.No. of doors3No. of inspection hatches 2 located on top of unit Cabinet materialMetalTank unit dimensions (LxWxH)1,980x1,130x2,000 mm Dry weight865 kgMAIN CRUSHER LUBRICATION SYSTEM System designClosed circuit, single pump, gravity return Oil tank reservoir capacity 400 liters Pump design Gear pump Standby pump N/APump capacity112 l/min @50 Hz 135 l/min @60 HzOil filters Filter type Filter element insert Filtration grade 25 µm Filter material Glass fiber No. of filters1TANK UNITLUBRICATION CONTROL (ACS)SETTING REGULATIONSOFTWARE PACKAGE (OPTIONAL)PINIONSHAFT LUBRICATION SYSTEM System designClosed circuit, single pump, gravity return Oil tank reservoir capacity52 liters Pump design Gear pump Pump capacity0.9 l/min @50 Hz 1.1 l/min @60 HzOil filter Filter type Spin-on Filtration grade10 µm Filter material Glass fiber No. of filters 1Pump motor Type Three-phase, squirrel cage Power 0.12 kW @50 Hz / @60 Hz Speed1,500 rpm @50 Hz 1,800 rpm @60 Hz Insulation class F Protection classIP55OPERATOR’S PANEL Dimensions (LxHxD)316X251X72.5 mm Weight3.5 kgOperational temperature -25°C to +70°C Protection class IP65Power supply10–30 VDCMONITORING FUNCTIONS(AVAILABLE WITH METRIC AND IMPERIAL UNITS)Energy consumption Hydroset hydraulic pressure Main shaft positionCalculated CSS (based on main shaft position)Lubrication oil temperatureTemperature close to the spider bearing Liner wear Historical data logAutomatic liner wear compensation (Only available for CH-models)AUTOMATION & CONNECTIVITY SYSTEM (ACS) REGULATION FUNCTIONS (CRUSHING MODES)CSS (Auto CSS)Keep CSS constant Peak Pressure (Auto Load)Keep load constant Multi-CSS (Multi – CSS)Alternate between two CSS settings10 customized programs can be storedOTHER FUNCTIONS & CABINET DIMENSIONS Push button box for manual setting of CSS Setting regulation cabinet (LxHxD)1200x600x250 mm Connection box crusher (LxHxD)600x350x155 mm Network repeater box (LxHxD)(Recommended for distances over 100m)300x300x210 mmSAFETY FUNCTIONSProtects the crusher from overload by automatically regulating the crusher based on preset operational limits and the real-time input from the crusherAlarm severity levels: Direct Stop, Sequential Stop, Feeder stop, Notices and EventsSignal permitting operation of the crusher drive motor Alarm logELECTRICAL HARDWARE Setting regulation control Power measurement unit Customer interface gateway Connection box crusher Cable kitPump motor Type Three-phase, squirrel cage Power 4 kW @50 Hz 4.8 kW @60 Hz Speed1,500 rpm @50 Hz 1,800 rpm @60 Hz Insulation class F Protection class IP55Oil heaters No. of heaters 2 (Optional 3)Type Immersion heater Rating1.65 kWInstallation typeImmersion heater tube Phases3Communication gateway interfaceControlNet DeviceNet Ethernet/IP Modbus TCP Profibus ProfinetWINiOperating system compatibility:Windows 10, Windows 8, Windows 7, Windows Vista, Windows XP, Windows 2000Simultaneously control up to 9 different crushers with ACS from a PC via Ethernet networkControl the ACS remotely using the same graphical user interface ACS ReporterExport data from theAutomation & Connectivity System to a PC for analysis and storageOFFLINE FILTER UNIT FOR MAIN LUBRICATION MANUALSPurposeRemoves particles and water from the main lubrication system in a continuous slow offline filtration process Model 27/54Oil capacity20 litersDimensions (LxWxH)650x450x1,055mm Weight 100 kg Pump designGear wheelOil filter Filter type Filter Insert Filtration grade 3 µm Filter material Cellulose Filter housing material Cast iron No. of filters 2Pump motorType Three-phase, squirrel