V52信号描述

- 格式:pdf

- 大小:350.22 KB

- 文档页数:10

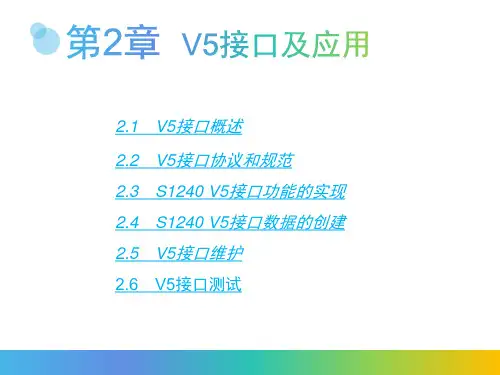

第三部分V5接口概述目录课程说明课程介绍本教材介绍了V5接口的基本原理,主要内容包括:✓V5接口概述✓V5接口的三层结构与对接介绍课程目标完成本课程学习,学员能够:✓了解V5接口的基本原理✓掌握V5接口的数据配置方法✓掌握用户端口的数据配置方法✓掌握V5接口查询和维护✓掌握用户端口的查询和维护✓了解V5接口的三层结构✓掌握正常的V5接口对接流程✓掌握正常的呼叫流程第一节 V5接口基本原理本节内容主要讲述V5接口的产生、基本的体系结构、所包含的基本协议、工作流程等原理性的内容,重点要求掌握V5接口标识、物理/逻辑C 通道、主/次链路等概念,并明晰哪些参数值需要由AN与LE共同协商决定。

1.1 概述1.1.1 V5接口的由来V5接口是专为接入网发展而提出的本地交换机和接入网之间的接口。

90年代,美国贝尔通信研究所(BELLCORE)把交换机与接入设备之间的模拟连接改变为TR303接口的标准化的数字连接,解决了过去模拟连接传输性能差、设备费用高、数字业务发展难等问题。

1993-1994年,欧洲电信标准化组织(ETSI)颁布了V5接口标准,使该接口更加完善、通用性更好。

鉴于V5接口的重要性和接入网发展的迫切性,国际电信联盟(ITU-T)于1994-1995年以加速程序通过了V5接口规范,包括V5.1(ITU-T建议G.964)和V5.2接口规范(ITU-T建议G.965)。

我国相应的V5接口标准经过多次评审和修改,于1996年10由电信总局发布,12月由原邮电部颁布并在1997年3月起实施(YDN 020-1996,YDN 021-1996)。

1.1.2 引入V5接口的优势V5.2接口是一个适应范围很广、标准化程度相当高的数字接口,其主要优点表现在以下几个方面:(1)V5.2接口的通用性、开放性和标准化引入V5.2接口可以有效地取代交换机原有的模拟接口、各种专线及ISDN用户接口。

由于V5接口是统一和开放的,不同厂家的交换设备和不同厂家的接入网设备可以互相组合,利于在平等的基础上公平竞争,使网络运营者能够选择最好的系统设备组织接入网。

移动Adhoc⽹络的特点及应⽤移动Ad hoc⽹络的特点及应⽤1 Ad hoc⽹络的定义Ad hoc⽹是⼀种多跳的、⽆中⼼的、⾃组织⽆线⽹络,⼜称为多跳⽹(Multi-hop Network)、⽆基础设施⽹(Infrastructure less Network)或⾃组织⽹(Self-organizing Network)。

整个⽹络没有固定的基础设施,每个节点都是移动的,并且都能以任意⽅式动态地保持与其它节点的联系。

在这种⽹络中,由于终端⽆线覆盖取值范围的有限性,两个⽆法直接进⾏通信的⽤户终端可以借助其它节点进⾏分组转发。

每⼀个节点同时是⼀个路由器,它们能完成发现以及维持到其它节点路由的功能。

Ad hoc⽹络凭借其基于IP的分组交换技术,可以提供⾼速率(现有的移动蜂窝⽹的传输速率不超过2Mbit/s,⽽Ad hoc⽹络在2~6GHz频段上可提供2~50Mbit/s的数据速率)的数据业务和多媒体业务,从⽽成为第三代全球移动通信系统的⼀个重要补充;另⼀⽅⾯,Ad hoc⽹络也可以作为Internet⽹络的⽆线延伸。

2 Ad hoc⽹络的特点Ad hoc⽹络的主要特征有以下⼏点:1)最⼩化的基础设施⽀持。

2)⾃组织和⾃管理。

既然⽹络基础结构是不具可⽤性的,这些节点必须通过⾃⼰组织和维护⽹络(要求有⾃主的分布式控制)。

节点能侦测到其它节点的存在,并和它们⼀起加⼊⽹络。

3)⼤部分甚⾄所有节点都在移动,导致⽹络拓扑动态变化。

当节点移动时,⽹络拓扑变化,新的节点加⼊,⼀些节点离开,或者是⼀些路由中断。

经常出现频繁的、临时的、突发性的⽹络连接损失。

4)⽆线链路。

既然⼤多数节点是移动的,那就意味着只能是⽆线通信⽅式。

5)节点既是⼀个主机,⼜是⼀个路由器。

⼀个节点可能想连接到超出单跳距离外的另⼀个节点,那么对每⼀个节点⽽⾔,路由功能是必需的,因为⽹络没有下部结构⽀持,节点不必是同⼀类型(可以是电话、PDA、膝上型电脑、传感器等)。

