控制计划(样本容量频率示例)

- 格式:doc

- 大小:51.00 KB

- 文档页数:1

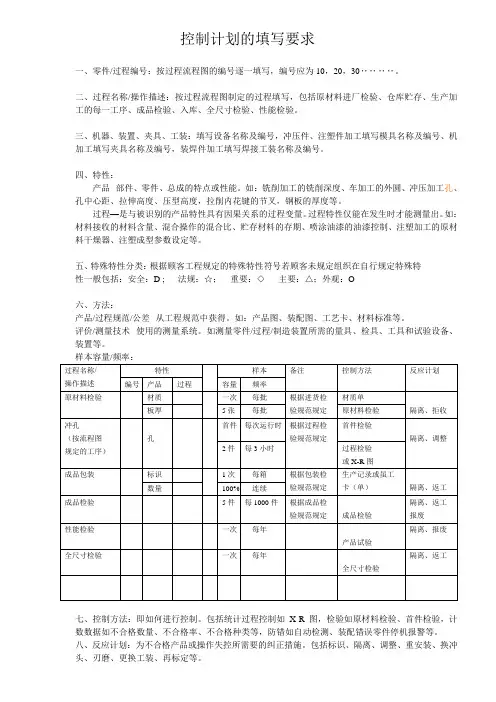

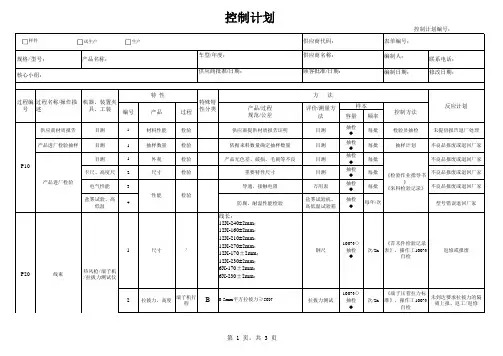

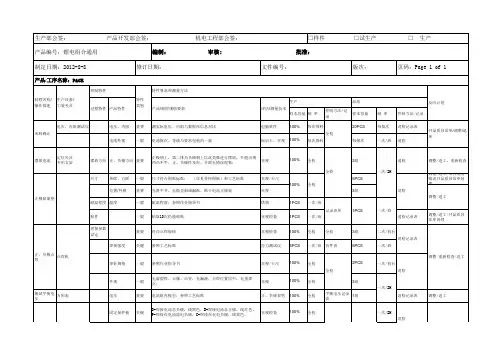

控制计划的填写要求一、零件/过程编号:按过程流程图的编号逐一填写,编号应为10,20,30‥‥‥‥。

二、过程名称/操作描述:按过程流程图制定的过程填写,包括原材料进厂检验、仓库贮存、生产加工的每一工序、成品检验、入库、全尺寸检验、性能检验。

三、机器、装置、夹具、工装:填写设备名称及编号,冲压件、注塑件加工填写模具名称及编号、机加工填写夹具名称及编号,装焊件加工填写焊接工装名称及编号。

四、特性:产品--部件、零件、总成的特点或性能。

如:铣削加工的铣削深度、车加工的外圆、冲压加工孔、孔中心距、拉伸高度、压型高度,拉削内花键的节叉,钢板的厚度等。

过程—是与被识别的产品特性具有因果关系的过程变量。

过程特性仅能在发生时才能测量出。

如:材料接收的材料含量、混合操作的混合比、贮存材料的存期、喷涂油漆的油漆控制、注塑加工的原材料干燥器、注塑成型参数设定等。

五、特殊特性分类:根据顾客工程规定的特殊特性符号若顾客未规定组织在自行规定特殊特性一般包括:安全:D ; 法规:☆;重要:◇主要:△;外观:O六、方法:产品/过程规范/公差--从工程规范中获得。