cage Capacity 200 @50 Hz 240 @60 Hz Speed915 rpm @50 Hz 1,120 rpm @60 Hz Protection classIP55Operator’s manual Any language Installation manualAny language Installation manual appendix Any language Maintenance manual Any language Spare parts catalogueEnglish onlyKg Lb Top shell assembly 6,35814,017Bottom shell assembly 5,77212,725Main shaft assembly4,2019,262Pinion shaft housing assembly 244538Hydroset cylinder assembly 1,0802,381Feed hopper assembly 1,4403,175Eccentric assembly 7951,753Dust collar assembly239527Hoses and protection assembly 51112Crusher weight 20,27844,706Subframe1,3843,051Electric motor (max.)2,6505,842Tolat weight(incl. subframe and drive)25,26855,707OIL COOLING SYSTEMS(FOR MAIN CRUSHER LUBRICATION)STANDARD AIR/OIL COOLERS No. of units1Dry weight (incl. stand)240 kg Material Aluminum Oil volume 12.8 liters Max. air flow2.8 kg/s @50 Hz3.3 kg/s @60 HzHOT CLIMATE AIR/OIL COOLERS No. of units1Dry weight (incl. stand)390 kg Material Aluminum Oil volume 19.0 liters Max. air flow7,8 kg/s @50 Hz 9,3 kg/s @60 HzAIR COOLER FAN MOTOR Type Three-phase, squirrel cage Power 2.2 kW @50 Hz 3.6 kW @60 Hz Speed1,500 rpm @50 Hz 1,800 rpm @60 HzAIR COOLER FAN MOTOR Type Three-phase, squirrel cage Power 5,5 kW @50 Hz 6,3 kW @60 Hz Speed1,500 rpm @50 Hz 1,800 rpm @60 HzCH840i CONNECTED – NOMINAL CAPACITY* (MTPH)ConcaveEC C MC M F Max. feed size (mm)F85**14111681--F901721411279773F10025020515912192Max. motor power (kW)330330*********Eccentric throw (mm)28-5228-5228-5228-5228-52CSS (mm)810131619222529323538414448---162-193174-272186-290198-309214-334226-352238-371250-366261-335273-324289---177-210190-297203-317216-337233-364246-384259-356272-349285-312298----187-254201-313214-334228-356246-384260-406274-427287-421301-385315-374333--155-213167-261180-280192-299204-299220-282233-254245----103-132109-170119-185128-200137-214147-215156-214169-200178-----MantleA/B/FFA/B/FFA/B/FFA/BA/B* based on material with bulk density of 1,600 kg/m 3** Additional feed size requirement applicable for FF mantle only (FlexiFeed)PERFORMANCEWEIGHT (KG)T S 5-1227:03/E N G /M E T R I C © S a n d v i k M i n i n g a n d R o c k T e c h n o l o g y 2019 S A N D V I K i s a r e g i s t e r e d t r a d e m a r k o w n e d b y S a n d v i k I n t e l l e c t u a l P r o p e r t y A B i n S w e d e n a n d o t h e r c o u n t r i e s.Sandvik Mining and Rock Technology reserves the right to make changes to the information on this data sheet without prior notification to users. Please contact a Sandvik representative for clarification on specifications and options.ROCKTECHNOLOGY.SANDVIK* Always refer to the installation manualsDIMENSIONS*4159 mm (Max)2160 mm3393 m m。

KEY FEATURES Hydraulic rock drill HL510 LH-38, 16 kW Bolting head CBH Bolting boom TBR60Cable bolt length 25 m Turning width (T-section) 4 100 mmTramming / bolting width 2 735 mm / 3 975 mm Tramming height 2 940 mm / 2 940 mm Transport / bolting length 11 955 mm / 12 415 mmTotal weight25 000 kg depending on optionsSandvik DS421 is a rock reinforcement drill rigspecialized for cement grouted cable bolt installation in the underground mines and tunnels.Sandvik DS421 is capable of installing up to 25 meter long cable bolts with several steel strands per hole. The drill rig is provided with an on board cement mixer, cement bag platform and steel strand reel. It is therefore autonomous for more than a shift.The drill rod handling system has a capacity for 19 pieces of 1 ¼” diameter, round MF drill rods. Therecommended drill hole size for this application is 51 mm. However alternative hole size