变压器8D报告(骨架pin距尺寸偏小)实例

- 格式:xls

- 大小:875.50 KB

- 文档页数:11

XXX 精密机械有限公司America XXpin short XX由于产品不良给贵司带来的麻烦深表歉意,收到贵司的信息后,我们即将展开调查。

Very sorry for the defect makes you getting in trouble, while received your information, we investigated the matter immediately:Feedback date:ITEM NO:Resin blister排针骨架起泡Defect content: pin short defect500ppmDefect rate: 500ppm该产品骨架材料为尼龙PA46,具有易吸水的材料特性。

周转和存储条件对于排针骨架有很大的影响.当环境湿度较大时,产品吸水大,过炉后骨架中水分受高温,骨架起泡的不良率高。

目前我司在生产前,原材料都要求在温度100-105C烘箱中先干燥24hr,然后按照规定的成型条件注塑生产。

但对于配组品的排针配件,内部在周转时用布袋包装,没有特殊的防水措施,产品在出货时,有在箱子中放20包干燥剂防止产品吸水。

因此我们认为起泡不良产品周转中因包装不妥,储存时间长后在环境中吸水导致骨架过炉起泡的。

The resin material of the product is PA46, and it has the sop characteristic.The flow process and the storage conditions have great influence to the resin.The higher of humidity of environment, the more water the resin sop ,and after the resin through oven ,the higher blister defect rate it will get.Before production in my company, the raw material is need to be baked in the temperature of 1000~105 for 24 hrs. Then molding under the required mounding condition. In the flow process we use cloth bag to pack for we have consider special waterproof measures before shipment we put 20pcs of seals to preventThe suck of water. Therefore we think the reason of the blister is the bad packing. The resin will suck after long time storage.:1. 我司产品内部过炉时,因都没有装排针,因此检验时没有发现。

