Duplex SS fabrication

- 格式:pdf

- 大小:650.24 KB

- 文档页数:24

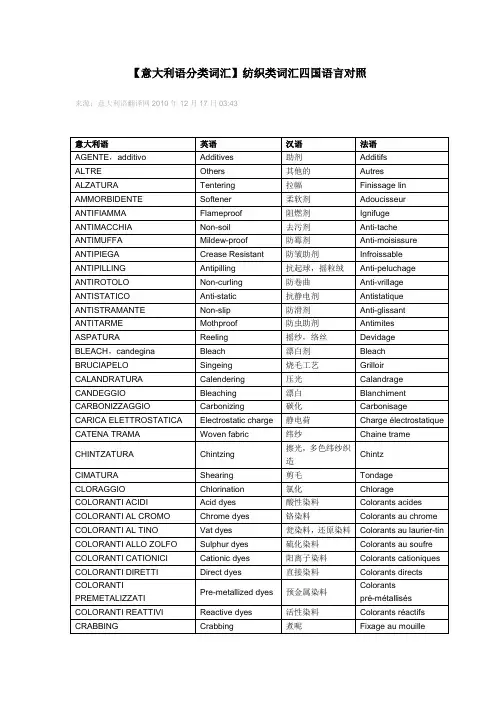

纺织品专业词汇翻译中英文对照表纺织品[转]纺织品专业词汇翻译中英文对照表纺织品braided fabric 编织物 deformation 变形;走样 fast colours 不褪色;色泽牢固 punch work 抽绣 embroidery 刺绣品acetate fibre 醋酯纤维 hemp 大麻 damp proof 防潮 sanforizing, pre-shrunk 防缩textiles 纺织品 crochet 钩编编织物gloss, lustre 光泽 synthetic fibre 合成纤维 chemical fibre 化学纤维 jute 黄麻 gunny cloth (bag)黄麻布(袋)mixture fabric, blend fabric 混纺织物woven fabric 机织织物spun silk 绢丝 linen 麻织物 woolen fabrics 毛织物(品) cotton textiles 棉纺织品 cotton velvet 棉绒 cotton fabrics 棉织物(品) non-crushable 耐绉的 viscose acetal fibre 黏胶纤维matching, colour combinations 配色rayon fabrics 人造丝织物 artificial fibre 人造纤维 crewel work 绒线刺绣mulberry silk 桑蚕丝 , 家蚕丝 silk fabrics 丝织物 silk spinning 丝纺linen cambric 手帕亚麻纱 plain 素色figured silk 提花丝织物 jacquard 提花织物 applique embroidery 贴花刺绣discolourization 褪色 mesh fabric 网眼织物 bondedfibre fabric 无纺织物embroidered fabric 绣花织物 flax 亚麻 linen yarn 亚麻纱 knitting 针织 knitwear 针织品 hosiery 针织物 textile fabric 织物 ramee, ramie 苎麻 tussah silk 柞蚕丝服装--- clothes 衣服, 服装 wardrobe 服装 clothing 服装 habit 个人依习惯 .身份而着的服装 ready-made clothes, ready-to-wear clothes garments 外衣 town clothes 外衣 double-breasted suit 双排扣外衣 suit 男外衣 dress 女服 tailored suit 女式西服 everyday clothes 便服 three-piece suit 三件套 trousseau 嫁妆 layette 婴儿的全套服装uniform 制服 overalls 工装裤 rompers 连背心的背带裤 formal dress 礼服 tailcoat, morning coat 大礼服evening dress 夜礼服 dress coat, tails 燕尾服 , 礼服nightshirt 男式晚礼服成衣dinner jacket 无尾礼服(美作:tuxedo) fulldress uniform 礼服制服 frock coat 双排扣长礼服gown, robe 礼袍 tunic 长袍 overcoat 男式大衣 coat 女大衣 topcoat 夹大衣 fur coat 皮大衣 three-quarter coat 中长大衣 dust coat 风衣mantle, cloak 斗篷 poncho 篷却(南美人的一种斗篷) sheepskin jacket 羊皮夹克 pelisse 皮上衣jacket 短外衣夹克 anorak, duffle coat 带兜帽的夹克 , 带风帽的粗呢大衣 hood 风帽 scarf, muffler 围巾 shawl 大披巾 knitted shawl 头巾, 编织的头巾fur stole 毛皮长围巾 muff 皮手筒 housecoat, dressing gown 晨衣(美作 :duster) short dressing gown 短晨衣 bathrobe 浴衣 nightgown, nightdress 女睡衣 pyjamas 睡衣裤(美作 ajamas) pocket 衣袋lapel (上衣)翻领 detachable collar 假领 ,活领wing collar 硬翻领 ,上浆翻领V-neck V 型领 sleeve 袖子 cuff 袖口 buttonhole 钮扣孔 shirt 衬衫 blouse 紧身女衫 T-shirt 短袖圆领衫 ,体恤衫 vest 汗衫(美作:undershirt) poloshirt 球衣 middy blouse 水手衫 sweater 运动衫short-sleeved sweater 短袖运动衫 roll-neck sweater 高翻领运动衫 round-neck sweater 圆领运动衫 suit, outfit, ensemble 套服 twinset 两件套 ,运动衫裤jerkin 猎装 kimono 和服 ulster 一种长而宽松的外套jellaba, djellaba, jelab 带风帽的外衣 cardigan 开襟毛衣 mac, mackintosh, raincoat 橡胶雨衣 trousers 裤子jeans 牛仔裤 short trousers 短裤 knickers 儿童灯笼短裤 knickerbockers 灯笼裤 plus fours 高尔夫球裤 ,半长裤 braces 裤子背带(美作 :suspenders)turnup 裤角折边 ,挽脚 breeches 马裤 belt 裤带skirt 裙子 divided skirt, split skirt 裙裤underskirt 内衣 underwear , underclothes 内衣裤underpants, pants 内衣裤(美作 :shorts) briefs 短内裤 ,三角裤 panties 女短内裤 knickers 女半短内裤 , 男用灯笼短裤 brassiere, bra 乳罩 corselet 紧身胸衣 stays, corset 束腰 ,胸衣waistcoat 背心 slip, petticoat 衬裙 girdle 腰带stockings 长袜 suspenders 袜带(美作 :garters)suspender belt 吊袜腰带(美作:garter belt)socks 短袜tights, leotard 紧身衣裤handkerchief 手帕 bathing trunks 游泳裤bathing costume, swimsuit, bathing suit游泳衣bikini 比基尼泳衣 apron 围裙 pinafore(带护胸)围裙 shoe 鞋 sole 鞋底 heel 鞋后跟lace 鞋带 moccasin 鹿皮鞋 patent leather shoes 黑漆皮鞋 boot 靴子 slippers 便鞋 sandal 凉鞋canvas shoes, rope soled shoes 帆布鞋 clog 木拖鞋galosh, overshoe 套鞋 glove 手套 tie 领带(美作 :necktie) bow tie 蝶形领带 cravat 领巾 cap 便帽 hat 带沿的帽子 bowler hat 圆顶硬礼帽 top hat 高顶丝质礼帽 Panama hat 巴拿马草帽 beret 贝蕾帽peaked cap, cap with a visor 尖顶帽 broad-brimmed straw hat 宽边草帽 headdress 头饰 turban 头巾natural fabric 天然纤维 cotton 棉 silk 丝 wool 毛料 linen 麻 synthetic fabric 混合纤维 acryl 压克力polyester 伸缩尼龙 nylon 尼龙 worsted 呢料cashmere 羊毛 patterns 花样tartan plaid 格子花(美作:tartan)dot 圆点花 stripe 条纹 flower pattern 花纹花样veil 面纱颜色--- pink 粉红色 salmon pink 橙红色 baby pink 浅粉红色 shocking pink 鲜粉红色 brown 褐色 , 茶色 beige 灰褐色 chocolate 红褐色 , 赭石色sandy beige 浅褐色 camel 驼色 amber 琥珀色khaki 卡其色 maroon 褐红色 green 绿色 moss green 苔绿色 emerald green 鲜绿色 olive green 橄榄绿 blue 蓝色 turquoise blue 土耳其玉色 cobalt blue 钴蓝色 , 艳蓝色 navy blue 藏青色 , 深蓝色 , 天蓝色 aquamarine blue 蓝绿色 red 红色 scarlet 绯红 , 猩红 mauve 紫红 wine red 葡萄酒红purple, violet 紫色 lavender 淡紫色 lilac 浅紫色 antique violet 古紫色pansy 紫罗兰色 white 白色 off-white 灰白色 ivory 象牙色 snowy white 雪白色oyster white 乳白色gray 灰色 charcoal gray 炭灰色 smoky gray 烟灰色 misty gray 雾灰色End==wedoliya 提供 ==End ++ 感谢: Handson 提供 ++Begin==Handson 提供==Begin 服装专业词汇[分享]服装专业词汇A 色牢度试验项目 COLOUR FASTNESS TESTS 皂洗牢度 washing 摩擦牢度rubbing/crocking 汗渍牢度 perspiration 干洗牢度 drycleaning 光照牢度light 水渍牢度 water 氯漂白 chlorine bleach spotting 非氯漂白 non-chlorine bleach 漂白 bleaching实际洗涤(水洗一次) actual laundering (one wash) 氯化水 chlorinated water 含氯泳池水 chlorinated pool water 海水 sea-water 酸斑 acid spotting 碱斑 alkaline spotting 水斑 water spotting 有机溶剂 organic solvent 煮呢 potting 湿态光牢度 wet light 染料转移 dye transfer 热(干态) dry heat 热压 hot pressing 印花牢度 print durability 臭氧 ozone 烟熏 burnt gas fumes 由酚类引起的黄化 phenolic yellowing 唾液及汗液saliva and perspiration B 尺寸稳定性(缩水率)及有关试验项目(织物和成衣)DIMENSIONAL STABILITY (SHRINKAGE) AND RELATED TESTS (FABRIC & GARMENT) 皂洗尺寸稳定性 dimensional stability to washing (washing shrinkage) 洗涤/手洗后的外观 appearance after laundering / hand wash 热尺寸稳定性dimensional stability to heating 熨烫后外观 appearance after ironing 商业干洗稳定性 dimensional stability to commercial drycleaning (drycleaning shrinkage)商业干洗后外观 ( 外观保持性) appearance after commercial drycleaning (appearance retention)蒸汽尺寸稳定性 dimensional stability to steaming 松弛及毡化dimensional stabilty to relaxation and felting 缝纫线形稳定性dimensional stability for sewing thread C 强力试验项目STRENGTH TESTS 拉伸强力 tensile strength 撕破强力 tear strength 顶破强力 bursting strength 接缝性能 seam properties双层织物的结合强力 bonding strength of laminated fabric 涂层织物的粘合强力 adhesion strength of coated fabric 单纱强力 single thread strength 缕纱强力 lea strength 钩接强力 loop strength 纤维和纱的韧性tenacity of fibres and yarn D 织物机构测试项目 FABRIC CONSTRUCTION TESTS织物密度(机织物 ) threads per unit length (woven fabric construction) 织物密度(针织物 ) stitch density (knittted fabric) 纱线支数 counts of yarn 纱线纤度(原样) denier counts as received 织物幅宽 fabric width 织物克重 fabric weight 针织物线圈长度 loop length of knitted fabric 纱线卷曲或织缩率 crimp or take-up of yarn 割绒种类 type of cut pile 织造种类 type of weave 梭织物纬向歪斜度 distortion in bowed and skewedfabrics received and after one wash) 圈长比 terry to ground ratio 织物厚度 fabric thickness E 成分和其他分析试验项目COMPOSITION AND OTHER ANALYTICAL TESTS 纤维成分 fibre composition 染料识别 dyestuff identification 靛蓝染料纯度 purity of indigo 含水率 moisture content 可萃取物质 extractable matter 填充料和杂质含量 filling and foreign matter content 淀粉含量 starchcontent 甲醛含量 formaldehyde content 甲醛树脂 presence offormaldehyde resin 棉丝光度 mercerisation in cotton PH 值PH value 水能性 absorbance F 可燃性试验项目 FLAMMABILITYTESTS 普通织物的燃烧性能 flammability of general clothingtextiles 布料的燃烧速率( 45。

