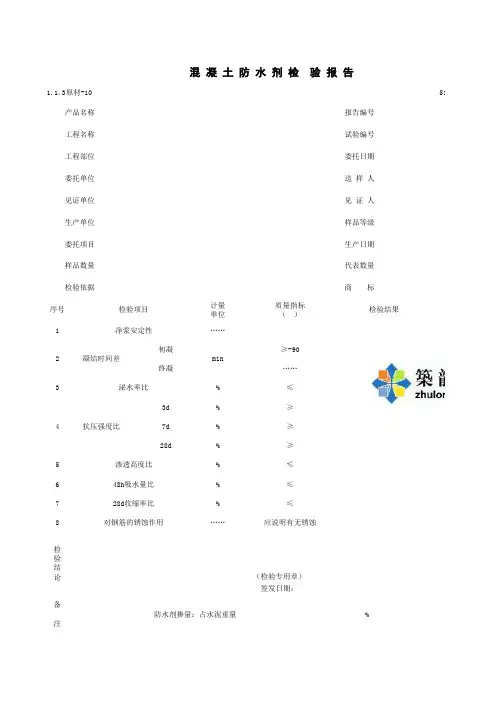

防水剂受检混凝土吸水量比试验记录表

- 格式:xls

- 大小:43.50 KB

- 文档页数:1

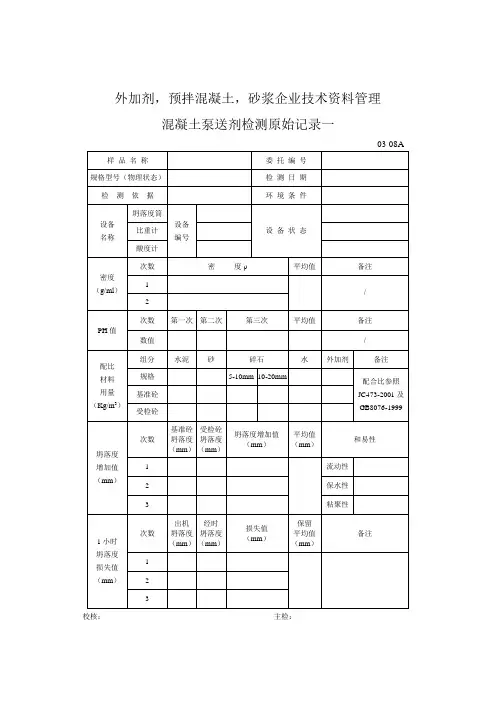

外加剂,预拌混凝土,砂浆企业技术资料管理混凝土泵送剂检测原始记录一03-08A 样品名称委托编号规格型号(物理状态)检测日期检测依据环境条件设备名称坍落度筒设备编号设备状态比重计酸度计密度(g/ml)次数密度ρ平均值备注1/ 2PH值次数第一次第二次第三次平均值备注数值/配比材料用量(Kg/m3)组分水泥砂碎石水外加剂备注规格5-10mm 10-20mm配合比参照JC473-2001及GB8076-1999 基准砼受检砼坍落度增加值(mm)次数基准砼坍落度(mm)受检砼坍落度(mm)坍落度增加值(mm)平均值(mm)和易性1 流动性2 保水性3 粘聚性1小时坍落度损失值(mm)次数出机坍落度(mm)经时坍落度(mm)损失值(mm)保留平均值(mm)备注123校核:主检:说明此表由试验室人员填写1、填写时应参考的标准主要有:(1)《混凝土泵送剂》JC473(2)《混凝土外加剂应用技术规范》GB50119。

