轴承系列标准件参数化程序建库设计

- 格式:pdf

- 大小:225.39 KB

- 文档页数:13

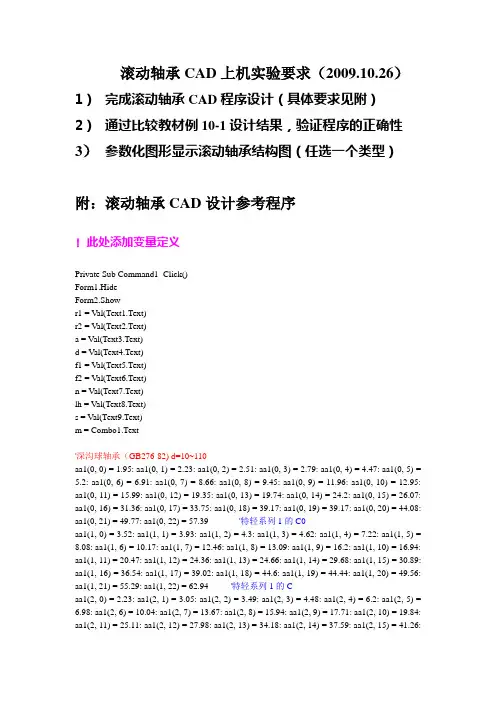

滚动轴承CAD上机实验要求(2009.10.26)1)完成滚动轴承CAD程序设计(具体要求见附)2)通过比较教材例10-1设计结果,验证程序的正确性3)参数化图形显示滚动轴承结构图(任选一个类型)附:滚动轴承CAD设计参考程序!此处添加变量定义Private Sub Command1_Click()Form1.HideForm2.Showr1 = Val(Text1.Text)r2 = Val(Text2.Text)a = Val(Text3.Text)d = Val(Text4.Text)f1 = Val(Text5.Text)f2 = Val(Text6.Text)n = Val(Text7.Text)lh = Val(Text8.Text)s = Val(Text9.Text)m = Combo1.Text'深沟球轴承(GB276-82) d=10~110aa1(0, 0) = 1.95: aa1(0, 1) = 2.23: aa1(0, 2) = 2.51: aa1(0, 3) = 2.79: aa1(0, 4) = 4.47: aa1(0, 5) = 5.2: aa1(0, 6) = 6.91: aa1(0, 7) = 8.66: aa1(0, 8) = 9.45: aa1(0, 9) = 11.96: aa1(0, 10) = 12.95: aa1(0, 11) = 15.99: aa1(0, 12) = 19.35: aa1(0, 13) = 19.74: aa1(0, 14) = 24.2: aa1(0, 15) = 26.07: aa1(0, 16) = 31.36: aa1(0, 17) = 33.75: aa1(0, 18) = 39.17: aa1(0, 19) = 39.17: aa1(0, 20) = 44.08: aa1(0, 21) = 49.77: aa1(0, 22) = 57.39 '特轻系列1的C0aa1(1, 0) = 3.52: aa1(1, 1) = 3.93: aa1(1, 2) = 4.3: aa1(1, 3) = 4.62: aa1(1, 4) = 7.22: aa1(1, 5) = 8.08: aa1(1, 6) = 10.17: aa1(1, 7) = 12.46: aa1(1, 8) = 13.09: aa1(1, 9) = 16.2: aa1(1, 10) = 16.94: aa1(1, 11) = 20.47: aa1(1, 12) = 24.36: aa1(1, 13) = 24.66: aa1(1, 14) = 29.68: aa1(1, 15) = 30.89: aa1(1, 16) = 36.54: aa1(1, 17) = 39.02: aa1(1, 18) = 44.6: aa1(1, 19) = 44.44: aa1(1, 20) = 49.56: aa1(1, 21) = 55.29: aa1(1, 22) = 62.94 '特轻系列1的Caa1(2, 0) = 2.23: aa1(2, 1) = 3.05: aa1(2, 2) = 3.49: aa1(2, 3) = 4.48: aa1(2, 4) = 6.2: aa1(2, 5) = 6.98: aa1(2, 6) = 10.04: aa1(2, 7) = 13.67: aa1(2, 8) = 15.94: aa1(2, 9) = 17.71: aa1(2, 10) = 19.84: aa1(2, 11) = 25.11: aa1(2, 12) = 27.98: aa1(2, 13) = 34.18: aa1(2, 14) = 37.59: aa1(2, 15) = 41.26:aa1(2, 16) = 45.09: aa1(2, 17) = 53.28: aa1(2, 18) = 60.76: aa1(2, 19) = 70.85: aa1(2, 20) = 79.36: aa1(2, 21) = 89.59: aa1(2, 22) = 100.43 '轻窄系列2的C0aa1(3, 0) = 3.93: aa1(3, 1) = 5.24: aa1(3, 2) = 5.87: aa1(3, 3) = 7.36: aa1(3, 4) = 9.88: aa1(3, 5) = 10.78: aa1(3, 6) = 14.96: aa1(3, 7) = 19.73: aa1(3, 8) = 22.71: aa1(3, 9) = 24.36: aa1(3, 10) = 26.98: aa1(3, 11) = 33.35: aa1(3, 12) = 36.73: aa1(3, 13) = 44.01: aa1(3, 14) = 46.76: aa1(3, 15) = 50.83: aa1(3, 16) = 55.03: aa1(3, 17) = 63.98: aa1(3, 18) = 73.83: aa1(3, 19) = 84.82: aa1(3, 20) = 93.94: aa1(3, 21) = 102.26: aa1(3, 22) = 110.78 '轻窄系列2的Caa1(4, 0) = 3.47: aa1(4, 1) = 3.92: aa1(4, 2) = 5.43: aa1(4, 3) = 6.56: aa1(4, 4) = 7.81: aa1(4, 5) = 11.39: aa1(4, 6) = 14.17: aa1(4, 7) = 17.92: aa1(4, 8) = 22.38: aa1(4, 9) = 30#: aa1(4, 10) = 35.71: aa1(4, 11) = 41.91: aa1(4, 12) = 48.61: aa1(4, 13) = 56.68: aa1(4, 14) = 63.48: aa1(4, 15) = 71.67: aa1(4, 16) = 80.35: aa1(4, 17) = 89.52: aa1(4, 18) = 100.76: aa1(4, 19) = 113.75: aa1(4, 20) = 131.18: aa1(4, 21) = 142.84: aa1(4, 22) = 167.64 '中窄系列3的C0aa1(5, 0) = 5.88: aa1(5, 1) = 6.56: aa1(5, 2) = 8.79: aa1(5, 3) = 10.44: aa1(5, 4) = 12.26: aa1(5, 5) = 17.21: aa1(5, 6) = 20.77: aa1(5, 7) = 25.66: aa1(5, 8) = 31.35: aa1(5, 9) = 40.67: aa1(5, 10) = 47.59: aa1(5, 11) = 55.06: aa1(5, 12) = 62.89: aa1(5, 13) = 72.21: aa1(5, 14) = 80.1: aa1(5, 15) = 87.26: aa1(5, 16) = 94.57: aa1(5, 17) = 102.06: aa1(5, 18) = 110.82: aa1(5, 19) = 120.52: aa1(5, 20) = 133.07: aa1(5, 21) = 141.31: aa1(5, 22) = 157.67 '中窄系列3的Caa1(6, 0) = 0: aa1(6, 1) = 0: aa1(6, 2) = 0: aa1(6, 3) = 11.9: aa1(6, 4) = 16.79: aa1(6, 5) = 21.33: aa1(6, 6) = 26.78: aa1(6, 7) = 31.43: aa1(6, 8) = 36.67: aa1(6, 9) = 45.55: aa1(6, 10) = 55.55: aa1(6, 11) = 62.71: aa1(6, 12) = 70.3: aa1(6, 13) = 78.33: aa1(6, 14) = 99.53: aa1(6, 15) = 114.78: aa1(6, 16) = 124.98: aa1(6, 17) = 137.76: aa1(6, 18) = 158.18: aa1(6, 19) = 0: aa1(6, 20) = 0: aa1(6, 21) = 0: aa1(6, 22) = 0 '重窄系列4的C0aa1(7, 0) = 0: aa1(7, 1) = 0: aa1(7, 2) = 0: aa1(7, 3) = 17.46: aa1(7, 4) = 23.81: aa1(7, 5) = 29.42: aa1(7, 6) = 36.41: aa1(7, 7) = 42.68: aa1(7, 8) = 48.99: aa1(7, 9) = 59.49: aa1(7, 10) = 70.96: aa1(7, 11) = 77.4: aa1(7, 12) = 83.88: aa1(7, 13) = 90.82: aa1(7, 14) = 107.23: aa1(7, 15) = 118.18: aa1(7, 16) = 125.48: aa1(7, 17) = 134.45: aa1(7, 18) = 147.97: aa1(7, 19) = 0: aa1(7, 20) = 0: aa1(7, 21) = 0: aa1(7, 22) = 0 '重窄系列4的Caa1(8, 0) = 0.014: aa1(8, 1) = 0.028: aa1(8, 2) = 0.056: aa1(8, 3) = 0.085: aa1(8, 4) = 0.11: aa1(8, 5) = 0.17: aa1(8, 6) = 0.28: aa1(8, 7) = 0.42: aa1(8, 8) = 0.56: aa1(8, 9) = 0: aa1(8, 10) = 0: aa1(8, 