CA型静音无油空气泵使用说明书模板

- 格式:docx

- 大小:68.41 KB

- 文档页数:11

无油空气压缩机安全操作规程范本一、前言为了确保无油空气压缩机的安全运行,防止事故的发生,保护人员的生命财产安全,制定本安全操作规程。

二、适用范围本规程适用于无油空气压缩机的日常操作与维护。

三、安全操作规程1. 操作前的准备1.1 熟悉无油空气压缩机的结构、原理、工作流程和安全操作规程。

1.2 穿戴必要的个人防护装备,如护目镜、防护手套、防滑鞋等。

1.3 检查无油空气压缩机的工作环境是否符合操作要求,确保通风良好。

1.4 检查无油空气压缩机的电源是否接地可靠,电器设备是否正常运行。

2. 启动与停止操作2.1 启动操作2.1.1 打开压缩机的电源开关。

2.1.2 仔细观察电器设备的运行状态,确保压缩机正常启动。

2.1.3 检查压缩机出口的压力表是否正常工作。

2.1.4 将操作面板上的压力开关调至所需压力值。

2.2 停止操作2.2.1 将操作面板上的压力开关调至最低值。

2.2.2 关闭压缩机的电源开关。

2.2.3 等待压缩机内的气体完全排放干净后,才能进行维护操作。

3. 维护操作3.1 定期清洁压缩机的进气口和出气口,防止灰尘、杂物进入。

3.2 定期检查油滤器和空气滤清器的工作状态,如有损坏及时更换。

3.3 定期检查压力表和温度表的准确性,如有不正常情况及时修理或更换。

3.4 定期检查压缩机的润滑情况,如需加油或更换润滑剂应按说明书要求进行操作。

3.5 维修和更换压缩机的零部件时,应按照相关技术标准进行操作,严禁私自拆卸和更换零部件。

4. 应急处理4.1 如出现压缩机异常声音、温度升高或震动等异常情况,应立即停机检查原因,并采取相应措施。

4.2 如发生压缩机漏气、泄漏润滑油或者其他异常情况,应立即采取紧急停机并进行处理。

4.3 如压缩机发生火灾、爆炸等危险情况,应迅速撤离人员,及时通知有关部门,并采取安全措施进行扑救。

4.4 如压缩机发生电气故障,应立即切断电源,并进行修复或报修。

五、总结本安全操作规程是无油空气压缩机的操作和维护的基本要求,所有操作人员必须严格遵守。

ULTRA QUIET & OIL FREEAIR COMPRESSOROwnER'S MAnUALCALIFORnIA AIR TOOLS20040C4.0 HP20 gAL. Customer Support 1-866-409-45812TAbLe OF CONTeNTSIntroductIon __________________________________2Important Safety InStructIonS _______________5aIr compreSSor componentS__________________6pre-operatIon checklISt ______________________7package contents & assembly____________________7Inspect for damage _____________________________7Save packaging ________________________________7compressor location ___________________________7electrical power ________________________________8operatIng the aIr compreSSor ________________8Introduction ___________________________________8assembly _____________________________________8test run & Break-in period_______________________9daily operation_________________________________9maIntenance _________________________________10draining the air tank & air dryer _________________10changing the air filter__________________________10testing for leaks ______________________________10cleaning _____________________________________10Storage ______________________________________10trouBleShootIng ____________________________11SpecIfIcatIonS________________________________12electrical circuit _______________________________12air passage drawing ___________________________12Warranty ____________________________________13product regIStratIon________________________15thank you for purchasing a california air tools, Inc.air compressor.record the model and serial numbers indicated on your air compressor’s nameplate:model no.________________________________________Serial no.________________________________________date of purchase:_________________________________Store/dealer:_____________________________________3Customer Support: 1-866-409-4581how to find a local service center:even quality built equipment might need service or repair parts.Contact the California Air T ools Customer Service department:Phone: 1-866-409-4581Online: please provide the information below:Model number and Serial number and specifications shown on the Model number/Serial number plate.Part number or numbers shown in the parts list section of the owner’s manual for your air compressor model.A brief description of the trouble with the air compressor.do not return your air compressor for service or parts to the store/dealer where purchased.IMPORTANT SAFeTy INSTRuCTIONSSafety messages & Signal Words:4Customer Support: 1-866-409-45815Customer Support: 1-866-409-45816Customer Support: 1-866-409-4581pre-operatIon checklISt package contentsmodel: 20040cpackage contents:*Air Compressor* Air Filters (4)*Owner's Manualassembly:Install the air filters.1. Screw the four air filters into the 4 ports located onthe top left and right sides of the motor heads.Inspect for damagebefore using the air compressor, make sure the air tank is not damaged, inspect all parts for damage, and check that all pipes are firmly connected.do not use the air compressor if any damage is found. If damaged, have an authorized service center inspect and test the air compressor to ensure that is working properly.Save packagingSave all outside packaging in case you ever need to return the product for service or repair.compressor locationuse on flat SurfaceFor proper operation, the air compressor must be placed on a flat surface with an incline no greater than 15 degrees.maintain a clear areaIt is very important that the air compressor is positioned so that there is adequate airflow around the machine. There must be at least 2 feet of obstacle-free space surrounding and above the air compressor.use in areas with clean airFor proper operation and to maximize the longevity of the air compressor, it is very important that the air drawn into the air compressor is clean. The air compressor should not be used in areas where dust or particulates are in the air. This will damage the motor and impair proper operation.Important:Always use the air filter, properly installed.7 Customer Support: 1-866-409-45818Customer Support: 1-866-409-4581electrical powerelectrical power requirementsbefore using the air compressor, refer to the serial label for voltage and amperage requirements. Make sure you have asufficient electrical supply for supporting the motor's requirements. use a dedicated circuit for the best results.Low voltage and/or an overload circuit can cause the motor's overload protection system circuit breaker to trip.electrical extension cordInspect all electrical extension cords to ensure that they are free ofInspect all electrical extension cords to ensure that they are free of damage.When using an extension cord, use a heavy-duty cord that is no more than 25 feet long and at least 14 gauge.use only a 3-wire extension cord that has a 3-blade grounding plug.OPeRATINg The AIR COMPReSSORSave this manual for future reference.IntroductionThis air compressor features a compact structure, stable,performance, a high airflow rate, easy operation and lowmaintenance. because the air compressor produces no oil in the airflow, it can be used for air supplies that need oil-free air.. The motor directly drives the pistons and does not need any lubrication or oil to function for a long period of time.assembly1.Attach the air hose to the 1/4” (universal / Industrial) coupler.2.Make sure the drain valve is off and that the power switch is in the OFF position.3. ensure that the power supply you are going to use is operating normally.4.Insert the power supply cord into the power supply socket.9Customer Support: 1-866-409-4581AIR COMPRESSORtest runbefore using the air compressor for the first time, complete a test run as follows:1.Turn the power switch to the OFF position. Plug the power supply cord into a power supply socket. Start the aircompressor by turning the power switch to the ON position.The pressure gauge reading will slowly rise as pressureincreases inside the air tank. When the gauge reading reaches 120 -125 PSI, the pressure switch will automatically turn the power off. This indicates the compressor is working normally. 2.Starting the compressor:1.Turn the power switch to the OFF position.2.Attach the air hose to the 1/4” (universal / Industrial) coupler.3.Close the drain valve.4.Plug the power supply cord into a power supply socket.5.Turn the power switch to the ON position.6.Let the motor run and tank fill until motor turns off.7. Operate air tool normally.8.T o regulate the air to the air hose. have the air compressor and air tool both turned on and running. Turn the regulator knob to the right to increase the pressure and to left to decrease the air pressure to the hose and air tool..Shutting down the compressor:1.Turn the power switch to the OFF position.2.unplug the power supply cord.3.Reduce the pressure in the air tank through the air supply hose.note: If the Air Compressor is not working properly, the pressure gauge will indicate that there is a decrease in pressure in the air tank. If there is an air leak from the compressor the pressure in the air tank decreases, the pressure switch resets and the motor automatically turns back on.If you detect an air leakage, turn the power switch to the Off position, release the air from the tank by pulling on the safety valve. unplug the power supply cord and contact Customer Support for Assistance.Turn the power switch to the Off position, unplug the power supply cord and release the air from the drain valve.At this point proceed to the next step (daily operations)starting the air compressor to continue to use.AIR COMPRESSOR MAINTeNANCedraining the air tankThe frequency at which you should drain the air tank depends on the environmental conditions and the amount of operating time logged.daily draining is recommended to not damage the air compressor motor, tank and other components.1.Place the air compressor above a container capable of holdingwater. A pan with a dry towel would be advised.Locate the drain valve at the bottom of the air tank.2.Without compressed air in the air tank, slowly turn the drain valveknob to the forward (open) or straight down position.The water in the air tank will drain out.3.After all of the accumulated water has drained out, turn the drainvalve knob to the closed or left position in order to avoid leakage.