米勒焊机操作说明书

- 格式:docx

- 大小:117.38 KB

- 文档页数:10

THERMAL ARC FABRICATOR 400SEPARATE WITHVF4EC WIRE FEED UNIT AND400W SEPARATE WITH VF4EW WIRE FEED UNITPROCESSMIGFLUX COREDPart Number Rated Output @ Duty Cycle Output RangeDimensions (H x W x D) Net Weight 10-9316 400 430A @ 35% 40 – 450A 610 x 700 x 920 mm 140 kg 10-9318 400W400A @ 60%40 – 450A610 x 700 x 920 mm155 kgMORE POWER TO YOU TMFeaturesBenefits40 Fine Welding Voltage Control Settings Provides full range balanced outputTrigger Latching Facility Allows trigger to be released for continuous long weld runsOverload ProtectionThermostat with Warning LightIndicates temperature overload without damage to the machineWire Inch Control Allows non-live feeding of the wire for spool changesGas Purge Control Allows gas flow without wire feed to purge gas supply hose and gunThe Fabricator 400 and 400W (dedicated built in water cooler unit) are DC constant voltage power sources with fully enclosed, 4 roll drive, heavy duty wire feed units. The rugged 450A unit is designed for MIG (GMAW) and flux cored arc welding (FCAW) in all medium and heavy fabrication and heavy maintenance applications.The Fabricator 400 has a three position inductance facility to give excellent characteristics throughout the output range. The Fabricator 400 has a strong chassis and large wheels to assist with portability for inside and outside applications. The heavy duty VF4EC and VF4EW wire feed units are fully enclosed and fitted with a wheeling base as standard. The units are supplied as standard with the following features: linear adjustment of wire feed speed, a heavy duty 4 roll drive mechanism, digital voltmeter and ammeter, trigger latching, thermostat overload protection, gas purge, inch control, spot and stitch facility.Stitch TimerAllows operator to set on/off times to produce stitch style short runs Machine SpecificationsSpot TimerAllows trigger to time out to give uniform tacks3 Phase Power Supply 400v Wire Feed Unit Specifications Input Frequency 50 / 60 Hz Wire Speed Range 0.5 – 17 m/min Maximum Input Current 30 Amps Wire Feed Type4 roll drive Welding Arc Voltage Range 19.8 – 47.5v Maximum Power Consumption 22 KVAProtection Factor IP23 Wire Diameter Range Hard Wire 0.6-1.6mmSoft Wire 0.8-1.6mm Cored Wire 0.8-1.6mmInsulation Class H Dimensions (H x W x D) 450 x 210 x 670 mm Approvals EN60974-1-EN50199 Weight 18.5 kg2 Years WarrantyMIG (GMAW) TRANSFORMER RECTIFIER MACHINEOrdering InformationPart Number Fabricator 400 with VF4EC Wire Feed unit complete with feed rolls for 0.8mm – 1.6mm solid wire, gas hose, 5minterconnecting cable, earth cable and clamp, swivel mount, feeder trolley, mains cable and operating manual10-9316Fabricator 400 with VF4EC Wire Feed unit complete with feed rolls for 0.8mm – 1.6mm solid wire, gas hose,10m interconnecting cable, earth cable and clamp, swivel mount, feeder trolley, mains cable and operatingmanual10-9317Fabricator 400W with VF4EW Wire Feed unit and integrated built in water cooler complete with feed rolls for0.8mm – 1.6mm solid wire, gas hose, 10m interconnecting cable, earth cable and clamp, swivel mount, feedertrolley, mains cable and operating manual10-9318 Optional Accessories0.6/0.8mm Hard Wire V groove feed roll U458061.0/1.2mm Hard Wire V groove feed roll U45810 1.2/1.6mm Hard Wire V groove feed roll U45812 1.0/1.2mm Soft Wire U groove feed roll U45820 1.2/1.6mm Soft Wire U groove feed roll U45822 1.6/2.0mm Soft Wire U groove feed roll U45826 1.0/1.2mm Cored Wire V groove feed roll U45830 1.2/1.6mm Cored Wire V groove feed roll U45832 Please Note : The above wire feed unit is a four roll system, therefore you will require two of any of the above drive rolls to complete one setHollandTel: (31) 23 561 4182 Fax: (31) 23 565 5074Thermadyne UKChorley, EnglandTel : (44) 1257 261755Fax: (44) 1257 224800ItalyTel: (39) 029 *******Fax: (39) 029 *******GermanyTel: (49) 2663 915666Fax: (49) 2663 915667。

![米勒焊机操作说明书[整理版]](https://uimg.taocdn.com/e5c440f2a417866fb94a8e75.webp)

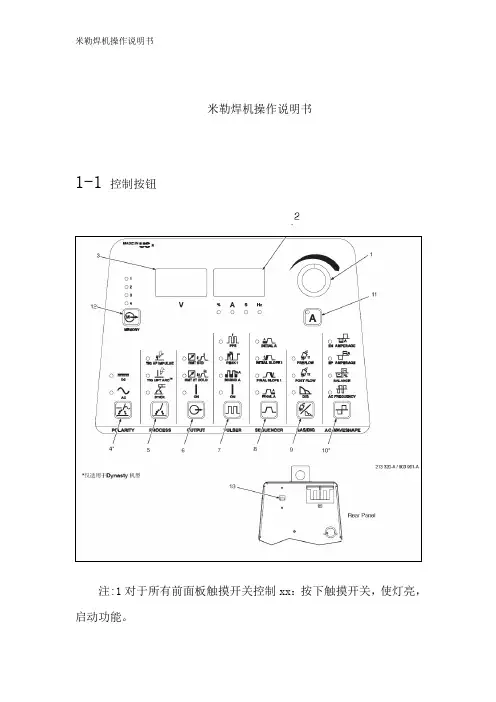

米勒焊机操作说明书[整理版]米勒焊机操作说明书1-1 控制按钮注:1对于所有前面板触摸开关控制钮:按下触摸开关,使灯亮,启动功能。

2铭牌上的绿标表示TIG功能,灰色表示正常的手弧焊功能。

1 编码控制钮2 电流及参数显示表3 电压表4 极性控制钮 5 工艺控制钮 6 输出控制钮 7 脉冲控制钮 8 工序控制钮 9 气体/电极力控制钮 10 交流波型控制钮 11 电流和点焊时间控制钮 12 存储按钮 13 电源开关1-2 编码控制钮1 编码控制钮利用本控制钮,与面板上的功能触摸开关一起设置该功能的参数值。

1-3 电流控制钮1 A 电流控制按钮2 编码控制钮3 电流表注:当脉冲功能起作用时,按下电流控制按钮,转动编码器,以设定焊接电流或峰值电流。

1-4 电流及参数显示表1 电流表电流表显示焊接时的电流值,也可以显示下列的预设参数:电流、时间、百分比或频率。

电流表正下方的LED等也变亮。

1-5 电压表1 电压表显示输出或开路电压。

如果输出关闭,电压表将显示(一)1-6 极性控制钮1 极性控制钮按下触摸按钮直道期望的LED等亮。

DC---对TIG 焊,设置机器到DCEN; 手弧焊设置到DCEP。

AC---对TIG和手弧焊使用交流。

1-7 工艺控制钮1 工艺控制钮触压触摸按钮,直到所选工艺的等变亮。

高频脉冲---是一种高频脉冲启弧方法,可用于交流或直流TIG焊接。

提弧启弧----是一种启弧方法,其中钨极必须与工件接触,该方法可用于交流和直流焊接。

1-8 高频启弧和高频TIG启动程序提升启弧:当提升启弧按钮灯亮,按下列步骤启弧,在焊接开始处把钨极触及工件,用焊枪触发开关、脚控器或手控器接通输出和保护气。

把钨极在工件上保持1-2秒,然后慢慢提升。

焊极提起后,电弧生成。

在钨极触及工件前不存在正常的开路电压,仅在钨极和工件间存在较低的感应电压,直到钨极触及工件后才激发固态输出接触器,因此钨极不会出现过热、粘条或被污染。

美国米勒焊机说明注:主输入电流消耗不能超过50A耐用而轻便的手工电弧焊/TIG焊接电源,专为建造行业设计。

280A焊接电流输出,是手工电弧焊(最大焊条直径4.8mm)及管与板TIG焊的理想选择。

通过一个双位置的手动开关,可非常简便地在电压范围之间进行切换。

开关安装在后板上,使用在焊机架上的电压切换变得简单。

操作简便的工艺选择旋钮,自动进行对于E6010与E7018焊条的DIG设定,提供出色的手工电弧焊性能。

Lift-Arc™提升引弧TIG焊技术,不需使用高频。

Fan-On-Demand™冷却系统只在需要时工作,提高电源效率并减小噪音。

落地放置或固定在支架上。

可选的4台或8台焊机架,常用于建造或造船行业中的多工位应用场合。

包括电源开关在内的所有控制装置均安装在机器前面,便于操作。

焊接电流遥控通过机器前面的14针接口实现,允许使用标准的电流控制装置。

可选择Tweco接口或Dinse接口。

Dinse接口包括一套阳插头;Tweco接口不包括。

•手工电弧焊(SMAW)•TIG(GTAW)•CST280焊机架•RCC-14遥控器 #151 086•RCCS-14遥控器 #043 688•RFCS-14遥控器 #043 554•RFCS-14 HD遥控器 #194 744•RHC-14 遥控器 #129 340•TIG焊枪请向您的米勒设备供应商咨询其它米勒常用选项与配件注:①. 4台小型焊机,14台大焊机,共报买18台焊机。

