4.21板川集成灶750系列,迷你你的私厨

- 格式:doc

- 大小:14.61 MB

- 文档页数:2

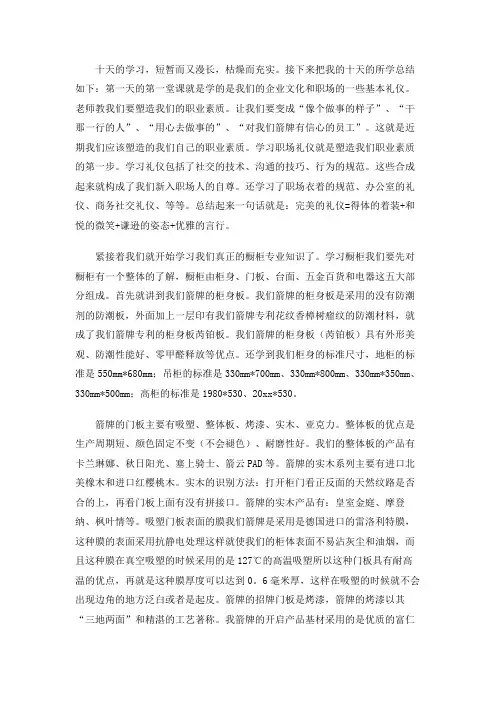

JJZT/Y-YD103437.5675265130800500265580550电源/启动键菜单键功能减功能加时间键温度键普通蒸高温蒸发酵解冻焙烤风焙烤消毒保温100℃/40mi n 120℃/15mi n36℃/50mi n 60℃/30mi n160℃/40mi n 160℃/40mi n 120℃/30mi n 70℃/30mi n MIN130照明键电源插头须要与带有可靠接地的16A插座连接,接通电源,蜂鸣器鸣叫1声,所有图标全亮,2秒钟后图标熄灭,进入关机状态。

提示:工作过程中,当加水时“ ”图标亮起,当缺水时“ ”图标闪烁,当门没有关好时,屏幕温度图标处显示dor图标并闪烁。

注意:缺水报警时,“ ”图标和电源图标“ ”闪烁,机器暂停工作按压一下水箱,水箱弹出,等水箱重新加满水后,装入水箱位置,推到底(听到“咔嗒”一声就到底了),重新装入水箱后,按开关电源图标“ ”确认,重新启动工作。

1.开机接通电源,在关机状态下长按电源键“ ”2秒,开机,屏幕中所有图标亮起,进入待机状态。

2.工作模式选择在待机状态下按菜单键“ ”,选择所需要的工作模式,被选择的工作模式图标闪烁,也可按“ ”,“ ”键切换模式,每个工作模式都有预设的工作温度和工作时长,应根据实际需要加工的食品种类和份量进行调整,调整后按电源键“ ”确认操作,然后进入工作状态。

3.工作温度和工作时长设置a.选择好工作模式后,按温度键“ ”,屏幕中温度图标闪烁,然后按增加键“ ”或缩减键“ ”调整设定温度;b.按时间键“ ”,屏幕中时间图标闪烁,然后按增加键“ ”或缩减键" "调整工作时长;调节好所需要的工作温度和工作时长后,按电源键“ ”确认操作,然后进入工作状态。

4.工作过程中工作温度和工作时长调整工作过程中,如果需要调整工作温度和工作时长,先按温度键“ ”或时间键" "屏幕闪烁,然后再按增加键“ ”或缩减键“ ”调整工作温度或工作时长,调整好后,再次按温度键“ ”或时间键“ ”确认操作,如果调整好温度或时间后,没有按温度键或时间键确认,则10秒后,系统自动确认设定的工作温度或工作时长。

I-CORE森歌智慧芯,启动智生活浙江森歌电器有限公司ZHEJIANG SENG ELECTRONIC APPLIANCE CO.,LTD.地 址:浙江省绍兴市嵊州市经济开发区(浦口街道)浦东大道138号 P.C.:312400 2021年2月第一版第一次修改全国客服热线售后服务热线400-103-2226400-826-4588手机网站官方微信致谢词感谢您购买并使用本公司的产品,为了您能全面了解并正确使用本产品,请在安装使用前仔细阅读本说明书,并请妥善保管,以备查阅。

对于不遵守本说明书有关要求,进行安装,使用,维修等所造成的损失,本公司概不承认任何责任。

本公司保留更改产品设计及更改相应产品安装使用说明书的权利,如有更改,届时恕不另行通知。

产品使用年限提醒:根据GB17905-2008«家用燃气燃烧器具安全管理规则»的规定:“燃气灶具从售出当日起,其判废年限应为8年。

”目录 (1)主要技术参数 (2)开关、按键操作说明 (3)功能模式介绍4点火、熄火操作和调节方法 (6)产品安装说明 (7)靠近灶体的柜体侧板开孔尺寸参照表 (8)整体安装尺寸参照表 (8)9常见故障的识别与处理 (10)............................................................................蒸烤箱安全注意事项................................................................蒸烤箱日常维护注意事项 (10)蒸烤箱安全使用注意事项 (11)保养与维修 (12)常见故障的识别与处理 (13)服务承诺 (14)随机附件及文件 (15)告用户环境影响书 (16)4、在待机状态或关机状态,按“照明一”键,吸风板照明灯亮,如果此时吸风板处于关闭状态,则同时打 开吸风板。

再按一次,关闭吸风板照明,同时关闭吸风板(如果烟机风机处于关闭状态)。

家用暖杯碟机WD14MG C7WD14BG 系列 系列HEALTHY&WARMTH HEALTHY WARMTH卡萨帝为了精确实现您的格调生活,对其家族每一类产品都赋予了专属的境界理念。

本产品为您带来的是洁净厨房。

12关于本产品的安全注意事项 .........................................................3本产品的安装 . (6)安装前的准备 .......................................................................6安装的步骤 ...........................................................................6电气连接 ..............................................................................7本产品外观及部件介绍 .. (8)各部件构成 ...........................................................................8控制旋钮 ..............................................................................8本产品的主要功能介绍 .. (9)暖杯碟机工作原理 ................................................................91.首次使用之前的准备 .....................................................92.使用暖杯碟机步骤 .........................................................93.温度选择开关 ..............................................................104.各类附加用途 ..............................................................105.加热时间参考 ...............................................................116.承载能力参考 ...............................................................11本产品的日常保养与维护 ...........................................................12清洁保养准备 .....................................................................12清洁各个部件 .....................................................................12有疑问?先看这儿! ..................................................................13保修说明 ....................................................................................14技术数据 . (1617)产品中有害物质名称及含量3尊敬的卡萨帝用户:您好!感谢您使用卡萨帝产品,为了您能更好的阅读本说明书和使用本产品,防止人身伤害及物品损坏事故,请务必仔细阅读并遵守本说明书中有以下标志符号的内容。

