PTP503压力传感器使用说明书

- 格式:pdf

- 大小:202.01 KB

- 文档页数:3

第一章概述一、用途JCQ-503B静力载荷测试仪是专为土木工程质量检测部门研制的一种智能化多功能仪器。

该仪器由主机和前端测控器组成,主机和测控器之间的通信方式为无线/有线两种方式。

该仪器配合压力传感器或力传感器、容栅式位移传感器、高压油泵、千斤顶等设备,可进行桩基础及其它地基基础的静荷载测试、土木工程试验中混凝土构件的结构性能及砌体轴压、抗剪等测试,也可用于其他有关荷载或位移检测试验。

仪器内嵌GPRS模块,可在试验过程中将测试数据实时上传至服务器,便于桩基检测机构或政府职能管理部门实现对测试现场、测试数据的有效监督、管理。

二、功能与特点1.硬件部分●仪器由主机和测控器两部分组成,两部分均为便携式一体化结构。

主机采用便携式高强度、一体化机箱。

内嵌功能强大的32位ARM微处理器并带有大容量非易失数据存储器用于存储测试数据,可实现真正的无纸化记录。

测控器测控一体化设计,可靠性高且功能强大。

●主机采用4.3寸(480*272)宽温真彩色液晶显示屏,现场可显示测试过程中的各种数据、曲线、测试状态和参数。

●主机为WINCE嵌入式操作系统,全中文界面,仪器采用按键操作,操作简洁方便。

●主机内嵌GPRS模块,用户需要时可通过GPRS网络将测试数据上传至服务器,为本单位或政府职能管理部门实行远程监管提供方便。

●测控器荷载测试通道既可连接测力传感器直接测力以适应高精度测试需要,也可连接压力传感器测量油压,通过油压自动换算成荷载值。

●测控器有4个独立的位移测试通道用于测量试桩的沉降。

●位移通道使用数字容栅式防水型位移传感器。

高精度,大量程,无时漂、温漂影响,完全满足了野外昼夜连续观测对时漂、温漂的严格要求。

●测控器内嵌油泵开关控制器,采用测试及控制一体化设计。

油泵开关控制器既可控制220V单相油泵电机,也可控制380V三相油泵电机,能实现全自动加载、补载、卸载。

●仪器可直接和用户现有的千斤顶、油泵配套使用,无需购置新的液压设备。

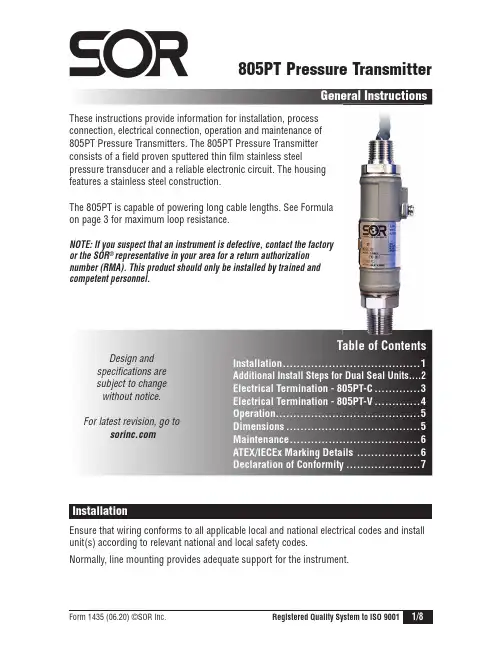

805PT Pressure TransmitterGeneral InstructionsThese instructions provide information for installation, process connection, electrical connection, operation and maintenance of 805PT Pressure Transmitters. The 805PT Pressure Transmitter consists of a field proven sputtered thin film stainless steelpressure transducer and a reliable electronic circuit. The housing features a stainless steel construction.The 805PT is capable of powering long cable lengths. See Formula on page 3 for maximum loop resistance.NOTE: If you suspect that an instrument is defective, contact the factory or the SOR ® representative in your area for a return authorization number (RMA). This product should only be installed by trained and competent personnel.Design and specifications are subject to change without notice. For latest revision, go toTable of ContentsInstallation .....2Maintenance .InstallationEnsure that wiring conforms to all applicable local and national electrical codes and install unit(s) according to relevant national and local safety codes.Normally, line mounting provides adequate support for the instrument.1st Step: Make the Process Connectionn The process connection is threaded onto a fitting within an adequately supported process piping system.o Use two open end wrenches when connecting the pressure port to a process piping system: one wrench to hold the process fitting, the other at the hex flat to tighten the pressure transmitter.p Process connection pipe or tubing may be rigid or flexible.NOTE: Do not use the 1/2” NPT(M) connection on pressures higher than 5000 psi.2nd Step: Make the Electrical Connectionn The electrical connection may be installed on an adequately supported rigid conduit system. Use suitable locknuts (not provided) when mounting the instrument to an unthreaded (knockout) hole.o Securely connect the conduit pipe or fitting by holding the flats on the electrical connection while tightening.p Electrical connection may be rigid or flexible conduit.work area is declassified. Failure to do so could result in severe personal injuryor substantial property damage.“Dual Seal” instruments. An improper installation will voidthe warranty.Vertical Installationn The figure on the right depicts the verticalinstallation profile; with the electricalleads on top. The instrument may beinstalled with the electrical leads on thebottom.o The nameplate (tag) should cover the setscrew (annunciation path). Position thenameplate slot opposite the set screw;i.e., the nameplate slot should be located180° from the set screw.Formula for determiningmaximum loop resistanceR L (MAX) = V Supply - 8V 20mAHorizontal Installationn The following figure depicts the proper horizontal installation profile; with the externalground provision and set screw (annunciation path) oriented downward.o The nameplate (tag) should not cover the set screw.PROVISIONRed (+) Black (–) Blue Green White Brown Not Used (trimmed at factory) Bare Drain Wire - Connected toEarth Ground (trimmed at factory)NOTE: An external ground screw is included for additional earth ground connection.Drawing 0190315Once the transmitter is installed and wired into a control or display loop, it is ready for use. Before applying power, check that the polarity and excitation voltage are correct.Dimensions are for reference only.Contact the factoryfor certified drawingsfor a particular model number.(First Two Numbers Indicate Year of Manufacture)TrademarkInformationThread Form InformationIdentificationDrawing 0720524For ATEX/IECEx Certified ModelsThe 805PT contains no user serviceable parts and cannot be repaired on site. It must be returned to the factory. Disassembly of the instrument by unauthorized persons will invalidate the warranty. If there is a risk of debris accumulating in the pressure port, it should be cleaned. Care and caution must be taken when cleaning the pressure port to prevent damage to the diaphragm.Special Condition for Safe UseFlamepath joints are not intended to be repairedEU Declaration of Conformity14685 West 105th Street, Lenexa, KS 66215-2003913-888-2630 • 800-676-6794 USA • 913-888-0767 FAXEngineered to Order with Off-the-Shelf SpeedProduct Manufacturer Place of Issue800 Series Electronic Pressure Transmitters SOR Inc.14685 West 105th Street II 2 G Ex db IIC T5 Gb, Ta + -40°C to IP66FM 09 ATEX 0045 Michael J. Bequette14685 West 105th Street, Lenexa, KS 66215 913-888-2630 800-676-6794 USA 。