11) = 0: aa1(8, 12) = 0: aa1(8, 13) = 0: aa1(8, 14) = 0: aa1(8, 15) = 0: aa1(8, 16) = 0: aa1(8, 17) = 0: aa1(8, 18) = 0: aa1(8, 19) = 0: aa1(8, 20) = 0: aa1(8, 21) = 0: aa1(8, 22) = 0 '相对轴向载荷A/C0aa1(9, 0) = 0.19: aa1(9, 1) = 0.22: aa1(9, 2) = 0.26: aa1(9, 3) = 0.28: aa1(9, 4) = 0.3: aa1(9, 5) = 0.34: aa1(9, 6) = 0.38: aa1(9, 7) = 0.42: aa1(9, 8) = 0.44: aa1(9, 9) = 0: aa1(9, 10) = 0: aa1(9, 11) = 0: aa1(9, 12) = 0: aa1(9, 13) = 0: aa1(9, 14) = 0: aa1(9, 15) = 0: aa1(9, 16) = 0: aa1(9, 17) = 0: aa1(9, 18) = 0: aa1(9, 19) = 0: aa1(9, 20) = 0: aa1(9, 21) = 0: aa1(9, 22) = 0 ' 界限系数eaa1(10, 0) = 2.3: aa1(10, 1) = 1.99: aa1(10, 2) = 1.71: aa1(10, 3) = 1.55: aa1(10, 4) = 1.45: aa1(10, 5) = 1.31: aa1(10, 6) = 1.15: aa1(10, 7) = 1.04: aa1(10, 8) = 1: aa1(10, 9) = 0: aa1(10, 10) = 0: aa1(10, 11) = 0: aa1(10, 12) = 0: aa1(10, 13) = 0: aa1(10, 14) = 0: aa1(10, 15) = 0: aa1(10, 16) = 0: aa1(10, 17) = 0: aa1(10, 18) = 0: aa1(10, 19) = 0: aa1(10, 20) = 0: aa1(10, 21) = 0: aa1(10, 22) = 0 '轴向载荷系数y'圆柱滚子轴承(GB283-87) d=30~100aa2(0, 0) = 11.4: aa2(0, 1) = 17.5: aa2(0, 2) = 24: aa2(0, 3) = 25.7: aa2(0, 4) = 29.2: aa2(0, 5) = 36.2: aa2(0, 6) = 44: aa2(0, 7) = 52.5: aa2(0, 8) = 52.5: aa2(0, 9) = 65.4: aa2(0, 10) = 76.4: aa2(0, 11) = 87.4: aa2(0, 12) = 106: aa2(0, 13) = 114: aa2(0, 14) = 127 '轻窄系列2的C0aa2(1, 0) = 18.8: aa2(1, 1) = 27.8: aa2(1, 2) = 36.5: aa2(1, 3) = 38.5: aa2(1, 4) = 42: aa2(1, 5) = 51.2: aa2(1, 6) = 61: aa2(1, 7) = 71.3: aa2(1, 8) = 71.3: aa2(1, 9) = 86.4: aa2(1, 10) = 99.5: aa2(1, 11) = 112.5: aa2(1, 12) = 138: aa2(1, 13) = 147: aa2(1, 14) = 163 '轻窄系列2的Caa2(2, 0) = 20.6: aa2(2, 1) = 25.6: aa2(2, 2) = 31: aa2(2, 3) = 43.6: aa2(2, 4) = 50.7: aa2(2, 5) = 66.4: aa2(2, 6) = 81.3: aa2(2, 7) = 86.9: aa2(2, 8) = 105: aa2(2, 9) = 120: aa2(2, 10) = 129: aa2(2, 11) = 155: aa2(2, 12) = 169: aa2(2, 13) = 184: aa2(2, 14) = 216 '中窄系列3的C0aa2(3, 0) = 32.6: aa2(3, 1) = 39.8: aa2(3, 2) = 47.3: aa2(3, 3) = 64.9: aa2(3, 4) = 74.3: aa2(3, 5) = 95: aa2(3, 6) = 113: aa2(3, 7) = 120: aa2(3, 8) = 142: aa2(3, 9) = 161: aa2(3, 10) = 170: aa2(3, 11) = 207: aa2(3, 12) = 221: aa2(3, 13) = 238: aa2(3, 14) = 275 '中窄系列3的Caa2(4, 0) = 36.3: aa2(4, 1) = 46.5: aa2(4, 2) = 60.9: aa2(4, 3) = 68.8: aa2(4, 4) = 82.3: aa2(4, 5) = 89.8: aa2(4, 6) = 110: aa2(4, 7) = 121: aa2(4, 8) = 158: aa2(4, 9) = 185: aa2(4, 10) = 214: aa2(4, 11) = 235: aa2(4, 12) = 268: aa2(4, 13) = 290: aa2(4, 14) = 327 '重窄系列4的C0aa2(5, 0) = 55.6: aa2(5, 1) = 68.9: aa2(5, 2) = 87.9: aa2(5, 3) = 99: aa2(5, 4) = 117: aa2(5, 5) = 126: aa2(5, 6) = 151: aa2(5, 7) = 166: aa2(5, 8) = 210: aa2(5, 9) = 244: aa2(5, 10) = 277: aa2(5, 11) = 304: aa2(5, 12) = 343: aa2(5, 13) = 367: aa2(5, 14) = 405 '重窄系列4的Caa2(6, 0) = 18.9: aa2(6, 1) = 30.4: aa2(6, 2) = 36.3: aa2(6, 3) = 38.9: aa2(6, 4) = 41.5: aa2(6, 5) = 52.7: aa2(6, 6) = 70.9: aa2(6, 7) = 86.5: aa2(6, 8) = 0: aa2(6, 9) = 98.7: aa2(6, 10) = 118: aa2(6, 11) = 138: aa2(6, 12) = 160: aa2(6, 13) = 178: aa2(6, 14) = 202 '轻宽系列5的C0aa2(7, 0) = 28: aa2(7, 1) = 42.8: aa2(7, 2) = 50.5: aa2(7, 3) = 53.3: aa2(7, 4) = 55.6: aa2(7, 5) = 68.8: aa2(7, 6) = 88.7: aa2(7, 7) = 105: aa2(7, 8) = 0: aa2(7, 9) = 119: aa2(7, 10) = 140: aa2(7, 11) = 161: aa2(7, 12) = 186: aa2(7, 13) = 208: aa2(7, 14) = 233 '轻宽系列5的C'角接触球轴承(7C)(GB292-83) d=12~100aa3(0, 0) = 2.42: aa3(0, 1) = 2.95: aa3(0, 2) = 3.22: aa3(0, 3) = 5.25: aa3(0, 4) = 6.22: aa3(0, 5) = 8.45: aa3(0, 6) = 11.5: aa3(0, 7) = 12.2: aa3(0, 8) = 16.2: aa3(0, 9) = 17.2: aa3(0, 10) = 24.5: aa3(0, 11) = 25.8: aa3(0, 12) = 27.8: aa3(0, 13) = 34: aa3(0, 14) = 35.8: aa3(0, 15) = 43.2: aa3(0, 16) = 45.2: aa3(0, 17) = 53.8: aa3(0, 18) = 56.5: aa3(0, 19) = 60.5 '特轻系列1的C0aa3(1, 0) = 4.08: aa3(1, 1) = 4.8: aa3(1, 2) = 5.08: aa3(1, 3) = 8.05: aa3(1, 4) = 8.98: aa3(1, 5) = 11.5: aa3(1, 6) = 14.8: aa3(1, 7) = 15.5: aa3(1, 8) = 19.8: aa3(1, 9) = 20.5: aa3(1, 10) = 28.5: aa3(1, 11) = 29.5: aa3(1, 12) = 30.8: aa3(1, 13) = 34.2: aa3(1, 14) = 38.2: aa3(1, 15) = 45: aa3(1, 16) = 46.2: aa3(1, 17) = 54.8: aa3(1, 18) = 56.5: aa3(1, 19) = 61.2 '特轻系列1的Caa3(2, 0) = 3.35: aa3(2, 1) = 4.19: aa3(2, 2) = 5.38: aa3(2, 3) = 7.46: aa3(2, 4) = 8.95: aa3(2, 5) = 12.8: aa3(2, 6) = 17.5: aa3(2, 7) = 20.5: aa3(2, 8) = 23.8: aa3(2, 9) = 26.8: aa3(2, 10) = 33.8: aa3(2, 11) = 37.8: aa3(2, 12) = 46: aa3(2, 13) = 49.2: aa3(2, 14) = 54.2: aa3(2, 