Chemlok adhesive application开姆洛克胶粘剂应用

- 格式:ppt

- 大小:5.03 MB

- 文档页数:103

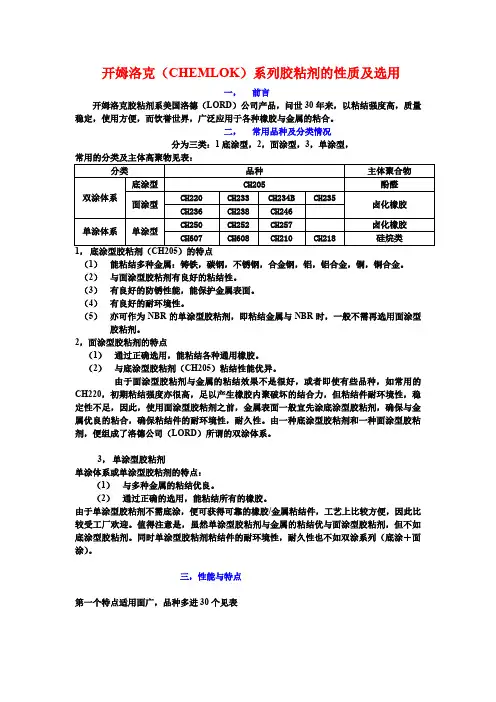

开姆洛克C H E M L O K胶粘剂的性质及选用 Coca-cola standardization office【ZZ5AB-ZZSYT-ZZ2C-ZZ682T-ZZT18】开姆洛克(CHEMLOK)系列胶粘剂的性质及选用一,前言开姆洛克胶粘剂系美国洛德(LORD)公司产品,问世30年来,以粘结强度高,质量稳定,使用方便,而饮誉世界,广泛应用于各种橡胶与金属的粘合。

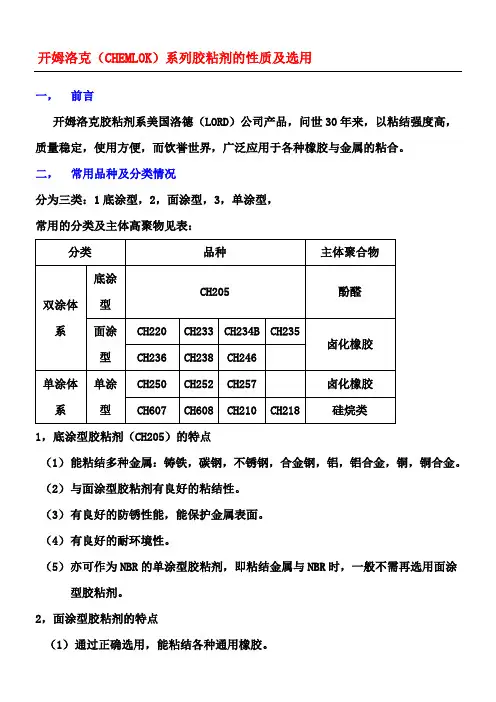

二,常用品种及分类情况分为三类:1底涂型,2,面涂型,3,单涂型,(1)能粘结多种金属:铸铁,碳钢,不锈钢,合金钢,铝,铝合金,铜,铜合金。

(2)与面涂型胶粘剂有良好的粘结性。

(3)有良好的防锈性能,能保护金属表面。

(4)有良好的耐环境性。

(5)亦可作为NBR的单涂型胶粘剂,即粘结金属与NBR时,一般不需再选用面涂型胶粘剂。

2,面涂型胶粘剂的特点(1)通过正确选用,能粘结各种通用橡胶。

(2)与底涂型胶粘剂(CH205)粘结性能优异。

由于面涂型胶粘剂与金属的粘结效果不是很好,或者即使有些品种,如常用的CH220,初期粘结强度亦很高,足以产生橡胶内聚破坏的结合力,但粘结件耐环境性,稳定性不足,因此,使用面涂型胶粘剂之前,金属表面一般宜先涂底涂型胶粘剂,确保与金属优良的粘合,确保粘结件的耐环境性,耐久性。

由一种底涂型胶粘剂和一种面涂型胶粘剂,便组成了洛德公司(LORD)所谓的双涂体系。

3,单涂型胶粘剂单涂体系或单涂型胶粘剂的特点:(1)与多种金属的粘结优良。

(2)通过正确的选用,能粘结所有的橡胶。

由于单涂型胶粘剂不需底涂,便可获得可靠的橡胶/金属粘结件,工艺上比较方便,因此比较受工厂欢迎。

值得注意是,虽然单涂型胶粘剂与金属的粘结优与面涂型胶粘剂,但不如底涂型胶粘剂。

同时单涂型胶粘剂粘结件的耐环境性,耐久性也不如双涂系列(底涂+面涂)。

三,性能与特点第一个特点适用面广,品种多进30个见表(1)硫化粘结各种橡胶与多种金属粘合,如铁,钢,不锈钢,合金钢,铝,铝合金,铜,铜合金等。

开姆洛克(CHEMLOK)胶粘剂的性质及选用1,2,底涂型胶粘剂(CH205)的特点(1)能粘结多种金属:铸铁,碳钢,不锈钢,合金钢,铝,铝合金,铜,铜合金。

(2)与面涂型胶粘剂有良好的粘结性。

(3)有良好的防锈性能,能保护金属表面。

(4)有良好的耐环境性。

(5)亦可作为NBR的单涂型胶粘剂,即粘结金属与NBR时,一般不需再选用面涂型胶粘剂。

2,面涂型胶粘剂的特点(1)通过正确选用,能粘结各种通用橡胶。

(2)与底涂型胶粘剂(CH205)粘结性能优异。

由于面涂型胶粘剂与金属的粘结效果不是很好,或者即使有些品种,如常用的CH220,初期粘结强度亦很高,足以产生橡胶内聚破坏的结合力,但粘结件耐环境性,稳定性不足,因此,使用面涂型胶粘剂之前,金属表面一般宜先涂底涂型胶粘剂,确保与金属优良的粘合,确保粘结件的耐环境性,耐久性。

由一种底涂型胶粘剂和一种面涂型胶粘剂,便组成了洛德公司(LORD)所谓的双涂体系。

3,单涂型胶粘剂单涂体系或单涂型胶粘剂的特点:(1)与多种金属的粘结优良。

(2)通过正确的选用,能粘结所有的橡胶。

由于单涂型胶粘剂不需底涂,便可获得可靠的橡胶/金属粘结件,工艺上比较方便,因此比较受工厂欢迎。

值得注意是,虽然单涂型胶粘剂与金属的粘结优与面涂型胶粘剂,但不如底涂型胶粘剂。

同时单涂型胶粘剂粘结件的耐环境性,耐久性也不如双涂系列(底涂+面涂)。

三,性能与特点第一个特点适用面广,品种多进30个见表开姆洛克胶粘剂选用指南胶种单涂胶粘剂法双涂胶粘剂法NR 250 252 257 402 220,233,234B,236 SBR 250 252 257 402 220,233,234B,BR 250 252 257 402 220,233,234BNBR 205 250 252 257220,233,234B,236 BN LJ210 402 607IIR 250 252 234B,236,238 EPDM 250,252硫黄607,DCP 252树脂236,238 CR 250 252 257 402 220,234B,236,238 聚硫胶205 218硅胶607 608 氟胶607聚氨酯胶210反应注模210,218浇铸型混炼型250,BN 233通过正确选用可以达到以下目的:(1)硫化粘结各种橡胶与多种金属粘合,如铁,钢,不锈钢,合金钢,铝,铝合金,铜,铜合金等。