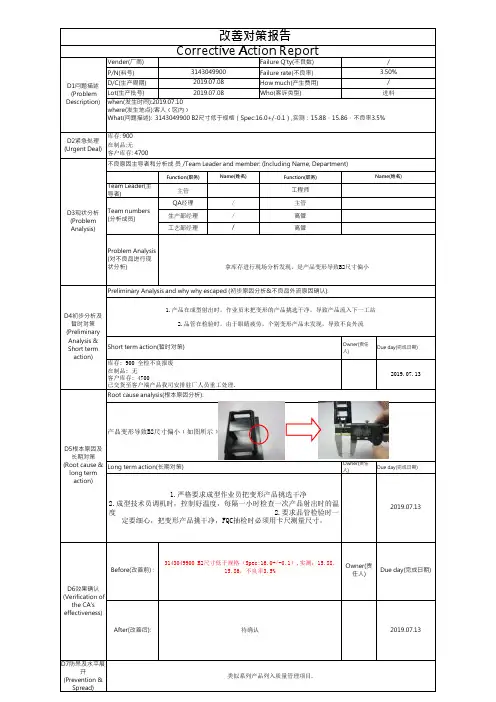

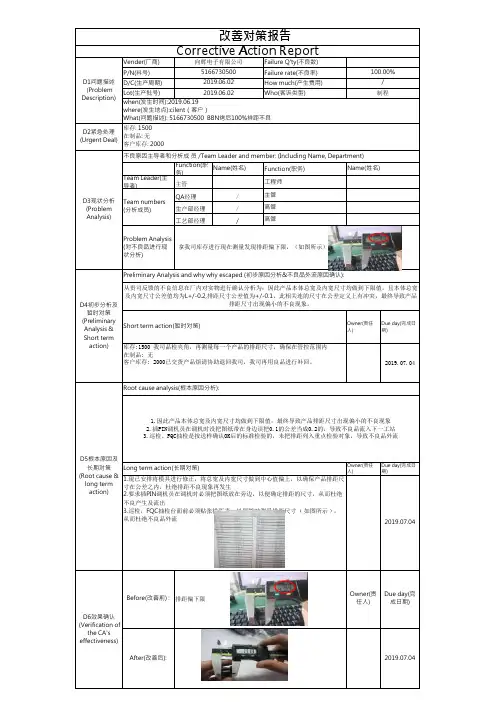

Vender(厂商)Failure Q'ty(不良数)P/N(料号)Failure rate(不良率)D/C(生产周期)How much(产生费用)Lot(生产批号)Who(客诉类型)D2紧急处理(Urgent Deal)Function(职务)Function(职务)Team Leader(主导者)主管工程师QA 经理主管生产部经理高管工艺部经理高管Owner(责任人)Due day(完成日期)Owner(责任人)Due day(完成日期)拿我司库存进行现在测量发现排距偏下限,(如图所示)2019.07.042019.07.04Due day(完成日期)2019.07.04排距偏下限1.因此产品本体总宽及内宽尺寸均做到下限值,最终导致产品排距尺寸出现偏小的不良现象2.插PIN调机员在调机时没把图纸带在身边误把0.1的公差当成0.2的,导致不良品流入下一工站3.巡检、FQC抽检是按送样确认OK后的标准检验的,未把排距列入重点检验对象,导致不良品外流1.现已安排将模具进行修正,将总宽及内宽尺寸做到中心值偏上,以确保产品排距尺寸在公差之内,杜绝排距不良现象再发生2.要求插PIN 调机员在调机时必须把图纸放在旁边,以便确定排距的尺寸,从而杜绝不良产生及流出3.巡检,FQC 抽检台面前必须贴张排距表,以便随时测量排距尺寸 ﹙如图所示﹚,从而杜绝不良品外流库存:1500 我司品检夹角,再测量每一个产品的排距尺寸,确保在管控范围内在制品: 无客户库存: 2000已交货产品烦请协助退回我司,我司再用良品进行补回。

D3现状分析(Problem Analysis)D4初步分析及暂时对策(PreliminaryAnalysis &Short term action)D5根本原因及长期对策(Root cause &long term action)D6效果确认 (Verification ofthe CA's effectiveness)Team numbers (分析成员)Problem Analysis(对不良品进行现状分析)Before(改善前) :After(改善后):Short term action(暂时对策)Root cause analysis(根本原因分析):Long term action(长期对策)Owner(责任人)//Preliminary Analysis and why why escaped (初步原因分析&不良品外流原因确认):从贵司反馈的不良信息在厂内对实物进行确认分析为:因此产品本体总宽及内宽尺寸均做到下限值,且本体总宽及内宽尺寸公差值均为L+/-0.2,排距尺寸公差值为+/-0.1,此相关连的尺寸在公差定义上有冲突,最终导致产品排距尺寸出现偏小的不良现象。

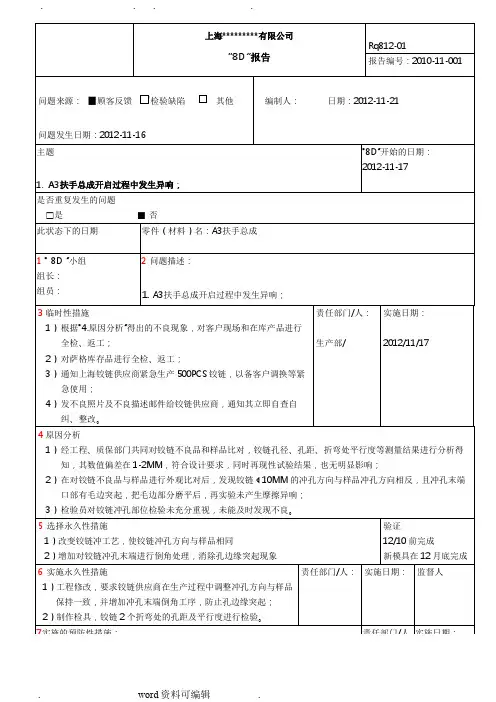

8D报告模板及实例公司D1.小组成员(部门/姓名)T eam Member(Dept/Name):D2.问题描述Problem Descrption:D3.确认并执行临时纠正措施Identify and Implement Containment Actions:(品质部负责)D4.根本原因分析Identify and Define Root Cause(s):(48小时内回覆)D5.确认永久纠正措施Identify Corrective Actions:(48小时内回覆)为什么会发生:针对发生原因:责任部门:生产部 X 车间签名/日期:XXX 日期为什么会未及时检出:针对流出原因:责任部门:品质部签名/日期:XXX 日期为什么会流出:针对未检出原因:责任部门:签名/日期:XXX 日期D7.预防再发生Actions to Prevent Recurrence:提交工程更改,验证更改工艺一个月周期,如无不良产生,修改CP ,PFMEA ,PPAP 文件。