如:产品图、装配图、工艺卡、材料标准等。

评价/测量技术--使用的测量系统。

如测量零件/过程/制造装置所需的量具、检具、工具和试验设备、装置等。

七、控制方法:即如何进行控制。

包括统计过程控制如X-R图,检验如原材料检验、首件检验,计数数据如不合格数量、不合格率、不合格种类等,防错如自动检测、装配错误零件停机报警等。

八、反应计划:为不合格产品或操作失控所需要的纠正措施。

包括标识、隔离、调整、重安装、换冲头、刃磨、更换工装、再标定等。

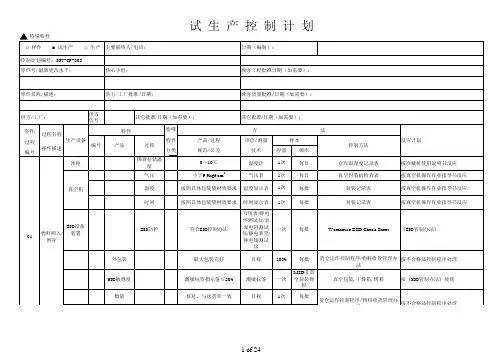

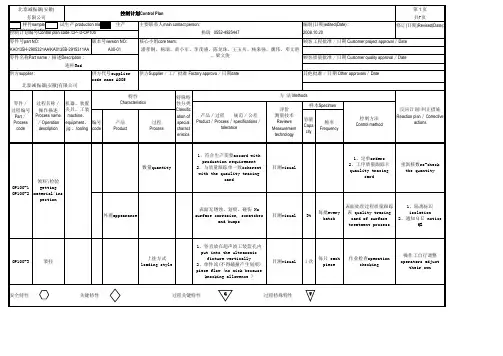

Regular Size 正常样本容量Regular Freq.正常频率Tighten Size 加严样本量Tighten Freq.加严频率1吸力测试RTD test ★-0.8 ~ -1.8KPa适配OK,有烟雾被吸出,两个LED 灯同时亮Normal mate & two Led light 吸烟治具RTD tester 重新制作及分析原因Readjust and analysis 2充电功能测试Charge function test★接上U020,两个LED 等呈呼吸灯,充电电流为0.35~0.4A two Led breathing light 直流电源 DC Power 重新制作及分析原因Readjust and analysis 3外观appearance★电池管外观无刮伤或生锈No scraped or get rusty目视Visual check重新制作及分析原因Readjust and analysis4实物组装assemble and install★依据SOP 定义作业手法以及BOM所用物料执行确认According to the requirements of SOP and the BOM for confirming.实物组装assemble and install 退料Return material to MRB1充电电压Charging voltage★ DC3.3V-4.2V充电板测试治具 Charging test fixture80pcs 2H 80pcs 1HIPQC 抽检IPQC Sampling退料Return material to MRB2充电电流Charging current★0.35A-0.4A充电板测试治具 Charging test fixture80pcs 2H 80pcs 1HIPQC 抽检IPQC Sampling退料Return material to MRB3静态电流Quiescent Current★<10μA主板测试治具PCBA test fixture80pcs 2H 80pcs 1HIPQC 抽检IPQC Sampling退不良物料Return defective materialto MRB4防静电环Anti-static ring★防静电阻大于106Ohn防静电环测试仪Anti-static ring tester所有防静电环All Anti-staticring4H所有防静电环All Anti-staticring2HIPQC 抽检IPQC Sampling返工Rework5充电PCBA 规格charge PCBA direction 闪红灯或依据BOM 定义Red light or According to BOM目视Visual check80pcs 2H 80pcs 1HIPQC 抽检IPQC Sampling退料Return material to MRB《产品制程巡检记录表》《IPQC process inspection record 》吸烟治具RTD TesterC078烟弹C078Cartridges U020充电器U020 charge 直流电源 DC Power《首检确认表》FAI checklist 充电板测试治具 Charging test fixture防静电环Anti-static ring 防静电环测试仪Anti-static ring tester充电测试/分板Charging test /Separate board 15PCS《首检确认表》FAI checklist《首检确认表》FAI checklist 《产品制程巡检记录表》《IPQC process inspection record 》《产品制程巡检记录表》《IPQC process inspection record 》《产品制程巡检记录表》《IPQC process inspection record 》《首检确认表》FAI checklist 电池首件品确认First Article Inspection (FAI)每天开拉时或订单变更时whenproduction linestart or order changedIPQC 抽检IPQC Sampling《产品制程巡检记录表》《IPQC process inspection record 》Methods 方法责任部门Responsible DepartmentsControl Method 控制方法Reaction plan 反应计划NO.编号Product 产品Process 过程Product/Process /Spec./Tolerance 产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan 抽样计划每天开拉时或订单变更时when production line start or order changed10PCSCore Team 核心小组:Customer Engineering Approve/Date (If Req'd)客户工程批准/日期:(如需要)NA Part name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date 供应商/工厂批准/日期:待定Customer Quality Approve/Date (If Req'd)客户质量批准/日期:(如需要)NA Supplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/Process NO.零件/过程编号Process Name/Operation Description过程名称/操作描述Machine,Device,Jig,Tools for MFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass 特性分类Tighten Sampling Plan should be applied if 1. customer required 2. Product quality concern 3. major customer complaint4. Management and/or CFT DecisionRegular Size 正常样本容量Regular Freq.正常频率Tighten Size加严样本量Tighten Freq.加严频率Methods 方法责任部门ResponsibleDepartmentsControl Method控制方法Reaction plan反应计划NO.编号Product产品Process过程Product/Process/Spec./Tolerance产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan抽样计划Core Team 核心小组:Customer Engineering Approve/Date(If Req'd)客户工程批准/日期:(如需要)NAPart name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date供应商/工厂批准/日期:待定Customer Quality Approve/Date(If Req'd)客户质量批准/日期:(如需要)NASupplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/ Process NO.