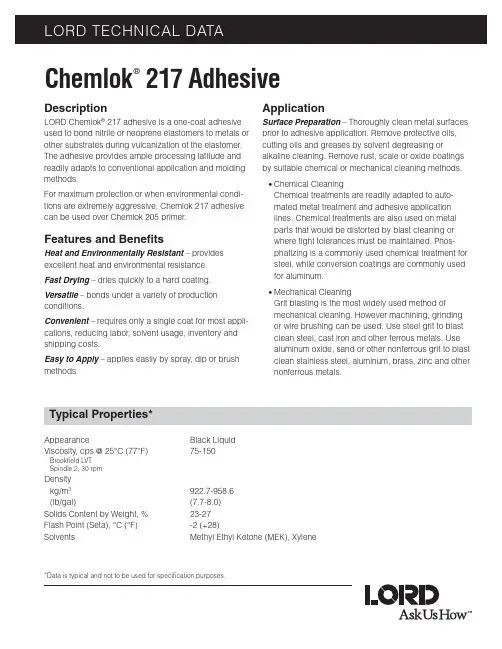

DescriptionLORD Chemlok ® 217 adhesive is a one-coat adhesive used to bond nitrile or neoprene elastomers to metals or other substrates during vulcanization of the elastomer. The adhesive provides ample processing latitude and readily adapts to conventional application and molding methods.For maximum protection or when environmental condi-tions are extremely aggressive, Chemlok 217 adhesive can be used over Chemlok 205 primer.Features and Benefi tsHeat and Environmentally Resistant – provides excellent heat and environmental resistance.Fast Drying – dries quickly to a hard coating.Versatile – bonds under a variety of production conditions.Convenient – requires only a single coat for most appli-cations, reducing labor, solvent usage, inventory and shipping costs.Easy to Apply – applies easily by spray, dip or brush methods.Chemlok ®217 AdhesiveApplicationSurface Preparation – Thoroughly clean metal surfaces prior to adhesive application. Remove protective oils, cutting oils and greases by solvent degreasing oralkaline cleaning. Remove rust, scale or oxide coatings by suitable chemical or mechanical cleaning methods.• Chemical CleaningChemical treatments are readily adapted to auto-mated metal treatment and adhesive application lines. Chemical treatments are also used on metal parts that would be distorted by blast cleaning or where tight tolerances must be maintained. Phos-phatizing is a commonly used chemical treatment for steel, while conversion coatings are commonly used for aluminum.• Mechanical CleaningGrit blasting is the most widely used method ofmechanical cleaning. However machining, grinding or wire brushing can be used. Use steel grit to blast clean steel, cast iron and other ferrous metals. Use aluminum oxide, sand or other nonferrous grit to blast clean stainless steel, aluminum, brass, zinc and other nonferrous metals.Typical Properties*AppearanceBlack Liquid Viscosity, cps @ 25°C (77°F)75-150Brookfi eld LVT Spindle 2, 30 rpmDensity kg/m 3 922.7-958.6(lb/gal) (7.7-8.0)Solids Content by Weight, % 23-27Flash Point (Seta), °C (°F) -2 (+28)Solvents Methyl Ethyl Ketone (MEK), Xylene*Data is typical and not to be used for specifi cation purposes.LORD provides valuable expertise in adhesives and coatings, vibration and motion control, and magnetically responsive technologies. Ourpeople work in collaboration with our customers to help them increase the value of their products. Innovative and responsive in an ever-changing marketplace, we are focused on providing solutions for our customers worldwide ... Ask Us How.LORD Corporation World Headquarters 111 Lord DriveCary, NC 27511-7923 USACustomer Support Center (in United States & Canada)+1 877 ASK LORD (275 5673)For a listing of our worldwide locations, visit /locations.Values stated in this technical data sheet represent typical values as not all tests are run on each lot of material produced. For formalized product specifi cations for specifi c product end uses, contact the Customer Support rmation provided herein is based upon tests believed to be reliable. In as much as LORD Corporation has no control over the manner in which others may use this information, it does not guarantee the results to be obtained. In addition, LORD Corporation does not guarantee the perfor-mance of the product or the results obtained from the use of the product or this information where the product has been repackaged by any third party, including but not limited to any product end-user. Nor does the company make any express or implied warranty of merchantability or fi tness for a particular purpose concerning the effects or results of such use.Chemlok and “Ask Us How” are trademarks of LORD Corporation or one of its subsidiaries.©2008 LORD Corporation OD DS3181 (Rev.3 8/08)For further detailed information on surface preparation of specifi c substrates, refer to Chemlok Adhesives appli-cation guide. Handle clean metal surfaces with clean gloves to avoid contamination with skin oils.Mixing – Thoroughly stir Chemlok 217 adhesive before using, and agitate suffi ciently during use to keep dispersed solids uniformly suspended.If dilution is needed, use a solvent mix ratio of 2 parts MEK and 1 part xylene. Drying time can be increased byadding greater amounts of xylene; drying time can bedecreased by adding lesser amounts of xylene.Applying – Apply Chemlok 217 adhesive to clean surfaces by brush, dip or spray methods.For optimum adhesion, dry fi lm thickness of Chemlok 217adhesive should be 5.1 micron (0.2 mil). Dry fi lm thick-ness between 2.5-10.2 micron (0.1-0.4 mil) will providesatisfactory adhesion and environmental resistance.Drying/Curing – Allow adhesive to dry at room temperature or elevated temperatures until visual examination of the fi lm has shown that all solvent has evaporated.Dried fi lms of Chemlok 217 adhesive are non-tacky;therefore, coated parts may be piled into tote pansfor subsequent processing. Wear clean gloves whenhandling coated parts and cover the tote pans to preventcontamination by dirt, grease, oil, etc. If coated parts are properly protected, they can be stored for up to 30 days before bonding.Compression or transfer molding, continuous vulcaniza-tion, and open steam curing methods are satisfactory methods for bonding. Chemlok 217 adhesive will cure under the normal curing time and temperature require-ments for the substrate. For best results, maintain curing temperature between 135-177°C (275-350°F).Cleanup – Use solvents such as MEK and xylene to remove adhesive before heat is applied. Remove cured adhesive by grit blasting, grinding or belt sanding.Shelf Life/StorageShelf life is one year from date of shipment when storedin a well ventilated area at 21-27°C (70-80°F) in original, unopened container.Cautionary InformationBefore using this or any LORD product, refer to the Mate-rial Safety Data Sheet (MSDS) and label for safe use and handling instructions.For industrial/commercial use only. Must be applied bytrained personnel only. Not to be used in householdapplications. Not for consumer use.。

开姆洛克胶粘剂工艺及应用胶粘剂是一种广泛应用于工业生产和日常生活中的材料,它能够将不同的物体牢固地粘合在一起。

开姆洛克胶粘剂是一种常见的胶粘剂品牌,具有优异的粘合性能和广泛的应用领域。

一、开姆洛克胶粘剂的工艺开姆洛克胶粘剂的制备工艺经过多年的研究和改进,具有高效、稳定的特点。

其制备过程主要包括以下几个步骤:1. 原料准备:开姆洛克胶粘剂的主要原料包括树脂、溶剂、填料等。

这些原料需要经过精确的配比和筛选,以确保胶粘剂的性能和质量。

2. 混合和搅拌:将准备好的原料按照一定的配方比例加入混合槽中,并进行搅拌混合。

搅拌的目的是使各种原料充分混合均匀,确保最终产品的质量稳定。

3. 精炼和过滤:混合后的胶粘剂需要进行精炼和过滤,以去除其中的杂质和颗粒。

这一步骤可以提高胶粘剂的纯度和透明度,同时减少使用过程中的堵塞和损坏。

4. 包装和贮存:经过精炼和过滤的胶粘剂需要进行包装和贮存,以确保其长期的保存和使用。

常见的包装方式包括桶装、管装等,根据不同的需求选择合适的包装方式。

二、开姆洛克胶粘剂的应用开姆洛克胶粘剂具有广泛的应用领域,以下是其中几个常见的应用场景:1. 工业制造:开姆洛克胶粘剂在工业制造中扮演着重要的角色。

它可以用于汽车制造、电子设备组装、家具制造等领域,用于固定、粘合和密封各种零部件,提高产品的质量和可靠性。

2. 建筑装修:在建筑装修中,开姆洛克胶粘剂可以用于地板安装、墙面装饰、瓷砖粘贴等工作。

它能够牢固地将各种材料粘合在一起,提供持久的粘合效果,同时具有防水、防霉等特性。

3. 包装行业:开姆洛克胶粘剂在包装行业中广泛应用。

它可以用于纸箱封口、标签粘贴、胶带制作等工作,提供可靠的粘合效果,确保包装的完整性和安全性。

4. 日常生活:开姆洛克胶粘剂在日常生活中也有许多应用。

比如,可以用于修补家具、粘贴照片、制作手工艺品等。

它方便易用,能够满足人们各种粘合需求。

总结:开姆洛克胶粘剂凭借其优异的粘合性能和广泛的应用领域,成为了胶粘剂市场的重要品牌之一。

开姆洛克(CHEMLOK)系列胶粘剂的性质及选用一,前言开姆洛克胶粘剂系美国洛德(LORD)公司产品,问世30年来,以粘结强度高,质量稳定,使用方便,而饮誉世界,广泛应用于各种橡胶与金属的粘合。

二,常用品种及分类情况分为三类:1底涂型,2,面涂型,3,单涂型,(1)能粘结多种金属:铸铁,碳钢,不锈钢,合金钢,铝,铝合金,铜,铜合金。

(2)与面涂型胶粘剂有良好的粘结性。

(3)有良好的防锈性能,能保护金属表面。

(4)有良好的耐环境性。

(5)亦可作为NBR的单涂型胶粘剂,即粘结金属与NBR时,一般不需再选用面涂型胶粘剂。

2,面涂型胶粘剂的特点(1)通过正确选用,能粘结各种通用橡胶。

(2)与底涂型胶粘剂(CH205)粘结性能优异。

由于面涂型胶粘剂与金属的粘结效果不是很好,或者即使有些品种,如常用的CH220,初期粘结强度亦很高,足以产生橡胶内聚破坏的结合力,但粘结件耐环境性,稳定性不足,因此,使用面涂型胶粘剂之前,金属表面一般宜先涂底涂型胶粘剂,确保与金属优良的粘合,确保粘结件的耐环境性,耐久性。

由一种底涂型胶粘剂和一种面涂型胶粘剂,便组成了洛德公司(LORD)所谓的双涂体系。

3,单涂型胶粘剂单涂体系或单涂型胶粘剂的特点:(1)与多种金属的粘结优良。

(2)通过正确的选用,能粘结所有的橡胶。

由于单涂型胶粘剂不需底涂,便可获得可靠的橡胶/金属粘结件,工艺上比较方便,因此比较受工厂欢迎。

值得注意是,虽然单涂型胶粘剂与金属的粘结优与面涂型胶粘剂,但不如底涂型胶粘剂。

同时单涂型胶粘剂粘结件的耐环境性,耐久性也不如双涂系列(底涂+面涂)。

三,性能与特点第一个特点适用面广,品种多进30个见表通过正确选用可以达到以下目的:(1)硫化粘结各种橡胶与多种金属粘合,如铁,钢,不锈钢,合金钢,铝,铝合金,铜,铜合金等。