*** draining the air tank protects parts from rust and corrosion***changing the air filterThe air filters are designed to reduce noise and help prevent particulates in the air from entering and damaging the air compressor.After being used for a period of time, the air filter will become clogged. This will reduce the air intake capabilities of the air compressor, reducing performance. Therefore, the air filter must be replaced regularly.1.Open the lid of the air filter and remove the old air filter element.2.Replace with a new air filter element and close the lid.testing for leaksMake sure all connections are tight. do not overtighten.A small leak in any hose or pipe connection will reduce the air compressor's performance.T o test for small leaks, spray a small amount of soapy water on the area suspected of leaking. If the soap bubbles, replace the broken part.cleaningClean items with a soft brush, or wipe with a moistened cloth using a biodegradable solvent.do not use flammable liquids such as gasoline or alcohol. Always keep parts clean from dirt and dust for better performance.STORAgebefore storing for a prolonged period of time:1.Turn off the power supply.2.disconnect the power cord from the power supply.3.Pull the relief valve and release all the pressure from the air tank.4.Clean the air compressor to remove all dirt and dust.5.Cover the air compressor with a cover to protect the unit fromdust and moisture.6.do not stack or store any items on top of or around the aircompressor. damage could occur.10AIR COMPRESSOR TROubLeShOOTINg11Customer Support: 1-866-409-458112Customer Support: 1-866-409-4581SPeCIFICATIONSelectrical circuitair passage drawingAIR COMPRESSORMotorEarth wire (Green)Red cords for CapacitorElectric cord for motorSolenoid valveElectric cord for motor Pressure switchOverload protector (MAX temperature 135°C)Pressure switchSafety valvePressure gaugeRegulatorPressure gaugeBall valveFilterDrain valveAir intakeCheck valveSolenoid valveCompressorTankAIR COMPRESSOR CALIFORNIA AIR TOOLS INC. LIMITed WARRANTyThis warranty is limited to Air Compressors distributed by:California Air Tools, Inc.8560 Sieper Viva Road, unit 3San diego, CA 92154limited WarrantyCalifornia Air T ools Inc. will repair or replace, free of charge, to the original retail customer who purchased a California Air T ools, Inc.Air Compressor from an authorized dealer, distributor or distributor’s dealer in North America.This warranty does not transfer to subsequent owners.California Air T ools Inc. will repair or replace, at its option, any parts of the portable air compressor that are proven by an authorized service center to be defective in material or workmanship under normal use during the applicable warranty time period as stated below. This limited warranty covers the cost of the replacement parts and labor for all defects when installed by an authorized service center. Transportation charges are the responsibility of the customer. Any part replaced under warranty becomes the property of California AirT ools Inc.All parts replaced under warranty will be considered as part of original product, and any warranty on those parts will expire coincident with the original product warranty.limited Warranty periodsNon-commercial / Non-rental (personal use by a retail customer): 12 months parts and laborCommercial / Rental (usage for income, business use):12 months parts and laborThe limited warranty period begins on the date of retail purchase by the original purchaser.disclaimers, limitations of remedies & exclusionsThis warranty gives you specific legal rights, and you may also have other rights which may vary from state to state.disclaimer of other WarrantiesT o the fullest extent permitted by applicable law, this limited warranty is exclusive and expressly in lieu of any and all other warranties, including, without limitation, any implied warranties of merchantability or fitness for a particular purpose or any other implied warranties that may arise from the course of dealing or usage of the trade. California Air T ools Inc. hereby declaims and excludes all other warranties. T o the extent that California Air T ools Inc. products are consumer products under applicable federal and state law with respect to any customer, the duration of any implied warranties (including but not limited to implied warranties of merchantability or fitness for a particular purpose) are limited to the shortest duration permitted by applicable law or the Limited Warranty period provided herein, whichever is longer.limitations of remediesCalifornia Air T ools Inc. shall not be liable to customer, or anyone claiming under customer, for any other obligations or liabilities, including but not limited to, obligations or liabilities airing out of breach of contract or warranty, negligence or other tort or any theory of strict liability, with respect to the air compressor or California Air T ools Inc. acts or omissions or otherwise. T o the fullest extent permitted by applicable law, California Air T ools Inc. shall not in any event be liable for incidental, compensatory, punitive, consequential, indirect, special or other damages, including but not limited to loss of use, loss of income, loss of time, loss of sales, injury to personal property, or liability customer incurs with respect to any other person, or any other type or form of consequential damage or economic loss.13exclusionsIn addition to the foregoing disclaimers, limitations and terms, this limited warranty shall not apply to and does not cover accessories, nor does it cover products that are in any way subject to any of the following:1.Improper setup, installation or storage.ck of proper maintenance and service.3.Accident, damage, abuse or misuse.4.Abnormal operating conditions or applications.5.Repair or modification by customer or any third party without written consent of California Air T ools Inc.e under operating conditions or in applications not recommended by California Air T ools Inc.7.Normal wear.8.The use of accessories or attachments not recommended by California Air T ools Inc.9.Acts of god.The application of these exclusions will be determined at the sole discretion of California Air T ools Inc.registrationWarranty registration with California Air T ools Inc. is required on all products.you can mail the enclosed registration form.Warranty is also available by keeping and showing your original receipt from the date of purchase to an Authorized California Air T ools Service Center.Servicedo not return your air compressor to the place of purchase.For all customer service inquiries.Contact California Air T ools Customer Service1-866-409-4581 (8am - 4pm) M - F Pacific Timego to customer Service tabclick on parts and Service tab14PROduCT RegISTRATIONT o register your product, please complete the information below and mail to the mailing address at the end of this page.1.personal Information:Full Name (Include Middle Initial):_______________________________________________________________Mailing Address:_____________________________________________________________________________City:___________________________________ State:_______________ Zip Code:_______________________Phone Number:_____________________________________________________________________________e-mail Address:_____________________________________________________________________________(Check here to receive product information and offers via e-mail)(Check here to receive product information from other companies via e-mail)2. product Information:date of Purchase:_____________________________________________________________(MM / dd / yyyy)Model Number:______________________________________________________________________________Serial Number:___________________________________________________________(Found on name plate)Purchased Location:__________________________________________________________________________Purchase Price:_____________________________________________________________________________Type of Primary use for this Product: home Recreation emergency Rental CommercialOther______________________________________________________________________________________Features Influencing Product Purchase: brand Portability Power Rating Price WarrantyOther Features (describe)_____________________________________________________________________What other Power equipment are you interested in purchasing in the future?_____________________________Thank you for registering your product.Mail to:California Air Tools8560 Sieper Viva Road, unit 3San diego, CA 9215415。

