CDI系统操作手册

- 格式:doc

- 大小:76.00 KB

- 文档页数:5

注意!1.在操作和维护Canpure TM EDI组件时必须始终遵守本使用手册中的有关规定2.必须完全理解本手册内容并经过相关技术培训才能使用Canpure TM EDI组件3.对于不符合本手册要求所造成的损失,制造商不承担任何责任4.Canpure TM EDI组件在使用期间出现异常现象,用户不得自行拆装,应立即通知售后服务商5.我们保留不断改进产品的权利,如有变动恕不另行通知目录目录 (2)第1章EDI技术介绍 (5)1.1 EDI技术本质 (5)1.2 EDI技术是水处理工业的革命 (5)1.3 EDI过程 (5)1.4 EDI的应用领域 (7)第2章组件简介 (8)2.2 EDI的组件结构 (8)2.3 EDI组件优势 (8)第3章运行条件 (9)3.1 运行参数 (9)3.2 运行电流及运行电压 (9)3.2.1 供电 (9)3.2.2 纯水质量与电流的关系 (10)3.2.3 电流与给水水质的关系 (10)3.2.4 稳定运行状态 (11)3.3 给水要求 (11)3.4 给水TEA与电导率 (13)3.5 污染物对除盐效果的影响 (13)3.6 浓水循环系统 (14)3.7 系统加盐系统 (14)3.8 离子性质与运行参数的关系 (15)3.8.1离子大小 (15)3.8.2 离子电荷 (15)3.8.3 离子相对树脂的选择系数 (16)3.8.4 弱带电物质 (16)3.9 温度与运行参数的关系 (16)3.9.1 压力损失与温度的关系 (16)3.9.2 水质与温度的关系 (17)3.9.3 电阻率仪表的温度补偿 (17)3.10 流量与运行参数的关系 (18)23.10.1 压力损失与流量的关系 (18)3.10.2 极水压力损失 (18)3.10.3 浓水压力损失 (18)3.10.4 给水-纯水的压力损失 (18)3.11 纯水对浓水压差对水质和内部泄漏的影响 (19)3.12 优化运行条件 (19)第4章包括EDI的水处理全系统设计 (20)4.1 EDI给水处理 (20)4.1.1 活性碳...............................................................................................................错误!未定义书签。

