原版奔驰凌特文件-sprinter_model_info

- 格式:pdf

- 大小:461.69 KB

- 文档页数:6

22-CHINA ·March奔驰C级插电混动车型C350eL 故障现象一辆2023年9月生产的2024款奔驰C 350e L ,搭载254 920型2.0T 发动机和95k W 永磁同步电机,VI N码为LE42061541L30****,行驶里程为2 025km,该车启动后,仪表台上出现“性能严重受限”的故障报警信息(图1)。

图1 故障车仪表台上的故障信息故障诊断与排除接车后进行功能检查,发现启动车辆后,故障车仪表台上出现“性能严重受限”的故障报警信息;挂入D挡上路行驶,发现动力明显不足。

连接诊断仪进行快速测试,在功率电子装置(SG-LE)控制单元N147中存储了多个故障码:P0CDB00-“电机A”位置传感器的电路3存在功能故障;P0C01FA-集成式启动电机A的电流值过高;P1CB400-端子30c的供电存在功能故障;P2D3C00-电机A在催化转换器加热过程中存在功能故障。

故障车型搭载了奔驰第四代插电混合动力系统,也是搭载该系统的首款车型。

奔驰第四代插电混合动力系统进一步优化,能耗表现进一步提升,综合油耗降至1.27L/100km。

另外,其105km的WLTC纯电续航里程,可以满足普通用户城市短途代步和通勤的需要。

2024款奔驰C350eL仪表显示奔驰C350eL车型的集成式混合动力驱动模块和模块化发动机共同构成了动感高效的插电式混合动力系统,各驱动部件如图2所示。

在其插电混动系统中,发动机最大功率150kW,峰值扭矩320N·m;电机最大功率95kW,峰值扭矩440N·m。

与发动机匹配的是9速自动变速器并可实现混合动力传动。

动力性能表现出色,0-100km/h加速时间仅为6.9s,并提供5种驾驶模式选择,以应对不同路况和驾驶需要。

1-高压动力电池;2-交流电充电器;3-直流电充电器;4-充电插口;5-功率电子装置;6-DC/DC 转换器;7-9G-TRONIC 自动变速器;8-发动机;9-前部电机。

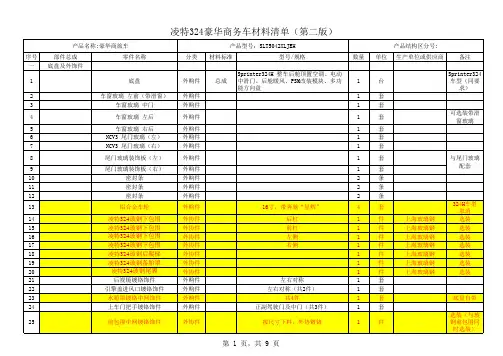

新凯奔驰凌特(斯宾特Sprinter324)房车版新凯奔驰凌特(斯宾特Sprinter324)房车版摘要: 新凯奔驰凌特324家庭版新凯奔驰凌特324家庭版房车的外形和普通的商务车看起来无二异,不知情的消费者以为是几十万的商务车,幸亏奔驰的Logo才证明了它的高档。

作为家庭版的奔驰房车,是摆脱城市高节奏压抑生活 ...新凯奔驰凌特324家庭版新凯奔驰凌特324家庭版房车的外形和普通的商务车看起来无二异,不知情的消费者以为是几十万的商务车,幸亏奔驰的Logo才证明了它的高档。

作为家庭版的奔驰房车,是摆脱城市高节奏压抑生活的首选方式而新凯凌特324家庭版的出现将家庭旅游的概念进行了一次成功的升华。

新凯奔驰凌特324家庭版房车华丽的外形下蕴涵的是睿智划分的温馨空间,以及宽敞的餐桌将旅途的美景与美食完美地结合在一起,从烹饪料理工作台到吧台酒柜,随时随地在天然自由的景致中与家人共享新鲜出炉的精美餐点,从冰箱中取出冰爽的饮料与水果,紧密整合的卫浴设施完全为你涤荡一天的疲倦,浑身放松地仰卧在舒适的大床上,小小的空间却蕴藏了渴望已久的无限自由。

奔驰凌特不是以驾驶为主的车型,所以驾驶室也没有太牛的功能,但无论是座椅的做工或中控台的设计仍不是一般商务车可比拟的,中间桃木的运用也很显华丽。

站在滑动门外,首先映入眼帘的便是两张看起来舒适感极强的电动按摩椅,按摩椅正前方便是32英寸高清液晶电视机,暖黄色的内饰气氛颇有居家风范,让人忍不住想快点进去看个究竟。

舒适的按摩椅撤了具备按摩解乏的功能外,还可以360度自由旋转,因此家庭版房车就是标志着自由选着座椅角度,或休息,或聊天等。

按摩椅的正上方并不是一个大天窗,而是一个夜景“满天星”灯饰,开灯后看,蓝色调灯光充满着梦幻和浪漫的情调。

从休息区向车后走,便到了房车主要构架去,这里卧室、卫生间、厨房俱在。

小小的空间容纳了各种道具,却没有拥挤的感觉,空间的艺术,在这里得到完美的展现。

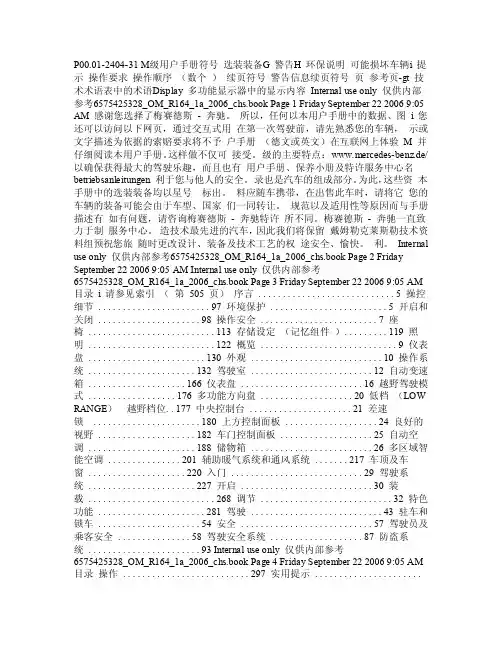

P00.01-2404-31 M级用户手册符号选装装备G 警告H 环保说明可能损坏车辆i 提示操作要求操作顺序(数个)续页符号警告信息续页符号页参考页-gt 技术术语表中的术语Display 多功能显示器中的显示内容Internal use only 仅供内部参考6575425328_OM_R164_1a_2006_chs.book Page 1 Friday September 22 2006 9:05 AM 感谢您选择了梅赛德斯- 奔驰。

所以,任何以本用户手册中的数据、图i 您还可以访问以下网页,通过交互式用在第一次驾驶前,请先熟悉您的车辆,示或文字描述为依据的索赔要求将不予户手册(德文或英文)在互联网上体验M 并仔细阅读本用户手册。

这样做不仅可接受。

级的主要特点:www.mercedes-benz.de/ 以确保获得最大的驾驶乐趣,而且也有用户手册、保养小册及特许服务中心名betriebsanleitungen 利于您与他人的安全。