无油式空气压缩机【操作规程】一、概述1、目的:本规程指导操作人员正确使用无油式空气压缩机2、使用设备:无油润滑空气压缩机6立方3台,10立方1台3、引用文件:二、操作步骤:1、开机前的准备工作1.1电器设备应单独调整,清理试验好,电机旋转方向正确,电压不低于340伏。

1.2各连接部位的紧固装置和安全防护装置良好。

1.3打开排污阀门,打开冷却水阀门。

1.4打开总管道阀门,检查水、油的压力和存量,确保空压机无负荷启动。

2、开机程序2.1先将电机启动,有异常声音后关闭电机。

2.2电机启动后,空压机先空载运行2~4分钟,然后关闭排污阀门,再使压缩机达到规定参数2.3开车后应注意压缩机运行是否正常,有无异常声音,安全阀是否正常,各连接部位有无漏油、漏气、漏水现象。

3、关闭程序3.1打开排污阀门,将积水和压缩空气放尽。

3.2关闭电源,空压机将停止工作。

3.3如全部空压机关闭,则关闭水泵和冷却风机,关闭进总管道的阀门。

4、故障停车程序4.1以下情况,将紧急停车,开其它备用机:1)当油压低于0.1Mpa经调节无效时2)压缩机有异常声响时3)安全阀打开压力过高4)压缩机任何部分温度超过允许值时5)电器设备出现异常声响时4.2压力容器严重漏气时;冷却水系统故障,将关闭所有压缩机。

4.3冷却水故障时,应及时打开补充水(消防水)。

发生意外故障时,应及时通知汇报组长和设施科。

三、运行参数1.油位应在两油标线的2/3高度上,油压为0.1~0.5Mpa,油温低于60度。

2.排气压力一级为0.18~0.22Mpa,二级为0.6~0.8Mpa,排气温度低于160度3.水压在0.2~0.4Mpa四、维修1.操作人员应做好设备的润滑保养。