CDI-S200SERIAL INTERFACE CARDLF Z1F R 230MUSIC MUTEZ NE ZONE 3MIC 1 ACCMUSIC EQMUSIC EQLF HF HFIG AN DIG/AN FR REMFR/REM 0V Z2Z3POWER 40-6 4FURATIN115SERIAL INTERFACE CARDInstallation Guide2CDI-S200 Installation Guide v1.0CDI-S200 Installation Guide v1.03ContentsIntroduction (4)Scope of this manual ...............................................................................4What’s in the box (4)Installation (4)Configuring the CDI-S200 .....................................................................4Baud Rate ..............................................................................................5Handshaking ..........................................................................................5CX263 jumper settings ......................................................................5Mechanical fitting and internal connection ........................................6CX263 switch settings .......................................................................7Partial music function control . (7)CDI-S200 Serial Control (8)Pinout .........................................................................................................8Port parameters .......................................................................................8Abridged command set ......................................................................81. Input selection ................................................................................102. Music Level......................................................................................103. Music Mute/Unmute .....................................................................114. Mute/unmute individual microphones ......................................115. Paging control (11)APPENDIX (12)Cable lengths (12)CDI-S200 Installation Guide v1.04IntroductionThe CDI-S200 is an optional RS-232C interface card designed specifically for use with the Cloud CX263 Zone Mixer. It allows theCX263 to be controlled by third-party systems (such as Crestron, AMX, etc.), using RS-232C serial data.When installed, the CDI-S200 permits the following CX263 functions to be controlled remotely:•Music source selection for each zone •Music level in each zone •Music muting•Muting of individual microphones •Activation of Mic 1’s paging accessPhysically, the CDI-S200 is a small printed circuit board (PCB), which is retrofitted internally in the CX263 such that the 9-pin D-type RS-232C connector is available at the rear panel.Scope of this manualThis manual describes the mechanicalinstallation of the card and the connections that need to be made to it. It also explains the various configuration options that the card offers, and the various jumper and switch settings that need to be made to the CX263 to achieve correct operation.The manual also gives a general overview of the RS-232C serial control protocol used by the CDI-S200, and some examples of the most useful commands. This information should be adequate for most installations, but please note that a full description of the RS-232C protocol is beyond the scope of this manual. The full protocol can be found at .What’s in the box•CDI-S200 PCB•Installation Guide (this document) • 2 qty M3 x 25 mm mounting pillarsInstallationConfiguring the CDI-S200Before installing the CDI-S200 in the CX263, various jumpers on the PCB need to be set correctly. (This step should be performed first because the PCB is installed in the CX263 upside-down, and access to the jumpers is very difficult once it is in position.)The jumpers are concerned with setting the parameters of the serial port (see “Port parameters” on page 8). The port parameters should be set to suit the control system being used. It is quite likely that the factory default settings will provide correct operation; nevertheless, it is important to check that this is so and alter the settings if necessary.T o move the jumpers, use small pliers to gently pull the jumper off the header pins and replace in the correct position. Do not use undue force, and do not use pliers which are too big.There are four jumpers, J1 to J4.CDI-S200 Installation Guide v1.05Baud RateJumpers J1 to J3 set the serial port’s baud rate. The default setting is 9600 baud . Check the baud rate of the controlling equipment. If a different baud rate is required, set the jumpersaccording to the diagram below:J1 J2 J3J1 J2 J3J1 J2 J3HandshakingRS-232C serial communication between equipment sometimes requires flow control (or “handshaking”), to confirm that transmitter (the controller) and receiver (the CDI-S200 in this case) are correctly synchronised. PCB jumper J4 controls handshaking.Handshaking may be via “hardware”,“software”, or off. Hardware handshaking is also referred to as “RTS/CTS”, and needs additional pins of the 9-pin serial connector to be wired (see “Pinout” on page 8).Software handshaking is also referred to as “Xon/Xoff”.The default setting is off (no handshaking); J4 is left attached to the centre pin of the header at the factory. If the controlling equipment requires handshaking, reset the jumper according to the following diagram:CX263 jumper settingsIn order for the CDI-S200 to fully control the CX263, it is necessary to correctly set some jumpers on the CX263 main PCB. These are J4 to J6, and J19 to J24. Because some of these jumpers will be inaccessible once the CDI-S200 PCB is installed, we recommend that they are set before fitting it.Jumpers J4 to J6 are all on 2-pin headers, and can thus be present or absent. See page 6 for a guide to their location. They determine how the CX263’s Mic Input 1 access control operates. When a CDI-S200 PCB is installed, all three jumpers must be absent (we recommend that the jumpers are electrically removed, but left in place on just one pin of the header, in case the unit needs to be reconfigured in the future).T o move the jumpers, use small pliers to gently pull the jumper off the header pins and replace in the correct position. Do not use undue force, and do not use pliers which are too big.Jumpers J19 to J24 determine how music source selection and music level in each zone are controlled remotely. T o allow a CDI-S200 PCB to fully control a CX263, all six jumpers must be in the ‘SW’position. These jumpers are all on the small “daughter-board” at the centre-rear of the CX263 which carries the DIG/AN and FR/REM switches for each zone.It is possible to configure the CX263 so that only certain unit functions are under the control of the CDI-S200. Refer to “CX263 switch settings” on page 7 for more details.CDI-S200 Installation Guide v1.06Mechanical fitting and internal connectionIf retrofitting the CDI-S200 to an existing CX263 installation, turn the CX263 off, remove its IEC mains lead and all other rear panel connections (marking as necessary to assist re-connection). If the CX263 is mounted in a rack, remove it.If fitting the CDI-S200 to a new CX263, unpack the CX263.In either case, place the CX263 on a flat surface, with the rear of the unit facing you.1. Undo the six screws securing the toppanel of the CX263; remove the panel. Retain the screws.2. Remove the blanking plate covering theserial interface module connector hole in the rear panel by removing the two self-tapping screws securing it.3. Identify the empty 16-pin header labelledCON2 on the main PCB behind the empty serial connector hole. Note there is an M3 screw immediately behind this connector, and another about 45 mm to the right. Both these screws are clearly marked with arrows; remove and retain them.CX263 PCB: CDI-S200 MOUNTING LOCATION4. Screw the threaded ends of the two25 mm mounting pillars supplied with the CDI-S200 into the holes vacated by the screws removed in Step 3.5. On the CDI-S200 board, remove the twosmall threaded bushes on the D-type connector; retain them. An M3 nut-driver is the best tool for this. Note that these bushes also retain the metal connector shell – be careful to keep it in place duringthe next two steps.REAR VIEW OF CDI-S200 PCB6. Plug the connector on the end of theribbon cable into connector CON2 on the CX263 main PCB. Note it can only be inserted one way round, with the cable exiting to the left.7. With the CDI-S200 PCB upside-down,insert the D-type connector through the hole in the rear panel. Y ou will see that the two holes at the other end of the PCB are aligned with the mounting pillars fitted in Step 4. Fix the board to the pillars using the screws removed in Step 3.8. Replace the two bushes removed in Step5 adjacent to the D-type connector by screwing them through the rear panel. The two self-tapping screws removed in Step 2 are no longer required.CDI-S200 Installation Guide v1.07CX263 switch settingsAfter the CDI-S200 card has been fitted, and J4 – J6 and J19 – J24 (on the CX263 main PCB) set as described above, the top cover of the CX263 can be replaced, using the original screws.The three blue rear panel switches DIG/AN (adjacent to the RSL-6 connectors) should now be set to DIG – i.e., in their ‘out’ position. The three blue rear panel switches FR/REM (next to them) should be set to REM – i.e. in their ‘in’ position. The CX263 is now ready for full serial remote control.Partial music function controlIt is also possible to configure the CX263 so that the CDI-S200 only controls certain unit functions, leaving others to be manually controlled, either from the front panel or from a Cloud RSL-6 remote control plate. If this is required, set the rear panel switches and the internal jumpers J19 to J24 according to thetable below.