纺织印染中英文对照大全公司内部编号:(GOOD-TMMT-MMUT-UUPTY-UUYY-DTTI-纺织印染中英文对照大全A 色牢度试验项目 COLOUR FASTNESS TESTS皂洗牢度 washing摩擦牢度 rubbing/crocking汗渍牢度 perspiration干洗牢度 drycleaning光照牢度 light水渍牢度 water氯漂白 chlorine bleach spotting非氯漂白 non-chlorine bleach漂白 bleaching实际洗涤(水洗一次) actual laundering (one wash)氯化水 chlorinated water含氯泳池水 chlorinated pool water海水 sea-water酸斑 acid spotting碱斑 alkaline spotting水斑 water spotting有机溶剂 organic solvent煮呢 potting湿态光牢度 wet light染料转移 dye transfer热(干态) dry heat热压 hot pressing印花牢度 print durability臭氧 ozone烟熏 burnt gas fumes由酚类引起的黄化 phenolic yellowing唾液及汗液 saliva and perspirationB 尺寸稳定性(缩水率)及有关试验项目(织物和成衣)DIMENSIONAL STABILITY (SHRINKAGE) AND RELATED TESTS (FABRIC & GARMENT)皂洗尺寸稳定性 dimensional stability to washing (washing shrinkage)洗涤/手洗后的外观 appearance after laundering / hand wash热尺寸稳定性 dimensional stability to heating熨烫后外观 appearance after ironing商业干洗稳定性 dimensional stability to commercial drycleaning (drycleaning shrinkage)商业干洗后外观(外观保持性) appearance after commercial drycleaning (appearance retention)蒸汽尺寸稳定性 dimensional stability to steaming松弛及毡化 dimensional stabilty to relaxation and felting 缝纫线形稳定性 dimensional stability for sewing threadC 强力试验项目STRENGTH TESTS拉伸强力 tensile strength撕破强力 tear strength顶破强力 bursting strength接缝性能 seam properties双层织物的结合强力 bonding strength of laminated fabric 涂层织物的粘合强力 adhesion strength of coated fabric单纱强力 single thread strength缕纱强力 lea strength钩接强力 loop strength纤维和纱的韧性 tenacity of fibres and yarnD 织物机构测试项目FABRIC CONSTRUCTION TESTS织物密度(机织物) threads per unit length (woven fabric construction)织物密度(针织物) stitch density (knittted fabric)纱线支数 counts of yarn纱线纤度(原样) denier counts as received织物幅宽 fabric width织物克重 fabric weight针织物线圈长度 loop length of knitted fabric纱线卷曲或织缩率 crimp or take-up of yarn割绒种类 type of cut pile织造种类 type of weave梭织物纬向歪斜度 distortion in bowed and skewed fabrics (report as received and after one wash)圈长比 terry to ground ratio织物厚度 fabric thicknessE 成分和其他分析试验项目COMPOSITION AND OTHER ANALYTICAL TESTS纤维成分 fibre composition染料识别 dyestuff identification靛蓝染料纯度 purity of indigo含水率 moisture content可萃取物质 extractable matter填充料和杂质含量 filling and foreign matter content淀粉含量 starch content甲醛含量 formaldehyde content甲醛树脂 presence of formaldehyde resin棉丝光度 mercerisation in cottonPH值 PH value水能性 absorbanceF 可燃性试验项目FLAMMABILITY TESTS普通织物的燃烧性能 flammability of general clothing textiles 布料的燃烧速率(45。