②. 现在报买的小型电焊机就是上面的美国米勒焊机,型号为CTS280需要4台,标配遥控器及线,二次线插头及地线夹。

③.大焊机是山东奥太焊机,型号ZX7---400ST 供 14台,,必须配遥控器及线和二次线插头。

美国米勒电器焊机简介美国米勒电气制造有限公司于1929年在威斯康新成立,其初衷是只要使用米勒焊机,你的工作会变得随心所欲,得心应手。

经过几拾年发展,米勒焊机以其高标准的质量和价值在北美,欧洲以及世界各地占有大部分市场份额。

1993年,美国米勒电气有限公司通过“iso 9001”质量体系认证(美国第一家通过“iso 9001”的焊接设备制造商)。

同年,美国米勒加入“itw焊接产业集团”,成为百年历史,世界500强、纳斯达克上市公司。

2004年,itw集团在中国投资成立了北京米勒电气制造有限公司,为国内用户提供广泛的培训服务和售后支持,同时也生产部分气体保护焊机。

目前,米勒在国内设有华东、华北、华南、西北、西南以及油气办等机构,负责指导片区授权代理商的销售及售后服务工作。

米勒焊机设计出厂试验:米勒焊机经过70多年的发展,技术成熟,焊机质量稳定,专业性强。

各类型号的米勒焊机在推出市场前,要经过大量的厂内试验。

包括:耐久性试验、耐尘试验、淋雨试验、耐潮湿介质试验、耐温度急变试验、抗高频试验、抗波动试验、抗运输撞击试验、摔落试验、钓力试验、抗紫外线老化试验。

米勒焊机从美国出厂时算起一般保修3年。

每台焊机的具体保修内容可参照用户手册的具体规定。

米勒焊机的设计寿命:米勒焊机的设计寿命是15年,实际使用寿命可达20年以上。

这决定于你的使用工况。

美国米勒焊机暂载率与中国、日本、欧洲机型对比:暂载率是表示焊机的连续焊接能力。

美国米勒用10分钟的标准测试。

如焊机暂载率为:450a:100%时,表示焊接电流在不超过4 50a时可以连续焊接。

而焊机暂载率为:450a:60%时,焊接电流在450a时每10分钟可连续焊接6分钟,休息4分钟。

中国、日本及欧洲均采用5分钟的标准测试,因此,美国米勒焊机的暂载率远远高于日本、中国及欧洲标准。

米勒焊机专利技术:米勒焊机熔敷金属控制技术(RMD:Regulated metal deposition)米勒焊机rmd技术是由软件控制的,对短路过渡作出精确控制的一种技术。

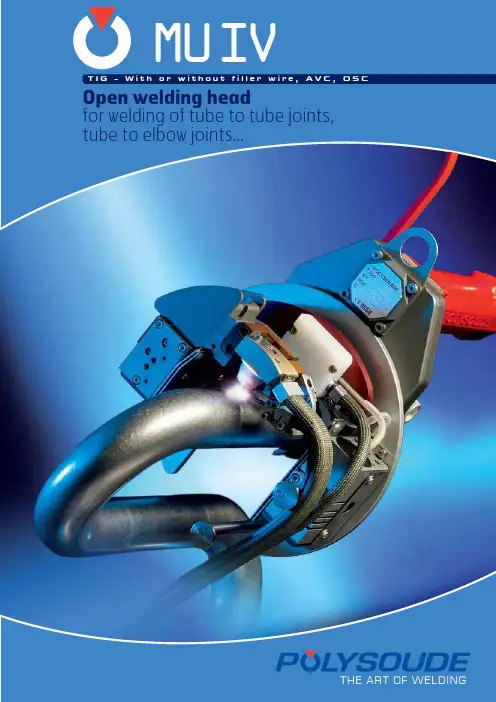

Open welding headfor welding of tube to tube joints,tube to elbow joints…THE ART OF WELDINGMU IV with AVC/OSCMU IV with integrated wire feederAdvantagesP roductivity increase of more than one third E asy to useC hallenging applications, even with delicate materials, can be weldedQ uick to set-up according to the workload making variations in production capacity trouble freeP recision engineered assemblies for a lifetime of trouble-free service Resulting from 50 years’ experience in mastering welding technologiesP S 164-2160 A, “all inclusive”,portable, single-phase power supplyA s s o c i a t e d P o w e r S o u r c e sGeneral characteristicsW i r e f e e d e r sOn-board wire feeder for 1.5 kg spool or external POL YFIL wire feeder for 15 kg spool with wire accessoires• P – Chuck clamping system;f ull range adjustable for frequent O.D. change Two interchangeable clamping systems (C and P):• C – C lamping shells per O.D., for precise and strongclamping, for heavy duty production, with water cooling for preheated tubesClosed loopregulation to ensure precise, constant or pulsed welding speedEncoder for positionbased control of the welding programPrecise and constant torch rotation by means of planetary driveMotorized Arc Voltage Control (AVC) and Torch Oscillation Control (OSC) for multi-pass welding of medium and heavy wall tubes2-axis wire adjustmentClosed loop water cooledwelding torchWelding torch with ceramic nozzle and gas lens for laminar gas protectionMechanical sensor for a constant distance between electrode and workpieceP 4170 A, “modular”,portable, programming by PC or touch screen, single-phase power supplyPolyfil seriesExternal portable wire feeders with spool protectionP 6300 A, “all applications”,programming by PC or touch screen, with Arc Voltage Control (AVC) and Torch Oscillation Control (OSC), three-phase power supplyDrive motor with angle gearbox for reduced axial clearanceMU IV for use with external wire feederA range of modular standard welding heads, perfectly adapted to your needsMU IVOpen welding headfor welding of tube to tube joints, tube to elbow joints…“As working conditions are betterthan in manual welding, a weldingoperator accomplishes onaverage 30% more welds per day.“Adapted for all your applications!Ø ACa> A/2B C / Cb DET echnical specificationsOptions and accessories•O n board wire feeder for 1.5kg spool or external POLYFIL wire feeder for 15kg spool with wire accessories• C lamp shells (C-clamping system) for all tube and pipe O.D.’s • E xtension cable (15m)• D ual welding head switch box• C ompact shipping case for transport andstorage• T ungsten electrodes, pre-sharpened and pre-cutCable length: 9mP – Chuck clamping system C – Shell clamping system NA = Non Applicable ✹ = reducedType Dimensions in mmP -c l a m p i n g - a d j u s t a b l e f o r t h e e n t i r e O .D . r a n g eMU IV CW Ømin./Ømax.Double clamping systemrecommended Min. O.D / Max. O.D.Ø A (mm)B (mm)C (mm)D (mm)E (mm)MU IV 8/38 CW P NA 1261659672MU IV 14/38 CW P ✹NA 961259672MU IV 19/80 CW P NA 17216597103MU IV 25/115 CW P NA 215165101148MU IV 25/128 CW P NA 24016599173MU IV 76/195 CW P NA 41030,514158,5208MU IV 114/275 CW PNA 50030,514172,5276C -c l a m p i n g - o n e s h e l l p e r O .DMU IV 14/38 CW C Ø 14 à 381261657972MU IV 14/38 CW C ✹Ø 14 à 38961257974MU IV 30/58 CW C ✹Ø 30 à 581551258893MU IV 30/80 CW C Ø 30 à 8017216588103MU IV 50/115 CW C Ø 50 à 11521516592148MU IV 50/128 CW C Ø 50 à 128240165108173MU IV 76/195 CW C NA 41030,514178208MU IV 114/275 CW CNA50030,514178,5276P -c l a m p i n g - a d j u s t a b l e f o r t h e e n t i r e O .D . r a n g eMU IV AVC/OSC CWØmin./Ømax.Double clamping systemrecommended Min. O.D / Max. O.DØ A (mm)B (mm)Amplitud D (mm)E (mm)Ca (mm)Cb (mm)MU IV 8/38 AVC/OSC CW P NA 14223202015072MU IV 19/80 AVC/OSC CW P NA 200162020136103MU IV 42/115 AVC/OSC CW P NA 235162020139148MU IV 42/128 AVC/OSC CW P NA 340162030134173MU IV 76/195 AVC/OSC CW P NA 410162030165208MU IV 114/275 AVC/OSC CW P NA 530162030179276S C -c l a m p i n g - o n e s h e l l p e r O .D .MU IV 14/38 AVC/OSC CW CØ 8 à 3814223202013072MU IV 14/38 AVC/OSC CW C ✹Ø 14 à 3813235,5202013074MU IV 30/51 AVC/OSC CW C ✹Ø 30 à 5114535,5202014294MU IV 30/64 AVC/OSC CW C ✹Ø 30 à 6415835,5202014294MU IV 30/80 AVC/OSC CW C Ø 30 à 80200162020126103MU IV 50/115 AVC/OSC CW C NA 235162*********MU IV 50/128 AVC/OSC CW C Ø 50 à 128340162030143173MU IV 76/195 AVC/OSC CW C NA 410162030185208MU IV 114/275 AVC/OSC CW CNA530162030184276POLYSOUDE S.A.S.+33 (0) 2 40 68 11 00******************SOUTH KOREACHEMIKO CO Ltd+82 (0) 2 567 5336****************POLYSOUDE IBERIA OFFICE+34 609 154 683*************************CO. INDUSTRI+45 (0) 39 56 06 76************************ SWITZERLAND POLYSOUDE (SWITZERLAND) Inc. +41 (0) 43 243 50 80********************TAIWAN R.O.C.FIRST ELITE ENT. CO. Ltd+886 (0) 287 97 88 99*******************.net THAILAND POLYSOUDE S.A.S.+33 (0) 2 40 68 11 00******************POLYSOUDE S.A.S.+33 (0) 2 40 68 11 00****************** UNITED ARAB EMIRATES POLYSOUDE S.A.S.+33 (0) 2 40 68 11 00****************** UKRAINE POLYSOUDE RUSSIA+7 (0) 495 564 86 81***************UNITED STATESASTRO ARC POLYSOUDE Inc. +1 661 702 01 41****************** VENEZUELAENRIVA C.A.+58 (0) 412 34 82 602****************T h i s d o c u m e n t i s n o t c o n t r a c t u a l. T y p o g r a p h i c a l e r r o r s & o m i s s i o n s e x。