* When the CDI-S200 is to control music level, jumpers J19, J21 and J23 may be set in either the DG or SW position. However, they must NOT be removed altogether.CDI-S200 Installation Guide v1.08CDI-S200 Serial Control PinoutThe rear panel serial connector is a female 9-pin Dsub.The pinout is shown in the table:For many installations, it will only be necessary to connect pins 2, 3 and 5. If the controlsystem’s serial port is also a 9-pin D-type, use a D9-to-D9 “straight” cable (i.e., one wired with pin 1 to pin 1, pin 2 to pin 2, etc.) If the control system’s serial port is a screw-terminal (or other type of) connector, the terminals will most likely be marked “Tx”, “Rx” and “Gnd”, or something similar. In this case, connect “Tx” to pin 3 on the CDI-S200, “Rx” to Pin 2 and “Gnd” to pin 5. See the following illustration for details.NOTE: Not all control systems interpret“Tx” and “Rx” the same way, and it may be necessary for a “crossed” cable to be used instead. A crossed cable is one with pin 2 connected to pin 3 at the other end, and vice-versa. If your CDI-S200 appears to ignore control system instructions and all connections, programming, etc., appear satisfactory, try reversing pins 2 and 3 at one end of the serial cable.The installer should also check whether the control system being used requiresRS-232C flow control (or “handshaking”) tobe implemented, and if so, whether hardware control or software control is used. Hardware handshaking (sometimes called RTS/CTS) requires pins 7 and 8 to be connected.CONTROLLERCDI-S 200TX“STRAIGHT” RS-232C SERIAL CABLENote that some installation require a “crossed” cable in thiscase, pins 2 and 3 should be reversed at one end.Abridged command setThe commands listed in the General Format table (page 9) are those most commonly required. For all other commands, data requests and responses, please refer to the CDI-S200’s full RS-232C protocol document at .The table provides the general format of each type of command. The commands are given in ASCII form; note that all characters in the command, including the non-alphanumeric ones, must be sent. The characters shown in italics must be replaced by specific numeric values when a command is sent.Following the table, an example of each command type is given; refer to the general format to see how the variable characters are replaced by specific values. The commands in the examples are given in both ASCII and hex form.CDI-S200 Installation Guide v1.09CDI-S200 Installation Guide v1.010Examples:1. Input selectionT o directly select a specific music source in a particular zone, the value of x in the general format is the number of the Line Input (1 to 6) to be selected, and the value of y is the number of the zone (1 to 3) to which the command applies. Note that x can also be set to zero to positively de-select all music sources in a zone.Alternatively, the music sources in any zone may be “stepped through” one at a time (in either direction), using increment or decrement commands. If an increment command is received when Line In 6 is already set, the command is ignored. If a decrement command is received when Line 1 is set, no music source is selected (equivalent to the “Line 0” command mentioned above). Any further decrement commands are ignored.If wished, all three zones may be set simultaneously to the same music source with a single command; again, the “all-zone” source may also be incremented or decremented as for a single zone. Note that the strings for “all-zone” commands merely omit the three ASCII characters which specify the zone number (Z y.).2. Music LevelThe music level in any zone (where y = 1 to 3) can either be set to an absolute value (in dBs), or increased/decreased by a specified number of dBs. Adjustment can be made in half-dB steps, and the values m , p and q in the General Format table represent the number of half-dB steps.For absolute levels, the value of m corresponds to attenuation rather than gain, thus 0 dB ismaximum level and at -90 dB the music channel is effectively muted. The value of m in the general format is the attenuation level in half-dBs, and may thus have a value of between 0 and 180. Therefore, to set the output level to 10 dB below the maximum level, m must be given a value of 20.T o alter the music level by a specified amount, the ASCII character ‘A’ is replaced by ‘U’ (up) or ‘D’ (down) in the string. The value of p or q in the general format is the level increase in half-dB steps (0 to 180), or the level decrease in half-dB steps (0 to 180) respectively. A command to increase the level by a number of dBs greater than the current attenuation will set the level to maximum. Similarly, a command to decrease the level by a number of dBs greater than (90 minus the current attenuation) will mute the music channel.CDI-S200 Installation Guide v1.011If wished, the music in all three zones may be set to the same level with a single command. Note that the strings for “all-zone” commands merely omit the three ASCII characters which specify the zone number (Z y.).3. Music Mute/UnmuteMusic may be muted or unmuted in any zone by replacing y in the General Format table with 1, 2 or 3. The commands to mute or unmute music in all zones contain no variables, thus those given inthe General Format table are always applicable.4. Mute/unmute individual microphonesThe CX263’s two mic inputs may be muted or unmuted. It is not possible to mute/unmute each mic input individually. There are no variables in the command string and thus those given in theGeneral Format table are always applicable.5. Paging controlPaging via Mic 1 input may be enabled for any combination of the CX263’s three zones by sending a command which includes the two ASCII characters “PA” followed immediately by a further three characters which define which zones are to be paged. The three zone characters represent zones 1, 2 and 3 respectively, and must be either an ASCII “X” (enable paging) or an ASCII “O” (don’tCDI-S200 Installation Guide v1.012enable paging). The following examples illustrate this.Paging may be cancelled – whatever combination of zones has been enabled – with a single “release” command, which contains no variables.Note that it is not possible to enable paging via Mic Input 2 by serial control.APPENDIX Cable lengthsRS-232C serial communication can use either shielded or unshielded cable. The longest cable run that can be practically used for error-free operation in a given installation will depend on several factors: cable type, the baud rate used and the amount and type of electrical noise present in the cable’s vicinity.A realistic figure for maximum cable length is 250 ft. (76 m.) using good-quality shielded cable and 100 ft. (30 m.) using unshielded cable, at 9600 baud (the most common data rate). However, the figure may be higher or lower in a particular installation.Lowering the baud rate will permit significantly longer cable runs to be used.Cloud Electronics Limited 140 Staniforth RoadSheffield S9 3HFEnglandT el: +44 (0)114 244 7051 Fax: +44 (0)114 242 5462 email:*************.ukweb: 。