D8.总结经验:□□□产品类别:XXX防错方式:预防再发生□□□□其他:缺陷图片:1)产品冲扁部位中段尺寸不合格,偏小,低于设计要求3.12mm 表单编号:XXX相关文件及标准更新:PFMEA 程序文件控制计划部门管理制度工艺文件/作业指导书PPAP文件2014-6-6进行中顾客现场0无需处理XXX已完成运输途中完成情况责任人公司英文名纠正预防措施8D报告D6.执行并验证永久纠正措施Implement and Verify Corrective Actions待验证工程部:品质部:生产部:业务部:生产部:采购部:物控部:生产线1生产线2管理层支持部门经理厂长总/副总经理说明首次发生重复发生三次以上发生---48小时无结果72小时无结果生产部:类别问题点描述:产品规格Φ5×113/Φ5×101数量区域24001955普通□较重□严重□发现人员客户IQC 发现地点客户进料区产品图号XXX顾客图号XXX发现时间XXX 成品库备注不良品/可疑品处置方式(24小时内反应)现场挑选不良品XXX 已完成调出库存,返工卡尺全检XXX 已完成XXX 通知各工序,已制品增加卡尺厚度测量,成品全数检验。

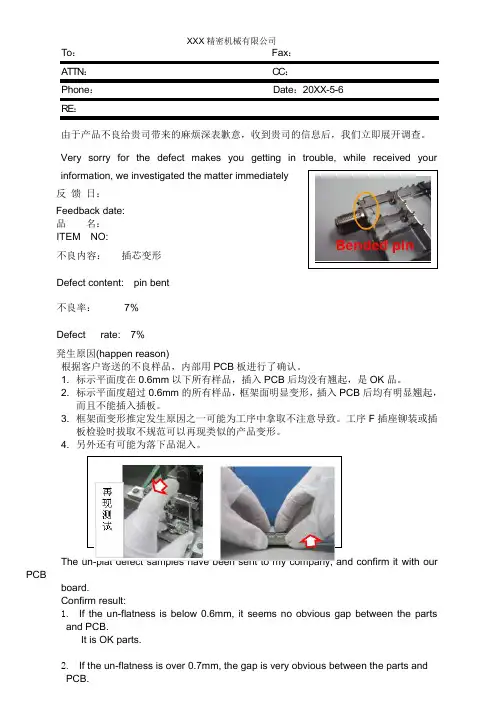

XXX精密机械有限公司To:Fax:ATTN: CC:Phone:Date:20XX-5-6RE:由于产品不良给贵司带来的麻烦深表歉意,收到贵司的信息后,我们立即展开调查。

Very sorry for the defect makes you getting in trouble, while received your information, we investigated the matter immediately反馈日:Feedback date:品名:ITEM NO:不良内容:插芯变形Defect content: pin bent不良率:7%·Defect rate: 7%発生原因(happen reason)根据客户寄送的不良样品,内部用PCB板进行了确认。

1. 标示平面度在0.6mm以下所有样品,插入PCB后均没有翘起,是OK品。

2. 标示平面度超过0.6mm的所有样品,框架面明显变形,插入PCB后均有明显翘起,而且不能插入插板。

3. 框架面变形推定发生原因之一可能为工序中拿取不注意导致。

工序F插座铆装或插板检验时拔取不规范可以再现类似的产品变形。

4. 另外还有可能为落下品混入。

The un-plat defect samples have been sent to my company, and confirm it with our PCBboard.Confirm result:1.If the un-flatness is below 0.6mm, it seems no obvious gap between the partsand PCB.It is OK parts.They can not be inserted into the PCB board and our jig. We can see that the parts bentobserved from the appearance. We think the bent maybe caused for the careless whenthe parts was take out from the jig in the caulking process. And also maybe it is thedefect parts mixed which had been dropped to the floor before. they can be reappeared forthe abnormal operation when drawing off the parts in the F connector caulking or jigcheck process .流出原因(outflow reason):1. 该产品的平面度没有在图纸上明确定义,因此内部并无列入管控。