十天的学习,短暂而又漫长,枯燥而充实。

接下来把我的十天的所学总结如下:第一天的第一堂课就是学的是我们的企业文化和职场的一些基本礼仪。

老师教我们要塑造我们的职业素质。

让我们要变成“像个做事的样子”、“干那一行的人”、“用心去做事的”、“对我们箭牌有信心的员工”。

这就是近期我们应该塑造的我们自己的职业素质。

学习职场礼仪就是塑造我们职业素质的第一步。

学习礼仪包括了社交的技术、沟通的技巧、行为的规范。

这些合成起来就构成了我们新入职场人的自尊。

还学习了职场衣着的规范、办公室的礼仪、商务社交礼仪、等等。

总结起来一句话就是:完美的礼仪=得体的着装+和悦的微笑+谦逊的姿态+优雅的言行。

紧接着我们就开始学习我们真正的橱柜专业知识了。

学习橱柜我们要先对橱柜有一个整体的了解,橱柜由柜身、门板、台面、五金百货和电器这五大部分组成。

首先就讲到我们箭牌的柜身板。

我们箭牌的柜身板是采用的没有防潮剂的防潮板,外面加上一层印有我们箭牌专利花纹香樟树瘤纹的防潮材料,就成了我们箭牌专利的柜身板芮铂板。

我们箭牌的柜身板(芮铂板)具有外形美观、防潮性能好、零甲醛释放等优点。

还学到我们柜身的标准尺寸,地柜的标准是550mm*680mm;吊柜的标准是330mm*700mm、330mm*800mm、330mm*350mm、330mm*500mm;高柜的标准是1980*530、20xx*530。

箭牌的门板主要有吸塑、整体板、烤漆、实木、亚克力。

整体板的优点是生产周期短、颜色固定不变(不会褪色)、耐磨性好。

我们的整体板的产品有卡兰琳娜、秋日阳光、塞上骑士、箭云PAD等。

箭牌的实木系列主要有进口北美橡木和进口红樱桃木。

实木的识别方法:打开柜门看正反面的天然纹路是否合的上,再看门板上面有没有拼接口。

箭牌的实木产品有:皇室金庭、摩登纳、枫叶情等。

吸塑门板表面的膜我们箭牌是采用是德国进口的雷洛利特膜,这种膜的表面采用抗静电处理这样就使我们的柜体表面不易沾灰尘和油烟,而且这种膜在真空吸塑的时候采用的是127℃的高温吸塑所以这种门板具有耐高温的优点,再就是这种膜厚度可以达到0。

板川安全集成灶

板川安全集成灶是一款集烹饪、烟气净化、安全防护于一体的厨房电器产品,

其独特的设计和功能使其成为现代厨房中不可或缺的一部分。

本文将为您详细介绍板川安全集成灶的特点、优势和使用方法,帮助您更好地了解和使用这款产品。

首先,板川安全集成灶采用先进的燃气燃烧技术,燃烧效率高,节能环保。

其

独特的烟气净化系统能够有效过滤油烟,保持厨房空气清新。

同时,集成灶还具备火焰监测、漏气报警等安全防护功能,为用户提供安全的烹饪环境。

其次,板川安全集成灶的设计简洁大方,操作便捷。

触摸式控制面板和智能化

操作系统使得烹饪过程更加轻松愉快。

不锈钢材质的灶台易于清洁,不易积存油污,保持厨房整洁。

另外,集成灶还具备多种烹饪模式和定时功能,满足不同用户的需求。

最后,使用板川安全集成灶的方法也很简单。

首先,接通电源和燃气管道,确

保灶具正常供电和燃气通畅。

然后,根据食材和菜谱选择合适的烹饪模式和火力大小。

在烹饪过程中,注意保持通风良好,避免油烟积聚。

烹饪结束后,及时关闭燃气阀门,清洁灶具表面和油烟净化系统,保持集成灶的良好状态。

总之,板川安全集成灶是一款功能强大、安全便捷的厨房电器产品,其独特的

设计和智能化操作为用户带来全新的烹饪体验。

希望本文能够帮助您更好地了解和使用板川安全集成灶,为您的厨房生活增添便利和舒适。

厨电产品导购推介说辞燃气灶篇|Ver 1.0前言:厨电产品购买以套餐购买居多,此说辞重点放在灶具单品购买。

说辞上以家装、服务为导向推介产品功能!讲解中注意观察、交流、演示。

1’[建立信任摸清需求]客户一进展厅,导购说:“欢迎光临美的厨卫,我们正在打折,随便看一下!”我们努力想营造一个良好的销售氛围,想留住顾客,但是这样的开场白没有任何作用,反而给人“不可靠”的感觉。

“欢迎光临美的厨卫”,这一句话没有传达出任何对顾客有价值信息;“我们正在打折”,促销信息可以通过物料传递,围绕促销的介绍不该频繁出现,更不应该在与顾客交流的开始尤其是第一时间就提及。

“随便看一下!”美的厨卫要做专业的品牌,凡进店的客户必须要感受到我们的专业。

您好,美的厨房为您量身打造!第一时间传达我们区别于竞品的售卖理念。

同时观察顾客表情和眼神,看外观?看价格签?请问您是用在新房还是老产品换购?换购的顾客在选择上受房屋新旧、前期开孔、厨房空间的限制;而新装修厨房的顾客没有太多顾虑,更倾向买一台性能好、外观漂亮的灶具。

摸清需求,后期推介中投其所好。

您新房的橱柜打好了吗?宽度是多少?颜色?材质?/以前那台灶是什么材质的?用起来感觉怎样?以前那台燃气灶开孔多大?不论对哪种顾客,不急于一开始就推产品、谈功能。

新购顾客的一般家装知识不会太足,站在专业顾问的角度,结合实际厨房环境给予意见;换购的用户,大部分会有一定恋旧的情结,那么就顺着这个情结往下交流。

如果对以前的面板材质不太满意,针对顾客不满意之处进行其他材质面板推介。

2’[找准方向开始进攻]通过初步交流摸清顾客需求后,帮助顾客锁定面板材质和大小,确立主推机型。

结合家装环境,进行面板优势介绍,适当进行演示。

观察顾客表情,有条理展开进攻。

为您推荐这一款产品,最新上市的/您眼光真好,这一款灶是我们最新上市的产品。

火盖砸玻璃面板:您看这块面板,光洁度非常好,放家里特高贵。

卖玻璃灶的消费者都怕碎,你看!此时手拿火盖平整的砸向两灶眼之间的宽阔区域,注意力度。

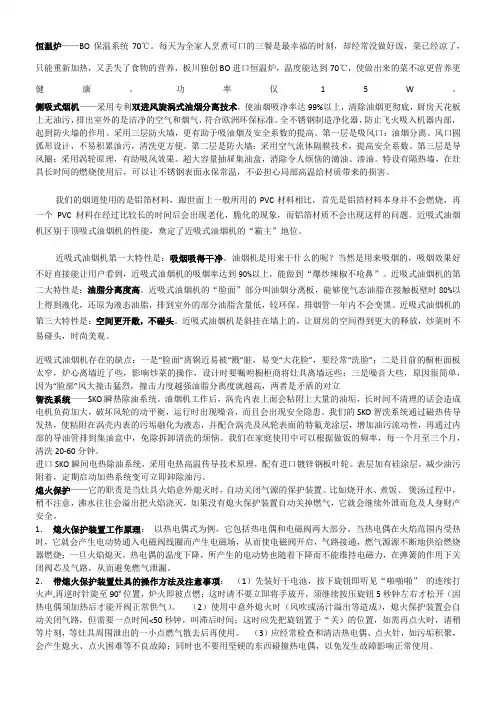

恒温炉——BO保温系统70℃。

每天为全家人烹煮可口的三餐是最幸福的时刻,却经常没做好饭,菜已经凉了,只能重新加热,又丢失了食物的营养,板川独创BO进口恒温炉,温度能达到70℃,使做出来的菜不凉更营养更健康。