CDI9000系列变频调速器使用说明书产品符合标准: GB/T12668.2-2002 / IEC61800.2:1998GB 12668.3-2004 / IEC61800.3:1996 □安装、使用产品前,请仔细阅读使用说明书,并妥善保管、备用。

德力西(杭州)变频器有限公司DELIXI (Hangzhou) Inverter Co., Ltd.目录 目 录第一章序言 (3)1.1安全运行的注意事项 (4)1.2 验收 (5)1.2.1验收检查 (5)1.2.2检查铭牌数据 (5)第二章 产品外形尺寸及规格 (6)2.1 产品外形尺寸 (6)2.2 CDI9000变频器系列规格 (8)第三章 变频器的安装及运行 (10)3.1安装 (10)3.2 卸下和重新装上前盖 (10)3.3 取下和重新装上数字操作健盘 (10)3.4 选择安装变频器的环境 (11)3.5 安装间隙 (12)3.6 接线 (13)3.6.1 主回路的接线 (13)3.6.2 外围设备和任选件的接线 (14)3.6.3 接地 (18)3.6.4 控制电路的接线 (19)3.7 运行 (22)3.7.1 操作方式的选择 (22)3.7.2 试运行前的检查 (23)3.7.3 试运行 (23)3.7.4 运行检查 (23)第四章键盘操作 (24)4.1 键盘按键及功能 (24)4.2 变频器显示方式 (25)4.3 设定数据的步骤 (LED键盘) (26)4.4 运行数据的监视步骤 (LED 键盘) (27)第五章 功能参数说明 (28)5.1 功能参数一览表 (28)5.2 参数设定准备 (36)5.2.1 参数设定 (36)5.2.2 开机显示画面选择(10-02) (36)5.2.3 自设定显示功能选择1(10-03)..375.2.4 自设定显示功能选择2(10-04)..375.2.5 输入端子状态显示(00-12) (37)5.2.6 输出端子状态显示(00-13) (37)5.3基本参数的设定 (38)5.3.1 V/f特性的设定 (38)5.3.2 频率限制(01-07,01-08) (39)5.3.3 使用2种加减速时间 (40)5.3.4 软启动特性(01-37) (41)5.4 运行指令 (41)5.4.1 模拟频率设定方式 (41)5.4.2 载波频率(01-26) (41)5.4.3 反转禁止 (02-21) (42)5.4.4 启动时直流制动时间(01-19) (42)5.4.5 选择停止方式(02-16) (42)5.4.6 滑差补偿增益(01-23) (43)第六章 输入输出功能介绍 (44)6.1 模拟表输出 (44)6.2 多功能输出选择 (44)6.3 频率检测(03-10,03-11) (45)6.4 输入功能介绍 (46)6.4.1 模拟输入 (46)6.4.2 端子运行控制方式(02-17) (47)6.4.3 上电处理端子运行选择(02-19)..486.3.4 复位启动方式选择(02-20) (48)6.4.5 点动频率(01-50) (48)6.4.6 使用多功能输入信号 (49)6.4.7 定时器功能 (50)6.4.8 禁止加减速指令 (50)6.4.9 UP/DOWN(上升/下降)指令 (50)6.4.10 计数器功能 (51)6.5 多段速度和程序运行 (52)6.5.1 多段速度的选择 (52)6.5.2 程序运行 (53)6.5.3 摆频运行 (57)6.6 PI控制参数 (57)6.6.1 外部V2给定值 (03-17,03-18) (57)6.6.2 外部IF反馈值 (03-21,03-22) (58)6.6.3 反馈滤波时间(03-24) (58)6.6.4 PI调节误差极性(05-01) (58)6.6.5 PI调节方式最小运行频率(05-09) (58)6.6.6 PI调节方式最大运行频率(05-10) (58)6.7 保护参数 (59)6.7.1过电压失速保护 (01-29) (59)6.7.2能耗制动选择(06-06) (59)6.7.3自动电压调整AVR(01-16) (59)6.7.4 电流限制(01-27) (60)6.7.5 过转矩检测 (61)6.7.6 电机保护 (62)6.8 其他功能 (63)6.8.1 瞬时停电再启动选择(02-11) (63)6.8.2 追踪启动方式(02-13) (63)6.8.3 跳跃频率 (64)6.8.4 自动转矩补偿(01-14) (64)6.8.5 节能控制(01-30) (64)目 录6.9 用RS-485通信进行控制 (65)6.9.1 通信参数设定: (65)6.9.2 通信规格 (65)第七章 故障 (66)7.1 故障诊断和排除措施 (67)7.2 报警显示和解释 (68)7.3 电动机故障和排除措施 (69)附录1: 技术规范 (70)附录2: 定期维护及检查方法 (71)附录3: RS-485通讯协议修正 (72)附录4: 用于注塑机改造的说明..76附录5: 典型接线图 (79)A5.1. 外部按钮调速接线图 (79)A5.2. 外接电位器调速接线图 (80)A5.3. PID闭环控制接线图 (81)A5.4. 多段速控制接线图 (82)A5.5. RS485通讯接线图 (83)附录6: 选件选用指南 (84)A6.1. 交流电抗器ACL (84)A6.2. 直流电抗器DCL (84)A6.3. 无线电噪声滤波器 (85)A6.4. 远方操作盘 (85)A6.5. 回生制动单元及回生制动电阻 (86)A6.6. 漏电保护器 (86)附录7:变频器知识问答 (87)第一章序言第一章序言感谢您选用德力西(杭州)变频器有限公司生产的CDI9000系列变频调速器。

