外文翻译---低合金结构钢的焊接性分析

- 格式:docx

- 大小:26.35 KB

- 文档页数:8

低合金高强度结构钢High Strength Low Alloy Steel一、定义中国国家标准GB/T13304-1991《钢分类》,参照国际标准,对钢的分类作了具体的规定。

低合金高强度钢HSLA是在碳素钢的基础上,通过加入少量合金元素并在热轧、控轧或热处理状态下,具有高强度、高韧性,较好的焊接性、成型性或耐腐蚀性等特征的钢材。

成分特点:低碳(Wc≤0.2%),低合金。

性能特点:比普通碳素结构钢有较高的屈服强度和屈强比、较好的冷热加工成型性、良好的焊接性、较低的冷脆倾向、缺口和时效敏感性,以及有较好的抗大气、海水等腐蚀能力。

二、低合金高强度钢的发展1867-1874年,美国含铬结构钢,1902-1906年,美国含镍结构钢,1915年,美国含锰1.6%桥梁用结构钢。

20世纪60年代以后,冶金生产工艺技术和低合金钢开发均取得巨大发展,锰、硅、铬、镍、钒、钛、铌等微合金元素的强化作用已清楚。

80年代后随着技术进步,通过钢质净化、晶粒细化、组织优化、基体强化等,促进了新型低合金钢的开发。

低合金钢是近30年来发展最快、产量最大、经济性最好、使用面最广、前景最广阔的钢类。

目前,新型的低合金高强度钢以低碳(≤0.1%)和低硫(≤0.015%)为主要特征。

我国是1957年在鞍钢试制成功第一炉低合金钢16Mn,随后研制出16Mn系列的桥梁用、船用、锅炉用、压力容器用、汽车用低合金钢。

1966年,低合金钢产量141万吨,占钢产量8%;至1979年,低合金钢产量254万吨,仍占钢产量8%。

1997年,低合金钢产量2368万吨,占钢产量22%。

各发达工业国家的低合金高强度钢产量约占钢产量的10%。

为进一步提高低合金高强度钢的性能,在低合金高强度钢的基础上,通过进一步降低碳质量分数、微合金化和控制轧制而发展了一系列新型低合金高强度结构钢,主要有以下四种:微合金化低碳高强度钢、低碳贝氏体型钢、低碳索氏体型钢、针状铁素体型钢。

低合金高强度钢焊接性能引言钢是最重要的结构材料。

这是由于钢具有很高的强度-价格比,同时还可以用焊接这种最经济的工艺来连接。

尤其是在采用高输入热和不预热的情况下,焊接工艺的经济性更好。

因而对于开发新型的性能更好的低合金高强度钢来说,焊接性能的研究是很重要的。

焊接性能的概念包括对焊缝裂纹的低敏感性和良好的使用性能,即适合的强度和对脆性以及塑性裂纹扩展的抗力。

无裂纹焊接接头导致焊接接头失效的原因主要是不适当的焊接条件或焊接内部的高应力。

一些焊接缺陷,如气孔、凝固裂纹不是本文讨论的内容。

然而因合金成分的影响而引起的焊缝也常发生,这时只有认真研究其物理冶金原理才能解决问题。

当热影响区局部的塑性不足以抵消工作内部的拘束应力和焊接过程中产生的热应力和相变应力时,就会在热影响区(HAZ)内出现冷裂纹。

显微组织中的硬脆相导致塑性下降。

钢中游离氢加剧冷裂纹倾向。

游离氢来源于烘干不充分的焊接材料。

热影响区的低塑性和游离氢的同时存在带来最严重的问题。

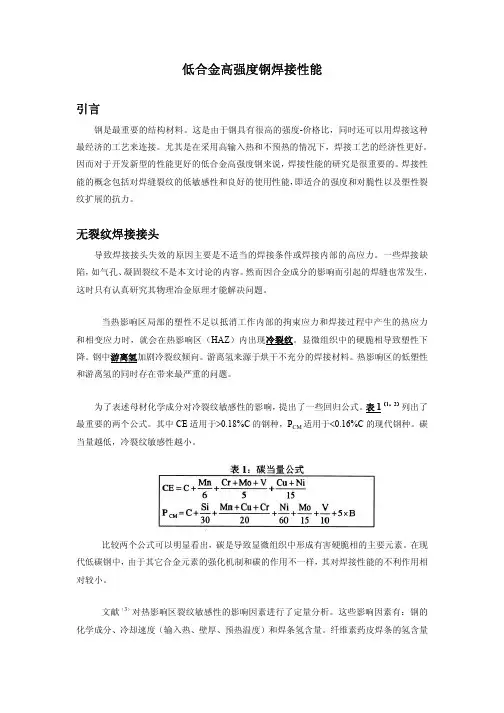

为了表述母材化学成分对冷裂纹敏感性的影响,提出了一些回归公式。

表1(1,2)列出了最重要的两个公式。

其中CE适用于>0.18%C的钢种,P CM适用于<0.16%C的现代钢种。

碳当量越低,冷裂纹敏感性越小。

比较两个公式可以明显看出,碳是导致显微组织中形成有害硬脆相的主要元素。

在现代低碳钢中,由于其它合金元素的强化机制和碳的作用不一样,其对焊接性能的不利作用相对较小。

文献(3)对热影响区裂纹敏感性的影响因素进行了定量分析。

这些影响因素有:钢的化学成分、冷却速度(输入热、壁厚、预热温度)和焊条氢含量。

纤维素药皮焊条的氢含量很高,冷裂纹经常在此发生。

图1(4)表明在近海平台用钢板的生产发展中,采用热机械扎制的碳含量低的钢种,其焊接性能得到改善。

不预热就可以实现无裂纹焊接,给用户带来了巨大的经济效益。

除了显微组织对裂纹倾向的影响外,钢的纯净度是另一个同样重要的因素。

尤其是在组焊壁厚T型接头时,厚度方向(Z向)的应力会导致平行于板面的裂纹的产生,这种现象即为大家所知的层状撕裂,其裂纹沿延伸的夹杂物扩展。

低合金高强度钢的焊接性分析低合金高强钢的焊接性主要包括两个方面,其一是裂纹敏感性,其二是焊接热影响区的力学性能。

众所周知,扩散氢、脆性组织和残余应力是冷裂纹产生的三要素,碳当量公式(如IIW的CEN公式)、热影响区最大硬度等都被用来评价钢材的冷裂敏感性。

(1)冷裂纹问题对于现代低合金高强度钢,由于热机械控制工艺技术和微合金化技术的广泛应用,碳含量和碳当量都大幅度降低,因此,其冷裂敏感性不明显,除非在极端情况下(很大的拘束度或扩散氢含量很高),一般不会遭遇冷裂纹。