录也是汽车的组成部分。

为此,这些资本手册中的选装装备均以星号标出。

料应随车携带,在出售此车时,请将它您的车辆的装备可能会由于车型、国家们一同转让。

规范以及适用性等原因而与手册描述有如有问题,请咨询梅赛德斯- 奔驰特许所不同。

梅赛德斯- 奔驰一直致力于制服务中心。

造技术最先进的汽车,因此我们将保留戴姆勒克莱斯勒技术资料组预祝您旅随时更改设计、装备及技术工艺的权途安全、愉快。

利。

Internal use only 仅供内部参考6575425328_OM_R164_1a_2006_chs.book Page 2 Friday September 22 2006 9:05 AM Internal use only 仅供内部参考6575425328_OM_R164_1a_2006_chs.book Page 3 Friday September 22 2006 9:05 AM 目录i 请参见索引(第505 页)序言. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 操控细节. . . . . . . . . . . . . . . . . . . . . . . 97 环境保护. . . . . . . . . . . . . . . . . . . . . . . . 5 开启和关闭. . . . . . . . . . . . . . . . . . . . . 98 操作安全. . . . . . . . . . . . . . . . . . . . . . . . 7 座椅. . . . . . . . . . . . . . . . . . . . . . . . . . 113 存储设定(记忆组件). . . . . . . . . 119 照明. . . . . . . . . . . . . . . . . . . . . . . . . . 122 概览. . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 仪表盘. . . . . . . . . . . . . . . . . . . . . . . . 130 外观. . . . . . . . . . . . . . . . . . . . . . . . . . . 10 操作系统. . . . . . . . . . . . . . . . . . . . . . 132 驾驶室. . . . . . . . . . . . . . . . . . . . . . . . . 12 自动变速箱. . . . . . . . . . . . . . . . . . . . 166 仪表盘. . . . . . . . . . . . . . . . . . . . . . . . . 16 越野驾驶模式. . . . . . . . . . . . . . . . . . 176 多功能方向盘. . . . . . . . . . . . . . . . . . . 20 低档(LOW RANGE)越野档位. . 177 中央控制台. . . . . . . . . . . . . . . . . . . . . 21 差速锁. . . . . . . . . . . . . . . . . . . . . . 180 上方控制面板. . . . . . . . . . . . . . . . . . . 24 良好的视野. . . . . . . . . . . . . . . . . . . . 182 车门控制面板. . . . . . . . . . . . . . . . . . . 25 自动空调. . . . . . . . . . . . . . . . . . . . . . 188 储物箱. . . . . . . . . . . . . . . . . . . . . . . . . 26 多区域智能空调. . . . . . . . . . . . . . . 201 辅助暖气系统和通风系统. . . . . . . 217 车顶及车窗. . . . . . . . . . . . . . . . . . . . 220 入门. . . . . . . . . . . . . . . . . . . . . . . . . . . 29 驾驶系统. . . . . . . . . . . . . . . . . . . . . . 227 开启. . . . . . . . . . . . . . . . . . . . . . . . . . . 30 装载. . . . . . . . . . . . . . . . . . . . . . . . . . 268 调节. . . . . . . . . . . . . . . . . . . . . . . . . . . 32 特色功能. . . . . . . . . . . . . . . . . . . . . . 281 驾驶. . . . . . . . . . . . . . . . . . . . . . . . . . . 43 驻车和锁车. . . . . . . . . . . . . . . . . . . . . 54 安全. . . . . . . . . . . . . . . . . . . . . . . . . . . 57 驾驶员及乘客安全. . . . . . . . . . . . . . . 58 驾驶安全系统. . . . . . . . . . . . . . . . . . . 87 防盗系统. . . . . . . . . . . . . . . . . . . . . . . 93 Internal use only 仅供内部参考6575425328_OM_R164_1a_2006_chs.book Page 4 Friday September 22 2006 9:05 AM 目录操作. . . . . . . . . . . . . . . . . . . . . . . . . . 297 实用提示. . . . . . . . . . . . . . . . . . . . . .353 技术数据. . . . . . . . . . . . . . . . . . . . . . 477 首1500 公里行车. . . . . . . . . . . . . . 298 到哪里能找到...?. . . . . . . . . . . . . . 354 梅赛德斯- 奔驰原厂零部件. . . . . . . 478 加油. . . . . . . . . . . . . . . . . . . . . . . . . . 299 显示信息. . . . . . . . . . . . . . . . . . . . . . 360 车辆电子设备. . . . . . . . . . . . . . . . . . 479 发动机机室. . . . . . . . . . . . . . . . . . . . 304 故障查找. . . . . . . . . . . . . . . . . . . . . . 392 车辆识别牌. . . . . . . . . . . . . . . . . . . . 481 车轮及轮胎. . . . . . . . . . . . . . . . . . . . 311 紧急锁止/ 解锁. . . . . . . . . . . . . . . . 423 发动机. . . . . . . . . . . . . . . . . . . . . . . . 483 冬季驾驶. . . . . . . . . . . . . . . . . . . . . . 319 复位触发的头枕. . . . . . . . . . . . . . . 427 动力性能. . . . . . . . . . . . . . . . . . . . . . 484 驾驶提示. . . . . . . . . . . . . . . . . . . . . . 322 更换电池. . . . . . . . . . . . . . . . . . . . . . 428 车轮及轮胎. . . . . . . . . . . . . . . . . . . . 485 海外驾驶. . . . . . . . . . . . . . . . . . . . . . 324 更换灯泡. . . . . . . . . . . . . . . . . . . . . . 430 车辆尺寸. . . . . . . . . . . . . . . . . . . . . . 491 在崎岖不平地区行驶. . . . . . . . . . . . 325 更换雨刮器叶片. . . . . . . . . . . . . . . . 442 挂车拖挂装置. . . . . . . . . . . . . . . . . 493 挂车牵引. . . . . . . . . . . . . . . . . . . . 335 泄气的轮胎. . . . . . . . . . . . . . . . . . . . 445 车辆重量. . . . . . . . . . . . . . . . . . . . . . 495 保养/ 维修. . . . . . . . . . . . . . . . . . . . 343 燃油系统放气. . . . . . . . . . . . . . . . . . 459 工作液及容积. . . . . . . . . . . . . . . . . . 496 护理. . . . . . . . . . . . . . . . . . . . . . . . . . 345 蓄电池. . . . . . . . . . . . . . . . . . . . . . . . 460 跨接启动. . . . . . . . . . . . . . . . . . . . . . 467 牵引. . . . . . . . . . . . . . . . . . . . . . . . . . 469 索引. . . . . . . . . . . . . . . . . . . . . . . . . . 505 保险丝. . . . . . . . . . . . . . . . . . . . . . . . 474 Internal use only 仅供内部参考6575425328_OM_R164_1a_2006_chs.book Page 5 Friday September 22 2006 9:05 AM 序言环境保护环境保护因此,请谨记:个人驾驶方式工作状态当启动发动机时,不要踩下油门踏H 环保说明避免短途驾驶,那会增加燃油消耗板。

新凯奔驰凌特(斯宾特Sprinter324)旅行版新凯奔驰凌特(斯宾特Sprinter324)旅行版摘要: 新凯奔驰凌特不但是专为商务人士开发的车型,而且是享受生活的保姆车。

新凯奔驰凌特sprinter324房车尊贵大气的外观、澎湃卓越的动力以及坚实可靠的性能,淋漓尽致的再现了奔驰汽车对于完美车型的不懈追求。

然而,奔 ...凌特324 (Sprinter 324)旅行版新凯奔驰凌特不但是专为商务人士开发的车型,而且是享受生活的保姆车。

新凯奔驰凌特sprinter324房车尊贵大气的外观、澎湃卓越的动力以及坚实可靠的性能,淋漓尽致的再现了奔驰汽车对于完美车型的不懈追求。

然而,奔驰凌特与其它商务车最大不同之处就是后面可以根据车主的意愿进行改造,只要你能想到的,奔驰厂家也能为你做到。

凌特324 Sprinter 324旅行版房车改写中国轻客市场原有的竞争格局,成为这一市场的新标杆。

奔驰凌特324作为中国轻客市场上的首个高端品牌,继承了奔驰房车品牌的血统,拥有卓越的安全性和品质,并且创新性地采用了航空舱式的设计理念,带来舒适的乘坐体验。

大型商务车凌特打破了以往轻客市场上缺乏高端品牌的尴尬,无可争议地成为陆上空客A380。

奔驰凌特外形看起来与厢式货车一样,但是仔细看各样细节自然又可以与奔驰设计风格文明发言起来。

车头巨大的三叉星标致很醒目,虽然车身外形并不像S600那样优雅,但是正是由于三叉星标致的存在,然任何人也不敢小看了他。

奔驰凌特的车头灯圆润饱满,与车头线条完美统一。

车侧两个宽大的后视镜让人不尽量想到了大客车,后视镜上集成的转向灯又为黑色的平淡的后视镜增添了一抹亮色。

从外观上就很容易看出奔驰凌特在同级别车型中的主要优势,高耸的车顶为车内空间提供了良好的保证。

由于不需要考虑太多操控层面的问题,凌特的车轮尺寸相对于整个车身来说是非常小的,不过也正是这样,车厢获得了更多可是应用的空间。

新凯奔驰凌特324 Sprinter 324旅行版驾驶室在所有商务车系中斯宾特的驾驶室算得上是简朴,整个驾驶室只有驾驶席有一张真皮座椅,副驾驶的位置被一个大容量冰箱所取代,相当朴素的仪表与奔驰三叉星的标识显得有些不符,简朴是奔驰斯宾特324驾驶室是留给人最大印象。

