德马输送辊筒产品选用手册-详细版样本2012 V2

- 格式:pdf

- 大小:12.41 MB

- 文档页数:92

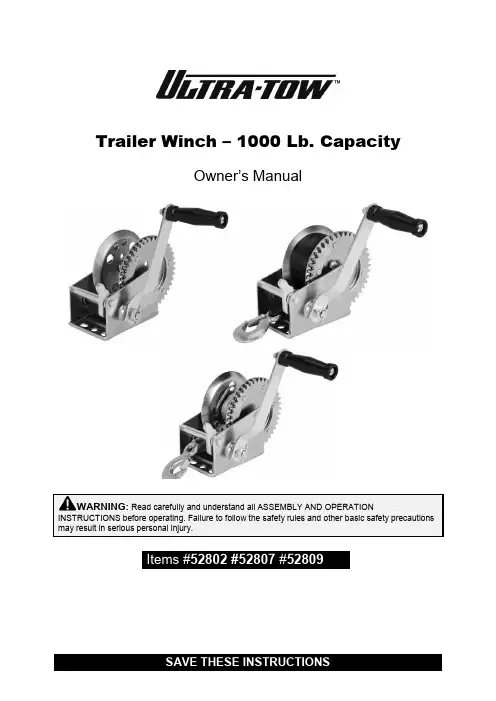

Trailer Winch – 1000 Lb. CapacityOwner’s ManualWARNING: Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety precautions may result in serious personal injury.Items #52802 #52807 #52809Thank you very much for choosing an Ultra-Tow™ product!For future reference, please complete the owner’s record below:Serial Number/Lot Date Code: ________________________________ Purchase Date: ____________________________________________ Save the receipt, warranty, and this manual. It is important that you read the entire manual to become familiar with this product before you begin using it.This winch is designed for certain applications only. Northern Tool & Equipment is not responsible for issues arising from modification or improper use of this product such as an application for which it was not designed. We strongly recommend that this product not be modifiedand/or used for any application other than that for which it was designed. For technical questions, please call 1-800-222-5381.Intended Use (4)Technical Specifications (4)Important Safety Information (5)Specific Operation Warnings (6)Winch Mounting and Cable Attachment (7)Main Parts of Winch (8)Assembly Instructions (8)Before Each Use (9)Operating Instructions (9)Moving or Tensioning Loads (9)After Each Use (10)Maintenance (10)Troubleshooting (10)Parts Diagram (11)Parts List (11)Replacement Parts (12)Limited Warranty (13)The Ultra-Tow Trailer Winch is designed for safer, easier boat loading and unloading. Pulling winches are best suited for boat trailers and other horizontal pulling applications which require the freewheeling feature of ratchet type winches.∙The winch is designed to be attached to a mounting plate or structure capable of supporting the load that is intended to pull (lift). Mounting location and hardware must support your Winch and load.∙For maximum strength and safety, this winch should be mounted with three 3 ⁄8" or M10 bolts, washers, and lock washers (not included, sold separately). The bolt should attach the winch to the mounting structure utilizing the outside rear holes or slots. The third bolt should be insertedthrough the winch frame and mounting structure in a manner to utilize the foremost remaining frame slot (hole).∙Select a winch line with breaking strength at least 1-1 ⁄2 times the winch rating and a hook 1-1 ⁄2 times stronger than the line.∙CABLE REPLACEMENT: Use extreme care when replacing cable, it is secured under tension by the cable clamp, and may spring back forcefully.a. Put pawl in reel out position. Reel the old cable all the way out by turning handle counterclockwise.b. Loosen the nut and remove the old cable from underneath the cable clamp.c. Remove the old cable.d. Route new cable end over bushing and through the hole to the outside of the drum.e. Install the cable under the cable clamp.f. Tighten the nut securely.g. Put pawl in reel in position, then reel the new cable onto drum by turning the handle clockwise,being careful not to allow kinking.h. Test winch for proper operation.∙If nylon strap is used, it should have a loop sewn in one end and be attached using a 3 /8" x 3" or1 /4" x 2-3/4" long bolt and locknut. Use a locknut, not a nut and lock the washer. Insert boltthrough slots in both reel side plates so that nut is on gear side.∙Tighten only until snug with bolt in bottom of slot next to reel hub.Insert handle and secure with a lock nut.Winding/unwinding the cable without load1. Place the ratchet lever in the center position.2. The cable reel now moves freely in both directions.3. Pull the steel cable at the fixed hook until the hook can be attached to the load to be moved.4. Wind back the excessive cable by turning the crank clockwise.Winding up the cable under load (towing, loading)1. Hold the crank firmly and push gently to relieve the ratchet lever2. Place the ratchet lever at position.3. Turn the crank clockwise to evenly wind up the steel cable.Unwinding the cable under load (lowering, unloading)1. Hold the crank firmly and push gently to relieve the ratchet lever.2. Place the ratchet lever at position.3. The steel cable should be fully retracted again after use.Ratchet switch1. There are 3 positions for the ratchet switch: The higher position is for pulling, the lower position isfor releasing, the middle position is for both pulling and releasing, but can only be used when the winch is loaded. Hold the crank handle tightly if you want to change the switch position.2. Before using, install the winch on a firm and flat surface. To install it, put the ratchet switch on themiddle position and pull the cable out until the holes on the bottom of the base are visible. Then use at least 3 sets of 3/8 inch bolts and locking nuts, in a triangular pattern, to affix the base to the surface. Use an extra metal or hardwood board when necessary.3. Then install the crank handle to the axis bolt with nut.4. Put the ratchet switch on the higher position and turn the crank handle clockwise to pull. Place theratchet switch on the lower position and turn the crank handle counterclockwise to release.5. When finished, attach the hook to the paw bushing.∙Wipe external surfaces of the winch with a clean cloth.∙Periodically, lubricate the wire rope with light oil. Lubricate the gear with gear grease.∙This winch has been fully lubricated at the factory; but, for continued smooth performance and increased life, occasional greasing of gears and reel shaft and an occasional drop of oil on drive shaft bearings are recommended.∙Inspect periodically all parts, steel cable, accessories and replace them if damaged or used.∙Have damaged parts replaced by an authorized service center.∙Check the nuts periodically and tighten them if they are loose.∙Keep winch in good working order. Damaged or severely-worn parts create unnecessary dangers and could result in personal injury or property damage.∙Always lock up product and keep out of children.Maintain the winch by adopting a program of conscientious repair and maintenance in accordance with the following recommended procedures. It is recommended that the general condition of any tool be examined before it is used. Keep your tool in good repair.The following chart is based on a normal operation schedule.∙For replacement parts and technical questions, please call Customer Service at 1-800-222-5381. ∙Not all product components are available for replacement. The illustrations provided are a convenient reference to the location and position of parts in the assembly sequence.∙When ordering parts, the following information will be required: item description, item model number, item serial number/item lot date code, and the replacement part number.∙The distributor reserves the rights to make design changes and or improvements to product lines and manuals without notice.Northern Tool and Equipment Company, Inc. ("We'' or '"Us'') warrants to the original purchaser only ("You'' or “Your”) that the Ultra-Tow product purchased will be free from material defects in both materials and workmanship, normal wear and tear excepted, for a period of one year from date of purchase. The foregoing warranty is valid only if the installation and use of the product is strictly in accordance with product instructions. There are no other warranties, express or implied, including the warranty of merchantability or fitness for a particular purpose. If the product does not comply with this limited warranty, Your sole and exclusive remedy is that We will, at our sole option and within a commercially reasonable time, either replace the product or product component without charge to You or refund the purchase price (less shipping). This limited warranty is not transferable.Limitations on the WarrantyThis limited warranty does not cover: (a) normal wear and tear; (b) damage through abuse, neglect, misuse, or as a result of any accident or in any other manner; (c) damage from misapplication, overloading, or improper installation; (d) improper maintenance and repair; and (e) product alteration in any manner by anyone other than Us, with the sole exception of alterations made pursuant to product instructions and in a workmanlike manner.Obligations of PurchaserYou must retain Your product purchase receipt to verify date of purchase and that You are the original purchaser. To make a warranty claim, contact Us at 1-800-222-5381, identify the product by make and model number, and follow the claim instructions that will be provided. The product and the purchase receipt must be provided to Us in order to process Your warranty claim. Any returned product that is replaced or refunded by Us becomes our property. You will be responsible for return shipping costs or costs related to Your return visit to a retail store.Remedy LimitsProduct replacement or a refund of the purchase price is Your sole remedy under this limited warranty or any other warranty related to the product. We shall not be liable for: service or labor charges or damage to Your property incurred in removing or replacing the product; any damages, including, without limitation, damages to tangible personal property or personal injury, related to Your improper use, installation, or maintenance of the product or product component; or any indirect, incidental or consequential damages of any kind for any reason.Assumption of RiskYou acknowledge and agree that any use of the product for any purpose other than the specifieduse(s) stated in the product instructions is at Your own risk.Governing LawThis limited warranty gives You specific legal rights, and You also may have other rights which vary from state to state. Some states do not allow limitations or exclusions on implied warranties or incidental or consequential damages, so the above limitations may not apply to You. This limited warranty is governed by the laws of the State of Minnesota, without regard to rules pertaining to conflicts of law. The state courts located in Dakota County, Minnesota shall have exclusive jurisdiction for any disputes relating to this warranty.Distributed by:Northern Tool & Equipment Company, Inc.Burnsville, Minnesota 55306Made in China。

