进料检验报告(中英文翻译)

- 格式:docx

- 大小:22.35 KB

- 文档页数:2

机电材料检验标准1.目的:Purpose :建立进料抽样检验标准,以确保进料质量能合乎既定之规范。

To establish the inspection standard of incoming sampling。

2.范围:Scope :2.1.有披覆之导线;裸导线; CABLE.Conducting wire with shield cover; naked cable; cable2.2.Bonding wire;2.3.CONNECTOR, SOCKET, SWITCH, PIN HEADER, RELAY, SHORT PLUG,WIRE(SILVER), COPPER WIRE, FUSE, FACK, BATTERY2.4.水晶振荡子(CRYSTAL)、振荡器(O.S.C.)--有引脚者。

(Lead wire.)--无引脚但有焊端(Termination.)--素芯片(Blank crystal)。

2.5.陶磁基片类(CERAMIC SUBSTRATE)Ceramic substrate.2.6.MIRROR类零件Mirror.3.权责:Expediency :3.1.平时IQC依照进料抽样检验标准作进料检验,VQA可视质量状况呈检验单位主管同意后,对特定料号于检验基准书上作检验项目及抽样数之更改。

Ordinary IQC follow inspection standard of incoming sampling to do income inspection, VQA can ask inspection department director for modifying the sampling item the according as quality state, after getting the director approve, to modify the inspection items and sampling quantity of inspection instruction for specially designate P/N.4.相关文件:Relevance documents:4.1.抽样计划AG-0801-M405-XXIncoming inspection sampling plan4.2.进料管制AG-0801-M402-XXIncoming control5.作业规定要点The essentials of assignments regulations5.1.材料名称:有披覆之导线;裸导线; CABLEMaterial: Conducting wire with shield cover; naked cable; cable 5.1.1.抽样计划: 抽样计划.各site VQA 可因应实际情况不同,调整相关抽样计划,经 site VQA主管同意后实行.Sampling Plan.Base on the different situation, site VQAcould revise this sampling plan and get the approval by siteVQA head before implement5.1.1.1.正常检验抽样标准AQL 0.65%, LEVEL 1,若线材为卷装则抽1卷作特性检验,而待验批在20卷(含)以下另抽3卷,20卷以上另抽5卷作一般外观检验。