2、主要填写内容包括:(1)密度:精确到小数点后两位,取两次结果平均值为检测最终结果。

(2)PH值:精确到小数点后一位,取三次结果平均值为检测结果。

(3)坍落度增加值:坍落度精确到5mm或10mm,以三次结果平均值为检测结果。

(4)坍落度保留值:坍落度精确到5mm或10mm,以取三次结果平均值为检测结果,坍落度保留值在备注中注明是1小时坍落度损失或半小时坍落度损失。

泵送剂检验报告一潍混试备证字号03-08B 委托单位报告编号工程名称检测编号样品名称工程部位环境条件规格等级检测依据送样日期生产厂家检测日期试验室地址邮政编码检测内容检测项目性能要求检验结果单项评定PH值应在厂控值的±1之内密度(g/cm3)应在厂控值的±0.02g/cm3之内坍度落增加值(mm)不小于100坍度落保留值(mm)综合结论检测说明批准:校核:主检:检测单位:(盖章)签发日期:说明此表由试验室人员填写,并经校核与批准。

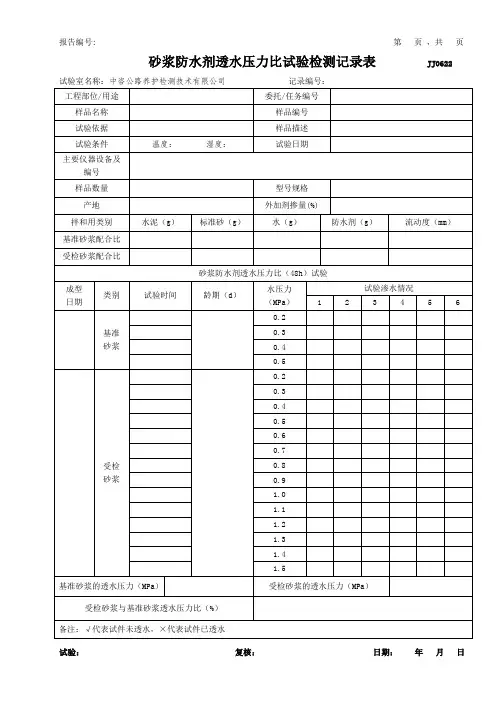

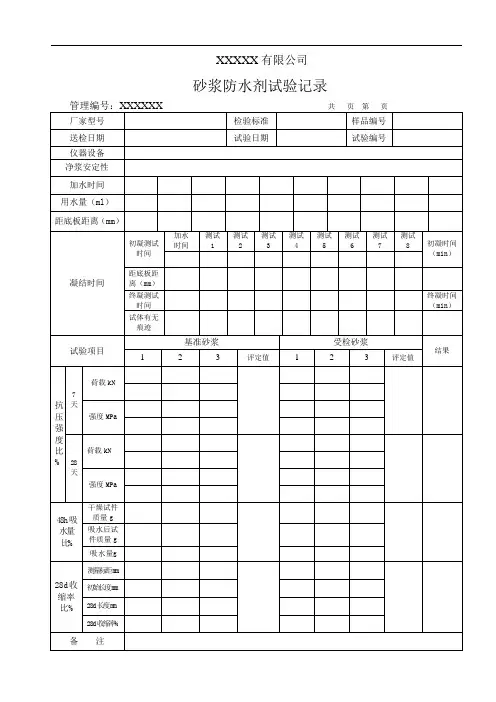

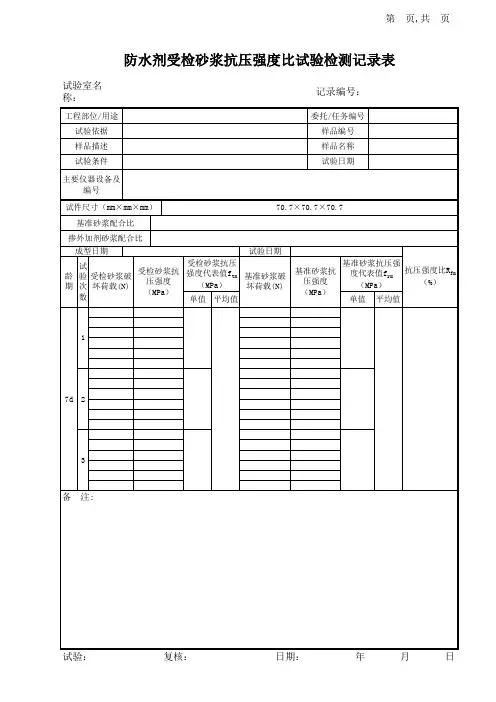

报告编号:第页,共页砂浆防水剂透水压力比试验检测记录表 JJ0622 试验室名称:中咨公路养护检测技术有限公司记录编号:

工程部位/用途委托/任务编号

样品名称样品编号

试验依据样品描述

试验条件温度:湿度:试验日期

主要仪器设备及

编号

样品数量型号规格

产地外加剂掺量(%)

拌和用类别水泥(g)标准砂(g)水(g)防水剂(g)流动度(mm)基准砂浆配合比

受检砂浆配合比

砂浆防水剂透水压力比(48h)试验

成型日期类别试验时间龄期(d)

水压力

(MPa)

试验渗水情况

1 2 3 4 5 6

基准

砂浆

0.2

0.3

0.4

0.5

受检

砂浆

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

基准砂浆的透水压力(MPa)受检砂浆的透水压力(MPa)

受检砂浆与基准砂浆透水压力比(%)

备注:√代表试件未透水,×代表试件已透水

试验:复核:日期:年月日。

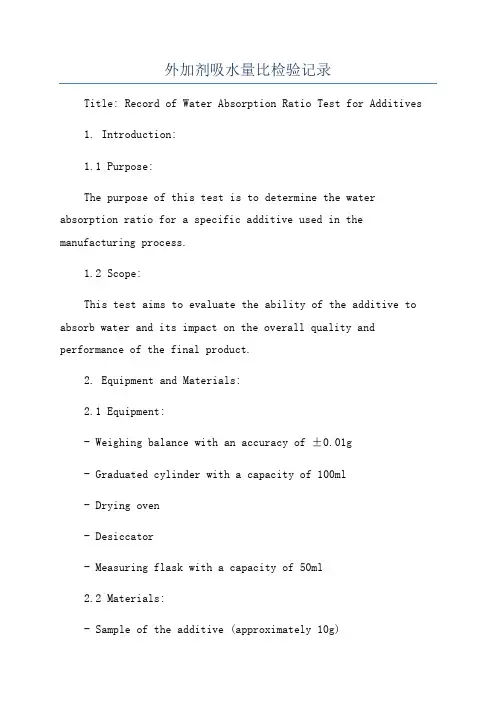

外加剂吸水量比检验记录Title: Record of Water Absorption Ratio Test for Additives1. Introduction:1.1 Purpose:The purpose of this test is to determine the water absorption ratio for a specific additive used in the manufacturing process.1.2 Scope:This test aims to evaluate the ability of the additive to absorb water and its impact on the overall quality and performance of the final product.2. Equipment and Materials:2.1 Equipment:- Weighing balance with an accuracy of ±0.01g- Graduated cylinder with a capacity of 100ml- Drying oven- Desiccator- Measuring flask with a capacity of 50ml2.2 Materials:- Sample of the additive (approximately 10g)- Distilled water- Oven-dried sand (approximately 200g)- Petri dishes3. Test Procedure:3.1 Sample Preparation:- Collect a representative sample of the additive, ensuring it is free from any impurities.- Dry the sample in a drying oven at a temperature of 105°C for 24 hours.- Once dried, cool the sample in a desiccator for at least 30 minutes.3.2 Test Setup:- Weigh approximately 100g of oven-dried sand and place it in a petri dish.- Weigh 10g of the dried additive and distribute it evenly on the surface of the sand in the petri dish.- Measure 50ml of distilled water using a measuring flask and slowly pour it over the sand and additive mixture in the petri dish.- Allow the mixture to stand undisturbed for 5 minutes.3.3 Measurement:- After 5 minutes, carefully pour the excess water from the petri dish, ensuring only the sand and additive remain.3.4 Drying:- Place the petri dish with the sand and additive mixture in a drying oven at a temperature of 105°C for 24 hours.- After 24 hours, remove the petri dish from the oven and cool it in a desiccator for at least 30 minutes.4. Calculation:4.1 Calculate the water absorption ratio using the following formula:Water absorption ratio (%) = [(W2 - W1) / W1] * 1005. Results and Discussion:- Record the water absorption ratio for the tested additive.- Analyze the impact of the water absorption ratio on the overall performance and quality of the final product.- Discuss any potential issues or improvements that need to be addressed.6. Conclusion:Based on the water absorption ratio test results, it can be concluded whether the tested additive meets the desired specifications and industry standards. This information isessential for maintaining product quality and ensuring efficient manufacturing processes.Note: This test should be performed under controlled laboratory conditions by trained personnel. Safety precautions, such as wearing lab coats and gloves, should be followed to ensure the well-being of the operators.。