can be selected with advice from your local Sandvik contact. The steel strand diameter is normally 15.2 mm, of either plain steel or bulb anchor strand.The bolting operation is performed by a single operator located away from the drilling, grouting and cable installing module (CBH Cable Bolting Head). As all the Sandvik drill rigs based on the NC7 carrier family, the Sandvik DS421 is designed for safety.For example, most of the daily and routine checks aredone with both feet on the ground.BOLTING BOOM Type of boom TBR60 (TS2-327)Boom extension 1 200 mm Boom weight, net 2 200 kg Roll-over angle 358°HYDRAULIC SYSTEM Powerpack HPP555 (1 x 55 kW)Percussion pump 100 cc (variable) Rotation pump33 cc (gear) Filtration size (pressure / return)20 µ / 10 µOil tank volume 270 liters Oil tank filling pump ElectricOil cooler (water actuated)OW30 oil-to-water (30 kW)HYDRAULIC ROCK DRILL Type of rock drill HL510 LH-38 (TS2-237)Percussion power 16 kW Percussion pressure Max. 175 bar Percussion rate 59 HzRotation speed Max. 250 rpm (with OMS 80)Rotation torque 630 Nm (with OMS 80)Hole size (bolting)51 - 64 mm Recommended rod R32 - T35Shank adapter R32 or T35 (male)Weight130 kgAIR AND WATER SYSTEMFlushingBy water Water pump type WBP2Water pump capacity 100 l/min Water pump inlet pressure 2 bar (Min.)Flushing water pressure 10 - 15 bar Shank lubrication device SLU1 (Air / oil mist) Air compressorCTN10, 1 m³/min (7 bar)Air cleaner for external air supply IP5Rock drill oil consumption 200 - 300 g/h Rock drill air consumption 250 - 350 l/minCONTROL SYSTEM Type of control system TPC501 EWPower control Adjustable full powerAdjustable collaring power Anti-jamming control Adjustable anti-jamming pressure Rotation control Adjustable rotation speed Reversible rotationFlushing controlWater flushing flow and pressure control air-mist flushing, optionELECTRIC SYSTEM Standard voltages 380 ... 690 V (± 10%), 50 or 60 Hz Total installed power 75 kW Main switch gear MSE 10IP classification Specification TS2-132Starting method Star delta 380 V - 690 V Soft starter 575 V Automatic cable reel TCR3ECable reel control Operator station and remote control at rear machine Batteries 2 x 12 V, 145 AhAuxiliary outlet 1 x 110 V or 1 x 230 V, 16 A Front lights(combined working and driving)6 x 50 W LED (4 200 lm, 6 000 K)Rear lights(combined working and driving)4 x 50 W LED (4 200 lm, 6 000 K)Remote search light1 x 50 W LED (4 200 lm, 6 000 K)Parking rear brake / park lights2 x Red LED Stair and service lights LED (24 V)CABLE BOLTING HEAD Type of bolting head CBH (TS2-330)Bolting head length 4’, 5’, 6’Rod handling system RC604, 5 or 619 + 1 rods Centralizer Pito 11LH Cuttings collector 3 090 mm Net weight2 150 kgGROUTING AND CABLING SYSTEM Cement mixer TCM200(incl. cement dust collector)Cement pump TP8Cement bags platform Max. weight 500 kg Cement hose reel 35 m capacityOPERATOR’S SAFETY CABIN Safety cabin FOPS / ROPS (ISO 3449 / 3471)OperationSeated drilling and tramming Sound pressure level according to EN 16228Operator station: 76 dB(A)SeatErgonomic, adjustable for tramming and drilling including seat belt Air conditioning system For drilling and tramming Audio system CD / MP3-player, radio and loudspeakers Boot washerAt cabin entrance Cabin safety grillStandardCARRIERType of carrier NC7S (frame-steered)Carrier articulation± 35°Rear axle oscillation± 10°Ground clearance420 mmDiesel engine MB OM904LA, 110 kW, Tier 3, Stage IIIA Exhaust catalyzer + muffler StandardTransmission Hydrodynamic, Spicer T20 000Axles Dana SpicerTires12.00-20Service brakes Hydraulic wet