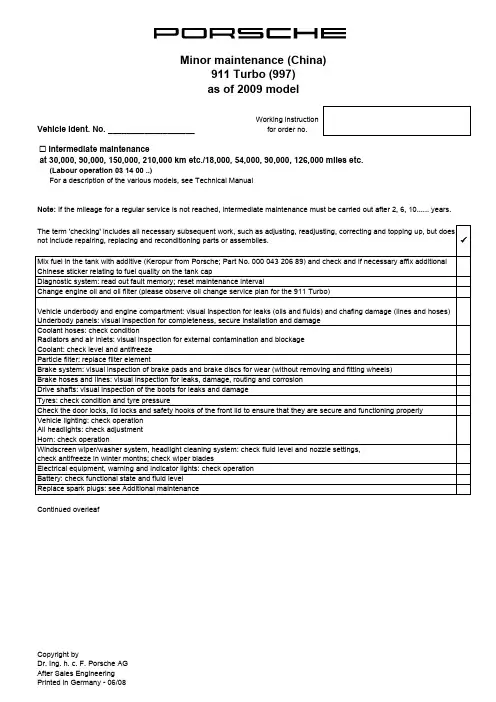

Vehicle Ident. No. ___________________Working instructionfor order no. Intermediate maintenanceat 30,000, 90,000, 150,000, 210,000 km etc./18,000, 54,000, 90,000, 126,000 miles etc.(Labour operation 03 14 00 ..)For a description of the various models, see Technical ManualContinued overleafCopyright byDr. Ing. h. c. F. Porsche AGAfter Sales EngineeringPrinted in Germany - 06/08Particle filter: replace filter elementMinor maintenance (China)Note: If the mileage for a regular service is not reached, intermediate maintenance must be carried out after 2, 6, 10...... years.911 Turbo (997)as of 2009 modelThe term 'checking' includes all necessary subsequent work, such as adjusting, readjusting, correcting and topping up, but doesnot include repairing, replacing and reconditioning parts or assemblies.Replace spark plugs: see Additional maintenanceTyres: check condition and tyre pressureVehicle lighting: check operation All headlights: check adjustmentHorn: check operation9Windscreen wiper/washer system, headlight cleaning system: check fluid level and nozzle settings,check antifreeze in winter months; check wiper bladesChange engine oil and oil filter (please observe oil change service plan for the 911 Turbo)Drive shafts: visual inspection of the boots for leaks and damageMix fuel in the tank with additive (Keropur from Porsche; Part No. 000 043 206 89) and check and if necessary affix additional Chinese sticker relating to fuel quality on the tank capBattery: check functional state and fluid levelCheck the door locks, lid locks and safety hooks of the front lid to ensure that they are secure and functioning properly Diagnostic system: read out fault memory; reset maintenance intervalElectrical equipment, warning and indicator lights: check operationBrake system: visual inspection of brake pads and brake discs for wear (without removing and fitting wheels)Vehicle underbody and engine compartment: visual inspection for leaks (oils and fluids) and chafing damage (lines and hoses)Underbody panels: visual inspection for completeness, secure installation and damageCoolant hoses: check conditionRadiators and air inlets: visual inspection for external contamination and blockageCoolant: check level and antifreezeBrake hoses and lines: visual inspection for leaks, damage, routing and corrosionVehicle Ident. No. _______________________Working instruction for order no. Additional maintenance for spark plugs(Labour operation 03 81 00 ..)9 Additional maintenance for drive belt (Labour operation 03 60 00 ..)(Labour operation 03 70 00 ..)Additional maintenance every 90,000 km/54,000 miles or every 6 years (Labour operation 03 83 00 ..)Additional maintenance every 180,000 km/108,000 miles or every 12 years (Labour operation 03 88 00 ..) Every 2 years Every 4 years After 4 years, then every 2 years After 4, 8, 10 years, then every 2 yearsSignature (fitter): _______________________________Test drive:Oils, fluids: visual inspection for leaksSignature (final check): _________________________Copyright byDr. Ing. h. c. F. Porsche AGAfter Sales EngineeringPrinted in Germany - 06/08Porsche Centre as of 2009 modelAncillary unit mounts and suspension: visual inspection of all rubber mountings and boots for damageChange brake fluidCheck tyre pressure monitoring system batteryAutomatic transmission: change oil in final driveFile condition report for long-life guaranteeCheck drive beltCheck drive belt Check drive beltIntermediate maintenance (China)every 30,000 km/18,000 miles or every 2 years every 20,000 km/12,000 miles or every 4 years 911 Turbo Remote control, front seats, footbrake and handbrake (also actuation travel), engine, clutch, steering, transmission, ParkAssist, cruise control, PSM switch, PASM switch, Sport switch, heating, air conditioning and instruments: check operation Automatic transmission: change ATF and ATF filterReplace tyre sealantAll-wheel final drive: change oilManual transmission: change oilReplace drive beltevery 60,000 km/36,000 miles or every 4 years every 150,000 km/90,000 miles or every 10 years every 240,000 km/144,000 miles or every 16 years Additional maintenance for convertible topService and maintain convertible top Replace fuel filter (911 Turbo only)Controlled all-wheel drive (911 Turbo): change oil911 Turbo (997)。

竭诚为您提供优质文档/双击可除saej1939协议(中文)篇一:saej1939协议saej1939协议_综述(转载)发表于20xx/10/2611:16:06saej1939协议是由美国汽车工程师协会——卡车和公共汽车电气电子委员会下的卡车和公共汽车控制和通讯网络分委员会制定的高层can网络通讯协议。

它主要用于为重型道路车辆上电子部件间的通讯提供标准的体系结构[1]。

1saej1939协议构成文件saej1939协议包括如下几部分内容:saej1939-11物理层, 250kbits/s, 屏蔽双绞线saej1939-13物理层, 离线诊断连接器saej1939-15简化的物理层, 250kbits/s, 非屏蔽双绞线saej1939-21数据链路层saej1939-31网络层saej1939-71车辆应用层saej1939-73应用层-诊断saej1939-81j1939网络管理协议-----------------------------------------------------------------------------------2各层协议的功能2.1物理层saej1939的物理层规范包含saej1939-11(物理层, 250kbits/s, 屏蔽双绞线)、saej1939-15(简化的物理层, 250kbits/s, 非屏蔽双绞线)和saej1939-13(物理层, 离线诊断连接器)三部分。

其中saej1939-11和saej1939-15给出了物理层为屏蔽双绞线和非屏蔽双绞线时的网络物理描述、功能描述、电气规范、兼容性测试、总线错误讨论。

而saej1939-13(物理层, 离线诊断连接器)则定义了离线诊断连接器的通用需求、性能需求和物理需求。

2.2数据链路层saej1939的数据链路层在物理层之上提供了可靠的数据传输功能。

通过数据链路层的组织, 发送的can数据帧具有必需的同步、顺序控制、错误控制和流控制等功能。

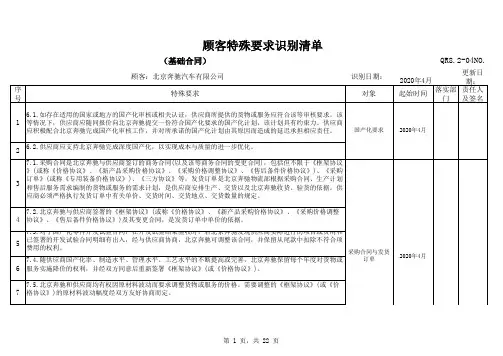

奔驶供应商评审中英文文件公司内部编号:(GOOD-TM\IT-\l\Il T-UUPTY-UUYY-DTTI-潜潜在供应商评估指南评估范围A - Management管理B - Technology and Development技术与开发C - Quality质量D - Production生产E - Engineering (Product and Process)工程(产品和过程)F - Logistics / Supply物流与供应G - Sub-supplier Management分供商管理H 一Cost Management成本管理Scoring Guide打分指南Team evaluation must be recorded into Excel file. Input comments on COMMENTS page.团队评价必须用Excel文件记录,在注释页上输入注释。

Points Color Definition Effect on DC processes在DC流程颜色表示的定义:0 red Supplier demonstrates neither a documented process/procedure nor an applied practice.0分红色供应商示范既无文件化流程/程序,又无应用的实例Process will certainly cause product failure and/or unsatisfactory communication with the customer 过程肯定会发生产品缺陷和招致顾客抱怨。

1red Documented process/procedure exists but is incomplete or notfully implemented.1分红色有文件化流程/程序,但不完善或没有完全的贯彻。

Process will probably cause product failure and/or unsatisfactory communication with the customer过程大概会发生产品缺陷和招致顾客抱怨。