15) = 63.2: aa3(2, 16) = 69.8: aa3(2, 17) = 87.8: aa3(2, 18) = 95.5: aa3(2, 19) = 115 '轻窄系列2的C0aa3(3, 0) = 5.65: aa3(3, 1) = 6.68: aa3(3, 2) = 8.38: aa3(3, 3) = 11.2: aa3(3, 4) = 12.8: aa3(3, 5) = 17.8: aa3(3, 6) = 23.5: aa3(3, 7) = 26.8: aa3(3, 8) = 29.8: aa3(3, 9) = 32.8: aa3(3, 10) = 40.8: aa3(3, 11) = 44.8: aa3(3, 12) = 53.8: aa3(3, 13) = 56: aa3(3, 14) = 60.8: aa3(3, 15) = 68.8: aa3(3, 16) = 76.9: aa3(3, 17) = 94.2: aa3(3, 18) = 102: aa3(3, 19) = 140 '轻窄系列2的Caa3(4, 0) = 5.22: aa3(4, 1) = 5.95: aa3(4, 2) = 8.62: aa3(4, 3) = 9.68: aa3(4, 4) = 15.8: aa3(4, 5) =18.5: aa3(4, 6) = 26.8: aa3(4, 7) = 32.3: aa3(4, 8) = 39.8: aa3(4, 9) = 47.2: aa3(4, 10) = 60.5: aa3(4, 11) = 70.2: aa3(4, 12) = 80.5: aa3(4, 13) = 91.5: aa3(4, 14) = 105: aa3(4, 15) = 118: aa3(4, 16) = 128: aa3(4, 17) = 142: aa3(4, 18) = 158: aa3(4, 19) = 175 '中窄系列3的C0aa3(5, 0) = 8.1: aa3(5, 1) = 9.38: aa3(5, 2) = 12.8: aa3(5, 3) = 14.2: aa3(5, 4) = 21.5: aa3(5, 5) = 25.2: aa3(5, 6) = 34.2: aa3(5, 7) = 40.2: aa3(5, 8) = 49.2: aa3(5, 9) = 53.5: aa3(5, 10) = 70.5: aa3(5, 11) = 80.5: aa3(5, 12) = 91.5: aa3(5, 13) = 102: aa3(5, 14) = 112: aa3(5, 15) = 122: aa3(5, 16) = 132: aa3(5, 17) = 142: aa3(5, 18) = 152: aa3(5, 19) = 162 '中窄系列3的Caa3(6, 0) = 0: aa3(6, 1) = 0: aa3(6, 2) = 0: aa3(6, 3) = 0: aa3(6, 4) = 0: aa3(6, 5) = 0: aa3(6, 6) = 0: aa3(6, 7) = 0: aa3(6, 8) = 0: aa3(6, 9) = 0: aa3(6, 10) = 0: aa3(6, 11) = 0: aa3(6, 12) = 0: aa3(6, 13) = 0: aa3(6, 14) = 0: aa3(6, 15) = 0: aa3(6, 16) = 0: aa3(6, 17) = 0: aa3(6, 18) = 0: aa3(6, 19) = 0 '重窄系列4的C0aa3(7, 0) = 0: aa3(7, 1) = 0: aa3(7, 2) = 0: aa3(7, 3) = 0: aa3(7, 4) = 0: aa3(7, 5) = 0: aa3(7, 6) = 0: aa3(7, 7) = 0: aa3(7, 8) = 0: aa3(7, 9) = 0: aa3(7, 10) = 0: aa3(7, 11) = 0: aa3(7, 12) = 0: aa3(7, 13) = 0: aa3(7, 14) = 0: aa3(7, 15) = 0: aa3(7, 16) = 0: aa3(7, 17) = 0: aa3(7, 18) = 0: aa3(7, 19) = 0 '重窄系列4的Caa3(8, 0) = 0.015: aa3(8, 1) = 0.029: aa3(8, 2) = 0.058: aa3(8, 3) = 0.087: aa3(8, 4) = 0.12: aa3(8, 5) = 0.17: aa3(8, 6) = 0.29: aa3(8, 7) = 0.44: aa3(8, 8) = 0.58: aa3(8, 9) = 0: aa3(8, 10) = 0: aa3(8, 11) = 0: aa3(8, 12) = 0: aa3(8, 13) = 0: aa3(8, 14) = 0: aa3(8, 15) = 0: aa3(8, 16) = 0: aa3(8, 17) = 0: aa3(8, 18) = 0: aa3(8, 19) = 0 '相对轴向载荷A/C0aa3(9, 0) = 0.38: aa3(9, 1) = 0.4: aa3(9, 2) = 0.43: aa3(9, 3) = 0.46: aa3(9, 4) = 0.47: aa3(9, 5) = 0.5: aa3(9, 6) = 0.55: aa3(9, 7) = 0.56: aa3(9, 8) = 0.56: aa3(9, 9) = 0: aa3(9, 10) = 0: aa3(9, 11) = 0: aa3(9, 12) = 0: aa3(9, 13) = 0: aa3(9, 14) = 0: aa3(9, 15) = 0: aa3(9, 16) = 0: aa3(9, 17) = 0: aa3(9, 18) = 0: aa3(9, 19) = 0 ' 界限系数eaa3(10, 0) = 1.47: aa3(10, 1) = 1.4: aa3(10, 2) = 1.3: aa3(10, 3) = 1.23: aa3(10, 4) = 1.19: aa3(10, 5) = 1.12: aa3(10, 6) = 1.02: aa3(10, 7) = 1: aa3(10, 8) = 1: aa3(10, 9) = 0: aa3(10, 10) = 0: aa3(10, 11) = 0: aa3(10, 12) = 0: aa3(10, 13) = 0: aa3(10, 14) = 0: aa3(10, 15) = 0: aa3(10, 16) = 0: aa3(10, 17) = 0: aa3(10, 18) = 0: aa3(10, 19) = 0 '轴向载荷系数y'角接触球轴承(7AC)(GB292-83) d=12~100aa4(0, 0) = 2.28: aa4(0, 1) = 2.78: aa4(0, 2) = 3.02: aa4(0, 3) = 4.92: aa4(0, 4) = 5.85: aa4(0, 5) = 7.92: aa4(0, 6) = 10.8: aa4(0, 7) = 11.5: aa4(0, 8) = 15.2: aa4(0, 9) = 16.2: aa4(0, 10) = 22.8: aa4(0, 11) = 24.2: aa4(0, 12) = 26.2: aa4(0, 13) = 31.8: aa4(0, 14) = 33.5: aa4(0, 15) = 40.5: aa4(0, 16) = 42.5: aa4(0, 17) = 50.5: aa4(0, 18) = 53: aa4(0, 19) = 56.8 '特轻系列1的C0aa4(1, 0) = 4: aa4(1, 1) = 4.58: aa4(1, 2) = 4.85: aa4(1, 3) = 7.72: aa4(1, 4) = 8.58: aa4(1, 5) = 11.2: aa4(1, 6) = 14.2: aa4(1, 7) = 14.5: aa4(1, 8) = 18.8: aa4(1, 9) = 19.5: aa4(1, 10) = 27.2: aa4(1, 11) = 27.8: aa4(1, 12) = 29.2: aa4(1, 13) = 35.2: aa4(1, 14) = 36: aa4(1, 15) = 42.5: aa4(1, 16) = 43.8: aa4(1, 17) = 52: aa4(1, 18) = 58.5: aa4(1, 19) = 57.8 '特轻系列1的Caa4(2, 0) = 3.15: aa4(2, 1) = 3.92: aa4(2, 2) = 5.05: aa4(2, 3) = 7#: aa4(2, 4) = 8.38: aa4(2, 5) = 12.2: aa4(2, 6) = 16.5: aa4(2, 7) = 19.2: aa4(2, 8) = 22.5: aa4(2, 9) = 25.2: aa4(2, 10) = 31.8: aa4(2, 11) = 35.5: aa4(2, 12) = 43.2: aa4(2, 13) = 46.2: aa4(2, 14) = 50.8: aa4(2, 15) = 59.2: aa4(2, 16) = 65.5: aa4(2, 17) = 82.2: aa4(2, 18) = 89.5: aa4(2, 19) = 100 '轻窄系列2的C0aa4(3, 0) = 5.45: aa4(3, 1) = 6.42: aa4(3, 2) = 8.05: aa4(3, 3) = 10.8: aa4(3, 4) = 12.2: aa4(3, 5) = 16.8: aa4(3, 6) = 22.5: aa4(3, 7) = 25.8: aa4(3, 8) = 28.2: aa4(3, 9) = 31.5: aa4(3, 10) = 38.8: aa4(3, 11) = 42.8: aa4(3, 12) = 51.2: aa4(3, 13) = 53.2: aa4(3, 14) = 57.8: aa4(3, 15) = 65.5: aa4(3, 16) =72.8: aa4(3, 17) = 89.8: aa4(3, 18) = 98.8: aa4(3, 19) = 108 '轻窄系列2的Caa4(4, 0) = 4.88: aa4(4, 1) = 5.58: aa4(4, 2) = 7.08: aa4(4, 3) = 9.1: aa4(4, 4) = 14.8: aa4(4, 5) = 17.5: aa4(4, 6) = 24.8: aa4(4, 7) = 30.5: aa4(4, 8) = 37.2: aa4(4, 9) = 44.5: aa4(4, 10) = 56.8: aa4(4, 11) = 65.8: aa4(4, 12) = 75.5: aa4(4, 13) = 86.7: aa4(4, 14) = 105: aa4(4, 15) = 108: aa4(4, 16) = 122: aa4(4, 17) = 135: aa4(4, 18) = 148: aa4(4, 19) = 178 '中窄系列3的C0aa4(5, 0) = 8.03: aa4(5, 1) = 9.08: aa4(5, 2) = 11.5: aa4(5, 3) = 13.8: aa4(5, 4) = 20.8: aa4(5, 5) = 24.8: aa4(5, 6) = 32.8: aa4(5, 7) = 38.5: aa4(5, 8) = 47.5: aa4(5, 9) = 55.5: aa4(5, 10) = 67.2: aa4(5, 11) = 77.8: aa4(5, 12) = 89.8: aa4(5, 13) = 98.5: aa4(5, 14) = 112: aa4(5, 15) = 118: aa4(5, 16) = 125: aa4(5, 17) = 135: aa4(5, 18) = 145: aa4(5, 19) = 165 '中窄系列3的C'圆锥滚子轴承(GB297-84) d=20~100aa5(0, 0) = 0: aa5(0, 1) = 0: aa5(0, 2) = 19.8: aa5(0, 3) = 26.2: aa5(0, 4) = 30.8: aa5(0, 5) = 34.8: aa5(0, 6) = 36.8: aa5(0, 7) = 51.8: aa5(0, 8) = 54.5: aa5(0, 9) = 57.5: aa5(0, 10) = 71.8: aa5(0, 11) = 74.8: aa5(0, 12) = 90.8: aa5(0, 13) = 94.2: aa5(0, 14) = 108: aa5(0, 15) = 108: aa5(0, 16) = 115 '特轻系列1的C0aa5(1, 0) = 0: aa5(1, 1) = 0: aa5(1, 2) = 23.2: aa5(1, 3) = 28.2: aa5(1, 4) = 33.2: aa5(1, 5) = 37.2: aa5(1, 6) = 38.2: aa5(1, 7) = 43.2: aa5(1, 8) = 54: aa5(1, 9) = 55.8: aa5(1, 10) = 69.8: aa5(1, 11) = 71.2: aa5(1, 12) = 86.5: aa5(1, 13) = 88.5: aa5(1, 14) = 102: aa5(1, 15) = 102: aa5(1, 16) = 105 '特轻系列1的Caa5(2, 0) = 0: aa5(2, 1) = 0: aa5(2, 2) = 0.26: aa5(2, 3) = 0.29: aa5(2, 4) = 0.28: aa5(2, 5) = 0.3: aa5(2, 6) = 0.32: aa5(2, 7) = 0.31: aa5(2, 8) = 0.33: aa5(2, 9) = 0.35: aa5(2, 10) = 0.34: aa5(2, 11) = 0.35: aa5(2, 12) = 0.34: aa5(2, 13) = 0.35: aa5(2, 14) = 0.34: aa5(2, 15) = 0.36: aa5(2, 16) = 0.37 '特轻系列1界限系数eaa5(3, 0) = 0: aa5(3, 1) = 0: aa5(3, 2) = 2.3: aa5(3, 3) = 2.1: aa5(3, 4) = 2.1: aa5(3, 5) = 2: aa5(3, 6) = 1.9: aa5(3, 7) = 1.9: aa5(3, 8) = 1.8: aa5(3, 9) = 1.7: aa5(3, 10) = 1.8: aa5(3, 11) = 1.7: aa5(3, 12) = 1.8: aa5(3, 13) = 1.7: aa5(3, 14) = 1.8: aa5(3, 15) = 1.7: aa5(3, 16) = 1.6 '特轻系列1轴向载荷系数yaa5(4, 0) = 0: aa5(4, 1) = 0: aa5(4, 2) = 0: aa5(4, 3) = 0: aa5(4, 4) = 0: aa5(4, 5) = 0: aa5(4, 6) = 0: aa5(4, 7) = 0: aa5(4, 8) = 0: aa5(4, 9) = 0: aa5(4, 10) = 0: aa5(4, 11) = 0: aa5(4, 12) = 0: aa5(4, 13) = 0: aa5(4, 14) = 0: aa5(4, 15) = 0: aa5(4, 16) = 0 '特轻系列1静轴向载荷系数y0aa5(5, 0) = 18.2: aa5(5, 1) = 23#: aa5(5, 2) = 29.57: aa5(5, 3) = 37.18: aa5(5, 4) = 42.95: aa5(5, 5) = 47.76: aa5(5, 6) = 55.12: aa5(5, 7) = 65.55: aa5(5, 8) = 74.49: aa5(5, 9) = 86.28: aa5(5, 10) = 97.61: aa5(5, 11) = 103.52: aa5(5, 12) = 119.89: aa5(5, 13) = 136.19: aa5(5, 14) = 152.8: aa5(5, 15) = 175.32: aa5(5, 16) = 198.87 '轻窄系列2的C0aa5(6, 0) = 26.8: aa5(6, 1) = 32.2: aa5(6, 2) = 41.24: aa5(6, 3) = 51.6: aa5(6, 4) = 59.63: aa5(6, 5) = 64.21: aa5(6, 6) = 72.12: aa5(6, 7) = 86.41: aa5(6, 8) = 97.85: aa5(6, 9) = 113: aa5(6, 10) = 124.12: aa5(6, 11) = 129.86: aa5(6, 12) = 150.7: aa5(6, 13) = 169.5: aa5(6, 14) = 188.92: aa5(6, 15) = 214.04: aa5(6, 16) = 239.94 '轻窄系列2的Caa5(7, 0) = 0.35: aa5(7, 1) = 0.37: aa5(7, 2) = 0.375: aa5(7, 3) = 0.375: aa5(7, 4) = 0.375: aa5(7, 5) = 0.405: aa5(7, 6) = 0.42: aa5(7, 7) = 0.405: aa5(7, 8) = 0.405: aa5(7, 9) = 0.405: aa5(7, 10) = 0.42: aa5(7, 11) = 0.435: aa5(7, 12) = 0.42: aa5(7, 13) = 0.42: aa5(7, 14) = 0.42: aa5(7, 15) = 0.42: aa5(7, 16) = 0.42 '轻窄系列2的界限系数eaa5(8, 0) = 1.7: aa5(8, 1) = 1.6: aa5(8, 2) = 1.6: aa5(8, 3) = 1.6: aa5(8, 4) = 1.6: aa5(8, 5) = 1.43: aa5(8, 6) = 1.48: aa5(8, 7) = 1.43: aa5(8, 8) = 1.43: aa5(8, 9) = 1.43: aa5(8, 10) = 1.48: aa5(8, 11) = 1.43: aa5(8, 12) = 1.48: aa5(8, 13) = 1.48: aa5(8, 14) = 1.48: aa5(8, 15) = 1.48: aa5(8, 16) = 1.48 '轻窄系列2的轴向载荷系数yaa5(9, 0) = 1: aa5(9, 1) = 0.9: aa5(9, 2) = 0.9: aa5(9, 3) = 0.9: aa5(9, 4) = 0.9: aa5(9, 5) = 0.8: aa5(9, 6) = 0.8: aa5(9, 7) = 0.8: aa5(9, 8) = 0.8: aa5(9, 9) = 0.8: aa5(9, 10) = 0.8: aa5(9, 11) = 0.8: aa5(9, 12) = 0.8: aa5(9, 13) = 0.8: aa5(9, 14) = 0.8: aa5(9, 15) = 0.8: aa5(9, 16) = 0.8 '轻窄系列2的静轴向载荷系数y0aa5(10, 0) = 20.8: aa5(10, 1) = 30#: aa5(10, 2) = 38.36: aa5(10, 3) = 50.28: aa5(10, 4) = 63.87: aa5(10, 5) = 76.17: aa5(10, 6) = 92.39: aa5(10, 7) = 110.46: aa5(10, 8) = 123.73: aa5(10, 9) = 