Yaohua XK3101-M2 Protable WIM Indicator user and calibration ManualXK3101M2 Portable WIM IndicatorOperator’s ManualOperator’s Manual of XK3101M2 Portable WIM Indicator for Axle Overload Detection 1. IntroductionWIM (weigh-in-motion) is the top technology in weighing field. Our company has long been engaged in the research, development and production of the axle load WIM system. In 2000, we developed the XK3101 indicator, which has the function of axle testing. And,due to its high reliability and precision in WIM, it gained the acceptance of most customers. And also our company is one of the few firms who have the intellectual property right of their own. This system (XK3101M2) was improved on the base of XK3101B; it is more reliable and more precise and can be used in portable vehicle scales and other axle load WIM systems.2. Features◆Excellent weighing function and high precision;◆Backlight lattice LCD, Clear both in daytime and nighttime;◆Can conveniently input full vehicle license number with letters;◆Can put in the name of the testing organization and operators;◆Built-in high speed printer to print the whole testing report form;◆Can store as many as 1300 vehicle testing records;◆mature inquiry and statistic function;◆AC/DC, real time battery capacity indicating. The battery can be used for 40 hours on end. Automatic shut off;◆The auto power supply system can be used for providing electricity and charging;◆The instrument can work independently. And it also can upload testing data to computers.3. Main Technical Index• (1)full-scale temperature coefficient: 5ppm/℃• (2) inner resolution: 24 bits(3) Sampling speed: 200 times/sec• (4) the speed of display renewal: 12.5times/sec• (5) system non-linearity <0.01%• (6) impulse source of sensor: DC 5V±2%• (7) operating temperature range: 0℃--40℃1This is a “Table of Contents preview” for quality assuranceThe full manual can be found at /estore/catalog/ We also offer free downloads, a free keyboard layout designer, cable diagrams, free help andsupport. : the biggest supplier of cash register and scale manuals on the net。

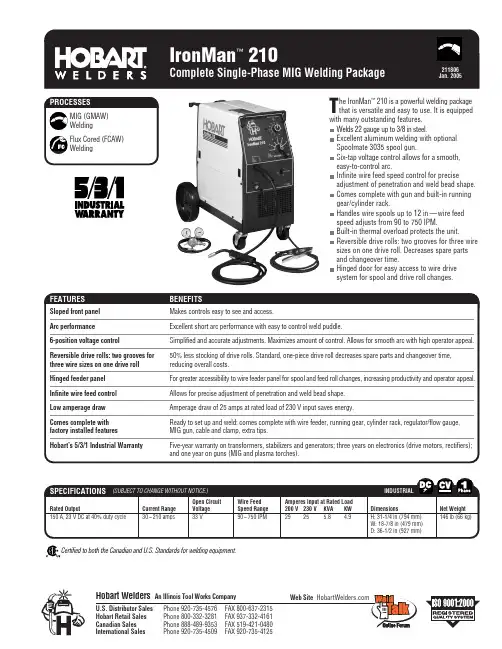

T he IronMan™210 is a powerful welding package Array that is versatile and easy to use. It is equippedwith many outstanding features.Welds 22 gauge up to 3/8 in steel.Excellent aluminum welding with optionalSpoolmate 3035 spool gun.Six-tap voltage control allows for a smooth,easy-to-control arc.Infinite wire feed speed control for preciseadjustment of penetration and weld bead shape.Comes complete with gun and built-in runninggear/cylinder rack.Handles wire spools up to 12 in—wire feedspeed adjusts from 90 to 750 IPM.Built-in thermal overload protects the unit.Reversible drive rolls: two grooves for three wiresizes on one drive roll. Decreases spare partsand changeover time.Hinged door for easy access to wire drivesystem for spool and drive roll changes.Certified to both the Canadian and U.S. Standards for welding equipment.2(Order from Hobart Service Parts.)Contact TipsContact Tip Adapter #169 716 Replacement Liners Nozzle #169 7151/2 in (13 mm) diameter orifice.Spot Nozzles#176 237#176 239#176 241Reversible V-Groove Drive Rollsfor Mild Steel Wire#202 925.023 and .030/.035 in (0.6 and 0.8/0.9 mm)Spoolmate™3035 #195 016Includes 20 ft (6 m) cable. When combinedwith the IronMan™210, this spool gun welds.023, .030 and .035 in (0.6, 0.8 and 0.9 mm)wires on 14 gauge to 1/4 in thick aluminum.#207 642 Switch and Gas Diverter required.3Litho in USAThe IronMan ™210 comes complete with:Constant-voltage DC power source Built-in wire feeder10 ft, M-10 MIG welding gun Regulator/flow gauge 5 ft gas hoseSample spool of solid welding wire 7 ft primary input cable with plug Dual groove drive roll – .023 and .030/.035 in10 ft work cable with clamp Extra contact tipsBuilt-in running gear/cylinder rack Weld, set-up and parts information chart。