disc brakesParking and emergencybrakesSAHR type, fail safewet disc brakesTramming speed 16 km/h (Horizontal) 5 km/h (14%=1:7=8°)Gradeability / sideways Max. 15° / 5°Fuel tank140 litersCarrier stabilization 2 x TJ40 (front) 2 x TJ60 (rear)Hand throttle StandardCentralized greasing points Specification TS2-463Hand held fire extinguisher 1 x 7.7 or 9 kg (type ABC) Tramming alarm StandardKnowledge Box™Connectivity solution (TS2-535) Colour scheme SandvikDocumentation 1 x Operator’s manual1 x Maintenance manual1 x T echnical manual (in English only)1 x Parts manual (in English only)2 x T oolman USB keyOPTIONAL FEATURES AND PACKAGESRock drill*HL510-LH45 rock drill with T35 (male) shank Bolting optionBolting head oiler Dry cement silo For BC and BCS system (TS2-291) 400 kg, above right mud guardHydraulic systemVacuum pump For hydraulic oil InstrumentationCable bolting instrumentation Access detector TMS DDSMandatory in Europe (TS2-211)OPTIONAL FEATURES AND PACKAGESAir and water system*Air compressorWater hose reel and hoseCompressed air outletCT28, 2.8 m³/min (19 kW)THR2.5E and Ø38 mm (1 ½”), 65 mQuick coupling for pneumatic toolsCleaning systemLP system with reelHP system with reelBolting module continuouswashing systemUp to 15 bar (TS2-343)Up to 180 bar (TS2-343)Remote controlledGreasing systemsManual systemAutomatic systemSpecification TS2-463Lincoln (complete)Electric system*Voltage optionElectric cableGround fault and overcurrentprotectionDewatering pump outletBattery jump startExtra working lightsAmber flashing light1 000 V (50 or 60 Hz) with Direct-On-Line starterSpecification TS2-121VYK (excluded US/CAN)380 - 690 V (Max. 8 kW)Optional2 x 50 W LED (4 200 lm, 6 000 K)LED (24 V)Operator’s safety cabin /canopy*Stainless steel cabin*Safety canopy with safety grillCabin heatingFOPS (ISO 3449)FOPS (ISO 3449)During tramming and drillingFire suppression systemAdditional fire extinguisherManual or automatic systemFire suppression system1 x 7.7 or 9 kg (type ABC)Ansul, 6 nozzles (TS2-460)Sandvik Eclipse™ (TS2-461)CarrierReduced tramming speedTramming cameraDiesel engine*Foam filled tiresFast filling systemsWheel chocks and holders3rd gear lockoutRear and sideQSB4.5, 119 kW, tier 4i, Stage IIIB4 pcsComplete2 SetsExtra ItemSpare rock drillSpare wheel assemblySpecial tools for rock drillDocumentationWarranty extensionPackage: Country specificoptions*Package: Harsh water*Package: Anti-freezingHL510 LH-3812.00-20 or foam-filledHL510 LH-38Extra, Catbase, Link one manualsOne year (excl. Kazakhstan)USC, AUS, EURBasic or advanced (TS2-049)Block heater for engine, heater forhydraulic oil, water circuit flushingwith air, antifreeze adding in watercircuit.*) Replaces standard featureT S 2-165:06/E N G /M E T R I C © S a n d v i k M i n i n g a n d R o c k S o l u t i o n s 2022 S A N D V I K i s a r e g i s t e r e d t r Sandvik Mining and Rock Solutions reserves the right to make changes to the information on this data sheet without prior notification to users. Please contact a Sandvik representative for clarification on specifications and options.ROCKTECHNOLOGY.SANDVIK。