功率仅15W。

侧吸式烟机——采用专利双进风旋涡式油烟分离技术,使油烟吸净率达99%以上,清除油烟更彻底,厨房天花板上无油污,排出室外的是洁净的空气和烟气,符合欧洲环保标准。

全不锈钢制造净化器,防止飞火吸入机器内部,起到防火墙的作用。

采用三层防火墙,更有助于吸油烟及安全系数的提高。

第一层是吸风口:油烟分离。

风口圆弧形设计,不易积累油污,清洗更方便。

第二层是防火墙:采用空气流体隔膜技术,提高安全系数。

第三层是导风圈:采用涡轮原理,有助吸风效果。

超大容量抽屉集油盒,消除令人烦恼的滴油、渗油。

特设有隔热墙,在灶具长时间的燃烧使用后,可以让不锈钢表面永保常温,不必担心局部高温给材质带来的损害。

我们的烟道使用的是铝箔材料,跟世面上一般所用的PVC材料相比,首先是铝箔材料本身并不会燃烧,再一个PVC材料在经过比较长的时间后会出现老化,脆化的现象,而铝箔材质不会出现这样的问题。

近吸式油烟机区别于顶吸式油烟机的性能,奠定了近吸式油烟机的“霸主”地位。

近吸式油烟机第一大特性是:吸烟吸得干净。

油烟机是用来干什么的呢?当然是用来吸烟的,吸烟效果好不好直接能让用户看到,近吸式油烟机的吸烟率达到90%以上,能做到“爆炒辣椒不呛鼻”。

近吸式油烟机的第二大特性是:油脂分离度高。

近吸式油烟机的“脸面”部分叫油烟分离板,能够使气态油脂在接触板壁时80%以上得到液化,还原为液态油脂,排到室外的部分油脂含量低,较环保,排烟管一年内不会变黑。

近吸式油烟机的第三大特性是:空间更开敞,不碰头。

近吸式油烟机是斜挂在墙上的,让厨房的空间得到更大的释放,炒菜时不易碰头,时尚美观。

近吸式油烟机存在的缺点:一是“脸面”离锅近易被“溅”脏,易变“大花脸”,要经常“洗脸”;二是目前的橱柜面板太窄,炉心离墙近了些,影响炒菜的操作,设计时要嘱咐橱柜商将灶具离墙远些;三是噪音大些,原因很简单,因为“脸部”风大撞击猛烈,撞击力度越强油脂分离度就越高,两者是矛盾的对立智洗系统——SKO瞬热除油系统。

型号目录产品特点................2安全注意事项..........2技术数据与装箱单...3安装指导. (4)产品使用说明 (5)故障排除及处理.......8使用前请仔细阅读说明书本公司保留说明书解释权产品外观以实物为准如遇产品技术改进,恕不另行通知本产品只适合在中国大陆销售和使用本产品执行标准:GB 16410-2020 GB 30720-2014产品部件介绍..........4清洁保养................7告用户环境影响书....8保修说明. (9)系列QHA938U1系列QHA93T1系列QHA73T112意外熄火保护功能欧式风格设计当火焰因风吹、溢锅等发生意外熄火后,熄火保护装置会动作,自动切断燃气灶内部的燃气通路,避免燃气大量泄漏,确保用户使用安全。

瞬燃点火功能点火采用瞬燃点火技术,只需要将旋钮按压到底并旋转90°,燃气灶就能实现瞬间开阀,实现快速点火功能。

采用优质钢化玻璃灶面,高强度,易清洁。

联网APP 操控功能(仅QHA938U1机型有此功能)使用海尔智家APP 可以进行定时、关火等操控。

定时功能(仅QHA938U1机型有此功能)烹饪过程中,左右灶头均可设置(1~180)min 的超长定时。

干烧保护功能(仅左灶头具有此功能)在使用该燃气灶的时候,若在大火加热时忘记关火而造成锅底温度过热,超过保护警戒温度时,防干烧过热保护装置将启动,发出“滴2s 停1s ”蜂鸣声(持续约20s )并切断燃气,避免因烧干锅引发火灾等安全事故;(请确保锅底和传感器有效接触,否则干烧保护功能不能可靠启动;该功能一般在锅具彻底烧干几分钟内启动;当锅内食物刚刚烧干、烧糊时,并不能立即关火。

)干烧保护后,若立即进行重新点火,则不能点火成功,待干烧保护恢复后才能正常点火。

不坐锅智能关火功能(仅左灶头具有此功能)若您将左灶头处于大火燃烧一段时间后,并且在支锅架不放置锅具,那么不坐锅智能关火功能会启动,发出“滴2s 停1s ”蜂鸣声(持续约20s )并切断燃气,为您节省燃气并保证您的安全;(如果传感器探头没有和锅底有效的接触,不坐锅智能关火功能判断为无锅状态,可能会报警并切断燃气。