2.设备维修、保养有动力维修工负责。

五、巡视检查1.操作人员至少每小时巡视抄表一次。

2.巡视时,注意冷却水和油位的情况是否正常。

3.如发生意外情况应及时采取措施,做好记录并马上告之组长。

4.储气罐每两小时排污一次排污时,排污缓慢开启不得快速开启,潮湿天气时视情况而定,多放为佳。

使用说明书充电式空气压缩机AC001G中文简体: 原本使用前请阅读。

保留备用。

中文简体 (原本)型号:AC001G L/***********(L/**********)34 L/min启动压力0.72 MPa (7.2 bar)停止压力0.93 MPa (9.3 bar)出口最大压力0.93 MPa (9.3 bar)罐径 x 行程 x 数量36 mm x 30 mm x 1电机RPM 6,000 r/min 罐尺寸7.6 L 润滑无油额定电压D.C. 36 V - 40 V 最大尺寸(长 x 宽 x 高)302 mm x 434 mm x 382 mm净重11.6 - 12.2 kg• 生产者保留变更规格不另行通知之权利。

• 规格和电池组可能因销往国家之不同而异。

适用电池组和充电器电池组BL4020 / BL4025 / BL4040* / BL4050F**:建议使用的电池充电器DC40RA / DC40RB / DC40RC注:不包括电池组和充电器。

符号以下显示本设备可能会使用的符号。

在使用工具之前,请务必理解其含义。

阅读使用说明书。

小心:在对本压缩机进行任何 工作前,必须取出电池组。

高温危险。

小心:本压缩机含有部分可能达到高温的部件。

意外启动危险。

注意,在断电而后重置的情况下,本压缩机可能自动启动。

Ni-MH Li-ion 仅用于欧洲国家由于本设备中包含有害成分,因此废弃的电气和电子设备、蓄电池和普通电池可能会对环境和人体健康产生负面影响。

请勿将电气和电子工具或电池与家庭普通废弃物放在一起处置!根据欧洲关于废弃电气电子设备、蓄电池和普通电池、废弃的蓄电池和普通电池的指令及其国家层面的修订法案,废弃的电气设备、普通电池和蓄电池应当单独存放并递送至城市垃圾收集点,根据环保法规进行处置。

此规定由标有叉形标志的带轮垃圾桶符号表示。

保证声功率级别符合欧盟室外噪音指令。

保证声功率级别符合UKCA室外噪音指令。

AEON-QP13-D11无油空气压缩机静音箱机组操作说明

一. 工作原理简介

设备通电后,空气压缩机运转,空气由滤清器吸入,经汽缸活塞压缩后,压缩空气通过管路单向阀储存在储气罐中。

调整调压阀打开球阀,便获得稳定压力的压缩空气。

机组开启、停止、运转由压力开关控制,压力表分别显示储气罐和排出空气压力数值。

二. 操作说明及注意事项

1.本设备机组使用电源为220V;开机前必须首先核实电源电压无误后,才能通电运行。

2.空气压缩机仅勇于抽取自然状态空气,不能抽吸其他带压或含污染、腐蚀有害气体。

3.空气压缩机、气缸体、缸盖、排气管路均有较高温度,操作者应小心,不得靠近和触摸以免烫伤,空气压缩机排出压缩气流均有较高温度和压力,应防止高压气流损伤。

4.本机为无润滑油空气压缩机,在使用过程中严禁加注任何润滑油。

5.空气压缩机有热保护器,当其电流过高时,热保护器会处于保护状态,空气压缩机突然停机,待温度下降后,按动保护器往复按钮,可恢复正常启动。

6.严禁空气压缩机正常工作时,带压、带电拆卸、紧固、维修空气压缩机零部件。

7.空气压缩机发现漏气,异常声响时,应立即断电停止运转,故障排除后才能通电运行。

8.空气压缩机严禁带压启动。

9.非指定人员不得拆卸、维修、调整一面造成空气压缩机零件损坏。

10.空气压缩机组应定期由放水阀排除储气罐中的水份。

11.干燥塔中的干燥剂使用寿命为4000小时,应按时更换干燥剂。

编制:审核:。

ZW 500D 无油低噪音空气压缩机说明书前言:一、多谢阁下赏识。

此机能提供稳定的无油气源。

避免油渍进入人体,影响粘固质量和工作环境,又能避免终端机器的非耐油管因有油和气压过高引发故障。

二、需水平安放在室内干燥、清洁、通风场所,特别注意远离粉尘之类的范围,如无法达到要求,必须增加过滤。

三、此机组额定电压110±5%V AC60Hz500W 5.0A,电流所经过的电源线、保护装置等必须接触良好和能承受电动机起动时约10安培的电流。

四、每季度清洁过滤器海绵的粉尘一次,每月查看电磁阀是否正常排空和每星期排水一次,排水方法:打开底部排水堵头,污水由排污口排出。

五、机组编号在500A 后面有七位数,前二位是生产年份、第三位是月份(按英文字母顺序排列)、最后四位数是当月生产第几台的序号。

如无购机凭证,保修期以出厂编号日期算起,一年内为保修期。

试机:插上电源插座,机组运行,关闭各气开关,充气至8.0bar 时自动关机并自动排空,静听无漏气现象,放气至4.0bar 时机组自动开机充气至8.0bar 自动停机 ,拉出插头,移致固定处水平放好,接好气管,插好插头,机组充满气停机,打开供气开关,观察压力表应无降压,确认终端机器无漏气现象,即可投入使用。

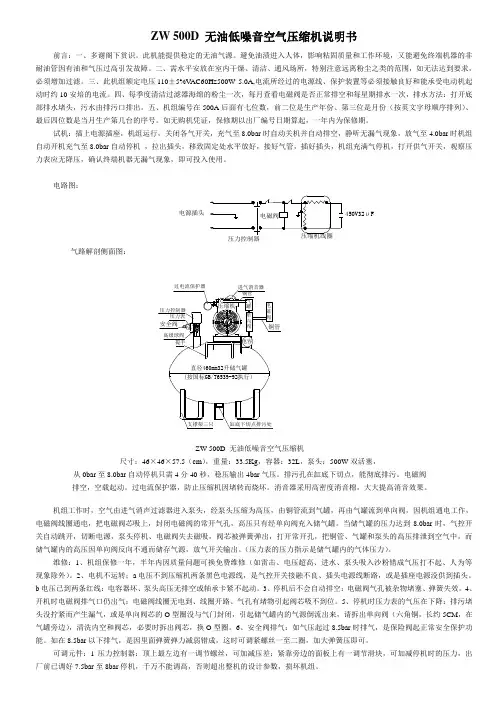

电路图:气路解剖侧面图:机组工作时,空气由进气消声过滤器进入泵头,经泵头压缩为高压,由铜管流到气罐,再由气罐流到单向阀,因机组通电工作,电磁阀线圈通电,把电磁阀芯吸上,封闭电磁阀的常开气孔,高压只有经单向阀充入储气罐。