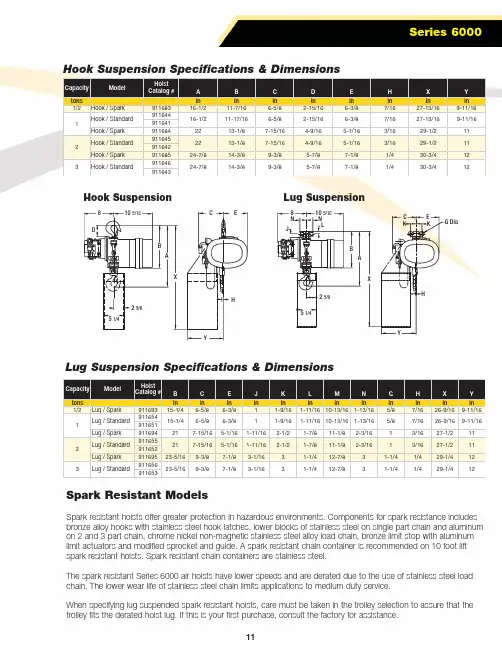

Series 6000HC E G DiaKKYXA B 2 5/8LN N 8J5 1/410 5/16ECHYXA B 2 5/88 5 1/410 5/16D11tons in in in in in in in in 1/2Hook / Spark 91168316-1/211-7/166-5/82-15/166-3/87/1627-13/169-11/16911644911641Hook / Spark9116842213-1/87-15/164-9/165-1/163/1629-1/211911645911642Hook / Spark 91168524-7/814-3/89-3/85-7/87-1/81/430-3/412911646911643H X Y Capacity Hoist Catalog #Model1D E B A C 13-1/87-15/164-9/165-1/166-5/82-15/166-3/816-1/222Hook / Standard23Hook / Standard Hook / Standard 11-17/167/1624-7/814-3/89-3/85-7/87-1/827-13/163/1629-1/21/430-3/49-11/161112tons in in in in in in in in in in in in 1/2Lug / Spark 91169315-1/46-5/86-3/811-9/161-11/1610-13/161-13/165/87/1626-9/169-11/16911654911651Lug / Spark911694217-15/165-1/161-11/162-1/21-7/811-1/82-3/1613/1627-1/211911655911652Lug / Spark 91169523-5/169-3/87-1/83-1/1631-1/412-7/831-1/41/429-1/412911656911653H X Y 11/429-1/4123/1627-1/2117/1626-9/169-11/1631-1/423-5/169-3/812-7/87-1/83-1/1631-1/41217-15/161-7/85-1/161-11/162-1/211-1/8G N 1-13/165/82-3/16Lug / Standard 23Lug / Standard Lug / Standard15-1/46-5/86-3/811-9/161-11/1610-13/16J K L M E B C Capacity Hoist Catalog #ModelLug Suspension Specifications & DimensionsHook Suspension Specifications & DimensionsHook SuspensionLug SuspensionSpark Resistant ModelsSpark resistant hoists offer greater protection in hazardous environments. Components for spark resistance includes bronze alloy hooks with stainless steel hook latches, lower blocks of stainless steel on single part chain and aluminum on 2 and 3 part chain, chrome nickel non-magnetic stainless steel alloy load chain, bronze limit stop with aluminum limit actuators and modified sprocket and guide. A spark resistant chain container is recommended on 10 foot lift spark resistant hoists. Spark resistant chain containers are stainless steel.The spark resistant Series 6000 air hoists have lower speeds and are derated due to the use of stainless steel load chain. The lower wear life of stainless steel chain limits applications to medium duty service.When specifying lug suspended spark resistant hoists, care must be taken in the trolley selection to assure that the trolley fits the derated hoist lug. If this is your first purchase, consult the factory for assistance.。

米勒PipePro300操作手册北京华盛海天科技发展有限公司制定: 闫磊版本: 130315一.常用操作术语●Pro-pulse --- 使用恒流的脉冲焊接法通过对峰值电流和基值电流的恒压控制进行操作。

自适应反应受峰值电流和最小电流控制。

优点是弧长较短,熔池控制水平更高,对焊嘴至工件的波动的容忍度更大,噪声较低,无电弧漂移,可提高在焊趾处填充焊缝的速度和沉积,并对装配不良和间隙有更高的承受能力。

●调节器 --- 用于改变或设定参数和功能的控制旋钮。

●电流 --- 指示焊接时的平均安培数和焊接结束时的 3 秒保持值。

●电弧调节值 --- 用于表示在脉冲焊程序中电长的调节量。

提高电弧调节值可增加实际弧长。

同样,减少电弧调节值可缩短弧长。

在熔化极保护焊(MIG)程序中,用电压值调节代替电弧调节值。

●电弧控制 --- 按下该按钮可在 MIG 模式中设定电感,或在脉冲焊、Pro-pulse 焊和 RMD-Pro焊中使电弧更锐利。

该按钮也可在手工电弧焊模式中设定电弧吹力。

●弧长 --- 焊丝末端至工件的距离。

●弧坑 --- 允许设定电弧端的电压值/电弧调节值、送丝速度和时间值(仅在“有电弧和有模拟输入”模式或“有电弧和无模拟输入”模式时有效)。

这些值可以由带文件管理/WaveWriter 软件的 PDA 来改变。

●气体类型 --- 选择应使用的保护气体。

●电感 --- 在短路 GMAW 焊中增加电感(而其它参数不变)将会减少每秒短路过渡的数目和增加电弧存在的时间。

增加电弧存在时间可提高焊接熔池的“流度”。

●熔化极保护焊 --- CV 焊法,单独设定电压和送丝速度。

●焊接方法 --- 对下列焊法所进行的选择:熔化极保护焊、脉冲焊、Pro-pulse 焊、RMD-Pro 焊、手工电弧焊、碳弧焊、药芯焊 (FCAW) 和提升引弧钨极氩弧焊。

●焊接方法设置 --- 输入程序的选择步骤。

●程序 --- 可提供八个有效的通道,用于选择各种焊接方法、焊丝类型和参数。

米勒焊机操作说明书1-1控制按钮注:1对于所有前面板触摸开关控制xx:按下触摸开关,使灯亮,启动功能。

2铭牌上的绿标表示TIG功能,灰色表示正常的手弧焊功能。

1 编码控制xx2 电流及参数显示表3 电压表4 极性控制xx5 工艺控制xx6 输出控制xx7 脉冲控制xx8 工序控制xx9 气体/电极力控制xx 10 交流波型控制xx 11 电流和点焊时间控制xx 12 存储按xx 13 电源开关1-2 编码控制xx1-3 电流控制xx1 A 电流控制按xx2 编码控制xx3 电流表注:当脉冲功能起作用时,按下电流控制按钮,转动编码器,以设定焊接电流或峰值电流。

1-4 电流及参数显示表1-5 电压表1-6 极性控制xx1-7 工艺控制xx提升启弧:当提升启弧按钮灯亮,按下列步骤启弧,在焊接开始处把钨极触及工件,用焊枪触发开关、脚控器或手控器接通输出和保护气。