TWO SIDEDGRILLSMODELGX10IG, IS, ISGGX14IG, IS, ISGGX20IG, IS, IGSInstallation andOperationInstructions2M-Z7971 Rev. L 12/2018 GX10IG2These symbols are intended to alert the user to the presence of important operating and maintenance instructions in the manual accompanying the appliance.RETAIN THIS MANUAL FOR FUTURE REFERENCENOTICEUsing any part other than genuine Star factory supplied parts relieves the manufacturer of all liability.notice. Such revisions do not entitle the buyer to corresponding changes, improvements, additions or replacements for previously purchased equipment.Due to periodic changes in designs, methods, procedures, policies and without notice. While Star International Holdings Inc., Company exercises good faith efforts to provide information that is accurate, we are notresponsible for errors or omissions in information provided or conclusions provided, the user assumes all risks in connection with such use.MAINTENANCE AND REPAIRSContact your local authorized service agent for service or required maintenance.Please record the model number, serial number, voltage and purchase date in the area below and have it ready when you call to ensure a faster service.SAFETY SYMBOLModel No.Serial No.Voltage Purchase DateBusiness 8:00 am to 4:30 p.m. Central Standard Time Hours: Telephone:(800) 264-7827Fax: (314) 781-2714E-mail****************************Website:Service Help DeskAuthorized Service Agent Listing Reference the listing provided with the unitorfor an updated listing go to:Website: E-mail****************************Mailing Address: Star Manufacturing International Inc.265 Hobson Street Smithville, TN 37166 U.S.AGENERAL INSTALLATION DATAThis equipment is designed and sold for commercial use only by personnel trained and experienced in its operation and is not sold for consumer use in and around the home nor for use directly by the general public in food service locations.All shipping containers should be checked for freight damage both visible and concealed. This unit has been tested and carefully packaged to insure delivery of your unit in perfect condition. If equipment is received in damaged condition, either apparent or concealed, a claim must be made with the delivering carrier.Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked, a request for inspection of concealed damage must be made with carrier within 15 days. Be certain to retain all contents plus external and internal packaging materials for inspection. The carrier will make an inspection and will supply necessary claim forms.VENTILATION AND CLEARANCESThe installation of any components such as a vent hood, grease extractors, and/or fire extinguishing systems, must conform to their applicable nationally recognized installation standards and/or local building codes.ELECTRICAL CONNECTIONBefore making any electrical connection be sure to read data plate which is located at the bottom of the unit .ELECTRICAL GROUNDING INSTRUCTIONSThis unit is equipped with a 3-prong (grounding) plug for your protection against shock hazard and must be plugged directly into a properly grounded 3-prong receptacle.DO NOT CUT OR REMOVE THIS PLUG OR GROUNDING PRONG FROM THE PLUG.CONNECT/PLUG UNIT INTO DEDICATED A.C. LINE ONLY SPECIFIED ON THEDATA PLATE OF THE UNIT.CAUTIONWARNINGCONNECT/PLUG UNIT INTO DEDICATED A.C. LINE ONLY SPECIFIED ON THE DATA PLATE OF THE UNIT.INITIAL START UPLevel unit using the adjustable feet under the unit (approximately 1/2" adjustment).Before using the unit for the first time, wipe down the exterior and grilling area with a damp cloth. Take to a well ventilated area and heat for approximately 30 minutes. The grill may emit a small amount of smoke as the cooking surfaces reaches 450°F. Do not be alarmed, as the smoke is caused by oils associated with the manufacturing process and will stop when the burn off is complete. Brush off any debris from the grilling surface.SEASONING THE COOKING SURFACESThe cooking surfaces must be "seasoned" in order to reduce product sticking. To season, bring grill to 300°F, until completed. Brush upper and lower cooking surfaces with a salt free liquid vegetable oil. If using an aerosol agent, first apply into a cup and then brush onto cooking surface. Let sit for 20 minutes, and then wipe clean using a warm damp cloth. Repeat if required.SETTING THE TEMPERATUREThe thermostat control knob is used to set the temperature to your requirements. The maximum set point is 450°F (232°C), the minimum set point is 175°F (79°C). See Knob Settings.DAILY OPERATIONCheck the power cord to insure that it is plugged into a proper outlet.Check that the thermostat control is turned on.The pilot light will come on when the thermostat control goes past the 175°F.Set the thermostat control knob to desired temperature.Always allow 20 minutes of preheat time before loading the unit with product.Failure to allow sufficient preheat time will result in unsatisfactory cooking of the first load.WARNINGOPERATING HINTS AND SAFETYDisconnect power to the unit with the switch at the end of each day of operation.Do not leave the unit in operation without an attendant.Turn thermostat down to 200°F (93°C) during idle periods. It will take only a few minutes to regain operating temperature.Use spatula to push excess grease into grease cup after each load of food is cooked. This will reduce smoking of hot grease and carbonizing.Do not leave the unit at high temperature when not in use or during idle periods. This will cause food particles and grease film to carbonize."Season" cooking surfaces with non-salted vegetable oil to reduce product sticking.MONTHLY LUBRICATION/INSPECTIONApply two (2) drops of non-toxic mineral or vegetable oil to hinge bracket at the rear.Check the bolts, screws and nuts, tighten if necessary.TOP HOUSING MAINTENANCEThe Spring setting which holds the top housing in the up position is set at the factory and should provide many years of use without the need of adjusting. After a extended period of time the top housing may not maintain its original setting, therefore the spring tension can be adjusted by tightening and loosening the Retainer bolts on the back of the unit.CLEANINGWhile holding top lid with one hand, apply only cleaners which are safe for aluminum and iron surfaces. Wipe with clean sponge or towel until unit is clean.1. If particles adhere to the cooking surface during the day, scrape them off with a spatulaor stiff brush.NOTE: It is best not to let food cook on to the grill, as build up of food on the grill will increase sticking and smoking. In addition, carbon may build up on the grill surface and reduce the cooking efficiency.2. At the end of the day, wipe down all surfaces with a warm, damp cloth, use a mild detergent onall non-cooking areas and then dry entire unit.3. Remove and empty to clean grease catcher cup as required using mild detergent and water.CLEANING CARBON BUILDUP1. When carbon build up occurs, use a carbon removal agent to clean cooking surface.When this process is completed, you must re-season the grill (See Seasoning Grill).2. Acidic cleaners are NOT recommended as a cleaning agent.DO NOT IMMERSE OR LET THE UNIT STAND IN WATER.DO NOT HOSE DOWN THE UNIT OR THE TABLE/COUNTER IF THE UNIT IS ONTHE TABLE/COUNTER.KEEP AWAY FROM RUNNING WATER.Above: Oiling the Hinge, Below: Tightening the top housingCAUTIONCLEANING contDO NOT USE SHARP OBJECTS TO REMOVE CARBON BUILD-UP .BEFORE CLEANING MAKE SURE POWER IS TURNED OFF, UNIT IS UNPLUGGED AND IS NOT TOO HOT.DO NOT SPLASH WATER ON FRONT CONTROL PANEL!DO NOT SPLASH WATER ON FLEX CONDUIT CONNECTING TOP ANDBOTTOM OF THE UNIT.Do not use ice or cold water to clean the cooking surfaces when the unit is hot. The surfacesare cast aluminum or cast iron and may crack or deform under the shock of rapid temperaturechange.OPERATION TROUBLESHOOTING1. Unit not heating.A . Check if unit is plugged in correct receptacle.B . Check incoming power line.C . Check that thermostat is set to proper temperature.If unit still does not operate contact the factory or one of its representatives or a local service company for service or required maintenance.CAUTIONWARNING WARNINGWARRANTY EXCLUSIONSTHE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.