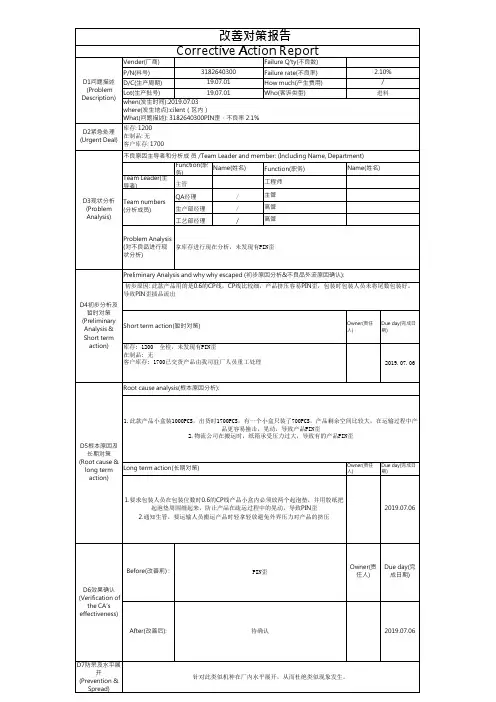

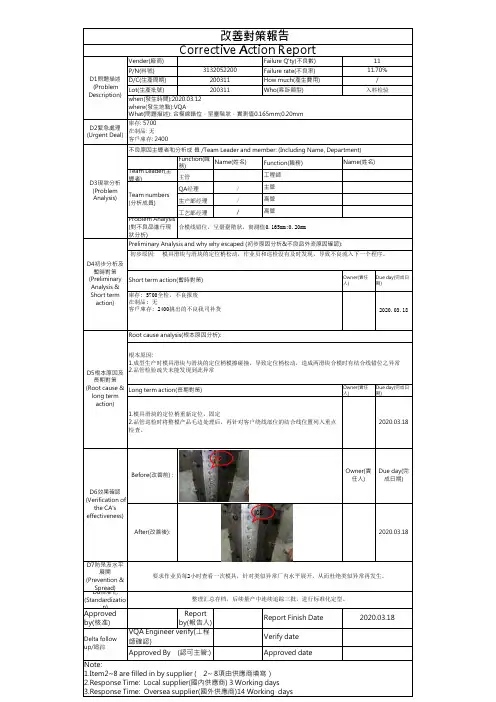

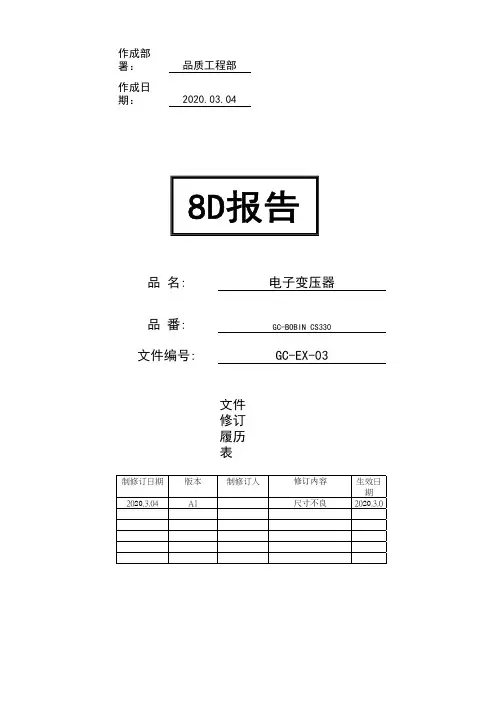

作成部署:作成日期:文件修订履历表文件编号:GC-EX-03品质工程部2020.03.04品 名:电子变压器品 番:GC-BOBIN CS330Vender(厂商)Failure Q'ty(不良数)P/N(料号)Failure rate(不良率)D/C(生产周期)How much(产生费用)Lot(生产批号)Who(客诉类型)D2紧急处理(Urgent Deal)Function(职务)Function(职务)Team Leader(主导者)主管工程师QA 经理主管生产部经理高管工艺部经理高管Owner(责任人)Due day(完成日期)Owner(责任人)Due day(完成日期)改善前: J1:28.00±0.25 28.35 28.42 尺寸偏大NG库存: 无在制品: 无客户库存: 200PCS已交货至客户端产品我司安排驻厂人员挑选处理.客人2020.03.05来料检验发现51688260200 J1尺寸超出公差,(如图)经驻厂人员确认J1宽度尺寸超出公差0.1-0.2量产模加工处理中,待确认。

产品“U"形端模具结构为:主体与滑块两部分组合而成,产生的根本原因一穴滑块制作精度不够(分析图例)产品成型后镶件边高于主模形成错位,致使J1尺寸偏大.1.停止使用样品模具,后续将量产新模滑块尺寸由原来3.7MM降低0.2MM (如图所示)2.样品订单,依据流程正常生产杜绝越流程化作业.(见D8项附档)Owner(责任人)2020.03.132020.03.13Due day(完成日期)2020.03.13D1问题描述 (Problem Description)D3现状分析(Problem Analysis)D4初步分析及暂时对策(PreliminaryAnalysis &Short term action)D5根本原因及长期对策(Root cause &long termaction)D6效果确认 (Verification ofthe CA's effectiveness)Team numbers (分析成员)Long term action(长期对策)Before(改善前) :After(改善后):/Preliminary Analysis and why why escaped (初步原因分析&不良品外流原因确认):初步原因分析:合模线错位引发产品“U”形端毛边,导致有一模号J1尺寸偏大.