Sandvik TIM3DOn top of accuracy Advanced navigation system for surface top hammer drillingSandvik TIM3D is a drill rig navigation system that brings drilling rigs into the realm of 3D machine automation. The system uses satel-lite navigation to guide the starting point and the correct course of drilling in accordance with the drilling plan. TIM3D consists of three essential operations: Rig navigation, feed align-ment and drilling. TIM3D is available for Sandvik DPi and DX series surface top hammer drill rigs.AccurAcy fOr AbSOluTe effIcIency The TIM3D navigation system improves hole quality and hole position accuracy. This trans-lates into better fragmentation and decreased amount of boulders and fines, resulting inincreased efficiency further in the production process, both in crushing and loading and hauling. The system also removes the need for surveying and for any hole marks, and thereby also the risk for marking errors, significantly speeding up drilling. Based on a multisatellite RTK GNSS navi-gation, TIM3D is compatible with GPS and GLONASS satellite systems. The navigation uses drilling plans made either with standard office programs or with the system itself. The plan is imported to the rig with a USB memoryin IREDES standard format, containing the target coordinates in three dimensions. Local base station, or VRS correction, keeps naviga-tion accuracy within 10 centimetres.A new era of navigation TIM3D improves drilling accuracy and efficiency in quarrying, construction and open pit mining applications. Accurate navigationClear user interfaceStraight to targetTIM3D allows deviationsfrom the drill plan. If this is done,a new course is automatically calculated.The drilling data – the actual parameters - arestored in the system memory from where it canbe imported in various programs, such as blast-ing simulation. The data includes a qualityreport, position and depth of the drilled holes,drilling time, and start and end points.reportsfor all needsAccurate drilling. Excellent fragmentationSAndvik Mining And ConStruCtion oyj B 2-53E N G -1210-3000. C o p y r i g h t S a n d v i k . S a n d v i k r e s e r v e s t h e r i g h t t o a l t e r s p e c i fi c a t i o n s w i t h o u t n o t i c e . N o t e : m a c h i n e s s h o w n i n p i c t u r e s a r e e q u i p p e d w i t h o p t i o n s .Productivity in Action Sandvik is a high-technology engineering group with world-leading positions in selected areas – tools for metal working, advanced materials technology, and mining and construction. We employ more than 47 000 people and are represented in 130 countries.Sandvik Mining and Construction represents one third of the overall Sandvik Group and serves a broad range of customers in construction, mineral exploration, mining and bulk materials handling. Our construction expertise covers quarrying, tunneling, demolition and recycling, and other civil engineering applications. Our mining products and services support customers on the surface and under ground, in all mineral, coal and metal mining applications from exploration to ore transportation.。

p~åÇîáâ=ieOMRiJjqÉÅÜåáÅ~ä=a~í~ ^mmif`^qflkpThe Sandvik LH205L is designed to work in low profile room and pillar mining and extra low profile reef mining.•Back heights as low as 1.6 m•Low profile mine production and development•Exta low profile mine development•Extra low profile mine production with a Reef Dozer`~é~ÅáíáÉëTramming capacity 5 000 kg11 000 lb. Break out force, lift128.6 kN28 900 lbf Break out force, tilt124.1 kN27 890 lbf Tipping load20 400 kg45 000 lb. Standard Bucket 2.2 m³ 2.9 yd³j~áå=aáãÉåëáçåëTotal length7960 mm313 in Maximum width 2 310 mm91 in Height without canopy 1 400 mm55 in Height with canopy 1 600 mm63 in _ìÅâÉí=jçíáçå=qáãÉëRaising time 4.7 sec. Lowering time 3.3 sec. Dumping time 4.0 sec.péÉÉÇë=cçêï~êÇ=C=oÉîÉêëÉ=EiÉîÉä=L=iç~ÇÉÇF1st gear 3.2 km/h 2.0 m.p.h. 2nd gear 6.3 km/h 3.9 m.p.h.afjbkpflkp=Epfab=sfbtFL H 205L1880(74 )3280 (128)8190 (323) 8400 (331)1400(55)2491 (98)990(39)1350 (53)2980 (117)3270 (129)1400 (55)1600 (63)203 (8 )3470 (137)1800 (71)afjbkpflkp=Eqlm=sfbtF2108(83)1780(70)2210 (87)3.6 m (11.9 f t )R 3190 (126)42°R5890(232)mltbo=qo^fksbef`ib=tbfdeqpbåÖáåÉDiesel engine Deutz BF4M2012COutput 93 kW (125 HP) @ 2 500 rpm Torque493 Nm (363 lbf-ft)@ 1 500 rpm Number of cylinders 4Displacement 4.04 l (246 in³)Cooling systemLiquid cooledCombustion principleTurbo charged, after cooled, direct in-jectedAir filtration Donaldson, dry type (power core)Electric system 24 V Emissions Tier 2Stage II Exhaust purification Catalytic purifier Avg. Fuel Consumption 20 l/h 5.0 US gal./h Fuel Tank Capacity 166 l 44 US gal.`çåîÉêíÉêDana SOH C 272Single stage, stall torque ratio:3.10:1,Offset Ratio: 1.13:1qê~åëãáëëáçåDana SOH RT203172-speed forward and reverse withmodulation^ñäÉëFront axle Dana, 37RM116 Posi-Stop with Posi-Torq w/o spring, fixed.Rear axleDana, 37RM116, Posi-Stop, No-spin,oscillating ± 5°qáêÉëTire size14.0,0 x 24, 20 PLY L5S Air pressure, front 552 kPa 5.52 bar 80 psi Air pressure, rear552 kPa5.52 bar 80 psiléÉê~íáåÖ=tÉáÖÜíëTotal15 300 kg 33 730 lb.front axle 6 636 kg 14 630 lb.rear axle8 664 kg19 100 lb.iç~ÇÉÇ=tÉáÖÜíëTotal 20 350 kg 44 870 lb.front axle 13 766 kg 30 350 lb.rear axle6 585 kg14 520 lb.pvpqbjppqbbofkd=evao^rif`pCentre articulated, power steering with two double acting cylinders. Steering control system is equipped with a propor-tional hydraulic joystick._r`hbq=evao^rif`pMonostick bucket and boom control equipped with gear pump that delivers oil to the bucket hydraulic main valve. The oil flow from steering hydraulic pump is directed to bucket hydraulics when steering is not used.cê~ãÉRear and front frame Welded steel box construction Material G40.21 - 50wt Cat.3Central hinge Welded steel box construction withhardened steel spherical bearings Material G40.21 - 50wt Cat.3qìêåáåÖ=o~ÇáìëTurning angle±42°inner 3 190 mm126 in outer 5 890 mm232 inj~áå=`çãéçåÉåíëHydraulic pump Gear pump Control valve Rexroth Steering cylinders100 mm bore x 50 mm rod Filtration10µmmêÉëëìêÉ=pÉííáåÖëMain relief21 MPa210 bar 3 045 psi Port relief valves12.5 MPa125 bar 1 812 psi j~áå=`çãéçåÉåíëLift cylinders180 mm bore x 90 mm rod Dump Cylinder160 mm bore x 90 mm rod Hydraulic pump Gear Pump Control valve RexrothmêÉëëìêÉ=pÉííáåÖëMain relief19 MPa190 bar 2 755 psi Bucket dump 6.5 MPa65 bar943 psi Bucket roll back25 MPa250 bar 3 625 psi Lift arms raise25 MPa250 bar 3 625 psi Lift arms lower 6.5 MPa65 bar943 psi Hyd. oil tank capacity166 l44 US gal.pq^ka^oa=_o^hbpService brakes are spring applied, hydraulically released mul-tidisc wet brakes (Posi-Stop) on all wheels.•Two separate circuits: one for the front and one for the rear axle.•Service brakes also function as an emergency and parking brake.•Electrically driven brake release pump•Automatic brake activation system, ABA.lqebo=pq^ka^oa=bnrfmjbkq •Electric indicator/warning lights•Electric transmission shift controls•Audible back-up alarm•Central manual lubrication system•SAE ORS hose fittings j^kr^ipAll manuals are delivered on CD-ROM in web based format with Adobe PDF output for printing extra copies and one pa-per copy. Extra printed copies are also available as an op-tion.lmqflk^i=bnrfmjbkq^iqbok^qfsb=lmqflkp•Deutz BF6L914 engine•Autolube system^aaJlk=lmqflkp•Dual camera closed circuit video monitor system •Extra manuals•Hand held fire extinguisher - 10 lb.