1.原理说明系统原理ZPW-2000A型无绝缘移频轨道电路系统,与UM71无绝缘轨道电路一样采用电气绝缘节来实现相邻轨道电路区段的隔离。

电气绝缘节长度改进为29m,由空心线圈、29m长钢轨和调谐单元构成。

调谐区对于本区段频率呈现极阻抗,利于本区段信号的传输及接收;对于相邻区段频率信号呈现零阻抗,可靠地短路相邻区段信号,防止了越区传输,这样便实现了相邻区段信号的电气绝缘。

同时为了解决全程断轨检查,在调谐区内增加了小轨道电路。

ZPW-2000A型无绝缘移频轨道电路将轨道电路分为主轨道电路和调谐区小轨道电路两个部分,并将短小轨道电路视为列车运行前方主轨道电路的所属“延续段”。

主轨道电路的发送器由编码条件控制产生表示不同含义的低频调制的移频信号,该信号经电缆通道(实际电缆和模拟电缆)传给匹配变压器及调谐单元,因为钢轨是无绝缘的,该信号既向主轨道传送,也向小轨道传送。

主轨道信号经钢轨送到轨道电路受电端,然后经调谐单元、匹配变压器、电缆通道,将信号传至本区段接收器。

调谐区小轨道信号由运行前方相邻轨道电路接收器处理,并将处理结果形成小轨道电路轨道继电器执行条件通过(XG、XGH)送至本轨道电路接收器,做为轨道继电器(GJ)励磁的必要检查条件之一。

本区段接收器同时接收到主轨道移频信号及小轨道电路继电器执行条件,判决无误后驱动轨道电路继电器吸起,并由此来判断区段的空闲与占用情况。

主轨道和调谐区小轨道检查原理示意图见图2-1。

该系统“电气—电气”和“电气—机械”两种绝缘节结构电气性能相同。

2.电路工作原理及冗余设计2.1 发送器2.1.1 用途ZPW-2000A型无绝缘移频轨道电路发送器在区间适用于非电码化和电码化区段18信息无绝缘移频自动闭塞,供自动闭塞、机车信号和超速防护使用。