把钨极在工件上保持1-2秒,然后慢慢提升。

焊极提起后,电弧生成。

在钨极触及工件前不存在正常的开路电压,仅在钨极和工件间存在较低的感应电压,直到钨极触及工件后才激发固态输出接触器,因此钨极不会出现过热、粘条或被污染。

应用:当不允许使用高频启弧或要取代划擦启弧时。

提升启弧用于DCEN或AC TIG 工艺。

高频启弧当高频启弧按钮灯亮,按下列步骤启弧,输出接通后,打开高频帮助启弧,启弧完成后关闭高频,断弧再次帮助重新启弧。

应用:当需要非接触启弧时,高频启弧用于DCEN GTAG工艺。

1-9 输出控制xx1 输出控制按钮按下按钮,直到希望参数的LED灯亮。

标准远控---应用:与脚踏或手控电流控制器一起使用远控触发。

注:脚控或手控远控电流控制器连接后,初始电流、起始坡升、终止坡降、及终止电流由远控器控制。

如果使用开/关型触发开关,它必须是一个维持开关,所有的程序功能有效,必须由操作者设定。

远控2T保持---应用:长距离焊接时,使用远控触发保持(2T)。

如果脚控或手控电流控制器连接到底电源上,仅触发输入有效。

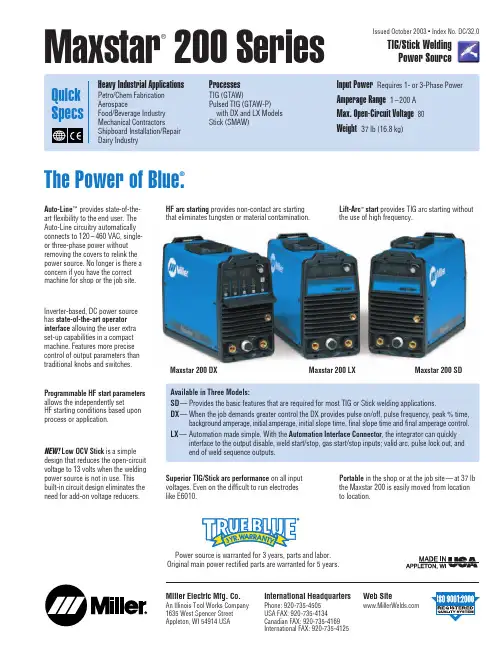

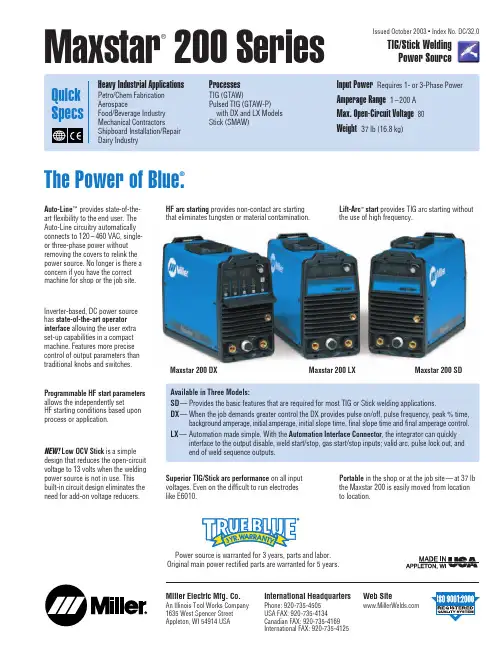

Miller Electric Mfg. Co. An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USAWeb Site International HeadquartersPhone: 920-735-4505USA FAX: 920-735-4134Canadian FAX: 920-735-4169International FAX: 920-735-4125Maxstar®200 Series TIG/Stick WeldingPower SourceIssued October 2003 • Index No. DC/32.0Auto-Line™provides state-of-the-art flexibility to the end user. TheAuto-Line circuitry automaticallyconnects to 120–460 VAC, single-or three-phase power withoutremoving the covers to relink thepower source. No longer is there aconcern if you have the correctmachine for shop or the job site.The Power of Blue®.Available in Three Models:SD—Provides the basic features that are required for most TIG or Stick welding applications.DX—When the job demands greater control the DX provides pulse on/off, pulse frequency, peak % time,background amperage, initial amperage,initial slope time, final slope time and final amperage control.LX—Automation made simple. With the Automation Interface Connector, the integrator can quicklyinterface to the output disable, weld start/stop, gas start/stop inputs; valid arc, pulse lock out, andend of weld sequence outputs.Portable in the shop or at the job site—at 37 lbthe Maxstar 200 is easily moved from locationto location.Superior TIG/Stick arc performance on all inputvoltages. Even on the difficult to run electrodeslike E6010.Inverter-based, DC power sourcehas state-of-the-art operatorinterface allowing the user extraset-up capabilities in a compactmachine. Features more precisecontrol of output parameters thantraditional knobs and switches.HF arc starting provides non-contact arc startingthat eliminates tungsten or material contamination.Lift-Arc™start provides TIG arc starting withoutthe use of high frequency.Programmable HF start parametersallows the independently setHF starting conditions based uponprocess or application.NEW!Low OCV Stick is a simpledesign that reduces the open-circuitvoltage to 13 volts when the weldingpower source is not in use. Thisbuilt-in circuit design eliminates theneed for add-on voltage reducers.Maxstar 200 DX Maxstar 200 LX Maxstar 200 SDPower source is warranted for 3 years, parts and labor.Original main power rectified parts are warranted for 5 years.2Control PanelCSA approval.Models with CE specifications are available and manufactured according to the Standards IEC-974-1 and EN-60974-1.*Indicates idle draw. **Sense voltage for Stick and Lift-Arc TIG.B.Initial Time (s)0.0–25 (LX only)C.Initial Amperage (A)1–200D.Initial Slope Time (s)0.0–25E.Weld Amperage (A)1–200G.Background Amperage (%)0–100H.Peak Percent Time (%)5–95I.Final Slope Time (s)0.0–25 J.Final Amperage (A)1–200L.Postflow Time (s) 0–0.50M.Dig (%)0–1003Performance DataAMPERES*115 VAC INPUTV O L T S0204060801001201400501001502002501401201006080402000 50 100 150 200 250AMPERES*OTHER INPUT VOLTAGESV O L T S*Amperage setting must be reduced toobtain currents less than highlighted data point.STICK MAX.TIG MAX.STICK/TIG MIN.DIG MAX.102030405060708090100% DUTY CYCLEDUTY CYCLE CHART250200150100500O U T P U T A M P E R E SIncluded AccessoriesNon-CE SD/DX Models Include:(2) International-style connectors 35/50(1) DA-917F torch adapter tointernational-style connector (#194 720)Non-CE LX Model Includes:(2) International-style connectors 35/50(1) 14-pin amphenol with clamp (1) 10-pin amphenol with clamp (1) 5/8 in - 18 gas fittingCE SD/DX Models Include:(2) International-style connectors 35/50(1) 14-pin amphenol with clamp (1) 5/8 in - 18 gas fitting (1) 3/8 in BSPP gas fittingOrdering InformationPower Source and Options Stock No.Description Qty.Price Maxstar®200 SD#903 701Basic controls for TIG/Stick, 120–460 VAC#903 768Basic controls for TIG/Stick, 120–460 VAC with CEMaxstar®200 DX#903 701-01-1Full-feature controls for TIG/Stick, 120–460 VAC#903 768-01-1Full-feature controls for TIG/Stick, 120–460 VAC with CEMaxstar®200 LX#903 701-01-2Full-feature controls with the required automation connections, 120–460 VACTIG AccessoriesTIG Torch Adapters#194 720DA-917F#190 219DA-1820L#194 724DA-26RContractor Kits#195 055150 A TIG/Stick with RCCS-14 fingertip control#195 054150 A TIG/Stick with RFCS-14 HD foot controlDiamondback™TIG Torches See Diamondback TIG Torch Selector GuideConsumables/Tungsten See Parts GuideGas Cylinder/Hose and FittingsRemote ControlsRFCS-14 HD#194 744Heavy-duty foot controlRCCS-14#043 688North/south fingertip controlRCC-14#151 086Side-to-side fingertip controlRMLS-14#129 337Momentary/maintained rocker controlRMS-14#187 208Momentary rubber dome switchExtension CordsCoolant SystemsCoolmate™3 #043 007115 VAC#043 007-01-2115 VAC with CE#043 008230 VAC#043 008-01-2230 VAC with CECoolmate™V3#043 009115 VAC#043 009-01-2115 VAC, 50/60 Hz with CECoolmate™4#042 288115 VAC#042 288-01-5115 VAC with CELow-Conductivity Coolant#043 810International-Style ConnectorsInternational-Style Connector Kit #042 418Dinse, (1) male plug-50 mmExtension Kit for International-Style#042 419Dinse, (1) plug and (1)receptacle-50 mmInternational/Tweco®Adapter #042 465 A one-piece adapter with International-style male plugInternational/Cam-Lok Adapter #042 466 A one-piece adapter with International-style male plugDate:Total Quoted Price:Distributed by:Litho in USA。

Miller Electric Mfg. Co. An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USAWeb Site International HeadquartersPhone: 920-735-4505USA FAX: 920-735-4134Canadian FAX: 920-735-4169International FAX: 920-735-4125Maxstar®200 Series TIG/Stick WeldingPower SourceIssued October 2003 • Index No. DC/32.0Auto-Line™provides state-of-the-art flexibility to the end user. TheAuto-Line circuitry automaticallyconnects to 120–460 VAC, single-or three-phase power withoutremoving the covers to relink thepower source. No longer is there aconcern if you have the correctmachine for shop or the job site.The Power of Blue®.Available in Three Models:SD—Provides the basic features that are required for most TIG or Stick welding applications.DX—When the job demands greater control the DX provides pulse on/off, pulse frequency, peak % time,background amperage, initial amperage,initial slope time, final slope time and final amperage control.LX—Automation made simple. With the Automation Interface Connector, the integrator can quicklyinterface to the output disable, weld start/stop, gas start/stop inputs; valid arc, pulse lock out, andend of weld sequence outputs.Portable in the shop or at the job site—at 37 lbthe Maxstar 200 is easily moved from locationto location.Superior TIG/Stick arc performance on all inputvoltages. Even on the difficult to run electrodeslike E6010.Inverter-based, DC power sourcehas state-of-the-art operatorinterface allowing the user extraset-up capabilities in a compactmachine. Features more precisecontrol of output parameters thantraditional knobs and switches.HF arc starting provides non-contact arc startingthat eliminates tungsten or material contamination.Lift-Arc™start provides TIG arc starting withoutthe use of high frequency.Programmable HF start parametersallows the independently setHF starting conditions based uponprocess or application.NEW!Low OCV Stick is a simpledesign that reduces the open-circuitvoltage to 13 volts when the weldingpower source is not in use. Thisbuilt-in circuit design eliminates theneed for add-on voltage reducers.Maxstar 200 DX Maxstar 200 LX Maxstar 200 SDPower source is warranted for 3 years, parts and labor.Original main power rectified parts are warranted for 5 years.2Control PanelCSA approval.Models with CE specifications are available and manufactured according to the Standards IEC-974-1 and EN-60974-1.*Indicates idle draw. **Sense voltage for Stick and Lift-Arc TIG.B.Initial Time (s)0.0–25 (LX only)C.Initial Amperage (A)1–200D.Initial Slope Time (s)0.0–25E.Weld Amperage (A)1–200G.Background Amperage (%)0–100H.Peak Percent Time (%)5–95I.Final Slope Time (s)0.0–25 J.Final Amperage (A)1–200L.Postflow Time (s) 0–0.50M.Dig (%)0–1003Performance DataAMPERES*115 VAC INPUTV O L T S0204060801001201400501001502002501401201006080402000 50 100 150 200 250AMPERES*OTHER INPUT VOLTAGESV O L T S*Amperage setting must be reduced toobtain currents less than highlighted data point.STICK MAX.TIG MAX.STICK/TIG MIN.DIG MAX.102030405060708090100% DUTY CYCLEDUTY CYCLE CHART250200150100500O U T P U T A M P E R E SIncluded AccessoriesNon-CE SD/DX Models Include:(2) International-style connectors 35/50(1) DA-917F torch adapter tointernational-style connector (#194 720)Non-CE LX Model Includes:(2) International-style connectors 35/50(1) 14-pin amphenol with clamp (1) 10-pin amphenol with clamp (1) 5/8 in - 18 gas fittingCE SD/DX Models Include:(2) International-style connectors 35/50(1) 14-pin amphenol with clamp (1) 5/8 in - 18 gas fitting (1) 3/8 in BSPP gas fittingOrdering InformationPower Source and Options Stock No.Description Qty.Price Maxstar®200 SD#903 701Basic controls for TIG/Stick, 120–460 VAC#903 768Basic controls for TIG/Stick, 120–460 VAC with CEMaxstar®200 DX#903 701-01-1Full-feature controls for TIG/Stick, 120–460 VAC#903 768-01-1Full-feature controls for TIG/Stick, 120–460 VAC with CEMaxstar®200 LX#903 701-01-2Full-feature controls with the required automation connections, 120–460 VACTIG AccessoriesTIG Torch Adapters#194 720DA-917F#190 219DA-1820L#194 724DA-26RContractor Kits#195 055150 A TIG/Stick with RCCS-14 fingertip control#195 054150 A TIG/Stick with RFCS-14 HD foot controlDiamondback™TIG Torches See Diamondback TIG Torch Selector GuideConsumables/Tungsten See Parts GuideGas Cylinder/Hose and FittingsRemote ControlsRFCS-14 HD#194 744Heavy-duty foot controlRCCS-14#043 688North/south fingertip controlRCC-14#151 086Side-to-side fingertip controlRMLS-14#129 337Momentary/maintained rocker controlRMS-14#187 208Momentary rubber dome switchExtension CordsCoolant SystemsCoolmate™3 #043 007115 VAC#043 007-01-2115 VAC with CE#043 008230 VAC#043 008-01-2230 VAC with CECoolmate™V3#043 009115 VAC#043 009-01-2115 VAC, 50/60 Hz with CECoolmate™4#042 288115 VAC#042 288-01-5115 VAC with CELow-Conductivity Coolant#043 810International-Style ConnectorsInternational-Style Connector Kit #042 418Dinse, (1) male plug-50 mmExtension Kit for International-Style#042 419Dinse, (1) plug and (1)receptacle-50 mmInternational/Tweco®Adapter #042 465 A one-piece adapter with International-style male plugInternational/Cam-Lok Adapter #042 466 A one-piece adapter with International-style male plugDate:Total Quoted Price:Distributed by:Litho in USA。

米勒焊机操作说明书文稿归稿存档编号:[KKUY-KKIO69-OTM243-OLUI129-G00I-FDQS58-米勒焊机操作说明书1-1控制按钮注:1对于所有前面板触摸开关控制钮:按下触摸开关,使灯亮,启动功能。

