美国帕斯菲达液压隔膜计量泵PPT简介

- 格式:pdf

- 大小:1.89 MB

- 文档页数:33

Get a free quote today:Commercial Industrial Supply 1444 East Main StreetRock Hill, SC 29730 USA Tel: (866) 777-8001Email: *****************Pulsafeeder ExpertiseSince 1936, Pulsafeeder has been the global leader in fluids handling technology and innovation in chemical dosing. Pulsafeeder has built a foundation of success with thousands of installations in fluid handling applications. Our extensive product breadth enables us to provide the convenience and efficiency of single-source solutions across various industries. 0912123135221008360002456831382669510.03.04.05.16.210.3180047675.7860160046.265.8175249435200114.9227.2422.710.36.25.13200845J K22 (5.8) 14 (3.8) 44(11.6) 28(7.5)75.7(20)49(13.0)102 (26.9) 66 (17.4)175 (46.2)113(30)128 (33.8) 83 (21.9)195 (51.5) 126 (33.4)249 (65.8) 161 (42.7)1300 (343) 843(222.6)1600 (423) 1037 (274.0)2600 (687) 1686 (445.3)3200 (845) 2074 (548.0)10.3 15010.3 15010.3 150 5.1 75 5.1 7510.3 15010.3 15010.3 150 4 60 4 60 4 60 4 6037 (24) 73 (47)125 (81) 73 (47)125 (81) 98 (64)146 (95)186 (121)146 (95)186 (121)146 (95)186 (121)0.18 0.250.18 0.250.18 0.250.18 0.250.18 0.250.37 0.50.37 0.50.37 0.51.1 1.51.1 1.51.1 1.51.1 1.550 Hz Flow LPH (GPH)Pressure SPM@ 50 Hz PowerModel1450 RPM940 RPMBar PSI1450 (940) RPM KW HP50HzJK26.5 (7) 17.5 (4.6) 53 (14) 35 (9.3) 91 (24) 60 (16)123 (32.4) 81 (21.4)212 (56) 140 (37)159 (42) 105 (27.7)246 (65) 163 (43) 313 (83) 207 (55)1440 (380) 952 (251)1800 (476) 1190 (314)2880 (761) 1903 (503)3600 (951) 2379 (638)10.3 15010.3 15010.3 150 5.1 75 5.1 7510.3 15010.3 15010.3 150 4 60 4 60 4 60 4 6044 (29) 88 (58)150 (99) 88 (58)150 (99)117 (77) 175 (116)223 (147)175 (116)223 (147)175 (116)223 (147)0.18 0.250.18 0.250.18 0.250.18 0.250.18 0.250.37 0.50.37 0.50.37 0.51.1 1.51.1 1.51.1 1.51.1 1.560 Hz Flow LPH (GPH)Pressure SPM@ 50 Hz PowerModel1725 RPM 1140 RPM Bar PSI 1725 (1140) RPM KW HP 60HzOMNI Series PumpsThe OMNI series is designed to be an economical, compact, rugged, simple, and reliable diaphragm metering pump. It features an industrial design to work in just about any application. OMNI series pumps are an outstanding choice for the customer looking for a simple and compact diaphragm metering pump. These reliable metering pumps are designed to perform in the widest range of chemical dosing applications.Product Specifications•Flows to 3600 l/h (951 GPH) at 60 Hz•Pressures to 10.3 Bar,(150 PSI)•Accuracy +/- 2% of flow•Temperatures to 65°C (150°F)•Viscosity up to 1000 CPS •Maximum 3m (10ft) NPSH •Maximum Suction Pressure 5 PSI or 0.4 bar less than design pressureMaterials of Construction•Head materials- PVDF, 316SS,or PP•Ball Valves - Ceramic or 316SS•Diaphragm - PTFE faced Hypalon on DC 2-4, solid PTFE on DC7Typical Applications•Acids •Caustics •Polymers •Bleaches •pH Control •Solvents •Dyes/Inks •Catalysts•Cleaning agents •And many moreOMNI ConfigurationsOMNI Series pumps are available in several configurations to meet any pumping challenge.Shown below: DC3, DC7 and DC7 Duplex.Mechanical Diaphragm TechnologyDiaphragm is mechanically attached to the reciprocating piston. The reciprocating diaphragm displaces controlled volume of process fluid through the suction and discharge valve mechanism.Benefits:•Eliminates hydraulic fluid•Simplifies commissioning and maintenance •Minimizes power requirements •Economical pumping solutionsCompletely non-vented Gearbox Design (DC7) prevents condensation and ingress of water and other containments. This provides exceptional durabiity and protection from the most extreme environments.Rugged Power Transmission Benefits:•Heavy duty worm gear is hardened and polished steel for DC7•DC2-DC4 worm gear is constructed of durable long life Bronze•Double shielded greased for life bearingsreduce your maintenanceSuction Stroke Discharge StrokeModel Specific QR CodePulsafeeder assists everyone in the field with information for THAT SPECIFIC PRODUCT , quickly and easily. No dedicated app needed. Simply use your QR Reader on your smart phone or tablet and scan the QR Code located on the Pulsafeeder product label, either Pump or Controller.