品质人员名称类:QC quality control品质管理人员F QC final quality control终点质量管理人员IP QC in process quality control制程中的质量管理人员O QC output quali y control最终出货质量管理人员IQC incoming quality control进料质量管理人员TQC total quality control全面质量管理POC passage quality control段检人员QA quality assurance质量保证人员OQ A output quality assurance出货质量保证人员Q Equality engineering品质工程人员二、品质保证类:FAI first article inspection新品首件检查FAA first article assurance首件确认TVR tool verification report模具确认报告3B3B模具正式投产前确认CP cap abi ity index能力指数CPK cap abi ity index of process模具制程能力参数SSQ A standardized supplier quality合格供货商品质评估OOB A out of box audit开箱检查QFD quality function deployment品质机能展开FMEA failure model effectiveness analysis失效模式分析8 disciplines 8项回复内容FA final audit最后一次稽核CAR corrective action request改正行动要求corrective action report改正行动报告三、F QC运作类AQL Acceptable Quality Level运作类允收品质水准S/S Sample size抽样检验样本大小ACC Accept允收REE Reject拒收CR Critical极严重的MAJ Major主要的MIN Minor轻微的A OQ Average Output Quality平均出厂品质A OQL Average Output Quality Level平均出厂品质Q/R/S Quality/Reliability/Service品质/可靠度服务MIL-STD Ml itary-Standard军用标准PPM Percent Per Milon百万分之一L/N Lot Number 生产批号四、制程统计品管专类:SPC Statistical Process Control统计制程管制SQC Statistical Quality Control统计质量管理R Range全距A RAver ary Range全距平均值UCL Upper Central Limit管制上限LCL Lower Central Limit管制下限MAX Maximum最大值MIN Minimum最小值GRR Gauge Reproducibility&Repeat abilty量具之再制性及重测性判断量可靠与否DIM Dimension尺寸DIA Diameter直径FREQ Frequency频率N Number样品数五、其它品质术语类:PDCA Plan Do Check Action计划执行检查总结QI Quali y Improvement品质改善QP Quality Policy目标方针SI-SIV Special l-SpecialⅣV特殊抽样水准等级P/N Part Number料号AOD Accept On Deviation特采UAI Use As It首件检查报告PPM Percent Per Million百万分之一QCC Quality Control Circle品质圈Plan Do Check Action计划执行检查总结ZD Zero Defect零缺点TQM Total Quality Management全面品质管理MRB Material Reject Bill退货单LQ L Limiting Quality Level最低品质水准RMA Return Material Audit退料认可Q AN Quality A me lion rate Notice品质改善活动ADM Absolute Dimension Measure mat全尺寸测量QT Quality Target品质目标7QC Tools 7 Quality Controll Tools品管七大手法六、QS-9000中的术语:APQP Advanced Product Quality Planning and Control Plan,产品质量先期策划和控制计划PPAP Production Part Approval Process,生产件批准程序FMEA Potential Failure Mode and Effects Analysi,潜在失效模式及后果分析MSA Measure System Analysis,测量系统分析SPC Statistical Process Control,统计过程控制六、QS-9000中的术语:APQP Advanced Product Quality Planning and Control Plan,产品质量先期策划和控制计划PPAP Production Part Approval Process,生产件批准程序FMEA Potential Failure Mode and Effects Analysis,潜在失效模式及后果分析MSA Measure System Analysis,测量系统分析SPC Statistical Process Control,统计过程控制Audit审核Audit 能力Capability 能力Capability Indices 能力指数Control Plans 控制计划Corrective Action 纠正措施文件Documentation 文件work instruction作业指导书Nonconformity 不符合项Nonconforming products不合格品Unqualified 不合格Defective Parts Per Milon,DPPM 每百万零件不合格数Preventive Action预防措施Procedures程序Process Flow Diagram过程流程图,Quality Manual质量手册Quality Plan质量计划Quality Planning质量策划Quality Records 质量记录Reaction Plan反应计划Repair返修返工Rework现场Site分承包方Subcontractors产品product质量quality质量要求quality requirement顾客满意customer satisfaction质量管理体系quality management system 质量方针quality policy质量目标qua ity objective质量管理quality management质量控制quality control质量保证quality assurance组织organization顾客customer供方supplier过程process服务service设计与开发design and development特性characteristic可追溯性traceability合格conformity缺陷defect纠正correction让步concession放行release报废scrap规范specification评审review测量measurement计数型数据Attributes Data普通原因CommonCause单值Individual均值Mean随机抽样Random Sampling 极差Range特殊原因Special Cause稳定性Stabi ity子组Subgroup计量型数据Variables Data 变差Variation固有变差Inherent Variation 总变差Total Variation偏倚Bias重复性Repeatability再现性Reproduc ibi ity稳定性Stability Linearity分辨率Resolution过程更改Process change过程更改Process change质量功能展开QFD过程特殊特性Special Process Characteristic产品特殊特性Special Product Characteristic外观项目Appearance Item初始过程能力Preliminary Process Capability材料清单Bill of Material设计确认Design Validation设计验证Design Verification顾客的呼声Voice of the Customer过程的呼声Voice of the Process七、常用缩略词语:ES工程规范Engineering SpecificationKCC关键控制特性(GM) Key Control CharacteristicKPC关键产品特性(GM) Key Product CharacteristicOEM整车厂Original Equipment ManufacturerSC重要(特殊) 特性Significant(Special) Characteristic ANOVA方差分析法Analysis of Variance CFT多方论证小组Cross function T eam DFMEA设计失效模式及后果分析Design Failure Mode and Effects Analysis DOE试验设计Design of Experiment DVP&R设计验证计划和报告Design verification Plan and ReportFTC试生产能力First Time CapabilityGR&R量具的重复性和再现性Gage Repeatability and ReproducibilityP FMEA过程失效模式及后果分析Process Failure Mode and Effect AnalysisSF ME A系统失效模式及后是分析System Failure Mode and Effect Analysis QSR 质量体系要求Quality System RequirementQFD质量功能展开Quality Function DeploymentTGR运行情况良好Things Gone RightTGW运行情况不良Things Gone WrongVE/VA价值工程/价值分析Value Engineering/Value AnalysisBOM物料清单Bill of MaterialCpk 稳定过程的能力指数Cap ablity for stable processLCL 下控制限Lower Control LimitUCL 上控制限Upper Control LimitLSL 工程规范下限Lower Specification LimitUS L 工程规范上限Upper Specification LimitPpk 性能指数The performance indexMRB 物料评审Material Review BoardPSW 零件提交保证书Part Submission WarrantX(-)--R图均值一极差图Average-Range ChartSR PC 供方要求产品更改Supplier Request for Product ChangeIAA临时批准授权Interim Approval AuthorizationAAR外观件批准报告Appearance Approval ReportPTR试生产(报告) Production Trial Run(Report)DCP尺寸控制计划(动态控制计划) Dimension Control Plan(Dynamic Control Plan) 防错(POKA-YOKE) Mistake ProofingECN:工程变更通知单BOM:物料清单SOP:作业指导书SIP:检验指导书AC:允收RE:拒收AQL:品质允收水准CR:致命缺陷9.MAX:严重缺陷MIN:轻微缺陷QA:品质保证IP QC:制程品质控制IQC:进料品质控制QE:品质工程F MEN:失效模式及后果分析SPC:统计过程控制CPK:工序能力指数SQC:统计品质管控QMS:质量管理体系ISO:国际标准化组织ISO 9000:质量管理体系ISO 14001:环境管理体系CAR:客户投诉不良改善报告CPAR:纠正/预防措施报告TQC:全面质量管理ROHS:电机电子产品之危害物质限用指令QCC:品管圈UCL:管制上限LCL:管制下限14.P DCA:计划、实施、检查、处置5M1E:人员、机器、物料、方法、测量、环境5W2H:何时、何地、何人、何事、为何、如何、几何(几多、多少) PCBA:印刷电路板SQM:供应商品质管理ECR:设计变更IQC:来料检验IP QC:制程检验F QC:最终检验(成品检验)O QC:出厂检验QA:品质保证QE:品质工程PQE:产品品质工程师PE:产品工程师PC:生产控制(生管)MC:物料控制ME:机械工程师FE:设备工程师SQC:统计品管TQC:全面品质管制QFD:质量机能展开we nku.con CW QC:日本模式TQC-全公司品管TQM:全面品质管理AQL:判定基准-不良率为%PPM:百万分之一不良率SOP:标准作业程序SIP:标准检验程序PDCA:戴明管理循环(Plan设计、Do制造,实施、Check检查、Action修正) BOM:物料清单ECO:工程变更指令MN:制造通知MPI:作业指导书TPI:测试指导书API:调试指导书Rev:版本WIP:在制品MAJ:主要缺点MIN:次要缺点CRI:严重缺点SAMPLE:样品。