值得注意的是焊缝金属冷裂纹问题。

冷裂纹倾向低合金高强钢随着强度等级的增高,焊接接头冷裂纹倾向增大。

冷裂纹又叫氢致裂纹或延迟裂纹,是指焊接接头冷却到较低温度(Ms温度以下)时产生的焊接裂纹冷裂纹一般产生在热影响区,有时也产生在焊缝金属内。

产生冷裂纹的三个主要因素是:裂缝金属内残留的扩散氢、热影响区或焊缝金属硬组织、焊接残余应力。

焊接低合金高强度钢时,氢的主要来源是焊条药皮中的水分和破口表面的水分、油污等杂质。

这些物质在电弧高温作用下分解出氢,溶解在熔池金属内,熔池冷却凝时氢来不及逸出,残留在焊缝内。

另外,焊接低合金高强度钢的一个重要特点是热影响区有较大的淬硬倾向,随强度等级的提高、含碳元素或合金元素含量增多,其淬硬性也增大。

当焊接浮大焊件或冷却速度过快时,热影响区或焊缝金属更容易产生淬硬组织。

焊接时由于不均匀的加热和冷却以及构件本身的拘束作用,在焊缝内仍然会产生很大的残余应力。

所以,低合金高强度钢焊接时有较大的冷裂倾向。

为防止冷裂纹的产生,焊前应严标按照说明书的规定烘干焊条,将坡口清理干净,并采取焊前预热、焊后保温缓冷及热处理等措施。

母材强度的提高和焊接性的改善,促使冷裂纹发生的位置从热影响区转移到焊缝。

基于焊后随时间变化氢对局部临界开裂应力的影响,国际焊接联合会提出了判别高强钢冷裂纹位置的基本方法,焊后焊缝中的氢含量随时间单调减少,而热影响区的氢含量先从母材基础值升高到峰值然后下降,整个过程只有几分钟,恰好与残余应力发生的过程同步,通过计算残余应力值-时间的变化、以及热影响区和焊缝受实时扩散氢含量影响的临界开裂应力,即可预测冷裂纹发生的位置。

浅谈低合金高强度结构钢焊接性能研究摘要:屈服强度为460MPa(S460M)及以上的结构钢用于桥梁、建筑和风电机组塔架的施工,以及铁路货运金属结构的制造。

与St3和09G2S产品相比,使用高强度轧制钢可使结构中的金属总含量降低80%,在这种强度等级的低合金钢结构中,其焊接性的研究成为一个相关的问题。

众所周知,在焊接过程中,金属热影响区(HAZ)会发生结构变化,从而导致力学性能的变化。

为此,本文研究了热焊接循环对金属热影响区性能和组织的影响,特别是抗冷裂性能的影响。

本文论证了S490钢强度用焊接材料的选择,分析了焊接性能的变化。

关键词:低合金;高强度;结构钢;焊接性能引言:强度等级S350及以上的结构钢被广泛应用于金属结构的制造中。

与St.3和09G2S级钢的产品相比,它们的应用大大降低了结构的总金属消耗。

本文研究了焊接热循环对热影响区金属支柱和组织的影响,以及焊接接头对冷裂纹形成的影响。

对S 490级强度钢焊接耗材的选择进行了论证,并对焊接接头力学性能的变化进行了分析。

结果表明,随着冷却速率的增加,模型试件的热影响区金属强度增加,延性降低。

1.低合金高强度结构钢现代工业、建筑业和电力工程的发展,对金属结构在降低金属消耗、提高可靠性方面提出了新的要求。

在现代生产中开发高强度钢主要有两种方法。

第一种方法是应用合金元素提高强度特性。

但这种方法导致轧制金属的成本明显增加。

合金化的替代方法是金属的热变形硬化或随后热处理的可控制轧制。

这些钢包括高强度低合金钢S460M(强度等级S490),与铌和钒微合金化。

根据标准EN10025-4的数据,该钢具有以下力学性能:s y>460MPa,st=540-720 MPa,d5>18%,KCV-40>27J/cm2。

[1]2.低合金高强度结构钢焊接性能研究2.1焊接接头的具体要求研究使用尺寸为120×12×12 mm的模型试样进行,这些试样在安装MSR-75[9]中按照焊接热循环进行热处理。

吉林化工学院外文翻译焊接工艺参数对实芯焊丝熔敷金属及接头组织与性能的影响Welding Parameters for Solid Wire Deposited Metal andJoint Microstructure and Properties性质:□毕业设计□毕业论文教学院:机电工程学院系别:材料成型及控制工程系学生学号:11470106学生姓名:吕尚志专业班级:材控 1101指导教师:王鑫职称:讲师起止日期:2015.3.1~2015.3.31吉林化工学院Jilin Institute of Chemical Technology电阻点焊焊接参数对高强度钢组织和力学性能的影响本文介绍的实验是通过硬度测试研究高强度钢电阻点焊焊接接头的物理机械性能( AISI 4130)。

以焊接电流和电弧电压作为实验参数。

通过焊接接头的拉伸剪切试验,以确定焊接区的强度。

硬度和微观检测是为了研究焊接工艺参数对焊接接头的影响。

硬度线测试焊接区大部分区域,包括热影响区和母材。

硬度测试主要研究电流对接头不同区域硬度和微结构的影响。

焊接过程中使用低电压高电流,增加了熔深。

通过使用 6.5 kA 的焊接电流获得一个最佳的焊接质量。

人们发现,电阻点焊试样的机械性能由熔宽和熔深控制。

结果表明,硬度测试技术为硬度标准和微结构检查提供了物理和机械研究的最好方法。

关键词:焊接电流;金相组织;硬度测试;熔深;熔敷金属1.简介热处理低合金钢因为其良好的耐腐蚀性和强度在船舶行业被广泛使用,电阻点焊用于连接金属薄板在汽车行业被广泛应用。

焊接电流是电阻点焊的最重要参数,随着电流的增大焊接热量增加,在电阻点焊过程中压力也被认为是作为一种重要的参数影响焊接质量,融合区大小或试块直径及其微观结构参数是影响点焊试样最重要的力学因素。