零件/过程编号Process Name/OperationDescription过程名称/操作描述Machine,Device,Jig,Tools forMFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass特性分类Tighten Sampling Plan should be applied if1. customer required2. Product quality concern3. major customer complaint4. Management and/or CFT DecisionPCBA test fixtureRegular Size 正常样本容量Regular Freq.正常频率Tighten Size加严样本量Tighten Freq.加严频率Methods 方法责任部门ResponsibleDepartmentsControl Method控制方法Reaction plan反应计划NO.编号Product产品Process过程Product/Process/Spec./Tolerance产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan抽样计划Core Team 核心小组:Customer Engineering Approve/Date(If Req'd)客户工程批准/日期:(如需要)NAPart name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date供应商/工厂批准/日期:待定Customer Quality Approve/Date(If Req'd)客户质量批准/日期:(如需要)NASupplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/ Process NO.零件/过程编号Process Name/OperationDescription过程名称/操作描述Machine,Device,Jig,Tools forMFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass特性分类Tighten Sampling Plan should be applied if1. customer required2. Product quality concern3. major customer complaint4. Management and/or CFT Decision主板测试治具Anti-static ring testerRegular Size 正常样本容量Regular Freq.正常频率Tighten Size加严样本量Tighten Freq.加严频率Methods 方法责任部门ResponsibleDepartmentsControl Method控制方法Reaction plan反应计划NO.编号Product产品Process过程Product/Process/Spec./Tolerance产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan抽样计划Core Team 核心小组:Customer Engineering Approve/Date(If Req'd)客户工程批准/日期:(如需要)NAPart name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date供应商/工厂批准/日期:待定Customer Quality Approve/Date(If Req'd)客户质量批准/日期:(如需要)NASupplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/ Process NO.零件/过程编号Process Name/OperationDescription过程名称/操作描述Machine,Device,Jig,Tools forMFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass特性分类Tighten Sampling Plan should be applied if1. customer required2. Product quality concern3. major customer complaint4. Management and/or CFT DecisionPCBA test fixture防静电环Anti-static ring防静电环测试仪/分板PCBA test /Separate boardRegular Size 正常样本容量Regular Freq.正常频率Tighten Size加严样本量Tighten Freq.加严频率Methods 方法责任部门ResponsibleDepartmentsControl Method控制方法Reaction plan反应计划NO.编号Product产品Process过程Product/Process/Spec./Tolerance产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan抽样计划Core Team 核心小组:Customer Engineering Approve/Date(If Req'd)客户工程批准/日期:(如需要)NAPart name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date供应商/工厂批准/日期:待定Customer Quality Approve/Date(If Req'd)客户质量批准/日期:(如需要)NASupplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/ Process NO.零件/过程编号Process Name/OperationDescription过程名称/操作描述Machine,Device,Jig,Tools forMFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass特性分类Tighten Sampling Plan should be applied if1. customer required2. Product quality concern3. major customer complaint4. Management and/or CFT DecisionRegular Size 正常样本容量Regular Freq.正常频率Tighten Size加严样本量Tighten Freq.加严频率Methods 方法责任部门ResponsibleDepartmentsControl Method控制方法Reaction plan反应计划NO.编号Product产品Process过程Product/Process/Spec./Tolerance产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan抽样计划Core Team 核心小组:Customer Engineering Approve/Date(If Req'd)客户工程批准/日期:(如需要)NAPart name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date供应商/工厂批准/日期:待定Customer Quality Approve/Date(If Req'd)客户质量批准/日期:(如需要)NASupplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/ Process NO.零件/过程编号Process Name/OperationDescription过程名称/操作描述Machine,Device,Jig,Tools forMFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass特性分类Tighten Sampling Plan should be applied if1. customer required2. Product quality concern3. major customer complaint4. Management and/or CFT DecisionRegular Size 正常样本容量Regular Freq.正常频率Tighten Size加严样本量Tighten Freq.