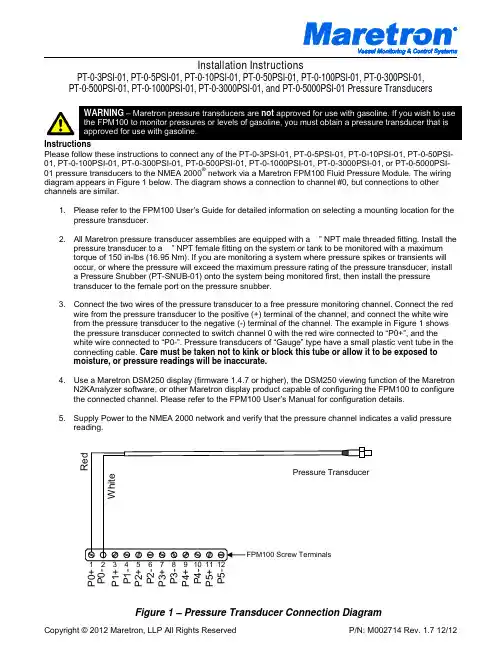

PT-0-3PSI-01, PT-0-5PSI-01, PT-0-10PSI-01, PT-0-50PSI-01, PT-0-100PSI-01, PT-0-300PSI-01, PT-0-500PSI-01, PT-0-1000PSI-01, PT-0-3000PSI-01, and PT-0-5000PSI-01 Pressure TransducersWARNING – Maretron pressure transducers are not approved for use with gasoline. If you wish to use the FPM100 to monitor pressures or levels of gasoline, you must obtain a pressure transducer that isapproved for use with gasoline.InstructionsPlease follow these instructions to connect any of the PT-0-3PSI-01, PT-0-5PSI-01, PT-0-10PSI-01, PT-0-50PSI-01, PT-0-100PSI-01, PT-0-300PSI-01, PT-0-500PSI-01, PT-0-1000PSI-01, PT-0-3000PSI-01, or PT-0-5000PSI-01 pressure transducers to the NMEA 2000® network via a Maretron FPM100 Fluid Pressure Module. The wiring diagram appears in Figure 1 below. The diagram shows a connection to channel #0, but connections to other channels are similar.1. Please refer to the FPM100 User’s Guide for detailed information on selecting a mounting location for thepressure transducer.2. All Maretron pressure transducer assemblies are equipped with a ¼” NPT male threaded fitting. Install thepressure transducer to a ¼” NPT female fitting on the system or tank to be monitored with a maximumtorque of 150 in-lbs (16.95 Nm). If you are monitoring a system where pressure spikes or transients will occur, or where the pressure will exceed the maximum pressure rating of the pressure transducer, installa Pressure Snubber (PT-SNUB-01) onto the system being monitored first, then install the pressuretransducer to the female port on the pressure snubber.3. Connect the two wires of the pressure transducer to a free pressure monitoring channel. Connect the redwire from the pressure transducer to the positive (+) terminal of the channel, and connect the white wire from the pressure transducer to the negative (-) terminal of the channel. The example in Figure 1 shows the pressure transducer connected to switch channel 0 with the red wire connected to “P0+”, and thewhite wire connected to “P0-”. Pressure transducers of “Gauge” type have a small plastic vent tube in the connecting cable. Care must be taken not to kink or block this tube or allow it to be exposed tomoisture, or pressure readings will be inaccurate.4. Use a Maretron DSM250 display (firmware 1.4.7 or higher), the DSM250 viewing function of the MaretronN2KAnalyzer software, or other Maretron display product capable of configuring the FPM100 to configure the connected channel. Please refer to the FPM100 User’s Manual for configuration details.5. Supply Power to the NMEA 2000 network and verify that the pressure channel indicates a valid pressurereading.P+P-P1-P1+P2+P2-P3+P3-P4+P4-P5+P5-Figure 1 – Pressure Transducer Connection DiagramPressure Transducer Mechanical DrawingPressure Transducer SpecificationsPart Number Range Accuracy TypePT-0-3PSI-01 0 to 3 PSI (0.21 bar) ±2% Full Scale Gauge (Vent Tube)PT-0-5PSI-01 0 to 5 PSI (0.34 bar) ±2% Full Scale Gauge (Vent Tube)PT-0-10PSI-01 0 to 10 PSI (0.69 bar) ±2% Full Scale Gauge (Vent Tube)PT-0-50PSI-01 0 to 50 PSI (3.45 bar) ±1% Full Scale Gauge (Vent Tube)PT-0-100PSI-01 0 to 100 PSI (6.89 bar) ±0.5% Full Scale Gauge (Vent Tube)PT-0-300PSI-01 0 to 300 PSI (20.68 bar) ±0.5% Full Scale Gauge (Vent Tube)PT-0-500PSI-01 0 to 500 PSI (34.47 bar) ±0.5% Full Scale Absolute (No Vent Tube) PT-0-1000PSI-01 0 to 1000 PSI (68.95 bar) ±0.5% Full Scale Absolute (No Vent Tube) PT-0-3000PSI-01 0 to 3000 PSI (206.84 bar)±0.5% Full Scale Absolute (No Vent Tube) PT-0-5000PSI-01 0 to 5000 PSI (344.74 bar)±0.5% Full Scale Absolute (No Vent Tube) Specification ValueCompatible Fluids / Gases Refrigerant, Motor Oil, Diesel, Hydraulic Fluid, Brake Fluid, Water, WasteWater, Hydrogen, Nitrogen, AirOperating Temperature -40°C to 105°CStorage Temperature -40°C to 105°CProof Pressure 2.4 × Full ScaleBurst Pressure 2.4 × Full ScaleReverse Voltage Protection ± 16V over 5 MinutessteelstainlessConstruction 304LCable Length 3 feet (0.91m)Pressure/Temperature Cycles 0 to FS @ 8Hz; and –40°C to 105°C for > 1.8x106 cyclesThermal Shock 105°C to –40°C, 0.5 hr soaks at Temp. (2s Transfer) for 300 cyclesVibration 100 to 2000 Hz, 20g Sinusoidal, 3 Axes for 144 hoursEMC Compatibility 10 Volts/meter per EN 61000-4-3Humidity 85°C and 90% to 95% R. H. for 250 hoursWeight 85gFor installation support, please contact:Maretron, LLP9014 N. 23rd Ave #10Phoenix, AZ 85021-7850Telephone: (+1) 866-550-9100E-mail:********************Web: 。