(2)硫化粘结各种橡胶与多种织物,纤维,如人造丝,尼龙,涤纶,玻纤,芳纶,碳纤维等。

粘合橡胶与织物常用的胶粘剂有四种:CH402,CH233,CH250,CH607。

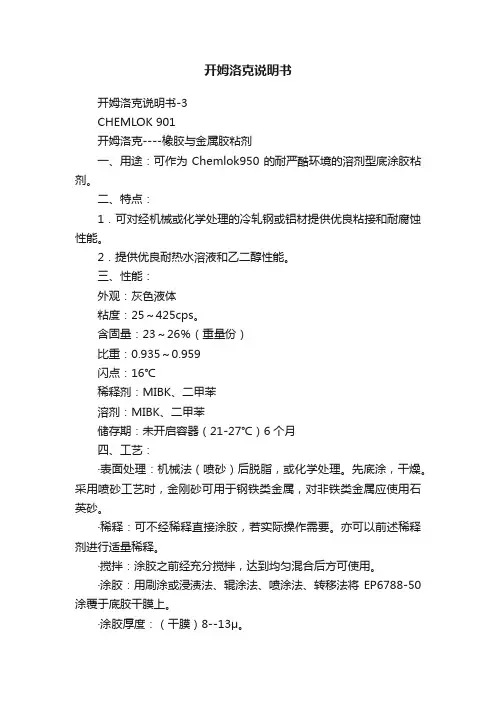

开姆洛克说明书开姆洛克说明书-3CHEMLOK 901开姆洛克----橡胶与金属胶粘剂一、用途:可作为Chemlok950的耐严酷环境的溶剂型底涂胶粘剂。

二、特点:1.可对经机械或化学处理的冷轧钢或铝材提供优良粘接和耐腐蚀性能。

2.提供优良耐热水溶液和乙二醇性能。

三、性能:外观:灰色液体粘度:25~425cps。

含固量:23~26%(重量份)比重:0.935~0.959闪点:16℃稀释剂:MIBK、二甲苯溶剂:MIBK、二甲苯储存期:未开启容器(21-27℃)6个月四、工艺:·表面处理:机械法(喷砂)后脱脂,或化学处理。

先底涂,干燥。

采用喷砂工艺时,金刚砂可用于钢铁类金属,对非铁类金属应使用石英砂。

·稀释:可不经稀释直接涂胶,若实际操作需要。

亦可以前述稀释剂进行适量稀释。

·搅拌:涂胶之前经充分搅拌,达到均匀混合后方可使用。

·涂胶:用刷涂或浸渍法、辊涂法、喷涂法、转移法将EP6788-50涂覆于底胶干膜上。

·涂胶厚度:(干膜)8--13μ。

·干燥:金属件可在65℃预热,涂胶后室温干燥至少45分钟,若加温干燥,时间可短些。

·停放:根据需要可在干燥后立即硫化,亦可停放较长时间再硫化,但要避免污染。

·硫化:取决于胶料硫化条件。

·清洗:可使用二甲苯、甲苯或丁酮。

五、注意事项:1.应贮存于干燥阴凉处,远离热源与明火。

2.溶剂易挥发,使用完毕请将容器盖紧。

3.溶剂蒸汽有害,工作场所防火通风,防止长期吸人或长期皮肤接触。

六、本产品系洛德公司(LORD Corp.)技术并生产,上海洛德化学有限公司提供技术咨询和销售。

CHEMLOK EP6788-50开姆洛克----橡胶与金属胶粘剂一、用途:多种未硫化橡胶与涂有Chemlok205的金属粘接的热硫化型胶粘剂。

二、特点:1.高强度粘接多种未硫化橡胶与涂有CH205的金属,适用橡胶有:丁苯胶、氯丁胶、丁腈胶、异戊橡胶和聚丁二烯橡胶。

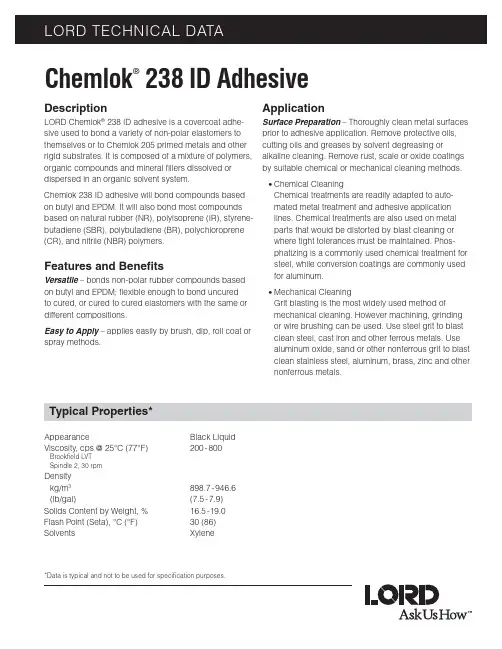

DescriptionLORD Chemlok ® 238 ID adhesive is a covercoat adhe-sive used to bond a variety of non-polar elastomers to themselves or to Chemlok 205 primed metals and other rigid substrates. It is composed of a mixture of polymers, organic compounds and mineral fi llers dissolved or dispersed in an organic solvent system.Chemlok 238 ID adhesive will bond compounds based on butyl and EPDM. It will also bond most compounds based on natural rubber (NR), polyisoprene (IR), styrene-butadiene (SBR), polybutadiene (BR), polychloroprene (CR), and nitrile (NBR) polymers.Features and Benefi tsVersatile – bonds non-polar rubber compounds based on butyl and EPDM; fl exible enough to bond uncured to cured, or cured to cured elastomers with the same or different compositions.Easy to Apply – applies easily by brush, dip, roll coat or spray methods.Chemlok ®238 ID AdhesiveApplicationSurface Preparation – Thoroughly clean metal surfaces prior to adhesive application. Remove protective oils, cutting oils and greases by solvent degreasing oralkaline cleaning. Remove rust, scale or oxide coatings by suitable chemical or mechanical cleaning methods.• Chemical CleaningChemical treatments are readily adapted to auto-mated metal treatment and adhesive application lines. Chemical treatments are also used on metal parts that would be distorted by blast cleaning or where tight tolerances must be maintained. Phos-phatizing is a commonly used chemical treatment for steel, while conversion coatings are commonly used for aluminum.• Mechanical CleaningGrit blasting is the most widely used method ofmechanical cleaning. However machining, grinding or wire brushing can be used. Use steel grit to blast clean steel, cast iron and other ferrous metals. Use aluminum oxide, sand or other nonferrous grit to blast clean stainless steel, aluminum, brass, zinc and other nonferrous metals.Typical Properties*AppearanceBlack Liquid Viscosity, cps @ 25°C (77°F)200 - 800Brookfi eld LVT Spindle 2, 30 rpmDensitykg/m 3898.7 - 946.6(lb/gal) (7.5 - 7.9)Solids Content by Weight, % 16.5 -19.0Flash Point (Seta), °C (°F) 30 (86)Solvents Xylene*Data is typical and not to be used for specifi cation purposes.For further detailed information on surface preparation of specifi c substrates, refer to Chemlok Adhesives appli-cation guide. Handle clean metal surfaces with clean gloves to avoid contamination with skin oils.Mixing – Special attention should be given to mixingthe adhesive. Agitation methods and times will vary depending on container size and time in inventory.The following guidelines must be followed to ensure a homogenous mix and uniform appearance.• Quart container – hand stirred with a paint stick orplaced on a paint shaker for 15-30 minutes.• Gallon container – hand stirred with a paint stick,placed on a paint shaker, or agitated with an air-driven mixer for 20-30 minutes.• 5-Gallon pail – fi rst hand stirred to loosen any sedi-ment followed by agitation with an air-driven mixer for 45-60 minutes.• 55-Gallon drum – hand cranked initially to loosenany sediment followed by agitation with an air-driven motor for 8 hours at 40-60 rpm. Drum roller can also be used to loosen any sediment by rolling at 30 rpm for 2 hours followed by agitation with an air-drivenmixer for 4 hours at 40-60 rpm.Evaluate all mixed containers for any remaining sediment prior to applying adhesive. Repeat recommended mixing procedure if sediment is found.Recommended Mixing ProceduresContainer Mixing Method Mixing TimeQuart (1.1 L)Hand stir10-15 minutes Paint Shaker10-15 minutesGallon (3.8 L)Hand stir20-30 minutes Paint Shaker20-30 minutes Air-driven mixer20-30 minutes5 Gallon(18.9 L)Hand stir and air-driven mixer45-60 minutes55 Gallon (208.2 L)Hand crank and air-driven mixer8 hoursRoller and air-driven mixer 2 hours (roller)4 hours (mixer)If the application method requires dilution, use xylene ortoluene as diluents. Xylene is the suggested diluent forspray application; toluene is suggested for dip or brushapplication.Applying – Apply Chemlok 238 ID adhesive by brush,dip, spray or any method that gives a uniform coatingand avoids excessive runs or tears.For optimum adhesion, the dry fi lm thickness of Chemlok238 ID adhesive should be 10.2-25.4 micron (0.4-1.0 mil). Thicker fi lms may be necessary on certain hard-to-bond rubber compounds. For bonding cured rubber,dry fi lm thickness of 25.4-38.1 micron (1.0-1.5 mil) isnormally used.Drying/Curing – Allow the applied adhesive to dryuntil visual examination of the fi lm has shown that allsolvent has evaporated. This will take approximately30-60 minutes at room temperature. Drying time can beshortened by either preheating the metal inserts or ovendrying after application. Metal parts may be preheatedto a maximum of 65°C (150°F) prior to adhesive applica-tion. For coated parts, moderate drying temperaturesshould be used, but temperatures as high as 149°C(300°F) may be used for very short periods of time.Maximum air fl ow at minimum temperatures will give thebest results.Dried fi lms of Chemlok 238 ID adhesive are non-tacky;therefore, coated parts can be piled into tote pansfor subsequent processing. Wear clean gloves whenhandling coated parts and cover tote pans to preventcontamination by dirt, dust, grease, oil, etc. If coatedparts are properly protected, long layover times betweenadhesive application and bonding usually have noadverse effect on the bond.Shelf Life/StorageShelf life is one year from date of shipment when stored in a well ventilated area at 21-27°C (70-80°F) in original, unopened container.Cautionary InformationBefore using this or any LORD product, refer to the Mate-rial Safety Data Sheet (MSDS) and label for safe use and handling instructions.For industrial/commercial use only. Must be applied by trained personnel only. Not to be used in household applications. Not for consumer use.Values stated in this technical data sheet represent typical values as not all tests are run on each lot of material produced. For formalized product specifi cations for specifi c product end uses, contact the Customer Support Center.Information provided herein is based upon tests believed to be reliable. In as much as LORD Corporation has no control over the manner in which others may use this information, it does not guarantee the results to be obtained. In addition, LORD Corporation does not guarantee the perfor-mance of the product or the results obtained from the use of the product or this information where the product has been repackaged by any third party, including but not limited to any product end-user. Nor does the company make any express or implied warranty of merchantability or fi tness for a particular purpose concerning the effects or results of such use.Chemlok and “Ask Us How” are trademarks of LORD Corporation or one of its subsidiaries.LORD provides valuable expertise in adhesives and coatings, vibration and motion control, and magnetically responsive technologies. Our people work in collaboration with our customers to help them increase the value of their products. Innovative and responsive in an ever-changing marketplace, we are focused on providing solutions for our customers worldwide ... Ask Us How.LORD CorporationWorld Headquarters111 Lord DriveCary, NC 27511-7923USACustomer Support Center (in United States & Canada)+1 877 ASK LORD (275 5673)For a listing of our worldwide locations, visit .©2012 LORD Corporation OD DS4094 (Rev.0 9/12)。