加严频率Methods 方法责任部门ResponsibleDepartmentsControl Method控制方法Reaction plan反应计划NO.编号Product产品Process过程Product/Process/Spec./Tolerance产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan抽样计划Core Team 核心小组:Customer Engineering Approve/Date(If Req'd)客户工程批准/日期:(如需要)NAPart name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date供应商/工厂批准/日期:待定Customer Quality Approve/Date(If Req'd)客户质量批准/日期:(如需要)NASupplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/ Process NO.零件/过程编号Process Name/OperationDescription过程名称/操作描述Machine,Device,Jig,Tools forMFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass特性分类Tighten Sampling Plan should be applied if1. customer required2. Product quality concern3. major customer complaint4. Management and/or CFT DecisionRegular Size 正常样本容量Regular Freq.正常频率Tighten Size加严样本量Tighten Freq.加严频率Methods 方法责任部门ResponsibleDepartmentsControl Method控制方法Reaction plan反应计划NO.编号Product产品Process过程Product/Process/Spec./Tolerance产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan抽样计划Core Team 核心小组:Customer Engineering Approve/Date(If Req'd)客户工程批准/日期:(如需要)NAPart name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date供应商/工厂批准/日期:待定Customer Quality Approve/Date(If Req'd)客户质量批准/日期:(如需要)NASupplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/ Process NO.零件/过程编号Process Name/OperationDescription过程名称/操作描述Machine,Device,Jig,Tools forMFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass特性分类Tighten Sampling Plan should be applied if1. customer required2. Product quality concern3. major customer complaint4. Management and/or CFT Decision1.螺套压到位(不可有明显缝Regular Size 正常样本容量Regular Freq.正常频率Tighten Size加严样本量Tighten Freq.加严频率Methods 方法责任部门ResponsibleDepartmentsControl Method控制方法Reaction plan反应计划NO.编号Product产品Process过程Product/Process/Spec./Tolerance产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan抽样计划Core Team 核心小组:Customer Engineering Approve/Date(If Req'd)客户工程批准/日期:(如需要)NAPart name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date供应商/工厂批准/日期:待定Customer Quality Approve/Date(If Req'd)客户质量批准/日期:(如需要)NASupplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/ Process NO.零件/过程编号Process Name/OperationDescription过程名称/操作描述Machine,Device,Jig,Tools forMFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass特性分类Tighten Sampling Plan should be applied if1. customer required2. Product quality concern3. major customer complaint4. Management and/or CFT DecisionNo defects of no light or flash,Smoke is sucked outRegular Size 正常样本容量Regular Freq.正常频率Tighten Size加严样本量Tighten Freq.加严频率Methods 方法责任部门ResponsibleDepartmentsControl Method控制方法Reaction plan反应计划NO.编号Product产品Process过程Product/Process/Spec./Tolerance产品/过程/规格/公差Evaluation/Measurement Tech.评价/测量技术Sampling plan抽样计划Core Team 核心小组:Customer Engineering Approve/Date(If Req'd)客户工程批准/日期:(如需要)NAPart name/Description零件名称/描述:C086电池组装C086 Battery assembly Supplier/Plant approval/Date供应商/工厂批准/日期:待定Customer Quality Approve/Date(If Req'd)客户质量批准/日期:(如需要)NASupplier/Plant供应商/工厂名称:SMACO Supplier/Plant Code供方代码:C086 BatteryOther Approval/Date(If Req'd)其他批准/日期(如需要):NAOther Approval/Date(If Req'd)其他批准/日期:(如需要) NAPart Number/Latest Change Level 零件号/最新更改水平: NAPart/ Process NO.零件/过程编号Process Name/OperationDescription过程名称/操作描述Machine,Device,Jig,Tools forMFG.material制造用机器、装置、夹具、工具、物料Characteristics 特性Characteristicclass特性分类Tighten Sampling Plan should be applied if1. customer required2. Product quality concern3. major customer complaint4. Management and/or CFT Decision号:SMC-R-06-0059Revision 版次:A/吸力测试/Torsional withcigarette holder /RTD test /RTD TesterC078烟弹C078Cartridges返工Rework 3《产品制程巡检记录表》《IPQC process inspection record》功能特性灯色正常与标识一致2.工作时不允许出现无灯,闪灯,有烟雾被吸出Led color is right.目视Visual check。