•Any product which has not been used, cleaned, maintained, or installed in accordance with the directions published in the appropriate installation sheet and/or owner's manual as well as national and local codes, including incorrect gas, electrical, or water connection. Star is not liable for any unit which hasbeen mishandled, abused, misapplied, subjected to chlorides, harsh chemicals, or caustic cleaners, damaged from exposureto hard water, modified by unauthorized personnel, damaged by flood, fire, or other acts of nature [or God], or which have an altered or missing serial number.• Installation, labor, and job checkouts, calibration of heat controls, air and gas burner/bypass/pilot adjustments, gas or electrical system checks, voltage and phase conversions, cleaning of equipment, or seasoning of griddle surface.• Replacement of fuses or resetting of circuit breakers, safety controls, or reset buttons.• Replacement of broken or damaged glass components, quartz heating elements, and light bulbs.• Labor charges for all removable parts in gas charbroilers and hotplates, including but not limited to burners, grates, and radiants.• Any labor charges incurred by delays, waiting time, or operating restrictions that hinder a service technician’s ability to perform service.•Parts that fail or are damaged due to normal wear or labor for replacement of Items that can easily be replaced during a dailycleaning routine. such as but not limited to silicone belts, PTFEnon-stick sheets, knobs, control labels, bulbs, fuses, quartz heatingelements, baskets, racks, and grease drawers.•Components that should be replaced when damaged or worn,but have been field-repaired instead [eg. field-welded fry pots]•Any loss of business or profits.ADDITIONAL WARRANTIESSpecialty/chain specific versions may also have additionalLIMITED EQUIPMENT WARRANTYStar Manufacturing [as well as its subsidiaries] warranties new products to be free from defects in material and/or workmanship for a period of one [1] year from the date of original installation, except as noted below. Defects that occur as a result of normal use, within the time period and limitations defined in this warranty, will at Star’s discretion have the parts replaced or repaired by Star or a Star-authorized service agency.THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS. Repairs performed under this warranty are to be performed by a Star- authorized service agency. Star will not be responsible for charges incurred or service performed by non-authorized repair agencies. In all cases, the nearest Star-authorized service agency must be used. Star will be responsible for normal labor charges incurred in the repair or replacement of a warrantied product within 50 miles (80.5 km) of an authorized service agency. Time and expense charges for anything beyond that distance will be the re s ponsibility of the owner. All labor will need to be performed during regular service hours. Any overtime premium will be charged to the owner. For all shipments outside the U.S.A. and Canada, please see the International Warranty for specific details.It is the responsibility of the owner to inspect and report any shipping damage claims, hidden or otherwise, promptly following delivery. No mileage or travel charges will be honored on any equipment that is deemed portable. In general, equipment with a cord and plug weighing less than 50 lb. (22.7 kg) is considered portable and should be taken orshipped to the closest authorized service agency, transportation prepaid . PORTABLE EQUIPMENT EXAMPLES•J4R popcorn machine •12NCPW and 15NCPW nacho merchandisers•nacho cheese warmers except 11WLA-series models•specialty food warmers except 130R, 11RW, and 11WSA models •all butter dispensers •all nacho chip merchandisers • 514LL fryer • 15MC and 18MCP hot food merchandisers• QCS1, QCS2, and RCS2 toasters • 16PD-A pretzel merchandisers • condiment dispensers except HPD- and SPD-series models • all pop-up toasters • all pastry display cabinets • all heat lamps• all accessoriesCONTACTShould you require any assistance regarding the operation or maintenance of any Star equipment; write, phone, fax or email our service department. In all correspondence mention the model number and the serial number of your unit, as well as the voltage or type of gas you are using.Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time Telephone Star/Toasmaster 314.678.6306Fax 314.781.2714********************************* • M O D E L : G X & P B F S I N G L E L I D S E R I E S , W I R E D I A G R A M , 120V /230/240VT H I S D R A W I N G C O N T A I N S I N F O R M A T I O N C O N F I D E N T I A L T O S T A R M F G . I N T 'L . I N C .N O R E P R O D U C T I O N O R D I S C L O S U R E O F I T S C O N T E N T S I S P E R M I T T E D .S T A R I N T E R N A T I O N A L H O L D I N G S I N C . C O M P A N YS K 2116 R e v -02/16/2005T O P E L E M E N TF O R R E F E R E N C E W I R I NG D I A G R A M I S SH O W N A S U NI T I S A S S E M B L E D W I T H T H E B O T T O M P L A T E R E M O V E D . I T E M S A R E I N G E N E R A L L O C A T I O N B U T M A Y B E R E L O C A T E D O R S C A L E D F O R C L A R I T Y .C E R T I L L U S S O M ET O P E L E M E N T F O R R E F E R E N C E W I R I N G D I A G R A M I S S H O W N A S U N I T I S A S S E M B L E D W I T H T H E B O T T O M P L A T E R E M O V E D . I T E M S A R E I N G E N E R A L L O C A T I O N B U T M A Y B E R E L O C A T E D O R S C A L E D F O R C L A R I T Y .T O P E L E M E N TC E R T A I N I N S T A N C E S M A Y N O T B E A V A I L A B L EI L L U S T R A T I V E P U R P O S E S O N L Y A N D I N M O D E L : G X & P B F D O U B L E L I D S E R I E S , W I R E D I A G R A M , 230/240VT H I S D R A W I N G C O N T A I N S I N F O R M A T I O N C O N F I D E N T I A L T O S T A R M F G . I N T 'L . I N C .N O R E P R O D U C T I O N O R D I S C L O S U R E O F I T S C O N T E N T S I S P E R M I T T E D .S T A R I N T E R N A T I O N A L H O L D I N G S I N C . C O M P A N YS K 2118 R e v -02/16/2005This drawing contains information confidential to Star Manufacturing International, Inc.No reproduction or disclosure of its CERTAIN INSTANCES MAY NOT BE AVAILABLE ILLUSTRATIVE PURPOSES ONLY AND INSOME ITEMS ARE INCLUDED FORcontents is permitted.MODEL GX10, GX14, GX20 SERIESGX20 SHOWNSTAR MANUFACTURING INTERNATIONAL, INC.SK2121 Rev. J11/12/2014111 D9-GR0239 1 TOP HOUSING & CONDUIT - 10 ALL2 2C-Z2054 1 CLAMP , THERMISTOR ALL3 2C-Z2893 8 NUT 10-24 Hex STL ZPALL 4 D9-GR0228 1 TOP INS. PLATE ASSY -10” ALL 5 D9-Z2908 1 INSULATION, 10”ALL 6 2A-Z6604 8 SPACER, INSULATION PLATE ALL 7 D9-Z76461 PLATE, ELE.