因为钢的机械性能高度依赖于组织和每个阶段的分布 ,所以,改变焊接电流即改变机械性能。

一些微观成分在焊接过程中产生的机械性能差,例如,不均匀的马氏体微观结构的韧性差。

Journal of Applied Sciences 10(8):658-663,2010ISIN 1812-5654@2010 Asian Network for Scientific Information气体保护药芯焊丝电弧焊焊接工艺参数对低碳钢焊缝宽度和焊缝金属拉伸性能的影响H.R.Ghazvinloo and A.Honarbakhsh Raouf材料工程系,塞姆南大学,塞姆南,伊朗摘要:一般来说,焊接过程中焊接工艺参数对接头质量有很大的影响。

高品质的焊接接头,保证了合适焊缝几何形状和可靠的焊件力学性能。

本实验研究了气体保护药芯焊丝电弧焊焊接工艺参数对低碳钢焊缝宽度和焊缝金属拉伸性能的影响。

工业生产中,选低碳钢作为实验对象,焊接电流,焊接电压和焊接速度作为可变参数。

焊接电流分别为240,280,320A,电弧电压分别为26,30和34V,焊接速度分别为40,50和60cm/min。

这项研究的结果有助于人们正确和快速的选择焊接工艺参数,以达到理想的焊缝几何形状和满足焊缝拉伸性能的要求。

关键词:药芯焊丝电弧焊,焊接参数,焊缝宽度,屈服强度,抗拉强度,热输入。

介绍:药芯焊丝电弧焊工艺采用完全自动化的过程,其中焊接电极及药芯焊丝接触焊缝区。

助焊剂材料是在药芯。

药皮传导电流形成电弧,不断燃烧消耗熔滴过渡成为填充金属(Aloraier et al , 2006)。

最近的研究表明(Ibrahim and Shehata, 1999, 2000; Sadek et al ,2001),药芯焊丝电弧焊同其他焊接技术有一个共同的优点,如使用手工金属电弧焊(MMAW)和活性/惰性气体保护焊 (GMAW)。

为研究不同焊接方法及工艺对焊缝几何形状和质量的影响,研究人员作了相应的实验研究(Benyounis et al. ,2005a,b; Xue et al .,2005; Correia et al.,Kim et al.,2002,2003,2005; Juang and Tarng, 2002)。

低合金高强钢焊接性分析0前言随着科学技术的发展和不断进步,社会生产力的不断提高,重型装备制造业不断向着大型化,专业化的方向发展,焊接结构设计日益趋向高参数、轻量化,及大型化发展,要求在自重增加不多的条件下大幅度提高焊接结构的承载能力,因此,对制造这些重型设备的钢材的力学性能,稳定性等提出了更高的要求,需要有更高强度要求的钢材与之相匹配,这种情况下须采用高强钢甚至超高强钢。

由于与普通低碳钢相比,高强钢中加入了较多的合金元素,化学成分较为复杂,各种力学性能都发生了较大的变化,因此,必然在焊接性上也发生了很大变化。

只有充分了解和掌握其焊接性,才能够在现场施工作业中,做好焊接质量控制工作。

1 S690高强钢焊接性分析20世纪50~80年代,美、英、德、日等先后开发出性能优异的低碳调质钢,用于重要焊接结构,取得了显著的经济效益。

目前屈服强度为690MPa的低碳调质钢,较为著名的有美国的ABS Grade EQ70、德国的Dillinger Dillimax 690、法国的INDUSTEEL Superelso 690 CR和奥地利的Aldur 700 QL1等,被广泛的用于起重设备制造、海洋采油平台制造、海上钻井船桩腿制造等方面。

S690高强钢是一种应用于大型装备制造业如重型起吊机,挖掘机,煤矿机械等设备的低合金高强度细晶粒结构钢,它是一种德国产钢材,国内相应钢种为HQ-80C[1],这种钢是我国在日本WEL-TEN80C钢基础上发展起来的屈服强度为685MPa级的工程机械用钢。

1.1 冷裂纹敏感性分析采用碳当量估算法,对S690高强钢冷裂纹敏感性进行分析。

所谓“碳当量”即把钢中包括碳在内的合金元素对淬硬、冷裂及脆化等的影响折合成碳的相当含量。

世界各国根据本国的具体情况相继建立了许多碳当量公式,国际焊接学会(IIW)推荐的碳当量公式如公式2.1所示:1.4 热影响区软化S690高强钢热影响区峰值温度高于母材回火温度至Ac1的区域会出现软化(强度、硬度降低)。

在激光作用下核压力容器钢焊接接头的显微组织和力学性能摘要:设计间接热冲压工艺,利用有限元法对零件的几何尺寸和力学性能进行了预测.在间接热冲压过程的情况下,生产性能与适应车身部件,冷却路径造成扩散和扩散控制的相变。

通过人脸的相变引起的体积膨胀为面心立方(FCC)为体心立方(BCC)和体心四方(BCT)马氏体的形成导致相变诱导株的整体应力热冲压的车身部件的计算是很重要的。

计算的应力和应变状态正确,它是必要的模型的扩散和扩散控制的相变现象,考虑到间接热冲压过程的边界条件。

现有的材料模型进行分析和扩展以提高计算铁氧体、珍珠岩的数量和分布,其预测的准确性,整个退火过程中贝氏体和马氏体.工业用新方法在有限元程序LS-DYNA 971实现关键词:核钢稳压器压水反应堆反应堆压力容器结构完整性焊接韧性SA508钢通常用于民用核反应堆的关键部件,如反应堆压力容器。

核部件通常采用电弧焊接工艺,但与设计为未来的新建设项目超过60年的生活,新的焊接技术正在寻求.在这种探索性的研究,为第一时间,自体激光焊接6毫米厚的进行SA508 Cl。

3钢板使用16千瓦激光系统在4千瓦的功率运行。

这个显微组织和力学性能(包括显微硬度、抗拉强度、延伸率等夏比冲击韧性)的特点和结构进行了比较电弧焊接.基于移动体热的三维瞬态模型源模型也发展到模拟激光焊接热循环,以估计冷却速率的过程。

初步结果表明,激光焊接工艺可以无宏观缺陷的焊缝,激光焊接的强度和韧性在这项研究中的联合,得到的值,在焊接的母材条件。

反应堆压力容器的寿命和安全运行(RPV),这是核电站中最关键的部件之一.取决于高温压力容器材料的耐久性,高压力和放射性环境.具有较高强度,韧性和抗辐照脆化的材料的需要是上升的,由于增加的发电容量和核电厂的设计寿命[1 ],[ 2 ],[ 3 ],[ 4 ],[ 5 ],[7 ],[8 ]和[ 6 ].SA508钢已经用于许多RPV?的压水反应堆制造因为他们提供的结合强度,延展性好,断裂韧性,相对于机械性能的均匀性,和他们的经济[9 ]、[ 10 ]、[ 11 ]和[12 ].无人机是采用焊接厚环形锻件或SA508钢板在一起。