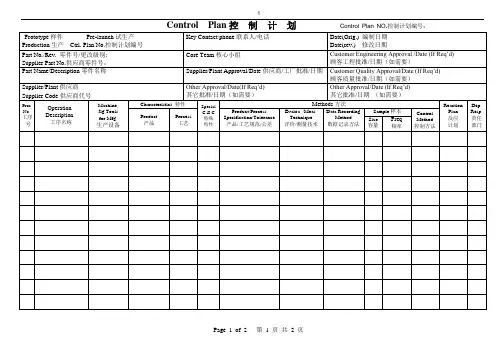

本文部分内容来自网络整理,本司不为其真实性负责,如有异议或侵权请及时联系,本司将立即删除!== 本文为word格式,下载后可方便编辑和修改! ==controlplan范例篇一:CONTROL PLAN-样本控制计划 CONTROL PLANPage 1 of 7Page 2 of 7Page 3 of 7Page 4 of 7Page 5 of 7篇二:CONTROL PLAN-控制计划样本中国3000万经理人首选培训网站控制计划 CONTROL PLAN篇三:Example-Control Plan篇四:Control Plan 编制说明控制计划方法控制计划第___页共___页下方是碰焊小組提供的碰焊問題點:1.脫焊2.分流3.虛焊4.炸火5.間隙6.變形7.焊芯小8.漏焊9.尺寸不良10.燒傷等目录概述1 控制计划栏目描述1) 样件、试生产、生产 2) 控制计划编号3) 零件编号/最新更改水平 4) 零件名称/描述 5) 供方/工厂6) 供方代号7) 主要联系人/电话 8) 核心小组9) 供方/工厂批准/日期 10) 日期(编制)11) 日期(修订)12) 顾客工程批准/日期 13) 顾客质量批准/日期 14) 其它批准/日期 15) 零件/过程号16) 过程名称/操作描述17) 制造用机器、装置、夹置、工装(生产设备)特性18) 编号 19) 产品 20) 过程21) 特殊特性分类方法22) 产品/过程规范/公差 23) 评价/测量技术 24) 样本容量/频率 25) 控制方法 26) 反应计划2. 过程分析3. 补充材料A) 设备:设定主要过程控制计划的示例B) 设备:以机加工为主的过程控制计划示例C) 设备:以夹具/输送台为主的过程控制计划示例D) 设备:以工装为主的过程控制计划示例E) 人员:以操作人员为主的过程控制计划示例 F) 材料:以材料或部件为主的过程控制计划示例 G) 方法:以预防维护为主的过程控制计划示例 H) 环境:以气候为主的过程控制计划示例 I) 控制计划表格J) 控制计划检查清单K) 控制计划特殊特性工作单L) 座标值。