在车站可适用于非电码化和电码化区段站内移频电码化发送,并可作站内移频轨道电路使用。

2.1.2 原理框图及电路原理简要说明同一载频编码条件,低频编码条件源,以反码形式分别送入两套微处理器CPU中,其中CPU1产生包括低频控制信号Fc的移频信号。

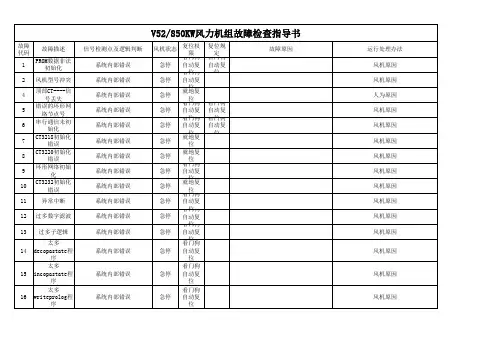

AAlarm low oil lubrication flow润滑油压低警告A.control 10:00v p.vel:控制电压10:00v,真实速度Automatic reestablish ok自动从新建立Asym vcltL2:452v(others):398v三相电压不平衡L2:452v 其他395V Automatic reestablish failed自动从新启动失败Alarm log reestablished报警记录从新建立A.CTRL 10:00v pvel:0.0s叶片变浆时控制电压与变浆角度不同Ambient temperature low -21℃环境温度低-21℃CCont=zfeed back r.failed:0K502不能打开,k502的反馈被动Ct 3220 initial error pos:10Ct 3220在pos.10初始化错误Cannot synchronize 445 RPM,st 0445转与发电机转速不匹配Can not synchronize 1167 RPM1167转与发电机转速不匹配Chock sensor trigged!1008.6RPM栔形传感器触发了Cont=0 feed back r.failed:0K500不能打开DDc overvoltage 869v变频直流电压高(标准800v)EExtr low voltage l1 326v外部一相电压低Error on all wind sensors风速仪故障Extreme yawerror 15.8m/s 45.2℃在15.8m/s偏航过量超过45.2℃Emergency circuit open紧急回路打开Emerg→stop,emc not conn紧急回路不能打开Exex low valtage l1 109vL1相低电压109vError yawcontrol:30000(0)偏航控制错误30000→不能顺时针(30010:不能逆时针) External 24v power supply外部的24v电压没有供给Exte RPM guard 1639 RPM so外部超速保护1639转Error temp sensor R402 205度R402温度传感器故障External RPM guard,1181RPM外部转速保护1181转Emery→stop emc not急停按钮打开Exthigh rotorliv phase:2外部超高转速第二相Ext high cur gridinv l2电网l2高电流Error 102 acknowladged manual手动过失操作102External 24v power supply eg外部24v电压没供给FFeed back=1 brake刹车反馈为主动(闭合)Feed back=1 yawing cw 0顺时针偏航反馈为1(开启)Feed back=1;hydrdnlicmotor液压电机反馈为主动(闭合)Feed back=0;naceue gan s307机舱风扇反馈为被动(开启)Freguency error 1:55.40+jz频率错误GGen.RPM:7524RPM,opst<run发电机转速7524转,状态为运行Grirlinv hw error l1电网侧变频板硬件故障HHigh temp vcs system 59度变频vcs系统温度为59℃High curr gen 0 l1:90A发电机l1相高电流High temp rotor lnv l2 70度发电机转子的l2相高温High temp grid lnv,l1 80度电网l1相高温80度Hydr temp perature high 66度液压油温度高High temp gear bearing1:91度齿轮箱轴承温度高High windspeed 25.2m/s高风速25.2m/sHigh remp erature gen1:136度发电机高温136度High temp vcp board 64度Vcp板的温度为64度High hydr pressure 249.0 bar液压站压力高(压力标准180-200) High gear temp perature:81度齿轮温度高High temp perature break disk刹车温度高Heating naceue and gear oil加热机舱和齿轮油Hydr oil temp too low液压油温度低Heating slipring (H=0/ph=1)0加热滑环IInvaid dats vs id:1风俗传感仪传送无效信号LLow gear temp:0 -0.3度齿轮油温度低-0.3度Low working pressure:129.2 bar低工作压力129.2bar,液压站压力不够Low processor temp in top顶部控制器低温Leak current 32A漏电流32ALnvalid turbine ld-number无效的风机ld号(ld号→风机编号) Low gear oil level齿轮油低油位Low oil-level hydraulic液压油位低Low batty ct3601 nacelle电3601电压电压不够Low batty ct291291的电池电压不够Item 23 updaterd by user 023被某人自动更新Low gear oil pressure齿轮油压力低Low oil level,1546RPM/51齿轮油温低,1546RPM/51℃MMax time hudy pumping 60 sec打压超时,超过60sMax auto yaw time 1000 sec最大自动偏航时间1000sMax rotor RPM:32.0 RPM叶轮超速Max run time without oil condi旁路滤芯运行超时Nmunication with vcpM和vcp没有通讯(vcpm微处理器) No communication with top和上面没有通讯No yawwpulscs 300l0,900s没有偏航脉冲New service state 2,2新的服务模式OOvp active vdc 972v state 0Ovp激活972v(ovp过电压保护) PPitch A ret:20.4? act:90变浆角度20.4℃,真实值90℃Pich too low:50.0?<80.0变速太慢50<80(80为标准) Phase l:2 failureL2相有错误Pitch A pos:29.87 vel:320.4?s变速位置29.87℃速度320.4℃/s Press,drop hydr figter 205度液压站滤芯达到205℃Pause over rcs远程复位Pause pressed on keyboard服务模式下按pause键,暂停RRotor:29.4RPM,gen:0.0RPM发电机的转速为0,风轮的转速29.4 Remote reboot远控从新启动Rotor inv hw error l2转子侧变频板有故障(l2相)Rcs disconnected dut to 0远控断开连接Rcs reconnected远控尝试连接Remote service panel taken 01远控的服务模式已经启动Remote service panel gree 0 0远控的服务模式启动结束SSafety – pressostst brake稳压器安全刹车Slip 23 above limits 2Start auto-outyawing lcw自动偏航顺时针转Stop auto-outyawing自动偏航停止Slipring temp too low启动温度太低TToo many auto-restavts:10自动启动次数太多,10次Timeout generator reconnecting发电机连接超时Telegram lost during xmission数据在传送中丢失Too many arcnet recong 10Ct3614arcnet的从新设置次数为10 Thermo error ext gen.fan F3491过载保护F3491的错误Trip Q8 feedback error反馈错误Q8被触发Top ct3220 missing(pos:10)顶部控制模块ct3320的(pos10)故障Thermo error gearoil cooler F410齿轮油冷却器的过载保护错误Thermo error hudraulicmotor液压油泵过载的保护错误Tow.acc X,alarm:0.38m/s^2.塔筒加速计(防震作用)警告0.38m/? Thermo error lnt vcs fan F546过载保护F546错误Timeout/checksum err vs.id:1风速仪检查Timeout comm.tower acc与顶部数据连接超时Thermistor fail oil condition齿轮油样温度接触器报故障Tow accX.warn:0.42m/s^2塔筒切速器每秒0.42m(晃动剧烈) Telegram lost during reception数据丢失Thermoerror naceue fan F307机舱风扇热F307保护故障UUs error ,turbine paused风速仪故障,风机暂停VVcpm state gueue overfiow维斯塔斯变频系统序列溢出Vdf data lost code 50,0Vdf数据的代码丢失Vcs low water level冷却水位置低Vaire block temp low (pause)阀块温度低WWatch dog was not trigged看门狗没有触发Warn low oil lubrication flow润滑油位低Warn difg press rough filter不同的滤芯操作压力(滤芯已坏) Warning loy reestablished警报记录从新复位(启动)Ws,invalid data:0无效警报数据为0YYawing manually stopped手动偏航停止。

A-B1320 V5接口与信令系统学习目标:●熟悉V5协议体系结构和各层功能●了解V5协议各层工作过程●熟悉V5第三层协议消息和常见信令流程●掌握V5信令跟踪方法并能对信令进行分析目录第一章接入网接口概述 (1)1.1接入网V系列接口 (1)1.2ZXA10(OLTB)的V5接口 (1)第二章V5协议 (4)2.1基本概念 (4)2.2V5.2协议分层体系结构 (5)2.2.1V5.2协议物理层 (6)2.2.2V5.2协议数据链路层 (6)2.2.3V5.2协议应用层 (8)2.3V5.1协议与V5.2协议的比较 (14)2.4V5协议各层功能在ZXA10(OLTB)中的分布 (14)第三章V5信令分析 (17)3.1V5第二层消息 (17)3.1.1封装功能子层消息结构 (17)3.1.2数据链路子层消息结构 (18)3.2V5第三层消息 (19)3.2.1消息结构 (19)3.3常见V5信令流程 (21)3.3.1V5.2接口启动 (21)3.3.2PSTN呼叫建立 (22)3.3.3PSTN呼叫拆除 (23)3.4V5信令跟踪工具的使用 (24)3.4.1启动跟踪 (25)3.4.2获取跟踪数据 (27)3.4.3结束跟踪 (30)第四章V5接口数据配置 (32)附录A PSTN协议消息的信息单元类型及内容 (33)附录B BCC协议消息的信息单元类型及内容 (38)附录C 控制协议消息的信息单元类型及内容 (41)附录D 链路控制协议消息的信息单元类型及内容 (45)附录E 保护协议消息的信息单元类型及内容 (46)附录F V5第三层消息类型编码 (49)- 4 -第一章接入网接口概述1.1接入网V系列接口接入网和交换机之间的数字接口统称为“V”接口,包括V1、V2、V3、V4、V5等类型。