CDA503系列产品使用说明-目录一、CDA503系列产品概述 (1)1.使用范围及条件 (1)2.特点 (1)3.外形尺寸 (1)4.运输、验收、存放、安装、维护 (1)二、CDA503电源单元 (1)1.主要功能及技术指标 (2)2.面板示意图 (2)1.主要功能及技术指标 (3)2.面板说明(面板功能按钮和指示灯的布置) (3)3.接线定义 (3)四、CDA503断路器控制单元 (4)1.主要功能及技术指标 (4)2.面板说明 (4)3.接线定义 (5)五、CDA503过流保护断路器控制单元 (5)1.主要技术指标 (5)2.主要功能 (5)3.面板说明 (5)4.LCD液晶显示及键盘操作 (6)5.接线定义7一、CDA503系列产品概述1.使用范围及条件海拔: 不大于2000m 环境温度: -25℃~+65℃相对湿度: 50%~95% 储存温度: -30℃~+85℃2、特点适用范围宽操作简便电机过流保护可远动控制合分闸操作抗震动、抗干扰能力强3.外形尺寸4.运输、验收、存放、安装、维护4.1 运输本产品必须包装运输, 不允许有强烈震动, 不允许倒置.4.2 验收(1)、开箱检查随机文件是否齐全....(2)、基本功能是否正常.注:随机文件..a.控制单元使用说明书一份.... b.合格证一份.4.3 存放产品应存放在室内清洁、干燥通风处, 存放时应小心, 谨防损坏.4.4 安全信息本产品为弱电设备, 但在现场安装、维护时, 附近有危险电压!本设备不能替代可见断开点, 工作时应遵循所在当地批准的安全规程;否则, 将因触高压导致严重人身伤亡.本手册并不能概括设备的安装、运行、维护等等的所有细节, 如有问题请与我公司联系.4.5安装步骤产品应安装在易操作的地方, 根据开关的位置的不同, 可安装在柱上的不同位置.安装步骤. (1)首先固定好控制单元.. (2)将外部接线接好.注: 本手册仅供参考, 如有更改, 恕不另行通知。