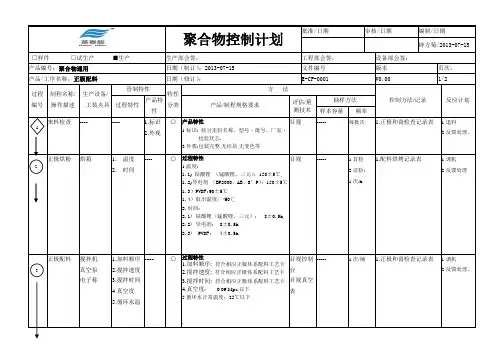

质量控制计划模板控制计划是一份用以描述生产作业工艺流程并定义确保制造出高质量产品的控制方法的文件。

控制计划在整个产品寿命周期中使用,它是动态文件,反映当前使用的控制方法和测量系统。

控制计划是APQP重要输出。

控制计划主要针对产品/过程特殊特性的控制。

1控制计划的构成?它由以下几列组成:控制对象,所属工步,是否CCP/OPRP?,采用设备、工装,控制方法,检测频率,备注等。

在小批量样品和量产过程中都需要用到控制计划,小批量样品CCP相对比较简单;量产CCP必须严格。

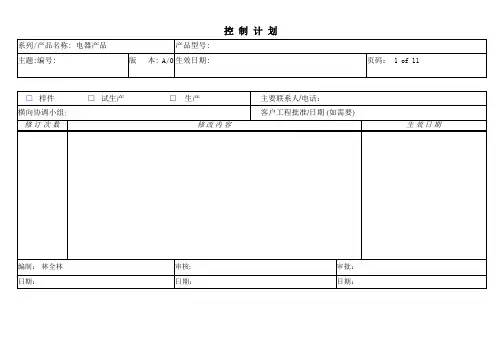

2控制计划的要求?①控制计划是指受控产品和过程事先的书面描述,也称为质量控制计划。

②公司编写文件的重点在于表明产品的重要性和工艺要求,每种产品都应编制控制计划,但在许多情况下,“系列”产品控制计划包括了在相同过程中的许多产品。

③顾客对控制计划一般要求在设计开发后、试生产前、生产件提交后(批产前),由相关部门进行批准。

④控制计划必须按照DFMEA+PFMEA来编写,工艺流程和工艺卡片必须按照控制计划编写。

3如何编写控制计划?(1)控制计划表的格式a. 如顾客未书面规定,控制计划采用APQP手册规定格式。

(如客户有指定或提供则使用其)。

b. 如顾客未要求提供控制计划,则一个单一的控制计划可以适用于相同过程、相同原材料生产出来的同一个系列的产品(如:同一产品的不同规格)。

当顾客有要求时,则须提供一份单一的控制计划。

(2)控制计划相应栏目应按如下要求填写和制定。

a. 样品、试生产、生产选择控制计划分类,根据所加工产品的不同过程时期的控制计划,在分类前的方框内打上“√”符号。

b. 控制计划编号:填入控制计划编号。

具体按《文件管制程序》要求编号。

c. 物料名称/描述:填入被控制产品的名称及控制过程的名称。

d. 供方/工厂:填入制定控制计划的公司名称。

e. 供方代号:填入由顾客给定的批号。

f. 主要联系人/电话:填写主要负责人的电话号码。

g. 项目小组: 填入负责制定控制计划最终版本的所有人员的姓名、部门和联系电话号码,若填写不下,可附页。

控制计划中的容量和频率理解英文文档:Title: Understanding Capacity and Frequency in Control PlansIn control plans, capacity and frequency are two essential components that play a significant role in the overall effectiveness and efficiency of a process or system.Here"s a detailed understanding of both: Capacity:Capacity in a control plan refers to the maximum amount of work or output that a process, machine, or system can handle within a given time frame.It is a measure of the resource availability and the ability to complete tasks.Understanding capacity is crucial because it helps in:1.Determining the appropriate resources required for the process.2.Avoiding overloading the system, which can lead to bottlenecks, delays, and reduced quality.3.Planning for contingencies and ensuring smooth operations.Frequency:Frequency, in the context of control plans, denotes the rate at which a particular task, operation, or inspection is performed.It is related to the timing and repetition of activities.The significance of frequency includes:1.Ensuring consistency and uniformity in the process.2.Detecting and addressing issues early, thereby preventing largerproblems.pliance with quality standards and regulatory requirements.Balancing Capacity and Frequency:Effectively managing capacity and frequency is vital for optimizing operations.Here are some considerations for achieving this balance:1.Demand forecasting: Accurately predicting the demand helps in determining the required capacity and frequency of operations.2.Resource allocation: Ensuring that resources are allocated efficiently to meet the desired capacity without overburdening the system.3.Flexibility: Building flexibility into the control plan to accommodate variations in demand and unforeseen circumstances.Conclusion:Understanding capacity and frequency is critical for developing effective control plans.It helps in optimizing resource utilization, improving process efficiency, and ensuring compliance with quality standards.By carefully managing these two components, organizations can achieve smooth operations and enhanced customer satisfaction.中文文档:标题:控制计划中容量和频率的理解在控制计划中,容量和频率是两个基本组成部分,对过程或系统的整体有效性和效率起着重要作用。