•Identify - Model Number, Serial number, KOPkit (Repair Kit)•View - Quickly find product information such as parts list, IOM, tech sheet and more •Contact - Call or email Tech Support immediately to assist you•Email - Send this information to yourself or someone else, to save or even view laterFeatures & BenefitsController Ready•MPC controller option for DC 2-4•Handheld remote controller on pump or wall mounted •Display in LPH or GPHEasy to Install, Rugged Construction•Simple, intuitive design is easy to operate and maintain•Oil free, greased for life bearing with no more oil to buy or change (DC 2-4, DC7 has oil bath)•Compact and lightweight•Designed to withstand both indoor or outdoor rigors•Fan cooled motor design(when protected from precipitation and direct sunlight)Manual Stroke Adjustment Mechanism (DC2-4 only)•Simple, click in place manual adjustment•Lock mechanism to assure desired setting is maintained•Turndown capacity adjustable up to 1000:1 with MPC controlsCartridge Check Valves (DC2-4 only)•Guided ball check system reduces back flow and enhances priming characteristics•Simple o-ring seals provide for reliable leak free performance and easy replacementPatented Stroke Adjustment Mechanism (DC7 only)•Metering accuracy to +/-2% of flow •Provides full motion operation •Easy to read adjustment knobPatented Quick Change Check Valve System•Unique ball valve design is easy to access and very accurate •Stands up to wide range of acids, caustics and solvents•Completely inline accessible. No need to remove piping to service •Includes PVDF, PP & 316 SS materials(DC7 only)OMNI ComponentsReagent Head IEC & NEMA MotorcapableLightweight AluminiumCaseManual StrokeAdjustment withLock MechanismMechanicallyDriven HardenedSteel PistonDurable Heavy Duty DiaphragmHypalon Backed TFE/Teflon FaceCartridge CheckValvesDC2-4ReagentHeadPatentedQuick Change Check Valve System Durable Heavy Duty DiaphragmPTFE Disk DiaphragmMechanicallyDriven HardenedSteel PistonPatented Full MotionStroke AdjustmentMechanismLightweight AluminiumCaseDC7IEC & NEMA Motor capableControl OptionsMetering Pump Controller(Models DC 2-4 only)•Automatically controls and displays flow with a 4-20 mA input, handheld keypad, and manual stroke control•Controls Pulsafeeder metering pumps up to 1000:1 turn down ratio•The IP56 (NEMA 4X) Handheld user inter face is attached to the pump with 4.5 feet (1.5 meters ) of cable•Optionally, the Handheld can be mounted up to 1000 feet (304 meters) away from the pump•Handheld displays flow rate of the pump in LPH or GPH•Use digital inputs and outputs to monitor and control :•Supply tank level•Pump flow verification•Remote status indication of pump (on/off)•Pump alarm status•Pump auto/manual statusFor high technology in a simple to understand package at an economical price, add an MPC to the OMNI pump to take advantage of a complete system integration between metering pump and process.SystemsWhen used in a system, the OMNI Pump can be used in applications such as:•Water Conditioning Service-Chlorination •Water Treatment Service-Odor Control •Wastewater Service-Polymer Injection •Process pH Treatment-Acids & Caustics •Process Water-Corrosion InhibitorBack Pressure Valves provide positive back pressure for systems with less than the minimum required pressure difference between the discharge and suction side of the metering pump to assure best metering performance.Parts & AccessoriesCalibration ColumnsThese columns are constructed of clear PVC tubes with PVC end caps or an option for Borosilicate glass with Teflon end caps and should be sidedfor a 30-second draw down.Pressure Gauges are relied on to measure pressure in the system. Proper pressure is necessary to insure flow. Pulsafeeder Pressure Gaugesare accurate and reliable.A KOPkit (Keep On Pumping) can help you cut downtime and put you back in business fast. Use KOPkits for preventive maintenance and to ensure continuous high performance from your Pulsafeeder meteringpump.Pulsafeeder’s Pulsation Dampeners improve pump system efficiency by removing pulsating flows from positive displacement pumps.PulsaLube is the only oil Pulsafeeder recommends for use in metering and transfer pumps. Pulsalube is a superior blend of oils designed to provide optimal lubrication and extend equipment life.prevent anoverpressurizationsituation from ever damaging your pumps or pipes. Overpressurization can occur when a valve is closed or a blockage occurs. They are always recommended equipment for any pump or skid system.Pressure Relief Valves OMS001 C15。