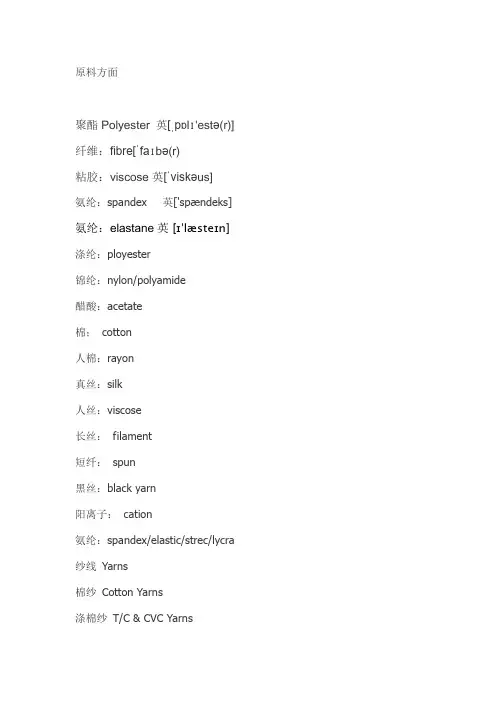

原料方面聚酯Polyester 英[ˌpɒlɪ'estə(r)] 纤维:fibre[ˌfaɪbə(r)粘胶:viscose英[ˌviskəus]氨纶:spandex 英['spændeks] 氨纶:elastane英 [ɪˈlæsteɪn]涤纶:ployester锦纶:nylon/polyamide醋酸:acetate棉;cotton人棉:rayon真丝:silk人丝:viscose长丝:filament短纤:spun黑丝:black yarn阳离子:cation氨纶:spandex/elastic/strec/lycra 纱线Yarns棉纱Cotton Yarns涤棉纱T/C & CVC Yarns粘棉纱Cotton/Rayon Yarns棉晴纱Cotton/Acrylic Yarns棉/氨纶包芯纱Cotton/Spandex Yarns棉与其他混纺纱Cotton/Others Blended Yarns毛纺系列纱线Woollen Yarn Series羊绒纱Cashmere Yarn Series全羊毛纱Wool (100%) Yarns毛晴纱Wool/Acrylic Yarns毛涤纱Wool/Polyester Yarns毛粘纱Wool/Viscose Yarns麻棉混纺布:linen/cotton blended fabric 粒粒绒布:pellet fleece velvet 麻棉交织布:linen/cotton mixed fabric 素色毛巾布:solid terry素色卫衣布:solid fleece彩条汗布color-stripes single jersey鱼网布:fleece里料:lining面料:fabric平纹:taffeta缎面:satin / charmeuse斜纹:twill绡:lustrine提花jacquard烂花:burnt-out格子:check条子:stripe双层:double – layer双色:two – tone花瑶:faille雪纺:chiffon高士宝:koshibo乔其:georgette塔丝隆:taslon弹力布:spandex/elastic/strec/lycra 牛仔布:jeanet牛津布:oxford帆布:cambric黑条纺:black stripe水洗绒/桃皮绒:peach skin卡丹绒:peach twill绉绒:peach moss玻璃纱:organdy服装面料英语(一)002,面料:FABRIC003,平纹:TAFFETA004,斜纹:TWILL005,缎面:SATIN CHARMEUSE 006,绡:LUSTRINE007,提花:JACQUARD008,烂花:BURNT-OUT009,春亚纺:PONGEE010,格子:CHECK011,条子:STRIPE012,双层:DOUBLE –LAYER 013,双色:TWO –TONE 014,花瑶:FAILLE015,高士宝:KOSHIBO017,乔其:GEORGETTE018,塔丝隆:TASLON019,弹力布:SPANDEXELASTICSTRECLYCRA 020,牛仔布:JEANET021,牛津布:OXFORD022,帆布:CAMBRIC023,涤棉:PC024,涤捻:TR025,白条纺:WHITE STRIPE026,黑条纺:BLACK STRIPE027,空齿纺:EMPTY STRIPE028,水洗绒桃皮绒:PEACH SKIN029,卡丹绒:PEACH TWILL030,绉绒:PEACH MOSS031,玻璃纱:ORGANDY032,涤纶:PLOYESTER033,锦纶:NYLONPOLYAMIDE034,醋酸:ACETATE035,棉;COTTON036,人棉:RAYON037,人丝:VISCOSE038,仿真丝:IMITATED SILK FABRIC 039,真丝:SILK040,氨纶:SPANDEXELASTICSTRECLYCRA 041,长丝:FILAMENT042,短纤:SPUN043,黑丝:BLACK YARN044,阳离子:CATION045,三角异形丝:TRIANGLE PROFILE046,空气变形丝:AIR-JET TEXTURING YARN 047,超细纤维:MICRO –FIBRIC048,全拉伸丝:FDY (FULL DRAWN YARN)049,预取向丝:POY(PREORIENTED YARN)050,拉伸变形丝:DTY(DRAW TEXTURED YARN)051,牵伸加捻丝:DT (DRWW TWIST)服装面料英语(二)052,靛蓝青年布:Indigo chambray053,人棉布植绒:Rayon cloth flocking054,PVC植绒:PVC flocking055,针织布植绒:Knitting cloth flocking056,珠粒绒:Claimond veins057,倒毛:Down pile making058,平绒:velveteen (velvet-plain)059,仿麂皮:Micro suede060,牛仔皮植绒:Jeans flocking061,尼丝纺:Nylon taffeta (Nylon shioze)062,尼龙塔夫泡泡纱:Nylon seersucker taffeta 063,素面植绒:plain flocking064,印花植绒:flocking(flower)065,雕印植绒:Embossing flocking066,皮革沟底植绒:Leather imitation flocking 067,牛仔植绒雕印:Embossing jeans flocking 068,兔羊绒大衣呢:Angora cachmere overcoating 069,双面呢:double-faced woolen goods羊毛070,立绒呢:cut velvet071,顺毛呢:over coating072,粗花呢:costume tweed073,弹力呢:lycra woolen goods074,塔丝绒:Nylon taslon075,塔丝绒格子:NTaslon ripstop076,桃皮绒:polyester peach skin077,涤塔夫:polyester taffeta078,春亚纺:polyester pongee纱线名称的中英文对照翻译纱线Yarns棉及其混纺纱线Cotton,CottonMixed&BlendedYarns棉纱CottonYarns涤棉纱T/C&CVCYarns粘棉纱Cotton/RayonYarns棉晴纱Cotton/AcrylicYarns棉/氨纶包芯纱Cotton/SpandexYarns棉与其他混纺纱Cotton/OthersBlendedYarns毛纺系列纱线WoollenYarnSeries羊绒纱CashmereYarnSeries全羊毛纱Wool(100%)Yarns毛晴纱Wool/AcrylicYarns毛涤纱Wool/PolyesterYarns毛粘纱Wool/ViscoseYarns毛/丝纱Wool/SilkYarnss羊毛/其他Wool/OtherYarns兔毛纱AngoraYarns雪兰毛线ShetlandYarns牦牛毛纱YakHairYarns羊仔毛纱LambswoolYarns真丝系列纱线SilkYarnSeries白厂丝WhiteSteamFilatureYarns 双宫丝DuppionSilkYarns柞蚕丝TussahSilkYarns绢丝SpunSilkYarns柞绢丝TussahSpunSilkYarns柚丝SilkNoilYarns真丝线SilkThreads丝棉混纺纱Silk/CottonBlendedYarns 麻纺系列纱线HalmYarnSeries大麻系列纱线HempYarnSeries亚麻系列纱线LinenYarnSeries苎麻系列纱线RamieYarnSeries黄麻系列纱线JuteYarnSeries其他植物纤维纱线OtherPlantYarns 剑麻系列纱线SisalYarnSeries人造纤维和合成纱线Manmade&SyntheticYarns晴纶纱AcrylicYarns晴纶仿羊绒Cashmere-likeAcrylicYarns仿兔毛SundayAngoraYarns锦纶丝PolyamideYarns涤纶纱/丝PolyesterYarns人造棉纱SpunRayonYarns天丝纱TencelYarns弹力纱线ElastaneYarns涤粘纱T/R(Polyester/Rayon)Yarns人棉混纺纱SpunRayonBlendedYarns其他化纤纱线OtherSyntheticYarns人造长丝或线ViscoseFilamentYarnsorThreads花色纱线fancyyarns雪尼尔纱ChenilleYarns大肚纱Big-bellyYarns带子纱TapeYarns马海毛纱MohairYarns羽毛纱FeatherYarns蜈蚣纱CentipedelikeYarns项链纱NecklineYarns辫子纱PigtailYarns梯子纱LadderYarns圈圈纱LoopYarnsTT纱TTYarns结子纱KnotYarns乒乓纱Ping-PongYarns其它花色纱线OtherFancyYarns金属纱线****lYarns竹节纱Slubby yarn雪兰毛线Shetland Yarns牦牛毛纱Yak Hair Yarns羊仔毛纱Lambswool Yarns真丝系列纱线Silk Yarn Series白厂丝White Steam Filature Yarns双宫丝Duppion Silk Yarns柞蚕丝Tussah Silk Yarns绢丝Spun Silk Yarns柞绢丝Tussah Spun Silk Yarns柚丝Silk Noil Yarns真丝线Silk Threads绳、索及缆Twine, Cordage, Rope & Cables金属纱线Metal Yarns乒乓纱Ping-Pong Yarns结子纱Knot YarnsTT 纱TT Yarns圈圈纱Loop Yarns梯子纱Ladder Yarns辫子纱Pigtail Yarns项链纱Neckline Yarns人棉混纺纱Spun Rayon Blended Yarns蜈蚣纱Centipede like Yarns羽毛纱Feather Yarns马海毛纱Mohair Yarns带子纱Tape Yarns大肚纱Big-belly Yarns雪尼尔纱Chenille Yarns花色纱线Fancy yarns人造长丝或线Viscose Filament Yarns or Threads其他化纤纱线Other Synthetic Yarns棉及其混纺纱线Cotton, Cotton Mixed & Blended Yarns 棉纱Cotton Yarns涤棉纱T/C & CVC Yarns粘棉纱Cotton/Rayon Yarns棉晴纱Cotton/Acrylic Yarns棉/氨纶包芯纱Cotton/Spandex Yarns棉与其他混纺纱Cotton/Others Blended Yarns毛纺系列纱线Woollen Yarn Series羊绒纱Cashmere Yarn Series丝棉混纺纱Silk/Cotton Blended Yarns麻纺系列纱线Halm Yarn Series大麻系列纱线Hemp Yarn Series亚麻系列纱线Linen Yarn Series苎麻系列纱线Ramie Yarn Series黄麻系列纱线Jute Yarn Series其他植物纤维纱线Other Plant Yarns剑麻系列纱线Sisal Yarn Series人造纤维和合成纱线Manmade & Synthetic Yarns 晴纶纱Acrylic Yarns晴纶仿羊绒Cashmere-like Acrylic Yarns仿兔毛Sunday Angora Yarns锦纶丝Polyamide Yarns涤纶纱/丝Polyester Yarns人造棉纱Spun Rayon Yarns天丝纱Tencel Yarns弹力纱线Elastane Yarns涤粘纱T/R (Polyester/Rayon) Yarns全羊毛纱Wool (100%) Yarns毛晴纱Wool/Acrylic Yarns毛涤纱Wool/Polyester Yarns毛粘纱Wool/Viscose Yarns毛/丝纱Wool/Silk Yarnss羊毛/其他Wool/Other Yarns兔毛纱Angora Yarns其它花色纱线Other Fancy Yarns纺织英语---各类纺纱方式英语传统纺纱CONVENTIONAL SPINNING翼锭纺FLYING SPINNING帽锭纺CAP SPINNING环锭纺RING SPINNING新型纺纱NEW METHOBS OF MAKING YARNS自由端纺纱或断裂纺OPEN-END OR BREAK SPINNING 无捻纺TWISTLESS SPINNING摩擦纺FRICTION SPINNING自捻纺SELF-TWIST SPINNING喷气纺AIR-JET SPINNING机械纺MECHANICAL SPINNING流体纺FLUID SPINNING静电纺ELECTROSTATIC SPINNING C:Cotton 棉纤维及辅料Wool 羊毛M:Mohair 马海毛RH:Rabbit hair 兔毛AL:Alpaca 羊驼毛S:Silk真丝J:Jute 黄麻L:linen 亚麻Ts:Tussah silk 柞蚕丝YH:Yark hair 牦牛毛Ly:lycra莱卡Ram:Ramine 苎麻Hem:Hemp 大麻T:Polyester 涤纶WS:Cashmere 羊绒N:Nylon 锦纶(尼龙)A:Acrylic 腈纶Tel:Tencel 天丝,是Lyocell莱赛尔纤维的商品名La:Lambswool 羊羔毛Md:Model 莫代尔CH:Camel hair 驼毛CVC:chief value of cotton涤棉倒比(涤含量低于60%以下)Ms:Mulberry silk 桑蚕丝R:Rayon 粘胶ACCESSORY 辅料,配件ACROSS MEASURE 横量ACRYLIC 腈纶ADHESIVE / FUSIBLE INTERLINING 粘衬ANTIQUE BRASS COATING 镀青古铜ANTISTATIC FINISH 防静电处理APPAREL 成衣APPEALING LOOK 吸引人的外表APPROV AL SAMPLE 批办APPROVED SAMPLE WITH SIGNING NAME 签名批办ARMHOLE 夹圈ASSEMBLING OF FRONT & BACK PART 前后幅合并ASSEMBLING SECTION 合并部分ATTACH COLLAR 上领ATTACH LABEL 上商标ATTACHMENT (车缝)附件BACK COVER FRONT 后搭前BACK MID-ARMHOLE 后背宽BACK ACROSS 后背宽BACK STITCH 返针,回针BACKLESS DRESS 露背装BAR CODED STICKER 条形码贴纸BARGAINING 讨价还价BAR-TACK 打枣BASTE 假缝BATILK 蜡染BEARER 袋衬BEARER & FACING 袋衬袋贴BEDFORD CORD. 坑纹布,经条灯心绒BELL BOTTOM 喇叭裤脚BELLOWS POCKET 风琴袋BELT 腰带BELT-LOOP 裤耳BIAS CUT 斜纹裁,纵纹裁BIFURCATE 分*BINDER 包边蝴蝶,滚边蝴蝶BINDING 包边BINDING OF SLV. OPENING R折BINDING OF TOP VENT 面*包边BINDING TAPE 包边BINDING/BOUND 滚条BLANKET 毛毯,地毯BLEACH 漂白BLEACH SPOT 漂白污渍BLEEDING 洗水后褪色BLEND FIBRE 混纺纤维BLENDS 混纺BLIND STITCH 挑脚线步BLOUSE 女装衬衫BODY PRESSING 衫身熨烫BODY RISE 直浪BOTTOM 衫脚,下摆BOTTOM VENT OF SLEEVE 细侧BOTTOMS 下装BOX-PLEATED 外工字褶BOY’S STYLE FLY / LEFT FLY 男装钮牌,左钮牌BRAID 织锦,织带BRANCH 分公司BREAK STITCHES 断线BRIEFS 男装紧身内裤BROCADE 织锦,织带BROKEN STITCHING 断线BUBBLING 起泡BUCKLE 皮带扣BUCKLE-LOOP 皮带扣BULK PRODUCTION 大量生产BUNDLE CODE 扎号BUNDLING 执扎BUTTON 钮扣BUTTON STAND 钮门搭位BUTTON-HOLE 钮门/ 扣眼BUTTON-HOLING 开钮门BUTTONING 钉钮BUTTONING WITH BUTTON SEWER 用钉钮机钉钮C/B VENT 后中*CALICO / GRAY CLOTHES 胚布CANV AS 马尾衬,帆布CARDBOARD 纸板CARDED 粗疏CARE LABEL 洗水唛CARTONNING 装箱,入箱CASE PACK LABEL 外箱贴纸CASH POCKET 表袋CASUAL WEAR 便装CATCHING FACING 钮子CENTER BACK 后中CENTER CREASE FOLD 中骨对折CENTER CREASE LINE 中骨线CENTER FRONT 前中CERTIFIED SUB-CONTRACTOR 认可加工厂CHAIN STITCH M/C 锁链车CHAIN STITCHES 锁链线步CHAMPRAY 皱布CHEMISE 宽松服装CHEST/BUST 胸围CHIC 时髦的,流行的CIRCULAR KNIT 圆筒针织布CLASSIC LOOK 经典款式CLASSIFICATION 分类CLEAN FINISH 还口CLEAN FINISH OF TOP VENT 面*还口CLEAN FINISH WITH 1/4“SINGLE NEEDLE 1/4“单针还口CLOSE FITTING 贴身CLOSE SIDE SEAM 埋侧骨COATING 外套大衣COIN POCKET 表袋COLLAR 领子COLLAR BAND 下级领COLLAR FALL 上级领COLLAR NOTCH 领扼位COLLAR POINT 领尖COLLAR STAND 下级领COLLAR STAY 领插竹COLLECTION 系列COLOR SHADING 色差COMBED 精梳CONSTRUCTED SPECIFICATION 结构细节CONTINUOUS PLACKET R折CONTROL OF LABOR TURNOVER 劳工流失控制CORDUROY 灯心绒COST SHEET 成本单COTTON STRING 棉绳COVERING STITCHING 拉冚线步(600类)CREASE & WRINKLY RESISTANT FINISH 防皱处理CREASE LINE 折线CREPE DE-CHINE 皱布CROSS CROTCH 十字缝CROSS CUT 横纹裁CROTCH POINT 浪顶点CTN. NO. 箱号CUFF 鸡英,介英CUFF ATTACHING TO SLEEVE 车鸡英到袖子上CUFF VENT/CUFF OPENING 袖侧CUFFED BOTTOM HEM 反脚,假反脚,脚级CUFFLESS BOTTOM 平脚CURVED POCKET 弯袋CUT & SEWN 切驳CUTTING PIECE 裁片CUTTING PIECE NUMBERING 给裁片编号D.K. JACQUARD 双面提花(针织)DAMAGE CAUSED BY NEEDLE 针孔DECORATIVE STITCHING 装饰间线DELIVERY DATE 落货期DENIER 旦尼尔DENIM 牛仔DENSITY 密度DESIGN SKETCH 设计图DESIGNED FEATURE 设计特征DIMENSION 尺寸、尺码DINNER JACKET 晚礼服DIRT STAINS AFTER WASHING 洗水后有污迹DIRTY SPOT 污点DISCOUNT / SALES OFF 打折DOBBY 织花布DOUBLE CUFF 双层鸡英DOUBLE END 双经DOUBLE JETTED POCKET 双唇袋DOUBLE NEEDLE FELL SEAM 双针埋夹DOUBLE PICK 双纬DOUBLING 并线DRESS COAT 礼服DRESSING ROOM 试衣间DRILLING 钻孔位DRY-CLEANED 干洗DUCK 帆布DYEING 染色EASING 容位EDGE STITCHING 间边线EDGE TRIMMER 修边器EDGE-FINISHING 边脚处理EDGE-STITCH DART 边线褶EDGE-STITCHING W/ 1/16“宽1/16“的边线ELASTIC 橡筋ELASTIC WAISTBAND IS EXTENSION OF BODY 原身出橡筋裤头ELBOW WIDTH 肘宽EMBROIDERY PATCH 绣花章EPAULET 肩章EVENING GOWN SET 晚睡袍EXCELLENT STYLE 漂亮的款式EXCESSIVE THREAD ENDS 多余的线头EXECUTIVE WEAR 行政装EXPIRY DATE 有效期EXPORT CARTON 出口箱EXTENSION OF WAISTBAND 裤头搭咀EYELET 凤眼FABRIC 布料FABRIC CONSTRUCTION 布料结构FABRIC DEFECTS 布疵FABRIC RUNS 走纱FABRIC SHADING 布料色差FABRIC SWATCH 布办FABRIC WIDTH 布封FABRICATION / FABRIC 布料FACING 贴FACING TO OUT-SIDE 折向侧骨FALSE FLY 暗钮牌FALSE PLACKET 假明筒,假反筒FASHION 时装FELL SEAM 埋夹6 FEED PIQUE 6模珠地FIGURE-CLINGING 紧身的,贴身胸围FILAMENT 长纤丝FINAL APPEARANCE 最终外观FINISHED APPEARANCE 完成后的外观FITTING 试身FLAMEPROOF FABRIC 防火布FLANNEL 法兰绒FLARE SKIRT 喇叭裙FLAT MACHINE 平车FLAT SEAM 平缝FLAX 亚麻FLOW CHART 流程图FOLD AND PACK 折叠包装,折装FOLD BACK FACING 原身出贴FOLD BACK HIDDEN PLACKET 原身双层钮筒FOLD FRONT EDGE 折前幅边FOLD LINE 折线FOLD PANTS 折裤子FOLD POCKET MOUTH 折反袋口FORM AND FOLD GARMENT 定型折衫FROCKS 礼服FRONT EDGE 前幅边FRONT MID-ARMHOLE 前胸宽FRONT OPENING 前开口FRONT PANEL 前幅FULLY FASHION SWEATER 全成型毛衫FULLY OPENING 全开口FUR 皮草FUR GARMENT 裘皮服装FURRY 毛皮制品FUSE INTERLINING 粘衬FUSIBLE INTERLINING 粘朴FUZZ BALLS 起球GABARDINE 斜纹呢GARMENT 成衣GARMENT DYE 成衣染色GARMENT FINISH 成衣后处理GARMENT SEWING TECHNOLOGY 成衣工艺GARMENT WASH 成衣洗水,普洗GATHERING 碎褶GIRL’S STYLE FLY / RIGHT FLY 女装钮牌,右钮牌GLACED FINISH 压光加工GOOD TASTE 高品味GR. WT.=GROSS WEIGHT 毛重GRADING 放码GRAY CLOTH 胚布GROMMET 凤眼GROWN-ON SLEEVE 原身出袖HALF OPENING 半开口HANDBAG 手袋HANDFEEL 手感HANDLING 执手HANGDLING TIME 执手时间HANGER 衣架HEA VY FABRIC 厚重面料HEM 衫脚,下摆HEM CUFF 反脚HEMMING 卷边,还口HEMMING WITH FOLDER 用拉筒卷边HEMP 大麻HERRINGBONE TWILL 人字斜纹布HEXAGONAL POCKET 六角袋HIDDEN PLACKET 双层钮筒HIDDEN BARTACK 隐形枣HIGH-WAISTED SKIRT 高腰裙HIP 坐围HIP POCKET 后袋HOOD HEIGHT 帽高HORIZONTAL PLAID 水平格INCORRECT LINKING 错误的连接INITIAL SAMPLE 原办,初办INNER EXTENSION 搭咀内层IN-SEAM 内骨INSPECTION 检查INSPIRATION 灵感INTERLACING 交织INTERLINING 衬,朴INTERLINING FOR FACING 贴粘衬INTERLOCK 双面布(针织)INVERTED PLEAT 内工字褶INVOICE 发票IRON OVERALL BODY 熨烫衫身IRON SPOT 烫痕JACQUARD 提花JEANS 牛仔裤JERSEY 平纹单面针织布JOIN CROTCH 埋小浪“J”SHAPED POCKET J形袋JUTE 黄麻KHAKI 卡其KNIT 针织KNITTED RIB COLLAR 针织罗纹领KNOTS 结头KNOWLEDGE OF MATERIAL 材料学24L BUTTON 24号钮L/G=LETTER OF GUARANTEE 担保证LABOUR COST 劳工成本LACE 花边LACOSTE 双珠地LAPEL 襟贴LAUNDRY 干洗LAYOUT 排唛,排料LEATHER 皮革LEFT COVER RIGHT 左搭右LEGGINGS 开裆裤LEISURE STYLE 休闲款式LEISURE WEAR 休闲服LEISURE WEAR SHOW 休闲装展示会LICENSE 许可证LIGHT CURVED POCKET 微弯袋LINEN 亚麻LINING 里布LINKING & CUP SEAMING 缝盆LOCK STITCH 平车线步LOOPED FABRIC 毛圈布LOOPING 起耳仔(疵点)LOOSE BUTTON 钮扣松散LOOSED THREAD CAUSING GRINNING 线太松导致起珠LUSTROUS 光泽MACHINE MAINTENANCE 机械保养MAGIC TAPE 魔术贴MAJOR DEFECT 大疵MAN-MADE FIBRE 人造纤维MANUFACTURER 制造商MARK BUTTONHOLE & BUTTON POSITION 标出钮门与钮扣的位置MARK POCKET POSITION WITH TEMPLATE 用纸板点袋位MARKER 唛架MARKING MID-POINT OF NECK 定领围中位MASS PRODUCTION 大批量生产MATCH COLOR 配色MATERIAL 物料MEASUREMENT 尺寸MELTON 领底绒MILDREW RESISTANT FINISH 防霉处理MISSING PARTS 漏裁片MOTH RESISTANT FINISH 防虫处理NAIL-BUTTON 钉脚钮扣NATURAL FIBRE 天然纤维NECK ACROSS/NECK WIDTH 领宽NECK DROP 领深NECK SEAM 颈圈NET WT. 净重NON-FUSIBLE INTERLINING 非粘朴NON-WOVEN FABRIC 非织布/ 无纺布NOTCH 扼位OFF PRESSING 终烫OGRAIN 布纹OIL STAIN 油污ONE PIECE DOUBLE FOLDED BELT-LOOP 一片双折裤耳ONE-PIECE DRESS 连衣裙OPEN SEAM 开骨OPERATION BREAK DOWN 分工序OUT-SEAM 外骨OUT-SEAM PKT. 侧骨袋OVERALL 工作服OVERALLS 吊带裤OVERLAP 重叠OVERLAPPING A FEW STITCHING 驳线OVERLOCK & BLIND-STITCH 折挑OVERLOCK W/ 5 THREADS 五线锁边OVERLOCK WITH 5 THREADS 五线锁边OVERTIME WORKING 加班工作PACKING LIST 包装单PACKING METHOD 包装方法PANEL KNITTING 针织裁片PASTEL 颜料PATCH POCKET 贴袋PATTERN 纸样PAYMENT 付款PEACH POCKET 杏形袋PIECE RATE 记件PIECED ON PLACKET 面车明筒PIECED PLACKET 一片钮筒PILE FABRIC 毛圈布PIPING 嵌边PIQUE 单珠地PLACKET 明筒PLAID MATCHING 对格PLAIDS / CHECKS 格仔布PLAIN WEA VE 平纹梭织PLANTS LAYOUT 厂房布置PLEAT WITH SINGLE NEEDLE 单针车褶PLEATS 活褶POCKET BAG CAUGHT IN BARTACK 袋布被枣打到(疵点)POCKET COVER 袋盖POCKET CREASING MACHINE 烫袋机POCKET FACING 袋贴POCKET FLAP 袋盖POCKET FLASHER 袋卡POCKET MOUTH 袋口POCKET OPENING 袋口POCKET-BAG (裁好的)袋布POCKETING (成卷的)袋布POINT SHAPE BELT-LOOP 三尖裤耳POLYBAG 胶袋POLYWARP 胶纸包POSITION COLLAR 定领位POST-WASH HANDFEEL 洗水后手感PRESHRINKING 预缩PRESS & OPENING SEAM 烫开骨PRESS OPEN 烫开骨PRESSING WORK IN PROGRESS 烫半成品PRINT FABRIC 印花布PRINTING 印花PROCEDURE 程序PRODUCTION SKETCH 生产图PUCKERING 沿缝线的皱褶QUALITY CONTROL / QC 质量控制QUILTING 打缆,间棉。