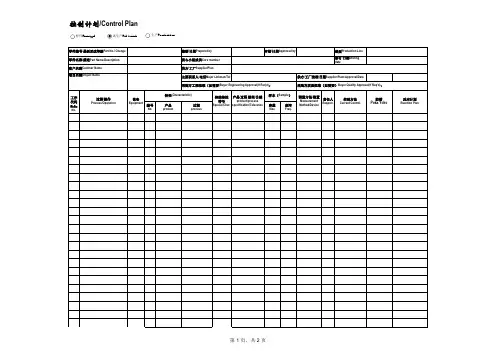

容量Size 频率Freq.入库move to storage材料规格、数量Material Specificationquantity送货单Bills of dilivery1每批per lot到货计划Material planA-1◇C≤0.15、Si≤0.05、Mn≤0.60、S≤0.035、P≤0.035化学成分分析Chemical elementanalysis1每批per lotA-2◇抗拉强度Tensile strength ≥305Mpa、屈服强度Yield strength≥175Mpa、断后伸长率Elongation≥29力学性能分析Mechanical propertiesanalysis1每批per lot2.5±0.20-25mm(0.001)外径千分尺outside micrometer3每批per lot1250(+10,0)2600(+40,0)0-3m(1)卷尺Tape measure3每批per lot存放Storage275±10-300mm(0.02)游标卡尺Calipers无毛刺No Burr目视Visual设备间隙Shears gap0.2(+0.05,0)目测设备间隙参数设定Visual equipment gapparameter settings1每班Every shift调整设备、上报Adjustment equipment ,reporting φ265±0.50-300mm(0.02)游标卡尺Calipers无毛刺No Burr目视Visualφ141.5(+1.0,0)0-150mm(0.02)游标卡尺Calipers50.5(+1.5,-1.0)0-300mm(0.02)高度尺Height Gages高度Height 首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs检验记录Inspectionrecord标识、隔离、检查模具Identification ,Separate ,Checkthe die供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)标识、隔离、调整设备Identification ,Separate,Adjustment device 生产设备Machine.DeviceJig.ToolsFor Mfg.特性Characteristics零件名称/描述Part Name/Description 端盖HP HUB CAP,GREASE NON-VENTEDJY32-315/315T油压机Hydraulic Press直径Diameter40冲压拉深成形Punch供方/工厂批准/日期Supplier/Plant Approval/Date过程名称/操作描述Process Name/OperationDescriptionHD130-H002/拉深模Drawing Die条料宽度尺寸Material widthdimension其它批准/日期(如需要)Other Approval/Date (If Req'd)检验记录Inspectionrecord用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change LevelE32629-1、E32629-3零件/过程编号Part/ Process Number评价/测量技术EvaluationMeasurementTechnique样本Sample控制方法ControlMethod特殊特性分类SpecialChar.Class方法Methods标识、隔离、退货Identification ,Separate ,Reject产品标识和防护控制程序 HD/PF02-SP09Product identification and protection control program反应计划Reaction Plan 编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance10原材料入厂检验Receiving Raw material and Inspection力学性能Mechanicalproperties原材料检验报告Raw materialsinspectionreport原材料长/宽尺寸Length/widthdimensions原材料检验记录Raw materialinspectionrecords化学成分chemical element原材料厚度尺寸thicknessdimension20剪板机下料Shears CuttingQC12Y-12*2500/液压剪板机Hydraulic shears外观Appearance首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs30冲压落料Punch首末检1件、巡检3件、自检3件first and endinspection1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and endinspection1,inspection every4hrs,self-inspectionevery hrs检验记录Inspectionrecord标识、隔离、检查模具Identification ,Separate ,Checkthe die外观AppearanceJA21-160/160T冲床PressesHD110-H009/落料模Blanking die直径Diameter容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance47±10-300mm(0.02)深度尺Depth Gages首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs首末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压力Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa目视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ142.5(+0.2,-0.3)0-150mm(0.02)游标卡尺Calipers 50.5(+1.5,-2.0)0-300mm(0.02)高度尺Height GagesA-3◇47±10-300mm(0.02)深度尺Depth Gages首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs首末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrs标识、隔离、检查模具Identification ,Separate ,Checkthe die B-1压力Pressure◇上缸Cylinder 15(+1,0)Mpa下缸Undercylinder9(+1,0)Mpa目视Visual1每班Every shift调整设备、上报Adjustment equipment ,reportingφ214±0.50-300mm(0.02)游标卡尺Calipers6×φ8.7±0.250-150mm(0.02)游标卡尺Calipers A-4◇HDJ-H0001检具Gage首末检1件、巡检5件、自检5件first and end inspection 1pcs,inspection 5pcs,self-inspection 5pcs末检1次、巡检每2小时、自检每1小时first and end inspection 1,inspection every 2hrs,self-inspectionevery hrsφ205±0.750-300mm(0.02)游标卡尺Calipers 深度Depth检验记录Inspection record50整形ShapingJY32-315/315T油压机Hydraulic Press 直径Diameter 首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs 首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs 检验记录Inspection recordHD134-H014/整形模Shaping Die高度Height检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,Checkthe die孔径diameter I.D.HD146-H011/切边冲孔模Trimming and Punching die位置度Location degreeJA21-160/160T冲床Presses深度Depth直径Diameter 检验记录Inspection