五金零件检验项目及抽样标准1.目的:Purpose订定进料检验项目及抽样标准,以做为进料检验之标准。

To set up incoming material inspection items and samplingstandard, to assure the incoming inspection.2.范围Scope:所有一般进料之五金类材料,包括所有螺丝、螺帽、冲压、压铸及其电镀、皮膜、表面涂装、组立、Lead Frame及开模之金属件等之五金件。

All of the incoming metal part include Screw, Nut, all stamping, die-casting and electroplate wiper and assembly etc.3.权责Responsibilty:IQC须依进料抽样检验标准作进料检验,VQA可适质量状况呈检验单位主管同意后作检验项目及抽样数之更改。

IQC inspectors according to the incoming sampling planning to inspect, VQA engineers can according to the material quality to change the inspection items and sampling planning before department manager agreement.4.相关文件:Relevance documents:4.1.抽样计划AT-0801-M405-XXIncoming inspection sampling plan4.2.进料管制AG-0801-M402-XXIncoming control5.作业规定要点:Detail operating procedure:5.1.抽样计划:各site VQA 可因应实际情况不同,调整相关抽样计划,经 site VQA主管同意后实行.Sampling Plan: Base on the different situation, site VQA could revise this sampling plan and get the approval by site VQA head before implement5.1.1.正常检验:AQL 0.65%,LEVEL I。

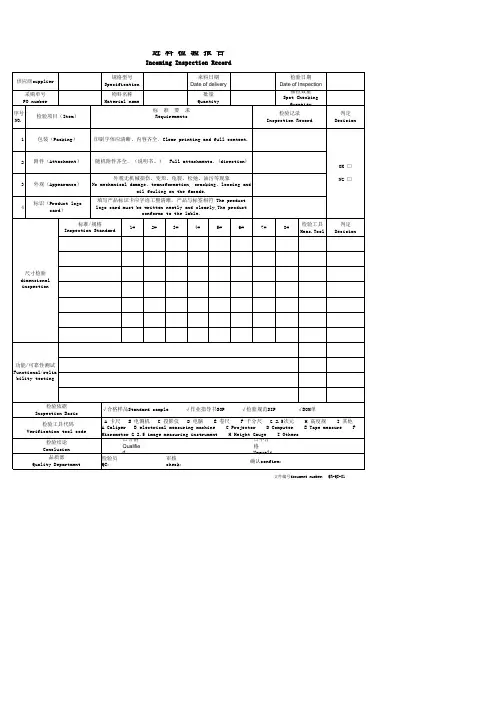

进料检验记录表中英文进料检验记录表是用于记录进货物料的检验过程和结果的文件,它在供应链管理中起着重要的作用。

以下是一个进料检验记录表的参考内容:进料检验记录表Material Inspection Record Form供应商信息Supplier Information供应商名称:________________________Supplier Name供应商地址:________________________Supplier Address联系人:________________________Contact Person联系电话:________________________Contact Number进货信息Purchase Information物料名称:________________________Material Name物料编号:________________________Material Number规格型号:________________________ Specification and Model批次号:________________________Batch Number进货日期:________________________Date of Purchase检验项目Inspection Items序号:______ 检验项目:________________________ No Inspection Item检验标准:________________________Inspection Standard检验要求:________________________Inspection Requirement检验结果Inspection Results检验员:________________________Inspector检验日期:________________________Date of Inspection检验结果:__________ 合格 / 不合格Inspection Result: Qualified / Not Qualified验收人:________________________Acceptance Person不合格处理Non-conformance Disposition不合格项目:________________________Non-conformance Item不合格原因:________________________Cause of Non-conformance不合格数量:______ 不合格率:________%(可选)Quantity of Non-conformance: Non-conformance Rate: %处理措施:________________________Corrective Actions验收人:________________________Acceptance Person备注Remarks其他要求:________________________Other Requirements其他说明:________________________Other Instructions签名Signature供应商代表:________________________Supplier Representative检验员:________________________Inspector进货部门:________________________Purchasing Department此为检验记录表样本,供参考使用。

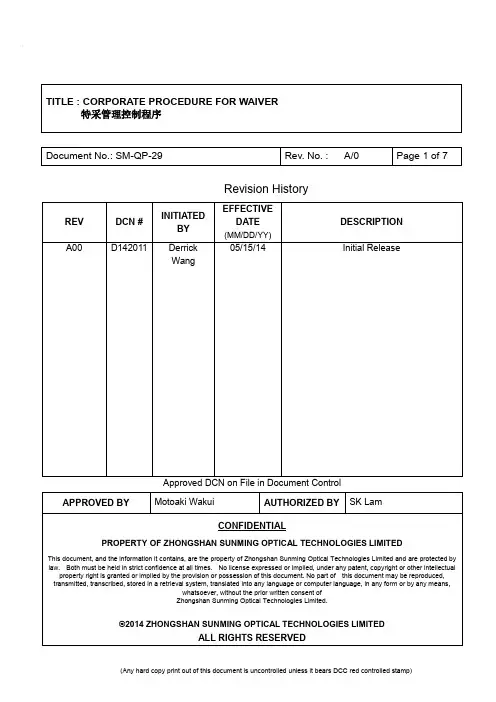

Revision HistoryApproved DCN on File in Document Control1.0 PURPOSE目的对于不符合公司品质之原物料进料,制程中半成品,成品,若不影响产品使用功能特性之前提件下,可依据本程序特采使用,以免影响正常生产或交期。