Pulsafeeder帕斯菲达计量泵机械部件浸入密闭油箱润滑油中,可做到无磨损运行驱动部件采用高质量的材料,提高其耐用性高质量的减速器、磨光硬化的钢制蜗杆,黄铜蜗轮采用锥形滚子轴承、延长了泵的使用寿命采用隔膜呼吸密封盖,可使机械往复运动时外部空气和周围污染气体不会污染油箱可单头,也可多头并联同时工作内设三个安全保护装置,确保无故障操作具有手动、电动、气动及变频等多种流量调节方式,油箱内往复运动活塞,以液压推动隔膜完成流体输送,隔膜不与活塞接触,两端液压平衡。

美国PULSAFEEDER加药泵,帕斯菲达加药泵100、150系列机械隔膜计量泵特点:安装容易,操作简便计量精确,输出量可随意调整抗化学腐蚀性强经济、实用金属加强隔膜,寿命长用途:反渗透、电渗析循环冷却水净化水、污水处理实验室、化验室其他各种小计量加液型号流量最大压力X003 0.47 7X007 1.1 7X015 2.36 7X024 3.78 7X030 4.72 7X068 10.72 4.2X100 15.774.2Pulsafeeder帕斯菲达计量泵880-S-E帕斯菲达PULSAFEEDER计量泵LBC4 PULSAFEEDER帕斯菲达X024美国PULSAFEEDER帕斯菲达计量泵7120 美国PULSAFEEDER帕斯菲达计量泵7440 美国PULSAFEEDER帕斯菲达计量泵7660 美国PULSAFEEDER帕斯菲达计量泵8480 美国Pulsafeeder帕斯菲达计量泵/LEH6SB-PTC3美国帕斯菲达小流量机械隔膜计量泵/X1145美国Pulsafeeder帕斯菲达计量泵/X007 美国Pulsafeeder帕斯菲达计量泵/X015 美国Pulsafeeder帕斯菲达计量泵/X254 美国Pulsafeeder帕斯菲达计量泵/X003 美国Pulsafeeder帕斯菲达计量泵/LVH7MB-KTC3美国Pulsafeeder帕斯菲达计量泵/LPE4MB-KTC3美国Pulsafeeder帕斯菲达计量泵/LPG5MB 美国Pulsafeeder帕斯菲达计量泵/LPH7MB-PTC3美国Pulsafeeder帕斯菲达计量泵/LPH5MB 美国Pulsafeeder帕斯菲达计量泵/LEH6SB-PTC3美国Pulsafeeder帕斯菲达计量泵/LEH5SB-PTC3美国Pulsafeeder帕斯菲达计量泵/LPG4MB-PTC1美国Pulsafeeder帕斯菲达电磁隔膜泵/LEF4SB-PTC1美国Pulsafeeder帕斯菲达电磁隔膜泵/LE33SB-KTC1美国Pulsafeeder帕斯菲达电磁隔膜泵/LPD3MB-PTC1美国Pulsafeeder帕斯菲达电磁隔膜泵/LPB2MB-KTC1美国Pulsafeeder帕斯菲达电磁隔膜泵/LPK2MB-KTC1美国Pulsafeeder帕斯菲达电磁隔膜泵/LPK2MB-PTC1美国Pulsafeeder帕斯菲达电磁隔膜泵/LPH4MB-PTC1美国Pulsafeeder帕斯菲达电磁隔膜泵/LEF4SB-KTC1美国Pulsafeeder帕斯菲达电磁隔膜泵/LEF4SB-PTC1泉州致泰贸易:联系人:林先生联系电话:0595-********/152******** QQ:2661368039。