2铭牌上的绿标表示TIG功能,灰色表示正常的手弧焊功能。

1 编码控制钮2 电流及参数显示表3 电压表4 极性控制钮5 工艺控制钮6 输出控制钮7 脉冲控制钮8 工序控制钮9 气体/电极力控制钮 10 交流波型控制钮 11 电流和点焊时间控制钮 12 存储按钮 13 电源开关1-2 编码控制钮1-3 电流控制钮1 A 电流控制按钮2 编码控制钮3 电流表注:当脉冲功能起作用时,按下电流控制按钮,转动编码器,以设定焊接电流或峰值电流。

1-4 电流及参数显示表1-5 电压表1-6 极性控制钮1-7 工艺控制钮1-8 高频启弧和高频TIG启动程序提升启弧:当提升启弧按钮灯亮,按下列步骤启弧,在焊接开始处把钨极触及工件,用焊枪触发开关、脚控器或手控器接通输出和保护气。

把钨极在工件上保持1-2秒,然后慢慢提升。

焊极提起后,电弧生成。

在钨极触及工件前不存在正常的开路电压,仅在钨极和工件间存在较低的感应电压,直到钨极触及工件后才激发固态输出接触器,因此钨极不会出现过热、粘条或被污染。

应用:当不允许使用高频启弧或要取代划擦启弧时。

提升启弧用于DCEN或AC TIG 工艺。

高频启弧当高频启弧按钮灯亮,按下列步骤启弧,输出接通后,打开高频帮助启弧,启弧完成后关闭高频,断弧再次帮助重新启弧。

应用:当需要非接触启弧时,高频启弧用于DCEN GTAG工艺。

1-9 输出控制钮1 输出控制按钮按下按钮,直到希望参数的LED灯亮。

标准远控---应用:与脚踏或手控电流控制器一起使用远控触发。

注:脚控或手控远控电流控制器连接后,初始电流、起始坡升、终止坡降、及终止电流由远控器控制。

如果使用开/关型触发开关,它必须是一个维持开关,所有的程序功能有效,必须由操作者设定。

美国米勒焊机说明注:主输入电流消耗不能超过50A耐用而轻便的手工电弧焊/TIG焊接电源,专为建造行业设计。

280A焊接电流输出,是手工电弧焊(最大焊条直径4.8mm)及管与板TIG焊的理想选择。

通过一个双位置的手动开关,可非常简便地在电压范围之间进行切换。

开关安装在后板上,使用在焊机架上的电压切换变得简单。

操作简便的工艺选择旋钮,自动进行对于E6010与E7018焊条的DIG设定,提供出色的手工电弧焊性能。

Lift-Arc™提升引弧TIG焊技术,不需使用高频。

Fan-On-Demand™冷却系统只在需要时工作,提高电源效率并减小噪音。

落地放置或固定在支架上。

可选的4台或8台焊机架,常用于建造或造船行业中的多工位应用场合。

包括电源开关在内的所有控制装置均安装在机器前面,便于操作。

焊接电流遥控通过机器前面的14针接口实现,允许使用标准的电流控制装置。

可选择Tweco接口或Dinse接口。

Dinse接口包括一套阳插头;Tweco接口不包括。

•手工电弧焊(SMAW)•TIG(GTAW)•CST280焊机架•RCC-14遥控器 #151 086•RCCS-14遥控器 #043 688•RFCS-14遥控器 #043 554•RFCS-14 HD遥控器 #194 744•RHC-14 遥控器 #129 340•TIG焊枪请向您的米勒设备供应商咨询其它米勒常用选项与配件注:①. 4台小型焊机,14台大焊机,共报买18台焊机。

②. 现在报买的小型电焊机就是上面的美国米勒焊机,型号为CTS280需要4台,标配遥控器及线,二次线插头及地线夹。

③.大焊机是山东奥太焊机,型号ZX7---400ST 供 14台,,必须配遥控器及线和二次线插头。

米勒焊机操作说明书1-1控制按钮注:1对于所有前面板触摸开关控制钮:按下触摸开关,使灯亮,启动功能。

2铭牌上的绿标表示TIG功能,灰色表示正常的手弧焊功能。

1编码控制钮2电流及参数显示表3电压表4极性控制钮5工艺控制钮6输出控制钮7脉冲控制钮8工序控制钮9气体/电极力控制钮10交流波型控制钮11电流和点焊时间控制钮12存储按钮13电源开关1-2编码控制钮1-3电流控制钮1A电流控制按钮2编码控制钮3电流表注:当脉冲功能起作用时,按下电流控制按钮,转动编码器,以设定焊接电流或峰值电流。

1-4电流及参数显示表1-5电压表1-6极性控制钮1-7工艺控制钮1-8高频启弧和高频TIG启动程序提升启弧:当提升启弧按钮灯亮,按下列步骤启弧,在焊接开始处把钨极触及工件,用焊枪触发开关、脚控器或手控器接通输出和保护气。