ApplicationThe IQAN-SP pressure transducers belong to the family of IQAN accessories developed to complement IQAN control systems. IQAN-SP is a range of 0-5V pressure transducers for mobile hydraulic applications. These transducers are available in two pressure ranges; 35 bar (507 psi) and 500 bar (7250 psi). To make the sensors suitable for mobile equipment, we have focused upon properties such as reliability, electromagnetic immunity and ease of installation. PropertiesReliabilityThe IQAN-SP has stainless steel construction for strength. The sensor cells use thin film technology with no internal o-rings or fluid. The high pressure capability makes the sensor very robust and able to withstand vibration.Electromagnetic immunityThe design of the IQAN-SP has an EMI cap that separates the sensor electronics from the connector. This ensures a high level of EMI protection. InstallationThe two interface types of the IQAN-SP are well designed for the mobile hydraulics industry.The first type, -B, has a G1/4 thread. The hex of the transducer has an integrated face seal to eliminate sealing washers. The integral 3 pin connector is a sealed AMP/Tyco Junior Timer type designed for automotive use.The second type, -D, has a SAE 6 (9/16”-18UNF) thread and an o-ring seal. The connector is a 4 pin Deutsch DT04 type and is attached via a short cable. Both connector types give the sensor IP65 protection for exposed outdoor applications. These features provide for easy installation and removal, even in field conditions.EN 13849-1MTTFd and failure mode distribution available on request.GeneralWeight 0.06 kgOperating temperature -40 °C to 125 °C Storage temperature -40 °C to 140 °C Pressure rangeSP035 0 - 35 barSP500 0 - 500 barOver pressureSP035 Max 100 barSP500 Max 1050 barBurst pressureSP035 Min 150 barSP500 Min 1500 barTotal error (-40°C to 105°C)1)Max 4.0 % FSTotal error ( 40°C to 80°C)1)Max 1.0 % FS Response time2) 5.0 msecEN 13849-1MTTFd, SP035 384 [y]MTTFd, SP500 402 [y]1) Total accuracy includes non- linearity, hysteresis,repeatability and temperature effects.2) Measured from initial value to output at 90%.Electrical specificationsOutput at FS 3) 4.5 VZero output 3)0.5 VSupply Voltage(Vs) 5.0+/-10%Vdc 4) Current supply Max 12.5 mALoad resistor Min 5 kΩLoad capacitor Max 0.1 µF3) The output is ratiometric to supply voltage (Vs)4) The max supply voltage with sensor operatingis 6 Volt. (switch off app. 6.2Volt)Threaded interface-B G1/4 BSP withintegral face seal-D 9/16”-18 UNF, SAE 6with nitrile o-ring Connector-B AMP/TycoIntegral to sensor-D Deutsch DT04-4P Ordering part numbersIQAN-SP035-B 5020026IQAN-SP500-B 5020027IQAN-SP035-D 2820008IQAN-SP500-D 28200092Parker HannifinMobile Systems Division EuropeMölnlycke, Sweden Electronic Control SystemsIQAN-SP SensorsCatalogue MSG17-8371/UK Technical InformationEnvironmental ProtectionEMIISO 11452-2 (immunity vs EM field) ISO 14982 (radiated emission) EN 55022 (conducted emission)ISO 11452-4 (immunity vs injected RF) ESDEN 61000-4-8 (external)Mechanical environment IEC 60068-2-64 Fh, 24-2000 Hz, 31 Grms, 3*8 h (vibration) IEC 60068-2-27 Es (shock)IEC 60068-2-29 Eb (bump)Climate environmentIEC 60068-2-18 Rb3 (water)IEC 60068-2-30 Db (var1, damp, cyclic)IEC 60068-2-3 Ca (damp, heat steady state) IEC 60068-2-2 Bb (heat) IEC 60068-2-1 Ab (cold)IEC 60068-2-14 Nb (change of temperature)Chemical environmentIEC 60068-2-52 Kb (salt mist, cyclic)unit = mmIQAN-SPxxx-DIQAN-SPxxx-Bunit = mm3Parker HannifinMobile Systems Division Europe Mölnlycke, SwedenElectronic Control Systems IQAN-SP SensorsCatalogue MSG17-8371/UKTechnical Information Offer of SalePlease contact your Parker representation for a detailed ”Offer of Sale”.FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.This document and other information from Parker Hannifin Corporation, its subsidiaries and authorized distributors provide product and/or system options for further investigation by users having technical expertise. It is important that you analyze all aspects of your application, including consequences of any failure, and review the information concerning the product or sys-tem in the current product catalogue. Due to the variety of operating conditions and applications for these products or systems, the user, through its own analysis and testing, is solely responsible for making the final selection of the products and systems and assuring that all performance, safety and warning requirements of the application are met.The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are subject to change by Parker Hannifin Corporation and its subsidiaries at any time without notice.WARNING!Parker WorldwideEMEA Product Information CentreFree phone: 00 800 27 27 5374(from AT, BE, CH, CZ, DE, DK, EE, ES, FI, FR, IE, IL, IS, IT, LU, MT, NL, NO, PL, PT, RU, SE, SK, UK, ZA) US Product Information CentreToll-free number: 1-800-272-7537 E d . 2 0 1 6 -0 4 -0 4Europe, Middle East, Africa AE – United Arab Emirates,DubaiTel: +971 4 8127100********************AT – Austria, Wiener Neustadt Tel: +43 (0)2622 23501-0*************************AT – Eastern Europe, Wiener NeustadtTel: +43 (0)2622 23501 900**************************** AZ – Azerbaijan, BakuTel: +994 50 22 33 458****************************BE/LU – Belgium, NivellesTel: +32 (0)67 280 900*************************BG – Bulgaria, SofiaTel: +359 2 980 1344**************************BY – Belarus, MinskTel: +48 (0)22 573 24 00************************CH – Switzerland, EtoyTel: +41 (0)21 821 87 00***************************** CZ – Czech Republic, Klecany Tel: +420 284 083 111******************************* DE – Germany, KaarstTel: +49 (0)2131 4016 0*************************DK – Denmark, BallerupTel: +45 43 56 04 00*************************ES – Spain, MadridTel: +34 902 330 001***********************FI – Finland, VantaaTel: +358 (0)20 753 2500*************************FR – France, Contamine s/Arve Tel: +33 (0)4 50 25 80 25************************GR – Greece, AthensTel: +30 210 933 6450************************HU – Hungary, BudaoersTel: +36 23 885 470*************************IE – Ireland, DublinTel: +353 (0)1 466 6370*************************IT – Italy, Corsico (MI)Tel: +39 02 45 19 21***********************KZ – Kazakhstan, AlmatyTel: +7 7273 561 000****************************NL – The Netherlands, OldenzaalTel: +31 (0)541 585 000********************NO – Norway, AskerTel: +47 66 75 34 00************************PL – Poland, WarsawTel: +48 (0)22 573 24 00************************PT – PortugalTel: +351 22 999 7360**************************RO – Romania, BucharestTel: +40 21 252 1382*************************RU – Russia, MoscowTel: +7 495 645-2156************************SE – Sweden, SpångaTel: +46 (0)8 59 79 50 00************************SK – Slovakia, Banská BystricaTel: +421 484 162 252**************************SL – Slovenia, Novo MestoTel: +386 7 337 6650**************************TR – Turkey, IstanbulTel: +90 216 4997081************************UA – Ukraine, KievTel: +48 (0)22 573 24 00************************UK – United Kingdom, WarwickTel: +44 (0)1926 317 878********************ZA – South Africa, Kempton ParkTel: +27 (0)11 961 0700*****************************North AmericaCA – Canada, Milton, OntarioTel: +1 905 693 3000US – USA, Cleveland(industrial)Tel: +1 216 896 3000US – USA, Elk Grove Village(mobile)Tel: +1 847 258 6200Asia PacificAU – Australia, Castle HillTel: +61 (0)2-9634 7777CN – China, ShanghaiTel: +86 21 2899 5000HK – Hong KongTel: +852 2428 8008ID – Indonesia, TangerangTel: +62 21 7588 1906IN – India, MumbaiTel: +91 22 6513 7081-85JP – Japan, FujisawaTel: +81 (0)4 6635 3050KR – South Korea, SeoulTel: +82 2 559 0400MY – Malaysia, Shah AlamTel: +60 3 7849 0800NZ – New Zealand, Mt WellingtonTel: +64 9 574 1744SG – SingaporeTel: +65 6887 6300TH – Thailand, BangkokTel: +662 186 7000TW – Taiwan, New Taipei CityTel: +886 2 2298 8987VN – Vietnam, Ho Chi Minh CityTel: +84 8 3999 1600South AmericaAR – Argentina, Buenos AiresTel: +54 3327 44 4129BR – Brazil, Cachoeirinha RSTel: +55 51 3470 9144CL – Chile, SantiagoTel: +56 2 623 1216MX – Mexico, TolucaTel: +52 72 2275 4200Catalogue MSG18-8371/UK. POD 09/2018 EMDC© 2008- 2018 Parker Hannifin Corporation. All rights reserved.Your local authorized Parker distributor。