143.16: aa5(10, 10) = 161.01: aa5(10, 11) = 186.85: aa5(10, 12) = 207.46: aa5(10, 13) = 228.64: aa5(10, 14) = 259.93: aa5(10, 15) = 281.81: aa5(10, 16) = 309.64 '中窄系列3的C0aa5(11, 0) = 31.5: aa5(11, 1) = 44.8: aa5(11, 2) = 55.78: aa5(11, 3) = 71.3: aa5(11, 4) = 86.15: aa5(11, 5) = 102.19: aa5(11, 6) = 122.32: aa5(11, 7) = 144.3: aa5(11, 8) = 161.48: aa5(11, 9) = 185.23: aa5(11, 10) = 207.16: aa5(11, 11) = 237.19: aa5(11, 12) = 262.35: aa5(11, 13) = 287.08: aa5(11, 14) = 322.39: aa5(11, 15) = 347.84: aa5(11, 16) = 382.3 '中窄系列3的Caa5(12, 0) = 0.3: aa5(12, 1) = 0.3: aa5(12, 2) = 0.315: aa5(12, 3) = 0.315: aa5(12, 4) = 0.345: aa5(12, 5) = 0.345: aa5(12, 6) = 0.345: aa5(12, 7) = 0.345: aa5(12, 8) = 0.345: aa5(12, 9) = 0.345: aa5(12, 10) = 0.345: aa5(12, 11) = 0.345: aa5(12, 12) = 0.345: aa5(12, 13) = 0.345: aa5(12, 14) = 0.345: aa5(12, 15) = 0.345: aa5(12, 16) = 0.345 '中窄系列3的界限系数eaa5(13, 0) = 2: aa5(13, 1) = 2: aa5(13, 2) = 1.9: aa5(13, 3) = 1.9: aa5(13, 4) = 1.74: aa5(13, 5) = 1.74: aa5(13, 6) = 1.74: aa5(13, 7) = 1.74: aa5(13, 8) = 1.74: aa5(13, 9) = 1.74: aa5(13, 10) = 1.74: aa5(13, 11) = 1.74: aa5(13, 12) = 1.74: aa5(13, 13) = 1.74: aa5(13, 14) = 1.74: aa5(13, 15) = 1.74: aa5(13, 16) = 1.74 '中窄系列3的轴向载荷系数y aa5(14, 0) = 1: aa5(14, 1) = 1: aa5(14, 2) = 1: aa5(14, 3) = 1: aa5(14, 4) = 1: aa5(14, 5) = 1: aa5(14, 6) = 1: aa5(14, 7) = 1: aa5(14, 8) = 1: aa5(14, 9) = 1: aa5(14, 10) = 1: aa5(14, 11) = 1: aa5(14, 12) = 1: aa5(14, 13) = 1: aa5(14, 14) = 1: aa5(14, 15) = 1: aa5(14, 16) = 1 '中窄系列3的静轴向载荷系数y0If d < 20 Thenj = Int(d / 3 - 2.5)Else: j = d / 5End Ifi = 0l = 0Select Case mCase "深沟球轴承"i = 0x = 0.56: x0 = 0.6: y0 = 0.5: a1 = a: t1 = a1 / r1: c = 3DoDo While l < lhw = a / aa1(i, j) * 1000feyIf t1 <= e Thenp1 = r1Else: p1 = x * r1 + y * a1End Ifp2 = r2If p1 > p2 Thenp = p1Elsep = p2End Ifl = 1000000 * (aa1(i + 1, j) * 1000 * f2 / f1 / p) ^ c / 60 / ni = i + 2fpoLoopLoop While s * p3 >= aa1(i - 2, j) * 1000b1 = i / 2fpinCase "园柱滚子轴承"i = 0c = 10 / 3DoDo While l < lhp1 = r1p2 = r2If p1 > p2 Thenp = p1Elsep = p2End Ifl = 1000000 * (aa2(i + 1, j - 6) * 1000 * f2 / f1 / p) ^ c / 60 / ni = i + 2fpoLoopLoop While s * p3 >= aa2(i - 2, j - 6) * 1000b1 = i / 2 + 1fpinCase "角接触球轴承(C型)"i = 0c = 3: x = 0.44: x0 = 0.5: y0 = 0.46: r = 0.4!按疲劳寿命和静强度设计角接触球轴承(C型)轴承Case "角接触球轴承(AC型)"i = 0x = 0.41: y = 0.87: x0 = 0.5: y0 = 0.38: r = 0.68: e = 0.68: c = 3faDoDo While l < lhIf t1 <= e Thenp1 = r1Else: p1 = x * r1 + y * a1End IfIf (t2 <= e) Thenp2 = r2Elsep2 = x * r2 + y * a2End IfIf p1 > p2 Thenp = p1Elsep = p2End Ifl = 1000000 * (aa4(i + 1, j - 1) * 1000 * f2 / f1 / p) ^ c / 60 / ni = i + 2fpoLoopLoop While s * p3 >= aa4(i - 2, j - 1) * 1000b1 = i / 2fpinCase "圆锥滚子轴承"i = 0x = 0.4: x0 = 0.5: c = 10 / 3!按疲劳寿命和静强度设计圆锥滚子轴承End SelectEnd SubPublic Function fey()If m = "深沟球轴承" ThenFor k = 0 To 10For g = 0 To 22bb(k, g) = aa1(k, g)Next gNext kEnd IfIf m = "角接触球轴承(C型)" ThenFor k = 0 To 10For g = 0 To 19bb(k, g) = aa3(k, g)Next gNext kEnd IfIf w <= bb(8, 0) Theny = bb(10, 0): e = bb(9, 0)ElseIf w >= bb(8, 8) Theny = bb(10, 8): e = bb(9, 8)ElseFor vv=1 to 8If w <= bb(8, vv) thenv = vv - 1end ifexit fornext vvEnd IfFor u = 9 To 10z = (bb(u, v + 1) - bb(u, v)) * (w - bb(8, v)) / (bb(8, v + 1) - bb(8, v)) bb(u, 9) = bb(u, v) + zNext ue = bb(9, 9): y = bb(10, 9)End FunctionPublic Function fpo()If m = "园柱滚子轴承" Thenp3 = r1: p4 = r2Elsep3 = x0 * r1 + y0 * a1p4 = x0 * r2 + y0 * a2End IfIf p3 < r1 Thenp3 = r1End IfIf p4 < r2 Thenp4 = r2End IfIf p3 <= p4 Thenp3 = p4End IfEnd FunctionPublic Function fa()a1 = r * r1a2 = r * r2If (a1 > a2 + a) Thena2 = a1 - aElsea1 = a2 + aEnd Ift1 = a1 / r1t2 = a2 / r2End FunctionPublic Function fpin()If m = "园柱滚子轴承" ThenForm2.MSFlexGrid1.TextMatrix(1, 0) = " N00" + LTrim(Str(b1 * 100 + j)) ElseIf m = "深沟球轴承" ThenForm2.MSFlexGrid1.TextMatrix(1, 0) = Str(60000 + b1 * 100 + j)ElseIf m = "角接触球轴承(C型)" ThenForm2.MSFlexGrid1.TextMatrix(1, 0) = Str(70000 + b1 * 100 + j) + "C" ElseIf m = "角接触球轴承(AC型)" ThenForm2.MSFlexGrid1.TextMatrix(1, 0) = Str(70000 + b1 * 100 + j) + "AC" ElseIf m = "圆锥滚子轴承" ThenForm2.MSFlexGrid1.TextMatrix(1, 0) = Str(30000 + b1 * 100 + j) + "E" End IfForm2.MSFlexGrid1.TextMatrix(1, 1) = Str(p)Form2.MSFlexGrid1.TextMatrix(1, 2) = Str(p3)Form2.MSFlexGrid1.TextMatrix(1, 3) = Str(l)End Function。