美国帕斯菲达液压泵880-S-E帕斯菲达成立于20世纪40年代初期,Larry Wilson 发明了Wilson 化学品进料设备 – 世界上第一台液压驱动泵隔膜计量泵.纽约州LeRoy 的LAPP Insulator 公司购买了Wilson 化学品进料设备的设计,并开始生产第一台帕斯菲达泵,用于心脏手术。

帕斯菲达于1992年5月加入IDEX 集团。

帕斯菲达在美国有三个大型生产基地,分别位于纽约州和佛罗里达州.全部都通过了ISO9001和ISO14001认证.郭工 0595 287 67 808TE 152 603 40 635帕斯菲达公司集70多年专业设计、生产高质量计量泵之经验,在全球范围内提供其系列产品及技术服务,是计量泵行业中的杰出代表。

帕斯菲达公司是计量泵及由计量泵和控制器组成的加药系统主要应用于如下行业:· 市政水处理和废水处理· 锅炉和冷却水处理 · 石化和化学工业的添加剂 · 纸、涂料及添加剂· 食品、饮料和制药行业· 实验室应用 · 冶金、电子行业 C ,A PLUS ,E,E PLUS,MP,CL,T7系列电磁驱动隔膜计量泵手动,自动控制,可编程控制最大流量:94.6L/H最高压力:21Bar100、150,100D、150D,200、250系列小流量机械隔膜计量泵调频控制,手动,电动最大流量:17L/H最高压力:15.75BarOMNI系列大流量机械隔膜计量泵调频控制,手动,电动最大流量:1600L/H最高压力:10BarPULSAR M 系列高性能机械隔膜计量泵调频控制,手动,电动最大流量:653L/H最高压力:21BarPULSA系列液压平衡隔膜计量泵调频控制,手动,电动最大流量:14556L/H最高压力:220Bar电导、PH、ORP控制器MICROtrac MCT110电导率控制器MCT120 PH控制器MC9000系列控制器Vision系列控制器。