第一章概述一、用途JCQ—503A型静力载荷测试仪是专为土木工程质量检测部门研制的一种智能化多功能仪器。

它配合应变式力传感器或压力传感器、容栅式位移传感器、油泵流量控制器或油泵开关控制器、高压油泵、千斤顶等设备,可进行桩基及其它地基基础的静力载荷测试。

也可进行土木工程中的混凝土构件的结构性能及砌体轴压、抗剪等方面的测试。

二、特点本仪器具有一个荷载测试通道和四个位移测试通道,可直接显示各测试通道的荷载值kN、沉降值mm,而不需人工换算。

荷载通道可以配用小至数十公斤,大至数百吨的各种量程测力传感器和无吨位限制的压力传感器。

荷载通道允许测力传感器并联使用。

可以进行从楼板、碎石桩、天然地基直至数千吨大桩的静力载荷试验。

本仪器有两路各自独立的油泵控制输出,可以对试桩的加载、补载自动控制。

其一为开关量输出,用我所提供的油泵开关控制器直接控制高压油泵,适用于要求不太高的荷载试验。

其二为D/A输出,用来控制我所提供的油泵流量控制器。

该控制器的机芯采用的是进口变频器,可以自动调节高压油泵流量,能同时满足小吨位复合地基试验及大吨位桩基测试多台千斤顶并联工作时对流量精细调节的要求。

仪器与传感器、油泵间采用电缆连接,测试人员可远距离操作,既提高了工作效率,减轻了劳动强度,又大大提高了测试精度。

本仪器荷载通道使用的测力传感器,除具有灵敏度高,线性好、分辨率高、长期稳定性好的优点外,还具有优良的抗偏载和抗侧向力性能,可有效避免反力及加载装置倾斜对测试精度的影响。

沉降测试通道使用本所研制的容栅式位移传感器,其具有的高精度、大量程、无时漂、温漂等优点,完全满足了野外昼夜连续观测对时漂、温漂的严格要求。

仪器可工作于两种不同的工作方式——独立工作方式或联机工作方式独立工作方式工作时仪器内部带有的不断电时钟及大容量非易失数据存储器可对测试数据实现真正的无纸化记录。

仪器内部带有六种不同试验规范所对应的判稳标准(用于自动判稳),一种人工判稳标准(用于特殊场合下人工判稳)、两种快速加载方式(不判稳直接加下一级荷载)。

空气质量气体传感器(型号:MP503)使用说明书版本号:1.4实施日期:2014.08.10声明本说明书版权属郑州炜盛电子科技有限公司(以下称本公司)所有,未经书面许可,本说明书任何部分不得复制、翻译、存储于数据库或检索系统内,也不可以电子、翻拍、录音等任何手段进行传播。

感谢您使用炜盛科技的系列产品。

为使您更好地使用本公司产品,减少因使用不当造成的产品故障,使用前请务必仔细阅读本说明书并按照所建议的使用方法进行使用。

如果您不依照本说明书使用或擅自去除、拆解、更换传感器内部组件,本公司不承担由此造成的任何损失。

您所购买产品的颜色、款式及尺寸以实物为准。

本公司秉承科技进步的理念,不断致力于产品改进和技术创新。

因此,本公司保留任何产品改进而不预先通知的权力。

使用本说明书时,请确认其属于有效版本。

同时,本公司鼓励使用者根据其使用情况,探讨本产品更优化的使用方法。

请妥善保管本说明书,以便在您日后需要时能及时查阅并获得帮助。

郑州炜盛电子科技有限公司MP503空气质量气体传感器产品描述MP503空气质量气体传感器采用多层厚膜制造工艺,在 微型Al 2O 3陶瓷基片的两面分别制作加热器和金属氧化物半 导体气敏层,封装在金属壳体内。

当环境空气中有被检测气 体存在时传感器电导率发生变化,该气体的浓度越高,传感 器的电导率就越高。

采用简单的电路即可将这种电导率的变 化转换为与气体浓度对应的输出信号。

传感器特点本品对酒精、烟雾、异丁烷、甲醛灵敏度高;具有响应恢 复快、低功耗、检测电路简单、稳定性好、寿命长等优点。

主要应用用于家庭环境及办公室有害气体检测、自动排风装置、 空气清新机等。

技术指标表1产品型号 MP503产品类型 平面半导体气体传感器金属封装标准封装 检测气体 酒精、烟雾、异丁烷、甲醛10~1000ppm(酒精)≤24V DC 检测浓度 回路电压 V C 加热电压 V H 负载电阻 R L加热电阻 R H标准 电路 条件 5.0V ±0.1V AC or DC可调95Ω±10Ω(室温) ≤300mW 标准 测试 条件 下气 敏元 件特 性 加热功耗 P H敏感体R S 1K Ω~30K Ω(in 50ppm 酒精)电阻 Rs(in air)/Rs(in 50ppm 酒灵敏度 S精)≥5 浓度斜率 α ≤0.6(R 100ppm /R 30ppm 酒精) 温度、湿度 标准测试电路 预热时间20℃±2℃;65%±5%RHV C :5.0V ±0.1V ; V H :5.0V ±0.1V标准 测试 条件图1 :传感器结构图不少于48小时基本电路图2: MP503测试电路说明:上图为MP503传感器的基本测试电路。

用户手册BPS305A50400KA2HA1A无锡必创传感科技有限公司免责声明本文档中给出的信息决不应被视为条件或特性的保证。

对于本文给出的任何示例或提示、本文所述的任何典型值和/或关于器件应用的任何信息,无锡必创传感科技有限公司特此否认任何类型的保证和责任,包括但不限于不侵犯任何第三方知识产权的保证。

信息有关技术、交货条款、条件和价格的更多信息,请联系无锡必创传感科技有限公司目录01.产品描述 (4)02. 功能描述 (5)03. 规范 (11)04. 命名图例 (12)05. 封装信息 (13)BPS305A50400KA2HA1A01. 产品描述BPS305A50400KA2HA1A 产品是一款集成扩散硅压阻式进气歧管压力传感器,其基于MEMS 芯片和ASIC 芯片的系统集成封装。

传感器通过MEMS 芯片将输入压力转换为电桥输出信号,再通过ASIC 芯片将电桥输出信号转换为模拟电压输出。

该传感器主要用于测量发动机进气管的压力。

高精度和高灵敏度特性使其非常适合于先进的汽车应用以及工业和消费应用。

1.1特征支持以下功能: ●高精度±1%FS @ 0℃~130℃●宽工作温度范围(-40℃~150℃) ●符合车载使用标准 ●环保贴片式封装 ●输出电压钳位1.2应用目标应用目标:●发动机进气歧管压力测量●工业控制 ●医疗应用 ●气象站●高度计02. 功能描述压力传感器由硅微压阻式MEMS压力传感器芯片和专用调理集成电路(ASIC)组成。