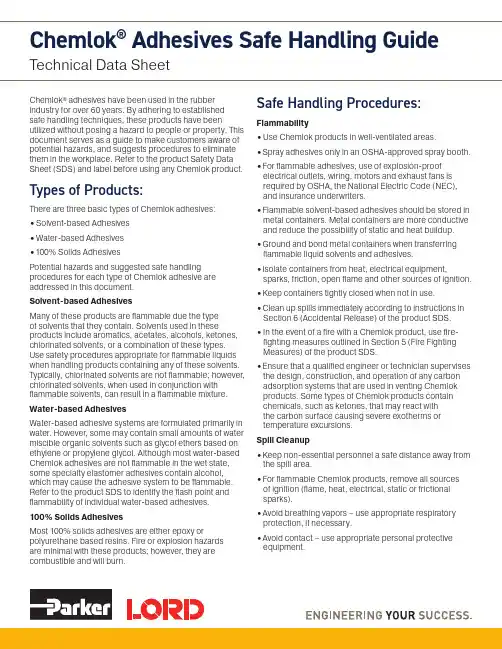

Chemlok® Adhesives Safe Handling Guide Technical Data SheetChemlok® adhesives have been used in the rubber industry for over 60 years. By adhering to established safe handling techniques, these products have been utilized without posing a hazard to people or property. This document serves as a guide to make customers aware of potential hazards, and suggests procedures to eliminate them in the workplace. Refer to the product Safety Data Sheet (SDS) and label before using any Chemlok product.Types of Products:There are three basic types of Chemlok adhesives:• S olvent-based Adhesives• W ater-based Adhesives• 100% Solids AdhesivesPotential hazards and suggested safe handling procedures for each type of Chemlok adhesive are addressed in this document.Solvent-based AdhesivesMany of these products are flammable due the typeof solvents that they contain. Solvents used in these products include aromatics, acetates, alcohols, ketones, chlorinated solvents, or a combination of these types. Use safety procedures appropriate for flammable liquids when handling products containing any of these solvents. Typically, chlorinated solvents are not flammable; however, chlorinated solvents, when used in conjunction with flammable solvents, can result in a flammable mixture. Water-based AdhesivesWater-based adhesive systems are formulated primarily in water. However, some may contain small amounts of water miscible organic solvents such as glycol ethers based on ethylene or propylene glycol. Although most water-based Chemlok adhesives are not flammable in the wet state, some specialty elastomer adhesives contain alcohol, which may cause the adhesive system to be flammable. Refer to the product SDS to identify the flash point and flammability of individual water-based adhesives.100% Solids AdhesivesMost 100% solids adhesives are either epoxy or polyurethane based resins. Fire or explosion hazardsare minimal with these products; however, they are combustible and will burn.Safe Handling Procedures: Flammability• U se Chemlok products in well-ventilated areas.• S pray adhesives only in an OSHA-approved spray booth.• F or flammable adhesives, use of explosion-proofelectrical outlets, wiring, motors and exhaust fans is required by OSHA, the National Electric Code (NEC), and insurance underwriters.• F lammable solvent-based adhesives should be stored in metal containers. Metal containers are more conductive and reduce the possibility of static and heat buildup.• G round and bond metal containers when transferring flammable liquid solvents and adhesives.• I solate containers from heat, electrical equipment, sparks, friction, open flame and other sources of ignition.• K eep containers tightly closed when not in use.• C lean up spills immediately according to instructions in Section 6 (Accidental Release) of the product SDS.• I n the event of a fire with a Chemlok product, use fire-fighting measures outlined in Section 5 (Fire Fighting Measures) of the product SDS.• E nsure that a qualified engineer or technician supervises the design, construction, and operation of any carbon adsorption systems that are used in venting Chemlok products. Some types of Chemlok products contain chemicals, such as ketones, that may react withthe carbon surface causing severe exotherms or temperature excursions.Spill Cleanup• K eep non-essential personnel a safe distance away from the spill area.• F or flammable Chemlok products, remove all sourcesof ignition (flame, heat, electrical, static or frictional sparks).• A void breathing vapors – use appropriate respiratory protection, if necessary.• A void contact – use appropriate personal protective equipment.•C ontain and remove the spilled product with inert absorbent material (and non-sparking tools for flammable Chemlok products).• N otify appropriate authorities, in accordance with applicable regulatory requirements, as necessary.• B efore attempting cleanup, refer to Section 6 (Accidental Release) of the product SDS.Personal Health and SafetyBecause of the variation of hazardous ingredients in Chemlok products and the resulting differing potential effects of personal exposure to workers, it is essentialto refer to the SDS and label for the specific product to ensure that it is stored, handled and used safely and that appropriate controls and personal protective equipment are utilized.• U se in well ventilated area. Avoid breathing vapors and spray mist.• A void skin and eye contact.• W ear approved respirators when occupational limits are exceeded.• U se safety eyewear including safety glasses with side shields and chemical goggles where splashing may occur.• W ear appropriate gloves.• U se disposable or impervious clothing. Remove and wash when contaminated.• W ash thoroughly before eating, smoking, or using toilet facility.• I f first aid measures are needed for ingestion, inhalation, eye contact or skin contact, refer to Section 4 (First Aid Measures) of the product SDS.Application/Spray Equipment• E nsure extinguishers are near application equipment and readily accessible.• F ixtures with excessive film buildup or film buildup that falls off a part or gets into the oven can increase the risk of smoldering/fires.• A utomated application equipment (chain-on-edge) and associated ovens should have safety interlocks that shut down the oven or stop the line in the event of a fire.• E lectric, steam coil or natural gas enclosed box-type ovens are preferred. IR ovens have an increased potential for causing Chemlok products to smolder or ignite.• U se flame retardant, heavyweight paper to line all floor areas in immediate application area to prevent buildup on floor. Dispose of dirty paper under proper regulatory guidelines.• U se disposable/peelable spray booth coating to protect all spray booth walls, etc. Sprinkler heads in the spray application areas should be covered according to local fire code to protect from excess spray debris building up on them. This covering will prevent excessive buildup, allowing proper functioning during a fire.• W arning: Due to the combustible nature of the dried film of Chemlok products and the potential for smolderingor fire, the accumulation and buildup of the dried filmon spray booth walls and floors, spindles, fixtures and other surfaces should be avoided, and any buildup should be removed. Refer to Cleaning section for more information. In the event of smoldering or a fire involving the dried product, Cold Fire® fire suppressing agent* is preferred as the extinguishing medium. If Cold Fire is not available, use water spray as the extinguishing medium. Take efforts to ensure that these agents reach the base of the smoldering or fire. LORD Corporation will notbe responsible for personal injuries, property damage or any other damages arising from the accumulation (buildup), cleaning/removal, or any related smoldering or fire resulting from the use of Chemlok products. Waste Disposal ProceduresGuidelines established here are for waste streams generated from the use of Chemlok products. Disposal should be done in accordance with national and local environmental waste control regulations. The waste stream should be evaluated for hazardous characteristics. If waste is determined to be hazardous, properly dispose per local requirements.• W aste containing residual solvent should be treated as a flammable hazard.• W aste streams comprised of dried Chemlok adhesive residue should be treated as ignitable solids per the Globally Harmonized System of classification.• L iquid or solid waste known to contain toxic contaminants such as persistent, bioaccumulative toxins should be treated a hazardous.*Note: Parker LORD has determined Cold Fire fire suppressing agentto be effective in extinguishing fires involving dried Chemlok adhesives. Parker LORD does not recommend any particular equipment or system for use in delivering or applying Cold Fire products. Customer is responsible for determining that Cold Fire products and any delivery equipment or system is appropriate and effective for customer’s specific needs.Parker LORDEngineered Materials Group 111 LORD DriveCary, NC 27511-7923USAphone +1 877 ASK LORD (275 5673)Values stated in this document represent typical values as not all tests are run on each lot of material produced. For formalized product specifications for specific product end uses, contact the Customer Support Center.Information provided herein is based upon tests believed to be reliable. In as much as Parker LORD has no control over the manner in which others may use this information, it does not guarantee the results to be obtained. In addition, Parker LORD does not guarantee the performance of the product or the results obtained from the use of the product or this information where the product has been repackaged by any third party, including but not limited to any product end-user. Nor does the company make any express or implied warranty of merchantability or fitness for a particular purpose concerning the effects or results of such use.WARNING — USER RESPONSIBILITY . FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise.The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of theapplication are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.©2022 Parker Hannifin - All Rights ReservedInformation and specifications subject to change without notice and without liability therefor. Trademarks used herein are the property of their respective owners.OD DS3100 03/22 Rev.8Housekeeping• P revention of dry film buildup is key for safe handling. Daily or weekly inspection of application equipment, including oven tunnels and associated equipment, is recommended. Dry Chemlok adhesive residue becomes more flammable as the thickness of the film increases. • R emove dried adhesive around any mixing shafts where heat could build up and cause smoldering/fire.• A void excessive buildup of dried Chemlok products on floors and other surfaces. CleaningIt is always recommended to avoid the buildup of dried Chemlok adhesive films. However, if a film buildup has to be cleaned, the following precautions should be followed. • N on-sparking brass brush or plastic scrapers can be used for cleaning. Caution should be exercised as brush/scraper can also generate sufficient heat from friction to initiate smoldering/fire.• T here are a variety of debris removal methods. Consult with your Parker LORD representative to determine suitable methods for debris removal from application equipment.• M ake sure that some sort of water reservoir is available to continually wet down the surfaces being cleaned.This keeps temperatures down and reduces the effect of frictional heat buildup during cleaning.• F or larger debris clean-ups, explosion-proof vacuums are suggested.Remember – There are no short cuts to Safety!Cautionary Information:Before using this or any Parker LORD product, refer to the Safety Data Sheet (SDS) and label for safe use and handling instructions.For industrial/commercial use only. Must be applied by trained personnel only. Not to be used in household applications. Not for consumer use.。