在AutoCAD 中应用Autolis p 实现轴承参数化绘图王弘慧1,李建辉2(1.哈尔滨轴承集团公司质量管理部,黑龙江哈尔滨150036;2.中航工业哈尔滨轴承有限公司研发中心,黑龙江哈尔滨150036)摘 要:以深沟球轴承的参数化绘图为示例,介绍了用A ut oli sp 对A ut oCA D 图形进行的参数化绘图程序设计。

实践表明,A ut olisp 语言功能强大,易学易用,是A ut oCA D 二次开发的重要工具。

关键词:A ut olisp A ut oCA D ;参数化;深沟球轴承中图分类号:TH133.33,TP319文献标识码:B 文章编码:1672-4582(2012)01-0055-03Achieving bear ing parameteric drawing with Autolisp based on AutoCADWang Honghui 1,Li Jianhui 2(1.Department of quality management,Harbin Bearing Group Corporation,Harbin 150036,China;2.Bearing R&D Center,A VIC Harbin Bearing Co.,Ltd.,Harbin 150036,China)Abstract:The deep groove ball bearing,for example,the AutoCAD graphic is achieved parametric drawing program design with Autolisp.The practice shows that Autolisp is powerfull,it is easy to study and use,and an important tool for AutoCAD secondary development.Key words:Autolisp AutoCAD;parameterization;deep groove ball bearings第33卷 第1期2012年3月Vo l.33No .1Mar.2012哈 尔 滨 轴 承JOU RNA L O F HA RBIN BEARIN G收稿日期:作者简介:2011-08-26.王弘慧(1965-),女,工程师.1 前言 AutoCAD 是由美国Autodesk 公司推出的通用绘图设计软件,功能强大,但其功能还仅限于帮助用户完成CAD 中的图形显示和绘制。

基于UG的滚动轴承的标准库制作设计目录1 绪论 (1)2 UG环境下标准件库的开发方法及参数化设计 (1)3 滚动轴承标准件库创建方法 (2)4 滚动轴承标准件库创建 (3)4.1 滚动轴承的分类 (3)4.2 深沟球轴承标准库的创建 (3)4.2.1 提取基本参数建立表达式 (3)4.2.2 深沟球轴承模型的创建 (3)4.2.3 深沟球轴承模型生成标准库 (5)4.3 角接触球轴承标准库的创建 (7)4.3.1 提取基本参数建立表达式 (7)4.3.2 角接触球轴承模型的创建 (8)4.3.3 角接触球轴承模型生成标准库 (10)4.4 推力球轴承标准库的创建 (11)4.4.1 提取基本参数建立表达式 (11)4.4.2 推力球轴承模型的创建 (11)4.4.3 推力球轴承模型生成标准库 (13)4.5 圆柱滚子轴承标准库的创建 (14)4.5.1 提取基本参数建立表达式 (14)4.5.2 圆柱滚子轴承模型的创建 (14)4.5.3 圆柱滚子轴承模型生成标准库 (16)4.6 圆锥滚子轴承标准库的创建 (17)4.6.1 提取基本参数建立表达式 (17)4.6.2 圆锥滚子轴承模型的创建 (17)4.6.3 圆锥滚子轴承模型生成标准库 (19)5 结束语 (20)谢辞 (21)参考文献 (22)1 绪论滚动轴承是现代机器中广泛应用的部件之一,它是依靠主要元件间的滚动解出来支撑转动零件的。

滚动轴承绝大多数已经标准化,也是部件典型参数化设计的系列化零件。

为了适应各种不同工况的需要,要求有各种不同特性的滚动轴承,以获得预期的使用效果[1]。

随着CAD/CAM技术的发展,产品的设计与制造有了新的发展,即从三维到二维的设计步骤,也就是首先要建立三维模型,然后自动生成二维的工程图纸,或者利用三维零件模型直接生成数控代码,实现无图纸加工,节约时间和成本[3]。

因此对滚动轴承进行直接、快速、高效、精确的三维造型显得尤为重要。

![基于UG的滚动轴承的标准库制作[全套CAD图纸]](https://uimg.taocdn.com/d5d1070659eef8c75fbfb3c9.webp)

目录1 绪论 (3)2 UG环境下标准件库的开发方法及参数化设计 (3)3 滚动轴承标准件库创建方法 (4)4 滚动轴承标准件库创建 (5)4.1 滚动轴承的分类 (5)4.2 深沟球轴承标准库的创建 (5)4.2.1 提取基本参数建立表达式 (5)4.2.2 深沟球轴承模型的创建 (5)4.2.3 深沟球轴承模型生成标准库 (7)4.3 角接触球轴承标准库的创建 (9)4.3.1 提取基本参数建立表达式 (9)4.3.2 角接触球轴承模型的创建 (10)4.3.3 角接触球轴承模型生成标准库 (12)4.4 推力球轴承标准库的创建 (13)4.4.1 提取基本参数建立表达式 (13)4.4.2 推力球轴承模型的创建 (13)4.4.3 推力球轴承模型生成标准库 (15)4.5 圆柱滚子轴承标准库的创建 (16)4.5.1 提取基本参数建立表达式 (16)4.5.2 圆柱滚子轴承模型的创建 (16)4.5.3 圆柱滚子轴承模型生成标准库 (18)4.6 圆锥滚子轴承标准库的创建 (19)4.6.1 提取基本参数建立表达式 (19)4.6.2 圆锥滚子轴承模型的创建 (19)4.6.3 圆锥滚子轴承模型生成标准库 (21)5 结束语 (22)谢辞 (23)参考文献 (24)英文文献名称(滚动轴承)摘 要 本文以UG为平台,介绍了参数化建模的基本思想,分析了在UG环境下进行滚动轴承标准库创建的方法。

根据滚动轴承的特点提取基本参数,采用草图造型、特征造型、表达式相关性等方法建立滚动轴承参数化模型,利用UG部件族功能调用Excel电子表格,创建了滚动轴承的标准库。

本文为轴承类零件的参数化设计和标准库制作提供了有益的探索途径。

关键词 :UG;标准库;参数化;滚动轴承 The manufacture of Rolling Contact Bearings standard storehousebased on UGAbstractIn this paper, the basic thought of parameterization and the methods about the making of Rolling Contact Bearings’s standard part library has been introduced. According to the features of Rolling Contact Bearings, the primary parameters has been picked out to bulid the model of the Rolling Contact Bearings in the way of sketch modelling, feature modelling and the function of expression ;and a standard part library of the Rolling Contact Bearings has been made by using the function of UG/Part Families modules which could call and edit the Excel. Bearing parts for the parameters of the design and production standards provide a useful way to explore.Key words: UG, standard part library, parameterization, Rolling Contact Bearings 1 绪论 滚动轴承是现代机器中广泛应用的部件之一,它是依靠主要元件间的滚动解出来支撑转动零件的。

基于UG的深沟球轴承参数化设计【摘要】本文以深沟球轴承的设计过程为例,利用UG软件,首先确定设计的关键尺寸变量,利用表达式将其他尺寸都和这些关键尺寸建立相关性,使用表达式中的公式完成零件建模,最终完成深沟球轴承的参数化设计。

当用户对参数进行修改,通过再生即可获得新参数下的实体模型。

参数化设计方便快捷,适用于结构形状定形的产品。

【关键词】UG;深沟球轴承;参数化;设计UG Based Parameter Design of Deep Groove Ball BearingCHENLi(Xuzhou Electromechanical Engineering Higher V ocational School,XuzhouJiangsu, 221011)【Abstract】Based on the deep groove ball bearing designprocess as AN example, using the software UG,first detemine the design of the key dimension variable, using the expression will beother dimensions and the key size to establishcorrelation ,using the expression formula of completed parts modeling,the final comepletion of the parameter design of deep groove ball bearing. When the useron the parameters to be modified,through the regeneration of new parameterscan be obtained under the entit model. Parametric designis convenient ,applicable to the shape structure of amorphous products.【Key words】UG;Deep groove ball bearing;Parametric;Design0引言滚动轴承是广泛应用于现代机器中的标准部件之一,该部件的主要功能是用来支承“轴”部件,使其正常工作,与滑动轴承相比,滚动轴承具有摩擦阻力小,功率消耗底,容易启动,结构紧凑等优点,因此应用极为广泛。