1988年版的CCITT建议Q.512中规定了V1~V4接口,但其中V1、V3和V4接口都专用于ISDN接入,而不支持非ISDN接入,V2接口虽然可以连接本地或远端一次群和二次群设备,但其通路类型、通路分配方式以及信令范围取决于具体的应用,也不在ITU-T建议的标准化范围之内,妨碍了V接口的推广使用。

通力小机房电梯控制系统(MINISPACE TM LCE)检修参考手册通力小机房控制系统1.4版本控制柜和驱动单元通力小机房控制系统(MINISPACE TM)1.5版本的控制柜和分离式驱动柜通力小机房控制系统(MINISPACE TM)1.5版本控制柜和驱动单元目录表1 介绍 --------------------------------------------------------------------------------------------------------- 3 1.1基本故障检查 ---------------------------------------------------------------------------------------------3 1.2相关文件 ---------------------------------------------------------------------------------------------------31.3预防电击危险的基本原则 ------------------------------------------------------------------------------32 安全准则 ----------------------------------------------------------------------------------------------- 42.1加强安全的方法 ------------------------------------------------------------------------------------------43 LCE板的更换 -------------------------------------------------------------------------------------------- 53.1安装新LON的协议 ------------------------------------------------------------------------------------ 54 LCE使用界面的介绍 ----------------------------------------------------------------------------------- 6 4.1LCE使用界面(LCECPU40)------------------------------------------------------------------------ 64.2怎么使用LCE使用界面 -------------------------------------------------------------------------------- 75 LCE板 ------------------------------------------------------------------------------------------------------ 8 5.1 LCE板的详述 -------------------------------------------------------------------------------------------- 8 5.2 LCECPU(主控CPU)-------------------------------------------------------------------------------- 9 5.3 LCEADO板(安全电路和ADO/ACL)-------------------------------------------------------------12 5.4 LCECAN板(网络控制区)---------------------------------------------------------------------------14 5.5 LCEREC板(整流板)>13140G04 ---------------------------------------------------------------- 15 5.6 LCEREC板(整流板)>13140G08 ---------------------------------------------------------------- 16 5.7 LCERAL板(远程报警板) -------------------------------------------------------------------------------17 5.8 LCEETS (紧急停止终端板) ----------------------------------------------------------------------------18 5.9 LCEHKM板 (香港模块) -------------------------------------------------------------------------------- 20 5.10 LCEGTW板 (转连接板) ------------------------------------------------------------------------------ 21 5.11光耦转连接板和RS485转接板 --------------------------------------------------------------------- 22 5.12 LCEOPT板(功能选择板) ---------------------------------------------------------------------------- 24 5.13 LCEEAQ板 (地震探测器板) ------------------------------------------------------------------------- 25 5.14 LCECCBLCE板 (轿顶连接板) ----------------------------------------------------------------------26 5.15 LCECCBN板 (轿顶连接板)-------------------------------------------------------------------------- 29 5.16 LCEAMAX板 (香港选择模块) -----------------------------------------------------------------------32 5.17 LCEFCB板 (楼层控制板) --------------------------------------------------------------------------- 335.18 LCEFOB板 (楼层选择板) --------------------------------------------------------------------------- 346 版本批准历史 ----------------------------------------------------------------------------------------------- 351介绍1.1基本故障检查这个文件给出了通力小机房电梯控制系统的电气基本故障检修的信息参考,这个文件使用在LCE故障规范清单为762780的LCECPU系统和LCE故障规范清单为813138的LCECPU40系统上。

原理说明1.系统原理ZPW-2000A型无绝缘移频轨道电路系统,与UM71无绝缘轨道电路一样采用电气绝缘节来实现相邻轨道电路区段的隔离。

电气绝缘节长度改进为29m,由空心线圈、29m长钢轨和调谐单元构成。

调谐区对于本区段频率呈现极阻抗,利于本区段信号的传输及接收;对于相邻区段频率信号呈现零阻抗,可靠地短路相邻区段信号,防止了越区传输,这样便实现了相邻区段信号的电气绝缘。

同时为了解决全程断轨检查,在调谐区内增加了小轨道电路。

ZPW-2000A型无绝缘移频轨道电路将轨道电路分为主轨道电路和调谐区小轨道电路两个部分,并将短小轨道电路视为列车运行前方主轨道电路的所属“延续段”。

主轨道电路的发送器由编码条件控制产生表示不同含义的低频调制的移频信号,该信号经电缆通道(实际电缆和模拟电缆)传给匹配变压器及调谐单元,因为钢轨是无绝缘的,该信号既向主轨道传送,也向小轨道传送。

主轨道信号经钢轨送到轨道电路受电端,然后经调谐单元、匹配变压器、电缆通道,将信号传至本区段接收器。

调谐区小轨道信号由运行前方相邻轨道电路接收器处理,并将处理结果形成小轨道电路轨道继电器执行条件通过(XG、XGH)送至本轨道电路接收器,做为轨道继电器(GJ)励磁的必要检查条件之一。

本区段接收器同时接收到主轨道移频信号及小轨道电路继电器执行条件,判决无误后驱动轨道电路继电器吸起,并由此来判断区段的空闲与占用情况。

主轨道和调谐区小轨道检查原理示意图见图2-1。

该系统“电气—电气”和“电气—机械”两种绝缘节结构电气性能相同。

2.电路工作原理及冗余设计2.1 发送器2.1.1 用途ZPW-2000A型无绝缘移频轨道电路发送器在区间适用于非电码化和电码化区段18信息无绝缘移频自动闭塞,供自动闭塞、机车信号和超速防护使用。