把钨极在工件上保持1-2秒,然后慢慢提升。

焊极提起后,电弧生成。

在钨极触及工件前不存在正常的开路电压,仅在钨极和工件间存在较低的感应电压,直到钨极触及工件后才激发固态输出接触器,因此钨极不会出现过热、粘条或被污染。

应用:当不允许使用高频启弧或要取代划擦启弧时。

提升启弧用于DCEN或ACTIG工艺。

高频启弧当高频启弧按钮灯亮,按下列步骤启弧,输出接通后,打开高频帮助启弧,启弧完成后关闭高频,断弧再次帮助重新启弧。

应用:当需要非接触启弧时,高频启弧用于DCENGTAG工艺。

1-9输出控制钮1输出控制按钮按下按钮,直到希望参数的LED灯亮。

标准远控---应用:与脚踏或手控电流控制器一起使用远控触发。

注:脚控或手控远控电流控制器连接后,初始电流、起始坡升、终止坡降、及终止电流由远控器控制。

如果使用开/关型触发开关,它必须是一个维持开关,所有的程序功能有效,必须由操作者设定。

远控2T保持---应用:长距离焊接时,使用远控触发保持(2T)。

如果脚控或手控电流控制器连接到底电源上,仅触发输入有效。

注:本开关的功能可以设置为3T、4T、微逻辑或点焊控制。

Maxstar ®200 SeriesTIG/Stick Welding Power SourceIssued July 2009 • Index No. DC/32.0The Power of Blue ®.Miller Electric Mfg. Co.An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USAWeb SiteInternational HeadquartersPhone: 920-735-4505USA FAX: 920-735-4134Canadian FAX: 920-735-4169International FAX: 920-735-4125Power source is warranted for 3 years, parts and labor.Maxstar 200 DXFingertip CompletePackageMaxstar 200 SD Models:Maxstar ®200 SDMaxstar ®200 DX (Advanced features, see pg. 3)Maxstar ®200 LX (Automation connection and features)NEW!Maxstar ®200 DX TIGRunner ®(Advanced features, water cooler and cart)NEW!Maxstar ®200 DX Foot Pedal orFingertip Complete (Complete Advanced Water Cooled System)See pg. 5 for complete list of included items.Allows for any input voltagehookup (115–460 V) with no manual linking, providing convenience in any job setting. Ideal solution for dirty or unreliable power.Fan-On-Demand ™power source cooling system operates only when needed,reducing noise, energy use and the amount of contaminates pulled through the machine.NEW!Complete Package — One stock number provides all the necessary items required for a water-cooled TIG welding system. See pg. 5 for packages.Lift-Arc ™starting provides x-ray clean welds without the use of high frequency.NEW!Blue Lightning ™—High Frequency Arc Starter for non-contact arc initiation.More consistent arc starts compared to traditional HF arc starters.Greater reliability and no maintenance on solid state components. Preset parameters for tungsten sizes from .020 –1/8 inch provide optimized starting for applications from thick to micro thin material. For unique applications, custom settings are programmable.DC TIG FeaturesExceptionally smooth and precise arc for welding exotic materials.Stick Features (DC)Tailored arc control (DIG) allows the arc characteristic to be changed for specific applications and electrodes. Smooth running 7018 or stiffer, more penetrating 6010. Hot Start ™adaptive control provides positive arc starts without sticking.*Indicates idle draw. **Sense voltage for Stick and Lift-Arc TIG.CSA approval.All CE models conform to the applicable parts of the IEC 60974 series of standards. Performance Data23Control Panel2.Voltmeter Display3.Process/TIG: HF Impulse, Lift Arc Arc Starting STICK: Adaptive Hot Start4.Output ControlStandard Remote,2T Trigger Hold, Output ON5.Encoder Control6.Amperage Control7.Adjust Postflow 0.0–50 Seconds DIG 0–100%8.Sequencer Control Initial Amps 1–200 A Initial Slope 0.0–25.0 Seconds Final Slope 0.0–25.0 Seconds Final Amps 1–200 A 9.Pulser ControlPulses per Second DC: 0.1–500 PPS Peak Time 5–95%Background Amps 5–95%Additional Setup Parameter Values Preprogrammed Starts.040 –1/8 in Tungsten Programmable Starts Amperage 5–200 A Time 1–200 Milliseconds Ramp Time 0–250 Milliseconds Minimum Amperage 1–20 AAdditional Triggers 3T, 4T, Mini Logic,4T Momentary Spot/Timer 0.1–25.0 Seconds OCV Low OCV, Normal OCV Stick Stuck Check On/OffLockouts Four levels Arc Timer0.0–9999 Hours and 0–59 Min Cycle Counter0–999,999 CyclesMaxstar 200 SDMaxstar 200 DX/LXAvailable in Three Models:SD —Provides the basic features that are required for most TIG or Stick welding applications.DX —When the job demands greater control the DX provides pulse on/off, pulse frequency,peak % time, background amperage, initial amperage,initial slope time, final slope time and final amperage control.LX —Automation made simple. With the Automation Interface Connector , the integrator canquickly interface to the output disable, weld start/stop, gas start/stop inputs; valid arc,pulse lock out, and end of weld sequence outputs.LX Additional Features:Initial start time 0.0–25.0 Seconds Weld cycle time 0.0–999 Seconds Final current time0.0–25.0 Seconds10-Pin Remote Connection Features:•Weld cycle start/stop •Gas start/stop•Final slope output signal •Pulse output signal •Valid arc output signalPulse TIG Controls45Packages(Dinse 50) connectors, (1) air-cooled TIGtorch adapter (#195 378)Note: See page 6 for recommended Contractor Torch Kit(Auto-Line ™120–460 VAC)Completely assembled.Package includes:Maxstar®200 DX (#903 701-01-1)Coolmate ™1, 120 VAC (#300 360) (2) international (Dinse 50) connectors 1 gallon of pre-mixed, low conductivity Coolant (#043 810)single cylinder cart with cable and torch holders. Easy to release and remove welder from cart for even more portability.Convenient tray for consumable storage and filler rod holders.Notes: TIG Torch Adapter must be ordered separately.See page 6 for recommended 250 A Water-Cooled Torch Kit (#300 185)The Coolmate 1 requires a separate source for electricity. The Maxstar 200 does not contain auxiliary power.Maxstar ®200 DX #907 354 (CE ROHS)(Auto-Line ™120–460 VAC)Adjustable shoulder strap, 10 ft (3 m)primary power cord, (2) international (Dinse 50) connectors, (1) air-cooled TIG torch adapter (#195 378)Note: See page 6 for recommend Contractor Torch KitAdjustable shoulder strap, 10 ft (3 m)primary power cord, (2) international (Dinse 50) connectors, (1) 14-pinreceptacle with mating plug, (1) 10-pin receptacle with mating plug(Auto-Line ™120–460 VAC)Maxstar ®200 DX Fingertip Complete #951 138 (CSA)(Auto-Line ™120–460 VAC)Completely assembled.Package includes:Maxstar ®200 DX TIGRunner ®(#903 701-01-1)Coolmate ™1, 120 VAC (#300 360) (2) international (Dinse 50) connectors 1 gallon of pre-mixed, low conductivity Coolant (#043 810)single cylinder cart with cable and torch holders. Easy to release and remove welder from cart for even more portability.Convenient tray for consumable storage and filler rod holders.Remote Foot Pedal (#194 744) or Fingertip Control (#043 688)250 A Water-Cooled Torch Kit and Accessories (#300 185) See pg. 7 for more details.Note: The Coolmate 1 requires a separate source for electricity. The Maxstar 200 does not contain auxiliary power.Maxstar 200 DX Foot PedalComplete Package6Running Gear2-Wheel Trolley Cart #300 480Easy to maneuver two-wheel cart features:single-cylinder rack, chain for cylinder,straps (quick and easy to detach and carry machine), cable holders, torch holder,storage area, and filler rod storage area.Works with Dynasty ®or Maxstar ®200 and Coolmate ™1.Contact you local distributor for filler material holders.Universal Carrying Cart and Cylinder Rack #042 934Holds power source, and gas cylinder up to 56 in (142.2 cm) high mea s ur i ng 6 to 9 in (15.2 to 22.8 cm) in dia m eter.Coolmate ™1#300 360 120 VAC 60 Hz CSA #300 360-00-1 120 VAC 60 Hz CE #300 459 240 VAC 50/60 Hz CSA #300 459-00-1 240 VAC 50/60 Hz CE 1-gallon water cooler designed for 200 amp portable welders. Features include: Fin-and-Tube heat exchanger, back-lit power switch, external filter, polyethylene tank and coolant level sight gauge.250 A Water-Cooled Torch Kit #300 18525 ft (7.6 m) Weldcraft ®WP20 torch Torch cable coverAK4C torch accessory kit includes shielding cups, collets, collet bodies and 2% cerium tungsten electrodes (1/16, 3/32 and 1/8 in)Smith ®regulator/flowmeter HM2051A-58012 ft (3.7 m) rubber gas hose (regulator to machine)Water-cooled Dinse torch adapter 15 ft (4.6 m) 1/0 weld lead with clamp (work or ground lead) and Dinse connector TIG Coolant #043 810 Sold inmultiples of 4.Pre-mixed low-conductivity Miller coolant containsethylene glycoland deionized water to protect from freezing and boiling -37˚ to 227˚F (-38˚ to 108˚C). 1-gallon plastic recyclable bottles.Water-Cooled Dinse #195 377Used to adapt WP20, WP18, and CS310 to dinse-style connector. Order from Miller Parts.Contractor Kits#195 054 Foot Pedal Kit #195 055 Fingertip KitRFCS-14HD foot or RCCS-14 fingertip control, protective carrying case, 150 Amp WP17 25 ft (7.6 m) TIG Torch withadapter, Smith ®flow gauge regulator and 12 ft (3.7 m) gas hose, AK2C Accessory Kit (.040, 1/16, and 3/32 in cerium tungsten,collets and cups), Stick electrode holder,200 Amp, 15 ft (4.6 m) #4 cable, and work clamp with 15 ft (4.6 m) #4 AWG cable.200 Amp Air-Cooled Torch#WP2612RM (12 ft)#WP2625RM (25 ft) Torch body gas valve models are availableNote: Adapter #195 379 required for WP26.Order from Miller Parts.Air-Cooled Torch Adapters#195 378WP17, WP9, WP50, WP23#195 379 WP26Order from Miller Parts.TIG Welding Gloves #227 813Small #227 815Large #227 814Medium #227 816X-Large Made from soft grain goatskin. Sewn with Kevlar ®thread.Order from Miller Parts.Genuine Miller Accessories#195 054 kit shown.7TungstenTungsten is 7 in length and available in pkgs of 10.Order from Miller Parts.2% Ceriated (orange) for AC/DC applications #WC040X7.040 in, 10–80 A #WC116X71/16 in, 70–150 A #WC332X73/32 in, 140–250 A #WC018X71/8 in, 225–400 A #WC532X75/32 in, 300–500 A1.5% Lanthanum (gold) for AC/DC applications #WL040X7.040 in, 10–80 A #WL116X71/16 in, 70–150 A #WL332X73/32 in, 140–250 A #WL018X71/8 in, 225–400 A #WL532X75/32 in, 300–500 AEducational MaterialGas Tungsten Arc (TIG) Welding Book #170 555To order, distributors can call the Miller Literature Distribution Center at 1-920-735-4356, or FAX 1-920-735-4011.Ron Covell TIG Welding Basics DVDTo order go to Remote Controls and SwitchesRCCS-14 Remote Contactor andCurrent Control #043 68814-pin plug North/south rotary-motion fingertip control fastens to TIG torch using two Velcro ®straps. Includes 26.5 ft (8 m) control cord.RFCS-14 HD Foot Control #194 744Maximum flexibility is accomplished with a reconfigurable cord that can exit the front, back or either side of the pedal. Foot pedal provides remote current and contactor control.Includes 20 ft (6 m) cord and 14-pin plug.RHC-14 Hand Control #129 340Miniature hand control for remote current and contactor control. Dimensions: 4 x 4 x 3-1/4 in (102 x 102 x 83 mm). Includes 20 ft (6 m) cord and 14-pin plug.RMLS-14 Switch #129 337Momentary- and maintained-contact rocker switch for contactor control. Push forward for maintained contact and backward for momentary contact. Includes 26.5 ft (8 m)cord and 14-pin plug.RMS-14 On/Off Control #187 208Momentary-contact switch for contactor control. Rubber-covered pushbutton dome switch ideal for repetitive on-offapplications. Includes 26.5 ft (8 m) cord and 14-pin plug.Extension Cords for 14-Pin Remote Controls #122 97325 ft (7.6 m)#122 97450 ft (15.2 m)#122 97575 ft (23 m)Genuine Miller Accessories (continued)Multi-Operator Rack4-Pack Rack (empty)#195 051Appropriate fuses required.Rugged enclosure provides a simple means for protecting and transporting multiple welding power sources for construction, power plant turn-arounds,and shipbuilding applications.Light-weight and small footprint for easy transportation. Low weight enables the use of elevators to move the rack.Top cover protects machines from falling debris.Lifting eye simplifies transportation using crane or overhead lifting device.Lift truck side and end fork pockets.One main disconnect box with fusedcircuit breaker switches for each mon output ground connection (for same polarity use only).4-Pack Rack Running Gear #195 114Large 5-inch diameter wheels enable the rack to be moved over grating anddriveway gravel.*Rack comes with 25 A fuses. Order appropriate fuses for primary voltageOrdering InformationEquipment and Options Stock No.Description Qty.Price Maxstar®200 SD#903 701Auto-Line™ 120–460 VAC, 50/60 Hz, CSA. 10 ft primary cordMaxstar®200 DX#903 701-01-1Auto-Line™ 120–460 VAC, 50/60 Hz, CSA. 10 ft primary cordMaxstar®200 DX International#907 354Auto-Line™ 120–460 VAC, 50/60 Hz, CE ROHS. 10 ft primary cord.Maxstar®200 LX#903 701-01-2Auto-Line™ 120–460 VAC, 50/60 Hz, CSA. 10 ft primary cordMaxstar®200 DX TIGRunner® #903 701-02-2Auto-Line™ 120–460 VAC, 50/60 Hz, CSA. 10 ft primary cordMaxstar®200 DX Foot Pedal Complete#951 137Auto-Line™ 120–460 VAC, 50/60 Hz, CSA. 10 ft primary cordMaxstar®200 DX Fingertip Complete#951 138Auto-Line™ 120–460 VAC, 50/60 Hz, CSA. 10 ft primary cordTIG Torch KitsWeldcraft®250 A Water-Cooled Torch Kit#300 185See page 6Contractor Kit Foot Pedal (Air-Cooled) #195 054See page 7Contractor Kit Fingertip (Air-Cooled)#195 055See page 7Consumables and Tungsten Distributor: See Miller Parts CatalogRemote ControlsRCCS-14#043 688North/south fingertip controlRFCS-14 HD#194 744Heavy-duty foot controlRHC-14#129 340Hand controlRMLS-14#129 337Momentary/maintained rocker switchRMS-14#187 208Momentary rubber dome switchExtension Cords#122 97325 ft (7.6 m)#122 97450 ft (15.2 m)#122 97575 ft (22.9 m)Accessories4-Pack Rack (empty) #195 051Order power source and fuses separately4-Pack Rack Running Gear #195 114(4) 5-in diameter wheels and bracketsFuses #199 795230 V, 30 A Individual fuse. 12 required for 4 Pack#220 514460 V, 15 A Individual fuse. 12 required for 4 Pack2-Wheel Trolley Cart #300 480See page 6Universal Carrying Cart and Cylinder Rack#042 934See page 6Coolmate™1#300 360120 VAC, 60 Hz, CSA. Requires coolant#300 360-00-1120 VAC, 60 Hz, CE. Requires coolant#300 459240 VAC, 50/60 Hz, CSA. Requires coolant#300 459-00-1240 VAC, 50/60 Hz, CE. Requires coolantTIG Coolant#043 810Sold in multiples of 4. 1-gallon plastic bottlesGas Tungsten Arc (TIG) Welding Book#170 555Order at /resources/tools/Ron Covell TIG Welding Basics DVD Order at /resources/tools/Water-Cooled Dinse#195 377Used to connect water-cooled torch to Dinse terminal machine.Order from Miller Parts For WP20, WP18 and SC310 (adapter included in Complete Package)Air-Cooled Dinse#195 378Used to connect WP17, WP9 and WP23 torch to Dinse terminal machineOrder from Miller Parts#195 379Used to connect WP26 torch to Dinse terminal machineDinse Connector 50 mm (1 male) #042 418Used to connect weld lead to Dinse terminal machineDinse Connector 50 mm (1 male, 1 female) #042 419Used to extend weld cablesTweco Terminal Adapter#042 465Male Dinse to female TwecoCam-Lok Terminal Adapter#042 466Male Dinse to female Cam-LokMiscellaneousStick ElectrodesWelding and Work CablesWelding Gloves and HelmetDate:Total Quoted Price:Distributed by:Litho in USA。