轴承端盖零件的参数化系统设计及NC加工仿真史永芳;焦力博【摘要】轴承端盖零件在机械行业中使用非常广泛,但是其种类繁多,设计及绘图非常烦琐,效率低下.从参数化的设计技术出发,基于Pro/ENGINEER软件平台,应用Pro/Toolkit和VC++对其进行二次开发,建立了轴承端盖零件三维参数化造型系统.该系统能够通过修改相应尺寸参数生成不同的零件模型,再根据生成的零件模型利用Pro/Engineer设计出对应的模具,并采用Mastercam软件对已经设计好的模具进行数控加工仿真.%The bearing cover parts are widely used in machinery industry,but its variety is numerous,the design and plot-ting are very cumbersome,and has low efficiency. From the designing technology view of parameterization,and based on Pro/En-gineer software platform,the parts were conducted with secondary development by Pro/Toolkit andVC++,and the 3D parameteriza-tion modeling system of the bearing cover parts was established. The corresponding mould was designed byPro/Engineer according to the generated parts model. The designed mould was proceeded with NC machining simulation by Mastercam software.【期刊名称】《现代电子技术》【年(卷),期】2015(038)021【总页数】3页(P127-129)【关键词】轴承端盖;参数化造型;二次开发;数控加工仿真【作者】史永芳;焦力博【作者单位】三峡大学科技学院,湖北宜昌 443002;中国水利水电第五工程局有限公司,四川成都 610000【正文语种】中文【中图分类】TN876-340 引言轴承端盖作为最常见的部件被广泛地应用于各种机械,但在其建模过程中,存在形状多种多样,设计过程重复率较高,效率低等问题。

收稿日期:2008-02-13;修订日期:2008-10-08作者简介:毛文武(1973-),男,福建浦城人,上海海洋大学讲师,主要从事工程图学、机械工程的教学和研究。

基于SolidWorks 的滚动轴承三维参数化图库开发毛文武,邬国军(上海海洋大学,上海201306)摘要:阐述了对SolidWorks 进行二次开发的机理,结合我国最新国家标准,详细分析了采用VB 语言和ACCESS 数据库在SolidWorks 平台上进行滚动轴承三维图库开发的具体方法和步骤,用户只要轻松点击滚动轴承类型和代号,就可以得到对应轴承的三维模型。

关键词:滚动轴承;参数化图库;SolidWorks ;VB中图分类号:TQ43212 文献标识码:A 文章编号:1001-3563(2008)12-0143-03Develop ment of 3D 2Pa ra meterized D rawing L ibra ryof Rolling Bea rings Based on SolidWorksM A O W en 2w u ,W U Guo 2j un(Shanghai Ocean University ,Shanghai 201306,China )Abstract :The mechanism of SolidWorks secondary development was introduced.The parameterized3D drawing library of roller bearing was developed according to the newest national standard and based on SolidWorks.The methods and procedures of establishing the library by using VB and ACCESS were ana er can easily get 3D model of the relevant bearing simply by clicks on the bearing type and code.Key words :rolling bearing ;parameterized drawing library ;SolidWorks ;VB 近年来,美国生信实维公司的S olidWorks 软件以其创新性、易用性和高效性,在包装机械设计和产品展示中得到了越来越多的应用[1-2],对提高包装机械的设计效率发挥了显著作用。

基于autocad轴承选择的参数化程序设计摘要本文介绍了基于autocad绘图软件且以lisp语言为基础,进行轴承的参数化绘图,事先介绍了lisp语言的特点,并且举例说明了lisp语言的一些常用语法,简单的阐述参数化绘图的特点,及其参数化绘图在机械设计中的一些应用领域。

然后分析了参数化轴承设计的流程图,依照流程图首先对autocad软件加载事先整理好的lisp程序,进入轴承参数化绘图主界面,然后根据对话框提示并按照轴承行业的各项技术标准输入所需要设计轴承的参数,最后得出所需要的型号及其规格的轴承图形,同时利用基于autocad参数绘制轴承这一应用实例的基础上,进一步阐述了利用autocad参数化程序设计在机械行业中类似零部件的一些设计实例。

关键词:参数化绘图,CAD ,lisp语言,轴承的参数化设计Autocad bearing on choice of program design parameters第1页AbstractThis article describes the software-based graphics and autocad to lisp language as the basis for drawing the parameters of bearings, pre-introduced feature of lisp language, and examples of some common lisp language syntax, a simple drawing on the characteristics of the parameters, and its parameters in the mechanical design drawings of some of the applications. And then analyzed the design parameters of the flow chart of bearings, in accordance with the flow chart of the first software loaded prior to finishing autocad good lisp procedure parameters into the bearings of the main graphics interface, and then in accordance with and in accordance with the prompt dialog box bearing the technical standards for industry input The bearings need to design parameters, and finally arrive at the required specifications of the model and its bearing graphics, of the use of autocad design parameters in the machinery industry in a similar zero - Examples of some of the design components.Key words: Parametric Drawing, CAD, lisp language, bearing design parameters第2页目录摘要 (1)目录 (2)前言 (3)第一章、lisp语言的特点及其一些语法1.1、lisp语言的特点 (7)1.2、lisp语言的一些语法 (7)第二章、autocad参数化设计在轴承选择上的应用2.1、轴承参数化选用设计流程图 (14)2.2、部分型号轴承参数化选用的实例 (14)第三章、autocad参数化设计在机械设计中的应用实例3.1、轴系零件的紧固件参数化设计绘图 (19)3.2、利用autocad进行轴的参数化选用设计 (22)结论 (25)设计感想及谢辞 (25)参考文献 (27)附录 (28)第3页前言参数化设计是RevitBuilding的一个重要思想,它分为两个部分:参数化图元和参数化修改引擎。

轴承选型软件编程(SQL)摘要:滚动轴承是标准零件在一般机械中广泛应用,在机械设计过程中应能熟练地选择滚动轴承的类型与规格。

而滚动轴承的类型与规格的选择需要查询、计算、对照手册然后得出型号。

费时费力,也容易出错。

本轴承选型软件采用VB编程,并与SQL数据库建立连接。

根据不同的轴承确定了不同参数,只需根据不同轴承直接输入已知条件,该软件会自动根据条件确定不同参数调出数值自动计算,并对照手册得出型号。

使滚动轴承的类型与规格的选择变得更加的简单、容易。

关键词:滚动轴承轴承选型 SQL目录引言 (3)第一章、滚动轴承 (4)1.1 滚动轴承的结构 (4)1.2 滚动轴承的基本类型和特点 (4)1.3 滚动轴承的代号 (6)第二章Sql Server2008的应用 (7)2.1 Sql Server 的概述 (7)2.2 Sql Server 的数据查询 (7)第三章、轴承选型软件的制作 (10)3.1轴承类型的选择 (10)3.1.1 轴承选择流程 (10)3.1.2 轴承选择应注意的问题 (10)3.1.3 轴承选择的范围 (11)3.2 按基本额定动载荷选择轴承 (11)3.2.1基本额定动载荷计算 (11)3.2.2当量动载荷P的计算 (13)3.3数据库与VB的连接 (14)3.3.1 轴承参数的录入 (14)3.3.2 SQL与VB的连接 (17)第四章、软件调试及实例测试 (22)4.1 软件调试 (22)4.2实例测试 (22)结论 (25)致谢语 (26)参考文献 (28)引言轴承的功用是支承轴及轴上的旋转零件,使其回转并保证一定的旋转精度,减少轴与支承之间的相对摩擦和磨损。

根据支承处相对运动表面的摩擦性质,轴承可分为滑动轴承和滚动轴承。

滚动轴承具有摩擦系数小,已标准化,设计、使用、润滑、维护方便等一系列优点,在一般机械中广泛应用。

因此本轴承选型软件针对的是常用的滚动轴承。

如深沟球轴承、调心滚子轴承、圆柱滚子轴承等。

基于AutoCAD典型机械零件库中轴的参数化设计胡迎春;刘晓莹;胡裔志;侯军燕【摘要】为增强AutoCAD设计功能,提高图纸绘制速度、精确度和灵活度,以轴类零件为例,对AutoCAD中典型零件参数化设计功能进行研发,采用面向对象的VB语言,在AutoCAD中开发了轴类零件参数化设计程序,以轴类零件的典型特征为基本图元参数,各图元按顺序一一衔接完成图形绘制,从而达到参数化设计目的。