当储气罐的压力达到8.0bar 时,气控开关自动跳开,切断电源,泵头停机、电磁阀失去磁吸,阀芯被弹簧弹出,打开常开孔,把铜管、气罐和泵头的高压排泄到空气中,而储气罐内的高压因单向阀反向不通而储存气源,放气开关输出。

(压力表的压力指示是储气罐内的气体压力)。

维修:1、机组保修一年,半年内因质量问题可换免费维修(如雷击、电压超高、进水、泵头吸入沙粉错成气压打不起、人为等现象除外)。

实验室用静音空压机无油无水气泵安全操作规定引言静音空压机无油无水气泵是实验室中常见的工具,可以用于压缩空气,驱动实验设备,也可以用于排气。

然而,使用气泵的时候,要注意安全使用,避免财产损失或人身伤害,因此本文主要介绍实验室使用静音空压机无油无水气泵的安全操作规定,以确保实验室工作的顺利进行。

使用前的准备工作在使用静音空压机无油无水气泵前,必须进行准备工作和安全检查。

如下:1.检查气泵是否正常运行。

检查过程包括检查压缩机,调整空压机和排气管道的清洁和安装,并检查气泵的使用说明书。

2.检查气泵的相关设施。

检查过程包括检查压缩机空气滤清器的清洁和安装,以及调整设备的气体压力,以确保其符合实验需求。

3.安装必要的安全装置。

在安装气泵时,必须配备必要的安全阀门和压力控制器,以确保安全。

4.设定安全控制模式。

在使用气泵时,必须在合适的机器设定模式下进行,以确保使机器更加安全和经济。

操作规定在使用静音空压机无油无水气泵时,应当遵守下列操作规定:1.操作前,必须进行查看,并确认气泵的使用条件和要求是否符合。

如果使用条件不符,应立即停止使用。

2.在使用气泵时,必须用于设计压力范围内,任何超过压力范围的行为都会导致机器损坏或更严重的后果。

3.在使用气泵时,必须永远遵循工作人员的安全操作规程,不要开启机器保护机制或关闭任何安全装置,也不应在机器上加装不属于正常配置的附件和部件,以确保安全稳定。

4.在气泵进入待机模式时,应停止排气活动,避免产生过多噪声和震动,并让气泵处于真正的冷却状态,以避免气泵因过热而受损。

5.在气泵的清洁上,应当严格按照使用说明书上规定的方法进行,不要用刻意更改等方式进行气泵的清洁,以免机器的本身设计规则受到破坏。

6.静音空压机无油无水气泵不应在高温、潮湿、易着火或易爆炸的地方使用,不应佩戴任何玩具、手表、项链等人造物品。

7.在维护气泵时,必须根据气泵使用须知进行清洁和运维,不得离开现场,避免危险情况发生。

纯无油空气泵安全操作及保养规程前言纯无油空气泵是一种常用的气源设备,广泛应用于医疗、食品、化工等领域,其性能优良、使用方便。

但是在使用过程中,必须要遵守安全规定和正确的保养方法,以确保设备的长时间稳定运行和人员的生命财产安全。

操作规程1.放置位置:设备放置要平坦,通风透气,干燥清洁,远离热源、火源及易燃易爆物品。

2.启动前的准备:–检查电源及电缆是否正常。

–查看压缩机外观是否有损坏或变形。

–检查进、出口管道密封是否良好。

–查看油位是否处于正常范围,并保持清洁。

3.启动:–插上电源。

–观察运行灯是否亮起,运行灯亮后,按启动按钮。

–关注气体压力表的变化情况,当气体压力达到工作压力时,设备进入正常工作状态。

4.关闭:–操作前,应先停掉气体进口,待停止运行后,关闭气泵电路开关,拔出电源插头,停用。

–关闭之前,应等待气泵完全停止运行,并确保气泵内无气体残留。

保养规程1.定期更换油:根据设备工作时间,定期清洗滤芯,并更换必要的密封件和油。

2.维护气泵进出口,防止管道和气阀堵塞。

3.检查气泵是否过热:当气泵工作时间超过工作时间时,注意检查设备是否过热,若发现过热现象,应立即联系维修人员进行检查维修操作。

4.严格执行泵腔保持清洁操作,防止污物和杂质进入设备内部。

5.根据设备使用要求进行定期检查和保养,及时维护保养设备,以确保设备长时间、稳定、安全地工作。

注意事项1.操作人员应通过学习相应的操作规程和安全措施后,才能上岗操作。

2.设备应由合格的维修人员进行维护、修理和保养,并定期进行检修和维护工作。

3.禁止未经安全培训和资格认证的人员进行操作和维护。

4.禁止对设备进行改装和拆卸,否则会影响设备的稳定性和使用寿命,严重者会造成设备的报废。

5.设备使用过程中,如出现异常或意外情况时,应立即停止设备运行,并及时联系维修人员进行维修处理。