快速定量装车站操作手册目录第1部分快速定量装车站介绍 (3)1.1系统概述 (3)1.2装车工艺 (3)1.3各子系统描述 (5)1.3.1钢结构 (5)1.3.2机械设备 (6)1.3.3称重系统 (7)1.3.4液压系统 (10)1.3.5配电系统 (10)1.3.6控制系统 (11)第2部分开车和停车顺序 (13)2.1原则 (13)2.2自动装车启动顺序 (14)2.3自动装车停止顺序 (15)2.4紧急停车 (16)第3部分装车运行前、中、后应检查的项目 (16)3.1运行前需检查的项目 (17)3.1.1基本要求 (17)3.1.2主要设备 (17)3.2生产过程中需检查的项目 (18)3.2.1基本要求 (18)3.2,2主要设备 (18)3.2.3停车后需检查的项目 (19)3.2.4 控制室操作人员须知 (19)第4部分常见问题及解决方法A.给煤/料系统 (19)B.装载系统 (20)第5部分计算机软件操作说明 (21)讲解列车编组、调入列车、设备控制、生产查询、报表打印、维护保养等要领第1部分:快速定量装车站介绍1.1系统概述大型快速定量装车站基于大型料斗秤的工作原理,预先在定量仓中按车皮标重装载,通过闸门和卸料溜槽控制,向行进中的车厢快速卸载,实现一次连续动态行进中的快速准确装车。