©2002 Whelen Engineering Company Inc.Form No.13719A (053007)A u t o m ot ive : For warranty information regarding this product, visit /warranty•Proper installation of this product requires the installer to have a good understanding of automotive electronics, systems and procedures.•Whelen Engineering requires the use of waterproof butt splices and/or connectors if that connector could be exposed to moisture.•Any holes, either created or utilized by this product, should be made both air- and watertight using a sealant recommended by your vehicle manufacturer.•Failure to use specified installation parts and/or hardware will void the product warranty.•If mounting this product requires drilling holes, the installer MUST be sure that no vehicle components or other vital parts could be damaged by the drilling process. Check both sides of the mounting surface before drilling begins. Also de-burr the holes and remove any metal shards or remnants. Install grommets into all wire passage holes.•If this manual states that this product may be mounted with suction cups, magnets, tape or Velcro®, clean the mounting surface with a 50/50 mix of isopropyl alcohol and water and dry thoroughly.•Do not install this product or route any wires in the deployment area of your air bag. Equipment mounted or located in the air bag deployment area will damage or reduce the effectiveness of the air bag, or become a projectile that could cause serious personal injury or death. Refer to your vehicle owner’s manual for the air bag deployment area. The User/Installer assumes full responsibility to determine proper mounting location, based on providing ultimate safety to all passengers inside the vehicle.•For this product to operate at optimum efficiency, a good electrical connection to chassis ground must be made. The recommended procedure requires the product ground wire to be connected directly to the NEGATIVE (-) battery post (this does not include products that use cigar power cords).•If this product uses a remote device for activation or control, make sure that this device is located in an area that allows both the vehicle and the device to be operated safely in any driving condition. •Do not attempt to activate or control this device in a hazardous driving situation.•This product contains either strobe light(s), halogen light(s), high-intensity LEDs or a combination of these lights. Do not stare directly into these lights. Momentary blindness and/or eye damage could result.•Use only soap and water to clean the outer lens. Use of other chemicals could result in premature lens cracking (crazing) and discoloration. Lenses in this condition have significantly reduced effectiveness and should be replaced immediately. Inspect and operate this product regularly to confirm its proper operation and mounting condition. Do not use a pressure washer to clean this product.•It is recommended that these instructions be stored in a safe place and referred to when performing maintenance and/or reinstallation of this product.•FAILURE TO FOLLOW THESE SAFETY PRECAUTIONS AND INSTRUCTIONS COULD RESULT IN DAMAGE TO THE PRODUCT OR VEHICLE AND/OR SERIOUS INJURY TO YOU AND YOUR PASSENGERS!Warnings to Installers Whelen’s emergency vehicle warning devices must be properly mounted and wired in order to be effective and safe. Read and follow all of Whelen’s written instructions when installing or using this device. Emergency vehicles are often operated under high speed stressful conditions which must be accounted for when installing all emergency warning devices. Controls should be placed within convenient reach of the operator so that they can operate the system without taking their eyes off the roadway. Emergency warning devices can require high electrical voltages and/or currents. Properly protect and use caution around live electrical connections.Grounding or shorting of electrical connections can cause high current arcing, which can cause personal injury and/or vehicle damage, including fire. Many electronic devices used in emergency vehicles can create or be affected by electromagnetic interference. Therefore, after installation of any electronic device it is necessary to test all electronic equipment simultaneously to insure that they operate free of interference from other components within the vehicle. Never power emergency warning equipment from the same circuit or share the same grounding circuit with radio communication equipment. All devices should be mounted in accordance with the manufacturer’s instructions and securely fastened to vehicle elements of sufficient strength to withstand the forces applied to the device. Driver and/or passenger air bags (SRS) will affect the way equipment should be mounted. This device should be mounted by permanent installation and within the zones specified by the vehicle manufacturer, if any. Any device mounted in the deployment area of an air bag will damage or reduce the effectiveness of the air bag and may damage or dislodge the device. Installer must be sure that this device, its mounting hardware and electrical supply wiring does not interfere with the air bag or the SRS wiring or sensors. Mounting the unit inside the vehicle by a method other than permanent installation is not recommended as unit may become dislodged during swerving; sudden braking or collision. Failure to follow instructions can result in personal injury. Whelen assumes no liability for any loss resulting from the use of this warning device. PROPER INSTALLATION COMBINED WITH OPERATOR TRAINING IN THE PROPER USE OF EMERGENCY WARNING DEVICES IS ESSENTIAL TO INSURE THE SAFETY OF EMERGENCY PERSONNEL AND THE PUBLIC.Warnings to Users Whelen’s emergency vehicle warning devices are intended to alert other operators and pedestrians to the presence and operation of emergency vehicles and personnel. However, the use of this or any other Whelen emergency warning device does not guarantee that you will have the right-of-way or that other drivers and pedestrians will properly heed an emergency warning signal. Never assume you have the right-of-way. It is your responsibility to proceed safely before entering an intersection, driving against traffic, responding at a high rate of speed, or walking on or around traffic lanes. Emergency vehicle warning devices should be tested on a daily basis to ensure that they operate properly. When in actual use, the operator must ensure that both visual and audible warnings are not blocked by vehicle components (i.e.: open trunks or compartment doors), people, vehicles, or other obstructions. It is the user’s responsibility to understand and obey all laws regarding emergency warning devices. The user should be familiar with all applicable laws and regulations prior to the use of any emergency vehicle warning device. Whelen’s audible warning devices are designed to project sound in a forward direction away from the vehicle occupants. However, because sustained periodic exposure to loud sounds can cause hearing loss, all audible warning devices should be installed and operated in accordance with the standards established by the National Fire Protection Association.Safety First This document provides all the necessary information to allow your Whelen product to be properly and safely installed. Before beginning the installation and/or operation of your new product, the installation technician and operator must read this manual completely. Important information is contained herein that could prevent serious injury or damage.Installation Guide:Option Kit KDCRLED Centurion™ Lightbar Steady ID Light 51 Winthrop Road Chester, Connecticut 06412-0684Phone: (860) 526-9504Internet: Salese-mail:*******************CustomerServicee-mail:*******************®ENGINEERING COMPANY INC.IMPORTANT! The lightbar should be located a minimum of 16" Array from any radio antennas!Installation:1.Remove the two Torx head screws that secure the end cap to thebase. (Fig. 1)2.Slide the lens sections off the end of the base and remove thedividers so you may gain access to the lightbar base. (Fig. 2) Besure to note the order in which the lenses were installed on thelightbar.Note:You will notice that the lenses are seated verytightly into the lens divider gaskets to preventleaks. You will need to insert a screwdriver at eachcorner (between the black endcap and aluminumbase) and gently pry the lens out to break it freefrom the dividers. Pry each side out just a little at atime, alternating from one side to the other untilthe lens slides out easily. Before reassembling,apply a very small amount of liquid dish detergentto the sides of the rubber gaskets to help themslide in easier and obtain a better seal.3.Measure the length of the lightbar base to find the exact centerand mark it with a pencil or marker. (See next page)4.Place the lighthead assembly onto thecenter of the lightbar base.Be sure to insert the lip on the end of the take-down assembly,into the slot in the base as shown in figure 3. Secure the assembly to the channel in the lightbar base, using two of the 3/8” hexhead screws provided.Wiring:1.Secure the ground lug for the filter assembly (the BLACK wire) to the channel in the lightbar base using the 1/4” hex headscrews provided as indicated. (Fig. 4)2.Connect the provided extension with the faston connectors, to the RED wire coming from the filter assembly. Run the extensionalong the lightbar base and connect the other end it to the GREY wire (or any unused wire) in the lightbar wiring harness. Note:The cable exiting the lightbar must be fused. (Refer to Fuse & Switch Information below.)3.Neatly dress and place any loose wires under the cable clamps to avoid interference with moving parts, then replace andsecure all domes.WARNING! All customer supplied wires that connect to the positive terminal of the battery must be sized to supply at least 125% of the maximum operating current and FUSED at the battery to carry that load. DO NOT USE CIRCUIT BREAKERS WITH THIS PRODUCT!WARNING!The outer surfaces of this product may be cleaned with mild soap and water. Use of any other chemicals may void product warranty. Do not use a pressure washer.。

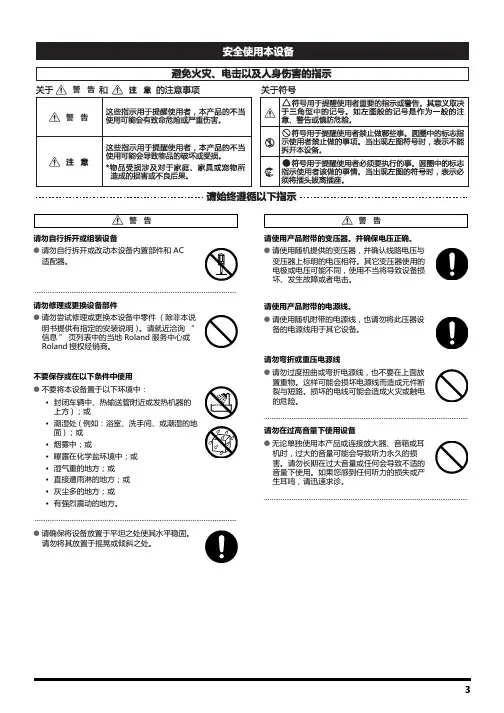

PowerMon OERATION MANUALKOLORIMETERSILIKOMETERIONOMETERNATRIOMETERTITROMETER在安装或开始运行系统时,请仔细阅读本手册。