开姆洛克(CHEMLOK)系列胶粘剂的性质及选用一,前言开姆洛克胶粘剂系美国洛德(LORD)公司产品,问世30年来,以粘结强度高,质量稳定,使用方便,而饮誉世界,广泛应用于各种橡胶与金属的粘合。

二,常用品种及分类情况分为三类:1底涂型,2,面涂型,3,单涂型,常用的分类及主体高聚物见表:1,底涂型胶粘剂(CH205)的特点(1)能粘结多种金属:铸铁,碳钢,不锈钢,合金钢,铝,铝合金,铜,铜合金。

(2)与面涂型胶粘剂有良好的粘结性。

(3)有良好的防锈性能,能保护金属表面。

(4)有良好的耐环境性。

(5)亦可作为NBR的单涂型胶粘剂,即粘结金属与NBR时,一般不需再选用面涂型胶粘剂。

2,面涂型胶粘剂的特点(1)通过正确选用,能粘结各种通用橡胶。

(2)与底涂型胶粘剂(CH205)粘结性能优异。

由于面涂型胶粘剂与金属的粘结效果不是很好,或者即使有些品种,如常用的CH220,初期粘结强度亦很高,足以产生橡胶内聚破坏的结合力,但粘结件耐环境性,稳定性不足,因此,使用面涂型胶粘剂之前,金属表面一般宜先涂底涂型胶粘剂,确保与金属优良的粘合,确保粘结件的耐环境性,耐久性。

由一种底涂型胶粘剂和一种面涂型胶粘剂,便组成了洛德公司(LORD)所谓的双涂体系。

3,单涂型胶粘剂单涂体系或单涂型胶粘剂的特点:(1)与多种金属的粘结优良。

(2)通过正确的选用,能粘结所有的橡胶。

由于单涂型胶粘剂不需底涂,便可获得可靠的橡胶/金属粘结件,工艺上比较方便,因此比较受工厂欢迎。

值得注意是,虽然单涂型胶粘剂与金属的粘结优与面涂型胶粘剂,但不如底涂型胶粘剂。

同时单涂型胶粘剂粘结件的耐环境性,耐久性也不如双涂系列(底涂+面涂)。

三,性能与特点第一个特点适用面广,品种多进30个见表通过正确选用可以达到以下目的:(1) 硫化粘结各种橡胶与多种金属粘合,如铁,钢,不锈钢,合金钢,铝,铝合金,铜,铜合金等。