2.0 SCOPE 范围2.1生产急用,于限期内必须完成的生产作业。

2.2本程序适用于进料检验及制造过程检验,成品检验等程序。

3.0 ASSOCIATED DOCUMENTS 有关文件无4.0 DEFINITIONS 定义无5.0RESPONSIBILITY职责5.1品质部:提交原材料检验报告,对检验报告中内容必要时进行说明;5.2工程部:特采尺寸之判定;5.3采购部:依据需求对原材料提出特采申请;5.4生产部:全检执行、标准作业规范执行,依据实际情况对制程中的半成品及成品提出特采;5.5销售部:依据需求对成品提出特采申请5.6各单位主管:审核特采申请,提列特采相关意见;5.7总经理:对特采申请进行最终裁决。

6.0 PROCEDURE 流程6.1.原物料特采流程:6.1.1原物料经IQC判定不合格时,将不良内容及数量填写在【进料检验报告】中交品质工程师审核。

6.1.2品质工程师核准后仍然判为不合格(拒收)物料,遇下列情况由供应商或采购向品质部提出予以特殊审核或提出特采申请:(1)供应商或采购人员认定判定有误时(2)该批物料生产急需使用时,且短期内无法采购到更好原物料时(3)该缺陷对后续加工、生产影响甚微时(4)其他特殊情况时6.1.3采购依据生产计划需求提出特采申请,填写“特采申请单”,并附【来料检验报告】交品质部总监。

6.1.4品质总监与相关部门的责任人根据实际的情况召开物料特采(MRB)会议,并做出如下判定:(1)由品质部门重新抽样(2)指定某单位执行全数检验予以筛选(3)放宽标准特准使用(让步接收)(4)经加工后使用(5)维持不合格判定6.1.5若各主管会签同意特采,则交总经理核准,如有不同意见,则由总经理裁决,如不允许特采,则拒收该批物料。