在车站可适用于非电码化和电码化区段站内移频电码化发送,并可作站内移频轨道电路使用。

2.1.2 原理框图及电路原理简要说明同一载频编码条件,低频编码条件源,以反码形式分别送入两套微处理器CPU中,其中CPU1产生包括低频控制信号Fc的移频信号。

Signal Description, V52-850 kW History of this DocumentChanges in this document:Rev.no.: Date: Description of changeUpdated1 2002-02-142 2004-06-02 AGO option on S750 & S751 added Related DocumentationItem no. T itleContents...........................................................................................................................Page1.Gr.1 - Grid (3)2.Gr.2 - Yawing (3)3.Gr.3 - Hydraulic (4)4.Gr.4 - Ambient (5)5.Gr.5 - Rotation mech (6)6.Gr.6 - Generator/VCS (7)7.Gr.8 - Pitch (10)8.Gr.9a - Emergency and various (10)9.Gr.9b - User defined (10)Grid-1. Gr.1Input Assembly Module no Terminal LED Wire Name FunctionA1 VCS: A3 CT 294 X12.3 3 Voltage, Grid, L1-N Low VACA2 VCS: A3 CT 294 X12.5 5 Voltage, Grid, L2-N Low VACA3 VCS: A3 CT 294 X12.7 7 Voltage, Grid, L3-N Low VACA4 VCS: A3 CT 294 X13X.1 1 Current, Grid, I1 Low VACA5 VCS: A3 CT 294 X13X.3 3 Current, Grid, I2 Low VACA6 VCS: A3 CT 294 X13X.5 5 Current, Grid, I3 Low VACS7 VCS: A3 CT 294 X14.8 * 8 Circuit breaker, Q7 High = connect.High = connect. S8 Gnd: A1 X1 CT 291 DI1 A7 7 Main circuit breaker, Q8Main Circuit breaker, Q7S9A Gnd: A1 X1 CT 291 DI3 A8 8 OVP, Grid, Ground High = OKS9B Top: A2 X5 CT 3133 DI16 B0 * 20 OVP, Grid, Top High = OKOutput Assembly Module no Terminal LED Wire Name FunctionQ8 Gnd: A1 X1 CT 291 DO1 A3 3 Trip main circuit breaker, Q8 High = trip.-Yawing2. Gr.2Input Assembly Module no Terminal LED Wire Name FunctionHigh = connect. S100A Top: A2 X2 CT 3133 DI1 A3 * 3 Feedback yawing CW,M100A/BF100A Top: A2 X2 CT 3133 DI7 A6 * 6 Thermal relay, yawmotorHigh = OKM100AHigh = OKF101A Top: A2 X2 CT 3133 DI8 B6 * 16 Thermal relay, yawmotorM100BHigh = connect. S101A Top: A2 X2 CT 3133 DI2 B3 * 13 Feedback yawing CCW,M100A/BS102 Top: A2 X2 CT 3133 DI3 A4 * 4 Twist sensor, CW High = twisted S103 Top: A2 X2 CT 3133 DI4 B4 * 14 Twist sensor, CCW High = twisted S104 Top: A2 X2 CT 3133 DI5 A5 * 5 Twist stop Low = tw.stop S105 Top: A2 X2 CT 3133 DI6 B5 * 15 Yaw pulse High = PulseOutput Assembly Module no Terminal LED Wire Name FunctionK100 Top: A2 Y1 CT 3153 DO1 A3 * 3 Contactor, yawmotors CW High = connect. K101 Top: A2 Y1 CT 3153 DO2 B3 * 13 Contactor, yawmotors CCW High = connect.3. Gr.3Hydraulic-Input Assembly Module no Terminal LED Wire Name FunctionS200 Top: A2 X3 CT 3218 DI3 Dsub3 * 5 Oil level, Hydraulic High = OKHigh = OKS201 Top: A2 X2 CT 3133 DI10 B7 * 17 Diff.pressure filter,Hydr.power unitS202 Top: A2 X2 CT 3133 DI11 A8 * 8 Pressure sensor, Brake High = OKA203 Top: A2 X4 CT 3220 AI2 B3 13 Pressure, Hydraulic 4..20mA/4..24mAHigh = OKF204 Top: A2 X2 CT 3133 DI13 A9 * 9 Thermal relay, Hydraulicmotor, PitchS204 Top: A2 X2 CT 3133 DI9 A7 * 7 Feedback, Hydraulic motor,High = connect.PitchR206 Top: A2 X1 CT 3220 AI1 B2 12 Temperature, Hydraulic oil PT100S207 Top: A2 X2 CT 3133 DI12 B8 * 18 Thermistor, Brake High = OKS208 Top: A2 X5 CT 3133 DI1 A3 * 3 Feedback, Brake Low = braked S209 Top: A2 X5 CT 3133 DI9 A7 * 7 Ext. 24V, Hydraulic OK High = OKOutput Assembly Module no Terminal LED Wire Name FunctionK204 Top: A2 Y1 CT 3153 DO9 A7 * 7 Contactor, Hydraulic motor High = connect. Y210 Top: A2 Y1 CT 3153 DO5 A5 * 5 Emergency pitch valve Low = opensY211_V2Top: A2 Y1 CT 3153 DO7 A6 * 6 Brake valve Low = braking 7..V524. Gr.4-AmbientInput Assembly Module no Terminal LED Wire Name Function R300 Top: A2 X1 CT 3220 AI2 B3 13 Temperature, Ambient PT100S304_V4 7..V80VC S Gnd: A1 CT 291 ITtemp A2 * 2 Thermostate, GROUND High = Temp.OKS305_V4 7..V80VC S Top: A1 X3 CT 3218 DI8 Dsub8 * 10 Thermostate, TOP High = Temp.OKR306 Top: A2 X1 CT 3220 AI8 B9 19 Temperature, Nacelle PT100F307 Top: A2 X5 CT 3133 DI3 A4 * 4 Thermal relay, Ventilator,Nacelle, LowspeedHigh = OKS307 Top: A2 X5 CT 3133 DI2 B3 * 13 Feedback, Ventilator,Nacelle, LowspeedHigh = connect. R310 Top: A2 X1 CT 3220 AI7 B8 18 Temperature, Top controller PT100S313 Top: A2 X5 CT 3133 DI4 B4 * 14 Feedback, Ventilator,Nacelle, High/MediumspeedHigh = connect.F313 Top: A2 X5 CT 3133 DI5 A5 * 5 Thermal relay, Ventilator,Nacelle, High/Medium sp.High = OKB323 Top: A2 X3 CT 3218 DI6 Dsub6 * 8 Nacelle position 1 High = PulseB324 Top: A2 X3 CT 3218 DI7 Dsub7 * 9 Nacelle position 2 High = PulseB325 Top: A2 X3 CT 3218 DI4 Dsub4 * 6 Reset, Nacelle position High = PulseR326 Gnd: A1 CT 291 AI1 X31.B2 12 Temperature, GroundcontrollerPT100A327 Top: A2 X3 CT 3218 Dsub9 * 0 Wind direction sensor Seriel, 0..360B328 Top: A2 X6 CT 3133 DI1 A3 * 3 Smoke detektor High = OK (nosmoke detected) S344 Gnd: A1 X1 CT 291 DI7 X30.A0 10 Signal, Lightning detector,TowerHigh = PulseS346 Gnd: A1 X1 CT 291 DI8 X30.B0 20 Power OK, Lightningdetector, TowerHigh = OKS349B Top: A2 X6 CT 3133 DI10 B7 * 17 Feedback, Ventilator,Generator, HighspeedHigh = connect.S349A Top: A2 X6 CT 3133 DI9 A7 * 7 Feedback, Ventilator,Generator, LowspeedHigh = connect.F349A Top: A2 X6 CT 3133 DI15 A0 * 10 Thermal relay, Ventilator,Generator, LowspeedHigh = OKF349B Top: A2 X6 CT 3133 DI16 B0 * 20 Thermal relay, Ventilator,Generator, HighspeedHigh = OKOutput Assembly Module no Terminal LED Wire Name FunctionK307 Top: A2 Y1 CT 3153 DO11 A8 * 8 Contactor, Ventilator,Nacelle, LowspeedHigh = connect.K313 Top: A2 Y1 CT 3153 DO12 B8 * 18 Contactor, Ventilator,Nacelle, High/MediumspeedHigh = connect.D328 Top: A2 Y3 CT 3153 DO1 A3 * 3 Enable smoke detektor High = enable D345 Gnd: A1 X1 CT 291 DO8 X30.B616 Reset, Lightning detector,TowerHigh = resetK349B Top: A2 Y3 CT 3153 DO10 B7 * 17 Contactor, Ventilator,Generator, HighspeedHigh = connect.K349A Top: A2 Y3 CT 3153 DO9 A7 * 7 Contactor, Ventilator,Generator, LowspeedHigh = connect.5. Gr.5 - Rotation mech.Input Assembly Module no Terminal LED Wire Name FunctionB400 Top: A2 X3 CT 3218 DI2 Dsub2 * 4 Tachosignal, Rotor High = PulseB401 Top: A2 X3 CT 3218 DI1 Dsub1 * 3 Tachosignal, Generator High = PulseR402 Top: A2 X1 CT 3220 AI3 B4 14 Temperature, Gearoil PT100S403 Top: A2 X2 CT 3133 DI14 B9 * 19 Vibration sensor High = OKS404 Top: A2 X5 CT 3133 DI12 B8 * 18 Gear oil level High = OKS405 Top: A2 X2 CT 3133 DI15 A0 * 10 VOG OK High = OKPT100R406 Top: A2 X1 CT 3220 AI6 B7 17 Temperature, GearBearings 1S410 Top: A2 X6 CT 3133 DI11 A8 * 8 Feedback, Gear oil pump High = connect.High = OKF410 Top: A2 X6 CT 3133 DI5 A5 * 5 Thermal relay, Gear oilpumpHigh = OKS412 Top: A2 X5 CT 3133 DI6 B5 * 15 Flow/filter error, Gear oilcooling systemA419 Top: A2 X4 CT 3220 AI7 B8 18 Accelleration, Logitudinal 4..20mAA420 Top: A2 X4 CT 3220 AI8 B9 19 Accelleration, Transverse 4..20mAS425 Top: A2 X5 CT 3133 DI13 A9 * 9 Gear oil filter High = OKHigh = OKF426 Top: A2 X5 CT 3133 DI14 B9 * 19 Thermistor, Pump,GearoilconditioningHigh = OKS426 Top: A2 X6 CT 3133 DI4 B4 * 14 Pressostate ,GearoilconditioningOutput Assembly Module no Terminal LED Wire Name FunctionU405 Top: A2 Y1 CT 3153 DO13 A9 * 9 Control signal, VOG High = syncrone K410 Top: A2 Y3 CT 3153 DO11 A8 * 8 Contactor, Gear oil pump High = connect. K414 Top: A2 Y1 CT 3153 DO4 B4 * 14 Heating, Gear oil High = connect. D426 Top: A2 Y3 CT 3153 DO4 B4 * 14 Contactor, Pump,High = connect.Gearoilconditioning6. Gr.6-Generator/VCSInput Assembly