人造革压延成型加工技术

- 格式:ppt

- 大小:1.54 MB

- 文档页数:43

pvc普通人造革压延工艺流程PVC synthetic leather is a popular material in the fashion and interior design industries due to its affordability and versatility. It is commonly used in the production of handbags, shoes, upholstery, and clothing. The manufacturing process of PVC synthetic leather involves a series of steps, including mixing raw materials, melting and blending, calendering, cooling, embossing, and cutting.PVC人造革是时尚和室内设计行业中常用的材料,因其价格实惠和多功能性而备受青睐。

它常用于生产手提包、鞋子、室内装饰和服装。

PVC人造革的制造过程涉及一系列步骤,包括混合原材料、熔融混合、压延、冷却、压花和裁剪。

Firstly, the raw materials for PVC synthetic leather production include PVC resin, plasticizers, stabilizers, colorants, and other additives. These materials are mixed together in specific proportions to achieve the desired properties of the synthetic leather. The PVC resin serves as the base material, while plasticizers are added to impart flexibility and softness. Stabilizers are used to enhance the durability andweather resistance of the synthetic leather, and colorants provide the desired color and design.首先,PVC人造革生产的原材料包括PVC树脂、增塑剂、稳定剂、着色剂和其他添加剂。

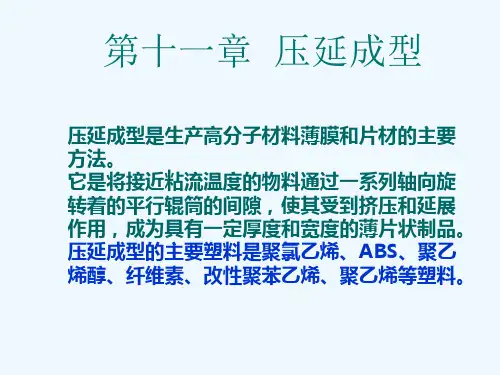

压延人造革生产工艺

压延人造革(Rolled Synthetic Leather)是一种常见的人造革生产工艺,主要用于制造鞋类、箱包、衣物等产品。

下面将介绍压延人造革的生产工艺流程。

首先,原料准备。

压延人造革的主要原料包括PVC(聚氯乙烯)树脂、液态塑化剂、填充剂、稳定剂等。

这些原料需要按照一定比例混合,并进行预混合和熔融处理,以提高材料的流动性和柔韧性。

接下来,将混合好的原料送入压延机。

压延机是生产人造革的核心设备,通过将混合好的原料加热到一定温度,使其变得粘稠,并通过机械辊压制,将原料均匀地铺在基布上。

基布可以是纺织物、纸张或薄膜,用来增加人造革的稳定性和强度。

然后,进行压延。

在压延过程中,原料被机械辊压制和拉伸,使其形成一定的薄片状,这个过程中的温度和湿度需要严格控制,以确保原料能够充分融合并形成均匀的表面。

接下来,进行固化处理。

在压延完成后,人造革需要经过高温固化处理,使其更加牢固和耐磨。

这个过程中,人造革需要经过一定的冷却、卷取和切割等工序,以满足不同产品的要求和规格。

最后,进行加工和后处理。

压延人造革可以根据需要进行印花、压花和涂层等加工,以增加表面的装饰效果和功能性。

同时,人造革还需要进行裁剪、缝制、包边等后处理,以制成最终的

产品。

总结一下,压延人造革的生产工艺主要包括原料准备、混合、压延、固化处理和后处理等环节。

这种工艺简单高效,可以生产出具有良好强度、柔软度和表面等观感的人造革,广泛应用于各种产品中。

pvc人造革挤出压延法工艺流程下载温馨提示:该文档是我店铺精心编制而成,希望大家下载以后,能够帮助大家解决实际的问题。

文档下载后可定制随意修改,请根据实际需要进行相应的调整和使用,谢谢!并且,本店铺为大家提供各种各样类型的实用资料,如教育随笔、日记赏析、句子摘抄、古诗大全、经典美文、话题作文、工作总结、词语解析、文案摘录、其他资料等等,如想了解不同资料格式和写法,敬请关注!Download tips: This document is carefully compiled by theeditor. I hope that after you download them,they can help yousolve practical problems. The document can be customized andmodified after downloading,please adjust and use it according toactual needs, thank you!In addition, our shop provides you with various types ofpractical materials,such as educational essays, diaryappreciation,sentence excerpts,ancient poems,classic articles,topic composition,work summary,word parsing,copy excerpts,other materials and so on,want to know different data formats andwriting methods,please pay attention!按照[pvc人造革挤出压延法工艺流程]为主题,以实际应用情况写一篇流程,回答要求步骤详细,回答字数不少于800字。