record标识、隔离、检查模具Identification ,Separate ,Checkthe die40冲压拉深成形Punch冲压切边冲孔Trimming and PunchingJB21-160B-SM/160T冲床直径Diameter首末检1件、巡检3件、自检3件first and endinspection首末检1次、巡检每4小时、自检每1小时first and end inspection60首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection3pcs,self-inspection 3pcs首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/Tolerance10(+2,0)0-300mm(0.02)高度尺Height Gages85°±0.5°0-360°(2′)万能角度尺Universal angle rulerA-5◇首末检、巡检0-10mm(0.01)百分表/自检 0-1mm塞尺First and endinspection 0-10mm(0.01) Dialindicator/Self-inspection 0-1mmFeeler首末检1件、巡检5件(X-R图)、自检5件first and end inspection 1pcs,inspectio n 5pcs(X-R chart),self-inspection 5pcs末检1次、巡检每2小时、自检每1小时first and endinspection1,inspection every2hrs,self-inspection everyhrsφ4(+2,-1)0-150mm(0.02)游标卡尺Calipers 1±0.250-300mm(0.02)高度尺Height Gages90无油污No dirt 目测Visual全检Full inspection每批per lot检验记录Inspection record 标识、隔离、退货Identification ,Separate ,Reject喷塑气压Spray pressure0.4-0.5MPa喷塑电压Spray voltage 50-60KV烘烤温度Bakingtemperature 180-200℃烘烤时间Baking time30-40min 无漏喷No leakage jet目测Visual调整设备、上报Adjustment equipment ,reporting100喷塑SprayXNG-36-1B/粉末喷涂生产线Powder coating production lines目测Visual1产线外观Appearance全检Full inspectionper lot70冲压翻边成形FlangingJB21-160B-SM/160T冲床Presses件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs80冲压压字Pressure logoJA21-160/160T冲床Presses孔径diameter I.D.首末检1件、巡检3件、自检3件first and end inspection 1pcs,inspection 3pcs,self-inspection 3pcs标识、隔离、检查模具Identification ,Separate ,Checkthe die角度AngleHD124-H008/翻边模Flanging die平面度Flatness高度Height 标识、隔离、检查模具Identification ,Separate ,Checkthe dieHD150-H006/压字模Pressure logo die(E32629-3)HD150-H005/压字模Pressure logo die(E32629-1)高度Height检验记录Inspection record首末检1次、巡检每4小时、自检每1小时first and end inspection 1,inspection every 4hrs,self-inspectionevery hrs检验记录Inspection record外观Appearance外协镀锌Outsourcing galvanized检验记录Inspection record每班Every shift检验记录Inspection record容量Size频率Freq.供方/工厂Supplier/Plant:山东慧达汽车部件有限公司Shandong HuiDa Automotive Parts Co., Ltd.其它批准/日期(如需要)Other Approval/Date(If Req'd)生产设备Machine.Device Jig.Tools For Mfg.特性Characteristics 零件名称/描述Part Name/Description端盖HP HUB CAP,GREASE NON-VENTED供方/工厂批准/日期Supplier/Plant Approval/Date 过程名称/操作描述Process Name/OperationDescription其它批准/日期(如需要)Other Approval/Date (If Req'd)用户工程批准/日期(如需要)User Engineering Approval/Date (If Req'd)用户质量批准/日期(如需要)User Quality Approval/Date (If Req'd)聂建钦,彭亮,李庆平,刘客,张守东,张栋,苗秀宝、王树龙供方代号Supplier Code零件号/最新更改水平Part Number/Latest Change Level E32629-1、E32629-3零件/过程编号Part/Process Number评价/测量技术Evaluation Measurement Technique样本Sample控制方法Control Method特殊特性分类SpecialChar.Class方法Methods反应计划Reaction Plan编号NO.产品Product过程Process产品/过程/规范/公差Product/ProcessSpecification/ToleranceA-5◇0.15mm塞尺(端盖平放在大理石台面,上面压5kg物体)/0.15mm feeler ( cover flat on the marble countertops, pressure5kg objects above )盐雾试验≥1000小时/Salt spray test≥1000hrs盐雾腐蚀试验机/Salt spray corrosiontest machine3每季度Each quarter 盐雾试验报告Salt spray testreport 110丝印完整Full screen目测Visual全检Full inspection每批per lot检验记录Inspection record标识、隔离、退货Identification ,Separate ,RejectA-3◇47±10-300mm(0.02)深度尺Depth Gages10A-4◇HDJ-H0001检具Gage 10A-5◇0.15mm塞尺(端盖平放在大理石台面,上面压5kg 物体)/0.15mm feeler (cover flat on the marble countertops,pressure 5kg objectsabove )10包装规范Packaging Specifications点数Counting 2箱2 box标识、隔离、返工Identification ,Separate ,Rework清晰Clear 目测Visual 包装规范Packaging Specifications 目测Visual 物资发货单Material Invoice点数Counting标识、隔离、返工Identification ,Separate ,Rework平面度Flatness防腐蚀性能Corrosion100喷塑SprayXNG-36-1B/粉末喷涂生产线Powder coating production lines全检Full inspection每批per lot外协丝印Outsourcing Screen外观Appearance 检验记录Inspection record深度Depth120抽检并包装Sampling inspection and packaging标识、隔离、处理Identification ,Separate ,Dealwith位置度Location degree平面度Flatness数量Quantity 每批per lot检验记录Inspection record标识Label标识、隔离、返工Identification ,Separate ,Rework包装Package 数量Quantity130入库&出货Warehousing & shipping全检Full inspection每批per lot 物资发货单Material Invoice。