(如图):外流原因分析:因样品订单数量较小,生产排程未进行正常排单QC人员未检验,样品负责人直接入仓出货,导致J1尺寸不良重复发生.Short term action(暂时对策)Root cause analysis(根本原因分析):Problem Analysis (对不良品进行现状分析)//20.03.04进料库存: 无在制品: 无客户库存: 200PCS不良原因主导者和分析成 员 /Team Leader and member: (Including Name, Department)Name(姓名)Name(姓名)when(发生时间):2020.03.04where(发生地点):客人(区内)What(问题描述): 5168260200 J1尺寸超出规格实测:28.35,28.42,不良率5%/51688260200 5.00%20.03.04/ 改善对策报告Corrective Action Report毛边主体面OK 滑块面NG3.7MM3.7MM制定《样品制作管理程序》实现流程化作业.(如附档)样品制作管理程序.doc。

8D报告制订单位:品保课生效日期:2020.2.13核准:审查:制定:退貨揀用寬放嚴重Discipline2团队成员 / Team Members:工 程/ Engineering: 品 保/ Quality Control: 制 造/ Manufacturing:Discipline3原因分析 / Root Cause Analysis:完成日/ Finish day:A. 不良流出原因:①外检作业站是用钢尺100℅测量剥头长度的,钢尺量测读取最小数值为mm ,而不能精确到0.00mm ,造成超出公差范围0.13mm-0.62mm 的剥头未被检出,导致不良品流出。

②FQC ,OQC 未抽检到剥头长不良导致不良品流入客户端。

B.不良产生原因:尾部剥头是尾部处理机(分叉,脱皮,扭线,比剪一起完成)生产的,经调查是作业过程中挂线架与尾部处理机的距离过远,造成线材尾端放入尾部处理机生产过程中,线材被尾部处理机拉直且有后退现象,比剪作业时由于线材后退,比剪掉的铜丝过少,导致剥头尺寸过长。

Discipline4短期改善对策 / Temporary Corrective Action:完成日/ Finish day: 2020.2.13①无库存品,无在途品,无在制品。

②客户端库存品,请帮忙特采使用。

Discipline5永久改善对策 / Permanent Corrective Action:完成日/ Finish day: 2020.2.12①召集班长、IPQC 、尾部处理作业员、外检作业员现场分析宣导。

要求尾部处理作业时,挂线架与尾部处理机的距离不能过远,线材放入尾部处理机作业移动过程中,线材必须始终保持弯曲状态,避免尾部处理过程中因线材被拉直后退造成剥头尺寸长不良,并规定尾部处理线架放线不可超过1000PCS/架。