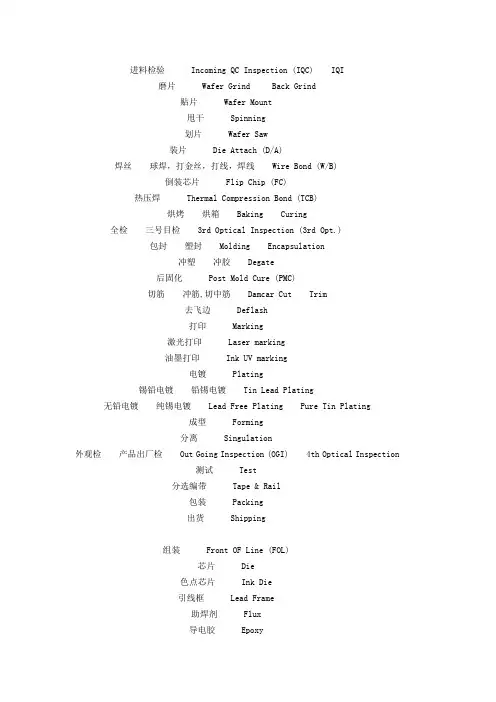

进料检验 Incoming QC Inspection (IQC) IQI磨片 Wafer Grind Back Grind贴片 Wafer Mount甩干 Spinning划片 Wafer Saw装片 Die Attach (D/A)焊丝球焊,打金丝,打线,焊线 Wire Bond (W/B)倒装芯片 Flip Chip (FC)热压焊 Thermal Compression Bond (TCB)烘烤烘箱 Baking Curing全检三号目检 3rd Optical Inspection (3rd Opt.)包封塑封 Molding Encapsulation冲塑冲胶 Degate后固化 Post Mold Cure (PMC)切筋冲筋,切中筋 Damcar Cut Trim去飞边 Deflash打印 Marking激光打印 Laser marking油墨打印 Ink UV marking电镀 Plating锡铅电镀铅锡电镀 Tin Lead Plating无铅电镀纯锡电镀 Lead Free Plating Pure Tin Plating成型 Forming分离 Singulation外观检产品出厂检 Out Going Inspection (OGI) 4th Optical Inspection测试 Test分选编带 Tape & Rail包装 Packing出货 Shipping组装 Front OF Line (FOL)芯片 Die色点芯片 Ink Die引线框 Lead Frame助焊剂 Flux导电胶 Epoxy蓝膜 Blue Tape / Mounting tape圆片 Wafer金丝 Gold wire推晶 Die shear弧高 Loop Height弧度 Wire Loop布线图 Bond diagram布线错误 Wrong Bonding焊丝拉力测克,拉丝 Wire Pull 推球金球剥离 Ball shear细刀 Capillary扭曲 Bending翘曲 Bow / Warpage硅屑 Silicon Dust沾污 Contaminate压伤 Dented变形 Distort缺角 Chip Die锡膏回流 Solder Reflow银厚度 Silver Thickness毛刺针刺 Burr塌丝 Depress Wire超波膜 UV Tape火山口 Crater Ring断丝 Broken Wire昂球 Lifted Bond飞球 Sky Ball金属剥落 Lifted Metal昂楔 Lifted Wedge高尔夫球 Golf Ball扁球 Flat Ball半球 Insufficient Ball Size 不粘 Non-Stick芯片裂缝 Crack Die 错方向 Wrong Orientation焊不牢 Incomplete Bond无焊 No Bonding翘芯片 Lifted Die误置芯片 Misplaced Die芯片装斜 Tilted Die芯面粘胶 Epoxy On Die导电胶不足 Insufficient Epoxy多胶 Excess Epoxy导电胶气孔 Epoxy Void镀层气孔 Solder Void导电胶裂缝 Epoxy Crack金属划伤 Saw Into Metal擦痕 Scratches墨溅 Ink Splash薄膜气泡 Tape Bubbles边沿芯片 Edge Die镜子芯片 Mirror Die飞片 Fly Die封装 End Of Line (EOL)排气 Air vent托块 Insert刀片 Punch型腔 Cavity料饼塑料,树脂,环氧 Mold Compound Mold pallet基岛 Paddle (PAD) DAP共面性 Coplanity点温计 Digimite空封 Dummy Molded Strip废胶跑料,废料 Mold Flash小脚 Gate Remain脚间距开档,总宽,跨度 Lead Tip to Tip Total Width, Lead Distance.包封偏差 Molding Mismatch包封模具 Mold Chase冲切,成型模具 Dieset清模 Mold Cleaning多肉 Package Bump引线条 Molded Strip溢胶 Mold Bleed包反 Wrong Orientation Molding印偏 Offset Marking焊丝冲弯 Wire Sweep错位 Molding Mismatch偏心 Molding Offset气孔空洞,气泡 Void排气不畅 Air Vent Clog偏脚 Offset Punch注浇口,进浇口 Injection Gate 1st Gate上料框 Frame Loader冲圆 Fan Out模温 Mold Temperature表面粗糙 Rough Surface未填充 Incomplete Mold料饼醒料 Compound Aging顶针 Ejector Pin顶孔顶料孔 Ejector Pin hole定位块 Locator Block粘模 Sticky Mold烘箱 Oven麻点镀层起毛 Solder Blister锡桥搭锡 Solder Bridge镀层起泡拉尖 Solder Bump镀层剥落 Solder Peel Off锡丝 Solder Flick露铜露底材 Expose Copper细脚小脚 Narrow Lead镀层厚度 Plating Thickness变色 (发黄,发黑,发花,水渍,酸斑) Discolor (Yellowish, Blacken, WaterMark)锡球 Solder Pad镀层偏厚或偏薄 Thick or Thin Plating易焊性 Solderability退锡 Solder Remove站立高度 Stand Off切中筋凸出或凹陷 Dambar Protrusion or Intrusion连筋 Uncut Dambar脚长 Lead Length管脚刮伤 Lead Scratches管脚反翘 Lead Tip Bend反切 Wrong Orientation Forming.缺脚缺管,断脚 Missing Lead Broken Lead裂缝胶体破裂 Crack Package微裂缝 Micro Crack崩角缺角,缺损 Chip Package Chip Off成型角度 Foot angle共面性 Coplanarity倒角 Touch Up印章印记 Marking Layout断字 Broken character印记磨糊褪色 Fad Mark打印不良 Illegible Marking打印字间距 Mark Character Distance印记倾斜 Slant Marking漏打 No marking缺字 Missing Character错字 Wrong Marking弄脏 Smear定位针 Location Pin烧氢 Hydrogen Frame扫描打印 Writing laser模板激光 Mask Laser常用的术语集成电路 Integrated Circuit (IC)塞头 Plug托盘 Tray编带, 带盖 Rail, Rail Cover料管 Tube静电袋 Anti Static Bag支持棒 Suspension Bar Fishtail, tie bar 随件单 Traveling Card Run Card去离子水 D.I. Water散热片 Heat Sink品管 Quality Control (QC)品保 Quality Assurance (QA)关卡 QC Gate校验 Calibrate照明放大镜 Dazor Light Ring Light显微镜 Microscope返工 Rework质量标准 Criteria扩散批 Wafer Lot Mother Lot批 Lot抽样 Sample Size (SS)良品 Accept Unit (Acc)不良品 Reject Unit (Rj)良率 Yield次品率不良率 Yield Lost外次率 O.G.I. YieldX管率 X-ray Yield目检 Visual Inspection正面 Top Surface反面 Bottom surface冷藏库料饼存放库 Cold Room Compound storage 表面贴装式 Surface Mount Technology (SMT)报废 Scrap开短路 Open short调机 Machine Buy Off单列直插式 Single Side Lead Insert双列直插式 Dual Side Lead Insert Type 内控 Internal / In-house Control在制品 Work In Progress (WIP)。