Bran+Luebbe公司不对由不遵守说明书而造成的损坏负责,并且质保期也会随之失效.使用非Bran+Luebbe原装的配件也会导致质保期的失效。

本说明书中的内容可以由Bran+Luebbe公司单方面更改而无需另行通知。

未经Bran+Luebbe公司的书面许可,本手册的任何部分都不允许以任何方式——电子地或机械地——被复制,传播.即便本手册被译为多种语言的版本,德文的版本为原始版本.目录1 介绍 (4)1.1 本手册的惯例 (4)2 安全建议 (5)3 运行操作 (6)3.1 概述 (6)3.2 触摸屏 (6)3.2.1 初始化 (7)3.2.2 PowerMon 的结构和布局 (8)3.3 结果 (8)3.3.1 表格 (9)3.3.2 图表 (10)3.3.3 信息 (10)3.4菜单 (11)3.4.1 系统 (11)3.4.2 传感器列表 (12)3.4.3 参数列表 (17)3.4.4应用 (17)3.4.5 服务 (23)3.4.6 帮助 (34)3.5 操作模式 (35)3.5.1 测量模式 (36)3.5.2 校准模式 (36)3.5.3 停止模式 (36)3.5.4 错误模式 (37)4 报错信息 (38)4.1 概述 (38)4.2 报错信息概述 (38)1 介绍Bran+Luebbe公司的PowerMon系列分析仪表是新一代完全自动化的在线分析仪表的。

他们用湿化学的方法,可以连续不断地测量液体样品中的多种成分的浓度。

本手册说明了以下两种分析仪表:· POWERMON KOLORIMETER·POWERMON SILIKOMETER·POWERMON LONOMETER·POWERMON NATRIOMETER·POWERMON TITROMETER操作人员需要有一定的基础技术知识.在安装调试前请仔细阅读本手册.将手册一直放在系统的附近,以方便查阅。

菜鸟惠阳项目(皮带输送机)维护及操作指南说明书浙江德马科技股份有限公司目录1绪言 (4)2维修人员安全指导 (5)2.1清洁系统与模块 (6)2.2机械维护安全 (6)2.3电气维护安全 (7)2.4安全准则 (8)2.5运行安全 (9)2.6狭窄空间 (9)2.7防护罩 (10)2.8端部防护罩 (10)2.9底部防护罩 (11)2.10安全标签 (11)2.11本地安全考虑 (13)3技术规格 (14)3.1环境条件 (14)3.2输送速度 (14)4竣工系统总体介绍 (15)4.1水平皮带输送机 (15)4.1.2尾部 (19)4.1.3机身 (21)4.1.4侧板 (21)4.2转弯皮带机 (24)5更换零部件 (26)5.1尾部的维修 (26)5.1.1尾部滚筒的拆装 (26)5.2驱动部的维修 (27)5.2.1驱动的构成 (27)5.2.2改向滚筒的更换 (29)5.2.3张紧滚筒的更换 (29)5.2.4驱动滚筒的更换 (30)5.3转弯部滚筒的更换 (31)6设备维护与保养 (32)6.1常见故障及原因 (32)6.2皮带跑偏 (33)6.2.1皮带跑偏的危害 (33)6.2.2皮带跑偏的原因 (34)6.2.3皮带跑偏的处理 (34)6.3系统维护 (36)6.3.1总则 (36)6.3.2设备安全检查措施 (36)6.3.3设备检查人员安全措施 (37)6.3.4机械设备检查措施 (37)6.3.5工具,准备和材料要求 (37)6.3.6日常性维护及保养 (38)6.4链条的维护及保养 (39)6.4.1影响链条使用寿命的因素及磨损点 (39)6.4.2链条的维护 (40)6.4.3链条润滑方法的选择 (40)6.5润滑 (41)6.5.1润滑注意事项 (41)6.5.2润滑说明 (41)6.6带座轴承的维护 (42)6.6.1带座轴承的结构 (42)6.6.2带座轴承拆装方法 (43)6.6.3维护保养(定期检查) (44)6.6.4润滑脂的补充 (45)6.6.5润滑脂补充间隔时间 (45)6.6.6润滑脂的补充方法 (46)6.6.7轴承的更换 (48)7常见问题解答 (49)1 绪言此菜鸟惠阳项目是浙江德马集团与菜鸟(集团)双方经过多次技术交流、实地勘查、讨论、结合以前提供给菜鸟其他项目输送机相关案例进行的设计、制造,为贵公司量身定做的一套半自动化输送系统。

焦作瑞丰纸业有限公司废弃物焚烧供热系统工程输送设备操作手册(第一版)编制:审核:批准:焦作瑞丰纸业有限公司动力车间2009年6月17日输送设备操作规程一、燃料输送工艺流程1.1 燃料输送系统1.1.1输煤系统的范围包括:从干煤棚至锅炉的卸煤、储煤、上煤全部系统。