外检工站后续改为用卡尺量测剥头长度。

责任人: 执行日期:2020.2.12②FQC 、OQC 针对此不良加严抽检三批,由二级抽样标准提高到三级抽样标准进行抽样检验,直至连续三批没有发现此类不良则转为正常检验。

8d报告生产案例范文案例背景近日,我司生产线上出现了一起质量问题,部分产品出现了严重的尺寸偏差现象。

为了彻底解决这个问题,我们迅速展开了8D报告的问题解决流程,并于XX月XX日完成功能过该案例。

问题描述在生产线上生产的产品尺寸偏差较大,超过了允许范围。

该问题对产品的质量造成了严重影响,需要尽快解决。

初步原因分析通过对问题进行初步调查和分析,我们发现可能的原因有:1. 模具老化导致的尺寸不稳定。

2. 操作工操作不当,没有按照规定的工艺流程进行生产。

3. 人为因素,例如操作工操作不规范。

问题解决措施针对问题的初步原因分析,我们制定了以下解决措施:1. 进行模具更换,确保新的模具尺寸稳定。

2. 重新培训操作工,提醒他们严格按照规定的工艺流程进行生产。

3. 强调操作工严格操作的重要性,加强对操作工的监督和管理。

8D报告步骤第一步:组建问题解决小组我们成立了一个专门的问题解决小组,由相关的技术人员、质量人员和生产人员组成。

第二步:问题描述和原因分析我们详细描述了问题,按照8D方法分析了问题的原因。

第三步:紧急应对措施在问题暴露后,我们立即采取了紧急应对措施,暂停了全部产线,并进行了模具的更换。

第四步:根本原因分析通过对问题的深入调查和分析,我们发现问题的根本原因是操作工操作不规范导致的。

第五步:长期解决方案为了彻底解决问题,我们制定了长期解决方案:重新培训操作工,提醒他们严格遵守操作规程,确保生产过程规范。

第六步:实施长期解决方案为了确保长期解决方案的有效实施,我们组织了培训课程,并加强了对操作工的管理和监督。

第七步:验证解决方案的有效性我们对解决方案进行了实际生产和质量监控,验证了解决方案的有效性。

第八步:预防措施为了避免类似问题再次发生,我们进一步加强了对模具使用寿命的监控和管理,并加强了操作工的培训和管理。

结果和总结通过本次的8D报告问题解决流程,我们成功解决了生产线上的尺寸偏差问题,并且在以后的生产中没有再次出现类似问题。

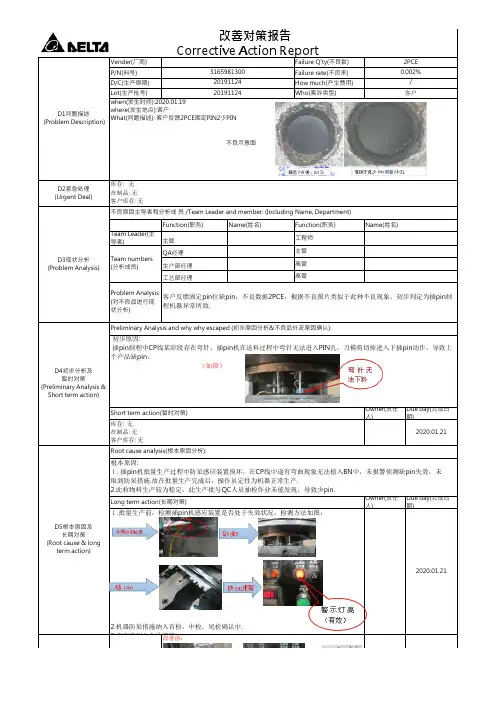

Vender(厂商)Failure Q'ty(不良数)P/N(料号)Failure rate(不良率)D/C(生产周期)How much(产生费用)Lot(生产批号)Who(客诉类型)D2紧急处理(Urgent Deal)Function(职务)Function(职务)Team Leader(主导者)主管工程师QA 经理主管生产部经理高管工艺部经理高管Owner(责任人)Due day(完成日期)Owner(责任人)Due day(完成日期)拿库存进行现在分析,发现有PIN漏铜如图所示2019.07.062019.07.06Due day(完成日期)2019.07.06P IN漏铜确认O K插PIN时咬花盘未回位,使咬花刀未完全张开,操作员未发现此现象,继续生产,导致不良品流出1.再次生产时换跟拉力大的拉簧,﹙如图所示﹚使咬花盘回位2.