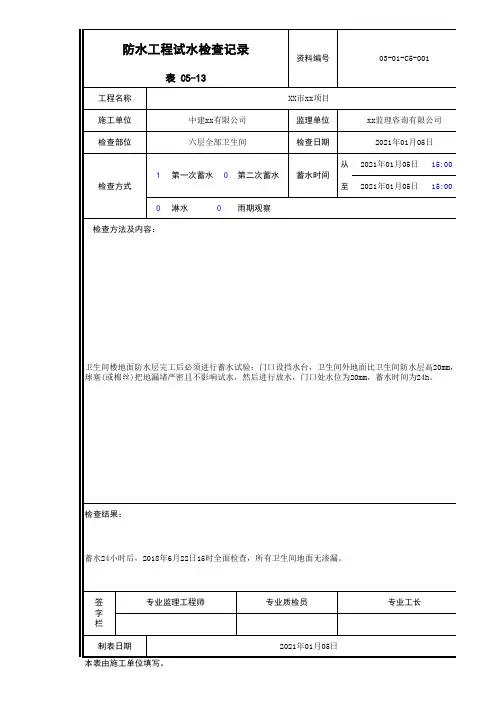

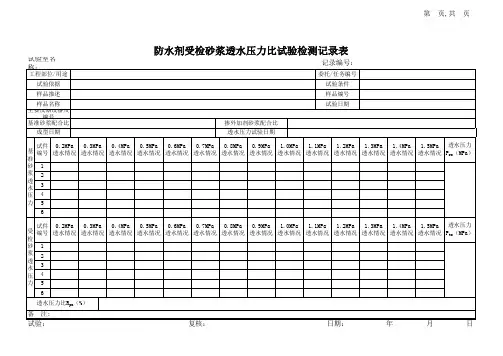

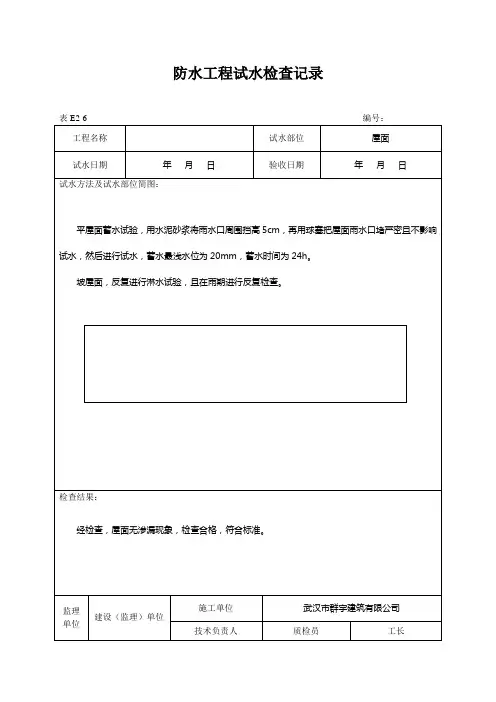

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

表E2-3编号:本表由施工单位填写,建设单位、施工单位、城建档案馆各保存一份。

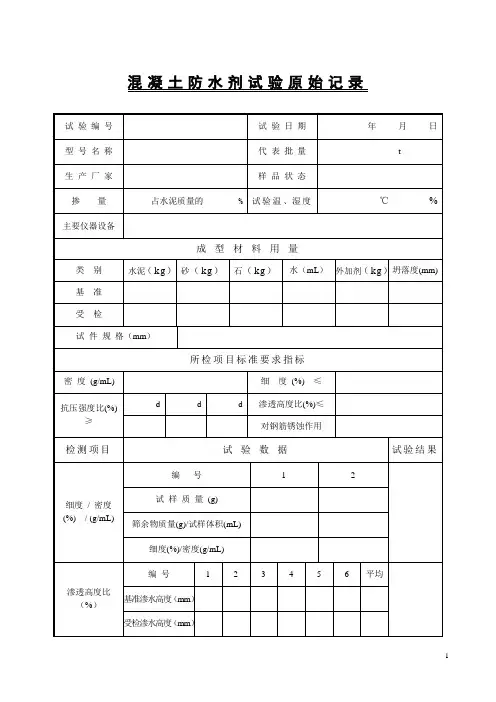

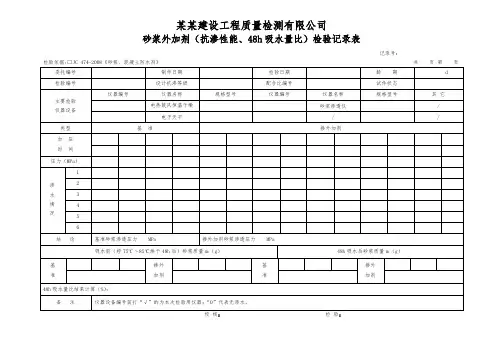

新砂浆防水剂吸水量比试验检测记录表模版背景近年来,随着建筑物高度和密度的增加,建筑物的外墙、屋顶等防水工程变得越来越重要。

为了提高建筑物的防水性能,新型防水材料不断涌现,成为市场的热门产品之一。

本次实验旨在比较不同新型砂浆防水剂的吸水量,以确定其防水性能的优劣。

实验设计实验材料•A新砂浆防水剂•B新砂浆防水剂•C新砂浆防水剂•普通水泥砂浆实验步骤1.按照比例将水泥、砂子和水混合搅拌成均匀的砂浆2.将搅拌好的砂浆分别添加A、B、C三种新砂浆防水剂,按照说明书的用量添加3.将处理好的三组样品分别放置在温度相同、湿度相同的条件下静置48小时4.断面切割:将每组样品的砂浆体切成规定的尺寸,尺寸要求相同5.砂浆浸水:将每个断面尺寸相同的砂浆样品浸泡在水中5分钟,浸泡前、中、后称量吸水量实验结果将被记录在下面的表格中。

实验记录表格试验编号实验日期砂浆种类防水剂类型断面尺寸初始重量(g)浸泡后重量(g)吸水率(%)12020/9/1A砂浆A防水剂101010300310 3.3322020/9/1A砂浆B防水剂101010300315532020/9/1A砂浆C防水剂101010300318642020/9/1B砂浆A防水剂101010300312452020/9/1B砂浆B防水剂101010300317 5.6662020/9/1B砂浆C防水剂101010300321772020/9/1C砂A防1010103003155试验编号实验日期砂浆种类防水剂类型断面尺寸初始重量(g)浸泡后重量(g)吸水率(%)浆水剂82020/9/1C砂浆B防水剂101010300319.5 6.592020/9/1C砂浆C防水剂1010103003248实验分析根据以上表格中的数据,可以得出以下结论:1.C型新砂浆防水剂的吸水率最高,达到了8%2.A型新砂浆防水剂的吸水率最低,仅为3.33%3.不同种类的砂浆在添加相同类型的防水剂后,吸水率的差异较小综上,C型新砂浆防水剂具有较好的防水性能,可以在建筑防水工程中得到应用。