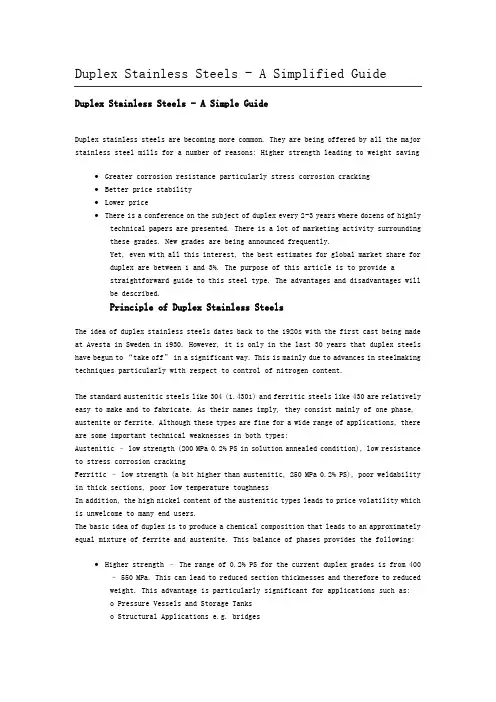

Duplex Stainless Steels - A Simplified Guide Duplex Stainless Steels - A Simple GuideDuplex stainless steels are becoming more common. They are being offered by all the major stainless steel mills for a number of reasons: Higher strength leading to weight saving∙Greater corrosion resistance particularly stress corrosion cracking∙Better price stability∙Lower price∙There is a conference on the subject of duplex every 2-3 years where dozens of highly technical papers are presented. There is a lot of marketing activity surroundingthese grades. New grades are being announced frequently.Yet, even with all this interest, the best estimates for global market share forduplex are between 1 and 3%. The purpose of this article is to provide astraightforward guide to this steel type. The advantages and disadvantages willbe described.Principle of Duplex Stainless SteelsThe idea of duplex stainless steels dates back to the 1920s with the first cast being made at Avesta in Sweden in 1930. However, it is only in the last 30 years that duplex steels have begun to “take off” in a significant way. This is mainly due to advances in steelmaking techniques particularly with respect to control of nitrogen content.The standard austenitic steels like 304 (1.4301) and ferritic steels like 430 are relatively easy to make and to fabricate. As their names imply, they consist mainly of one phase, austenite or ferrite. Although these types are fine for a wide range of applications, there are some important technical weaknesses in both types:Austenitic –low strength (200 MPa 0.2% PS in solution annealed condition), low resistance to stress corrosion crackingFerritic – low strength (a bit higher than austenitic, 250 MPa 0.2% PS), poor weldability in thick sections, poor low temperature toughnessIn addition, the high nickel content of the austenitic types leads to price volatility which is unwelcome to many end users.The basic idea of duplex is to produce a chemical composition that leads to an approximately equal mixture of ferrite and austenite. This balance of phases provides the following:∙Higher strength – The range of 0.2% PS for the current duplex grades is from 400 – 550 MPa. This can lead to reduced section thicknesses and therefore to reducedweight. This advantage is particularly significant for applications such as:o Pressure Vessels and Storage Tankso Structural Applications e.g. bridges∙Good weldability in thick sections –Not as straightforward as austenitics but much better than ferritics.∙Good toughness – Much better than ferritics particularly at low temperature, typically down to minus 50 deg C, stretching to minus 80 deg C.∙Resistance to stress corrosion cracking – Standard austenitic steels are particularly prone to this type of corrosion. The kind of applications where thisadvantage is important include:o Hot water tankso Brewing tankso Process planto Swimming pool structuresHow the Austenite/Ferrite Balance is AchievedTo understand how duplex steels work, first compare the composition of two familiarsteels austenitic 304 (1.4301) and ferritic 430 (1.4016).The important elements in stainless steels can be classified into ferritisers and austenitisers. Each element favours one structure or the other:Ferritisers – Cr (chromium), Si (silicon), Mo (molybdenum), W (tungsten), Ti (titanium), Nb (niobium)Austenitisers – C (carbon), Ni (nickel), Mn (manganese), N (nitrogen), Cu (copper) Grade 430 has a predominance of ferritisers and so is ferritic in structure. Grade 304 becomes austenitic mainly through the use of about 8% nickel. To arrive at a duplex structure with about 50% of each phase, there has to be a balance between the austenitisers and the ferritisers. This explains why the nickel content of duplex steels is generally lower than for austenitics.Here are some typical compositions of duplex stainless steels:In some of the recently developed grades, nitrogen and manganese are used together to bring the nickel content to very low levels. This has a beneficial effect on price stability.At present, we are still very much in the development phase of duplex steels. Therefore, each mill is promoting its own particular brand. It is generally agreed that there are too many grades. However, this is likely to continue until the “winners” emerge.Corrosion Resistance of Duplex SteelsThe range of duplex steels allows them to be matched for corrosion resistance with the austenitic and ferritic steel grades. There is no single measure of corrosion resistance. However, it is convenient to use the Pitting Resistance Equivalent Number (PREN) as a means of ranking the grades.PREN = %Cr + 3.3 x %Mo + 16 x %NThe following table shows how the duplex steels compare with some austenitic and ferritic grades.It must be emphasised that this table is only a guide to material selection. It is always important to assess the suitability of a particular with a full knowledge of the corrosive environment.Stress Corrosion Cracking (SCC)SCC is a form of corrosion which occurs with a particular combination of factors: Tensile stressCorrosive environmentSufficiently high temperature. Normally 50 deg C but can occur at lower temperatures around 25 deg C in specific environments, notably swimming pools.Unfortunately, the standard austenitic steels like 304 (1.4301) and 316 (1.4401) are the most susceptible to SCC. The following materials are much less prone to SCC:Ferritic stainless steels∙Duplex stainless steels∙High nickel austenitic stainless steelsThe resistance to SCC makes duplex steels suitable materials for many processeswhich operate at higher temperatures, notably:Hot water boilers∙Brewing tanks∙DesalinationStainless steel structures in swimming pools are known to be prone to SCC. The useof standard austenitic stainless steels like 304 and 316 is forbidden in thisapplication. The best steels to use for this purpose are the high nickel austeniticsteels such as the 6% Mo grades. However, in some cases, duplex steels such as 2205(1.4462) and the superduplex grades can be considered.Barriers to Using Duplex SteelsThe attractive combination of high strength, wide range of corrosion resistance,moderate weldability would seem to offer great potential for increasing the marketshare of duplex stainless steels. However, it is important to understand thelimitations of duplex stainless steels and why they are alwa ys likely to be “nicheplayers”.The advantage of high strength immediately becomes a disadvantage when consideringformability and machinability. The high strength also comes with lower ductilitythan austenitic grades. Therefore, any application requiring a high degree offormability, for example, a sink, is ruled out for duplex grades. Even when theductility is adequate, higher forces are required to form the material, for examplein tube bending. There is one exception to the normal rule of poorer machinability,grade 1.4162.The metallurgy of duplex stainless steels is much more complex than for austeniticor ferritic steels. This is why 3 day conferences can be devoted just to duplex!This factor means that they are more difficult to produce at the mill and to fabricate.In addition to ferrite and austenite, duplex steels can also form a number ofunwanted phases if the steel is not given the correct processing, notably in heattreatment. Two of the most important phases are illustrated in the diagram below:phase475 degreeembrittlementBoth of these phases lead to embrittlement, i.e. loss of impact toughness.The formation of sigma phase is most likely to occur when the cooling rate during manufacture or welding is not fast enough. The more highly alloyed the steel, the higher the probability of sigma phase formation. Therefore, superduplex steels are most prone to this problem. 475 degree embrittlement is due to the formation of a phase called α′ (alpha prime). Although the worst temperature is 475 deg C, it can still form at temperatures as low as 300 deg C. This leads to a limitation on the maximum service temperature for duplex steels. This restriction reduces the potential range of applications even further. At the other end of the scale, there is a restriction on the low temperature use of duplex stainless steels compared to austenitic grades. Unlike austenitic steels duplex steels exhibit aductile-brittle transition in the impact test. A typical test temperature is minus 46 deg C for offshore oil and gas applications. Minus 80 deg C is the lowest temperature that is normally encountered for duplex steels.Going Further with Duplex Stainless SteelsMore detailed information on duplex can be found in:Practical Guidelines for the Fabrication of Duplex Stainless SteelsSummary of Duplex Characteristics∙Twice design strength of austenitic and ferritic stainless steels∙Wide range of corrosion resistance to match application∙Good toughness down to minus 80 deg C but not genuine cryogenic applications ∙Particular resistance to stress corrosion cracking∙Weldable with care in thick sections∙More difficult to form and machine than austenitics∙Restricted to 300 deg C maximum。