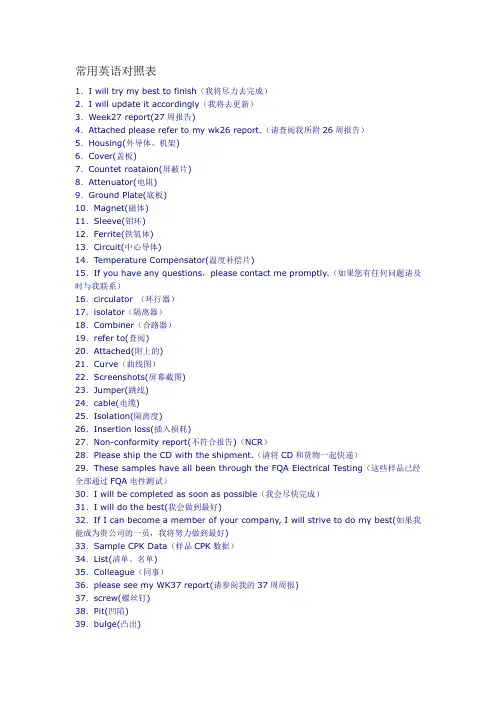

常用英语对照表1.I will try my best to finish(我将尽力去完成)2.I will update it accordingly(我将去更新)3.Week27 report(27周报告)4.Attached please refer to my wk26 report.(请查阅我所附26周报告)5.Housing(外导体、机架)6.Cover(盖板)7.Countet roataion(屏蔽片)8.Attenuator(电阻)9.Ground Plate(底板)10.Magnet(磁体)11.Sleeve(铝环)12.Ferrite(铁氧体)13.Circuit(中心导体)14.Temperature Compensator(温度补偿片)15.If you have any questions,please contact me promptly.(如果您有任何问题请及时与我联系)16.circulator (环行器)17.isolator(隔离器)18.Combiner(合路器)19.refer to(查阅)20.Attached(附上的)21.Curve(曲线图)22.Screenshots(屏幕截图)23.Jumper(跳线)24.cable(电缆)25.Isolation(隔离度)26.Insertion loss(插入损耗)27.Non-conformity report(不符合报告)(NCR)28.Please ship the CD with the shipment.(请将CD和货物一起快递)29.These samples have all been through the FQA Electrical Testing(这些样品已经全部通过FQA电性测试)30.I will be completed as soon as possible(我会尽快完成)31.I will do the best(我会做到最好)32.If I can become a member of your company, I will strive to do my best(如果我能成为贵公司的一员,我将努力做到最好)33.Sample CPK Data(样品CPK数据)34.List(清单、名单)35.Colleague(同事)36.please see my WK37 report(请参阅我的37周周报)37.screw(螺丝钉)38.Pit(凹陷)39.bulge(凸出)40.针孔(Pin hole)41.破洞(hole)42.Attached please find my WK38 report(请查收我的38周周报)43.Duplexer(双工器)44.Please give directions(请给予指示)45.Attenuator(衰减器)46.Thanks for your report(感谢你的报告)47.cosmetic defect(外观不良)48.dimension defect(尺寸不良)49.Oxidation(氧化)50.Department(部门)51.Dept(部门)52.Quality dept(品质部)53.production dept(生产部)54.R&D dept(研发部)55.engineering dept(工程部)56.Technology dept(技术部)57.Data sheet (数据表单、记录表)58.update(更新)59.Reply(回复)60.Base plate(底座)61.surface treatment(表面处理)62.Express(快递)63.Pack(包裹)64.load(负载)65.attachment(附件)66.Also(也,同样)67.Network analyzer(网络分析仪)68.Requirement(要求)69.Please let me know if you have any question on this.(如果你有任何问题,请及时与我联系)70.Thanks for the information(谢谢你提供的信息)71.Give feedback (意见反馈)72.Thanks to inform us the problem and help us to improve our product quality(感谢你告知我们的问题,帮助我们改善产品的质量)73.How are you?(你好吗)74.Hope you have a happy weekend.(祝你周末愉快)75.Please see comments below.(请看下面的评论)76.My answers are in blue below.(我的回答已标示蓝色)77.Greeting message (祝福)78.Hope you have a good trip back. (祝旅途愉快)79.Any question, please let me know.( 有任何问题,欢迎和我们联系)80.Your comments and suggestions are welcome! (欢迎您的评论和建议! )81.Do you have any idea about this? (对于这个您有什么建议吗? )82.What do you think about this?(这个你怎么想? )83.Look forward to your feedbacks and suggestions soon. (期待您的反馈建议! )84.How is the project going on? (项目进行顺利吗? )85.Attached please find today’s meeting notes. (今天的会议记录在附件里。