(2) 硫化粘结各种橡胶与多种织物,纤维,如人造丝,尼龙,涤纶,玻纤,芳纶,碳纤维等。

开姆洛克胶粘剂操作规程

《开姆洛克胶粘剂操作规程》

一、胶粘剂搅拌

1. 打开胶粘剂桶盖,用搅拌棒将胶粘剂充分搅拌均匀,确保不出现分层现象。

二、胶粘剂使用

1. 在需要粘合的物体表面均匀涂抹一层胶粘剂。

2. 将两个需要粘合的物体迅速压合,并保持一定时间。

三、胶粘剂存放

1. 胶粘剂桶盖密封好,存放在阴凉干燥处。

2. 避免胶粘剂受潮或曝晒于阳光直射下。

四、胶粘剂注意事项

1. 使用时请戴上手套,避免胶粘剂直接接触皮肤。

2. 避免胶粘剂溅入眼睛,如不慎溅入眼睛,请立即用清水冲洗并就医。

五、事故应急处理

1. 如意外吞咽胶粘剂,立即饮用大量清水,并就医。

2. 如意外接触胶粘剂,立即用清水冲洗受伤处,并就医。

六、其他注意事项

1. 本操作规程仅用于开姆洛克胶粘剂的安全操作,其他胶粘剂不适用。

2. 使用胶粘剂时应确保操作环境通风良好,避免吸入有害气体。

七、规程修改

1. 如有任何操作规程需要修改或更新,请联系相关负责人员并及时更新。

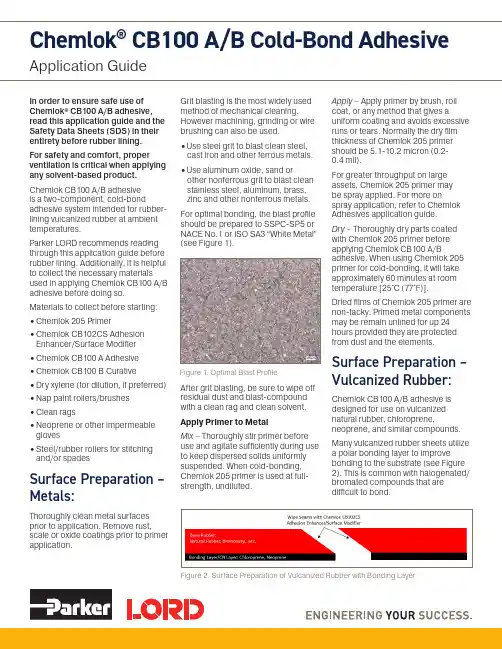

Chemlok® CB100 A/B Cold-Bond Adhesive Application GuideIn order to ensure safe use of Chemlok® CB100 A/B adhesive, read this application guide and the Safety Data Sheets (SDS) in their entirety before rubber lining.For safety and comfort, proper ventilation is critical when applying any solvent-based product. Chemlok CB100 A/B adhesiveis a two-component, cold-bond adhesive system intended for rubber-lining vulcanized rubber at ambient temperatures.Parker LORD recommends reading through this application guide before rubber lining. Additionally, it is helpful to collect the necessary materials used in applying Chemlok CB100 A/B adhesive before doing so. Materials to collect before starting:•C hemlok 205 Primer•C hemlok CB102CS Adhesion Enhancer/Surface Modifier•C hemlok CB100 A Adhesive•C hemlok CB100 B Curative•D ry xylene (for dilution, if preferred)•N ap paint rollers/brushes•C lean rags•N eoprene or other impermeable gloves•S teel/rubber rollers for stitching and/or spadesSurface Preparation –Metals:Thoroughly clean metal surfaces prior to application. Remove rust, scale or oxide coatings prior to primer application. Grit blasting is the most widely usedmethod of mechanical cleaning.However machining, grinding or wirebrushing can also be used.•U se steel grit to blast clean steel,cast iron and other ferrous metals.•U se aluminum oxide, sand orother nonferrous grit to blast cleanstainless steel, aluminum, brass,zinc and other nonferrous metals.For optimal bonding, the blast profileshould be prepared to SSPC-SP5 orNACE No.1 or ISO SA3 “White Metal”(see Figure 1).After grit blasting, be sure to wipe offresidual dust and blast-compoundwith a clean rag and clean solvent.Apply Primer to MetalMix – Thoroughly stir primer beforeuse and agitate sufficiently during useto keep dispersed solids uniformlysuspended. When cold-bonding,Chemlok 205 primer is used at full-strength, undiluted.Figure 1. Optimal Blast ProfileApply – Apply primer by brush, rollcoat, or any method that gives auniform coating and avoids excessiveruns or tears. Normally the dry filmthickness of Chemlok 205 primershould be 5.1-10.2 micron (0.2-0.4 mil).For greater throughput on largeassets, Chemlok 205 primer maybe spray applied. For more onspray application, refer to ChemlokAdhesives application guide.Dry – Thoroughly dry parts coatedwith Chemlok 205 primer beforeapplying Chemlok CB100 A/Badhesive. When using Chemlok 205primer for cold-bonding, it will takeapproximately 60 minutes at roomtemperature [25°C (77°F)].Dried films of Chemlok 205 primer arenon-tacky. Primed metal componentsmay be remain unlined for up 24hours provided they are protectedfrom dust and the elements.Surface Preparation –Vulcanized Rubber:Chemlok CB100 A/B adhesive isdesigned for use on vulcanizednatural rubber, chloroprene,neoprene, and similar compounds.Many vulcanized rubber sheets utilizea polar bonding layer to improvebonding to the substrate (see Figure2). This is common with halogenated/bromated compounds that aredifficult to bond.Figure 2. Surface Preparation of Vulcanized Rubber with Bonding LayerIf you are unsure what substrate you are bonding, ask your rubber supplier if a ‘bonding layer’ or ‘CN-layer’ is included on your rubber. The bonding layer is often a noticeably different color.For Rubber With a Bonding Layer •W ipe the bonding layer clean with a dry solvent. For best results, apply Chemlok CB102CS adhesion enhancer/surface modifier to clean and activate the surface as it contains functional chemistry that will further enhance the polarity of the bonding layer.•S eams, and mating skives, where the bonding layer is not present should always be treated with Chemlok CB102CS adhesion enhancer/surface modifier with a rag wipe (see Figure 2). DO NOT SPRAY.For Rubber Without a Bonding Layer•A moderate buff is recommended. Buffing will remove surface contaminates, such as antioxidants and waxes, that may have bloomed to the bond surface and willinhibit the bond. Buffing will also mechanically abrade the bond interface; improving its topography and making it more available to the bonding agent.•U tilize Chemlok CB102CS adhesion enhancer/surface modifier to clean the buffed area and treat seams. When used properly, Chemlok CB102CS adhesion enhancer/surface modifier will dry in approximately 5 minutes at 25°C (77°F).All rubber compounds are different, and Parker LORD recommends testing Chemlok CB100 A/B adhesive to determine fitness for use in your application. If you do not havethe facilities to test your substrate combination, contact Parker LORDat 877-ASK-LORD to discuss having our labs assist in determining whether Chemlok CB100 A/B adhesive is an appropriate fit for your application. Mixing Adhesive:If using Chemlok CB100 A/B adhesivein bulk, the mix ratio by weight is:•12 parts Chemlok CB100 A adhesive•1.0 parts Chemlok CB100 B curativeChemlok CB100 A and B componentsused in quart and gallon form aredesigned as ‘dump-and-mix,’meaning the chemistry has beenpre-measured by Parker LORD foryour convenience such that ChemlokCB100 B curative can be poureddirectly into the container for ChemlokCB100 A adhesive and mixed withoutmeasuring.Mix Chemlok CB100 A and Bcomponent by hand for 3-5 minutes.You will notice a physical change inviscosity when mixed appropriately. Ifusing a pneumatic drill or pneumaticmixer, low RPMs are encouraged astoo high a RPM could incorporate airinto the system.DilutionChemlok CB100 A/B adhesive has agreater solids content than most cold-bonding adhesives. This is intentionalas it:•R educes the number of coatsrequired to achieve recommendedfilm thicknesses,•B etter coats porous substrates likeconcrete and aggressive steel gritblasts, and• A llows user to dilute the mixedchemistry to their preferred workingviscosity for their application.Generally, the larger the asset, theeasier it is to roll Chemlok CB100 A/Badhesive in its neat form. The smallerthe asset, and you may find it easierto brush and roll in a diluted form.To dilute Chemlok CB100 A/Badhesive, add up to 4 oz (120 mL) ofdry xylene for each mixed quart, andup to 16 oz (480 mL) per gallon kit.For best results when diluting,add Chemlok CB100 B curative toChemlok CB100 A adhesive and mixfor 2-3 minutes. Then add the desiredamount of diluent and mix for anadditional 2-3 minutes.Applying Adhesive –Rubber-to-Metal:Coats required to sufficiently bondassets will vary by geometry anddilution of Chemlok CB100 A/Badhesive.Generally, in its undiluted form:•E xterior-diameter parts and flatplates benefit from the followingcombination: one coat of adhesiveon primed metal and one coat ofadhesive on the prepared rubber.If the adhesive is diluted, a secondcoat on the rubber only is generallyrecommended.•I nterior-diameter parts generallybenefit from the followingcombination: one coat of adhesiveon the metal and two coats ofadhesive applied to the rubber.When used in practice, the firstcoat to the metal and rubber areapplied simultaneously. The secondcoat applied to the rubber is usedas a ‘wet-swaging’ lubricant. Theadhesive allows the lining to bepushed into place more easily and,as solvent evaporates, adheres therubber lining to the inner diameter ofthe radii.Differences in geometry, rubberdurometer, and manufacturingpreferences will dictate the bestcombination of dilution and coatswhich are suitable. Parker LORDrecommends testing Chemlok CB100A/B adhesive before implementing itin manufacturing.ApplyUsing a nap roller or brush, applyapproximately 22-26 wet mils (640microns) of Chemlok CB100 A/Badhesive to prepared rubber. Applyan equal amount of adhesive tothe primed metal. (If desired, whenusing a second coat on the rubber,apply an additional 22-26 wet mils15-30 minutes after the first coat wasapplied.)If applied correctly, the adhesive will appear uniform and you will not be able to see the underlying primer on the metal or color of the rubber. If you are having difficulty applying Chemlok CB100 A/B adhesive or find that you are ‘pushing’ instead of rolling it, try diluting adhesive per instructions. TackAllow 45-60 minutes for tack to develop. Chemlok CB100 A/B adhesive will transition from a glossy appearance to matte appearance. Depending on airflow, tack time will vary.Chemlok CB100 A/B adhesive will feel slightly dry to the touch with minor tack. This is by design to allow for easier rubber handling. When Chemlok CB100 A/B adhesive is mated to another surface coated with Chemlok CB100 A/B adhesive, it will stick tenaciously.FresheningDepending on humidity and temperature, adhesive can be freshened by wiping with a xylene soaked rag. Be sure to allow adequate time for the xylene toflash (dry off) before mating. Chemlok CB100 A/B adhesive may be freshened up to 2 hours after application.MateMate rubber to metal, and stitch with rubber roller or apply spade pressure to eliminate air-gaps and ensure good entanglement of metal and rubber coats.CureDepending on the asset size and geometric complexity, most assets can be moved immediately after rubber-lining as long as the bondline is not stressed. Although cure will occur in a 24-72 hour period, full strengths are reached in seven days. Applying Adhesive –Rubber-to-Rubber(Seams):First CoatUsing a nap roller or brush, apply auniform coat of Chemlok CB100 A/Badhesive, approximately 22-26 wetmils (640 microns), to each face ofthe prepared rubber.DryAllow 15-30 minutes to dry at 77°F(25°C).Second CoatApply a second coat to both rubberinterfaces.TackAllow 45-60 minutes for tack todevelop. Chemlok CB100 A/Badhesive will feel slightly dry to thetouch with minor tack. This is bydesign to allow for easier rubberhandling. When Chemlok CB100 A/Badhesive is mated to another surfacecoated with Chemlok CB100 A/Badhesive, it will stick tenaciously.FresheningDepending on humidity andtemperature, adhesive can befreshened by wiping with a xylenesoaked rag. By sure to allow adequatetime for the xylene to flash (dry off)before mating. Chemlok CB100 A/Badhesive may be freshened up to2 hours after application.MateMate seams by first testing tack, stickthe tip of one end of the seam to thebase of the second end. If this holdswith no stretching, close the seam therest of the way.CureDepending on the asset size andgeometric complexity, most assetscan be moved immediately afterrubber-lining as long as the bondlineis not stressed. Although cure willoccur in a 24-72 hour period, fullstrengths are reached in seven days.Common Problems &Troubleshooting:Stringing of adhesive fromsubstrate around a radius or ata seam – This is often a function ofeither too much adhesive applied orinadequate drying before mating. Toresolve, try applying less adhesiveusing a roller or diluting the adhesive.Diluting will speed the evaporationand allow the product to be appliedthinner.Adhesive layers won’t stickto themselves – The adhesivehas become too dry and must befreshened. Soak a rag with dry xyleneand wipe onto the surface of theadhesive, allowing tack to develop.If outside of the freshening window,apply another thin layer of ChemlokCB100 A/B adhesive.Adhesive is too thick to roll – Trydiluting the adhesive up to 4 oz(120 mL) of dry xylene per quartChemlok CB100 A/B adhesive.Maintaining SurfaceConditions DuringApplication:Maintaining optimum surfacecleanliness is essential to goodbonding.•A void exposure to dust, moisture,chemical fumes, mold releaseagents and other possiblecontaminants.•W hen handling substrates, wearchemical resistant gloves, such asnitrile; avoid latex gloves.•K eep solvents and cleaningsolutions free from contaminationand replace when necessary.•E nsure grits and abrasives remainclean and free of contaminants.•C heck the purity of rinse water and“drying” air frequently, ensuringminimal contamination.Parker LORDEngineered Materials Group 111 LORD DriveCary, NC 27511-7923USAphone +1 877 ASK LORD (275 5673)Values stated in this document represent typical values as not all tests are run on each lot of material produced. For formalized product specifications for specific product end uses, contact the Customer Support Center.Information provided herein is based upon tests believed to be reliable. In as much as Parker LORD has no control over the manner in which others may use this information, it does not guarantee the results to be obtained. In addition, Parker LORD does not guarantee the performance of the product or the results obtained from the use of the product or this information where the product has been repackaged by any third party, including but not limited to any product end-user. Nor does the company make any express or implied warranty of merchantability or fitness for a particular purpose concerning the effects or results of such use.WARNING — USER RESPONSIBILITY . FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.This document and other information from Parker-Hannifin Corporation, its subsidiaries and authorized distributors provide product or system options for further investigation by users having technical expertise.The user, through its own analysis and testing, is solely responsible for making the final selection of the system and components and assuring that all performance, endurance, maintenance, safety and warning requirements of theapplication are met. The user must analyze all aspects of the application, follow applicable industry standards, and follow the information concerning the product in the current product catalog and in any other materials provided from Parker or its subsidiaries or authorized distributors.To the extent that Parker or its subsidiaries or authorized distributors provide component or system options based upon data or specifications provided by the user, the user is responsible for determining that such data and specifications are suitable and sufficient for all applications and reasonably foreseeable uses of the components or systems.©2021 Parker Hannifin - All Rights ReservedInformation and specifications subject to change without notice and without liability therefor. Trademarks used herein are the property of their respective owners.OD AG1031 10/21 Rev.1The water break test can be used to check for oil and grease removal. If a surface can support an unbroken film of deionized water for 60 seconds or more, it is considered essentially free from grease or oil.Safe Handling:Proper handling of Chemlok CB100 A/B adhesive is essential for safe and effective application. We recommend these procedures be followed:Routes of ExposureSolvents and isocyanates enter the body primarily through inhalation or skin exposure however consider oral and eye contact.Health Effects• I nhalation of isocyanates and solvents can cause respiratory irritation/sensitization in people or lead to occupational asthma. • I ndividuals with a history of asthma should not work in areas with the potential for isocyanate exposure.• S olvents and their vapors/mists have various effects on human health. Many of them have a narcotic effect, causing fatigue, dizziness and intoxication. Highdoses may lead to unconsciousness and death. Exposure to large doses of solvents may slow down reaction- time and affect rational judgement.• R epeat or prolonged solvent content may cause burns or dermatitis or skin defatting.• S kin sensitization can occur due to the irritant nature of isocyanates in contact with the skin surface, which may result in dermatitis.Recommendations• T o ensure the air exchange and ventilation system of the work area is appropriate for the process, air monitoring may be considered, ensuring the levels are below the occupational exposure limits reported in Section 8 of the product SDS.• I f this is not possible, work with isocyanates should be isolated away from other areas of the workplace using engineeringcontrols, for example, local exhaust ventilation (LEV), spray booths with appropriate PPE (e.g. airline respirators, suitable gloves, overalls and goggles).• G ood personal hygiene should be practiced and a separate storage area utilized for work clothing to prevent the contamination of regular clothing.• H ands should always be washed before eating, drinking, smoking and before leaving work. • B iological monitoring forisocyanates in workers urine can be performed as an additional precautionary measure.Key Points• C onsult relevant SDS and product labels to assist in determining appropriate control measures. • D o not spray apply.• L iquid and vapors are flammable. Avoid all heat, sparks, and flame sources.• A lways assume that exposure islikely to occur and protect according to the level of risk identified from risk assessment.• E nsure appropriate PPE is correctly selected, used and maintained.• A void skin contact through the use of impervious gloves and protective clothing.• U se tools for product manipulation, if necessary.• W ear safety glasses, goggles, or face shield.• D o not use within an enclosed space.• A void inhalation by ensuring ventilation is adequate and functioning properly.• P erform chemical air monitoring, as necessary.• A lways wash hands before eating, drinking, smoking, and leaving work. • C lean processing equipment regularly.• D ispose of waste according to federal, state, and local regulations.。