Mercedes BenzUnimog∙Edad: 37 – 96 meses∙Peso máximo: 30 kilos∙Este producto contiene partes pequeñas que deben ser ensambladas solo por un adulto. ∙Asegúrese de cargar la batería por 8b horas antes del primer uso.Mercedes‐Benz”, , y el diseño del producto adjunto están sujetos a protección de propiedad intelectual propiedad de Daimler AG.Son utilizados por Pinghu City Xiao Ming Xing Children's Products Co., Ltd. bajo licencia.Pinghu City Julong Children’s Commodity Factory es una fábrica de productos para niños que integra Investigación & Desarrollo, ingeniería, producción, control de calidad y ventas. Los productos principales son autos eléctricos y bicicletas para niños y otros productos. La compañía tiene varias líneas de producción profesional, con una producción anual que alcanza los cientos miles de vehículos.La compañía tiene un equipo profesional de ingeniería de Investigación & Desarrollo, el cual ha estado trabajando por muchos años, con completos equipos de prueba para asegurar la calidad de los productos fabricados por la compañía, los que cumplen completamente con los requerimientos de las normas nacionales.Modelo Batería: 12V7Ah (o 12V10Ah o 12V14Ah)Peso máximo: 30 kilosVelocidad: 3‐5 km/hCargador: DC 12V1000mAEdad: 37‐96 mesesTamaño Vehículo: 1080x800x880 mmTiempo Normal de Carga: 8‐12 horasFusible: WHPTCMotor: Motor de Dirección: 12V380#6600Motor Conducción: 12V 390#16000∙Después del uso del producto, regularmente debe revisar (se sugiere una vez cada dos semanas) los elementos principales, incluida la batería, dispositivo de carga, cables, revestimiento exterior, cambiador de circuito y válvula de cambio. Se debe revisar si las abrazaderas están sueltas. En caso de daños, se debe detener el uso del producto hasta que este solucionado.∙El vehículo debe limpiarse con un paño de algodón húmedo (sin gotas de agua). También se puede utilizar limpiador de muebles sin cera para mantener la superficie brillante y limpia. No utilice disolventes químicos para limpiar las partes plásticas del juguete para evitar que estas se disuelvan. El auto no puede ser limpiado con agua y jabón, ya que el agua dañará el motor y la batería, provocando cortocircuito del sistema eléctrico.∙Después de usarlo por un periodo de tiempo, favor lubrique las piezas de hierro para evitar la corrosión. El auto debe permanecer lejos de altas temperaturas y humedad, ya que las partes plásticas podrían derretirse. Cuando cargue, favor manténgase alejado de materiales inflamables para evitar fuego.∙Al detener el uso por un largo periodo de tiempo, favor corte el poder. Todos los cambiadores de circuito deben estar en “OFF” o “STOP”. La estructura y sistema de cables no pueden ser alterados sin autorización. La mantención y reemplazo de las partes cruciales debe ser supervisado por profesionales.∙En áreas donde el suministro de energía es inestable, se recomienda instalar un regulador de energía para proteger la batería. Cuando se recarga no utilice cables no incluidos con el productoN° NOMBRE N° NOMBRE N° NOMBRE1 Armazón 6 Asiento 11 Caja engranaje x2 (ox4)2 Reflector Trasero 7 Parabrisas 12 Arandela3 Defensa 8 Manubrio 13 Tuerca M10 x44 Respaldo asiento 9 Cubierta rueda x4 14 Amortiguador5 Sujetador bajo asiento 10 Rueda x4 15Asegúrese que todas las partes indicadas estén incluidas en la caja.Recomendamos guardar el embalaje hasta que la unidad este completamente ensamblada, para asegurar que no se pierden piezas.El armado del vehículo toma aproximadamente 30 minutos.Armado debe ser realizado por un adulto.ADVERTENCIA: Los niños pueden resultar lesionados por piezas pequeñas, bordes y puntas afiladas del vehículo desarmado o por elementos eléctricos.ADVERTENCIA: RIESGO DE ASFIXIA‐ partes pequeñas. No apto para niños.Herramientas requeridasDestornillador Phillips (no incluido), Alicate (no incluido)Llave Hexagonal (incluida), Llave Tubo (incluida)Opcional: Caja de Cambios *2 o Caja de Cambios *4Instale los amortiguadores delanteros y el eje delantero▪Instale el armazón en una superficie plana antes de armar.▪Retire el tornillo y la tuerca de la parte inferior de los amortiguadores. Coloque la parte inferior amortiguadores en el conducto “U” del eje. Vuelva a colocar el tornillo en los amortiguadores ajuste la tuerca con la llave hexagonal.▪Repita al otro lado.▪El tubo cuadrado del eje debe coincidir con el conducto, mientras que el orificio debe coincidir con el eje de dirección. Atornille la parte superior de los amortiguadores en el armazón con tornillos 4*12. ▪Inserte arandela 10MM en el eje de dirección. Deslice el resorte en el conducto del eje de direcciónInstale la caja de cambio delantera y la rueda delantera▪Inserte la caja de cambios en el eje delantero. Inserte el cableado de la caja de cambios en la interfaz de la caja de batería. (Nota: La caja de cambios está dividida en FL/FR). (Este paso es indicado para caja de cambios *4)▪Deslice la rueda, arandela 10MM en el eje delantero,atornille la tuerca con la llave de tubo. (Nota: Laprotuberancia de la rueda debe coincidir debecoincidir con la caja de cambios).▪Coloque la tapa de la rueda en la rueda, presionefirmemente hasta que encaje en su lugar.▪Repita al otro lado.Instale amortiguadores traseros▪ Retire el tornillo y la tuerca de la parte inferior de losamortiguadores. Coloque la parte inferioramortiguadores en el conducto “U” del eje.▪ Vuelva a colocar el tornillo en los amortiguadoresajuste la tuerca con la llave hexagonal.▪ Repita al otro lado.Instale las ruedas traseras▪ Inserte el eje trasero en el orificio del soporteposterior.▪ Inserte arandela 12MM , caja de cambios, rueda,arandela 10MM, tuerca en el eje trasero. ((Nota: Lacaja de cambios está dividida en FL/FR. Laprotuberancia de la rueda debe coincidir debecoincidir con la caja de cambios).▪ Repita al otro lado.▪ Coloque la tapa de la rueda en la rueda, presionefirmemente hasta que encaje en su lugar.▪ Repita al otro lado.Instale el sujetador bajo el asiento▪ Coloque la parte inferior del sujetador bajo el asientoen el armazón del auto, presione hacia abajo.▪ Atornilleambos lados del sujetador con tornillos4*12 MM.Instale la defensa▪Coloque la defensa en las ranuras del armazón, presione hasta que encaje en su lugar. ▪Atornille ambos lados de la defensa en el armazón del vehículo con tornillos 4*12MM.Instale el asiento▪Nota: Conecte la interfaz de los cables de la caja de cambios antes de instalar el asiento. La interfaz NO está dividida en L/R. ▪Atornille el cinturón de seguridad en el medio del sujetador bajo el asiento con tornillos 4*12MM. ▪Inserte el respaldo del asiento en las ranuras del armazón, presione firmemente hasta que encaje en su lugar. ▪Deslice el asiento en el conducto del respaldo del asiento. Atornille el asiento en el sujetador bajo el asiento con tornillos 4*12MMInstalación reflectores traseros▪Conecte la interfaz del reflector al conector en la parte trasera. ▪Inserte las barras en el soporte del reflector, presione firmemente hasta que encaje en su lugar. (Figura 1). ▪Coloque toda la barra trasera en las ranuras del armazón del vehículo, presione firmemente hasta que encaje en su lugar. (Figura 2). (Nota: Tenga cuidado con el cable de luz). ▪Conectelainterfaz delcable de luz en el conector bajo el armazón del auto.Instale el manubrio▪Conecte la interfaz del manubrio a l conector de la base fija de la barra de dirección.▪Presione el conector enchufado y la interfaz en la base.▪Inserte el manubrio en la base fija de la barra de dirección, empuje hacia abajo el manubrio hasta que haga click y se fije en su lugar.Instale el parabrisas▪Posiciones el parabrisas en las ranuras del armazón.Con suavidad presiones hasta que haga click y se fije en su lugar.Conecte el poder▪Abra el capo, enchufe la interfaz de la batería al conector. (Figura 1).▪Cierre el capo, atornille al armazón con tornillos 4+12MM (Figura 2)ADVERTENCIAAsegúrese que el vehículo este totalmente detenido antes de cambiar la marcha adelante/reversa para evitar daños en la caja de cambios.Instrucciones de UsoEncendido: Presione el botón de encendido para prender el vehículo.Presione el botón de encendido nuevamente para apagar el vehículo.Pedal: Presione el pedal para avanzar. Libere el pedal para detenerse.Adelante/Reversa: Presione el botón D para moverse hacia adelante. Presione el botón a R para iren reversa. Presione P para detenerse.Izquierda/Derecha: Utilice el manubrio para girar hacia la derecha o izquierda.Botón Luces: Presione el botón de luces para apagarlas o encenderlas.Bocina: Presione el botón de la derecha para hacerla sonar.Música: Presione el botón de la izquierda para cambiar entre los canales de música.Botón 2/4W: Presione el botón para cambiar la tracción de dos ruedas a todas las ruedas. (Estebotón solo está disponible en tracción total)Utilice el Control Remoto 2.4 GInstale o cambie las baterías: Presione hacia abajo la tapa ubicada en el control remoto para abrirla. Instale dos baterías AAA en la polaridad correcta (+,‐) cierre la cubierta.Primer uso: Empareje el Vehículo con el Control Remoto.Mantenga presionadas los Botones de Avance y Retroceso por 3 segundos.El indicador de luz parpadea. Encienda el vehículo. El indicador de velocidad se iluminará. Emparejamiento correcto.Si empareja de manera errónea, el indicador de velocidad no se encenderá, apague el auto y repita los pasos.El vehículo debe estar emparejado al reemplazar las baterías antes de usarlo.Uso generalBotón S: Botón de velocidad – Selecciona 3 velocidad diferentes.Baja Velocidad – Indicador de Velocidad 1 luz LEDMedia Velocidad – Indicador de Velocidad 2 luz LEDAlta Velocidad – Indicador de Velocidad 3 luz LEDConsejos: Cada velocidad elegida tienen un inicio lento.Botón P: Detiene el vehículo – Indicar de Velocidad parpadea.Adelante: Mueve el vehículo hacia adelante.Reversa: Mueve el vehículo hacia atrás.Izquierda: Mueve el vehículo hacia la dirección izquierda.Derecha: Mueve el vehículo hacia la dirección derecha.1010Precauciones:∙ El control remoto solo funciona en un rango de 15m del vehículo.∙ El control remoto solo debe ser usado por un adulto. Mantenga fuera del alcance de los niños. ∙ Lea cuidadosamente el manual antes de usar. Adultos deben estar familiarizados con laoperación antes que los niños utilicen el vehículo.∙ El control remoto tiene configuración de ahorro de energía. Cuando no se usa, este se apagarádespués de 15 segundos.∙ NUNCA utilice en o cerca de carreteras, agua, terrenos empinados. Utilice en terrenos lisos. ∙ Mantenga el control remoto lejos del agua u otros líquidos, ya que podría dañarse. ∙ No reutilice baterías. Cambie ambas baterías al mismo tiempo.∙ Asegúrese que las baterías estén bien instaladas antes de encender.∙ Retire las baterías del control durante periodos largos de inactividad.∙ Las baterías deben ser reemplazadas cuando el control remoto funcione a menos de 3 m delvehículo.Presione el botón en el manubrio, hará un sonido o reproducirá música.11 111. Apague el poder cuando se agote la batería.2. Tome la manilla que esta en el medio de la parte trasera, levante el vehículo en 45 grados yarrastre.3.Cuando arrastre el vehículo que no esté con niños.4. Solo debe ser realizado por un adulto.。