1.1.2燃料输送系统及运行制式燃料输送系统采用单路皮带机,分时段输煤和输送废木渣。

输煤时皮带机出力Q=30t/h,带宽B=500mm,带速v=1.0m/s。

按1台15t/h锅炉100%MCR纯燃煤,采用3班制,每班运行约0.5小时。

按1台15t/h锅炉100%MCR混烧工况,运煤采用一班制,每班运行约1小时。

运废木渣采用间歇运行方式,每班运行约0.5小时,每天7次。

1.2燃料输送工艺流程1.2.1输煤流程自卸汽车来煤→煤堆(干煤棚)→ZL50型装载机→受煤斗→电磁振动给料机→1#皮带机→除铁器→2#皮带机(配电子皮带称)→炉前煤仓1.2.2输废木渣流程厂内车辆来废木渣→生物质堆(生物质棚)→ZL50型装载机→往复式给料机→1#皮带机→犁式卸料器→炉侧生物质仓(储存)→螺旋给料机→星型给料阀1.3燃料输送设备性能1.3.1电磁振动给煤机1) 设备位号:2012) 型号:GZ-43) 数量:1台4) 给料量:30t/h5) 废木渣粒度:小于50×30×5mm6) 给煤粒度:≤50mm7) 电机功率:0.45kW8) 电压:380V9) 频率:50Hz10) 防护等级:IP5411) 绝缘等级:F级12) 接线方式:Y21.3.2 1# 带式输送机1) 设备位号:2022) 型号:TD753) 数量:1台4) 给料量:30t/h5) 带宽:B=500mm6) 带速:v=1.0m/s7) 水平长度:Lh=63.7m8) 输送高度:H=16.3m9) 电机功率:7.5kW10) 电压:380V11) 频率:50Hz12) 防护等级:IP5413) 绝缘等级:F级14) 接线方式:Y21.3.3 2# 带式输送机1) 设备位号:2032) 型号:TD753) 数量:1台4) 给料量:30t/h5) 带宽:B=500mm6) 带速:v=1.0m/s7) 水平长度:Lh=8.4m8) 电机功率:3.0kW9) 电压:380V10) 频率:50Hz11) 防护等级:IP5412) 绝缘等级:F级13) 接线方式:Y21.3.4 螺旋给料机1) 设备位号:2042) 型号:LS-4003) 数量:1台4) 给料量:0~5t/h5) 螺旋直径:400mm6) 螺旋形式:等距螺旋7) 带速:v=1.0m/s8) 输送距离:7500mm9) 变频电机功率:5.5kW10) 电压:380V11) 频率:50Hz12) 防护等级:IP5413) 绝缘等级:F级14) 接线方式:Y21.3.5 炉前星型给料器1) 设备位号:1022) 数量:1台3) 给料量:0~5t/h4) 出口尺寸:400mmx400mm5) 变频电机功率:2.2kW6) 电压:380V7) 频率:50Hz8) 防护等级:IP549) 绝缘等级:F级10) 接线方式:Y21.3.6 电子皮带秤1) 设备位号:2052) 数量:1台3) 带宽:500mm4) 精度:±0.5%5) 螺旋形式:变距螺旋6) 带速:v=1.0m/s7) 输送距离:7500mm8) 电机功率:0.1kW9) 电压:220V10) 频率:50Hz1.3.7 电动双侧犁式卸料器1) 设备位号:2062) 数量:1台3) 适用带宽:500mm4) 适用带速:v=1.0m/s5) 电机功率:0.75kW6) 电压:380V7) 频率:50Hz8) 防护等级:IP549) 绝缘等级:F级10) 接线方式:Y21.3.8 悬挂式永磁除铁器1) 设备位号:2072) 型号:RCYB-53) 数量:1台4) 适用带宽:500mm5) 适用带速:v=1.0m/s6) 电机功率:0.75kW7) 电压:380V8) 频率:50Hz9) 防护等级:IP5410) 绝缘等级:F级11) 接线方式:Y2二、开车应具备的条件所有与输送系统相关的设备已经安装完成;所有设备已经具备通电条件;所有润滑点已经加注润滑油(脂);皮带连接已经达到强度要求;三、开车方法和步骤3.1 固定式皮带输送机3.1.1螺旋输送机试运转前,应符合下列要求:3.1.1.1润滑油(脂)的名称、型号、主要性能和加注的数量应符合螺旋输送机技术文件的规定。