《材料焊接性》实验指导书目录实验一:低合金结构钢焊接性试验 (1)实验二:低合金结构钢焊接接头显微组织和冷裂纹形态的观察 (3)实验三:铸铁焊接 (5)实验一低合金结构钢焊接性试验一、实验目的1、初步了解低合金结构钢焊接性试验方法。

2、掌握斜Y坡口对接裂纹试验方法及试验结果的一般分析方法。

二、实验原理合金结构钢焊接时的主要问题之一是裂纹,强度级别越高的钢,其冷裂纹倾向越大。

焊接冷裂倾向的测定方法很多。

常用的测定方法有:最高硬度法,斜Y坡口对接裂纹试验法(“小铁研式”抗裂试验)、插销试验等。

按照接头的拘束类型可把抗裂试验分成自拘束型抗裂试验和外拘束型抗裂试验两大类。

外拘束型抗裂试验适用于定量评定材料的裂纹倾向,并可以比较深入地进行有关理论研究工作,但这类试验都需要专用的试验机,其中插销试验法,试验装置简单,应用灵活,节省试验材料和时间,因此比较容易普及。

自拘束型抗裂试验方法很多,其中“小铁研式”抗裂试验是常用的抗裂性试验之一。

此法所用的试样如图1所示,试板用被焊材料制成,两端各60mm范围内先用焊缝固定,试板之间予留间隙2—3mm。

图1 斜Y坡口对接裂纹试样试板中间(80mm处)焊试验焊缝(单道焊),焊接规范为标准规范,焊条直径φ4mm,焊接电流170A,电弧电压24V,焊速150mm/min。

试验焊缝两端都不得与拘束焊缝相连,应各相距2—3mm,试验焊缝焊后至少放置24小时,然后进行裂纹检查。

首先用放大镜目测检查焊缝金属表面裂纹,然后沿焊缝长度方向均匀截成六段,从同一侧面检查每一试片的断面裂纹,计算出裂纹率。

由于两端固定,对试验焊缝有拘束作用,其拘束程度往往比实际结构的长焊缝还要大,所以一般认为只要表面裂纹率不超过20%,在实际生产中就不致发生裂纹。

三、实验内容1、了解常用的焊接性试验方法,重点了解斜Y型坡口试验方法及特点。

2、对斜Y型坡口对接裂纹试验的结果进行分析。

四、实验报告1、说明插销试验法和斜Y型坡口对接裂纹试验方法的特点及应用。

A588 GR A低合金高强钢焊接性研究及应用对美标钢板A588 GR A的焊接性能进行研究,分析了钢板在焊接过程中的冷裂倾向,热裂倾向,进行预热温度的确定,进行了三种焊接方法的焊接工艺评定,并成功应用于实际产品制造中。

标签:低合金高强钢;焊接性;焊接材料1 前言A588 GR A是美国标准ASTMA 588/ A588M-05中一种抗大气腐蚀的高强度低合金钢。

我公司负责制造的AP1000压水堆核电站某设备主体采用该材料焊接而成,该设备对控制棒驱动机构进行支持和保护及冷却,其制造质量直接关系到核电站的安全运行。

为高质量的完成该设备的制造,对该材料进行必要的焊接性研究及试验显得非常有必要。

2 A588 GR A钢的焊接性分析A588 GR A钢的化学成分及力学性能见表1(供货值)。

表1 化学成分及力学性能(%)该钢中作为合金元素有Si、Mn、Cr、Ni、Cu、V等,V的加入可以起到细化晶粒和沉淀强化的作用,其他元素均属固溶强化。

这些元素的加入,在提高钢的强度的同时,也恶化了钢的焊接性。

该钢通过加入Cu元素合金化来提高耐大气腐蚀,Cu的含量较高,达到0.32%,而Cu元素是容易引起焊接热裂纹的元素。

淬硬倾向分析:按照国际焊接学会(IIW)推荐的碳当量公式计算该钢种的CE:CE=C+Mn/6+(Cu+Ni)/15+(Cr+Mo+V)/5=0.48%;因CE值处于0.40%与0.60%之间时,钢材有一定的淬硬倾向,焊接前需要预热。

热裂纹敏感性分析:采用热裂纹敏感系数公式计算热裂纹敏感系数:HCS=1000C(S+P+Si/25+Ni/100)/(3Mn+Cr+Mo+V)=0.95≤2,不会产生热裂纹。

3 焊接方法的确定及焊接材料的选择由于被焊产品主体为大直径筒形构件,在筒体上还接了许多其他零部件,设计对筒体尺寸精度要求很高,需要严格控制焊接变形,同时该零件的焊缝长度比较长,焊接量较大,焊接时需要全位置焊接。

低合金高强度结构钢High Strength Low Alloy Steel一、定义中国国家标准GB/T13304-1991《钢分类》,参照国际标准,对钢的分类作了具体的规定。

低合金高强度钢HSLA是在碳素钢的基础上,通过加入少量合金元素并在热轧、控轧或热处理状态下,具有高强度、高韧性,较好的焊接性、成型性或耐腐蚀性等特征的钢材。

成分特点:低碳(Wc≤0.2%),低合金。

性能特点:比普通碳素结构钢有较高的屈服强度和屈强比、较好的冷热加工成型性、良好的焊接性、较低的冷脆倾向、缺口和时效敏感性,以及有较好的抗大气、海水等腐蚀能力。

二、低合金高强度钢的发展1867-1874年,美国含铬结构钢,1902-1906年,美国含镍结构钢,1915年,美国含锰1.6%桥梁用结构钢。

20世纪60年代以后,冶金生产工艺技术和低合金钢开发均取得巨大发展,锰、硅、铬、镍、钒、钛、铌等微合金元素的强化作用已清楚。

80年代后随着技术进步,通过钢质净化、晶粒细化、组织优化、基体强化等,促进了新型低合金钢的开发。

低合金钢是近30年来发展最快、产量最大、经济性最好、使用面最广、前景最广阔的钢类。

目前,新型的低合金高强度钢以低碳(≤0.1%)和低硫(≤0.015%)为主要特征。

我国是1957年在鞍钢试制成功第一炉低合金钢16Mn,随后研制出16Mn系列的桥梁用、船用、锅炉用、压力容器用、汽车用低合金钢。

1966年,低合金钢产量141万吨,占钢产量8%;至1979年,低合金钢产量254万吨,仍占钢产量8%。

1997年,低合金钢产量2368万吨,占钢产量22%。

各发达工业国家的低合金高强度钢产量约占钢产量的10%。

为进一步提高低合金高强度钢的性能,在低合金高强度钢的基础上,通过进一步降低碳质量分数、微合金化和控制轧制而发展了一系列新型低合金高强度结构钢,主要有以下四种:微合金化低碳高强度钢、低碳贝氏体型钢、低碳索氏体型钢、针状铁素体型钢。