纺织品专业词汇翻译中英文对照表纺织品[转]纺织品专业词汇翻译中英文对照表纺织品braided fabric 编织物 deformation 变形;走样 fast colours 不褪色;色泽牢固 punch work 抽绣 embroidery 刺绣品acetate fibre 醋酯纤维 hemp 大麻 damp proof 防潮 sanforizing, pre-shrunk 防缩textiles 纺织品 crochet 钩编编织物gloss, lustre 光泽 synthetic fibre 合成纤维 chemical fibre 化学纤维 jute 黄麻 gunny cloth (bag)黄麻布(袋)mixture fabric, blend fabric 混纺织物woven fabric 机织织物spun silk 绢丝 linen 麻织物 woolen fabrics 毛织物(品) cotton textiles 棉纺织品 cotton velvet 棉绒 cotton fabrics 棉织物(品) non-crushable 耐绉的 viscose acetal fibre 黏胶纤维matching, colour combinations 配色rayon fabrics 人造丝织物 artificial fibre 人造纤维 crewel work 绒线刺绣mulberry silk 桑蚕丝 , 家蚕丝 silk fabrics 丝织物 silk spinning 丝纺linen cambric 手帕亚麻纱 plain 素色figured silk 提花丝织物 jacquard 提花织物 applique embroidery 贴花刺绣discolourization 褪色 mesh fabric 网眼织物 bondedfibre fabric 无纺织物embroidered fabric 绣花织物 flax 亚麻 linen yarn 亚麻纱 knitting 针织 knitwear 针织品 hosiery 针织物 textile fabric 织物 ramee, ramie 苎麻 tussah silk 柞蚕丝服装--- clothes 衣服, 服装 wardrobe 服装 clothing 服装 habit 个人依习惯 .身份而着的服装 ready-made clothes, ready-to-wear clothes garments 外衣 town clothes 外衣 double-breasted suit 双排扣外衣 suit 男外衣 dress 女服 tailored suit 女式西服 everyday clothes 便服 three-piece suit 三件套 trousseau 嫁妆 layette 婴儿的全套服装uniform 制服 overalls 工装裤 rompers 连背心的背带裤 formal dress 礼服 tailcoat, morning coat 大礼服evening dress 夜礼服 dress coat, tails 燕尾服 , 礼服nightshirt 男式晚礼服成衣dinner jacket 无尾礼服(美作:tuxedo) fulldress uniform 礼服制服 frock coat 双排扣长礼服gown, robe 礼袍 tunic 长袍 overcoat 男式大衣 coat 女大衣 topcoat 夹大衣 fur coat 皮大衣 three-quarter coat 中长大衣 dust coat 风衣mantle, cloak 斗篷 poncho 篷却(南美人的一种斗篷) sheepskin jacket 羊皮夹克 pelisse 皮上衣jacket 短外衣夹克 anorak, duffle coat 带兜帽的夹克 , 带风帽的粗呢大衣 hood 风帽 scarf, muffler 围巾 shawl 大披巾 knitted shawl 头巾, 编织的头巾fur stole 毛皮长围巾 muff 皮手筒 housecoat, dressing gown 晨衣(美作 :duster) short dressing gown 短晨衣 bathrobe 浴衣 nightgown, nightdress 女睡衣 pyjamas 睡衣裤(美作 ajamas) pocket 衣袋lapel (上衣)翻领 detachable collar 假领 ,活领wing collar 硬翻领 ,上浆翻领V-neck V 型领 sleeve 袖子 cuff 袖口 buttonhole 钮扣孔 shirt 衬衫 blouse 紧身女衫 T-shirt 短袖圆领衫 ,体恤衫 vest 汗衫(美作:undershirt) poloshirt 球衣 middy blouse 水手衫 sweater 运动衫short-sleeved sweater 短袖运动衫 roll-neck sweater 高翻领运动衫 round-neck sweater 圆领运动衫 suit, outfit, ensemble 套服 twinset 两件套 ,运动衫裤jerkin 猎装 kimono 和服 ulster 一种长而宽松的外套jellaba, djellaba, jelab 带风帽的外衣 cardigan 开襟毛衣 mac, mackintosh, raincoat 橡胶雨衣 trousers 裤子jeans 牛仔裤 short trousers 短裤 knickers 儿童灯笼短裤 knickerbockers 灯笼裤 plus fours 高尔夫球裤 ,半长裤 braces 裤子背带(美作 :suspenders)turnup 裤角折边 ,挽脚 breeches 马裤 belt 裤带skirt 裙子 divided skirt, split skirt 裙裤underskirt 内衣 underwear , underclothes 内衣裤underpants, pants 内衣裤(美作 :shorts) briefs 短内裤 ,三角裤 panties 女短内裤 knickers 女半短内裤 , 男用灯笼短裤 brassiere, bra 乳罩 corselet 紧身胸衣 stays, corset 束腰 ,胸衣waistcoat 背心 slip, petticoat 衬裙 girdle 腰带stockings 长袜 suspenders 袜带(美作 :garters)suspender belt 吊袜腰带(美作:garter belt)socks 短袜tights, leotard 紧身衣裤handkerchief 手帕 bathing trunks 游泳裤bathing costume, swimsuit, bathing suit游泳衣bikini 比基尼泳衣 apron 围裙 pinafore(带护胸)围裙 shoe 鞋 sole 鞋底 heel 鞋后跟lace 鞋带 moccasin 鹿皮鞋 patent leather shoes 黑漆皮鞋 boot 靴子 slippers 便鞋 sandal 凉鞋canvas shoes, rope soled shoes 帆布鞋 clog 木拖鞋galosh, overshoe 套鞋 glove 手套 tie 领带(美作 :necktie) bow tie 蝶形领带 cravat 领巾 cap 便帽 hat 带沿的帽子 bowler hat 圆顶硬礼帽 top hat 高顶丝质礼帽 Panama hat 巴拿马草帽 beret 贝蕾帽peaked cap, cap with a visor 尖顶帽 broad-brimmed straw hat 宽边草帽 headdress 头饰 turban 头巾natural fabric 天然纤维 cotton 棉 silk 丝 wool 毛料 linen 麻 synthetic fabric 混合纤维 acryl 压克力polyester 伸缩尼龙 nylon 尼龙 worsted 呢料cashmere 羊毛 patterns 花样tartan plaid 格子花(美作:tartan)dot 圆点花 stripe 条纹 flower pattern 花纹花样veil 面纱颜色--- pink 粉红色 salmon pink 橙红色 baby pink 浅粉红色 shocking pink 鲜粉红色 brown 褐色 , 茶色 beige 灰褐色 chocolate 红褐色 , 赭石色sandy beige 浅褐色 camel 驼色 amber 琥珀色khaki 卡其色 maroon 褐红色 green 绿色 moss green 苔绿色 emerald green 鲜绿色 olive green 橄榄绿 blue 蓝色 turquoise blue 土耳其玉色 cobalt blue 钴蓝色 , 艳蓝色 navy blue 藏青色 , 深蓝色 , 天蓝色 aquamarine blue 蓝绿色 red 红色 scarlet 绯红 , 猩红 mauve 紫红 wine red 葡萄酒红purple, violet 紫色 lavender 淡紫色 lilac 浅紫色 antique violet 古紫色pansy 紫罗兰色 white 白色 off-white 灰白色 ivory 象牙色 snowy white 雪白色oyster white 乳白色gray 灰色 charcoal gray 炭灰色 smoky gray 烟灰色 misty gray 雾灰色End==wedoliya 提供 ==End ++ 感谢: Handson 提供 ++Begin==Handson 提供==Begin 服装专业词汇[分享]服装专业词汇A 色牢度试验项目 COLOUR FASTNESS TESTS 皂洗牢度 washing 摩擦牢度rubbing/crocking 汗渍牢度 perspiration 干洗牢度 drycleaning 光照牢度light 水渍牢度 water 氯漂白 chlorine bleach spotting 非氯漂白 non-chlorine bleach 漂白 bleaching实际洗涤(水洗一次) actual laundering (one wash) 氯化水 chlorinated water 含氯泳池水 chlorinated pool water 海水 sea-water 酸斑 acid spotting 碱斑 alkaline spotting 水斑 water spotting 有机溶剂 organic solvent 煮呢 potting 湿态光牢度 wet light 染料转移 dye transfer 热(干态) dry heat 热压 hot pressing 印花牢度 print durability 臭氧 ozone 烟熏 burnt gas fumes 由酚类引起的黄化 phenolic yellowing 唾液及汗液saliva and perspiration B 尺寸稳定性(缩水率)及有关试验项目(织物和成衣)DIMENSIONAL STABILITY (SHRINKAGE) AND RELATED TESTS (FABRIC & GARMENT) 皂洗尺寸稳定性 dimensional stability to washing (washing shrinkage) 洗涤/手洗后的外观 appearance after laundering / hand wash 热尺寸稳定性dimensional stability to heating 熨烫后外观 appearance after ironing 商业干洗稳定性 dimensional stability to commercial drycleaning (drycleaning shrinkage)商业干洗后外观 ( 外观保持性) appearance after commercial drycleaning (appearance retention)蒸汽尺寸稳定性 dimensional stability to steaming 松弛及毡化dimensional stabilty to relaxation and felting 缝纫线形稳定性dimensional stability for sewing thread C 强力试验项目STRENGTH TESTS 拉伸强力 tensile strength 撕破强力 tear strength 顶破强力 bursting strength 接缝性能 seam properties双层织物的结合强力 bonding strength of laminated fabric 涂层织物的粘合强力 adhesion strength of coated fabric 单纱强力 single thread strength 缕纱强力 lea strength 钩接强力 loop strength 纤维和纱的韧性tenacity of fibres and yarn D 织物机构测试项目 FABRIC CONSTRUCTION TESTS织物密度(机织物 ) threads per unit length (woven fabric construction) 织物密度(针织物 ) stitch density (knittted fabric) 纱线支数 counts of yarn 纱线纤度(原样) denier counts as received 织物幅宽 fabric width 织物克重 fabric weight 针织物线圈长度 loop length of knitted fabric 纱线卷曲或织缩率 crimp or take-up of yarn 割绒种类 type of cut pile 织造种类 type of weave 梭织物纬向歪斜度 distortion in bowed and skewedfabrics received and after one wash) 圈长比 terry to ground ratio 织物厚度 fabric thickness E 成分和其他分析试验项目COMPOSITION AND OTHER ANALYTICAL TESTS 纤维成分 fibre composition 染料识别 dyestuff identification 靛蓝染料纯度 purity of indigo 含水率 moisture content 可萃取物质 extractable matter 填充料和杂质含量 filling and foreign matter content 淀粉含量 starchcontent 甲醛含量 formaldehyde content 甲醛树脂 presence offormaldehyde resin 棉丝光度 mercerisation in cotton PH 值PH value 水能性 absorbance F 可燃性试验项目 FLAMMABILITYTESTS 普通织物的燃烧性能 flammability of general clothingtextiles 布料的燃烧速率( 45。