巡检、FQC 抽检时重点检查PIN 漏铜,杜绝不良品外流库存: 200 全检,把不良品报废处理在制品: 无客户库存: 450已交货产品换货处理D3现状分析(Problem Analysis)D4初步分析及暂时对策(PreliminaryAnalysis &Short term action)D5根本原因及长期对策(Root cause &long term action)D6效果确认 (Verification ofthe CA's effectiveness)Team numbers (分析成员)Problem Analysis(对不良品进行现状分析)Before(改善前) :After(改善后):Short term action(暂时对策)Root cause analysis(根本原因分析):Long term action(长期对策)Owner(责任人)//Preliminary Analysis and why why escaped (初步原因分析&不良品外流原因确认):插PIN 调机员在调机时未发现有PIN 漏铜现象,导致不良品流入下一工站Name(姓名)Name(姓名)/19.07.01/19.07.01进料库存: 200在制品: 无客户库存: 450不良原因主导者和分析成 员 /Team Leader and member: (Including Name, Department)when(发生时间):2019.07.03where(发生地点):cilent(区内)What(问题描述): 5169000200PIN漏铜,不良率 10%改善对策报告Corrective Action Report516900020010.00%D1问题描述 (Problem Description)E:\向辉ISO文件\三階文件\插针课\插针作业标准书.doc。

案例:以下通过一件发生在我们身边的平常小事,来说明8D报告(纠正/预防措施)的写法。

事由:出租屋内,一日早晨,小王正在水龙边洗脸准备上班,刚洗完脸,突然家中打来电话,于是把脸帕一挂就去屋内接电话,接完电话就去上班。

下午下班回家时发现家中全部被水淹了。

铺在地上的草席和被子全都漂在水中。

D1-成立改善小组:马上叫上住在隔壁的几个同事,组成事故处理小组。

小组成员:张三、李四、王五。

D2(第二步):问题描述王五家中被水淹,家中所有摆放在地上的物品都浸在水中(不良率100%)。

如:草席、被子和书本等。

D3(第三步)-暂时围堵行动(即应急对策或叫临时对策)1、马上与小组成员一起把家中的水设法排放出去。

负责人:张三2、立即把浸在水中的物品捞起并摊开到阳台去凉干。

负责人:李四D4(第四步)---根本原因分析:1、早晨洗完脸时,接听家中突然打来的电话,然后忘记关水,造成水淹小屋。

2、下水道出口太小,而且都采用网格式的盖子盖住。

昨天洗菜洗出来的小片烂蔬菜叶梗在网格上,致使下水道出水很慢,长时间积累后,大量未及时排放出去的水把小屋淹了。

分析人:王五审核:王五妻子D5(第五步)---制订永久对策(即长期对策)1、把下水道出口上的网格式盖子去掉,以便加大出水口,不会造成被水淹的情况。

责任人:王五预计完成时间:2007-10-12D6(第六步)---实施/确认PCA1、经过王五实际操作,把下水道出口加大后,小片蔬菜叶不会再梗在出水口处,堵住废水往外流。

并且即使把水龙头打开到最大,水仍能及时地从下水道出水口完全地流出去。

现确认此永久对策有效,并已经执行。

验证人:王五D7(第七步)---防止再发生(即采取预防措施)1、早晨上班出门前一定要检验水龙头是否关闭。

2、以后洗蔬菜时一定要把烂蔬菜叶丢到垃圾筐里,并且要把地面清理干净。

3、早晨洗脸时不能带电话在身上。

在洗脸过程中,就算电话铃响起也不能接。

直到洗漱完毕后才能接听手机。

责任人:王五预计完成时间:2007-**-**D8(第八步)---结案并祝贺:此问题已经完全处理清楚,可以结案(close)。