Module no Terminal LED Wire Name FunctionS500 VCS: A3 CT 294 X14.3 * 3 Feedback, Generator 1 High = connect. A500 VCS: A3 CT 294 X12.1 1Grid-voltage,L1-L2 5.6VrmsS501_V4 7..v80VC S VCS: A3 CT 294 X14.4 * 4 Feedback, Delta connectionof statorHigh = starconn.S502_V4 7..v80VC S VCS: A3 CT 294 X14.5 * 5 Feedback, Star connectionof statorHigh = S-connectionR503B Top: A2 X4 CT 3220 AI4 B5 15 Temperature, Generator 1,Phase 2PT100R503C Top: A2 X4 CT 3220 AI5 B6 16 Temperature, Generator 1,Phase 3PT100R503A Top: A2 X4 CT 3220 AI3 B4 14 Temperature, Generator 1,Phase 1PT100R518 Top: A2 X1 CT 3220 AI4 B5 15 Temperature, GeneratorBearingsPT100S519A VCS: A3 CT 294 X19.3 3 OVP, VCS active High = not active S519B VCS: A3 CT 294 X19.5 5 OVP, VCS Power OK High = OKR521 VCS: A3 CT 294 X20.10 20 Temperature, Grid inverter,U0..10 VDCA521 VCS: A3 CT 294 X20.11 22 Current, Grid inverter, U -10..10 VDCS521 VCS: A3 CT 294 X20.14 3 Error, Grid inverter, U Low = OKF521 VCS: A3 CT 294 X20.18 11 Overtemp., Grid inverter, U Low = OKS522 VCS: A3 CT 294 X20.3 6 Error, Grid inverter, V Low = OKA522A VCS: A3 CT 294 X20.19 13 Voltage, DC-link Low = OKA522 VCS: A3 CT 294 X20.12 24 Current, Grid inverter, V -10..10 VDCS523 VCS: A3 CT 294 X20.17 9 Error, Grid inverter, W Low = OKA523 VCS: A3 CT 294 X20.13 26 Current, Grid inverter, W -10..10 VDCF524X VCS: A3 CT 294 X24X.3 5 Overtemp., Rotor inverter,K, branch XLow = OKS524X VCS: A3 CT 294 X24X.2 3 Error, Rotor inverter, K,branch XLow = OKA524X VCS: A3 CT 294 X24X.15 14 Current, Rotor inverter, K,branch X-10..10 VDCR524X VCS: A3 CT 294 X24X.14 12 Temperature, Rotor inverter,K, branch X0..10 VDCS525X VCS: A3 CT 294 X25X.2 3 Error, Rotor inverter, L,branch XLow = OKR525X VCS: A3 CT 294 X25X.14 12 Temperature, Rotor inverter,L, branch X0..10 VDCA525X VCS: A3 CT 294 X25X.15 14 Current, Rotor inverter, L,branch X-10..10 VDCF525X VCS: A3 CT 294 X25X.3 5 Overtemp., Rotor inverter, L,branch XLow = OKF526X VCS: A3 CT 294 X26X.3 5 Overtemp., Rotor inverter,M, branch XLow = OKR526X VCS: A3 CT 294 X26X.14 12 Temperature, Rotor inverter,M, branch X0..10 VDCS526X VCS: A3 CT 294 X26X.2 3 Error, Rotor inverter, M,branch XLow = OKA526X VCS: A3 CT 294 X26X.15 14 Current, Rotor inverter, M,branch X-10..10 VDCB527 VCS: A3 CT 294 X16.1 1 Encoder 1, not in use High = PulseB528 VCS: A3 CT 294 X16.2 2 Encoder 2, not in use High = PulseInput Assembly Module no Terminal LED Wire Name FunctionR529 VCS: A3 CT 294 X17.1 1 Temperature, Cooling water PT100R530 VCS: A3 CT 294 X17.3 3 Temperature, Drossel coils PT100S536 VCS: A3 CT 294 X14.2 * 2 Feedback, Grid inverter High = connect. F537 VCS: A3 CT 294 X14.6 * 6 Thermal relay, Charge ofHigh = OKDC linkHigh = connect. S537 VCS: A3 CT 294 X14.1 * 1 Feedback, Charge of DClinkR539 VCS: A3 CT 294 On board Temperature, VCP board LM50BHigh = OKF542 Top: A2 X6 CT 3133 DI2 B3 * 13 Thermistor, Vent, Sliprings,VCSPT100Sliprings,R542 Top: A2 X4 CT 3220 AI6 B7Temperature,17VCSHigh = OKF546 Top: A2 X6 CT 3133 DI12 B8 * 18 Thermistor, Internalventilator, VCS coolingHigh = connect. S546 Top: A2 X6 CT 3133 DI6 B5 * 15 Feedback, Internalventilator, VCS coolingS555 Top: A2 X5 CT 3133 DI12 B8 * 18 VCS cooling water level High = OKS558 VCS: A3 CT 294 X16.3 3 Encoder reset, not in use High = ResetS559 VCS: A3 CT 294 X16.4 4 Encoder OK, not in use High = OKS804 Top: A2 X5 CT 3133 DI10 B7 * 17 External 24V Pitch High = connect.Output Assembly Module no Terminal LED Wire Name FunctionK500 Top: A3 CT 294 X18.3 * 3 Contactor, Generator 1 High = connect.K501_V4 7..V80VC S VCS: A3 CT 294 X18.4 * 4 Contactor, Delta connectionof