非织造布专业英语一、原料 raw materials聚合物 : polymer树脂:resin切片:chips橡胶:rubber低熔点聚酯切片:Low Melting Point Polyester Chip天然纤维:Natural fibers人造纤维: man-made fiber合成纤维:synthetic fiber化学纤维:chemical fiber特种纤维:specialty fiber复合纤维:composite fiber双组份纤维bicomponent fiber棉纤维:cotton羊毛:wool蚕丝:silk黄麻:jute亚麻:flax粘胶纤维:viscose木浆纤维:wood pulp fiber涤纶:polyester(pet)锦纶:polyamide fiber(pa)晴纶:polyacrylic fiber (pan)丙纶:polypropylene fiber(pp)聚苯硫醚纤维polyphenylene sulfide fibre(易氧化:oxidation) 芳纶:aramid fiber (易水解:hydrolyze)芳砜纶:aromatic polysulphone 玻璃纤维:glass fiber熔点:melting point热固性:thermosetting热塑性:thermoplastic金属纤维:metallic fiber不锈钢纤维:stainless fiber 中空纤维:hollow fibers超细纤维:microfiber填充棉:fiberfill长丝:filament短纤维:staple fiber特:tex线密度:linear density偏差:deviation纤维密度:fiber density纤维直径:fiber diameter纤维细度:fiber fineness纤维强度:fiber strength纤维长度:fiber length纤维厚度:fiber thickness二、化工料活性炭:activated carbon热溶胶:hot-melt adhesive热溶材料:thermo-melt material热粘合粉:thermo-bonding powder酸:acids耐酸:acid-proof/resistant碱:alkalies胶乳:latex (分解:decompose)染料:dyes颜料:pigment涂料:coating pigment海绵:sponge添加剂:additives粘合剂:adhesive,binder助剂:auxiliary agent防老化剂:anti-oxidant抗静电剂:antistatic agent杀菌剂:bactericide阻燃剂:flame retardant agent消光剂:delustrant干燥剂:dehumidizer荧光增白剂:optical brightener防污剂:soil-repellent清洗剂:cleaning agent三、生产工艺及设备technology and equipment开包机:bale opener开松:opening开棉机:opener混棉机:blender梳理:carding针布:carding cloth(基厚:thread高度:height代码:code)道夫:doffer罗拉:roller打手:beater金属针布:metallic card clothing 铺网机:lapping machine交叉铺网:cross lapping平行铺网:parallel laying杂乱铺网:random laying气流成网:air-laid烘燥:drying烘缸:drying cylinders烘箱:drying oven滚筒:dram滚筒干燥:cylinder drying尘笼:dust cage输送帘:lattice calendar卷绕:winding切边机:edge cutting machine烧毛机:singeing machine轧光机:calender针刺法:needle-punching针刺机:needling machine化学粘合法:chemical bonding process化学粘合剂:chemical binder泡沫粘合法:foam bonding浆点机:paste point machine粉点机:powder point machine热粘合:thermal bonding印花:printing热轧法:thermal calendaring成网:web formation熔喷法:melt blown纺粘非织造布:spun-bonded fabric四:非制造布仿里皮:imitation leather成人尿布:adult diaper婴儿尿布:baby diaper婴儿擦拭布:baby wipe人造革基布:artificial leather substrate 汽车地毯:automotive carpet汽车顶蓬:automotive headliner毯子:blanket妇女卫生巾:feminine hygiene衬布:interlining土工膜:geomembrane土工网:geonets罩衣:gown家具布:home furnishings家用毯子:house-wrap工业滤布:industrial filterling cloth工业擦拭布:industrial wipe汽车内装垫衬:interior decoration lining for automobile 胸衬:interling for front part鞋帽衬:interling for shoes and hat实验工作服:lab coat口罩:mask医用绷带:medical bandage医用纱布:medical gauze医用口罩:medical mask枕套:pillow case防护服:protective apparel卷材:roll goods屋顶材料:roof material卫生巾:sanitary napkin肩垫:shoulder padding喷胶棉:spray-bonded nonwovens手术帘:surgical drape台布:table cover擦拭布:wipe五、非制造布质量及性能耐磨性:abrasion resistance透气性:breathabilitiy定重:basis weight舒适性:comfortability耐用性:durability柔韧性:flexibility功能性:functionality耐热性:heat resistance亲水性:hydrophility疏水性:hydrophobicity强度:intensity加工性能:processability防护性:repellency回弹性:resiliency收缩性:shrinkage稳定性:softness硬挺度:stiffness耐温性:temperature resistance厚度:thickness防水性:water resistance湿强度:wet strength抗皱性:wrinkle resistance四:非制造布成人尿布:adult diaper婴儿尿布:baby diaper婴儿擦拭布:baby wipe人造革基布:artificial leather substrate 仿里皮:imitation leather汽车地毯:automotive carpet汽车顶蓬:automotive headliner毯子:blanket妇女卫生巾:feminine hygiene衬布:interlining土工膜:geomembrane土工网:geonets罩衣:gown家具布:home furnishings家用毯子:house-wrap工业滤布:industrial filterling cloth工业擦拭布:industrial wipe汽车内装垫衬:interior decoration lining for automobile胸衬:interling for front part鞋帽衬:interling for shoes and hat实验工作服:lab coat口罩:mask医用绷带:medical bandage医用纱布:medical gauze医用口罩:medical mask枕套:pillow case防护服:protective apparel卷材:roll goods屋顶材料:roof material卫生巾:sanitary napkin肩垫:shoulder padding喷胶棉:spray-bonded nonwovens手术帘:surgical drape台布:table cover擦拭布:wipeI have long been engaged in the production technology job in the field of textile industry ;i as familiar with and waster many major foreign sowestic cotton-textile equipment in technical properties&technology;and I offer some technical consulting service in innovating the technique and in trorducting the freign engineering project.长期从事纺织工业生产技术工作,熟悉并掌握国内外棉纺织主要设备的工艺,技术性能,可提供技改,引进项目等技术咨询服务。

纺织品材料英语词汇整理我有的时候真是佩服在纺织品行业工作的外贸业务朋友们。

这个行业相关的专业术语和英语词汇太多了。

特别是当你看到这些怎么读都读不通的专业名词的的时候,更加头痛。

靛蓝青年布:Indigo chambray人棉布植绒:Rayon cloth flockingPVC植绒:PVC flocking针织布植绒:Knitting cloth flocking珠粒绒:Claimond veins倒毛:Down pile making平绒:velveteen (velvet-plain)仿麂皮:Micro suede牛仔皮植绒:Jeans flocking尼丝纺:Nylon taffeta (Nylon shioze)尼龙塔夫泡泡纱:Nylon seersucker taffeta素面植绒:plain flocking印花植绒:flocking(flower)雕印植绒:Embossing flocking皮革沟底植绒:Leather imitation flocking牛仔植绒雕印:Embossing jeans flocking兔羊绒大衣呢:Angora cachmere overcoating双面呢:double-faced woolen goods羊毛立绒呢:cut velvet顺毛呢:over coating粗花呢:costume tweed弹力呢:lycra woolen goods塔丝绒: Nylon taslon塔丝绒格子:N/Taslon ripstop桃皮绒:polyester peach skin涤塔夫:polyester taffeta春亚纺:polyester pongee超细麦克布:Micro fiber锦棉稠(平纹):Nylon-cotton fabric (plain)重平锦棉稠:Nylon-cotton-cotton fabric(double weft) 人字锦棉纺:Nylon-cotton fabric斜纹锦棉纺:Nylon-cotton fabric (twill)素色天鹅绒:solid velvet抽条磨毛天鹅绒:Rib fleece velvet雪花天鹅绒:melange velvet轧花天鹅绒:ginning velvet粒粒绒布:pellet fleece velvet麻棉混纺布:linen/cotton blended fabric麻棉交织布:linen/cotton mixed fabric素色毛巾布:solid terry蚂蚁布:fleece in one side素色卫衣布:solid fleece鱼网布:fleece彩条汗布:color-stripes single jerseyT/R弹力布:T/R bengalineT/C色织格子布:T/C solid check fabric弹力仿麂皮:Micro suede with spandexT/R仿麂皮:T/R Micro suede仿麂皮瑶粒绒复合布:100%polyester micro suede bounding with polar fleece 仿麂皮针织布复合:100% polyester bounding with knitting micro suede fabric 仿麂皮羊羔绒复合布:100% polyester micro suede bounding with lamb fur蜡光缎:cire satine全消光尼丝纺:Full dull nylon taffeta半消光尼丝纺:semi-dull nylon taffeta亮光尼龙:Trilobal nylon全消光塔丝隆:Full dull nylon taslan全消光牛津布:full dull nylon oxford尼龙格:Nylon rip-stop塔丝隆格:Taslan rip-stop哑富迪:Full dull Micro polyester pongee全消光春亚纺:Full dull polyester pongee春亚纺格子:polyester pongee rip-stop全消光涤纶桃皮绒:Full dull polyester peach宽斜纹桃皮绒:Big twill polyester peach涤锦复合桃皮绒:poly/nylon peach涤纶格子:polyester taffeta rip-stop涤纶蜂巢塔丝隆:polyester honey taslan全消光涤纶低弹牛津布:Full dull poly textured oxford涤锦交织桃皮绒:Nylon/polyester inter-woven peach原文来自必克英语 /topic-3147.html。

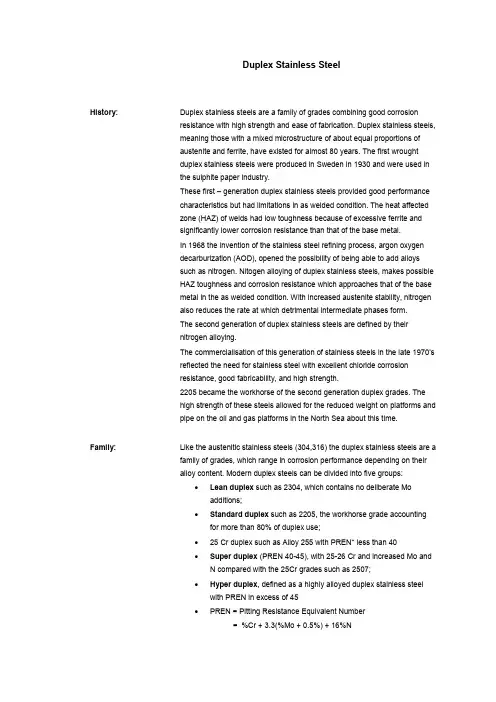

Duplex Stainless SteelHistory:Duplex stainless steels are a family of grades combining good corrosionresistance with high strength and ease of fabrication. Duplex stainless steels,meaning those with a mixed microstructure of about equal proportions ofaustenite and ferrite, have existed for almost 80 years. The first wroughtduplex stainless steels were produced in Sweden in 1930 and were used inthe sulphite paper industry.These first– generation duplex stainless steels provided good performancecharacteristics but had limitations in as welded condition. The heat affectedzone (HAZ) of welds had low toughness because of excessive ferrite andsignificantly lower corrosion resistance than that of the base metal.In 1968 the invention of the stainless steel refining process, argon oxygendecarburization (AOD), opened the possibility of being able to add alloyssuch as nitrogen. Nitogen alloying of duplex stainless steels, makes possibleHAZ toughness and corrosion resistance which approaches that of the basemetal in the as welded condition. With increased austenite stability, nitrogenalso reduces the rate at which detrimental intermediate phases form.The second generation of duplex stainless steels are defined by theirnitrogen alloying.The commercialisation of this generation of stainless steels in the late 1970’sreflected the need for stainless steel with excellent chloride corrosionresistance, good fabricability, and high strength.2205 became the workhorse of the second generation duplex grades. Thehigh strength of these steels allowed for the reduced weight on platforms andpipe on the oil and gas platforms in the North Sea about this time.Family: Like the austenitic stainless steels (304,316) the duplex stainless steels are afamily of grades, which range in corrosion performance depending on theiralloy content. Modern duplex steels can be divided into five groups:∙Lean duplex such as 2304, which contains no deliberate Moadditions;∙Standard duplex such as 2205, the workhorse grade accountingfor more than 80% of duplex use;∙25 Cr duplex such as Alloy 255 with PREN* less than 40∙Super duplex (PREN 40-45), with 25-26 Cr and increased Mo andN compared with the 25Cr grades such as 2507;∙Hyper duplex, defined as a highly alloyed duplex stainless steelwith PREN in excess of 45∙PREN = Pitting Resistance Equivalent Number= %Cr + 3.3(%Mo + 0.5%) + 16%NBy altering the additions of Chromium, Molybdenum, Nitrogen and Nickel differingdegrees of strength and corrosion protection can be achieved in duplex stainlesssteels. The levels of these alloys also affects processing and fabricabilityCorrosion Resistance: Duplex stainless steels exhibit a high level of corrosion resistance in most environments where the standard austenitic grades are used. However, there are some notable exceptions where they are decidedly superior. This results from the alloying that is undertaken.Acids: Both 2205 and 2507 duplex stainless steels outperform many high nickel austenitic stainless steels in solutions containing up to 15% acid. They are better than type 316 or 317 through at least 40% acid. The duplex grades can also be very useful in oxidising acids of this kind containing chlorides. The duplex stainless steels do not have sufficient nickel to resist the strong reducing conditions of mid-concentration sulphuric acid solutions, or hydrochloric acid. Their resistance to oxidising conditions makes duplex stainless steels good candidates for nitric acid service and the strong organic acids. Although types 304 and 316 will handle these strong organic acids at ambient temperatures, 2205 and other duplex grades are superior in many processes involving organic acids at high temperature. The duplex stainless steels are also used in processes involving halogenated hydrocarbons because of their resistance to pitting and stress corrosion.Caustics: The high chromium content and presence of ferrite provides for good performance of duplex stainless steels in caustic environments. At moderate temperatures, corrosion rates are lower than those of the standard austenitic grades.Pitting and crevice corrosion and resistance: Pitting and crevice corrosion and resistance are generally measured with reference to CPT* and CCT**.These are critical temperatures for crevice and pitting on stainless steels. The high Chromium and Molybdenum and Nitrogen contents in duplex grades provide very good resistance to chloride-induced localised corrosion in aqueous environments. Depending on the alloy content, some duplex grades are among the best performing stainless steels. Because they contain relatively high chromium content, duplex stainless steels provide a high level of corrosion resistance very economically.Reference material: Practical Guidelines for the Fabrication of Duplex Stainless Steel – ISBN 978 -1 -907470 -00 -4 – 2nd Edition 2009, published by International Molybdenum Assoc. (IMOA) London UK。