2012届毕业设计外文翻译Weldability of Structural Steels焊接结构钢学生姓名:***指导教师:崔晓东、任芝兰职称:工程师、副教授专业:机械设计制造及其自动化班级:机本0804班完成时间:2012年5月附录1英文原文Lecture 2.6: Weldability of Structural SteelsThe lecture briefly discusses the basics of the welding process and then examines the factors governing the weldability of structural steels.SUMMARYThe fundamental aspects of the welding process are discussed. The lecture then focuses on the metallurgical parameters affecting the weldability of structural steels. A steel is considered to exhibit good weldability if joints in the steel possess adequate strength and toughness in service.Solidification cracking, heat affected zone - liquation cracking, hydrogen-induced cracking, lamellar tearing, and re-heat cracking are described. These effects are detrimental to the performance of welded joints. Measures required to avoid them are examined.1. INTRODUCTION1.1 A Brief Description of the Welding ProcessWelding is a joining process in which joint production can be achieved with the use of high temperatures, high pressures or both. In this lecture, only the use of high temperatures to produce a joint is discussed since this is, by far, the most common method of welding structural steels. It is essentially a process in which an intense heat source is applied to the surfaces to be joined to achieve local melting. It is common for further "filler metal" to be added to the molten weld pool to bridge the gap between the surfaces and to produce the required weld shape and dimensions on cooling. The most common welding processes for structural steelwork use an electric arc maintained between the filler metal rod and the workpiece to provide the intense heat source.If unprotected, the molten metal in the weld pool can readily absorb oxygen and nitrogen from the atmosphere. This absorption would lead to porosity and brittleness in the solidified weld metal. The techniques used to avoid gas absorption in the weld pool vary according to the welding process. The main welding processes used to join structural steels are considered in more detail below.1.2 The Main Welding Processesa. Manual Metal Arc welding (MMA)In this process, the welder uses a metal stick electrode with a fusible mineral coating, in a holder connected to an electrical supply. An arc is struck between the electrode and the weld area which completes the return circuit to the electricity supply. The arc melts both the electrode and the surface region of the workpiece. Electromagnetic forces created in the arc help to throw drops of the molten electrode onto the molten area of the workpiece where the two metals fuse to form the weld pool.The electrode coating of flux contributes to the content of the weld pool by direct addition of metal and by metallurgical reactions which refine the molten metal. The flux also provides a local gaseous atmosphere which prevents absorption of atmospheric gases by the weld metal.There are many types of electrodes. The main differences between them are in the flux coating. The three main classes of electrode are shown below:1. Rutile: General purpose electrodes for applications which do not require strict control of mechanical properties. These electrodes contain a high proportion of titanium oxide in the flux coating.2. Basic: These electrodes produce welds with better strength and notch toughness than rutile. The electrodes have a coating which contains calcium carbonate and other carbonates and fluorspar.3. Cellulosic: The arc produced by this type of electrode is very penetrating. These electrodes have a high proportion of combustible organic materials in their coating.b. Submerged Arc Welding (SAW)This process uses a bare wire electrode and a flux added separately as granules or powder over the arc and weld pool. The flux protects the molten metal by forming a layer of slag and it also stabilises the arc.The process is used mainly in a mechanical system feeding a continuous length of wire from a coil whilst the welding lead is moved along the joint. A SAW machine may feed several wires, one behind the other, so that a multi-run weld can be made. Submerged arc welding produces more consistent joints than manual welding, but it is not suitable for areas of difficult access.c. Gas shielded weldingIn this process, a bare wire electrode is used and a shielding gas is fed around thearc and weld pool. This gas prevents contamination of the electrode and weld pool by air. There are three main variations of this process as shown below:1. MIG (metal-inert gas) welding - Argon or helium gas is used for shielding. This process is generally used for non-ferrous metals.2. MAG (metal-active gas) welding - Carbon dioxide (usually mixed with argon) is used for shielding. This process is generally used for carbon and carbon-manganese steels.3. TIG (tungsten-inert gas) - Argon or helium gas is used for shielding and the arc struck between the workpiece and a non-consumable tungsten electrode. This process is generally used for thin sheet work and precision welding.1.3 Welded Joint Design and PreparationThere are two basic types of welded joints known as butt and fillet welds [1]. Schematic views of these two weld types are shown in Figure 1. The actual shape of a weld is determined by the preparation of the area to be joined. The type of weld preparation depends on the welding process and the fabrication procedure. Examples of different weld preparations are shown in Figure 2. The weld joint has to be located and shaped in such a way that it is easily accessible in terms of both the welding process and welding position. The detailed weld shape is designed to distribute the available heat adequately and to assist the control of weld metal penetration and thus to produce a sound joint. Operator induced defects such as lack of penetration and lack of fusion can be difficult to avoid if the joint preparation and design prevent good access for welding.The intense heat involved in the welding process influences the microstructure ofboth the weld metal and the parent metal close to the fusion boundary (the boundary between solid and liquid metal). As such, the welding cycle influences the mechanical properties of the joint.The molten weld pool is rapidly cooled since the metals being joined act as an efficient heat sink. This cooling results in the weld metal having a chill cast microstructure. In the welding of structural steels, the weld filler metal does not usually have the same composition as the parent metal. If the compositions were the same, the rapid cooling could result in hard and brittle phases, e.g. martensite, in the weld metal microstructure. This problem is avoided by using weld filler metals with a lower carbon content than the parent steel.The parent metal close to the molten weld pool is heated rapidly to a temperature which depends on the distance from the fusion boundary. Close to the fusion boundary, peak temperatures near the melting point are reached, whilst material only a few millimetres away may only reach a few hundred degrees Celsius. The parent material close to the fusion boundary is heated into the austenite phase field. On cooling, this region transforms to a microstructure which is different from the rest of the parent material. In this region the cooling rate is usually rapid, and hence there is a tendency towards the formation of low temperature transformation structures, such as bainite and martensite, which are harder and more brittle than the bulk of the parent metal. This region is known as the heat affected zone (HAZ).The microstructure of the HAZ is influenced by three factors:The chemical composition of the parent metal.The heat input rate during welding.The cooling rate in the HAZ after welding.The chemical composition of the parent metal is important since it determines the hardenability of the HAZ. The heat input rate is significant since it directly affects the grain size in the HAZ. The longer the time spent above the grain coarsening temperature of the parent metal during welding, the coarser the structure in the HAZ. Generally, a high heat input rate leads to a longer thermal cycle and thus a coarser HAZ microstructure. It should be noted that the heat input rate also affects the cooling rate in the HAZ. As a general rule, the higher the heat input rate the lower the cooling rate. The value of heat input rate is a function of the welding process parameters: arc voltage, arc current and welding speed. In addition to heat input rate, the cooling rate in the HAZ is influenced by two other factors. First, the joint design and thickness areimportant since they determine the rate of heat flow away from the weld during cooling. Secondly, the temperature of the parts being joined, i.e. any pre-heat, is significant since it determines the temperature gradient which exists between the weld and parent metal.1.5 Residual Welding Stresses and DistortionThe intense heat associated with welding