开姆洛克(C H E M L O K)系列胶粘剂的性质及选用一,前言开姆洛克胶粘剂系美国洛德(LORD)公司产品,问世30年来,以粘结强度高,质量稳定,使用方便,而饮誉世界,广泛应用于各种橡胶与金属的粘合。

二,常用品种及分类情况分为三类:1底涂型,2,面涂型,3,单涂型,常用的分类及主体高聚物见表:1,底涂型胶粘剂(CH205)的特点(1)能粘结多种金属:铸铁,碳钢,不锈钢,合金钢,铝,铝合金,铜,铜合金。

(2)与面涂型胶粘剂有良好的粘结性。

(3)有良好的防锈性能,能保护金属表面。

(4)有良好的耐环境性。

(5)亦可作为NBR的单涂型胶粘剂,即粘结金属与NBR时,一般不需再选用面涂型胶粘剂。

2,面涂型胶粘剂的特点(1)通过正确选用,能粘结各种通用橡胶。

(2)与底涂型胶粘剂(CH205)粘结性能优异。

由于面涂型胶粘剂与金属的粘结效果不是很好,或者即使有些品种,如常用的CH220,初期粘结强度亦很高,足以产生橡胶内聚破坏的结合力,但粘结件耐环境性,稳定性不足,因此,使用面涂型胶粘剂之前,金属表面一般宜先涂底涂型胶粘剂,确保与金属优良的粘合,确保粘结件的耐环境性,耐久性。

由一种底涂型胶粘剂和一种面涂型胶粘剂,便组成了洛德公司(LORD)所谓的双涂体系。

3,单涂型胶粘剂单涂体系或单涂型胶粘剂的特点:(1)与多种金属的粘结优良。

(2)通过正确的选用,能粘结所有的橡胶。

由于单涂型胶粘剂不需底涂,便可获得可靠的橡胶/金属粘结件,工艺上比较方便,因此比较受工厂欢迎。

值得注意是,虽然单涂型胶粘剂与金属的粘结优与面涂型胶粘剂,但不如底涂型胶粘剂。

同时单涂型胶粘剂粘结件的耐环境性,耐久性也不如双涂系列(底涂+面涂)。

三,性能与特点第一个特点适用面广,品种多进30个见表通过正确选用可以达到以下目的:(1)硫化粘结各种橡胶与多种金属粘合,如铁,钢,不锈钢,合金钢,铝,铝合金,铜,铜合金等。

(2)硫化粘结各种橡胶与多种织物,纤维,如人造丝,尼龙,涤纶,玻纤,芳纶,碳纤维等。

上海市企业标准Q/GHJH 1-2006代替 Q/GHJH 1-2002Q/GHJH 1-2006目次前言.................................................................................Ⅱ 1 范围...............................................................................1 2规范性引用文件.....................................................................1 3产品牌号、规格 .....................................................................1 4技术要求...........................................................................1 5试验方法...........................................................................2 6检验规则...........................................................................2 7标志、包装、运输、贮存............................................................3Q/GHJH 1-2006前言本标准等效采用美国LORD®公司的胶粘剂规格DS10-3135C(1992)而制订的。

本标准就Q/GHJH 1-2002的标准不变,仅对年份进行了修改。

本标准按照GB/T 1.3-1997《标准化工作导则 第1单元:标准的起草与表述规则 第3部分:产品标准编写规定》和GB/T 1.1-2002《标准化工作导则 第1部分:标准的结构和编写规则》进行编写。

DescriptionLORD Chemlok ® 252X adhesive is a general purpose one-coat adhesive that will bond a variety of vulcanized or unvulcanized rubber compounds to metal or other dissimilar rubber compounds. It is composed of a mixture of polymers, organic compounds and mineral fi llers dissolved or dispersed in an organic solvent system.A single coat of Chemlok 252X adhesive will bond compounds based on natural rubber (NR), polyiso-prene (IR), styrene-butadiene (SBR), polybutadiene (BR), polychloroprene (CR), nitrile (NBR), butyl (IIR) and EPDM polymers to metals. These metals include carbon and alloy steels, stainless steel, aluminum, copper and copper alloys, magnesium and zinc, as well as a variety of plastics.For maximum protection or when environmental condi-tions are extremely aggressive, Chemlok 252X adhesive can be used over Chemlok 205 primer.Features and Benefi tsVersatile – bonds a wide range of elastomers and toler-ates a variety of differences in compounding.Chemlok ®252X AdhesiveNon-Chlorinated Solvent System – suitable for solvent incineration, saving cost of recovery equipment.Convenient – requires only a single coat for most appli-cations, reducing labor, solvent usage, inventory and shipping costs.Application Surface Preparation – Thoroughly clean metal surfaces prior to adhesive application. Remove protective oils, cutting oils and greases by solvent degreasing oralkaline cleaning. Remove rust, scale or oxide coatings by suitable chemical or mechanical cleaning methods.•Chemical CleaningChemical treatments are readily adapted to auto-mated metal treatment and adhesive application lines. Chemical treatments are also used on metal parts that would be distorted by blast cleaning or where tight tolerances must be maintained. Phos-phatizing is a commonly used chemical treatment for steel, while conversion coatings are commonly used for aluminum.Typical Properties*AppearanceBlack Liquid Viscosity, seconds20 - 40Zahn Cup #3Density kg/m 3 950.0 - 990.0(lb/gal)(7.9-8.3)Solids Content by Weight, % 22 - 24Flash Point (Seta), °C (°F) 26 (79)SolventsXylene*Data is typical and not to be used for specification purposes.• Mechanical CleaningGrit blasting is the most widely used method ofmechanical cleaning. However machining, grindingor wire brushing can be used. Use steel grit to blast clean steel, cast iron and other ferrous metals. Usealuminum oxide, sand or other nonferrous grit to blast clean stainless steel, aluminum, brass, zinc and other nonferrous metals.For further detailed information on surface preparation of specifi c substrates, refer to Chemlok Adhesives appli-cation guide. Handle clean metal surfaces with clean gloves to avoid contamination with skin oils.Mixing – Thoroughly stir Chemlok 252X adhesive before use, and agitate suffi ciently during use to keep dispersed solids uniformly suspended. Mix drums for 8 hours at30-60 rpm before using. If needed, proper dilution for the various application methods is best achieved by experi-ence.Applying – Apply Chemlok 252X adhesive by spray, dip or brush methods. Chemlok 252X adhesive is best suited for spray application.When using Chemlok 252X adhesive as a one-coat adhesive, the dry fi lm thickness should be 20.3-25.4 micron (0.8-1.0 mil) for optimum adhesion and environmental resistance. When used as a covercoat over Chemlok 205 primer, the dry fi lm thickness of the Chemlok 252X adhesive should be 10.2-17.8 micron (0.4-0.7 mil).• SprayingDilute adhesive to a Zahn Cup #2 viscosity of 25-28seconds. Use xylene or toluene in a ratio of approxi-mately 60 parts adhesive to 40 parts solvent, byweight or by volume. Tip sizes of 1.07-1.40 mm(0.042-0.055 in) are appropriate. Maintain atomiza-tion pressures at 0.345-0.379 MPa (50-55 psi) for best atomization.• DippingUse full strength. In many instances, a single dipapplication of Chemlok 252X adhesive will be suffi -cient to provide excellent adhesion. A single dipis appropriate when Chemlok 205 primer is usedunder Chemlok 252X adhesive. Where rubber-to-metal bonded assemblies are likely to be exposedto aggressive environmental conditions, it may benecessary to double dip Chemlok 252X adhesivediluted at a ratio of 5 parts adhesive to 1 part solvent, by volume, in order to achieve dry fi lm thicknesses of20.3-25.4 micron (0.8-1.0 mil).• BrushingApply full strength.Drying/Curing – Allow the applied adhesive to dryuntil visual examination of the fi lm has shown that all solvent has evaporated. This will take approximately30-60 minutes at room temperature. Drying time can be shortened by either preheating the metal inserts or oven drying after application. Metal parts may be preheated to a maximum of 65°C (150°F) prior to adhesive applica-tion. For coated parts, moderate drying temperatures should be used, but temperatures as high as 149°C (300°F) may be used for very short periods of time. Maximum air fl ow at minimum temperatures will give the best results.Dried fi lms of Chemlok 252X adhesive are non-tacky; therefore, coated parts can be piled into tote pansfor subsequent processing. Wear clean gloves when handling coated parts and cover the tote pans to prevent contamination by dirt, dust, grease, oil, etc. If coated parts are properly protected, long layover times between adhesive application and bonding usually have no adverse effect on the bond. If Chemlok 252X adhe-sive has been removed by chipping or abrasion during handling, these damaged areas can be recoated before bonding.Chemlok 252X adhesive can be used to bond rubberby compression, transfer, injection or other molding procedures used to make bonded parts. As with other Chemlok adhesives, maximum adhesion is obtained when the rubber has completely cured. Ideal bonding conditions exist when both the adhesive and the rubber cure at the same time. To accomplish this, load the adhe-sive coated metal parts in the mold and quickly fi ll the cavity with rubber.While it is desirable to keep mold loading cycles to a minimum to prevent pre-cure of the adhesive and the rubber, Chemlok 252X adhesive will resist prebaking times up to 15 minutes at 160°C (320°F) or the equiva-lent at other temperatures without affecting bond performance. Transfer or injection molds need properly designed runners and sprues, as well as adequate pres-sures. This prevents rubber pre-curing before the mold cavities are completely fi lled.Post-Vulcanization Bonding – Chemlok 252X adhe-sive exhibits excellent post-vulcanization (PV) bonding capability with vulcanized compounds of NR, SBR, chlo-roprene, nitrile, butyl, Hypalon® and EPDM. For further details on post-vulcanization bonding, refer to Post-Vulcanization Bonding Guide for Chemlok Adhesives.Shelf Life/StorageShelf life is one year from date of shipment when stored at 21-27°C (70-80°F) in original, unopened container. Do not store or use near heat, sparks or open fl ame.Cautionary InformationBefore using this or any LORD product, refer to the Mate-rial Safety Data Sheet (MSDS) and label for safe use and handling instructions.For industrial/commercial use only. Must be applied by trained personnel only. Not to be used in household applications. Not for consumer use.Hypalon is a registered trademark of E.I. DuPont de Nemours.Values stated in this technical data sheet represent typical values as not all tests are run on each lot of material produced. For formalized product specifi cations for specifi c product end uses, contact the Customer Support Center.Information provided herein is based upon tests believed to be reliable. In as much as LORD Corporation has no control over the manner in which others may use this information, it does not guarantee the results to be obtained. In addition, LORD Corporation does not guarantee the perfor-mance of the product or the results obtained from the use of the product or this information where the product has been repackaged by any third party, including but not limited to any product end-user. Nor does the company make any express or implied warranty of merchantability or fi tness for a particular purpose concerning the effects or results of such use.Chemlok and “Ask Us How” are trademarks of LORD Corporation or one of its subsidiaries.LORD provides valuable expertise in adhesives and coatings, vibration and motion control, and magnetically responsive technologies. Our people work in collaboration with our customers to help them increase the value of their products. Innovative and responsive in an ever-changing marketplace, we are focused on providing solutions for our customers worldwide ... Ask Us How.LORD CorporationWorld Headquarters111 Lord DriveCary, NC 27511-7923USACustomer Support Center (in United States & Canada)+1 877 ASK LORD (275 5673)For a listing of our worldwide locations, visit .©2012 LORD Corporation OD DS3126 (Rev.6 9/12)。