结语本文介绍了纯无油空气泵的安全操作及保养规程,方法简单易行,但能让设备稳定运转、安全、长寿命。

气泵安全使用方法范本气泵是一种常见的机械设备,用于充气、吹气或抽气等工作。

它广泛应用于汽车、自行车、游泳圈、气垫床等设备的充气以及污水处理、工业生产中的气体输送等领域。

然而,由于气泵运行时可能产生高温、高压等危险因素,正确使用和维护气泵至关重要。

本文将详细介绍气泵的安全使用方法,以确保操作人员和设备的安全。

一、安装和操作前的准备工作1.选择合适的气泵:根据实际需要选择恰当的气泵型号和规格,且要确保其达到您所要求的充气或抽气压力和流量。

2.检查气泵外观:在使用气泵之前,仔细检查气泵外观,确保其无损坏、漏油、漏气、堵塞等现象。

如发现问题,应立即联系售后服务部门进行维修或更换。

3.检查电源和电压:确认气泵的电源电压与使用环境的电源电压一致,如有差异应进行调整。

4.清理工作区域:确保气泵周围的工作区域干净整洁,无障碍物。

需要特别注意气泵周围的通风情况,避免气泵运行时产生的热量无法排除。

5.安装气泵:根据气泵的类型和工作环境,正确安装气泵,并确保紧固牢固、线路连接正确、冷却系统顺畅等。

二、操作注意事项1.熟悉气泵的使用说明书:在操作气泵之前,务必详细阅读气泵的使用说明书,并按照要求进行操作。

特别要注意气泵的启动和停止方法,以及紧急停机、排放压力等功能的操作。

2.佩戴个人防护装备:在操作气泵时,操作人员应佩戴适当的个人防护装备,如安全帽、护目镜、防护手套等,以防止可能发生的事故伤害。

3.远离高温区域:在操作气泵时,应远离高温区域,以免造成烫伤。

4.注意电源连接和线路敷设:在操作气泵时,应注意电源连接的正确性,避免线路接错或接触不良。

线路敷设应避免交叉和压弯,以免引起线路短路或损坏。

5.禁止超载使用:严禁将气泵用于超过其额定工作压力和流量的工作场合,以免造成设备损坏或人员伤亡。

6.定期检查气泵:在气泵正常运行期间,应定期进行检查,并及时清理和更换运行中的磨损部件。

若发现异常情况或故障,应立即停止使用并联系售后服务部门进行维修。

型静音无油空气泵安全操作及保养规程型静音无油空气泵是一款以电机为动力源,通过高速旋转离心力将空气压缩并喷出,用于实现一些需要空气动力的操作。

其具有无油润滑、安静无声、体积小、重量轻等优点。

操作型静音无油空气泵时,需要注意以下安全操作和保养规程:安全操作规程1. 选址安装在安装型静音无油空气泵的过程中,需要考虑到安装地点的选择问题。

应选取干燥、通风、安全、空气流通的位置进行安装,并在泵的周围保持良好的尘埃、离子等污染物排放。

2. 电源接线在使用型静音无油空气泵前,需要先连接好电源线,连接时需要确保电源线和插座电压一致,并确保接线正确、接头紧固。

再启动电源开关时,应该先观察指示灯的状态,确保电源供给正常,然后再进行操作。

3. 操作步骤在操作型静音无油空气泵时,需要注意以下步骤:•先检查泵的外观是否有明显损伤或异物卡住•打开泵的进气阀门•启动空气泵,并将调节手柄调节至所需气压值•根据需要,接入需要使用空气泵的设备或器材,并开启设备或器材的开关•使用完毕后,关闭泵的进气阀门,并关闭空气泵电源开关4. 注意事项在使用型静音无油空气泵时,需要注意以下事项:•长时间不使用空气泵时,需要关闭电源,拔掉电源插头•不要超载使用空气泵,应按照泵的额定气流和气压使用,不得超过允许范围•不要在高温、潮湿、易燃、易爆环境中使用空气泵•注意空气泵的使用寿命,当寿命 end-of-life 时应该及时更换或进行维护保养规程1. 清洁保养在使用型静音无油空气泵后,需要对气泵进行清洁和保养以保证气泵的正常运转。

应该每周清理一次泵体表面和进气口,清理时需要使用干净的软毛刷、气泵清洁剂、棉花、气枪和细毛刷等工具。

注意不要在潮湿或湿润环境中进行清洁保养操作。

2. 维护保养除了定期的清洁保养,型静音无油空气泵还需要进行更为细致的维护保养操作。

在执行这些操作时,需要注意以下事项:•注意维护保养操作的时机,在停机后需要等待泵冷却后,方可进行维护操作•检查泵的气流是否正常,使用气压表检测气体压力是否正常•检查泵的进气阀门是否正常•检查泵的过滤器是否需要更换或清洁,是否存在堵塞情况•检查泵的油封和密封是否完好•检查泵的电源电压是否符合要求总结在操作型静音无油空气泵时,需要对其进行合理、安全的操作。