上海米勒焊机的操作方法

上海米勒焊机的操作方法如下:

1. 将焊机接入电源,并确保安全地接地。

2. 针对当前焊接任务的材料和焊接过程的需求,选择适当的焊接模式和参数设置。

3. 将工作件置于焊接夹具中,并按照需要进行对位、定位等操作。

4. 准备好所需焊接材料(如焊丝),并进行适当的处理(如除锈)。

5. 打开焊接枪开关,保持恰当的焊接姿势,进行焊接操作。

6. 进行多次焊接过程时,注意及时清理焊接点、清除氧化物和油污。

7. 焊接结束后,关闭焊接枪开关,清理工作区域,并断开电源。

8. 对焊机进行日常维护,按照需要更换损耗品,保证设备的稳定工作。

Dynasty ™300 SeriesTIG/Stick Welding Power SourceIssued February 2001 • Index No. AD/5.0Miller Electric Mfg. Co.An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USAWeb SiteInternational HeadquartersPhone: 920-735-4505USA FAX: 920-735-4134Canadian FAX: 920-735-4169International FAX: 920-735-4125SD:Provides the basic features that arerequired for most AC/DC TIG or Stick welding applications.DX:When the job demands greatercontrol the DX provides pulse on/off,pulse frequency, peak % time, back-ground amperage, initial amperage,initial slope time, final slope time and final amperage control.LX:Automation made simple. With theAutomation Interface Connector , the integrator can quickly interface to the output disable, weld start/stop, gas start/stop inputs; valid arc, pulse lock out, and end of weld sequence outputs.®Auto-Link ™provides connection to 230 V or 460 V single- or three-phase power without having to remove the covers and relink the power source.Inverter-based, AC/DC power source has state-of-the-art operator interface allowing the user extra set-up capabilities in a compact machine. Features more precise control of output parameters than traditional knobs and switches.Lift-Arc ™start for TIG arc starting without the use of high frequency.Superior arc performance even on difficult to run electrodes like E6010.HF start for non-contact arc starting that eliminates tungsten or material contamination.Advanced Squarewave arc for improved weldability on aluminum and magnesium using low power. Continuous high-frequency is NOT needed because of the advanced Squarewave arc, and extended balance control allows you to fine-tune the duration of the electrode negative portion of the cycle from 50 to 90%. This provides precise cleaning control and prolonged tungsten life.Power source is warranted for 3 years, parts and labor.Original main power rectified parts are warranted for 5 years.Dynasty 300 LXDynasty 300 DX TIGRunnerDynasty 300 SDProgrammable HF start parameters allows the operator to independently set HF starting conditions based upon process and memory selection.2Control Panels1.Voltmeter2.Ammeter3.Polarity Control4.Process Control5.Output Control6.Encoder Control7.Amperage Control8.AC Waveshape Control9.Adjust Control10.Sequencer Controls 11.Pulser ControlCertified by Canadian Standards Association to both Canadian and U.S. Standards.Conforms to European standards.Dynasty 300 SDDynasty 300 DX/LXB.Initial Time (s)0.0–25 (LX only)C.Initial Amperage (A)5–300D.Initial Slope Time (s)0.0–25E.Weld Amperage (A)5–300G.Balance Control (%EN)50–90H.Background Amperage (%)0–100I.Pulse Frequency (Hz)0.1–500J.Peak Percent Time (%)5–95L.Final Amperage (A)5–300M.Final Time (s)0.0–25 (LX only)N.Postflow Time (s)0.0–50O.Dig (%)0–100For Multivoltage UnitsFor Single-Voltage UnitsPerformance DataIncluded Accessories TIGRunner®PackagesNon-CE SD/DX Models Include:(1) DA1820L torch adapter(2) International-style connectors 35/50Non-CE LX Model Includes:(1) DA1820L torch adapter(2) International-style connectors 35/50 (1) 14-pin amphenol with clamp(1) 10-pin amphenol with clamp CE SD/DX Models Include:(2) International-style connectors 35/50(1) 14-pin amphenol with clamp(1) 5/8 in - 18 gas fittingCE LX Model Includes:(2) International-style connectors 35/50(1) 14-pin amphenol with clamp(1) 10-pin amphenol with clamp(1) 5/8 in - 18 gas fittingDynasty 300 SD w/TIGRunner #903 840Dynasty 300 DX w/TIGRunner #903 841Includes Dynasty 300 SD or DX, AuxiliaryPower, Coolmate™3, Deluxe Carrying Cartand Cylinder Rack, and Remote Foot Control(completely assembled).Dynasty 300 SD w/TIGRunner and Torch#903 840-01-1Dynasty 300 DX w/TIGRunner and Torch#903 841-01-1Includes Dynasty 300 SD or DX, AuxiliaryPower, Coolmate™3, Deluxe Carrying Cartand Cylinder Rack, and Remote Foot Control(completely assembled). Also a 25-ft250-Amp, Water-Cooled DB20M25RDiamondback Torch, Work Clamp,10-ft Gas Hose, Regulator/Flowmeter,Cable Cover, and an AK-4 Accessory Kit.3Genuine Miller Accessories4Universal Carrying Cart and Cylinder Rack Running Gear/Cylinder Rack #042 537Genuine Miller Accessories (Continued)56Note: All Dynasty power sources are equipped with International-style connectors for secondary connections. (Power source is shipped with two 50-mm male International-style plugs for use with #1 or #2 AWG size cable.)International-Style Connector Kit #042 41850 mmAccepts #1 or #2 AWG cable size. Required if male plugs shipped with power source must be replaced, if additional plugs are needed.Kit includes one International-style male plug which attaches to the work and/or weld cables and plugs into the International-style receptacles on the power source.Extension Kit for International-Style Cable Connectors#042 41950 mmAccepts #1 or #2 AWG size ed to adapt or extend weld and/or work cables. Kit includes one male International-style plug and one in-line female International-style receptacle.International/Tweco ®Adapter #042 465A one-piece adapter which has an International-style male plug (to powersource) on one end and a female Tweco receptacle (for weld cable connection) on other end.International/Cam-Lok Adapter #042 466A one-piece adapter which has an International-stylemale plug (to power source) on one end and a Cam-Lok receptacle (for weld cable connection) on other end.International-Style Connectors (Will accept Dinse™or other International connectors.)Coolant SystemsFor more information, see the Miller Coolant Systems literature sheet, Index No. AY/7.2.Coolmate ™3#043 007 115 VAC#043 007-01-2 115 VAC, CE #043 008 230 VAC#043 008-01-2 230 VAC, CEFor use with water-cooled torches rated up to 500 amps. Unique paddle-wheel indicator,external filter and easy-fill spout.Coolmate ™V3 #043 009115 VAC#043 009-01-2115 VAC, CEFor use with water-cooled torches rated up to 500 amps. Vertical design conveniently mounts to Miller cylinder rack in place of one cylinder.Coolmate ™4 #042 288115 VAC#042 288-01-5115 VAC, CEFor use with water-cooled torches rated up to 600 amps. Tough molded polyethylene case with carrying handle.Low-Conductivity Coolant #043 810Sold in multiples of four in 1-gallonrecyclable plastic bottles. Primarily used in TIG (high-frequency) applications, but can also be used in MIG systems where aluminum is not in the water path. Miller coolants contain a base of ethylene glycol and deionized water to protect against freezing to -37°F (-38°C) or boiling to 227°F (108°C). Also contains a compound that resists algae growth.Aluminum-Protecting Coolant #043 809Sold in multiples of four in 1-gallonrecyclable plastic bottles. Primarily used in MIG products, such as the water-cooled XR, which has an aluminum drive housing,or in any system where high frequency is not used. Miller coolants contain a base of ethylene glycol and deionized water to protect against freezing to -37°F (-38°C) or boiling to 227°F (108°C). Also contains a compound that resists algae growth.Genuine Miller Accessories (Continued)Coolmate 3Coolmate 4Coolmate V3Typical Installations7Ordering InformationEquipment and Options Stock No.Description Qty. Price Power SourceDynasty™300 SD#903 832Basic controls, 230/460 VAC, 50/60 Hz#903 834Basic controls, 400 VAC, 50/60 Hz, CE#903 832-01-1Basic controls w/115 V auxiliary power, 230/460 VAC, 50/60 Hz#903 834-01-1Basic controls w/115 V auxiliary power, 400 VAC, 50/60 Hz, CEDynasty™300 DX#903 832-01-2Full feature controls, 230/460 VAC, 50/60 Hz#903 834-01-2Full feature controls, 400 VAC, 50/60 Hz, CE#903 832-02-1Full feature controls w/115 V auxiliary power, 230/460 VAC, 50/60 Hz#903 834-02-1Full feature controls w/115 V auxiliary power, 400 VAC, 50/60 Hz, CEDynasty™300 LX w/Auxiliary Power#903 832-02-2Full feature controls w/115 V auxiliary power & required automation connections#903 834-02-2Full feature controls w/115 V aux. power & required automation connections, CEDynasty™300 SD w/TIGRunner™#903 840Basic controls w/TIGRunner package (see pg 3)Dynasty™300 SD w/TIGRunner™and Torch#903 840-01-1Basic controls w/TIGRunner & 250 A torch package (see pg 3)Dynasty™300 DX w/TIGRunner™#903 841Full feature controls w/TIGRunner package (see pg 3)Dynasty™300 DX w/TIGRunner™and Torch#903 841-01-1Full feature controls w/TIGRunner & 250 A torch package (see pg 3)TIG AccessoriesTIG Torch Adapters#194 720DA-917F#190 219DA-1820L#194 724DA-26RDiamondback™TIG Torches See Diamondback TIG Torch Selector GuideConsumables, Tungsten See Parts GuideGas Cylinder, Gas Hose and FittingsStick AccessoriesStick ElectrodesRemote ControlsRFCS-14 HD#194 744Heavy-duty foot controlRFCS-14#043 554Foot controlRCCS-14#043 688North/south fingertip controlRCC-14#151 086Side-to-side fingertip controlRMLS-14#129 337Momentary/maintained rocker controlRMS-14#187 208Momentary rubber dome switchCarts and RacksDeluxe Carrying Cart and Cylinder Rack#043 867Universal Carrying Cart and Cylinder Rack#042 934Running Gear/Cylinder Rack#042 537Inverter Rack#043 562Educational ResourcesGas Tungsten Arc (TIG) Welding Book#170 555TIG Fundamentals Welding CD#196 567Coolant SystemsCoolmate™3 #043 007115 VAC#043 007-01-2115 VAC, CE#043 008230 VAC#043 008-01-2230 VAC, CECoolmate™V3 #043 009115 VAC#043 009-01-2115 VAC, CECoolmate™4 #042 288115 VAC#042 288-01-5115 VAC, CEAluminum-Protecting Coolant#043 809Low-Conductivity Coolant#043 810Cooling System HosesInternational-Style ConnectorsInternational-Style Connector Kit #042 41850 mmExtension Kit for International-Style#042 41950 mmInternational/Tweco®Adapter #042 465 A one-piece adapter with International-style male plugInternational/Cam-Lok Adapter #042 466 A one-piece adapter with International-style male plugDate:Total Quoted Price:Distributed by:Litho in USA。