开姆洛克C H E M L O K胶粘剂的性质及选用 Pleasure Group Office【T985AB-B866SYT-B182C-BS682T-STT18】开姆洛克(C H E M L O K)系列胶粘剂的性质及选用一,前言开姆洛克胶粘剂系美国洛德(LORD)公司产品,问世30年来,以粘结强度高,质量稳定,使用方便,而饮誉世界,广泛应用于各种橡胶与金属的粘合。

二,常用品种及分类情况分为三类:1底涂型,2,面涂型,3,单涂型,常用的分类及主体高聚物见表:1,底涂型胶粘剂(CH205)的特点(1)能粘结多种金属:铸铁,碳钢,不锈钢,合金钢,铝,铝合金,铜,铜合金。

(2)与面涂型胶粘剂有良好的粘结性。

(3)有良好的防锈性能,能保护金属表面。

(4)有良好的耐环境性。

(5)亦可作为NBR的单涂型胶粘剂,即粘结金属与NBR时,一般不需再选用面涂型胶粘剂。

2,面涂型胶粘剂的特点(1)通过正确选用,能粘结各种通用橡胶。

(2)与底涂型胶粘剂(CH205)粘结性能优异。

由于面涂型胶粘剂与金属的粘结效果不是很好,或者即使有些品种,如常用的CH220,初期粘结强度亦很高,足以产生橡胶内聚破坏的结合力,但粘结件耐环境性,稳定性不足,因此,使用面涂型胶粘剂之前,金属表面一般宜先涂底涂型胶粘剂,确保与金属优良的粘合,确保粘结件的耐环境性,耐久性。

由一种底涂型胶粘剂和一种面涂型胶粘剂,便组成了洛德公司(LORD)所谓的双涂体系。

3,单涂型胶粘剂单涂体系或单涂型胶粘剂的特点:(1)与多种金属的粘结优良。

(2)通过正确的选用,能粘结所有的橡胶。

由于单涂型胶粘剂不需底涂,便可获得可靠的橡胶/金属粘结件,工艺上比较方便,因此比较受工厂欢迎。

值得注意是,虽然单涂型胶粘剂与金属的粘结优与面涂型胶粘剂,但不如底涂型胶粘剂。

同时单涂型胶粘剂粘结件的耐环境性,耐久性也不如双涂系列(底涂+面涂)。

三,性能与特点第一个特点适用面广,品种多进30个见表通过正确选用可以达到以下目的:(1)硫化粘结各种橡胶与多种金属粘合,如铁,钢,不锈钢,合金钢,铝,铝合金,铜,铜合金等。

开姆洛克胶粘剂工艺及应用上海洛德化学有限公司2005/11/181溶剂型胶粘剂工艺及影响因素•胶粘剂的搅拌及储存•金属表面处理•胶粘剂涂胶:-刷涂-浸涂-喷涂•胶粘剂涂胶厚度•涂胶件的停放2胶粘剂的搅拌及储存•5Gal以下的包装-使用前,用木棒搅拌或机械搅拌。

1.搅拌至少10~15min.直至胶粘剂混和均匀。

2.机械搅拌应采用防爆电机;或采用气动马达。

-搅拌之前,将桶底部的沉淀物搅松,再搅拌。

-胶粘剂使用过程中,建议定时搅拌。

3胶粘剂的搅拌及储存•55Gal 的包装-使用前,以40-60 rpm 转速搅拌8小时。

-使用中,建议连续搅拌。

•储存:-环境温度:10~32C,远离热源。

-良好的通风环境。

4金属表面处理•为了获得良好的粘接性能及耐环境性能•表面处理-清除尘、油及其他污染物。

-机械处理或化学处理。

•选择表面处理方式应考虑的因素:-成本。

-现有设备。

-耐环境要求。

-政府法规。

5金属表面处理方法•机械处理:-砂纸打毛-钢丝刷打磨-钢丝轮打磨-车削-喷砂6喷砂工艺中的有关因素•磨粒材料:石英砂、钢粒、氧化铝等•磨粒尺寸:40目•喷射角度:30~60°•喷射时间:金属喷砂后,应当日涂胶;不锈钢应在半小时内涂胶。

7金属表面处理方法•化学处理-磷化:磷化膜厚度3.5g/m2,磷化膜呈微晶结构。

-镀锌-阳极氧化8不锈钢-化学处理方法一•蒸汽脱脂•在下述溶液中50℃浸渍15分钟浓硫酸(S.P. 1.84)1000ml / 饱和Na2Cr2O7 溶液35ml•冷水洗,开水洗,干燥。

*30分钟内涂胶9不锈钢-化学处理方法二•90℃碱洗脱脂10分钟水洗•在下述溶液中65℃浸渍10分钟,草酸10 重量份硫酸10 重量份水80 重量份•水冲洗,干燥。

*30分钟内涂胶10黄铜-化学处理方法一•脱脂•室温,浸于下述溶液1~2分钟FeCl3(42%浓度)15 重量份HNO3(1.42)30 重量份水197 重量份•彻底冲洗,尽快干燥,立即涂胶。

橡胶粘接胶水使用规范

一:选用类型

目前针对我司使用的胶水为205和220两种;

二:稀释比例

205是在底层使用的,可以用丁酮来稀释,稀释比例为1:4;

220是在面层使用的,也可以用甲苯来稀释,稀释比例为1:4;

三:涂抹方法:

1.金属表面先用稀释好的205涂抹在金属的上下面和四周,注意涂抹时候不能太厚,只需要薄薄的一次就可以了,然后将金属放入70°的烘箱里面干燥10~15分钟,后取出金属,进行第二层的的涂抹;

2.把金属的表面在涂抹好205并干燥之后,把稀释好的220胶水按照之前的方法同样把上面和四周涂抹好,放入70°的烘箱干燥10~15分钟就可以了;

注意事项:70°的烘箱环境可以根据情况而定,如果在没有烘箱情况

可以用压机的环境来进行烘烤,注意时间不同变化而定;

四:粘接要求

根据粘接剂公司标准如下:

205底面必须要求涂抹,220面层可以根据情况和粘接强度来改变厚度:

一层一般在20~25微米,如果两层,底面在5~10微米,面层在10~15微米;

一层220的粘接力为4~5MPa 二层220的粘接力为5~8MPa。