statorHigh = connect.K502_V4 7..V80VC S VCS: A3 CT 294 X18.5 * 5 Contactor, Star connectionof statorHigh = connect.K506 Top: A2 Y1 CT 3153 DO10 B7 * 17 Heating, Generator High = connect. K519 VCS: A3 CT 294 X19.1 1 OVP, VCS gate driver signal High = activates V521A VCS: A3 CT 294 X20.1 2 IGBT ON, Bottom, Gridinverter, U+15 = ONV521B VCS: A3 CT 294 X20.2 4 IGBT ON, Top, Gridinverter, U+15 = ONV522A VCS: A3 CT 294 X20.15 5 IGBT ON, Bottom, Gridinverter, V+15 = ONV522B VCS: A3 CT 294 X20.16 7 IGBT ON, Top, Gridinverter, V+15 = ONV523B VCS: A3 CT 294 X20.5 10 IGBT ON, Top, Gridinverter, W+15 = ONV523A VCS: A3 CT 294 X20.4 8 IGBT ON, Bottom, Gridinverter, W+15 = ONV524AX VCS: A3 CT 294 X24X.9 2 IGBT ON, Bottom, Rotorinverter, K, branch X+15 = ONV524BX VCS: A3 CT 294 X24X.10 4 IGBT ON, Top, Rotorinverter, K, branch X+15 = ONV525AX VCS: A3 CT 294 X25X.9 2 IGBT ON, Bottom, Rotorinverter, L, branch X+15 = ONV525BX VCS: A3 CT 294 X25X.10 4 IGBT ON, Top, Rotorinverter, L, branch X+15 = ONV526BX VCS: A3 CT 294 X26X.10 4 IGBT ON, Top, Rotorinverter, M, branch X+15 = ONV526AX VCS: A3 CT 294 X26X.9 2 IGBT ON, Bottom, Rotorinverter, M, branch X+15 = ONK536 VCS: A3 CT 294 X18.2 * 2 Contactor, Grid inverter High = connect. K537 VCS: A3 CT 294 X18.1 * 1 Contactor, Charge of DClinkHigh = connect.K542B Top: A2 Y3 CT 3153 DO3 A4 * 4 Contactor, Heat/Vent,Sliprings, VCSHigh = connect.K542A Top: A2 Y3 CT 3153 DO2 B3 * 13 Contactor, Vent, Sliprings,VCSHigh = connect.K545 Top: A2 Y3 CT 3153 DO5 A5 * 5 Contactor, Water pump,VCS coolingHigh = connect.K546 Top: A2 Y3 CT 3153 DO6 B5 * 15 Contactor, Internalventilator, VCS coolingHigh = connect.Pitch-7. Gr.8Input Assembly Module no Terminal LED Wire Name FunctionA800 Top: A2 X4 CT 3220 AI1 B2 12 Pitchposition 0..10 VDCOutput Assembly Module no Terminal LED Wire Name FunctionY800 Top: A2 Y2 CT 3232 AO1 B2 2 Controlvoltage, Proportional-10..10 VDCvalve, Pitchvel.K801 Top: A2 Y1 CT 3153 DO15 A0 * 10 Software debug High = Pulse 8. Gr.9a - Emergency and variousInput Assembly Module no Terminal LED Wire Name FunctionS902 Top: A2 X2 CT 3133 DI16 B0 * 20 Emergency circuit,High = OKTopcontrollerHigh = OKS903 Gnd: A1 CT 291 DI2 X30.B7 17 Emergency circuit,Ground/Nac.controllerS906 Top: A2 X5 CT 3133 DI15 A0 * 10 Watchdog WD activated S931 Top: A2 X5 CT 3133 DI11 A8 * 8 Nacelle in sector High = in sector H943 Gnd: A1 CT 291 X31.B8 * 18 Auxillary supply OK High = OKH944 Gnd: A1 CT 291 X31.B9 * 19 Temperature circuit OK High = OKOutput Assembly Module no Terminal LED Wire Name FunctionK900 Top: A2 Y1 CT 3153 DO16 B0 * 20 Emergency circuit, Top/nacLow = emrg.controllerLow = emrg.K901 Gnd: A1 CT 291 DO2 X30.B313 Emergency circuit, GroundcontrollerK906 Top: A2 Y1 CT 3153 DO15 A0 * 10 Trig, Watchdog High = Trigpulse9. Gr.9b - User definedInput Assembly Module no Terminal LED Wire Name FunctionS750 Gnd: A1 CT 291 DI5 X30.A9 9 Normal mode High = OKS751 Gnd: A1 CT 291 DI6 X30.B9 19 UPS OK High = OKS752 Gnd: A1 CT 291 DI7 X30.A0 10 Digital input 3, User UserS753 Gnd: A1 CT 291 DI8 X30.B0 10 Digital input 4, User UserA758 Gnd: A1 CT 291 AI3 X31.B4 14 Analog input 1, User UserA759 Gnd: A1 CT 291 AI4 X31.B5 15 Analog input 2, User UserOutput Assembly Module no Terminal LED Wire Name FunctionD754 Gnd: A1 CT 291 DO5 X30.A5 5 Digital output 1, User UserD755 Gnd: A1 CT 291 DO6 X30.B5 15 Digital output 2, User UserD756 Gnd: A1 CT 291 DO7 X30.A6 6 Digital output 3, User UserD757 Gnd: A1 CT 291 DO8 X30.B6 16 Digital output 4, User UserD760 Gnd: A1 CT 291 AO1 X31.B6 16 Analog output 1, User UserD761 Gnd: A1 CT 291 AO2 X31.B7 17 Analog output 2, User User。