通过减速箱典型实例说明该方法可提高AutoCAD中轴类零件的多样化绘图效率,增强AutoCAD的设计智能化程度,方便设计人员使用。

%In order to improve the function of AutoCAD in drawing speed,accuracy and flexibility,this study develops a program of parametric design of typical axial parts parameterization in AutoCAD interface using VB language.The typical characteristic of axis parts is designed as basic primitive and parametric design is achieved by order joining every primitive together.A gearbox example shows that this method can improve efficiency of diversity of axial parts and intelligent level of AutoCAD as well as convenience for designers.【期刊名称】《桂林理工大学学报》【年(卷),期】2014(000)004【总页数】4页(P771-774)【关键词】AutoCAD 二次开发;VB;特征图元;参数化设计【作者】胡迎春;刘晓莹;胡裔志;侯军燕【作者单位】广西师范大学职业技术师范学院,广西桂林 541004;广西师范大学职业技术师范学院,广西桂林 541004;桂林海威科技有限公司,广西桂林 541004;柳州铁道职业技术学院,广西柳州 545006【正文语种】中文【中图分类】TP391.7AutoCAD 是一个功能强大的绘图软件,在机械、电子、建筑、服装等行业得到了广泛应用[1]。

目录1 绪论 (1)2 UG环境下标准件库的开发方法及参数化设计 (1)3 滚动轴承标准件库创建方法 (2)4 滚动轴承标准件库创建 (3)4.1 滚动轴承的分类 (3)4.2 深沟球轴承标准库的创建 (3)4.2.1 提取基本参数建立表达式 (3)4.2.2 深沟球轴承模型的创建 (3)4.2.3 深沟球轴承模型生成标准库 (5)4.3 角接触球轴承标准库的创建 (7)4.3.1 提取基本参数建立表达式 (7)4.3.2 角接触球轴承模型的创建 (8)4.3.3 角接触球轴承模型生成标准库 (10)4.4 推力球轴承标准库的创建 (11)4.4.1 提取基本参数建立表达式 (11)4.4.2 推力球轴承模型的创建 (11)4.4.3 推力球轴承模型生成标准库 (13)4.5 圆柱滚子轴承标准库的创建 (14)4.5.1 提取基本参数建立表达式 (14)4.5.2 圆柱滚子轴承模型的创建 (14)4.5.3 圆柱滚子轴承模型生成标准库 (16)4.6 圆锥滚子轴承标准库的创建 (17)4.6.1 提取基本参数建立表达式 (17)4.6.2 圆锥滚子轴承模型的创建 (17)4.6.3 圆锥滚子轴承模型生成标准库 (19)5 结束语 (20)谢辞 (21)参考文献 (22)1 绪论滚动轴承是现代机器中广泛应用的部件之一,它是依靠主要元件间的滚动解出来支撑转动零件的。

滚动轴承绝大多数已经标准化,也是部件典型参数化设计的系列化零件。

为了适应各种不同工况的需要,要求有各种不同特性的滚动轴承,以获得预期的使用效果[1]。

随着CAD/CAM技术的发展,产品的设计与制造有了新的发展,即从三维到二维的设计步骤,也就是首先要建立三维模型,然后自动生成二维的工程图纸,或者利用三维零件模型直接生成数控代码,实现无图纸加工,节约时间和成本[3]。

因此对滚动轴承进行直接、快速、高效、精确的三维造型显得尤为重要。

由此可知滚动轴承的标准库建立显得非常有意义。

目录摘要 (2)Abstract (3)前言 (4)第一章绪论 (5)1.1课题研究的背景及意义 (5)1.2国内外有关研究现状 (5)1.2.1零件图库的研究现状 (5)1.2.2 Solid Edge软件的发展现状 (7)第二章 Solid Edge 二次开发基础 (8)2.1 Solid Edge 二次开发的理论基础 (8)2.1.1 ActiveX Automation技术 (8)2.1.2 So1id Edge的对象层次结构 (9)2.2 Solid Edge 二次开发的技术基础 (9)2.2.1 引用Solid Edge类型库 (9)2.2.2 调用Solid Edge应用程序 (10)2.2.3 程序运行方式 (11)第三章 Solid Edge 变量化设计与开发 (12)3.1 参数化设计与变量化设计 (12)3.2 变量化设计的实现方法 (12)3.2.1 Solid Edge变量化设计过程 (12)3.2.2 利用Solid Edge 的变量表实现变量化设计 (12)3.2.3 通过Solid Edge 程序开发实现变量化设计 (13)3.2.4 将Solid Edge 变量表与程序开发相结合实现变 (13)3.3 变量化设计的意义 (13)第四章 ZLY系列焊接式减速器轴承标准件库设计 (15)4.1 特征分析 (15)4.1.1 轴承的主要特征:轴承外圈实体、轴承内圈实体、滚子、倒角、滚道。

(15)4.1.2轴承特征分析 (15)4.2 建模过程 (16)4.2.1轴承的建模过程 (16)第五章变量表与电子表格建立关联 (24)5.1 建模过程中所涉及的变量 (24)5.2 变量表与电子表格建立关联 (24)5.3 前期准备工作的补充说明 (24)第六章工程设计及程序编写 (25)6.1 VB界面设计及说明 (25)6.1.1 窗体FormFold (25)6.1.2 窗体FormInfo (26)6.1.3 窗体FormMain (26)6.1.4 窗体FormPrgBar (28)6.2 关键程序的说明 (29)6.2.1程序段的说明 (29)总结 (34)参考文献 (35)致谢 (36)摘要本课题研究基于Solid Edge三维造型系统,应用Visual Basic开发平台,设计ZLY系列焊接式减速器标准轴承件库。

第一步:在知识工程中输入以下参数

第二步:建立草图一, 将sketch定义为工作对象,选择yz平面建立如下草图

图中的尺寸4.375的参数为A/4,尺寸14的参数为E,尺寸36.25的参数为d /2+A /2,尺寸15度的参数为a。

第三步:定义roller几何体为工作对象,将草图一进行旋转的到一个滚子,如图所示

然后在对滚子进行倒斜角如图所示然后在进行环形矩阵如图所示

得到下图

第四步:将sketch定义为工作对象,选择yz平面建立如下草图。

图中的构造线为滚子的两条对称线,图中的两个尺寸为4.375的参数为a,尺寸22的参数为B,尺寸27.5的参数为d/2,尺寸8.75为A/2,尺寸14的参数为E。

第五步:将内圈定义为当前工作对象,将草图2进行旋转操作如图所示然后将内圈的两个端面进行倒圆角如下图所示

得到内圈如下图

第六步:将sketch定义为工作对象,选择yz平面做草图如下图所示

图中尺寸4.375的参数为A/4,图中20的参数为C,23的参数为T,45的参数为D/2,图中的构造线为滚子的轮廓线和轴线。

第七步:将外圈定义为工作对象,将草图三进行旋转如下图所示。

轴承图素库的设计目录摘要 (1)一.引言 (5)二.AutoCAD二次开发语言及工具介绍 (5)三.基于三维图素的零件详细设计…………………………………………71.轴承图素库的功能及特点 (7)2.轴承图素库的制作方法 (8)3.轴承实体的生成 (9)四.轴图素库应用实例 (10)五.本课题的特色和创新之处 (12)六.结论 (13)七.今后工作展望 (13)致谢 (15)参考文献 (16)翻译 (17)开题报告 (2)一.课题的来源 (2)二.本课题研究的意义 (2)三.工作量及工作进度安排 (3)开题报告一.课题的来源设计是一项复杂的创造性工作,也正由于它的复杂性,迄今为止,人们对设计规律尚无成熟的认识,还没有形成严格的理论体系。

由于计算机技术、信息技术的发展,基于计算机的设计理论与方法学,显得异常活跃,例如并行设计、协同设计、虚拟设计、大规模定制设计(Mass Customization Design)、分形设计(Fractal Design)等[7]。

AutoCAD可以绘制任意二维和三维图形,并且同传统的手工绘图相比,用AutoCAD绘图速度更快、精度更高、而且便于个性,它已经在航空航天、造船、建筑、机械、电子、化工、美工、轻纺等很多领域得到了广泛应用,并取得了丰硕的成果和巨大的经济效益。

AutoCAD荣登全球绘图软件的龙头宝座,主要是因为它具有开放的体系结构。

它允许用户和开发者采用高级编程语言对其进行扩充和修改,即二次开发,能最大限度地满足用户的特殊要求。

目前大家广泛使用的是AutoCAD R14,最新版本是AutoCAD 2004,其二次开发语言及工具也在不断地涌现。

制作图素库实际上是构造程序库,即编制每一种图素的参数化绘图程序库。

从库的结构上看,各个图素的参数化绘图程序是平行的。

每个图素都由以下模块组成:图素调用模块,特征尺寸输入模块和交互绘图模块。

利用给程序制作的图素库包含有画轴用的各种图素。