硅微压阻式MEMS压力传感器芯片通过四个应变敏感电阻构成的惠斯通电桥,输出与被测量压力成比例的电压信号,该信号被ASIC芯片放大、温度补偿和线性化,以获得与施加压力成规定关系的输出电压。

传递函数的线性化和温度补偿由ASIC中的数字处理电路实现,通过多项式补偿算法和多个温度下的多点压力标定技术,实现了全工作温度范围内的高精度压力测量。

压力传感器的传递函数由以下参数创建:●最小和最大额定压力●最小和最大额定压力下的电压值●钳位电压完整校准算法所需的所有参数(如偏移、增益、偏移和增益的温度系数以及线性化参数)在校准后确定并存储在ASIC 内部的E²PROM 中。

USER MANUALSALES OFFICE (301) 975-1000TECHNICAL SUPPORT (301) 975-1007Part# 07M503P-C Doc# 074201U Rev. D Revised 1/21/08An ISO-9001Certified Company1.0 WARRANTY INFORMATIONPatton Electronics warrants all Model 503P and 503PC components to be free from defects, and will—at our option—repair or replace the product should it fail within one year from the first date of shipment. This warranty is limited to defects in workmanship or materials, and does not cover customer damage, abuse or unauthorized modification. If this product fails or does not perform as warranted, your sole recourse shall be repair or replacement as described above. Under no condition shall Patton Electronics be liable for any damages incurred by the use of this product. These damages include, but are not limited to, the following: lost profits, lost savings and incidental or consequential damages arising from the use of or inability to use this product. Patton Electronics specifically disclaims all other warranties, expressed or implied, and the installation or use of this product shall be deemed an acceptance of these terms by the user.2.0 SERVICE AND SUPPORT1.2 SERVICEAll warranty and nonwarranty repairs must be returned freight prepaid and insured to Patton Electronics. All returns must have a Return Materials Authorization number on the outside of the shipping container. This number may be obtained from Patton Electronics Technical Support: (301) 975-1007; ; or,******************.Notice: Packages received without an RMA number will not be accepted.Patton Electronics' technical staff is also available to answer any questions that might arise concerning the installation or use of your Patton Model 503P and 503C. Technical Service hours: 8AM to 5PM EST, Monday through Friday.1.3 CE NOTICEThe CE symbol on your Patton Electronics equipment indicates that it is in compliance with the Electromagnetic Compatibility (EMC) directive and the Low Voltage Directive (LVD) of the Union European (EU). A Certificate of Compliance is available by contacting Technical Support.12.0 GENERAL INFORMATIONThank you for your purchase of this Patton Electronics product. This product has been thoroughly inspected and tested and is warranted for One Year parts and labor. If any questions arise during installation or use of the unit, contact Patton Electronics Technical Support: (301) 975-1007; ; or,******************.2.1 PRODUCT DESCRIPTIONThe Patton Model 503P and 503PC guard PC parallel interfaces against data loss and damage due to transient surges. These units employ a solid state circuit using Silicon Avalanche Diodes, and can handle repeated surges up to 1500 Watts. The Model 503P connects directly between the DB-25 parallel port of a PC or workstation and the parallel printer cable. The Model 503PC connects to the parallel printer cable, and then plugs directly into the 36-pin Centronics®printer port. Both units divert surge energy to chassis ground through the metal connector shell. For complete protection of your parallel line, we recommend that a Model 503P and 503PC be used together, one at each end of the line.Warning:These products will not provide complete protection should your equipment be subject to a direct lightning hit.2.2SURGE PROTECTION BENEFITSThe method of surge protection used in the 503P and 503PC adds four benefits to your syste.1. High Surge Capability. The 503P and 503PCdissipate up to 1.5 kwatts for up to 1 mes.2.Quick Response. The 503P and 503PC feature a responsetime of 500 nsec, 503PC clamps at +8V and -3V the 503Pclamps to 6.8V3.Low Impedance. Connect the 503P directly to RS-232 portswith minimal load to your system — about the same as agender changer.4.“Fail Safe” Design. Unlike some other surge suppressors, the503P fails short to ground should your system experience anextreme transient or severe current overload. Therefore, Iifthe unit fails, data and surges are diverted to ground instead ofback into your equipment.23.0 INSTALLATIONPatton's Model 503P and 503PC units are simple to install, and require no user configuration. Follow these installation steps.1. Turn off your PC/printer’s power and disconnect the powercord(s) from the wall outlet(s).2. Unplug (disconnect) the existing connection between theparallel cable and your PC/printer’s parallel port(s).3. Install the Model 503P between the parallel cable and the DB-25 parallel port. Install the Model 503PC between the parallelcable and the Centronics®-36 connector of your parallelprinter. For best results, both protectors should be used–oneat each end of the cable.3APPENDIX APATTON MODEL 503P AND 503C SPECIFICATIONSLInes Protected: Model 503P protects 24 lines on the DB-25parallel interface; Model 503PC protects 34lines on the 36-pin Centronics®interface. Peak PowerDissipation: 1500 Watts for up to 1 msecClamp Voltage: 503P6.8 V; 503PC +8, -3VGrounding: Surge energy diverted to chassis groundthrough metal D-shell (or 36-pinCentronics®) connectors. Alternate groundconnection for Model 503P provided byexternal grounding wire.4NOTES__________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________5NOTES__________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________ __________________________________________6Dear Valued Customer,Thank you for purchasing Patton Electronics products! We do appreciate your business. I trust that you find this user manual helpful.We manufacture one of the widest selections of data communications products in the world including CSU/DSU's, network termination units, powered and self-powered short range modems, fiber optic modems, interface converters, baluns, electronic data switches, data-line surge protectors, multiplexers, transceivers, hubs, print servers and much more. We producethese products at our Gaithersburg, MD, USA, facility, and can custom manufacture products for your unique needs.We would like to hear from you. Please contact us in any of the following ways to tell us how you like this product and how we can meet your product needs today and in the future.Web: Sales E-mail: ****************Support E-mail: ******************Phone - Sales (301) 975-1000Phone - Support (301) 975-1007Fax: (301) 869-9293Mail: Patton Electronics Company7622 Rickenbacker DriveGaithersburg, MD 20879 USAWe are committed to a quality product at a quality price. Patton Electronics is ISO 9001 certified. We meet and exceed the highest standards in the industry (CE, UL, etc.).Please contact us and let us know how we may provide you with the answers to your needs.Thank you.Burton A.PattonVice PresidentP.S. Please tell us where you purchased this product._________________________________________________________ __________________________________________________________________________________________________________________ _________________________________________________________ _________________________________________________________。