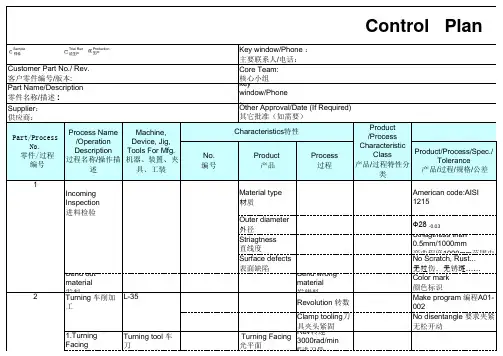

TS16949进料检验作业程序Incoming inspection procedure 文件更改历史记录Amendment HistoryTS16949进料检验作业程序Incoming inspection procedure1.0 目的:本程序旨在建立适切之进料检验作业管制,以确保外购的生产性材料材质符合环境要求,质量符合本公司的设计要求.Attempt: The procedure is to establish unanimous incoming inspectoperations, in order to make sure those purchasing stuff canmanage environment requirement and the quality can come up todesign .2.0 范围:适用于本公司所有外购的生产性物料的进料检验.Range: Apply to all incoming inspection of purchasing stuff.3.0 定义: Definition3.1 IQC: 进料检验单位(Incoming Quality Control).3.2 SQE :供货商质量工程(Supplier Quality Engineer).3.3 客供配件:由客户提供,代为出货包装用之配件,并不参与成品组立、加工作业流程.(此种配件不纳入零件承认规范内,仅作资材面处理).Customer supplied parts: Customer supplied parts are used to delivery package parts, not participate in final-products、operation procedure.(the parts are not bring into parts recognition rules, only be regarded as stuff management)4.0 权责: Rights and responsibility4.1 品保部负责物料的检验、判定、检验后的标识及不合格品的改善追踪工作.QA Dep. manage stuff inspection、judgment、mark and rejects improving or tracking after inspection.4.2 资材部采购员负责与供货商联络,并协助来料质量异常的处理及改善追踪.Material purchaser manage and communicate with suppliers, then support dealing and tracking anomaly.5.0 作业内容: Contents5.1 检验规划:Inspection planning5.1.1 抽样计划:IQC依MIL-STD-105E(II)对进料实施抽样检验.Sampling scheme: IQC refer to MIL-STD-105E(II)to execute sampling action.5.1.2 正常检验:IQC依MIL-STD-105E(II)对进料实施抽样检验.Regular inspection: IQC refer to MIL-STD-105E(II)to execute sampling action.5.1.3 抽样时机:IQC依照MIL-STD-105E(II)对物料进行抽验检验,取样需平均抽样,在仓库平均取样后,在IQC室依照该物料之承认书与图纸执行检验。

加工贸易合同备案办事指南Processing trade contract for the record flow第一步:新企业勘验First Step: The new enterprise inquisition.企业携带以下文件,前往加工地主管海关申请加工贸易企业勘验。

The enterprise takes the following documentation to local customs to apply for the inquisition.1.企业法人营业执照Business license2.加工企业生产能力证明Certification of productive capacity3.加工贸易合同或副本Processing trade contract or copy contract4.海关注册登记表Customs registration form5.土地使用证或产权证Land use certificate or Certificate of title6.加工贸易业务批准证Approval form for processing trade7.企业验资报告Capital verification report8.上年度企业审计报告Audit report for last year9.税务登记证Tax registration certificate10.主要设备的清单和发票Major equipment list and related invoice.第二步:合同备案企业应交验的必备单证;Second step: The enterprises should submit the necessary documentation for the record.1.商务部门签发的有效的《加工贸易业务批准证》;"Approval form for processing trade" issue by Commerce department.2.商务部门签发的《加工贸易加工企业生产能力证明》;"Certification of productive capacity"issue by Commerce department.3.加工贸易合同或合同副本,以复印件备案的必须加盖企业公章;Processing trade contract or copy contract, if use copy contract for the record, it must stamp a company seal.4.已填写合同内容并加盖企业公章的加工贸易登记手册;“Processing trade registration handbook”, already filled out the information from the processing trade contract and stamp a company seal.5.国税部门备案证明(来料加工除外);Certification issue by National tax department(Except accept customers' materials for processing)6.产品生产工艺流程;Production process7.为确定单耗和损耗率所需的有关资料;Other related documentations to calculate unit consumption and attrition rate.8.海关认为需要的其他单证或资料。