无油空气压缩机安全操作规程模版一、目的为了确保无油空气压缩机的安全运行,保护工作人员的人身安全和设备的完好性,制定本安全操作规程。

二、适用范围本安全操作规程适用于所有使用无油空气压缩机的工作人员。

三、安全要求1. 在操作无油空气压缩机之前,工作人员应接受相关安全培训并持有相应的操作证书。

2. 工作人员应在使用无油空气压缩机前仔细阅读压缩机的操作手册,并了解其工作原理和操作要求。

3. 在操作无油空气压缩机时,应穿戴合适的工作服装和个人防护用具,包括安全帽、防护眼镜、防护手套等。

4. 定期检查和维护无油空气压缩机,确保其正常运行。

如发现异常情况,应立即停机并上报相关人员。

5. 操作无油空气压缩机的工作人员应经常保持良好的工作环境,确保工作区域干净整洁,并清除可能导致滑倒和摔倒的障碍物。

6. 严禁在使用无油空气压缩机时进行任何拆卸、维修或调整工作,除非经过正规授权的维修人员。

四、操作流程1. 在操作无油空气压缩机之前,先检查压缩机的电源和气源是否正常并连接稳固。

2. 按照操作手册的要求,启动无油空气压缩机,并注意观察其运行情况。

3. 在无油空气压缩机运行期间,工作人员应保持机器周围的安全距离,并注意观察机器的运行状态,如有异常情况应及时停机并上报相关人员。

4. 在无油空气压缩机运行结束后,首先切断电源和气源,等待机器停止运行后再进行下一步操作。

5. 完成操作后,及时清理无油空气压缩机及周围的工作区域,确保无油空气压缩机处于干燥、整洁的环境中。

五、紧急处理1. 在无油空气压缩机运行过程中如发生异响、异常振动等现象,应立即切断电源和气源,并上报相关人员进行检修。

2. 如发生漏气、火灾等紧急情况,应立即按照紧急预案进行应急处理,并通知相关人员。

六、责任1. 无油空气压缩机的日常巡检和维护由专人负责,并做好相应的记录。

2. 所有使用无油空气压缩机的工作人员应严格按照本安全操作规程进行操作,并对操作中的错误行为承担相应的责任。

无油空压机是一种高效、环保、节能的空气压缩机,广泛应用于工业、医疗、科研等领域。

以下是关于无油空压机的使用说明书:一、概述无油空压机是一种以空气为工作介质,通过压缩空气来产生高压气体的设备。

它主要由电动机、压缩机构、冷却系统、控制系统等组成。

无油空压机的主要特点是无需润滑油,因此不会产生油雾和污染,同时具有高效、低噪音、低维护等特点。

二、工作原理无油空压机的工作原理是利用电动机驱动压缩机构,将空气吸入压缩腔内,通过压缩机构的作用将空气压缩,从而产生高压气体。

在压缩过程中,压缩机构会消耗一定的能量,同时产生热量。

为了降低压缩机的温度和效率,通常会配备冷却系统来对压缩机进行冷却。

三、使用方法1. 安装:将无油空压机安装在干燥、通风良好的地方,确保电源稳定、可靠。

在安装过程中,请按照制造商的指导进行操作,并遵守相关的安全规范。

2. 电源连接:将电源插头插入电源插座,确保电源稳定。

请注意,电源电压应与压缩机额定电压相符。

3. 启动:按下启动按钮,无油空压机开始工作。

在启动过程中,请注意观察压缩机的运行状态和声音。

如果发现异常情况,请立即停止运行并联系专业人员进行检修。

4. 调节:根据实际需求,可以通过调节控制面板上的参数来改变压缩机的输出压力和流量。

请注意,不要超出压缩机的额定压力范围。

5. 停止:按下停止按钮,无油空压机停止工作。

在停止过程中,请注意观察压缩机的运行状态和声音。

四、注意事项1. 在使用过程中,请定期检查压缩机的运行状态和声音,确保压缩机正常运行。

2. 在使用过程中,请注意观察控制面板上的参数变化,及时调整参数以满足实际需求。

3. 在使用过程中,请注意保持压缩机的清洁和干燥,避免灰尘和水分对压缩机的影响。

4. 在使用过程中,请注意遵守相关的安全规范和操作规程,确保操作人员的安全和健康。

5. 如果发现压缩机出现异常情况或故障,请立即停止运行并联系专业人员进行检修。

五、维护与保养1. 定期检查压缩机的各个部件是否正常工作,如电动机、轴承、密封件等。

无油静音空压机安全操作规定无油静音空压机是一种比传统空压机更加环保、节能、静音的设备。

在使用该设备时,必须遵守以下安全操作规定,以确保使用安全和机器寿命。

1.设备安装•安放在安装区域时,必须选择坚实和平整的地面。

•确保安装区域具有良好的通风和排气条件。

尽量避免潮湿、阴冷和高温环境。

•空压机和空气管道的安装必须符合国家标准和行业规范,使用规定数量和规格的法兰或接头连接。

•如果需要电气接线,请确保电源线的颜色符合国家规定,并正确连接。

2.空压机启动•首次使用或空压机长时间停止后,必须在空压机内注满新的润滑剂,并按照说明书操作启动。

•启动前要检查每个连接点的安全性和周围的卫生条件,保持空气入口的干净。

•启动空压机时,要按照说明书步骤操作,不能随意更改操作程序。

启动后要观察并检查各项指标,并及时进行调整,保持设备正常运行。

3.操作环境•空压机必须在干燥、洁净、通风的环境下正常运转。

•不得在有爆炸危险的环境中使用空压机,如易燃气体等。

•操作时,不得在机器周边摆放杂物,以免影响空气循环和散热,导致设备过热、损坏或运行不正常。

4.日常维护•定期检查空压机各部件的连接情况,及时补充润滑剂。

•定期清洗和更换空气过滤器,以保证空气的干净和无尘。

•定期检查并清理风扇和散热排气口,保持通畅的散热条件。

•不要将高温对象放置在空压机周围,以防止高温导致空气管道膨胀破裂。

5.紧急情况应对•如果出现空气管道泄漏,立即关闭空压机,并检查及更换相关部位。

•如果空压机出现异常声音或抖动,立即停机并进行检查。

•如果出现火灾等情况,按照安全预案和消防员指示进行应对。

6.使用注意事项•空压机操作时,要穿戴符合操作要求的防护装备,如护目镜等。

•空压机仅限于用于压缩空气和干燥空气,不能用于其他用途。

•在维护和清洁空压机时,应先将电源断开,以免意外操作导致人员伤害。

•禁止对空压机进行修改和私自拆卸,如需维护和调整,应请专业人员进行。

以上是无油静音空压机的安全操作规定,使用者必须严格遵守以上规定,确保安全、高效地使用该设备。

二、WX型无油旋片式真空泵使用说明1、概述WX型无油真空泵和2XZ型旋片真空属于两种不同系列产品,WX型系列真空泵是一种不需用油润滑即能运转工作的真空泵,故称为无油真空泵。

它具有结构简单、操作容易、维护方便、不会污染环境等优点,是一种使用范围非常广泛的机械真空泵。

WX型无油真空泵在国内尚属首创,获国家专利。

该泵耐用性好,可以广泛地使用于各种需要获得真空的设备上。

我公司还有一种防爆无油旋片式真空泵系列WXF型,它适用于防爆等级为IIA、IIB;温度组别为T1-T4级的易燃易爆气体。

广泛适用于石油、化工、矿井、油库、加油站、液化站、煤气管道、航空航天、军事部门等领域。

WX型真空泵的主要特点1、由于WX型无油真空泵不存在油蒸汽,因此,当其使用时,工作环境和被处理的产品不会被油污染,是一种使用在严格要求无油蒸汽的工业中理想的真空设备。