Controls Opening/Closing the Power Sliding Doors*The power sliding doors can be operated by pressing the power sliding door buttonon the keyless remote, pressing the power sliding door switches on the dashboardor door pillars, or using the door handle.The power sliding doors can be operated when:•The sliding door main switch is in the ON position.•The power sliding door is unlocked.•The fuel fill door is closed (on the driver’s side sliding door only).•The power mode is in VEHICLE OFF or the remote engine start mode is active withuse of the keyless remote.•The transmission is in P, the brake pedal is depressed, or the parking brake isapplied (with the power mode in ON) when using the power sliding door switcheson the dashboard.1Opening/Closing the Power Sliding Doors*If the transmission is in a position other than P, andrelease the brake pedal and the parking brake:While opening – The sliding door stops and is leftajar.While closing – The beeper sounds until the doorcloses.Check that passengers, especially children, do nothave their hands on the sliding doors or on the doorpillars before its operation. If someone is caught inthe opening or closing sliding door, it can causeserious injury.Before replacing a rear tire, turn the power slidingdoor main switch to OFF.Operate the power sliding doors only when thevehicle is at a complete stop. Make sure you apply thebrake when rear passengers are boarding or exiting.ControlsAutomatic operation: Select the ON position of the sliding door main switch.Manual operation: Select the OFF position of the sliding door main switch.2Opening/Closing a Sliding Door P.183■Switching between manual and automatic operations1Opening/Closing the Power Sliding Doors *Do not turn the main switch off while the power sliding door is in operation on a slope. The power sliding door’s fail-safe mode activates and the beeper sounds continuously.When the fail-safe mode is active, turn the main switch on and close the door automatically.The following can deactivate the fail-safe mode and the sliding door may close by its own weight:•Using the door handle•Turning the main switch from ON to OFF If you replace the battery or the power sliding door fuse while the door is open, the power sliding door may be disabled. The power sliding door resumesonce you manually close the door.OFFONControlsThe power sliding door opens when you pressthe OPENside of theWhile the power sliding door is in operation, ifyou press the switch that corresponds to thatpower sliding door, the beeper sounds andthe operation stops.To resume the power sliding door operation,press the same switch again.■Power Sliding Door Switches1Opening/Closing the Power Sliding Doors*Auto ReverseDo not touch the pinch sensor located at the frontedge of the power sliding door. Do not damage thesensor. The power sliding door may not operateproperly.If the power sliding door senses resistance whenclosing automatically, it will stop closing and reversedirection. The beeper sounds.Before the power sliding door operation, make surethere are no people or obstacles near the door. Theauto reverse function should be activated in case ofemergency only. If someone is caught in the openingor closing sliding door, it can cause serious injury. Payspecial attention to children.Closing a power sliding door on someone’s hand orfingers can cause serious injury. Some parts of thedoor edge do not sense resistance when the door isnear closing.PinchSensorControlsPress the power sliding door button for more than one second to operate.While the power sliding door is in operation, if you press the button that corresponds to that power sliding door, the beeper sounds and the operation stops.If you press the same button again, the sliding door reverses its direction.■Customizing when to open the sliding doorsAnytime: The power sliding door unlocks and opens at the same time. This is the default setting.When Unlocked: The door opens when all doors are unlocked.2Customized Features P.463■Remote Transmitter1Remote TransmitterWhen you press the power sliding door button to open the door, the front door on the same side unlocks.Passenger’s Side Power Sliding Door Button1Customizing when to open the sliding doorsIn When Unlocked , trying to operate the power sliding door without unlocking the door triggers the beeper to sound.Controls■Outer handlesPull the outer handle toward you. The slidingdoor starts opening or closing.When the power sliding door is locked, pullingthe outer handle unlocks all the doors andtailgate while the keyless remote is in yourpossession.The power sliding door handle you pulloperates the door automatically.While a power sliding door is in operation, ifyou pull its handle, the beeper sounds and theoperation stops.Pull the same handle again, the power slidingdoor reverses direction.■Door Handles1Opening/Closing the Power Sliding Doors*The beeper will sound and the power sliding door willnot open if you pull the inner or outer handle underthe following conditions:•The power mode is in ON.•The transmission is not in P.•The brake pedal is released.•The parking brake is released.If you leave the power sliding door half open on asteep hill with the engine off, the door starts to slidedown toward the hill bottom after 30 minutes. Whilethe door slides down, the beeper sounds.Outer HandleControls■Inner handlesPull it rearward to automatically open the sliding door, and pull it forward to automatically close the door.While a power sliding door is in operation, if you pull its handle, the beeper sounds and the operation stops.To resume the power sliding door operation, pull the same handle in the same direction again.Inner HandleCloseOpen。

福建奔驰目录企业介绍奔驰品牌介绍生产车型奔驰改装车公司大事记企业介绍公司名称:福建奔驰汽车工业有限公司成立时间:2007年外文名称:Fujian Benz经营范围:福建奔驰商务车总部地点:福建福州公司性质:合资企业主要产品:梅赛德斯-唯雅诺Viano、梅赛德斯-威霆Vito、梅赛德斯-凌特Sprinter福建奔驰简介:福建戴姆勒汽车工业有限公司(简称福建戴姆勒)于2012年3月1日正式更名为福建奔驰汽车工业有限公司(简称福建奔驰)。

公司成立于2007年6月,由福建省汽车工业集团有限公司、戴姆勒轻型汽车(香港)有限公司(该公司系德国戴姆勒股份公司与台湾中华汽车工业股份有限公司的合资企业)各出资50%组建而成。

作为福建省委省政府大力支持的重点支柱产业,福建奔驰的成立标志着福建汽车工业从闽台合作成功走向了国际合作。

福建奔驰位于福建省福州市闽侯县青口投资区内,总投资2.08亿欧元。

其中,注册资本1.60亿欧元,建设总投资额1.88亿欧元,总规划生产及物流用地66万平方米,一期用地33万平方米,建筑面积14.9万平方米。

工厂导入梅赛德斯-奔驰生产系统(MPS),推行严格的质量管理体系,配套设施完备,是一座世界级水平的现代化工厂,一期规划年产能4万辆。

公司汇聚了来自中国、德国、西班牙等地的专业人才,优势互补,造就了一支年轻、自律、敬业、高效的国际化团队。

福建戴姆勒是戴姆勒在中国的南方项目,是戴姆勒全球战略的重要生产基地。

作为戴姆勒集团在亚洲及大洋洲的唯一商务车生产基地,也是产品线最全的基地,福建奔驰秉承梅赛德斯百年造车之精义,导入戴姆勒旗下的梅赛德斯-奔驰中高档商务车唯雅诺Viano、威霆Vito、凌特Sprinter,为国内客户提供全方位商务出行解决方案。