How to Weld Type 2205 Code Plus T wo®Duplex Stainless SteelMaterial Description2205 is a duplex (austenitic-ferritic) stainless steel that combines many of the best properties of austenitic and ferritic stainless steels. High chromium and molybdenum contents provide excellent resistance to pitting and crevice corrosion. The duplex structure is highly resistant to chloride stress corrosion cracking. 2205 has outstanding strength and toughness and possesses good weldability.The trademark Code Plus T wo®indicates the commitment, not only to meet the requirements for S31803 as established in ASTM and ASME, but also to meet two additional requirements. The first requirement was that nitrogen should be in the 0.14 to 0.20% range to gain its benefits in higher strength, higher corrosion resistance, greater metallurgical stability, and superior properties after welding. The second requirement was thatall mill products should pass a test for the absence of detrimental intermetallic phases. The tests developed by Outokumpu Stainless for this purpose have been formalized as the ASTM A 923 standard test method.These special requirements now define a new quality of 2205, designated S32205. S32205 is dual certifiable as S31803, but represents what users have come to expect of 2205 steel. BothS31803 and S32205 are included in all applicable ASTM product specifications.The increased strength of S32205, relative to that of S31803, resulting from its higher nitrogen is now being recognized by ASTM and ASME. The ASTM has designated S32205 as 2205.Forming, Heat Treatment, and Machining Hot Forming2205 is hot formed in the range 2250–1750°F (1230–955°C). In this range, the material has low mechanical strength and good hot ductility. If slow cooled or held at temperatures between 600 and 1750°F (315–955°C), the combination of strain and temperature can lead to rapid room temperature embrittlement by the formation of sigma phase and other detrimental intermetallic compounds. Full annealing with rapid cooling, ideally water quenching, is recommended after hot forming. Cold FormingBecause of its higher strength, 2205 requires higher forces for cold forming than those typical for austenitic stainless steels. Additional allowance for springback is necessary. Outokumpu Stainless 2205 may be formed on equipment typically used for forming austenitic stainless steels, once allowance has been made for its higher strength. Designs with 2205 frequently have used its higher strength to permit reductions of gauge, significantly easing many forming applications. Full annealing and quenching is recommended after severe cold forming. Heat Treatment2205 is annealed at 1900°F (1040°C) minimum with subsequent rapid cooling, ideally waterUNS S32205, S31803 (wrought products)UNS S39209 (bare welding wire)UNS J92205 (cast products)ASTM ASME Plate, Sheet, Strip A 240, A 480SA-240, SA-480 Bar, Billet A 276, A 479SA-479Pipe, Tubing A 789, A 790, A 928SA-789, SA-790 Forgings, Fittings A 182, A 815SA-182, SA-815 Castings A 890Testing A 923ASME Code Case 2186 (Embossed Assemblies)ASME/ANSI B16.34 for A 182, A 240, A 479, A 789, A 790ASME/ANSI B16.5, ASME/ANSI B31.1 Code Case 153ASME/SFA 5.4, SFA 5.9, and SFA 5.22 P No. 10H, Group 1AWS/A5.4 E 2209-XX, A5.9 ER 2209, A5.22 E 2209T0-XNACE MR0175SpecificationsType 2205 Code Plus Two® Duplex Stainless Steel 2quenching. This treatment applies for both full solution annealing and stress-relief annealing. Machining2205 may be machined with high-speed steel tooling at the same speeds and feeds as Type 316L austenitic stainless steel. With carbide tooling, positive rake angle, and C-5 and C-6 grades for roughing and finishing, respectively, should be used. Cutting speeds should be reduced by about 20% from those typical for Type 316L. The high strength of 2205 requires powerful machines and exceptionally strong and rigid tool mounting. Welding–General GuidelinesThe goal in welding any duplex stainless steel is to obtain fusion and heat-affected zones having the excellent corrosion resistance of the base metal and sufficiently high impact toughness for the application. 2205 Code Plus T wo®base metalhas an annealed structure with ferrite content in the range of 30–55%, and is virtually free of intermetallic phases. Welding procedures should be designed to produce this same structure in the weld metal and heat-affected zones. The weld thermal cycle, as well as filler metal and protection atmosphere, will control this structure. Near the fusion temperature, the structure of duplex stainless steels is entirely ferrite. The desired 30–55% ferrite can be achieved only if the cooling rate is slow enough to allow austenite to re-form as the weld cools. If the cooling rate is too slow, however, embrittling intermetallic phases may form in spite of the presence of the optimum ferrite content. Extremely low heat input followed by rapid cooling will produce a predominantly ferritic heat-affected zone with reduced toughness and corrosion resistance. This might occur with a GTAW wash pass or resistance spot welding. On the other hand, excessive time in the 1300–1800°F (705–980°C) range can lead to formation of intermetallic phases having a similar detrimental effect on properties.Outokumpu Stainless 2205 Code Plus T wo has been produced to assist the welder. One important feature is that 2205 Code Plus T wo has 0.14–0.20% nitrogen, compared to the 0.08–0.20% nitrogen permitted by ASTM and ASME. This higher nitrogen helps austenite re-form quickly during cooling so that the weld and heat-affected zoneare more easily converted back to the optimal austenitic-ferritic balance. In addition, special quality assurance procedures combined with the higher nitrogen content make 2205 Code Plus T wo more resistant to formation of intermetallic phases. Avesta Welding Products 2205 filler metals, typically designated as 2209, are more highly alloyed with nickel relative to the base metal to assure a fusion zone with austenite-ferrite balance,toughness, and corrosion resistance similar to those of the base metal. With Outokumpu Stainless 2205 base metal and filler, the welder has a workable range of operating conditions. By following the guidelines provided in properly qualified procedures,the welder can produce economical constructions with consistent, high-quality welds.Control of Intermetallic Phases2205 duplex stainless steel can experienceseveral precipitation reactions. The intermetallic compound, sigma phase, can precipitate between 1300–1800°F (705–980°C). Carbides canFigure 1 Time—Temperature Precipitation DiagramType 2205 Code Plus Two® Duplex Stainless Steel3precipitate between 800–1500°F (425–815°C), and “885 (425°C) embrittlement” can occur inthe temperature range of 650–950°F (340–510°C). If 2205 is held for sufficiently long times in any of these temperature ranges, precipitation reactions will occur. The formation of precipitates can embrittle 2205, reducing its ambient temperature ductility and toughness, and can reduce its corrosion resistance. The rate of the precipitation reactions is dependent on the chemical composition of 2205 and other metallurgical factors. Figure 1 shows a Time-Temperature-Precipitation curve for a 2.25 inch (57 mm) thick 2205 plate with 0.14% nitrogen. The curve corresponds to an ambient temperature impact toughness of 20 ft.-lb. (27J). Time-temperature combinations to the right of the curve have less than 20 ft.-lb. of toughness.Low Temperature Impact TestsLow temperature impact testing may be required by the ASME code (e.g., Section VIII Div. 1 UHA-51), by a customer specification, or a requirement to meet ASTM A 923 Method B, which calls for a single impact test at -40ºF (-40ºC). Many factors may adversely affect the low temperature impact properties of welds, e.g., elevated ferrite content, presence of deleterious phases, and elevated oxygen content. The latter is a factor in welding processes that use a flux, and is affected by the type of flux. Welds may not meet the minimum requirements of A 923 Method B, because these acceptance criteria were established for solution annealed plate, but that does not necessarily mean detrimental intermetallic phases are present. As a general guideline, it is possible to arrange the welding processes in order of increasing impact toughness as follows: SMAW-rutile coating; FCAW; SMAW-basic coating; SAW, GMAW, GTAW. Outokumpu Stainless is willing to assist in choosing the proper welding consumable for the procedure qualifications based ontest temperature.Pitting TestThe standard pitting test used on 2205 is ASTM A 923 Method C. Prior to the creation of A 923, the pitting test was often referred to as “ASTM G 48 Practice B modified.” T esting is done in a ferric chloride solution at a specific temperature, 25ºC for base material and 22ºC for annealed welds for 24 hours. Other temperatures may be set by customer specifications, sometimes with minor variations to the test method. The performance of welds in this solution may have no correlation to corrosion performance in other media and is not intended as a fitness for service test in any specific service environment. As with impact toughness, the welding process can influence corrosion performance. The welding processes in order of increasing corrosion resistance in this solution are: GTAW; GMAW; FCAW and SAW; SMAW-basic coating; SMAW-rutile coating. The low ranking of the GTAW process is explained by a loss of nitrogen from the weld pool. To counteract this effect, it is possible to either add nitrogen to the torch gas or use an overalloyed filler metal, e.g., Avesta Welding Products P100 (25Cr-9.5Ni-3.6Mo-0.22N).Joint DesignSome joint designs that can be used for 2205 are shown in Joint Designs 1–8. The goal of the designs is full penetration with minimal risk of burn-through. Many other designs are possible. For example, when the material thickness exceeds 0.5 inch (12 mm) and it is possible to weld from both sides, the joint designs in Joint Designs 3–5 can be made symmetrical.The root bead may be deposited using either GTAW (TIG) or SMAW (coated electrodes).If GTAW is used, an inert backing gas should be applied when tacking. The root side of a root bead deposited by SMAW should be cleaned afterSquare Butt Joint Joint Design 1Type 2205 Code Plus Two ® Duplex Stainless Steel4welding. A suitable electrode diameter is 5⁄64–3⁄32inch (2–2.4 mm), depending on base metal thickness, welding position, and accessibility for root-side grinding.Selection of a joint design should accommodate the following guidelines:1. It should be easy to achieve full penetrationwith a good margin of safety.2. The welder should keep slag formation and theweld pool under observation.3. Adequate backing gas shielding should beprovided to avoid root defects harmful to corrosion resistance or mechanical properties.4. Excessive weaving and wide molten poolsshould be avoided to prevent excessively high heat input and high stresses.5. Extremely low heat inputs with rapid quenchingshould be avoided to prevent predominantly ferritic heat-affected zones.Joint Preparation CleaningCleaning of joints and adjacent surfaces before welding is good practice for all stainless steels.Dirt, oils, and paint can cause weld defects.Common solvents such as acetone or mineral spirits can be used as cleaning agents. Moisture in the joint can cause porosity or weld metal cracking.It is important that joint preparation follow the desired joint design accurately. Large variations in preparation can cause substantial variations in the land thickness or the gap distance, thereby affecting the consistency of the weld. Edge preparationSquare Butt JointJoint Design 2Single V JointJoint Design 3Single V JointJoint Design 5Single U JointJoint Design 4Type 2205 Code Plus Two® Duplex Stainless Steel5Preheating and Post-WeldHeat TreatmentPreheating of 2205 is not normally necessary. It may be helpful in cold ambient conditions to avoid the risk of condensation and possible resultant porosity. In such cases the 2205 may be heated carefully and uniformly to less than 200°F (95°C), and only after the weld joint has been thoroughly cleaned.If the 2205 is greater than about 0.625 inch (16 mm) thickness, and welding is to be done with very low heat input (≤12 kJ/inch, 0.5 kJ/mm), preheating to the range of 200–300°F (95–150°C) can be useful. The purpose of this preheating is to avoid excessively rapid cooling and a resulting extremely high ferrite content. A similar upper temperature limit applies to interpass temperatures.Postweld heat treatment is not normally necessary. If it becomes necessary for any reason,it should be done at 1900°F (1040°C) minimum, followed by rapid cooling. Exposure in the range 1200–1830°F (650–1000°C) is very harmful to toughness and corrosion resistance because of formation of carbides, or sigma or other intermetallic phases.Interpass TemperatureThe maximum interpass temperature for 2205 is 300ºF (150ºC).DistortionControlling distortion of 2205 is not significantly different from controlling distortion of austenitic stainless steels. Good practice includes proper fixturing, cross supports, braces, staggered bead placement, and weld sequence, etc. The edges of the plate or sheet should be squared, aligned, and tacked prior to welding. The coefficient of thermal expansion of 2205 is intermediate to those for carbon steel and for austenitic stainless steels such as Type 304L.Workmanship, Inspection, andQuality Assurance2205 should be welded in accordance with predetermined fabrication and inspection plansby skilled and trained operators.6Type 2205 Code Plus Two® Duplex Stainless Steel Fabrication of components in 2205 is not Array difficult but it does require some modification ofthe practices commonly used for Type 316L. 2205has high strength, which may require changes oftechnique in cold forming. Welding can be donewith little risk of hot cracking, but the welder shouldbe aware that a high cooling rate, weld spatter,strike scars, damp electrodes, and high interpasstemperatures can lead to embrittlement and reducedcorrosion resistance.T o obtain welded joints with corrosion resistanceand mechanical properties equivalent to those ofthe base metal, the welders and inspectors shouldbe informed in advance of the special aspects offorming and welding 2205. Preparing writtenwelding procedures and having welders performtrial welds are sensible precautions prior tobeginning production.Because 2205 is often selected for criticalcomponents in highly corrosive environments,welded joints must be inspected carefully.Incomplete fusion, incomplete penetration, apoorly cleaned root side, spatter, and strike scarsmust be remedied. Suitable nondestructive testingmethods are X-ray inspection, liquid penetrantinspection, hydrostatic testing, leak detection, andferrite measurement. Destructive testing methodsinclude bend tests, impact tests, and metallographicexamination. A corrosion test such as that inASTM A 923, Method C, may also be useful.Ferrite Measurement2205 Code Plus T wo is controlled to have anaustenitic-ferrite balance with 30–55% ferrite,typically about 45% ferrite. Substantial deviationsof the austenite-ferrite ratio from this range canadversely affect the mechanical properties andcorrosion resistance of the welded joint. Excessivelylow ferrite content (<25%) can result in reducedstrength and a risk of stress corrosion cracking.Excessively high ferrite content (>75%) can lead toreduced corrosion resistance and impact toughness.Metallographic measurement of ferrite is adestructive test and very time consuming, requiringa well-equipped laboratory. A less precise but non-destructive test method is determination offerrite number by a Magnegage equipped with acounterweight. The Magnegage determines theType 2205 Code Plus Two® Duplex Stainless Steel7nominal composition 21.5Cr-15Ni-2.7Mo-0.025C max) and Avesta Welding Products P5 electrodes and flux cored wire (AWS E309LMo, nominal composition 22.5Cr-13Ni-2.7Mo-0.04C max). For joining 2205 to an austenitic stainless steel, Avesta Welding Products P5 or another low carbon austenitic stainless filler metal with molybdenum content greater than that of the lesser of the dissimilar metals may be used. Consideration should be given to whether the filler metal will provide adequate strength in these dissimilar welds.Removal of Dirt, Slag, and Heat TintT o obtain the best corrosion resistance, it is essential to remove oxide, tarnish, heat tint, and other surface contamination by mechanical or chemical methods, ideally both. Because there is a very thin, chromium-depleted layer below the heat tint, wire brushing the heat tint alone is not sufficient to restore maximum corrosion resistance.Mechanical methods include fine grinding and polishing, and abrasive blasting with 75–100 micron soda-lime glass beads. Subsequent chemical cleaning is not required if it is certain that the mechanical cleaning methods will not transfer iron to the surface. However, a chemical cleaning with nitric acid or similar media, as described in ASTM A 380 or A 967, subsequent to mechanical cleaning is good practice because it guards against contami-nation from the cleaning medium. Mechanical cleaning with steel brushes or an abrasive blasting medium capable of transferring iron (for example, a steel blasting medium or any blasting medium pre-viously used on steel) must be avoided unless there is to be a subsequent complete chemical cleaning.If mechanical cleaning is not to be used, then the removal of oxide or heat tint will require the use of pickling, a more aggressive form of chemical treatment than the removal of free iron, commonly called “passivation.” 2205 is more difficult to pickle than the 300-series austenitic stainless steels and requires an aggressive pickling solution. Pickling is readily accomplished using Avesta Welding Products RedOne 140 paste or 240 spray gel or a solution of 20% nitric acid and 5% hydrofluoric acid in water. Avesta Welding Products regular pickling paste may be used also but requires longer pickling times (e.g., two 2-hour applications vs. a single 3-hour application with RedOne 140 paste or 240 spray gel). All of these chemicals are aggressive and appropriate precautions for personal safety, and the safety of others that you work with, as defined in ASTM A 380 must be followed. Proper environmental procedures are required for the disposal of wash liquors from pickling operations.When SMAW or FCAW is used as a root pass, it is especially important to remove all weld splatter, slag, and heat tint from the root side. This is best accomplished by mechanical means followedby pickling.Gas Tungsten Arc Welding (GTAW, TIG) EquipmentGas tungsten arc welding, also called TIG, maybe performed manually or by machine. A constant-current power supply should be used, preferably with a high-frequency circuit for starting the arc and a stepless control current delay unit incorporated in the power supply unit. GTAW should be done using direct current straight polarity (DCSP), electrode negative. Use of direct current reverse polarity (DCRP) will result in rapid electrode deterioration. Choice of Filler Metal and ElectrodeThe nonconsumable electrode shall meet the requirements of AWS specification 5.12 Classification EWTh-2 (2% thoriated tungsten electrode). Good arc control is achieved by grinding the electrode to a point. Vertex angles of 30–60 degrees with a small flat at the point are generally used. For automatic GTAW, the vertex angle will affect penetration. A few simple tests prior to actual fabrication should be made to determine the best electrode configuration.For optimal corrosion performance, GTAW welds should be made with filler metal. For GTAW welding with filler, Avesta Welding Products provides a 2209 wire that is more highly alloyed with nickel relative to the 2205 base composition. It has 7.0 to 9.0% nickel as compared to the 5.5% nickel typically in the base metal. Extensive studies demonstrated that higher nickel was the most reliable and effective method of maintaining the desired austenite-ferrite balance in the weld metal8Type 2205 Code Plus Two® Duplex Stainless Steel with mechanical properties and corrosion resistance Array equivalent to those of the base metal.Weld Pool ProtectionThe weld pool in GTAW should be protected fromatmospheric oxidation by inert gas flowing throughthe weld torch. T urbulence of the inert gas, withthe resulting entrainment of air, can be minimizedby a gas diffuser screen (gas lens) on the torch.Operating procedures should be adjusted toassure adequate inert gas shielding. Gas flow shouldprecede arc initiation by several seconds and shouldbe held over the pool for at least five seconds afterthe arc is extinguished. If the flow is too low, theweld pool will not be adequately protected. If theflow is too high, gas turbulence may aspirate airinto the weld region. Argon backing gas is requiredon the back side of the joint for all root passes,regardless of joint design. The argon should bewelding grade 100% argon with a purity of at least99.95% argon.Approximate flow rates are 0.4–0.6 cfm (12–18liters/minute) {0.2–0.3 cfm (6–8 liters/minute) ifusing a normal gas nozzle} for the electrode, and0.1–0.7 cfm (3–20 liters/minute) for the backingpurge, depending on the root volume. The enclosedvolume should be purged a minimum of seventimes before welding. Argon should be fed at thebottom and out at the top because of its weightrelative to air.Addition of up to 3% dry nitrogen may beconsidered in the torch gas for enhanced corrosionperformance; however, increased electrode wearmay result. Addition of helium may be useful insome circumstances. Additions of oxygen andcarbon dioxide to the argon welding gas aredetrimental to the corrosion resistance of the weld.There should be regular inspections of O-ringsfor water-cooled torches and of gas hoses to assurethat only pure, dry shielding gas is delivered to theweld area.Welding TechniquesThe joint should be prepared in one of the suggestedgeometries with attention to surface preparation,edge preparation, alignment, and root spacing.A non-copper backing bar may be installed toType 2205 Code Plus Two® Duplex Stainless Steel9 Gas Metal Arc Welding (GMAW, MIG) Array EquipmentGas metal arc welding, also called MIG, is performedusing a constant voltage power supply with variableslope and variable inductance control or withpulsed arc current capability. Three arc transfermodes are available.Short-Circuiting TransferThis mode requires separate slope and secondaryinductance controls. It is useful for material upto 0.125 inch (3 mm) thick. Short-circuitingtransfer occurs with low heat input and is particularlyuseful for joining thin sections that could bedistorted by excessive heat. It is also useful forout-of-position welding.Pulsed Arc TransferThis mode requires two power sources, one for eachof the two ranges. Switching sources produces thepulsed output. The current has its peak in the spraytransfer range and its minimum in the globularrange. This method provides the benefits of sprayarc but limits heat input, making the method usefulin all positions.Spray TransferThis mode provides a stable arc and high depositionrates but occurs with high heat input. It is generallylimited to flat position welding. The best results aregenerally achieved with synergic pulsed arc. GMAWshould be done with direct current reverse polarity(DCRP), electrode positive.Choice of Filler Metal and WeldingParametersGMAW uses a consumable electrode in the form ofa continuous solid wire fed through the GMA torchby an automatic wire feed system. Avesta WeldingProducts 2209 filler metal is more highly alloyedwith nickel relative to the base metal to helpachieve the desired ferrite-austenite balance in theweld metal.Shielding gas is typically 80% welding-grade argon with additions of helium, nitrogen,10Type 2205 Code Plus Two® Duplex Stainless Steel a microstructure with a very high ferrite content, a Array structure susceptible to cracking and possibly lowerin corrosion resistance. Such defects should beremoved by fine grinding.The root pass should be made using AvestaWelding Products 2209 filler metal with theappropriate shielding gas. There should be notack welds at the starting point of the actual rootpass weld. To avoid cracking of the root pass weldrelated to tack welds, the welder should interruptthe root pass before a tack weld. Either grind awaythe tack completely with a slitting wheel grinder,or make the tack shorter by grinding the start andfinish of the tack prior to restarting the root pass.The width of the root gap should be maintainedagainst shrinkage.The start and finish of the root pass weld shouldbe ground prior to the start of any fill passes.The fill passes should be made with straight stringerbeads. The metal should be allowed to cool to lessthan 300°F (150°C) between passes. The jointmay be filled using 0.035-, 0.045-, or 0.063-inch(1.0-, 1.2-, or 1.6-mm) diameter Avesta WeldingProducts 2209 filler metal. GMA welding givesthe best results when done in the flat position butvertical welds can be made successfully. The torchshould be as near to perpendicular to the workpieceas possible. Excessive deviation from the perpendicularmay cause air to be drawn into the shielding gas.The filler metal and guide tube should be keptclean at all times. Filler wire should be stored in acovered container.Removal of Dirt, Slag, and Heat TintAll welds should be cleaned in accordance with theprocedures outlined on page 7.Flux Cored Wire Welding (FCW)EquipmentFlux cored wire welding is closely related to GMAW.The flux-filled wire is automatically fed throughthe center of the gun using the same equipment aswhen GMA welding. The shielding gas is suppliedthrough the gun. The flux inside the wire will pro-tect the weld from the atmosphere because it formsa slag which covers the weld. The FCW process canType 2205 Code Plus Two® Duplex Stainless Steel11 removed by fine grinding. Array Tack welds of appropriate length and spacingshould be made with full argon shielding. The rootpass should be made using Avesta Welding Products2209 filler metal with appropriate shielding gasflow. There should be no tack weld at the startingpoint of the actual root pass weld. T o avoid crackingof the root pass weld related to tack welds, thewelder should interrupt the root pass before a tackweld. Either grind away the tack completely with aslitting wheel grinder, or make the tack shorter bygrinding the start and finish of the tack prior torestarting the root pass. The width of the root gapshould be maintained against shrinkage. The startand finish of the root pass weld should be groundprior to the start of any fill passes. The fill passesshould be made with straight stringer beads. Themetal should be allowed to cool to less than 300°F(150°C) between passes. The filler metal and guidetube should be kept clean at all times. Flux coredwire should be stored in a covered container.Removal of Dirt, Slag, and Heat TintAll welds should be cleaned in accordance with theprocedures outlined on page 7.Shielded Metal Arc Welding (SMAW)EquipmentShielded metal arc welding, also called stick orcovered electrode welding, is performed using aconstant current power supply. SMA welding isdone using direct current reverse polarity (DCRP),electrode positive.Electrode Selection and UseSMA welding uses a consumable electrode having astainless steel core wire with a flux coating. Thiscoating provides arc stability, shields the moltenmetal during arc transfer, and protects the weldduring solidification.Avesta Welding Products offers four electrodesfor welding 2205 duplex stainless steel. 2205 Basicprovides the highest impact toughness. 2205-PW-17is an all-position electrode. 2205-17 AC/DC is anall purpose electrode for long, flat welds. 2205-VDXis for vertical down welding. All Avesta Welding。