&INS RET. -10” ALL 8 2C-08-07-0285 8 SCREW 10-24 x 3/4 3/8ALL 9 PS-Z7761 1 ELEMENT, TOP , 600W, 120V-10” 120 V PS-Z2019 1 ELEMENT, HEATING 800W/240V 230/240 V 10 1O-E1500 3" SLEEVING #4 .208ID GLASS ALL11 2F-Z7657 1 CASTING, IRON, TOP GR - 10” GROOVED MODELS 2F-Z7737 1 CASTING, IRON, TOP SM. -10”SMOOTH MODELS 12 2V-Z7641 2 ROD, ARM CONNECTION COMMON ALL 13 2B-Z7860 2 ARM, SIDE COMMONALL 14 2V-Z7662 1 HANDLE -10” GRILL EXPRESS ALL 15 D9-Z8769 1 COVER, HINGE 10ALL 16 2V-Z3252 1 ROD - TOP HOUSING LATCH ALL 17 2V-Z7863 2 SPACER, INSIDE 10” ALL 18 2P-Z8824 1 SPRING, TORSION LH ALL 19 2P-Z8823 1 SPRING, TORSION RHALL 20 2V-Z8407 2 COLLAR, 2 PIECE COMMON ALL 21 2V-Z7862 2 SPACER, OUTSIDE COMMON ALL 22 2V-Z7861 1 ROD, HINGE 10”ALL 23 2F-Z8529 2 RETAINER, HANDLE COMMON ALL 24 D9-Z8444 1 BRACKET, MTG - TOP LATCH ROD ALL 25 2C-Z2992 2 BOLT 1/4”-20X1 PHP STL NP ALL 26 2F-Z7910 2 RETAINER, SPRING ALL 27 D9-GR0253 1 BODY ASSY - 10”ALL 28 2T-Y2313 1 THERMOSTAT 118V-236V ALL 29 2M-Z8848 1 OVERLAY EXP GRILL - 10” ALL 30 2R-Z8847 1 KNOB, T-STAT CONTROL ALL 31 2E-Z2894 1 TERMINAL BLOCK (304) ALL 32 2J-Y6689 1 PILOT LIGHT 120V 120 V 2J-Z2329 1 PILOT LIGHT 240 V 230/240 V 33 2V-Z8859 2 SPACER, SIDEALL 34 D9-Z7697 1 PLATE, BOTTOM-10” ALL 35 2A-Z1485 4 FOOT 1” ADJUSTABLE ALL 36 2K-Y3240 1 BUSHING HEYCO SR 17-2 ALL 37 2E-Z2898 1 CONDUIT ASSY , PTFE ALL 38 2C-Z3917 2 RIVET, POPALL 39 2E-Z3768 1 LOCKNUT, CONDUIT 1/2 IN ALL 40 2C-Z3780 2 RETAINER, CONDUITALL 41 2A-Z3827 1 PLATE, STAMPING - CONDUIT ALL 42 D9-Z8861 1 CORD SET 14/3 120V 15A120 V 2E-Y9251 1 CORD SET CONT EUR 16AMP 230V 2E-Z2770 1 CORD, POWER, 14-3, 6-15240 V43 2F-Z7730 1 CASTING, IRON, BOTTOM GR - 10” GROOVED MODELS 2F-Z7756 1 CASTING, IRON, BOT., SM.-10” SMOOTH MODELS 44 D9-GR0229 1 BRACKET ASSY , THERMOSTAT ALL 45 2N-Z7765 1 ELEMENT, BOT, 800W, 120V-10 120 V 2N-Z2020 1 ELEMENT, HEATING 1000W/240 230/240V 46 D9-Z7677 1 ELEMENT PLATE, BOTTOM-10” ALL 47 D9-Z7676 1 INS. PLATE, BOTTOM-10” ALL 48 D9-Z8842 1 GREASE CUP 10”ALL 49 2C-1512 6 SCREW 10-24X3/8 RHP STL NP ALL 53 2M-Z2620 1 LABEL CAUTION,BI-LINGUAL ALL 54 2C-6260 2 WASHER #10 INT STL NP ALL 55 2C-2559 2 NUT 10-24 ACHD BR NP ALL 56 2A-Z84082 PIN, SLOTTED SPRING-S.S. ALL 57 2C-08-07-0236 4 SCREW 10-32 X 3/4 SHCS ALL58 D9-Z12061 - SCRAPER-GROOVES ACCESSORY 59 2C-Z5193 8 SCREW 10-24 X .75 PH SS ALL602C-15152SCREW 10-24X.75 ST RH NPSome items are included for illustrative purposes only and in certain instances may not be available.Number Per UnitDescriptionPartNumberKey Number121 D9-GR0233 1 TOP HOUSING ASSY 14” ALL2 2C-Z2054 1 CLAMP , THERMISTOR ALL3 2C-Z2893 8 NUT 10-24 Hex STL ZPALL 4 D9-GR0232 1 TOP INS. PLATE ASSY -14” ALL 5 D9-Z7991 1 INSULATION, 14”ALL 6 2A-Z6604 8 SPACER, INSULATION PLATE ALL 7 D9-Z78461 PLATE, ELE.&INS RET. -14” ALL 8 2C-08-07-0285 8 SCREW 10-24 x 3/4 3/8ALL 9 PS-Z7769 1 ELEMENT, TOP , 800W, 120V-14” 120 V PS-Z7771 1 ELEMENT, TOP , 1250W,240V-14 230/240 V 10 1O-E1500 0.333 SLEEVING #4 .208ID GLASS ALL11 2F-Z7741 1 CASTING, IRON, TOP GR - 14” GROOVED MODELS 2F-Z7742 1 CASTING, IRON, TOP SM. -14”SMOOTH MODELS 12 2V-Z7641 2 ROD, ARM CONNECTION COMMON ALL 13 2B-Z7860 2 ARM, SIDE COMMONALL 14 2V-Z7992 1 HANDLE -14” GRILL EXPRESS ALL 15 D9-Z8429 1 COVER, HINGE 14ALL 16 2V-Z3252 1 ROD - TOP HOUSING LATCH ALL 17 2V-Z7863 2 SPACER, INSIDE 10” ALL 18 2P-Z8756 1 SPRING, TORSION LH ALL 19 2P-Z8755 1 SPRING, TORSION RHALL 20 2V-Z8407 2 COLLAR, 2 PIECE COMMON ALL 21 2V-Z7862 2 SPACER, OUTSIDE COMMON ALL 22 2V-Z7994 1 ROD, HINGE 14”ALL 23 2F-Z8529 2 RETAINER, HANDLE COMMON ALL 24 D9-Z8444 1 BRACKET, MTG - TOP LATCH ROD ALL 25 2C-Z2992 2 BOLT 1/4”-20X1 PHP STL NP ALL 26 2F-Z7910 2 RETAINER, SPRING ALL 27 D9-GR0254 1 BODY ASSY - 14”ALL 28 2T-Y2313 1 THERMOSTAT 118V-236VALL 29 2M-Z8849 1 OVERLAY 14” EXPRESS GRILL ALL 30 2R-Z8847 1 KNOB, T-STAT CONTROL ALL 31 2E-Z2894 1 TERMINAL BLOCK (304) ALL32 2J-Y6689 1 PILOT LIGHT 120V 120V, 120VC-CANADA 32 2J-Z2329 1 PILOT LIGHT 240 V 230/240 V 33 2V-Z8859 2 SPACER, SIDEALL 34 D9-Z7842 1 PLATE, BOTTOM-14” ALL 35 2A-Z1485 4 FOOT 1” ADJUSTABLE ALL 36 2K-Y3240 1 BUSHING HEYCO SR 17-2 ALL 37 2E-Z2898 1 CONDUIT ASSY , PTFE ALL 38 2C-Z3917 2 RIVET, POPALL 39 2E-Z3768 1 LOCKNUT, CONDUIT 1/2 IN ALL 40 2C-Z3780 2 RETAINER, CONDUITALL 41 2A-Z3827 1 PLATE, STAMPING - CONDUIT ALL 42 D9-Z8861 1 CORD SET 14/3 120V 15A 120VD9-Z8917 1 CORD SET 120V 5-20P120VC-CANADA 2E-Y9251 1 CORD SET CONT EUR 16AMP 230V 2E-Z2770 1 CORD, POWER, 14-3, 6-15240 V43 2F-Z7758 1 CASTING, IRON, BOTTOM GR - 14” GROOVED MODELS 2F-Z7757 1 CASTING, IRON, BOT., SM.-14” SMOOTH MODELS 44 D9-GR0229 1 BRACKET ASSY , THERMOSTAT ALL 45 2N-Z7772 1 ELEMENT, BOT, 1000W, 120V-14 120 V 2N-Z7774 1 ELEMENT, BOT, 1500W,240V-14 230/240V 46 D9-Z7843 1 ELEMENT PLATE, BOTTOM-14” ALL 47 D9-Z7844 1 INS. PLATE, BOTTOM-14” ALL 48 D9-Z8843 1 GREASE CUP 14”ALL 49 2C-1512 6 SCREW 10-24X3/8 RHP STL NP ALL 53 2M-Z2620 1 LABEL CAUTION,BI-LINGUAL ALL 54 2C-6260 2 WASHER #10 INT STL NP ALL 55 2C-2559 2 NUT 10-24 ACHD BR NP ALL 56 2A-Z84082 PIN, SLOTTED SPRING-S.S. ALL 57 2C-08-07-0236 4 SCREW 10-32 X 3/4 SHCS ALL58 D9-Z12061 - SCRAPER-GROOVES ACCESSORY 59 2C-Z5193 8 SCREW 10-24 X .75 PH SS ALL602C-15152SCREW 10-24X.75 ST RH NPNumber Per UnitDescriptionPartNumberKey Number131 D9-GR02392 TOP HOUSING & CONDUIT - 10 ALL 2 2C-Z2054 2 CLAMP , THERMISTOR ALL3 2C-Z2893 16 NUT 10-24 Hex STL ZPALL 4 D9-GR0228 2 TOP INS. PLATE ASSY -10” ALL 5 D9-Z2908 2 INSULATION, 10”ALL 6 2A-Z6604 16 SPACER, INSULATION PLATE ALL 7 D9-Z76462 PLATE, ELE.&INS RET. -10” ALL 8 2C-08-07-0285 16 SCREW 10-24 x 3/4 3/8ALL 9 PS-Z2019 2 ELEMENT, HEATING 800W/240V ALL 10 1O-E1500 0.666 SLEEVING #4 .208ID GLASS ALL11 2F-Z7657 1 or 2 CASTING, IRON, TOP GR - 10” GROOVED MODELS (depending on unit) 2F-Z7737 1 or 2 CASTING, IRON, TOP SM. -10”SMOOTH MODELS (depending on unit) 12 2V-Z7641 4 ROD, ARM CONNECTION COMMON ALL 13 2B-Z7860 4 ARM, SIDE COMMONALL 14 2V-Z7662 2 HANDLE -10” GRILL EXPRESS ALL 15 D9-Z8417 2 COVER, HINGE 10ALL 16 2V-Z3252 2 ROD - TOP HOUSING LATCH ALL 17 2V-Z7863 4 SPACER, INSIDE 10” ALL 18 2P-Z8824 2 SPRING, TORSION LH ALL 19 2P-Z8823 2 SPRING, TORSION RHALL 20 2V-Z8407 4 COLLAR, 2 PIECE COMMON ALL 21 2V-Z7862 4 SPACER, OUTSIDE COMMON ALL 22 2V-Z7861 2 ROD, HINGE 10”ALL 23 2F-Z8529 4 RETAINER, HANDLE COMMON ALL 24 D9-Z8444 2 BRACKET, MTG - TOP LATCH ROD ALL 25 2C-Z2992 4 BOLT 1/4”-20X1 PHP STL NP ALL 26 2F-Z7910 4 RETAINER, SPRING ALL 27 D9-GR0255 1 BODY ASSY - 20”ALL 28 2T-Y2313 2 THERMOSTAT 118V-236VALL 29 2M-Z8850 1 OVERLAY 20” EXPRESS GRILL ALL 30 2R-Z8847 2 KNOB, T-STAT CONTROL ALL 31 2E-Z2894 2 TERMINAL BLOCK (304) ALL 32 2J-Z3157 2 PILOT LIGHT 250V AMBER ALL 33 2V-Z8859 2 SPACER, SIDEALL 34 D9-Z7918 1 PLATE, BOTTOM-20” ALL35 2A-Z1485 4 FOOT 1” ADJUSTABLE ALL manufactured on or before 2/4/08 2R-200716 4 LEG, 2.5" IN METALALL manufactured after 2/5/08 36 2K-Y6764 1 BUSHING - STRAIN RELIEF ALL 37 2E-Z2898 2 CONDUIT ASSY , PTFE ALL 38 2C-Z3917 2 RIVET, POPALL 39 2E-Z3768 2 LOCKNUT, CONDUIT 1/2 IN ALL 40 2C-Z3780 4 RETAINER, CONDUITALL 41 2A-Z3827 2 PLATE, STAMPING - CONDUIT ALL 42 2E-Z2905 1 CORD SJTO 12/3 NEMA 6-20P ALL 2E-Y9251 1CORD SET CONT EUR 16AMP230V43 2F-Z7730 1 or 2 CASTING, IRON, BOTTOM GR - 10” GROOVED MODELS (depending on unit) 2F-Z7756 1 or 2 CASTING, IRON, BOT., SM.-10” SMOOTH MODELS (depending on unit) 44 D9-GR0229 2 BRACKET ASSY , THERMOSTAT ALL 45 2N-Z2020 2 ELEMENT, HEATING 1000W/240 ALL 46 D9-Z7677 2 ELEMENT PLATE, BOTTOM-10” ALL 47 D9-Z7676 2 INS. PLATE, BOTTOM-10” ALL 48 D9-Z8838 1 GREASE CUP 20”ALL 49 2C-1512 8 SCREW 10-24X3/8 RHP STL NP ALL 53 2M-Z2620 1 LABEL CAUTION,BI-LINGUAL ALL 54 2C-6260 4 WASHER #10 INT STL NP ALL 55 2C-2559 4 NUT 10-24 ACHD BR NP ALL 56 2A-Z84084 PIN, SLOTTED SPRING-S.S. ALL 57 2C-08-07-0236 8 SCREW 10-32 X 3/4 SHCS ALL58 D9-Z12061 - SCRAPER-GROOVES ACCESSORY 59 2C-Z5193 8 SCREW 10-24 X .75 PH SS ALL602C-15152SCREW 10-24X.75 ST RH NPPARTS LIST September 22, 2010, Rev J20" TWO SIDED GRILLSNumber Per UnitDescriptionPartNumberKey NumberMODELGX20IG, GX20IGS, GX20ISSTAR MANUFACTURING INTERNATIONAL INC.Star - Holman - Lang - Wells - Toastmaster265 HOBSON ST. SMITHVILLE, TN 37166。