该系列产品以其乘坐的舒适性、功能的实用性、空间的灵活性、驾驶的安全性及操控的动力性而闻名于世。

唯雅诺、威霆与凌特分别于2010年5月与2011年11月21日全面上市。

ORIGINAL :UNITED NATIONS of March 20, 1995E/ECE/324 )Rev.1/Add.93/Amend.4E/ECE/TRANS/505 )April 1, 2003STATUS OF UNITED NATIONS REGULATIONECE 94UNIFORM PROVISIONS CONCERNING THE APPROVAL OF:VEHICLES WITH REGARD TO THE PROTECTION OF THEOCCUPANTS IN THE EVENT OF A FRONTAL COLLISIONIncorporating:00 series of amendments Date of Entry into Force: 01.10.95 Supplement 1 to the 00 series of amendments Date of Entry into Force: 12.08.96 01 series of amendments Date of Entry into Force: 12.08.98 Supplement 1 to the 01 series of amendments Date of Entry into Force: 21.02.02 Supplement 2 to the 01 series of amendments Date of Entry into Force: 31.01.03 Corr. 1 to the 01 series of amendments Date of Entry into Force: 26.06.02ORIGINAL :UNITED NATIONS of March 20, 1995 E/ECE/324)E/ECE/TRANS/505 )Rev.1/Add.93/Amend.4April 1, 2003TITLE:Frontal Collision - ISSUE:4 Regulation No. 94Protection Apr/2003PAGE: IUNITED NATIONS AGREEMENTCONCERNING THE ADOPTION OF UNIFORM TECHNICAL PRESCRIPTIONS FOR WHEELED VEHICLES, EQUIPMENT AND PARTS WHICH CAN BE FITTED AND/OR BE USED ON WHEELED VEHICLES AND THE CONDITIONS FOR RECIPROCAL RECOGNITION OFAPPROVALS GRANTED ON THE BASIS OF THESE PRESCRIPTIONS (*)Revision 2, including the amendments which entered into force on October 16, 1995)Addendum 93: Regulation No. 94Amendment 4Supplement 2to the 01 series of amendments – Date of entry into force: January 31, 2003UNIFORM PROVISIONS CONCERNING THE APPROVAL OF VEHICLES WITH REGARD TO THEPROTECTION OF THE OCCUPANTS IN THE EVENT OF A FRONTAL COLLISION(*)Former title of the Agreement:Agreement Concerning the Adoption of Uniform Conditions of Approval and Reciprocal Recognition of Approval for Motor Vehicle Equipment and Parts, done at Geneva on March 20, 1958.ORIGINAL :UNITED NATIONS of March 20, 1995Regulation No. 94UNIFORM PROVISIONS CONCERNING THE APPROVAL OF VEHICLES WITH REGARD TO THE PROTECTION OF THE OCCUPANTS IN THE EVENT OF A FRONTAL COLLISION CONTENTSREGULATION1. Scope2. Definitions3. Application for approval4. Approval5. Specifications6. Instructions for users of vehicles equipped with airbags7. Modification and Extension of approval of the vehicle type8. Conformity of production9. Penalties for non-conformity of production10. Production definitely discontinued11. Transitional provisions12. Names and addresses of technical services responsible for conducting approval tests, and ofadministrative departmentsANNEXESAnnex 1 - Communication concerning the approval or extension or refusal or withdrawal of approval or production definitely discontinued of a vehicle type with regard to the protection of theoccupants in the event of a frontal collision, pursuant to Regulation No. 94Annex 2 - Arrangements of the approval markAnnex 3 - Test procedureAnnex 4 - Determination of performance criteriaAnnex 5 - Arrangement and installation of dummies and adjustment of restraint systemsTITLE:Frontal Collision - ISSUE:1 Regulation No. 94 Protection Jan/1999PAGE: IIORIGINAL :UNITED NATIONS of March 20, 1995Regulation No. 94Annex 6 - Procedure for determining the "H" point and the actual torso angle for seating positions in motor vehiclesAppendix 1 - Description of the three-dimensional "H" point machineAppendix 2 - Three-dimensional reference systemAppendix 3 - Reference data concerning seating positionsAnnex 7 - Test procedure with trolleyAppendix - Equivalence curve - Tolerance band for curve _V = f (t)Annex 8 - Technique of measurement in measurement tests: instrumentationAnnex 9 - Definition of the deformable barrierAnnex 10 - Certification procedure for the dummy lower leg and foot.TITLE:Frontal Collision - ISSUE:1 Regulation No. 94 Protection Jan/1999PAGE: IIIORIGINAL :UNITED NATIONS of March 20, 1995TITLE:Frontal Collision - ISSUE:1 Regulation No. 94Protection Jan/1999PAGE: 1Regulation No. 941.SCOPE1.1.This regulation applies to power-driven vehicles of Category M 1(1)of a total permissible mass not exceeding 2.5 tonnes; heavier vehicles may be approved at the request of the manufacturer;1.2.It shall apply at the request of the manufacturer for the approval of a vehicle type with regard to the protection of the occupants of the front outboard seats in the event of a frontal collision. 2.DEFINITIONSFor the purposes of this Regulation:2.1."Protective system" means interior fittings and devices intended to restrain the occupants and contribute towards ensuring compliance with the requirements set out in Paragraph 5 below;2.2."Type of protective system" means a category of protective devices which do not differ in such essential respects as: Their technology; Their geometry;Their constituent materials;2.3."Vehicle width" means the distance between two planes parallel to the longitudinal median plane (of the vehicle) and touching the vehicle on either side of the said plane but excluding the rear-view mirrors, side marker lamps, tyre pressure indicators, direction indicator lamps, position lamps, flexible mud-guards and the deflected part of the tyre side-walls immediately above the point of contact with the ground;2.4. "Overlap" means the percentage of the vehicle width directly in line with the barrier face; 2.5. "Deformable barrier face" means a crushable section mounted on the front of a rigid block;2.6."Vehicle type" means a category of power-driven vehicles which do not differ in such essential respects as:2.6.1. The length and width of the vehicle, in so far as they have a negative effect on the results of the impact test prescribed in this Regulation,2.6.2.The structure, dimensions, lines and materials of the part of the vehicle forward of the transverse plane through the "R" point of the driver's seat, in so far as they have a negative effect on the results of the impact test prescribed in this Regulation,(1)As defined in the Consolidated Resolution on the Construction of Vehicles (R.E.3), Annex 7 (document TRANS/SC1/WP29/78/Amend.3), i.e., motor vehicles used for the carriage of passengers and comprising not more than eight seats in addition to the driver's seat.ORIGINAL :UNITED NATIONS of March 20, 19952.6.3.The lines and inside dimensions of the passenger compartment and the type of protectivesystem, in so far as they have a negative effect on the results of the impact test prescribedin this Regulation,2.6.4.The siting (front, rear or centre) and the orientation (transversal or longitudinal) of theengine,2.6.5.The unladen mass, in so far as there is a negative effect on the result of the impact testprescribed in this Regulation,2.6.6.The optional arrangements or fittings provided by the manufacturer, in so far as they have anegative effect on the result of the impact test prescribed in this Regulation,2.7."Passenger compartment"means the space for occupant accommodation, bounded bythe roof, floor, side walls, doors, outside glazing and front bulkhead and the plane of the rearcompartment bulkhead or the plane of the rear-seat back support;2.8."R point" means a reference point defined for each seat by the manufacturer in relation thevehicle's structure, as indicated in Annex 6;2.9."H point"means a reference point determined for each seat by the testing serviceresponsible for approval, in accordance with the procedure described in Annex 6;2.10."Unladen kerb mass"means the mass of the vehicle in running order, unoccupied andunladen but complete with fuel, coolant , lubricant, tools and spare wheel (if these areprovided as standard equipment by the vehicle manufacturer).2.11."Airbag"means a device installed to supplement safety belts and restraint systems inpower-driven vehicles, i.e. systems which, in the event of a severe impact affecting thevehicle, automatically deploy a flexible structure intended to limit, by compression of the gascontained within it, the gravity of the contacts of one or more parts of the body of anoccupant of the vehicle with the interior of the passenger compartment.2.12."Passenger airbag"means an airbag assembly intended to protect occupant(s) in seatsother than the driver's in the event of a frontal collision.2.13."Child restraint"means an arrangement of components which may comprise acombination of straps or flexible components with a securing buckle, adjusting devices,attachments, and in some cases a supplementary chair and/or an impact shield, capable ofbeing anchored to a power driven vehicle. It is so designed as to diminish the risk of injuryto the wearer, in the event of a collision or of abrupt deceleration of the vehicle by limitingthe mobility of the wearer's body.2.14."Rearward-facing" means facing in the direction opposite to the normal direction of travelof the vehicle.TITLE:Frontal Collision - ISSUE:1 Regulation No. 94 Protection Jan/1999PAGE: 2ORIGINAL :UNITED NATIONS of March 20, 19953.APPLICATION FOR APPROVAL3.1.The application for approval of a vehicle type with regard to the protection of the occupantsof the front seats in the event of a frontal collision shall be submitted by the vehiclemanufacturer or by his duly accredited representative.3.2.It shall be accompanied by the undermentioned documents in triplicate and followingparticulars;3.2.1. A detailed description of the vehicle type with respect to its structure, dimensions, lines andconstituent materials;3.2.2.Photographs, and/or diagrams and drawings of the vehicle showing the vehicle