Users’ Manual for EMAGE-2D Laurel Industrial Company, Inc.Table of ContentsChapter 1 System Overview (3)1.1 Brief Description of Main Features of EMAGE-2D (3)1.2 Requirement for Computer System (4)1.3 Install and Run EMAGE-2D (4)Chapter 2 Data Manipulation and Analysis (7)2.1 Data Input (7)2.2 Brief Description about Data Manipulation Toolbar (10)2.3 Viewing Data (11)2.4 Data Manipulation (17)2.5 Saving Data (27)Chapter 3 RRI 2-D Inversion (31)3.1 Choose Data for RRI Inversion (31)3.2 Initial Model Construction (32)3.3 Set RRI Inversion Parameter (35)3.4 Save RRI files (39)3.5 Run RRI Inversion (40)3.6 Retrieve Inversion Result (41)Chapter 4 RM2D Inversion (44)4.1 Brief Description about Model Manipulation Toolbar (44)4.2 Data Selection for RM2D Inversion (46)4.3 Set RM2D Starting Model (47)4.4 Model Display and Modification (49)4.5 Set RM2D Inversion Parameters (52)4.6 Save RM2D Files (53)4.7 Run RM2D Inversion (55)4.8 Retrieve Inversion Result (56)Chapter 5 PW2D Forward (58)5.1 Introduction to Finite Element Modeling (58)5.2 Frequency Definition (61)5.3 Mesh Initialization (61)5.4 Model Display and Manipulation (62)5.5 Set Model 1-D Background (63)5.6 Boundary Extension (63)5.7 Set Site Location (64)5.8 Clear Current Model (65)5.9 Save PW2D Files (65)5.10 Run PW2D Forward (66)5.11 Retrieve PW2D Forward Result (67)Appendix: Software Document for RM2D inversion (68)References (78)Disclaimer (79)Chapter 1 System Overview1.1 Brief Description of Main Features of EMAGE-2DEMAGE-2D is a MT/AMT data processing and modeling software package, which can be divided into four modules including Data Manipulation and Analysis, RRI Inversion, RM2D Inversion and PW2D Forward. Below is a brief introduction to the major features of each module.1.Data Manipulation and Analysis∙Viewing data parameters such as apparent resistivity, impedance phase, coherency, skew, strike, polar diagram, Bostick transform etc. ∙Impedance rotation∙Data interpolation∙Frequency and site selection∙TE/TM mode definition∙Static shift analysis and correction∙Duplicate site handle2.RRI Inversion∙Data selection for inversion∙Starting model construction∙Set inversion parameters∙Save RRI files and run RRI∙Retrieve and display inversion result3.RM2D Inversion∙Data selection for inversion∙Starting model construction∙Model manipulation∙Set inversion parameters∙Save RM2D files and run RM2D∙Retrieve and display inversion result4.PW2D Forward∙Frequency selection for forward problem∙Model construction and manipulation∙Auto padding for the extension of model boundary∙Save PW2D files and run PW2D∙Retrieve and display forward calculation result1.2 Requirement for Computer SystemEMAGE-2D is a window application that can be run on Window 95/98, Window NT 4.0. It is recommended to run EMAGE-2D on a high performance computer because of the computational intensity of 2-D inversion and forward algorithm.1.Minimum RequirementCPU: Pentium 200Memory: 32 megabytesHard Disk: 100 megabytes free spaceDisplay: support 800X600 resolution under 256-color mode2.Recommended RequirementCPU: Pentium-II 400Memory: 128 megabytesHard Disk: 500 megabytes free spaceDisplay: support 1024X768 resolution under 16 bites color mode1.3 Install and Run EMAGE-2DEMAGE-2D InstallationInsert the EMAGE-2D CDROM into your computer‟s CDROM drive, then run the file setup.exe so the installation wizard will be launched. It will guide you through the entire installation procedure.When you begin the setup program, you will be presented the Choose Destination Location dialog (figure 1.1) which gives you chance to specify which folder to install EMAGE-2D.EMAGE-2D executable and all other supported files will be automatically copied into this folder by installation wizard. The default folder isC:\EMAGE-2D. If you hope to change it, click Browse button, then the Choose Folder dialog (figure 1.2) will be displayed on the screen. You can specify the EMAGE-2D installation folder on it, then click OK button to return Choose Destination Location dialog in which you can click Next button to begin to copy files.Figure 1.1 Choose Destination Location DialogFigure 1.2 Choose Folder DialogIf your operation system is Window NT, you also need run ntdrv.exe under subfolder “NTDRV” in the EMAGE-2D folder to install dongle driver on your machine.Run EMAGE-2DEMAGE-2D can only be run on the machine on which the hardware key (dongle) supplied with EMAGE-2D is installed. In order to install dongle, it is better shut down your computer first, then attach the dongle to the parallel printer port of your computer. You can attach the 25-pin connector of the printer to the other end of the key. After making sure the dongle is installed properly, click EMAGE-2D item on the Program submenu of Start menu on your computer to launch EMAGE-2D. You also can double click EMAGE-2D.EXE in the directory where EMAGE-2D is installed to run it.Chapter 2 Data Manipulation and Analysis2.1 Data InputEMAGE-2D supports Z file format of EH4, RES file format of MT-1 and the output of PW2D forward output as input data at present time.1.EH4 Data InputFor EH4 data, there are two ways to prepare input data. Below is step by step description about how to input EH4 data into EMAGE-2D.1)Using @(or @l)File as Input DataFigure 2.1 Open EH4 @ Files Dialog(1)Create a working directory in your hard disk.(2)For high frequency data, copy @ file and the impedance files (the files preceded by Z) of your survey data from your EH4 instrument into the working directory; For low frequency data copy @l and the impedance files (the files preceded by W) into the working directory. (3)Select Open EH4 @ file…in File menu, then Open EH4 @ file dialog (figure 2.1) will be popup on the screen. When Auto Selectcheckbox is checked, EMAGE-2D will determine whether the data is high or low frequency data according to the file name. Sometime you may rename @ or @l file for some reasons. In this case, EMAGE-2D has no idea about the data type, so you need set it manually. High Freq and Low Freq radio button will be enabled after Auto Check is unchecked. If the data to be input is high frequency data, High Freq should be checked, otherwise, Low Freq should be checked.(4)Click OK button on the dialog to begin inputting data.(5)When an impedance file in @ or @l does not exist in the current directory, a warning message will be given to indicate that this file does not exist in the current directory and inquire whether to continue without it or quit to check the data.2)Edit EH4 line definition file (EH4 File) as input data.Figure 2.2 Open EH4 File Dialog(1)Create a working directory in the hard disk, then copy the impedance files preceded by Z or W into the working directory.(2)Use text editor such as Notepad in Windows or Edit on Dos promptmode to create a line definition file with an extension of EH4. If you use word processor such as Word to create line definition file, be sure save it as pure text format. Below is an example to demonstrate the format of EH4 line definition file.Line 1 Format: EH4Line 2 This is an example of line definition file for EH4 dataLine 3 There are three sites in the data setLine 4 Data:Line 5 Ztest.001 X: 0 Y: 0 Z: 0Line 6 Ztest.002 X: 30 Y: 0 Z: 0Line 7 Ztest.003 X: 60 Y: 0 Z: 0Line 1 always is “Format: EH4”, indicating that the input data is EH4 data. After that, you can write any number of comment lines (such line 2 and line 3 in above example). The “Data:” line (line 4 in above example) after comment lines indicates the lines below are the data lines that will be taken as input by EMAGE-2D. Each site takes one line consisting of the impedance file name and coordinates for the site.(3)Click Open EH4 File in File menu to popup Open EH4 File dialog (figure 2.2). Open EH4 data line definition file to input data.2.MT-1 Data Input(1)Create a working directory in the hard disk, then copy the RES files output by MT-1 processing program into the working directory.(2)Use text editor such as Notepad in Windows or Edit on Dos prompt mode to create a line definition file with an extension of MT1. If you use word processor such as Word to create line definition file, be sure save it as pure text format. Below is an example to demonstrate the format of MT-1 data line definition file.Line 1 Format: MT-1Line 2 This is an example of line definition file for MT-1 dataLine 3 Data:Line 4 Demo1.res X: 0 Y: 0 Z: 400Line 5 Demo2.res X: 1000 Y: 0 Z: 510Line 6 Demo3.res X: 2000 Y: 0 Z: 450Line 1 always is “Format: MT-1”, indicating that the input data is MT-1 data. After that, you can write any number of comment lines (line 2 in above example). The “Data:” line (line 3 in above example) after comment lines indicates the lines below are the data lines that will be taken as input by EMAGE-2D. Each site takes one line, consisting of the impedance file name and coordinates for the site.Figure 2.3 Open MT-1 File Dialog(3)Click Open MT-1 File in File menu then popup Open MT-1 File dialog (figure 2.3). Open MT-1 data line definition file to input data. 3.PW2D Forward Calculation Data InputDetailed description about how to input PW2D data is discussed in Chapter 5.2.2 Brief Description about Data Manipulation ToolbarFigure 2.4 Data Manipulation ToolbarIn order to edit and display the input data, user need to access the controls on the Data Manipulatio n Toolbar (figure 2.4). When data input has been done, the toolbar will be enabled. Below are brief descriptions about themain functions of the controls from left to right in the toolbar.Plot Button:Click it to refresh the content in plot area.Edit Button:Any graphical edit operation cannot be functioned unless this button is checked.Mask Button:This button is used to control whether or not to display the disabled frequencies. When it is checked , the disabled frequencies will not be displayed, otherwise, the disabled frequencies will be displayed in gray color.Static Shift Button:This button is used control to display the data without static shift correction or corrected data. If it is unchecked, the displayed data will be raw data without static correction, otherwise, corrected data will be displayed. Another function of this button is for static correction operation. Static shift correction operation is allowed only if the button is checked. Interpolation Button:It is used to control if display raw data or interpolated data. If this button is unchecked, raw data will be displayed, otherwise you can view and edit the interpolated data.Switch Button:When this button is checked, you can switch XY and YX mode impedance (rotate±90 °) frequency by frequency.Plot Type Selection List Box:Can be used to select different parameters to view and edit.Site Selection List Box:Set the selected site as current site, so you can view and edit the parameters of the current site.2.3 Viewing DataEMAGE-2D can display twenty-first type of parameter about the data set (figure 2.5)1.Site Location MapSelect this item to display Site Location Map. After data input is completed, EMAGE-2D will display Site Location Map in plot area(figure 2.6). A triangle sign represents each site. The impedance file name of the site taken as site name is displayed above or below it. If you hope not to display site name on the map, click Show Site Name in Site Location Map in Data Manipulation menu to uncheck it.Figure 2.5 Plot Type In Selection List BoxFigure 2.6 Site Location Map2.Apparent Resistivity CurveThe apparent resistivity curve of current site will be displayed in plot area when user selects Apparent Resistivity item in Plot Type Selection list box (figure 2.7). For raw data, XY and YX mode are represented as rectangle and triangle signs respectively. If interpolated data is displayed, XY and YX model will be shown by red and blue dot respectively. Mask, Static Shift and Interpolation button on the Data Manipulation toolbar can be used to control the display mode of apparent resistivity curve.∙When Mask button is checked, the disabled frequencies will not be shown, otherwise, the disabled frequencies will be displayed in gray color.∙When Static Shift button is checked, the data after static shift correction will be displayed, otherwise the uncorrected data will be shown.