•Foam filled tiresj~áå=`çãéçåÉåíëPressure accumulator Piston type with charge valve Brake pedal valve Modulatedbib`qof`^i=bnrfmjbkqAlternator24 V 35 A min. Batteries 2 x 12 V, 950 CCA Starter24 V Heavy Duty Driving and working lights 4 front, 6 rear aáëíêáÄìíáçåSpare Parts Manual 2 Copies 1 Copy Operator’s Manual 2 Copies 1 Copy Service Manual 2 Copies 1 Copylmqflk^i=mltbo=qo^fkléíáçå~ä=båÖáåÉDiesel engine Deutz BF6L914Output (net)104 kW (140 HP) @ 2 500 rpm Torque493 Nm (387 lbf-ft)@ 1 600 rpm Number of cylinders6Displacement 6.5 l (395 in³)Cooling system Air cooledCombustion principle Turbo charged, direct injectedAir filtration Donaldson, dry type (power core) Electric system24 VEmissions Tier 2Stage IIExhaust purification Catalytic purifierAvg. Fuel Consumption20 l/h 5.0 US gal./hFuel Tank Capacity166 l44 US gal.`çåîÉêíÉêDana SOH C 272Single stage, stall torque ratio:3.10:1,Offset Ratio: 0.96:1qê~åëãáëëáçåDana SOH RT203172-speed forward and reverse withmodulation ^ñäÉëFront axle Dana, 37RM116 Posi-Stopwith Posi-Torq w/o spring, fixed. Rear axle Dana, 37RM116, Posi-Stop, No-spin,oscillating ± 5°qáêÉëTire size14.0,0 x 24, 20 PLY L5S Air pressure, front552 kPa 5.52 bar80 psi Air pressure, rear552 kPa 5.52 bar80 psiM N M =p ~åÇîáâp ~åÇîáâ=áë=~=êÉÖáëíÉêÉÇ=íê~ÇÉã~êâ=çÑ=íÜÉ=p ~åÇîáâ=d êçìé。

Technical Specification07511-22007-05-01 Sandvik DP1100© 2007 Sandvik Mining and Construction 1 / 3 1 1 0 0 D PAPPLICATIONSandvik DP1100 is a hydraulic, self-propelled, self-contained, crawler based surface drilling rig equipped with a cabin and a rod changer. It drills 89 - 140 mm (3 ½" - 5 ½") vertical, inclined or horizontal holes with 51 mm and 60 mm (2" and 2 3/8") extension rods or 102 - 140 mm (4" - 5 ½") vertical, inclined or horizontal holes with 76 and 87 mm (3" and 3 ½") tubes. Good results in difficult ground conditions are obtained by using pilot tube drilling, where the first rod is replaced by a 76 or 87 mm (3" or 3 ½") special tube.DP1100 is equipped with HL 1010, hydraulic top hammer rock drill. With high rotation torque, proper flushing and sophisticated, ergonomic Rock Pilot control system the rig adapts itself easily into varying rock conditions. The rig has a telescopic boom for fast hole spotting and set up of the feed. The cylinder feed for max. 6,1 m (20 ') starter rod for single pass drilling together with carousel type rod changer with a possibility to use 4,3 m (14 ') rods add productivity of drilling.The powerpack of DP1100 consists of Caterpillar diesel engine and a gearbox, which divides the power for hydraulic pumps (two variable displacement pumps) and flushing air compressor. All panel sections can be opened for easy access to service spots. Powerpack is mounted crosswise at the rear of the rig to balance the weight of the boom and the feed.DP1100 has an ergonomic and roomy full vision cabin to increase operator's comfort and efficiency. The cabin is certified for F.O.P.S. and R.O.P.S. (Falling Object Protection Structure and Roll-Over Protection Structure). Windows are safety laminated and the noise level in the cabin is less than 80 dB(A). Optimal visibility to the drilling spot is achieved by locating all controls on seat arm rests and side panels of the cabin. Drilling functions are proportionally controlled by one joystick on right hand side. Rod changer functions are controlled by another joystick on left-hand side. Cabin exceeds all standards for operator's working environment.DP1100 is designed for efficient production drilling in medium large to large quarries or open pit mines and construction work sites. It suits well also for wall control and development works. To customize the rig it can be equipped with a variety of options to meet special requirements.COVERAGE AREADIMENSIONS© 2007 Sandvik Mining