2、无油真空泵与需要油润滑的真空泵相比,经常性的维护和保养可大大减少,不必为缺少真空泵油,给维修带来诸多不便和烦恼。

3、采用电机直接连接,结构紧凑,重量轻,外型尺寸小于其它同类型泵。

4、应用多旋片高速转动,避免了吸气和排气中的脉冲波动。

5、WX型无油真空泵可以敞开大气连续运转。

2、技术性能规范3、工作原理与结构简述WX型真空泵系无油旋片式真空泵,是一种获得真空的设备之一。

WX型真空泵的极限真空为6×10-2M P a。

该泵是由转子偏心地置于泵身内,转子和旋片的旋转,不断地改变泵身内两侧的容积:一侧容积扩大吸入气体,另一侧容积缩小排出气体。

由此周期地完成气体的吸入排出,从而获得真空。

不同规格泵的结构略有不同。

如WX-4、8的排气管在泵的底部,请各用户能加以注意。

结构原理图如下WX-0.5、1、2 WX-4、81、进气管2、橡胶垫圈3、导流盘 1、进气管 2、气箱盖 3、气箱4、空气滤芯5、滤芯座6、O形圈 4、进气(大)滤芯 5、泵身7、泵身8、转子9、旋片 6、旋片 7、转子 8、排气管10、排气管 11、消音部件 9、排气(小)滤芯 10、消音部件11、排气嘴 12、排气连接管图(一)图(二)4、用途与一般油润滑的真空泵相比,无油真空泵的使用范围更广泛,应用于各种物品的吸收和输送,自动机械的物料供给设备,例如:在食品、医药、印刷、书籍装订、牛奶场、院校研究所、实验室、医院吸引等各种机械设备上的配套使用。

静音无油空压机常规款安全操作及保养规程简介静音无油空压机是一种高效、可靠、节能、环保的气动设备。

该设备适用于工业、化工、制药、食品、电子、航空、航天等领域。

本文将介绍静音无油空压机常规款的安全操作和保养规程。

安全操作1. 安装前准备工作在安装前,需要做以下准备工作:•检查电压是否符合设备要求。

•确认设备能够承受安装位置的重量。

•清理安装位置,确保无杂物和垃圾。

2. 安装过程中的注意事项在安装过程中,需要注意以下事项:•应按照设备的安装说明进行安装。

•安装过程中应使用专门的工具和器材。

•安装完成后应检查管路连接是否严密。

•启动前应检查所有设备是否处于正常状态。

3. 使用时的注意事项在使用时,需要注意以下事项:•操作者应具备相关的技术知识和安全意识。

•操作时应正确使用设备的控制面板。

•操作时应注意设备的工作状态,并及时发现问题。

•停止使用后应关闭电源,并清理设备外部和周围环境。

保养规程1. 日常保养日常保养应包括以下内容:•定期清洁设备外部,并保持设备周围环境干净整洁。

•检查仪表和管路连接是否正常并有无漏气现象。

•定期检查和更换滤芯。

•对设备进行润滑,以保证设备的正常工作。

2. 定期保养定期保养应包括以下内容:•定期清洗和更换冷却系统中的水和防冻液。

•定期检查和更换冷却系统中的水泵。

•定期更换气缸、活塞环和气门组件。

•定期清洗和更换冷却塔中的水和防腐液,检查和更换冷却塔中的水泵。

结论通过对静音无油空压机常规款的安全操作和保养规程的介绍,我们可以发现,只有正确地使用和保养设备,才能保证设备的正常工作和使用寿命,并优化设备的工作效率和运行成本。

因此,建议在使用设备前充分了解和掌握相关的安全操作和保养规程,确保设备的安全运行和稳定运行。

感谢您选用武汉科林普丰仪器有限公司生产的气源产品!本公司客户服务电话,CA—1型静音无油空气泵使用说明书武汉科林普丰仪器有限公司一、概述:CA-1型静音无油空气泵采用全封闭式压缩机为动力, 将自然空气经过三级净化, 除去空气中的水份、油污和杂质, 经稳压装置输出稳定、洁净的空气。

CA-1型静音无油空气泵具有输出压力稳定、噪音低、净化能力强的特点, 是替代高压空气钢瓶的理想空气源。

该产品不但能够满足各种型号国产和进口色谱仪及各类分析实验室的使用, 而且也能够做为高纯氮气发生器的空气源。

二、仪器特点:1.替代高压钢瓶, 使实验室仪器化。

2.体积小, 重量轻, 结构合理, 操作简单, 使用方便。

3.振动小, 噪音低, 输出压力稳定, 气压波动不大于±0.003MPa4.安全可靠,配有过压,过流二级保护装置。

5.使用寿命长, 可连续使用也可间断使用, 性能稳定, 流量、纯度不衰减。

三、主要技术参数:1.空气纯度: 无油3级2.输出流量: 0-1000ml/min3.输出压力: 0-0.4MPa( 压力可调)4.工作条件: 电源电压: 220V±10%, 50Hz±5%环境温度: 10-43℃相对湿度: ≤85%环境无大量粉尘污染及腐蚀性气体5.工作噪声: <40分贝6.仪器功率: ≤100W7.安全阀开启压力: 0.82±0.01MPa8.外型尺寸: 445(L)×230(W) ×340(H) (单位:mm)9.仪器质量: 约15Kg四、仪器使用前的准备工作:1.开箱检查( 1) 开箱后按装箱单清点验收。

( 2) 检验仪器外观, 是否因运输造成损坏。

( 3) 若发现异常现象, 请速与我公司联系, 以便及时解决。

2.开机前的准备工作(1) 仪器应平稳放置, 电源开关呈”OFF”状态(2) 使用前检查电路接线是否正确, 应有可靠地线。

(3) 将仪器后面红色进气管上的封口段剪去, 将进气管插入干燥管上的快速接头。