∙When Interpolation Button is checked, the interpolated data will be displayed, otherwise the raw data will be shown.Figure 2.7 Apparent Resistivity Curve3.Impedance Phase CurveThe impedance phase curve of current site will be displayed in plot areawhen you select Impedance Phase item in Plot Type Selection list box. For raw data, XY and YX mode are represented as rectangle and triangle signs respectively. If the interpolated data is displayed, XY and YX model will be shown by red and blue dot respectively. The display mode of impedance phase curve controlled by Mask and Interpolation button is the same as that of apparent resistivity.4.StrikeThe strike curve of current site will be displayed in plot area when you select Strike item in Plot Type Selection list box. The display mode of strike curve controlled by Mask and Interpolation button is the same as that of apparent resistivity.5.SkewThe skew curve of current site will be displayed in plot area when you select Skew item in Plot Type Selection list box. The display mode of skew curve controlled by Mask button is the same as that of apparent resistivity.6.CoherencyThe coherency curve of current site will be displayed in plot area when you select Mult Coh (E, H) item in Plot Type Selection list box. The data of XY mode and YX mode is represented as rectangle and triangle signs respectively. The display mode of coherency curve controlled by Mask button is the same as that of apparent resistivity.There is no coherency data in the MT-1‟s RES file, so EMAGE-2D set them to 1 in order to be compatible with EH-4 data.7.Polar DiagramThe polar diagram of current site will be displayed in the plot area when you select Polar Diagram item in Plot Type Selection list box (figure 2.8). The polar of each frequency is contained in a rectangle where the frequency value is printed on upper part of the rectangle. Red polar and blue polar are principal impedance and auxiliary impedance components respectively.Figure 2.8 Polar Diagram8.Bostick TransformThe relation between impedance and frequency can be transformed to the relation between resistivity and depth by Bostick transform, roughly reflecting the earth resistivity distribution versus depth.The Bostick transform curve of current site will be displayed in plot area when you select Bostick Transform item in Plot Type Selection list box. For raw data, XY and YX mode are represented as rectangle and triangle signs respectively. If the interpolated data is displayed, XY and YX model will be shown by red and blue dot respectively. The display mode of Bostick transform curve controlled by Static Shift and Interpolation button is the same as apparent resistivity.Cross SectionsIn order to view cross section of the data, you need to define profile first. If you want to show the cross section of TM or TE mode data, you shoulddefine the mode of each site also. A detailed description about how to define profile and TM/TE mode is presented later in this manual. EMAGE-2D can show twelve types of cross sections (table 2.1).Table 2.1 The type of cross section Item in the listbox of plot typeApparent resistivity in XY mode App. Resistivity Freq Section-RhoXY Impedance phase in XY mode Phase Freq Section-PhsXYApparent resistivity in YX mode App. Resistivity Freq Section-RhoYX Impedance phase in YX mode Phase Freq Section-PhsYXApparent resistivity in TM mode App. Resistivity Freq Section-RhoTM Impedance phase in TM mode Phase Freq Section-PhsTMApparent resistivity in TE mode App. Resistivity Freq Section-RhoTE Impedance phase in TE mode Phase Freq Section-PhsTEBostick resistivity in XY model Bostick Depth Section-BostXYResBostick resistivity in YX model Bostick Depth Section-BostYXResBostick resistivity in TM model Bostick Depth Section-BostTMResBostick resistivity in TE model Bostick Depth Section-BostTERes Static shift and Interpolation buttons on Data Manipulation toolbar can be used to control display manner of cross section. When Static Shift button is checked, the data you have seen is statically corrected data, otherwise uncorrected data is shown. Interpolation button acts similar way, checked for interpolated data, unchecked for raw data.EMAGE-2D will create default color scale for each type of cross section according to data value. If you want set it manually, click Set Color Scale For Contour in Data Manipulation menu and popup Set Color Scale For Contour dialog (figure 2.9). Double-click any item in Scale List box, the scale value will appear in Enter Color Scale Value so you can modify it manually. Default Color Scale checkbox gives you the option to use default color scale or not. If you check Blank No Data Area, the area without data will be blanked.Static Correction Reference CurveIn order to display static correction reference curve, you need also define profile first. After that, click Static Correction Reference Curve to display it. Please refer to Static Shift Correction section later in this manual for thedetailed discussion about it.Figure 2.9 Set Color Scale For Contour Dialog2.4 Data ManipulationMost of data edit operation will need to access Data Manipulation menu and Data Manipulation toolbar. If no explicit indication, submenu mentioned in this chapter refers to the item in Data Manipulation menu and toolbar is taken for Data manipulation toolbar.1.Duplicate Sites HandleIf there are duplicates sites whose X and Y coordinates are same, Check Duplicate Sites submenu will be enabled. Select it and popup Check Duplicate Sites modeless dialog (figure 2.10). When the dialog is displayed on the screen, you can do other operation outside the dialog so it is convenient to check duplicate sites‟ data quality while dealing with them.The first group of duplicate sites found by EMAGE-2D will be appear in Duplicate Sites list box when you open the dialog first time. EMAGE-2D will search another group of duplicate sites if there are ones when you click Find Next button. Select Restart will search duplicate sites again from very beginning. If you decide delete some site, highlight the site name in list box, then click Delete button to delete it. Sometime it may bebetter to combine duplicate sites into a new site. Click Combine… button to bring Input Combined Site Name dialog (figure 2.11) up. Put site name in Combined Site Name as the name of the new site. If you hope to delete the old sites after combination, please check Delete Old Sites checkbox. After click OK button, the combined site will display in Duplicate Site list box of Check Duplicate Sites dialog. It is recommended to disable bad frequencies of duplicate sites before doing combination.Figure 2-10 Check Duplicate Sites DialogFigure 2-11 Input Combined Site Name Dialog2.Fix ImpedanceIn MT/AMT theory, the impedance is calculated under right-handed coordinate system. If the orientation of electrical or magnetic sensors isnot set this way, the calculation of skew and polar will be incorrect, the auxiliary impedance component of polar and skew will be anomaly big. If the orientation of some site is suspected not being set properly, EMAGE-2D will fix it automatically. Sometime EMAGE-2D will make wrong decision because of the noise in the data and the complexity of the earth. In this case, you need fix it manually by check the skew and polar diagram. When the skew and auxiliary impedance component is too big, you can click Fix Impedance submenu to fix it.3.Vector Versus Tensor Data of EH4Vector impedance is not stable as the polarizing direction of incident electromagnetic field varies with time. This is the very reason why we often use tensor impedance for data interpretation in MT. When the measure time is short such as EH4 survey, the polarization may not change too much. It may be acceptable to use vector data for interpretation. In field survey, it is not unusual to have good data in one direction but bad in another direction due to culture noise. It maybe causes both XY and YX mode data noisy if you use tensor impedance data because the calculation of tensor data will use both direction data. As for vector impedance data, you only need electrical field in one direction and magnetic field in the perpendicular direction to get vector data in this direction. In this case, you may get good data in one direction for interpretation. This is why both vector and tensor data are contained in impedance file of EH4 data. It is recommended to use tensor impedance if the data of both directions is good.You can switch between tensor and vector data by click Show EH4Vector Data submenu. If vector data is being used, a check sign will appear on the left of the submenu. By the way, if you have done rotation on the data, the data will be tensor because there is no way to rotate vector data.4.Site and Frequency Selection(1)Site SelectionThere are two ways to select sites into current data set.Figure 2.12 Data Selection DialogThe first one is to select sites on Data Selection dialog. Select Data Selection submenu to bring up Data Selection dialog (figure 2.12). A site will be selected into the current data set if you highlight it in Site Name list box, unhighlight it will delete it from the current data set. Clicking site name in the list box will switch between selection and deletion. You can select or delete all sites by clicking Select All Sites button. If all sites are already selected, clicking Select All Sites button will delete all sites, otherwise all sites will be selected. Actually, deleted sites will not be considered it in data analysis, display and interpretation process. You can include it later by reselecting it.The second way for site selection can be done though Site Location Map.A triangle sign represents each site. When Site location Map is shown, check Edit button on the toolbar first. Clicking the site sign will switch between selection and deletion. The selected sites are printed in blue color,deleted ones in gray color.(2)Frequency SelectionThere are three ways to select frequency.The first one is to do it in Data Selection dialog that is similar to site selection. Highlight a frequency in Frequency list box of the dialog (figure 2.12) to enable it, unhighlight it to disable it. Every frequency contained in any site will be listed in Frequency list box. It is not necessary to have all sites have same frequencies. If you enable or disable any frequency in the list box, this frequency will be enabled or disabled from the sites that have the data of this frequency. Select All Freq button can also be used to enable or disable all frequencies in the way which is similar to Select All Sites button for site selection.Figure 2-13 Frequency Auto-Selection DialogThe second way is to select frequencies automatically in Frequency Auto-Selection dialog. Selecting Frequency Auto-Selection submenu to popup Frequency Auto-Selection dialog (figure 2.13). Input cut-off value in Select Freq. By Coh(>=)so the frequencies will be disable automatically when their coherencies are below this value. Similarly, the frequencies will also be disabled when their skews are greater than the value in Select Freq. By Skew (<=).In other hand, you are provided an option to select frequencies for the current site or all sites in Site Selection radio button group and to select frequencies for which mode data in ModeSelection radio button group.The third way is to select frequencies on apparent resistivity, impedance phase and coherency curves. Interpreter normally needs to analyze data site by site during interpretation process and delete bad frequencies. Below are some suggestions for frequency selection.∙Coherency: It is recommended to delete the frequencies which coherency is below 0.6.∙Skew: Theoretically speaking, skew is a measure of the three dimensionality of the resistivity distribution near the site. But the noise in data will also make it big. When the skew of one frequency is much bigger than that of the rest, it is possible to be caused by noise and need to be deleted.∙Smoothness: Apparent resistivity and impedance should be smooth and continuous for high quality data. The outliers should be deleted before interpretation.To select frequencies this way, you need check Edit button on the toolbar first, then click left and right buttons of mouse to enable or disable frequencies XY and YX mode data respectively.5.Profile DefinitionIn order to display cross section, calculate static shift correction reference and prepare data for 2D inversion, you need define profile first. There are two methods to define profile in EMAGE-2D.(1)Define Profile in Data Selection DialogSelect beginning and ending site of the profile in Starting Site and Ending Site respectively in Data Selection dialog (figure 2.12), then click OK to complete profile definition. After that, a black line will be plotted in Site Location Map to indicate the orientation of the profile.(2)Define Profile in Site Location MapCheck Edit button in the toolbar and hold down Ctrl key in your computer keyboard, then click at the starting position of the profile on the map andmove mouse cursor while keeping left button of the mouse down. When the cursor has been moved to the ending position of the profile you hope to put, release mouse button to finish profile definition.6.Impedance RotationThe impedance of XY and YX mode will be same if the geology is one-dimensional. For non-1D geology, the data of XY and YX mode will be different. The impedance tensor can be rotated mathematically to any other orthogonal axis orientation. If the geology is truly two-dimensional this rotation will reach an angle such that auxiliary impedance become zero and the principal impedance becomes the principal impedance. This angle yields the impedance strike once it has been determined which of the XY or YX components reflects the impedance for the electrical field which is parallel to the strike. When we can rotate impedance so that X direction is perpendicular to the strike of the structure. The XY and YX components are defined as TM and TE mode respectively. If we undertake 1-D interpretation, it is better use the data of TE mode because 1-D inversion result of TE data is closer to the real geology than that of TM data. For 2-D inversion, usually it is best to use the combination of TE and TM data. If you choose one direction of data to do 2-D interpretation, it is widely argued that in 2-D model the goal should to match the TM curve, as it has higher lateral resolution and is less affected by 3-D distortions then the TE mode.There are five types of rotation implemented in EMAGE-2D(1)Analytic RotationImpedance can be rotated to principal axes, which is a related but different concept from the strike of structure, by analytic rotation. In two-dimensional geology, both strike and tip of structure are principal axes. Interpreter should refer to the geology and other kind information to determine if impedance is rotated to strike or tip.(2)Zxy Maximum RotationRotate impedance to one of two principal axes so that the apparent resistivities of X direction (ρx y) are always greater than those of Y direction (ρy x).。