品质专业术语ADM Administration Department 行政部AFR Annual Failure Rate 年度返修率ACC Acceptable 允许接收AOQ Average Output Quality 平均出货质量AQL Acceptable Quality Level 品质允收水准APQP Advanced Product Quality Plan 产品质量先期策划BOM Bill Of Material 材料清单B/R Batch Run 批量测试C/R Corrective Action 矫正措施CA Customer Service Department 客户服务部CAR Corrective Action Request 矫正措施要求CCC China Compulsory Certificate 中国强制认证CET Customer Experience Test 顾客体验测试CIP Capacity improvement plan 产能改善计划CP Capability index 准确度CPK Process Capability Index 工序能力指数CPI Continuous Process Improvement 连续工序改善CQA Customer Quality Assurance 客户质量保证CQC China Quality Certification Center 中国质量认证中心CR critical defect 严重缺点CS Customer Serves 客户服务CSDI检修DAS Defects Analysis System 缺陷分析系统DFA Design For Assembly 设计组装性DFM Design For Manufacturing 设计制造性DOE Design Of Experiments 实验设计DPP M Defect Parts Per Million 百万分之不良率DVT Design Verification Test 设计验证测试DAP Dead after Purchase 购买后损坏DOA Dead On Arrival 开箱损坏ECN Engineering Change Notice 工程变更通知ECR Engineering Change Requirment 工程变更需求EVT Engineering Verification Test 工程验证测试FA Failure Analysis 不良分析FAA First ArticleAffirm 首件确认FAI First Article Inspection 首件检验FIFO First In First Out 先进先出FIR Initial Field Incident Rate 市场不良率FMEA failure model effectiveness analysis 失效模式分析FPIR First Piece Inspection Report 首件检查报告FPYR First Pass Yield Rate 直通率FMEA Failure Mode Effect Analysis 失效模式影响分析FQA Final Quality Assurance 最终品质保证FQC Final quality control 最终检验ISO国际标准化组织ISA Industry Standard Architecture 工业标准体制结构IPQC In Process Quality Control 制程品质管理IQC Incoming Quality Control 进料品质管理KPI Key Performance Indication 关键业绩指标LAB Laboratory 实验室LCL Lower control limit 管制下限LQC Line Quality Control 生产线品质控制LRR Lot Reject Rate 批退率LSL Low Specification Limit 规格下限MA Major Defect 主要缺点MA Minor Defct 次要缺点ME Manufacturing Engineering 制造工程MC mater control 物料管理MO Manafacture Order 生产单MRB Material reject bill 退货单MSA Measurement System Analysis 测量系统分析NCM Non-Conformance Material 不合格品N/A None Available 不合适,不适用NG No Good 不良品NPL Non-Production Loss 非生产漏失ORT On Reliability Test 可靠性测试OQC Outgoing Quality Control 出货品质管理OEM Original equipment manufacturer 原设备制造者ODM Original Design Manufacturer 原设计制造者OBA Out of Box Audit 开箱检查PA purchasing agent 采购员PC producing control 生产管理PCN Process Change Notice 制程变更通知PPAP Production Part Approval Process 生产件批准程序P/N Part Number 料号P/O Purchase Order 采购单PD Production Department 生产部PE Product Engineering 产品工程部PQA Process Quality Assurance 制程品质保证PPR Production Pilot Run 生产试做QA Quality Assurance 品质保证-质量QAPS Quality Assurance Process Sheet 品质工程表QC Quality Control 品质管理QE Quality Engineer 品质工程QFD Quality Function Deployment 品质机能展开QRE Quality Reliability Engineer 品质可靠度工程QS Quality System 品质系统QSA Quality System Audit 品质系统审核QP Quality policy 目标方针QI Quality improvement 品质改善QPA Quality Process Audit 制程品质审核QT Quality target 品质目标REJ Reject 判退RMA Returned Material Authority 客户退品职责RPN Risk Priority Number 风险优先数SQE Supplier Quality Engineer 供应商品质工程师SCA R Supplier Corrective Action Report 供应商纠正措施报告SA Sample Approval 标准作业指导书SI Suspect inspection客户验货S/N Serial Number 序列号SPC Statistical Process Control 统计制程管制ST Shipment Ticket 出货单SIP Supplier Quality Report Card 检验标准指导书SOP Standard Operation Procedure 作业标准指导书S/O Sales Order 业务订单S/S Sample size 抽样检验样本大小SI-SIV Special I-Special IV 特殊抽样水平等级SQA Source Quality Assurance 供应商品质保证TE Testing engineering 测试工程TQC Total Quality Management 全面品质管理TQM Total Quality Control 全面品质管理UCL Upper control limit 管制上限USL Upper Specification Limit 规格上限VQA Vendor Quality Assurance 供应商品质保证WIP Work In Process 在制品W/H Ware House 仓库Y/R Yield Rate 良率。

进料检验作业指导书Incoming_Inspection_Work_Instruction(ISO9001:2015)1.0Purpose目的The objective of this procedure is to define a standard inspection method in performing inspection and testing of components or materials.本程序目的在于定义对元件或材料进行检验/测试的标准操作方法。

Scope适用范围This procedure is applicable to all components and materials that require the relevant inspection and testing, as specified in the individual Part or Material Specification.本程序适用于所有按照元件和材料规格进行检验和测试的元件和材料。

2.0Sampling / Equipment Used 取样 / 使用设备2.1Per sampling plan stated in the Incoming Inspection Procedure: AQL:MA=0.4、MI=1.0按照来料检验程序所规定的抽样计划;AQL:MA=0.4、MI=1.0级别进行抽样.2.2Inspection Aids检验工具4.2.1 LCR Meter / LCR 测量仪4.2.2 Fluke Multimeter / Fluke 万用表4.2.3 Caliper / Plug Gauge / Pin Gauge / 游标卡尺/ 塞规/针规4.2.4 Magnifier / Microscope / 放大镜 / 显微镜3.0Reference Documents参考文件3.1 Customer’s AVL / 客户接受的供应商清单3.2 Manufacturer Part Specification / 供应商的元件规格3.3 Yamaoka AVL List / 本公司的AVL3.4 QAP-010 : Incoming Inspection Procedure / 来料检验程序3.5 SOP-QA-003 : Material Aging Control Procedure / 物料保质期控制程序4.0Inspection Criteria / 检验要点4.1MFG AVL Verification / 生产厂商确认Verify that the parts are from the authorized vendor per AVL list.根据AVL清单验证元件是否为承认厂商。

流 程Flow path负责单位Duty dept.说明Description 库管员Librarian 1:供应商送货到我公司附送货单(订单、名称、数量、产品检测报告),仓库接收。

1.The supplier shall deliver the goods to our company's attached delivery list (order, name, quantity, product testreport), which will be received by the warehouse.库管员Librarian 2:仓库点收并确认接收后,如有紧急物料在收货单上标识,将供应商送货单交给IQC检验员,检验人员依照送货单零部件名称按AQL抽样水准去待检区抽样检验。

2: After the warehouse receives and confirms receipt, if there is urgent material on the receipt, the supplier delivery note will be handed over to the IQC inspector. The inspector will go to the inspection area according to the AQL sampling level according to the name of the delivery part. Sampling test.质量部Quality dept.IQC根据物料紧急程序安排检验计划IQC检验员根据产品名称,及图纸或SIP要求,选择合适的量检具,对产品进行检验IQC arranges inspection plans based on material emergency procedures The IQC inspector selects the appropriate gauge according to the product name, and the drawing or SIP requirements toinspect the product.质量部Quality dept.4:IQC需参照相对应零部件名称的图纸并依照SIP内容进行尺寸/性能等检验 。