type in front,side and rear elevation and design details of the forward part of the structure;3.2.3.Particulars of the vehicle's unladen kerb mass;3.2.4.The lines and inside dimensions of the passenger compartment;3.2.5. A description of the interior fittings and protective systems installed in the vehicle.3.3.The applicant for approval shall be entitled to present any data and results of tests carriedout which make it possible to establish that compliance with the requirements can beachieved with a sufficient degree of confidence.3.4. A vehicle which is representative of the type to be approved shall be submitted to thetechnical service responsible for conducting the approval tests.3.4.1. A vehicle not comprising all the components proper to the type may be accepted for testprovided that it can be shown that the absence of the components omitted has nodetrimental effect on the results of the test in so far as the requirements of this Regulationare concerned.3.4.2.It shall be the responsibility of the applicant for approval to show that the application ofParagraph 3.4.1. is compatible with compliance with the requirements of this Regulation. TITLE:Frontal Collision - ISSUE:1 Regulation No. 94 Protection Jan/1999PAGE: 3ORIGINAL :UNITED NATIONS of March 20, 1995 TITLE:Frontal Collision - ISSUE:3 Regulation No. 94Protection Apr/2003PAGE: 44.APPROVAL4.1. If the vehicle type submitted for approval pursuant to this Regulation meets the requirements of this Regulation , approval of that vehicle type shall be granted.4.1.1. The technical service appointed in accordance with Paragraph 10 below shall check whether the required conditions have been satisfied.4.1.2.In case of doubt, account shall be taken, when verifying the conformity of the vehicle to the requirements of this Regulation, of any data or test results provided by the manufacturer which can be taken into consideration in validating the approval test carried out by the technical service.4.2.An approval number shall be assigned to each type approved. Its first two digits (at present 01 corresponding to the 01 series of amendments), shall indicate the series of amendments incorporating the most recent major technical amendments made to the Regulation at the time of issue of the approval. The same Contracting Party may not assign the same approval number to another vehicle type.4.3.Notice of approval or of refusal of approval of a vehicle type pursuant to this Regulation shall be communicated by the Parties to the Agreement which apply this Regulation by means of a form conforming to the model in Annex 1 to this Regulation and photographs and/or diagrams and drawings supplied by the applicant for approval, in a format not exceeding A4 (210 X 297 mm) or folded to that format and on an appropriate scale.4.4.There shall be affixed, conspicuously and in a readily accessible place specified on the approval form, to every vehicle conforming to a vehicle type approved under this Regulation, an international approval mark consisting of:4.4.1. A circle surrounding the Letter "E" followed by the distinguishing number of the country which has granted approval (1)4.4.2.The number of this Regulation, followed by the Letter "R", a dash and the approval number, to the right of the circle prescribed in Paragraph 4.4.1.(1)1 for Germany,2 for France,3 for Italy,4 for the Netherlands,5 for Sweden,6 for Belgium,7 for Hungary,8 for the Czech Republic,9 for Spain, 10 for Yugoslavia, 11 for the United Kingdom, 12 for Austria, 13 for Luxembourg, 14 for Switzerland, 15 (vacant), 16 for Norway, 17 for Finland, 18 for Denmark, 19 for Romania, 20 for Poland, 21 for Portugal, 22 for the Russian Federation, 23 for Greece, 24 for Ireland, 25 for Croatia, 26 for Slovenia, 27 for Slovakia, 28 for Belarus, 29 for Estonia, 30 (vacant), 31 for Bosnia and Herzegovina, 32 for Latvia, 33 (vacant), 34 for Bulgaria, 35 (vacant), 36 for Lithuania,37 for Turkey, 38 (vacant), 39 for Azerbaijan, 40 for The former Yugoslav Republic of Macedonia, 41 (vacant), 42 for the European Community (Approvals are granted by its Member States using their respective ECE symbol), 43 for Japan, 44 (vacant), 45 for Australia, 46 for Ukraine, 47 for South Africa and 48 for New Zealand. Subsequent numbers shall be assigned to other countries in the chronological order in which they ratify to the Agreement concerning the Adoption of Uniform Technical Prescriptions for Wheeled Vehicles, Equipment and Parts which can be Fitted and/or be Used on Wheeled Vehicles and the Conditions for Reciprocal Recognition of Approvals Granted on the Basis of these Prescriptions, for Motor Vehicle Equipment and Parts, or in which they accede to that Agreement, and the numbers thus assigned shall be communicated by the Secretary-General of the United Nations to the Contracting Parties to the Agreement.ORIGINAL :UNITED NATIONS of March 20, 19954.5.If the vehicle conforms to a vehicle type approved, under one or more other Regulationsannexed to the Agreement, in the country which has granted approval under thisRegulation, the symbol prescribed in Paragraph 4.4.1. need not be repeated; in such a casethe Regulation and approval numbers and the additional symbols of all the Regulationsunder which approval has been granted in the country which has granted approval underthis Regulation shall be placed in vertical columns to the right of the symbol prescribed inParagraph 4.4.1.4.6.The approval mark shall be clearly legible and be indelible.4.7.The approval mark shall be placed close to or on the vehicle data plate affixed by themanufacturer.4.8.Annex 2 to this Regulation gives examples of approval marks.5.SPECIFICATIONS5.1.General specifications applicable to all tests5.1.1.The "H" point for each seat shall be determined in accordance with the procedure describedin Annex 6.5.1.2.When the protective system for the front seating positions includes belts, the beltcomponents shall meet the requirements of Regulation No. 16.5.1.3.Seating positions where a dummy is installed and the protective system includes belts, shallbe provided with anchorage points conforming to Regulation No. 14.5.2.SpecificationsThe test of the vehicle carried out in accordance with the method described in Annex 3 shallbe considered satisfactory if all the conditions set out in Paragraphs 5.2.1. to 5.2.6. beloware all satisfied at the same time.5.2.1.The performance criteria recorded, in accordance with Annex 8, on the dummies in the frontoutboard seats shall meet the following conditions:5.2.1.1. The head performance criterion (HPC) shall not exceed 1000 and the resultant headacceleration shall not exceed 80 g for more than 3 ms. The latter shall be calculatedcumulatively, excluding rebound movement of the head;TITLE:Frontal Collision - ISSUE:1 Regulation No. 94 Protection Jan/1999PAGE: 5ORIGINAL :UNITED NATIONS of March 20, 1995 TITLE:Frontal Collision - ISSUE:1 Regulation No. 94Protection Jan/1999PAGE: 65.2.1.2.The neck injury criteria (NIC) shall not exceed the values shown in Figures 1 and 2(1);Figure 1Neck Tension CriterionFigure 2 Neck Shear Criterion(1)Until October 1, 1998, the values obtained for the neck shall not be pass/fail criteria for the purposes of granting approval.The results obtained shall be recorded in the test report and be collected by the approval authority. After this date, the values specified in this paragraph shall apply as pass/fail criteria unless or until alternative values are adopted.ORIGINAL :UNITED NATIONS of March 20, 1995 TITLE:Frontal Collision - ISSUE:1 Regulation No. 94Protection Jan/1999PAGE: 75.2.1.3. The neck bending moment about the y axis shall not exceed 57 Nm in extension (1);5.2.1.4. The thorax compression criterion (ThCC) shall not exceed 50 mm; 5.2.1.5. The viscous criterion (V * C) for the thorax shall not exceed 1,0 m/s;5.2.1.6.The femur force criterion (FFC) shall not exceed the force-time performance criterion shownin Figure 3;Figure 3Femur Force Criterion5.2.1.7. The tibia compression force criterion (TCFC) shall not exceed 8 kN;5.2.1.8. The tibia index (TI), measured at the top and bottom of each tibia, shall not exceed 1,3 at either location;5.2.1.9. The movement of the sliding knee joints shall not exceed 15 mm.5.2.2.Residual steering wheel displacement, measured at the centre of the steering wheel hub, shall not exceed 80 mm in the upwards vertical direction and 100 mm in the rearward horizontal direction.(1)Until October 1, 1998, the values obtained for the neck shall not be pass/fail criteria for the purposes of granting approval.The results obtained shall be recorded in the test report and be collected by the approval authority. After this date, the values specified in this paragraph shall apply as pass/fail criteria unless or until alternative values are adopted.ORIGINAL :UNITED NATIONS of March 20, 19955.2.3.During the test no door shall open;5.2.4.During the test no locking of the locking systems of the front doors shall occur;5.2.5.After the impact, it shall be possible, without the use of tools, except for those necessary tosupport the weight of the dummy:5.2.5.1. To open at least one door, if there is one, per row of seats and, where there is no such door,to move the seats or tilt their backrests as necessary to allow the evacuation of all theoccupants; this is, however, only applicable to vehicles having a roof of rigid construction; 5.2.5.2. To release the dummies from their restraint system which, if locked, shall be capable ofbeing released by a maximum force of 60 N on the centre of the release control;5.2.5.3. To remove the dummies from the vehicle without adjustment of the seats.5.2.6.In the case of a vehicle propelled by liquid fuel, no more than slight leakage of liquid fromthe fuel feed installation shall occur on collision;5.2.7.If there is continuous leakage of liquid from the fuel-feed installation after the collision, therate of leakage shall not exceed 30 g/min; if the liquid from the fuel-feed system mixes withliquids from the other systems and the various liquids cannot easily be separated andidentified, all the liquids collected shall be taken into account in evaluating the continuousleakage.6.INSTRUCTIONS FOR USERS OF VEHICLES EQUIPPED WITH AIRBAGS6.1.The vehicles shall carry information to the effect that it is equipped with airbags for seats. 