压力传感器使用说明书1211131000/100110141100/11019158167176185194203212221一.仪表选型注1:标准型:仪表出厂前具有继电器输出和电压脉冲输出。

注2:如果仪表选串行通讯口,报警只能选该型号。

二.接线图电源报警2(-)AC90-260V (+)RS484报警3(-)通讯SSR 输出-(+)(D2)24V/20mA +电流互感器输入继电器AC5A 4-20mA 输出+报警1或热电偶PT100第二输出(带PD )安装尺寸(面板安装)1000/10011100/110150145+0.692+0.845+0.692+0.892+0.845+0.6深100mm深100mm深105mm注:为确保安装正确,请参阅英文版手册中的注意事项和警告。

三.功能说明1)输入种类热电偶:K、J、N、S、R、T热电阻:PT100电压:0-50mv,10-50mv电流:0-20mA,4-20mA,0-10mA(电流输入需在输入端并接2.5Ω或5Ω精密电阻)电流互感器输入2)输出输出1:继电器:端子额定电流5A/220VacSSR:24V/20mA电压脉冲DC输出:4-20mA输出2:用报警输出1,通过软件组态改为PD控制功能3)报警功能报警1可以带PD控制,触点电流5A报警2和3触点为常开,可以通过内部跳线改为常闭触点容量为3A/220Vac4)数字通讯(电流环/RS485)如果仪表有1200波特率无源电流环接口,接收二极管在端子8(RX+)和端子9(RX-)传输晶体管端子10(TX+)和(TX-)标准配置(并联到串行口)联接到二极管阻值为1千欧,集电极电阻为100Ω对串联连接,接到二极管阻值为100欧若配置为4线制RS485(1200波特率),输入端为8(RX+)和9(RX-)传输为10(TX+)和11(TX-)[参阅硬件组态]四.显示面板和按键说明A:显示测量值B:显示设定值1)显示过程设定值2)当AL1,AL2,AL3/HB灯闪烁时,设定报警值显示3)当字母“P”前面显示[0-99%]显示主输出功率4)可显示组态参数F:主输出灯,当第一输出动作时该灯亮G:报警输出指示C :功能键“F ”1)F 键用来选择设定值或报警值以便读取和修改设定值,如果未按住F 键,10秒钟后,修改值将自动存贮,同时返回显示过程设定值。

PDHD-503剩余电流式电气火灾监控探测器使用说明书(1-12路漏电)帕德赫德电气技术(深圳)有限公司网址:全国服务热线:400-803-0813本产品为智能型电子消防产品,使用前请详细阅读本说明书,并在使用前做通电测试。

如需要技术支持,请拨本公司售后服务热线电话获得技术支持,本产品如有技术升级,恕不另行通知。

目录一.概述 (1)二.使用范围 (1)三.使用条件和产品功能 (1)四.工作状态及设置说明 (2)五.安装说明 (7)六.注意事项 (9)七.两种不同接地方式的剩余电流监控保护系统应用 (9)八.存贮和运输 (10)九.售后服务 (10)概述PDHD-503本产品是一种智能型剩余电流式火灾监控探测器,它采用32位微型控制器、可全天候有效地监控被保护电气线路中由于漏电可能发生的火灾隐患,实时处理当前剩余电流值,将监测到的异常参数通过CAN总线通讯网络发送到监控中心。

同时发出声光报警信号,及时提醒工作人员检查故障,排除可能发生的电气隐患,防止重大事故的发生。

PDHD-503本产品实时监控度高、可靠性强,具有小型化、集成度高、功能齐全、简单实用、安装方便等特点。

本机采用1路4位数码管显示,亮度高,适合安装在恶劣的工作环境下。

二.使用范围PDHD-503剩余电流式火灾监控探测器依据GB14287.2—2014《电气火灾监控系统第二部分:剩余电流式电气火灾监控探测器》而设计,并符合本标准要求。

可广泛应用于工厂、学校、大型库房、办公室、商业建筑、宾馆、民用住宅及综合娱乐场所等电气火灾发生几率大、电气线路复杂的变电系统中。

但本产品不适用于易燃易爆和强腐蚀性环境。

剩余电流式电气火灾监控探测器,即可以为保护相对独立的用电区域而单独安装,也可以联网组成电气火灾监控报警系统。

三.使用条件和产品功能1、本产品的正常使用条件环境温度:-10℃—+50℃,24小时平均温度不超过35℃;相对湿度:10%—95%;海拔高度:小于4000米;污染等级:Ip3,无霜雪雨水侵蚀;2、主要技术参数额定工作电压:Ac220V50HZ;最大功耗:5W;报警输出:无源开关(俗称触点),触点最大容量220V5A;报警光讯号:红色LED;故障光讯号:黄色LED;报警声讯号:72db—115db;报警设定值:300mA—1000mA连续可调,最小可调1mA;漏电报警误差:设定值的80%—100%;四.工作状态及设置说明剩余电流式电气火灾监控探测器正常运行时无需人工干预。