causes the region of the weld to expand. On cooling contraction occurs. This expansion and subsequent contraction is resisted by the surrounding cold material leading to a residual stress field being set up in the vicinity of the weld. Within the weld metal the residual stress tends to be predominantly tensile in nature. This tensile residual stress is balanced by a compressive stress induced in the parent metal [2]. A schematic view of the residual stress field obtained for longitudinal weld shrinkage is shown in Figure 3. The tensile residual stresses are up to yield point in magnitude in the weld metal and HAZ. It is important to note that the residual stresses arise because the material undergoes local plastic strain. This strain may result in cracking of the weld metal and HAZ during welding, distortion of the parts to be joined or encouragement of brittle failure during service.Transverse and longitudinal contractions resulting from welding can lead to distortion if the hot weld metal is not symmetrical about the neutral axis of a fabrication [2]. A typical angular rotation in a single V butt weld is shown in Figure 4a.The rotation occurs because the major part of the weld is on one side of the neutral axis of the plate, thus inducing greater contraction stresses on that side. This leads to a distortion known as cusping in a plate fabrication, as shown in Figure 4b. Weld distortion can be controlled by pre-setting or pre-bending a joint assembly to compensate for the distortion or by restraining the weld to resist distortion. Examples of both these methods are shown in Figure 5. Distortion problems are most easily avoided by using the correct weld preparation. The use of non-symmetrical double sided welds such as those shown in Figure 2e and 2i accommodates distortion. The distortion from the small side of the weld (produced first) is removed when the larger weld is put on the other side. This technique is known as balanced welding.It is not possible to predict accurately the distortion in a geometrically complicated fabrication, but one basic rule should be followed. This rule is that welding should preferably be started at the centre of a fabrication and all succeeding welds be made from the centre out, thus encouraging contractions to occur in the free condition.If distortion is not controlled, there are two methods of correcting it; force and heat. The distortion of light sections can be eliminated simply by using force, e.g. the use of hydraulic jacks and presses. In the case of heavier sections, local heating and cooling is required to induce thermal stresses counteracting those already present.1.6 Residual Stress ReliefThe most common and efficient way of relieving residual stresses is by heating. Raising the temperature results in a lower yield stress and allows creep to occur. Creep relieves the residual stresses through plastic deformation. Steel welded components are usually heated to a low red heat (600C) during stress relieving treatments. The heating and cooling rates during this thermal stress relief must be carefully controlled otherwise further residual stress patterns may be set up in the welded component. There is a size limit to the structures which can be thermally stress relieved both because of the size of the ovens required and the possibility of a structure distorting under its own weight. It is possible, however, to heat treat individual joints in a large structure by placing small ovens around the joints or by using electric heating elements.Other methods of stress relief rely on thermal expansion providing mechanical forces capable of counteracting the original residual stresses. This technique can be applied in-situ but a precise knowledge of the location of the compressive residual stresses is vital, otherwise the level of residual stress may be increased rather than decreased. Purely mechanical stress relief can also be applied provided sufficient is available to accommodate the necessary plastic deformation.2. THE WELDABILITY OF STRUCTURAL STEELS2.1 IntroductionIf weld preparation is good and operator induced defects (e.g. lack of penetration or fusion) are avoided, all the common structural steels can be successfully welded. However, a number of these steels may require special treatments to achieve a satisfactory joint. These treatments are not convenient in all cases. The difficulty in producing satisfactory welded joints in some steels arises from the extremes of heating, cooling and straining associated with the welding process combined with microstructural changes and environmental interactions that occur during welding. It is not possible for some structural steels to tolerate these effects without joint cracking occurring. The various types of cracking which can occur and the remedial measures which can be taken are discussed below.2.2 Weld Metal Solidification CrackingSolidification of the molten weld pool occurs by the growth of crystals away from the fusion boundary and towards the centre of the weld pool, until eventually there is no remaining liquid. In the process of crystal growth, solute and impurity elements are pushed ahead of the growing interface. This process is not significant until the final stages of solidification when the growing crystals interlock at the centre of the weld. The high concentration of solute and impurity elements can then result in the production of a low freezing point liquid at the centre of the weld. This acts as a line of weakness and can cause cracking to occur under the influence of transverse shrinkage strains. Impurity elements such as sulphur and phosphorus are particularly important in this type of cracking since they cause low melting point silicides and phosphides to be present in the weld metal [3]. A schematic view of solidification cracking is shown in Figure 6.Weld metals with a low susceptibility to solidification cracking (low sulphur and phosphorous) are available for most structural steels, but cracking may still arise in the following circumstances:a. If joint movement occurs during welding, e.g. as a result of distortion. A typical example of this is welding around a patch or nozzle. If the weld is continuous, the contraction of the first part of the weld imposes a strain during solidification of the rest of the weld.b. If contamination of the weld metal with elements such a sulphur and phosphorus occur. A typical example of this is the welding of articles with a sulphur rich scale, such as a component in a sulphur containing environment.c. If the weld metal has to bridge a large gap, e.g. poor fit-up. In this case the depth to width ratio of the weld bead may be small. Contraction of the weld results in a large strain being imposed on the centre of the weld.d. If the parent steel is not suitable in the sense that the diffusion of impurity elements from the steel into the weld metal can make it susceptible to cracking. Cracking susceptibility depends on the content of alloying element with the parent metal and can be expressed in the following equation:Hot cracking susceptibility =Note: The higher the number, the greater the susceptibility.Solidification cracking can be controlled by careful choice of parent metal composition, process parameters and joint design to avoid the circumstances previously outlined.2.3 Heat Affected Zone (HAZ) Cracking2.3.1 Liquation cracking (burning)The parent material in the HAZ does not melt as a whole, but the temperature close to the fusion boundary may be so high that local melting can occur at grain boundaries due to the presence of constituents having a lower melting point than the surrounding matrix. Fine cracks may be produced in this region if the residual stress is high. These cracks can be extended by fabrication stresses or during service [3]. A schematic view of liquation cracking is shown in Figure 7.In steels the low melting point grain boundary films can be formed from impurities such as sulphur, phosphorus, boron, arsenic and tin. As with solidification cracking, increased carbon, sulphur and phosphorous make the steel more prone to cracking.There are two main ways of avoiding liquation cracking. First, care should be taken to make sure that the sulphur and phosphorus levels in the parent metal are low. Unfortunately, many steel specifications permit high enough levels of sulphur and phosphorus to introduce a risk of liquation cracking. Secondly, the risk of liquation cracking is affected by the welding process used. Processes incorporating a relatively high heat input rate, such as submerged arc or electroslag welding, lead to a greater risk of liquation cracking than, for example, manual metal arc welding. This is the case since the HAZ spends longer at the liquation temperature (allowing greater segregation of low melting point elements) and there is a greater amount of thermal strain accompanying welding.译文:结构钢的焊接性演讲简要讨论焊接工艺的基础,然后测试决定结构钢焊接性的因素。