德马输送辊筒产品选用手册-详细版样本2012 V21.引言在德马输送辊筒产品选用手册中,我们将提供详细的产品选用指导。

本手册旨在帮助用户了解德马输送辊筒产品的特点和适用范围,以便更好地根据工程需求进行选择。

2.产品概述2.1 产品分类本章节将介绍德马输送辊筒产品的分类,包括驱动辊筒和非驱动辊筒、重载辊筒和轻载辊筒、防尘辊筒和防水辊筒等。

2.2 产品特点与性能本章节将详细介绍德马输送辊筒产品的特点和性能,包括承载能力、转动阻力、运行平稳性等关键指标。

3.选择指南3.1 工程背景本章节将介绍进行辊筒选用时应考虑的工程背景信息,包括输送物料特性、环境条件、工作方式等。

3.2 选用步骤本章节将提供德马输送辊筒产品的选用步骤和依据,包括确定工作负荷、计算辊筒数量和间距、选择适配器和安装方式等。

4.产品型录在本章节中,我们将提供德马输送辊筒产品的完整型录,包括各类辊筒的规格尺寸、技术参数、适用范围等详细信息,以供用户参考。

5.安装与维护本章节将提供德马输送辊筒产品的安装和维护指南,包括安装步骤、注意事项、维护周期等,以确保产品的正常使用和延长使用寿命。

6.附件在本文档的附录部分,将提供相关附件,包括德马输送辊筒产品的技术图纸、安装示意图、维护记录表等,以供用户参考和使用。

7.法律名词及注释7.1 法律名词本章节将本文档中涉及的法律名词,并提供相应的解释和定义,以确保对相关法律概念的准确理解。

7.2 注释本章节将提供本文档中涉及的其他重要名词和概念的注释和解释,以帮助读者更好地理解和使用本文档。

【文档结尾】本文档涉及附件:1.德马输送辊筒产品型录2.德马输送辊筒技术图纸3.德马输送辊筒安装示意图4.德马输送辊筒维护记录表本文所涉及的法律名词及注释:1.法律名词:定义和解释清楚在文档中涉及的法律术语。

2.注释:提供其他名词和概念的注释和解释,以帮助读者更好地理解文档内容。

MG2×150/700–WD型交流电牵引采煤机说明书鸡西煤矿机械有限公司2007年10月MG2×150/700-WD 型交流电牵引采煤机鸡西煤矿机械有限公司1M G 2×150/700-W D 型电牵引采煤机三维数字样MG2×150/700-WD 型交流电牵引采煤机鸡西煤矿机械有限公司2前 言为了方便用户使用采煤机,确保对采煤机的正确操作、安全使用和维修保养,延长采煤机使用寿命,提高采煤机生产效率,我们编制了这本采煤机使用说明书。

说明书重点对MG2×150/700-WD 型采煤机的适用范围、结构特点、工作原理和维护保养做了较为详尽的介绍和说明。

希望用户在使用该采煤机前要认真阅读说明书,掌握工作原理和使用方法,并根据本单位实际情况,制定相应的采煤机使用、维护、保养岗位责任制。

因为采煤机使用范围不断扩展,以及随着科学技术的发展,本产品局部结构和外购配套件等,也需不断采用新材料和新技术,在不影响整体和主要件互换性的情况下,也有相应的持续改进;所以本说明书只限于采煤机的使用说明,供用户参考,不能作为订购采煤机备件的依据。

要掌握采煤机的详尽结构或采购备件,请参阅该采煤机的随机出厂图册。

本说明书的编制得到了有关用户的关心和支持,实际使用中还可能存在一些问题和不足,欢迎广大用户给予批评和指正。

鸡西煤矿机械有限2007年5月16日MG2×150/700-WD 型交流电牵引采煤机鸡西煤矿机械有限公司3目 录第一章概 述 (4)第一节 概述..............................................................................4 第二节 整机组成及工作原理.........................................................4 第三节 主要技术参数及配套设备...................................................7 第四节 采煤机的主要特点 (13)第二章 牵引部 ……………………………………………………………………15 第三章 截割部 ……………………………………………………………………22 第四章调高液压传动系统 (32)第五章 冷却喷雾系统 ..................................................................39 第六章 采煤机电控系统及其工作原理 (42)第一节 采煤机电控系统的结构......................................................42 第二节 系统的特点.....................................................................44 第三节 系统组成及功能...............................................................45 第四节 采煤机电气操作...............................................................47 第五节 电控系统的工作原理.........................................................49 第六节 采煤机的操作及维护.........................................................51 第七节 电控系统部件及组件明细表................................................53 第八节 采煤机电气图 (54)第七章 辅助系统………………………………………………………………… 59 第八章采煤机的使用与维护 (61)第一节 采煤机的井上检查与试运转…………………………………………61 第二节 采煤机的操作…………………………………………………………61 第三节 采煤机的注油…………………………………………………………63 第四节采煤机的维护 (65)附录一安标配套件明细............................................................... ...67 售后服务 .................................................................................... (68)MG2×150/700-WD 型交流电牵引采煤机鸡西煤矿机械有限公司4第一章 概述第一节 概述MG2×150/700-WD 型交流电牵引采煤机是采用多电机驱动、横向布置,用以开采较薄煤层的无链电牵引采煤机,机面高度低,装机功率大,具备截割硬煤、夹矸和爬坡的能力和过断层能力。