6.1.1.For a vehicle fitted with an airbag assembly intended to protect the driver, this informationshall consist of the inscription "AIRBAG" located in the interior of the circumference of thesteering wheel; this inscription shall be durably affixed and easily visible.6.1.2.For a vehicle fitted with a passenger airbag intended to protect occupants other than thedriver, this information shall consist of the warning label described in Paragraph 6.2. below.6.2. A vehicle fitted with one or more passenger frontal protection airbags shall carry informationabout the extreme hazard associated with the use of rearward-facing child restraints onseats equipped with airbag assemblies.TITLE:Frontal Collision - ISSUE:2 Regulation No. 94 Protection Apr/2003PAGE: 8ORIGINAL :UNITED NATIONS of March 20, 1995 TITLE:Frontal Collision - ISSUE:2 Regulation No. 94Protection Apr/2003PAGE: 96.2.1.As a minimum, this information shall consist of a label containing a pictogram and text warningas indicated below.The overall dimensions shall be 120 x 60 mm or the equivalent area, as a minimum. The label shown above may be adapted in such a way that the layout differs from the example above; however, the text content shall meet the above prescriptions.6.2.2.At the time of type approval, the label shall be in at least one of the languages of the Contracting Party where the application for approval is submitted. The manufacturer shall declare his responsibility for ensuring the warning is provided at least in one of the languages of the country in which the vehicle is to be sold.6.2.3.In the case of a frontal protection airbag on the front passenger seat, the warning shall be durably affixed to each face of the passenger front sun visor in such a position that at least one warning on the sun visor is visible at all times, irrespective of the position of the sun visor. Alternatively, one warning shall be on the visible face of the stowed sun visor and a second warning shall be on the roof behind the visor, so, at least one warning is visible at all times. The text size must allow the label to be easily read by a normal sighted user seated on the seat concerned.In the case of a frontal protection airbag for other seats in the vehicle, the warning must be directly ahead of the relevant seat, and clearly visible at all times to someone installing a rear-facing child restraint on that seat. The text size must allow the label to be easily read by a normal sighted user seated on the seat concerned.This requirement does not apply to those seats equipped with a device which automatically deactivates the frontal protection airbag assembly when any rearward-facing child restraint is installed.ORIGINAL :UNITED NATIONS of March 20, 1995 TITLE:Frontal Collision - ISSUE:2 Regulation No. 94Protection Apr/2003PAGE: 106.2.4.Detailed information, making reference to the warning, shall be contained in the owner's manual of the vehicle; as a minimum the following text in the official languages of the country where the vehicle is to be registered, must include:"Do not use a rearward facing child restraint on a seat protected by an airbag in front of it!"The text shall be accompanied by an illustration of the warning to be found in the vehicle.7.MODIFICATION AND EXTENSION OF APPROVAL OF THE VEHICLE TYPE7.1.Any modification affecting the structure, the number of seats, the interior trim or fittings, or the position of the vehicle controls or of mechanical parts which might affect the energy-absorption capability of the front of the vehicle shall be brought to the notice of the administrative department granting approval. The department may then either:7.1.1. Consider that the modifications made are unlikely to have an appreciable adverse effect and that in any case the vehicle still complies with the requirements; or7.1.2. Require the technical service responsible for conducting the tests to carry out a further test, among those described below, according to the nature of the modifications;7.1.2.1.Any modification of the vehicle affecting the general form of the structure of the vehicle and/or any increase in mass greater than 8% which in the judgement of the authority would have a marked influence on the results of the tests shall require a repetition of the test as described in Annex 3;7.1.2.2.If the modifications concern only the interior fittings, if the mass does not differ by more than 8 percent and if the number of front seats initially provided in the vehicle remains the same, the following shall be carried out:7.1.2.2.1. A simplified test as provided for in Annex 7 and/or,7.1.2.2.2. A partial test as defined by the technical service in relation to the modifications made. 7.2.Confirmation or refusal of approval, specifying the alterations, shall be communicated by the procedure specified in Paragraph 4.3. above to the Parties to the Agreement which apply this Regulation.7.3.The competent authority issuing the extension of approval shall assign a series number for such an extension and inform thereof the other Parties to the 1958 Agreement applying this Regulation by means of communication form conforming to the model in Annex 1 to this Regulation.8.CONFORMITY OF PRODUCTIONThe conformity of production procedures shall comply with those set out in the Agreement, Appendix 2 (E/ECE/324-E/ECE/TRANS/505/Rev.2) with the following requirements: 8.1.Every vehicle approved under this Regulation shall conform to the vehicle type approved, as regards features contributing to the protection of the occupants of the vehicle in the event of a frontal collision.8.2. The holder of the approval shall ensure that for each type of vehicle at least the tests concerning the taking of measurements are carried out;8.3.The authority which has granted type approval may at any time verify the conformity control methods applied in each production facility. The normal frequency of these verifications shall be once every two years.ORIGINAL :UNITED NATIONS of March 20, 19959.PENALTIES FOR NON-CONFORMITY OF PRODUCTION9.1.The approval granted in respect of a vehicle type pursuant to this Regulation may bewithdrawn if the requirement laid down in Paragraph 8.1. above is not complied with or if thevehicle or vehicles selected have failed to pass the checks prescribed in Paragraph 8.2.above.9.2.If a Contracting Party to the Agreement applying this Regulation withdraws an approval ithas previously granted, it shall forthwith so notify the other Contracting Parties applying thisRegulation, by means of a communication form conforming to the model in Annex 1 to theRegulation.10.PRODUCTION DEFINITELY DISCONTINUEDIf the holder of the approval completely ceases to manufacture the type of vehicle approvedin accordance with the Regulation, he shall so inform the authority which granted theapproval. Upon receiving the relevant communication that authority shall inform thereof theother Parties to the 1958 Agreement applying this Regulation by means of a communicationform conforming to the model in Annex 1 to this Regulation.11.TRANSITIONAL PROVISION11.1.As from the official date of entry into force of Supplement 1 to the 01 series of amendments,no Contracting Party applying this Regulation shall refuse to grant ECE approval under thisRegulation as amended by Supplement 1 to the 01 series of amendments.11.2.As from October 1, 2002Contracting Parties applying this Regulation shall grantECE approvals only to those types of vehicles which comply with the requirements of thisRegulation as amended by Supplement 1 to the 01 series of amendments.11.3.As from October 1, 2003 Contracting Parties applying this Regulation may refuse firstnational registration (first entry into service) of vehicles which do not meet the requirementsof this Regulation as amended by the 01 series of amendments.S AND ADDRESSES OF TECHNICAL SERVICES RESPONSIBLE FORCONDUCTING APPROVAL TESTS, AND OF ADMINISTRATIVE DEPARTMENTSThe Contracting Parties to the Agreement applying this Regulation shall communicate to theUnited Nations secretariat the names and addresses of the technical services responsiblefor conducting approval tests, of manufacturers authorised to carry out tests and of theadministrative departments which grant approval and to which forms certifying approval orrefusal or withdrawal of approval, issued in other countries, are to be sent.TITLE:Frontal Collision - ISSUE:2 Regulation No. 94 Protection June/2002PAGE: 11。