and Construction 2 / 3STANDARD COMPONENTS1. Rock drill HL 1010, hydraulic2. Feed LF15143. Rodchanger RC 15144. Boom ZB 1550 H, telescopic5. Carrier FL 6, oscillating6. Powerpack Diesel driven,hydraulic pumps andon board compressor7. Hydraulicsystem Load sensing and open center8. Controlsystem THC Pro with Rock Pilot 9. Operator'scabinErgo Pro10. Dust collectionsystemDC 1520 H, hydraulic11. Working lights 8 pcs12. Gauge set For accumulator pressurechecking13. Reversing alarm14. Manuals Service and spare partsmanuals:2 x paper copy2 x CD-ROM (Toolman) 15. EU-safety devicesTRANSPORT DIMENSIONSWeight 18 800 kgWidth 2.52 mHeight 3.2 mTotal length 10.5 m THE JAWS FOR DRILL STEELSDrill steel type Drill steeldiameterRecommendedhole diameter 1.Extension rods/ MF rods51 mm2"89 - 127 mm3 ½" - 5" 2.MF-rods 60 mm2 3/8"102 - 140 mm4" - 5 ½" 3.Pilot tube 76 mm3"89 - 127 mm3 ½" - 5"4.Pilot tube 87 mm3 ½"102 - 140 mm4" - 5 ½" 5.Tubes 76 mm3"89 - 140 mm3 ½" - 5½"6.Tubes 87 mm3 ½"102 - 140 mm4" - 5 ½"ADJUSTMENT INFORMATION FOR DELIVERY Rotation motor1. Rotation motor OMT 400for 76 - 127 mm, 3" - 5" holes2. Rotation motor OMT 500for 127 - 152 mm, 5" - 6" holesExtension rod lengths1. 3 660 mm 12’2. 4 270 mm 14’SELECTION OF OPTIONS1. Heating and air conditioning2. Rodgreasing3. P&Q electric angle indicator4. Electric angle indicator TIM 23025. Measuring system TIM 23036. Laser based measuring system TIM 23057. Powerextractor8. Electric filling pump for refuelling9. Remote control box & hydraulic winch (7 tons)10. Rollers for rod changer RC 151411. Hose reel12. Three-bar grouser plates13. Guides for grousers14. Flushing control automatics15. Shut-down of suction for water holes16. Water injection system17. Water injection system w/o tank18. Hydraulic ground support HM 7519. Fuel heater for cabin, hydraulic oil and engine20. Kit for alternative steels 21. Tube drilling kit22. Movable drill steel support23. Horizontal drilling kit (includes hose reel)24. Towing hook25. Readyness for Power extractor26. Extra manuals27. First service kit for DP110028. Special tools for HL 1010, field kit29. Special tools for HL 1010, complete30. Central lubrication system31. Fast fill connection for fuel and water tanks32. Fast fill connection for engine coolant,hydraulic oil, engine oil33. Sanrock Mini H hydraulic bit grinder34. Radio and CD player35. Biogradeable hydraulic oil, Shell naturelle HFE46 or HFE 68 (synthetic ester)36. Antifreeze for air linesSandvik Mining and Construction reserves the right to change this specification without further notice. Sandvik Mining and Construction OyP.O.Box 100, FIN–33311 Tampere, FinlandTel. +358 205 44 121, Telefax +358 205 44 4771© 2007 Sandvik Mining and Construction 3 / 3。

山特维克(Sandvik)液压凿岩机型号简介周志鸿,田翔(北京科技大学机械工程学院,北京100083)摘要:收集山特维克公司液压凿岩机的型号共23种,其中H大类凿岩机产品型号有14种,RD大类产品型号有9种,列岀了每种型号的主要技术参数。

产品型号分解成前缀、数字和后缀三个组成部分,诠释了H大类产品和RD大类产品型号的前缀、数字和后缀的含义。

关键词:山特维克;液压凿岩机;技术参数;型号含义中图分类号:TD421.2+2文献标志码:AIntroduction to Hydraulic Rock Drills Mdels from SandvikZHOU Zhi-hong,TIAN Xiang(School ofMechanical Engineering,University ofScience&Technology Beijing,Beijing100083) Abstract:The paper collects a total of23models of hydraulic rock drills from Sandvik,14models of which fall into H family and9models ofwhich belongs to RD family.Main specifications of each models are listed.Models are made up of3parts,that is,prefix,number,and suffix.The meanings of the prefix,number and suffx of models of H and RD families are explained.Key words:Sandvik;hydraulic rock drill;specification;1山特维克公司凿岩机简介山特维克(Sandvik)公司是一家高科技全球集团公司,总部位于瑞典斯德哥尔摩。