目录目录 (1)1. 软件概述 (3)2. 数据库安装 (3)3. 软件启动 (10)3. 功能模块 (13)3.1 快捷方式 (13)3.1.1 订单信息 (13)3.1.2 订单管理 (14)3.1.3合并订单 (27)3.1.4 财务查询 (28)3.1.5 帮助 (29)3.1.6 修改密码 (29)3.1.7 系统选项 (29)3.1.8 用户管理 (30)3.1.9 权限管理 (31)3.1.10 连接数据库 (31)3.1.11 退出程序 (32)3.2 物料定义 (32)3.2.1 封边材料 (32)3.2.2 板材库 (35)3.2.3 五金材料 (39)3.2.4 工件库 (45)3.2.5 产品库 (58)3.2.6线形体 (67)3.3 公用信息 (68)3.3.1 变量库 (68)3.3.2列表库 (71)3.3.3查询函数库 (74)3.3.4 延米价格 (75)3.3.5单元柜价格 (76)3.3.6 套餐价格 (76)3.4 加工定义 (76)3.4.1 生产工序 (77)3.4.2 生产设备 (78)3.4.3 刀具库 (78)3.5 生产系统 (80)3.5.1 工序跟踪 (80)3.5.2 五金包装 (81)3.5.3包装扫描 (82)3.5.4 订单入库 (83)3.5.5 订单发货 (83)3.5.6 生产查询 (84)3.5.7工序统计 (85)4. 参数化属性 (85)5. 坐标系规则及旋转规则 (88)6. 系统默认核价体系 (89)7. 制作数据库的一般流程 (89)8. 数据制作示例 (90)8.1 产品需求 (90)8.2 封边库 (90)8.3五金库 (90)8.4板材库 (91)8.5 工件库 (92)8.6 产品库 (93)8.6.1 产品参数 (93)8.6.2 产品五金 (94)8.6.3 产品工件 (94)附录 (97)1. 软件概述为了降低板式家具生产出错率,提高生产效率,治木软件(FinWood)应势而生。