Pressure sensor, Series PE5- Operating pressure -1 ... 0 -1 ... 1 0 ... 6 0 ... 10 0 ... 12 bar- electronic- Output signal analog 0 - 10 V DC, 4 - 20 mA- Output signal digital 2 x PNP, NPN, Push-pull PNP, NPN, Push-pull PNP, NPN, push-pull, 1xIO-Link- Electr. connection Plug M12x1 4-pin- Compressed air connection Internal thread G 1/4Type electronicCertificates CE declaration of conformity, cULus,RoHS, Conforms with REACH, Free ofsubstances that impair surface wetting inthe coating processCompressed air connection Internal thread G 1/4Ambient temperature min./max.0 ... 60 °CMedium temperature min./max.0 ... 60 °CMedium Compressed air (max. 40 μm)Max. oil content of compressed air40 mg/m³Measurement Relative pressureDisplay LCD display, 4 digits, Color setting: greenor redUnits displayed bar psi kPa MPa inHgSwitching logic NO/NC (adjustable)Shock resistance max.30 gVibration resistance 5 g (10 - 150 Hz)Precision (% of full scale value)±1.5% in temperature range of 10 - 30°C± 2 % including temperature driftRepeatability (% of full scale value)± 0,2 %Switching time 5 msSwitching point adjustable 0 ... 100%Resetting point adjustable 0 ... 100%Hysteresis adjustableDelayed hysteresis adjustableWindow function adjustableDC operating voltage min./max.17 ... 30 V DCAnalog output0 - 10 V DC, 4 - 20 mAQuiescent current consumption40 mAAnalog output linearity± 0.5% of the final valueMaximum load (analog current output)600 ΩShort circuit resistance Max. 600 ohms (current output) Min. 3Kohms (voltage output)Mounting types Directly on hat rail and wall mounting Forpanel installation using mounting kit viadouble nippleProtection class IP65 IP67 with connections assembledElectr. connection Plug M12x1 4-pinWeight0,04 kgOutput signal0 - 10 V DC-4 ... 20 mA1) The IO-Link device description (IODD) for the PE5 pressure sensor is available for download in the Media Centre.1) M12x1 electrical connection2) Mounting for hat rail and wall mounting3) Alternative pressure connection (G1/4) closed with plug4) Pressure connection G1/41) M12x1 electrical connection2) Mounting for hat rail and wall mounting3) Alternative pressure connection (G1/4) closed with plug4) Pressure connection, tubing Ø 4 mm1) LCD display2) Control panel with 3 buttonsH: HysteresisSP = switching pointRP = resetting pointOut (NC): switch output, break contact Out (NO): switch output, make contactH: HysteresisSP = switching pointRP = resetting pointOut (NC): switch output, break contactOut (NO): switch output, make contactdS: switching delaydR = reset delay1) period of pressure over the switching point dS: pressure sensor does not switch2) Period of pressure over the switching point > dS: pressure sensor switches3) Period of pressure under the resetting point > dR: pressure sensor switchesFH: pressure band, upper valueFL: pressure band, lower valueOut (NC): switch output, break contact Out (NO): switch output, make contact1) Internally stored parameter2) Adjustable parameter3) Output valueRL = storable postionRL = storable postionAllocation operational voltage + UBswitch output Out2, analog: A or V, digital: PNP, NPN, push-pull0 Vswitch output Out1, digital: PNP, NPN, push-pullAllocation Supply Voltage Switch output PNP/NPN/push-pull, switchable0 VSwitch output PNP/NPN/push-pull/leakage mode, digital switch input PNPAnalog output ( 0 to 10 V DC, 4 to 20 mA)Your local contact:/contactus/EmersonAutomationSolutions/company/Emerson-Automation-SolutionsAn example configuration is depicted on the title page. The delivered product may thus vary from that in the illustration. Subject to change. This Document, as well as the data, specifications and other information set forth in it, are the exclusive property of AVENTICS GmbH. It may not be reproduced or given to third parties without its consent. Only use the AVENTICS products shown in industrial applications. Read the product documentation completely and carefully before using the product. Observe the applicable regulations and laws of the respective country. When integrating the product into applications, note the system manufacturer's specifications for safe use of the product. The data specified only serve to describe the product. No statements concerning a certain condition or suitability for a certain application can be derived from our information.The information given does not release the user from the obligation of own judgement and verification. It must be remembered that the products aresubject to a natural process of wear and aging.of the Emerson family of companies. All other marks are the property of their respective owners. © 2020 Emerson Electric Co.All rights reserved.2020-12。

油压传感器,油压压力变送器,河南压力传感器

正负压压力变送器,恒压供水压力传感器,投入式液位变送器,防雷击液位变送器,锅炉压力传感器,微差压变送器,超高温压力传感器,超高压压力传感器,平膜压力传感器,防腐蚀压力变送器,通风管道压力变送器,高温微压变送器,空压机压力变送器,空调风压变送器,PY500智能数字压力控制仪表,动静态汽车称重设备,称重测力传感器

PTP503压力传感器/变送器采用全不锈钢封焊结构,具有良好的防潮能力及优异的介质兼容性。

广泛用于工业设备、水利、化工、医疗、电力、空调、金刚石压机、冶金、车辆制动、楼宇供水等压力测量与控制。

量程:0~1~150(MPa)

综合精度:0.2%FS、0.5%FS、1.0%FS

输出信号:4~20mA(二线制)、0~5V、1~5V、0~10V(三线制)

供电电压:24DCV(9~36DCV)

介质温度:-20~85~150℃

环境温度:常温(-20~85℃)

负载电阻:电流输出型:最大800Ω;电压输出型:大于50KΩ

绝缘电阻:大于2000MΩ(100VDC

密封等级:IP65

长期稳定性能:0.1%FS/年

振动影响:在机械振动频率20Hz~1000Hz内,输出变化小于0.1%FS

电气接口(信号接口):四芯屏蔽线、四芯航空接插件、紧线螺母

机械连接(螺纹接口):1/2-20UNF、M14×1.5、M20×1.5、M22×1.5等,其它螺纹可依据客户要求设计

产品名称:PY602压力温度仪表

规格:

产品备注:数显压力温度控制仪表|智能压力温度表|佛山市博润测控仪表有限公司

产品说明

PY602数显压力-温度控制仪表

产品特点及结构:

具有整机体积小、重量轻、耗电省、功能齐全、工作可靠、使用方便灵活,配用我公司PT100-系列高温熔体压力传感器或常温压力传感器,作为高精度压力测量与控制,可广泛地使用于液压、石油、塑料、橡胶、印染、纺织等行业的压力显示和自动化控制场合,还可与其他厂家的电阻应变式压力传感器配套使用;可以设定上下限值报警,具有发光管报警指示、继电器触点输出控制外部执行机构;具有高精度的电压输出模块、电流输出模块、继电器输出控制模块以及通讯模块供用户选择

主要技术参数:

显示器:双层四位高亮度绿色和红色发光数码管

显示分辨率:0001

显示数值范围:-001~-999~0001~9999Mpa(小数点可变),温度:000.1-400.0

仪表精度:0.25%FS±1位

压力输入信号:2mV/V、3.3mV/V、4-20mA、0-5VDC、0-10DC(定货时说明)

温度输入信号:J、K、E型热电偶

采样速度:20次/秒

输出控制:与满量程信号成线性的电压或电流输出;RS232;RS485

报警范围:-001~-999~0001~9999Mpa(小数点可变)

效准指示:显示传感器满量程80%值(传感器应空载),效准指示(CAE)亮

使用温度及湿度:0-55℃,≤80%RH

电源要求:85-265VAC50Hz-60Hz

外型尺寸:96×96×100mm

开孔尺寸:92×92mm。