《低合金钢焊条》英文English:"Low alloy steel welding rods are specifically designed electrodes used in arc welding processes to join low alloy steels. These rods are formulated with specific compositions of alloying elements such as manganese, nickel, chromium, molybdenum, and vanadium to enhance the mechanical properties and weldability of the resulting weld joint. The selection of low alloy steel welding rods depends on the base metal being welded, the required mechanical properties of the weld joint, and the welding process employed. Common classifications of low alloy steel welding rods include AWS (American Welding Society) for covered electrodes and AWS for gas-shielded flux-cored electrodes. These rods offer advantages such as improved strength, toughness, and resistance to corrosion and high temperatures compared to carbon steel electrodes. However, proper storage and handling are crucial to prevent moisture absorption and maintain the integrity of the electrode coating. Additionally, operators must adhere to recommended welding parameters and techniques to achieve high-quality welds with low alloy steel welding rods."中文翻译:"低合金钢焊条是专门设计的电焊条,用于电弧焊工艺中连接低合金钢。

《低合金钢焊条》英文English:Low alloy steel welding rod is a type of electrode used in welding low alloy steels, which are steels that contain a total alloy content of less than 5%. These welding rods are specifically designed to provide high tensile strength and toughness to the welded joints, making them ideal for applications in industries such as construction, automotive, shipbuilding, and machinery manufacturing. Low alloy steel welding rods are classified based on their chemical composition and mechanical properties, with different grades suitable for specific applications. They are typically coated with flux to protect the molten weld pool from contamination and ensure a clean, strong weld. The welding process using low alloy steel welding rods involves applying an electric current to the rod, creating an arc that melts the base metal and the rod, fusing them together. This results in a strong, durable weld that can withstand high stress and strain. Overall, low alloy steel welding rods are essential tools for joining low alloy steels and producing reliable, structurally sound welds.中文翻译:低合金钢焊条是一种用于焊接低合金钢的电极,低合金钢指的是含有总合金含量低于5%的钢材。

英文原文中文翻译低合金钢焊缝的硬化裂纹关键词:低碳钢、焊接、热裂纹、合金效应,凝固模式介绍硬化裂纹在低碳高强钢的焊接中一直是一个问题,因为这样的问题这些裂纹会导致突然性的断裂,突然失效。

这些裂纹在焊接过程中也可以在整个焊缝导致氢至裂纹。

大多数人认为,热裂纹的产生是由于在凝固末期低熔点共晶成分的熔化导致的杂质和合金元素的分离,这些又进一步导致当焊缝在手表面拉应力的作用是发生开裂,因此需要结合热裂纹的冶金和机械性能的综合条件。