米勒焊机操作说明书文稿归稿存档编号:[KKUY-KKIO69-OTM243-OLUI129-G00I-FDQS58-

米勒焊机操作说明书

1-1控制按钮

注:1对于所有前面板触摸开关控制钮:按下触摸开关,使灯亮,启动功能。

2铭牌上的绿标表示TIG功能,灰色表示正常的手弧焊功能。

1 编码控制钮

2 电流及参数显示表

3 电压表

4 极性控制钮

5 工艺控制钮

6 输出控制钮

7 脉冲控制钮

8 工序控制钮

9 气体/电极力控制钮 10 交流波型控制钮 11 电流和点焊时间控制钮 12 存储按钮 13 电源开关

1-2 编码控制钮

1-3 电流控制钮

1 A 电流控制按钮

2 编码控制钮

3 电流表

注:当脉冲功能起作用时,按下电流控制按钮,转动编码器,以设定焊接电流或峰值电流。

1-4 电流及参数显示表

1-5 电压表

1-6 极性控制钮

1-7 工艺控制钮

1-8 高频启弧和高频TIG启动程序

提升启弧:当提升启弧按钮灯亮,按下列步骤启弧,

在焊接开始处把钨极触及工件,用焊枪触发开关、脚控器或手控器接通

输出和保护气。

把钨极在工件上保持1-2秒,然后慢慢提升。

焊极提起

后,电弧生成。

在钨极触及工件前不存在正常的开路电压,仅在钨极和工件间存在较低

的感应电压,直到钨极触及工件后才激发固态输出接触器,因此钨极不

会出现过热、粘条或被污染。

应用:当不允许使用高频启弧或要取代划擦启弧时。

提升启弧用于DCEN

或AC TIG 工艺。

高频启弧

当高频启弧按钮灯亮,按下列步骤启弧,

输出接通后,打开高频帮助启弧,启弧完成后关闭高频,断弧再次帮助重新启弧。

应用:当需要非接触启弧时,高频启弧用于DCEN GTAG工艺。

1-9 输出控制钮

1 输出控制按钮

按下按钮,直到希望参数的LED灯亮。

标准远控---应用:与脚踏或手控电流控制器一起使用远控触发。

注:脚控或手控远控电流控制器连接后,初始电流、起始坡升、终止坡降、及终止电流由远控器控制。

如果使用开/关型触发开关,它必须是一个维持开关,所有的程序功能有效,必须由操作者设定。

远控2T保持---应用:长距离焊接时,使用远控触发保持(2T)。

如果脚控或手控电流控制器连接到底电源上,仅触发输入有效。

注:本开关的功能可以设置为3T、4T、微逻辑或点焊控制。

开启---选定2秒钟后,输出将通电。

应用:手弧焊(SMAW)或不使用远控器的提升启弧时使用输出开启

2 开启LED 输出时开启LED灯闪蓝光。

1-10 脉冲控制按钮

1 脉冲控制按钮

选择TIG焊工艺时可以使用脉冲,控制钮可以在焊接时按下按钮开启脉冲。

开启(ON)---该LED灯亮,关闭脉冲时,按下、释放按钮开启(ON)LED 灯熄灭。

2编码控制钮(设定数值)

3电流表(显示数值)

PPS(每秒钟的脉冲或脉冲频率),用于确定焊缝的外观;

PEAK t:每个脉冲循环内可处于峰值电流水平部分的比例;

BKGND A(基值电流):利用基值电流设定脉冲谷部的焊接电流,它可以冷却焊接熔池,影响整个加热输入,基值电流为峰值电流的百分比。

注:峰值电流由电流控制钮设定,峰值电流是脉冲循环中允许的最大焊接电流,焊接穿透直接随峰值电流改变。

应用:脉冲是指焊接输出的升高部分由宽度、高度和频率控制,形成焊接输出脉冲,这些脉冲及其间的低电流水平(称作为基值电流)循环地加热和冷却焊接熔池,这种组合影响可以更好的控制穿透、焊缝宽度、、余高、咬边及热量输入。

1-11 工序控制按钮

1 工序控制钮

选择TIG工艺时有工序控制功能,但在标准远控模式下,脚控或手控电流远程控制器与远程插座连接后,此功能不起作用。

按下按钮直到期望参数的LED灯亮。

2 编码控制钮(设定参数)

3 电流表(显示数值)

INITIAL A(初始电流):使用控制钮选择不同于焊接电流的初始电流。

应用:初始电流可用于在熔敷填充材料前帮助预热材料或确保软启弧。

INITIAL t (启始时间)(仅适用于带自动化选项的机型):再次按下工序控制钮,旋转编码钮,设定开始焊接前需要的时间。

INITIAL slope t (初始坡升时间):利用控制钮设定从初始电流上升到焊接电流所需的时间,设定为零时,无该功能。

4电流控制钮

焊接时间(仅适用于带自动化选项的机型):按下电流开关按钮两次,设定需要的焊接时间。

FINAL slope t(终止坡降时间):利用控制钮设定从焊接电流到终止电流所需的时间。

设定为零时,无该功能。

应用:焊材易产生裂纹或为了消除焊后弧坑时,应该采用终止坡降。

FIANL A(终止电流):用于设定焊接电流下降之后的电流。

FINAL t(终止时间)(仅适用于带自动化选项的机型):再次按下工序控制按钮,旋转编码钮,设定终止电流时间。

1-12 气体/电弧力控制按钮

1 气体/电弧力控制按钮

按下控制按钮,直到选定功能的LED灯亮。

2编码控制钮(设定数值)

3电流表(显示数值)

预先送气:高频TIG工艺时,预先送气显示在控制面板上,利用控制钮设置启弧前气流的时间。

应用:预先送气用于清理焊接区域,帮助启弧。

滞后停气:TIG焊工艺时,利用控制钮设定焊接停止后气流的时间。

应用:滞后停气用于冷却钨极和焊缝,防止钨极和焊缝的氧化,如果钨极和焊缝的外观发黑,增加滞后停气时间。

电弧力控制:直流手弧焊工艺时。

利用控制钮设定电弧力控制量。

设置为零时,低弧压下的短路电流与正常的焊接电流相同。

设置数增加,低弧压下的短路电流也增加。

应用:电弧力控制有助于启弧,通过增加低弧压下的电流进行垂直焊或仰焊,减少焊接时的粘条。

清理功能:为了打开气阀,启动清理功能,按下并保持调节按钮一定时间,清理时间可以设定为1到50秒,缺省设置为零。

调整时,按住控制按钮的同时旋转编码控制钮,使用清理功能时,左边显示[pug],右边显示清理时间。

按下任何开关,清理将结束显示,但气流仍继续,直到达到预设的时间。

应用:清理功能用于清洁气管。

1-13交流波型控制钮

1 交流波型控制按钮

按下控制按钮直到期望功能的LED 灯亮起。

2 编码控制钮(设定数值)

3 电流表(显示数值)

平衡:交流平衡控制仅在交流TIG时起作用,用于设定极性处于焊极负的时间的百分比。

应用:焊接氧化物形成材料,如铝和镁时,过度的清理没有必要。

要形成好的焊缝,仅需沿着焊脚侵蚀2.5毫米的区域。

使用交流平衡控制侵蚀区域的宽度。

焊缝形式、设置、工艺变量和氧化物的厚度可能影响设定。

交流频率:交流频率控制仅在交流TIG时起作用,利用该控制设定交流频率。

应用:交流频率控制电弧宽度和方向。

频率减少,电变宽、更分散,不容易控制方向,频率增加,电弧变窄、更集中,方向控制更容易,随着交频率的增加,焊接速度可能增加。

EN电流:使用该控制选择焊极负时的电流值。

EP电流:使用该控制选择焊极正时的电流值。

EN电流和EP电流可以使操作者分别控制正负半个循环的电流。

EN和EP 之比为2:1或3:1是一个很好的起始点。

这样可以有清理作用,并向工件输送更多的能量,焊接速度更快,熔深更深。

4电流控制按钮

5平衡电流控制:设定EN电流、EP电流、平衡和频率下,改变平均电流,而保证EN电流和EP电流比不变,欲改变平均电流值,按下电流控制按钮,旋转编码控制按钮,改变的电流值显示在电流表上。

1-14 点焊时间控制

1 点焊时间显示表

2 电流控制按钮

3 编码控制钮

设置点焊参数:按下电流按钮(显示表A LED 灯亮),旋转编码钮设置点焊时间(0.1---25秒),缺省设置为1秒。

应用:为拼焊和薄板连接提供定时的焊接方式。

1-15 存储

1 存储(程序存储1-4)按钮

2 极性控制按钮(仅适用于Dynasty机型)

3 工艺控制按钮

创造、改变或恢复一个焊接参数程序时,执行如下操作:

首先,按下存储按钮,直到所选的程序存储位置处的LED灯亮。

其次,按下极性控制按钮,直到希望的极性AC或DC的LED灯亮。

第三,按下工艺按钮,直到选择的工艺—高频脉冲TIG、提升启弧TIG、或手弧的LED灯亮。

第四,改变或设置所有的参数。