画面:热闹的街头,人来人往,各种美食香气四溢。

音乐:轻快欢快的背景音乐,营造热闹氛围。

【画面切换】画面:一位笑容满面的小哥,手持一盒精美的加盟手册。

旁白:“你是否厌倦了朝九晚五的生活,渴望自己创业,实现梦想?你是否对美食情有独钟,想要分享你的美味给更多的人?”【画面切换】画面:小哥将加盟手册递给路过的行人,行人接过手册,眼中闪过一丝好奇。

旁白:“机会来了!小餐饮加盟,让你轻松实现创业梦想,让你的美食走进千家万户!”【画面切换】画面:展示一系列成功的加盟案例,从店铺选址、装修风格、菜品研发到营销策略。

旁白:“我们拥有丰富的行业经验,专业的团队支持,为你量身定制一站式加盟服务。

成功案例遍布全国,助力你轻松开店,快速盈利!”【画面切换】画面:小哥介绍加盟优势。

旁白:“ 优势一:品牌优势我们拥有知名品牌,强大的品牌效应,让你开店无忧!优势二:选址支持专业团队为您精选黄金地段,降低经营风险!优势三:装修风格提供个性化装修方案,彰显您的品味与特色!优势四:菜品研发专业厨师团队为您研发特色菜品,满足消费者需求! 优势五:营销策略全方位营销支持,让您店铺生意火爆!优势六:培训体系提供全面培训,让您轻松上手,无忧经营!”【画面切换】画面:小哥展示加盟流程,简单易懂。

旁白:“ 加盟流程:1. 了解项目2. 资质审核3. 签订合同4. 店铺选址5. 装修指导6. 菜品培训7. 营销支持8. 开业庆典全程贴心服务,让您开店无忧!”【画面切换】画面:小哥介绍成功加盟商分享心得。

加盟商A:“加盟小餐饮后,我实现了自己的创业梦想,店铺生意越来越好,生活也变得更加充实!”加盟商B:“感谢品牌支持,让我在短时间内成功开店,现在每个月都有可观的收入!”【画面切换】画面:小哥鼓励观众行动起来。

旁白:“抓住机会,加入我们,一起开启您的创业之旅!心动不如行动,赶快联系我们,开启您的美食事业吧!”【视频结尾】画面:小哥留下联系方式,并附上二维码。

手机网站官方微信6、烘干控制:在待机状态下,关闭柜门,按烘干键, 柜门锁住,执行烘干功能,烘干时间60分钟,工作结束,门锁打开。

7、互锁功能:消毒和烘干键二键互锁,在选择过程中按另一键,即改变选择功能。

如果功能正在执行中,按 二键中的任一键,结束工作,相应功能指示灯灭,门锁打开。

8、联动功能:风机关闭状态下,当有点火信号(或电磁灶工作信号)持续保持一秒以上,自动开启风机,慢档 运行。

当信号消失,进入延时关风机状态,延时结束,风机停止。

在延时过程中按风速键则退出延时状 态,风机切换到相应风速。

9、防火墙功能:当防火墙功能触发时,自动关闭炉火和风机,并且发出声音报警。

需继续按压3-5开关旋钮。

(图3)u u OFF ”位置,再重新按点火方法开启即可。

u 火力调节:请参照开关旋钮的火力调节标记调整至您需要的火力。

(图4)(图5)3)4)(图5)11)(图2)u且熄火时无严重爆鸣声。

(图6)(图6)u 片,稍后重新点火。

u 为了安全使用燃气,在您使用燃气完毕后请将阀门关闭,晚睡前,请将煤气表的总阀门关闭。

-6-1、安装说明:本机安装由所在地区的经销机构提供专业服务。

2、安装方法:整体安装示意图如下:灶体底面灶体背面灶体风管孔注:不同产品的l 值、w 值、h 值、A 值、B 值、Φ1值、a 值、b 值、φ值、都不尽相同,具体产品的具体值请 参照“整体安装尺寸参照表”和“靠近灶体的柜体侧板开孔尺寸参照表”。

3、柜体侧板开孔示意图如下:温馨提示:目前市面上大致有两种深度规格的橱柜:一种是500mm 深度的柜体(即台面550mm 深度的那种),另一种是550mm 深度的柜体(即台面600mm),如果您的柜体比较特殊,请咨询橱柜设计师。

如果厨房出风口在集成灶的背面,则柜体不必开孔。

4、由安装人员进行安装后调试。

柜体背面柜体底面注:不同产品对柜体侧板的开孔要求不同,具体产品按照具体要求开孔,如图所示是对靠近灶体的柜体侧板的开孔示意图,其中下开孔用来穿过排风管,上开孔用来穿过电源线和燃气管,具体产品的具体值请参照“靠近灶体的柜体侧板开孔尺寸参照表”。

板川集成灶750系列,迷你你的私厨

有的人住着廉价的出租房,却如家般充实着,温馨满足着;有的人住着高大上的商品房,却如酒店般空虚着,落寞寂寥着。

大家逐渐认同,一个真正意义上的家,并不是用平方

来衡量,也不是用豪华来定夺。

70后现在已经逐渐在成为社会的中坚力量,而在8090后新生代日渐成长为社会新主力的时代,越来越多的人开始青睐小户型新房,90平米、80平米甚至70平米。

这也许跟他们独有的特性有关,誓要创新创业的他们,誓要独立自主的他们,或许还有那些被父母庇佑着的他们。

据调查显示,在新房的选购上,这些人会热衷选购小户型。

一、经济压力较大的年轻购房群体:年轻情侣在购置婚房时有时经济压力会比较大,会选择小公寓产品进行过渡。

二、想要居住在黄金地段的购房人群:配套设施完善、交通便利的地段,购买面积较大的住宅产品在经济上可能也有些压力。

这时,选择小户型公寓产品就成了一个两全齐美的办法。

三、单身族购房群体:对于一些单身贵族来说,为自己购买一处小公寓是很多人的计划之一。

忙碌的工作结束之后,可以回到自己面积不大但却温馨的小家里,下厨做饭,放松一下一天紧张工作的心情,享受片刻的宁静。

而为了能有个温馨的家,后续的新房装修也是另购房者头疼的一项大事。

客厅沙发电视柜,浴室淋浴马桶,卧室衣柜床品,厨房橱柜集成灶,一样都不能少。

装修凡事的亲力亲为,往往让我们的购房者在各大建材市场来回奔波,在各个促销超市忙碌赶场。

未等装修完成,我们的购房者却早已焦头烂额。

在这里,小编无法对其他家居家具进行点评帮我们的购房者出谋划策,但对于厨房集成灶的选择,小编可是行家!现在,小编为大家来推荐一款适合小户型厨房的板川750系列迷你集成环保灶吧!

板川750系列,只为点亮你的小户型私厨。

它独有75公分灵巧精致尺寸,和99.9%的高油烟净化率,完全迎合你的厨房私人空间却又带给你非一般的健康环保绿色烹饪体验。

它拥有高效的完美弧度的旋钮,让诱人美食开始于你的指尖!新颖设计的拉手,既方便快捷,又提高了烹饪效率,将人性化体验落实到方方面面!它的炫彩750系列,色彩前卫时尚,只为你一个打造五彩缤纷的童话式厨房!

750迷你系列,适合的才是最好。