涉及的力学条件等因素包括限制焊接接头、焊缝金属的体积和形状因子熔融焊缝成形,而冶金条件包括合成物和导致元素偏析的条件,如融滴中的热传导方向和晶粒取向。

硬化裂纹的问题在高强钢和低合金钢中已经被观察和研究很多年了,现在主要归咎于杂质(尤其是S),尽管像C和Ni这样的合金元素有非同寻常的贡献。

随着炼钢行业的发展,S在钢中的含量大大被降低,结构钢中的典型S含量也在百万分之几十左右。

同时这也降低了可焊钢中的C含量和焊缝金属中的C含量,这样的话,就可以提高材料的韧性。

随着焊接行业的机械化发展,越来越需要更高的焊接速度,能达到更高的生产效率。

焊缝的凝固裂纹过去在高能量输入的焊接过程中被发现,这也开始在结构钢的电弧焊过程中显示出来。

在这些杂质含量低的被焊件中的裂纹出现被归咎为C何Ni的分离。

很有趣的一项研究发现是大多数的出现在低碳钢和低合金钢中的裂纹会在C或合金含量增加的时候消失。

在工业管材的焊接中发现,裂纹出现在C含量在0.06—0.1%的钢中较多,在其他C含量较多或较少的钢种出现较少。

焊接裂纹也和焊缝中心在熔池凝固时形成的晶界有关。

裂纹还归咎于附加收缩应力有关,主要发生在凝固去前沿。

这正和人们认为的随着合金的含量增加开裂倾向增加的观点形成的对比。

裂纹在实际钢材焊缝中的行为是很复杂的,它受到不同因素的影响:凝固方式,还原剂例如Ti和Si,杂质的存在,焊接速度,晶粒取向。

在埋弧焊中,热裂纹呗发现和焊剂的本质,氧的含量以及焊接参数。

外文资料翻译WELDABILITY ANALYSIS OF Q345 STEELLOW STEEL ALLOY STRUCTURE OF WELDABILITYANALYSIS16Mn and 15MnV belong to the low-alloy steel hot rolled steel, these steel prices lower, and has satisfied the mechanical properties and processing performance, first of all to analyze this type of steel welding, welding on two points of typically Bianxian questions: First, due to a variety of welding defects, such types of steel for the main crack; Second, changes in material properties when welding on the type of steel is mainly embrittlement problem.1. Crack(1) Thermal crack: hot rolled carbon content generally lower, while the higher manganese content, so they Mn / S comparison, and has good resistance to thermal cracking performance. Normally, the weld hot cracking does not occur, but when the material component failure or serious segregation of carbon, sulfur content higher, Mn / S ratio is low, prone to hot cracking. Manganese in the steel with manganese sulfide sulfur to reduce the harmful effects of sulfur and enhance the performance of steel thermal cracking.(2) Cold crack: the crack depends on the cold steel, hardened steel, the tendency of the tendency toward hardening just depends on its chemical composition. Hot rolled steel contains a small amount of alloying elements because of its low carbon steel when the carbon equivalent is slightly high er than some, so this low carbon steel hardened tend to be bigger than that, but with the increase of steel strength level, the increase in alloying elements, it The hardening tendency increases should be based on the form and steel fittings to adjust the line thickness of the energy, preheating and post-heattemperature, to control the heat-affected zone of the cooling rate, while reducing the amount of weld metal hydrogen and other measures to prevent cold cracks.(3)Reheat cracking: Considerations from the chemical composition of steel, hot rolled steel does not contain as strong carbide forming elements, so again not sensitive to hot cracking, but also by increasing the preheating temperature and post weld heat such measures immediately after to prevent hot cracking.2. Embrittled(1)Hot zone embrittlement: hot rolled steel welding near the weld zone is heated to above 100 ℃coarse grain zone, easy to produce grain growth phenomenon is worst in welded joints of plastic parts, often to withstand the stress the role of the damage. To prevent the overheating zone embrittlement measures is to improve the cooling rate, in particular, to improve the stability of austenite within the minimum cooling rate, shorten the residence time in this temperature range, reduce or prevent the emergence of austenite to raise steel impact toughness, but also to prevent the overheating zone coarse-grained brittle, should not be using too much energy input.(2) Heat should be crisp: the heat should be crisp is the thermal stress during the welding process because the plastic deformation to dislocation multiplication, while nitrogen and carbon atoms induced rapid proliferation of dislocation accumulation area, there should be crisp of heat. 16Mn and 15MnV these two types of steel has got to be brittle tendency of heat, eliminating welding heat should be crisp and effective measures of post-weld annealing.LOW ALLOY STRUCTURAL STEEL WELDING1. Welding preparation:(1) The design of groove type of welding should be avoided not through or partial penetration of the groove, but also to minimize the weld cross-sectional area to reduce the residual stress in joints, it can also reducethe consumption of welding materials .(2) Groove to note when using thermal cutting edge of the base metal will prevent the formation of a certain depth of the hardened layer, this hardened layer of low ductility often cold cracking source.(3) Weld area before welding steel to eliminate surface moisture, groove surface oxide, rust, grease and other contaminants.(4)Before use welding materials manufacturer recommended specifications should be dry.(5)Orientation and assembly, and the formal weld seam must be the same type of electrode.2. Welding heat input of choice:Line energy parameters is welding current, arc voltage and welding speed. Low-alloy structural steel welding, heat input parameters to the need to ensure that joint penetration and weld, but also consider their joint performance. Welding of low carbon content and carbon content of hot-rolled steel lower side of the 16Mn steel, the welding heat input is not strictly limited, but improve the plasticity and toughness of hot zone or consider the use of smaller line energy is more favorable; when welding with 16Mn high carbon steel, in order to reduce the hardening tendency, to prevent cold cracks, welding heat input is too large to be more.3. Preheating, heat and heat treatment after(1) Preheating: welding low alloy steels, preheat the cold when the joints to prevent cracking, to improve the performance of joints, reducing the welding stress the importance of technological measures. Preheat the beneficial effect also in: ①Change in welding heat cycle, reduce the high temperature transformation of various welded joints and low transition temperature of the cooling rate, to avoid or reduce the formation of hardened tissue; ②Reduce the welding area Wendu gradient, reducing the stress of welded joints, and make it a more even distribution; ③To expand the temperature field of welding area so that welded joints in a wide area in the plastic state, and has reduced the adverse effects of welding stress; ④Extension the welding area in more than 100℃of the residence time is beneficial in the escape of hydrogen from the weld metal. Preheat temperature to determine, with the carbon equivalent of steel, thickness, degree of structural constraint increases, the ambient temperature rises.(2)After the heat and heat treatment: after heat is the weldment after welding the end of the entire weld immediately heated to 150 ~ 250℃temperature range, and maintain a period of time, after such a process referred to as hot. Its role is to first reduce the joints at low temperature change of cooling rate, the more pronounced effect than warm, followed by the extension of the joint in more than 100℃range of residence time, so that the hydrogen in weld metal have sufficient time outside proliferation. Proliferation phase of metallic hydrogen in the wind, virtually eliminating lead from the cold crack formation of mechanical factors. After the hot temperature and time, depending on the welded steel cold cracking, welding materials, hydrogen content and degree of joint restraint. The higher the temperature after the heat, the longer the holding time, the more obvious effects dehydrogenase.Dehydroepiandrosterone treatment is welded immediately after the welding heat to 300 ~ 400℃and the heat for some time, could accelerate the spread of welded joints of hydrogen escape. The exclusion of hydrogen depends on temperature and time, high temperature holding time may be shorter, low temperature dehydrogenase time would lengthen. Eliminate the production of hydrogen treatment temperature of 300 ~ 400℃, hydrogen consumption for 1 to 2 hours.Elimination of stress treatment is welded evenly heated to a certain speed AC1 points below the temperature high enough, holding a period of time evenly with the furnace cooled to 300 ~ 400℃, the last piece moved to the furnace will be cooled. Low alloy steel after welding to eliminate the purpose of dealing with stress the following points: ①To eliminate the hydrogen in weld metal, to improve the crack resistance of welded joints and toughness;②Reduce the involvement of stress in the welded joints; ③Improve the weld metal and heat affected zone, so that organizations undergo tempering thehardened joint districts to improve the toughness; ④Stability of low-alloy heat resistant steel weld metal and heat affected zone of carbide, high temperature lasting increase joint strength; ⑤Reduced weld and heat affected zone hardness, easy cutting.Q345焊接性分析低合金结构钢的焊接性分析16Mn和15MnV均属于低合金结构钢中的热轧钢,这类钢价格便宜,而且具有满意的综合力学性能和加工工艺性能,首先来分析一下这类钢的焊接性,焊接性通常变现为两方面的问题:一是焊接引起的各种缺陷,对这类钢来说主要是各类裂纹问题;二是焊接时材料性能的变化,对这类钢来说主要是脆化问题。