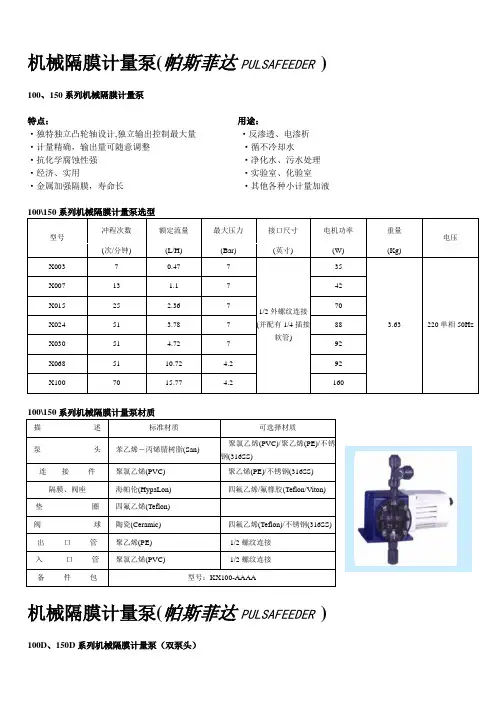

机械隔膜计量泵(帕斯菲达PULSAFEEDER ) 100、150系列机械隔膜计量泵特点:用途:·独特独立凸轮轴设计,独立输出控制最大量·反渗透、电渗析·计量精确,输出量可随意调整·循不冷却水·抗化学腐蚀性强·净化水、污水处理·经济、实用·实验室、化验室·金属加强隔膜,寿命长·其他各种小计量加液苯乙烯-丙烯腈树脂(San)聚氯乙烯(PVC)/聚乙烯(PE)/不锈钢(316SS)聚氯乙烯(PVC)聚乙烯(PE)/不锈钢(316SS)海帕伦(HypaLon)四氟乙烯/氟橡胶(Teflon/Viton)四氟乙烯(Teflon)陶瓷(Ceramic)四氟乙烯(Teflon)/不锈钢(316SS)聚乙烯(PE)1/2螺纹连接聚氯乙烯(PVC)1/2螺纹连接机械隔膜计量泵(帕斯菲达PULSAFEEDER ) 100D、150D系列机械隔膜计量泵(双泵头)特点:·独特独立凸轮轴设计,独立输出控制最大量·双头设计、独立调节,可同时输送两种化学性质不同的液体100D\150D系列机械隔膜计量泵选型型号冲程次数额定流量最大压力接口尺寸电机功率重量(次/分钟) (L/H) (Bar) (英寸) (W) (Kg)100D X1145 7 0.79 3.51/2外丝连接(并配有1/4插接软管)31 5.4 X1155 7 0.63 3.5 31 5.4 X1244 13 1.03 5.25 44 5.4 X1255 13 1.18 5.25 44 5.4 X1265 13 1.89 4.2 44 5.4 X1344 25 2.21 5.25 65 5.4 X1355 25 2.84 5.25 65 5.4 X1365 25 3.94 4.2 65 5.4 X1444 51 4.73 5.25 84 5.4150D X1455 51 5.2 5.25 84 5.4 X1465 51 10.93 4.2 84 5.4 X1466 51 10.88 4.2 84 5.4100D\150D系列机械隔膜计量泵材质描述标准材质可选择材质泵头苯乙烯-丙烯腈树脂(San)聚氯乙烯(PVC) / 聚乙烯(PE)/ 不锈钢(316SS)连接件聚氯乙烯(PVC)聚氯乙烯(PVC)、不锈钢(316SS)隔膜、阀座海帕伦(HypaLon)四氟乙烯(Teflon) / 氟橡胶(Viton)垫圈四氟乙烯(Teflon)阀球陶瓷(Ceramic)四氟乙烯(Teflon) / 不锈钢(316SS)出口管聚乙烯(PE)1/2螺纹连接入口管聚氯乙烯(PVC)1/2螺纹连接。

LM系列电子计量泵安装运行维护说明安装前仔细阅读所有警告信息安全说明使用化学进料泵时,务必遵守基本的安全预防措施,以降低火灾、电击和人身伤害的危险。

否则,可能导致死亡或严重的人身伤害事故。

阅读所有说明*** : 妥善保管化学药品和计量泵,置于儿童和宠物不易接触处。

*** 不要泵送易燃液体。

*** 不要将插头或接地片从电线上割下。

正确的安装或更换方法请向持证电工咨询。

**: 操作化学计量泵或在其附近工作时务必穿戴防护服,包括手套和护目镜。

** 定期检查管道有无破裂或老化,需要时更换。

(检查管道时一定要穿戴防护服和护目镜。

) ** 小心不要让手指靠近旋转部件。

** 如果计量泵受阳光直射,则应使用防紫外线管道。

** 遵守化学药品制造商提供的说明和警告信息。

用户有责任确定化学药品与化学计量泵的兼容性。

** 确认计量泵铭牌上的电压与装置电压一致。

如果泵不能启动,检查管线电压。

** 处理饮用水时应向当地的卫生官员和/或合格水水质处理专家咨询。

** 安装或断开计量泵管道前一定要使系统减压。

** 如果注入点低于化学药品储槽和泵,则应安装反虹吸阀。

** 不要修改泵。

这样会造成潜在的危险,并使质量担保失效。

*:所有泵在出厂前都用水试验过。

如果泵送的化学药品会和水起反应(如硫酸),则需卸下管道彻底干燥。

* 手动拧紧塑料接头(不要使用扳手)。

* 安装前向持证管子工和电工咨询,安装应符合当地规范。

* 注:计量泵必须在所有工况下校准,以获得精确的体积输出。

警告危险警告小心目录页次安全说明 (2)介绍 (3)拆开泵包装 (5)操作注意事项 (5)安装、管道和接线 (7)控制装置和操作说明 (13)控制选项 (14)继电器设置 (15)报警 (16)控制基准总结 (17)启动和运行 (20)维护 (23)故障排除 (25)分解图 (27)计量泵规格 (30)修理服务 (31)介绍此手册包含电子计量泵安装、操作和维护说明的相关信息。