双层丝织物工艺流程英文回答:The process of double-layer silk weaving involves several steps to create a beautiful and intricate fabric. First, the silk threads are carefully selected and prepared for weaving. This involves sorting and straightening the threads to ensure they are of the same length and thickness. Once the threads are prepared, they are then loaded ontothe loom.The weaving process begins with the warp threads, which are the vertical threads that run lengthwise on the loom. These threads are carefully threaded through the heddlesand reed of the loom, creating a strong foundation for the fabric. The weft threads, which are the horizontal threads that run across the warp threads, are then woven in and out of the warp threads to create the desired pattern or design.As the weaving process progresses, the fabric begins totake shape. The weaver carefully guides the weft threads through the warp threads, ensuring that the tension is even and the fabric is woven tightly. This requires skill and precision to create a fabric that is both durable and visually appealing.Once the weaving is complete, the fabric is carefully removed from the loom. It is then inspected for any defects or imperfections. If any issues are found, the fabric may need to be repaired or re-woven. Once the fabric passes inspection, it is ready for the finishing process.The finishing process involves several steps to enhance the appearance and feel of the fabric. This may include washing and steaming the fabric to remove any impurities or wrinkles. It may also involve dyeing or printing the fabric to add color or patterns. Additionally, the fabric may be treated with chemicals or finishes to improve itsdurability or texture.After the finishing process is complete, the fabric is ready to be used for a variety of applications. It can beused to create clothing, accessories, or even home decor items. The double-layer silk fabric is known for its luxurious feel and beautiful drape, making it a popular choice for high-end fashion and interior design.中文回答:双层丝织物的工艺流程包括多个步骤,以创造出美丽而复杂的织物。