快速定量装车系统主要由大型钢结构、装车机械设备、称重系统、液压系统、电控系统、软件系统组成。

缓冲仓的目的是存储一定量的煤炭,以确保在正常工作中有足够的煤炭用于装车,从而避免煤炭输送机频繁启动;定量称重装车用于快速准确定量装车;装车机械设备用于控制装车煤流;液压系统为各种机械设备提供动力;电控系统用于装车系统中所有设备监测和自动控制;自动润滑系统为装车机械设备提供润滑,保证设备的使用寿命;软件系统用于判断发出各种控制指令,调节装车精度,监测各设备的运行状态,记录存储装车记录和报警信息。

装车站工作制度同矿井,年工作300天,服务年限同矿井。

cdi使用注意事项

CDI是一种点火器,在使用CDI时,需要注意以下事项:

- 对于交流点火的CDI点火器,可以在点火线圈的初级加一个熄火开关,对地短路来实现熄火,这种方式对其他配件的影响较小。

- 对于直流点火的CDI点火器,在高压包初级上加熄火开关,容易造成里面元件损坏,可以把熄火开关并联在触发正极,或者串联在点火器电源里边。

- 如果直接断开点火器的12伏电源,可以实现熄火,冲击非常小,但需要厂家对电路进行改进。

在使用CDI点火器时,建议遵循车辆的使用手册,并注意安全操作。

如果遇到任何问题或疑虑,应咨询专业人士。

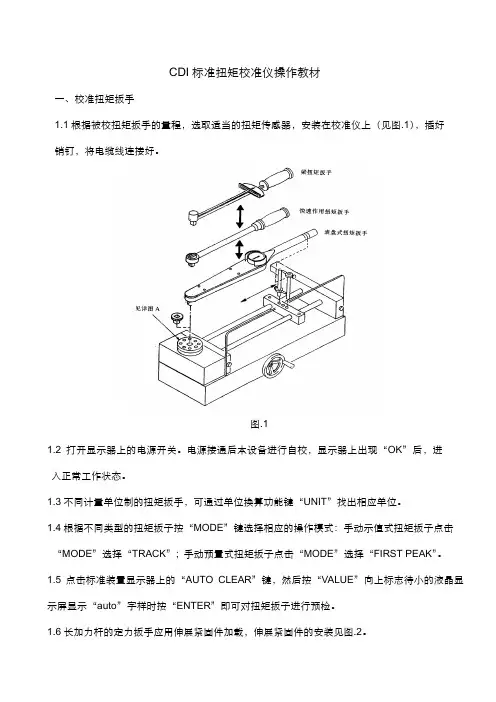

CDI标准扭矩校准仪操作教材一、校准扭矩扳手1.1根据被校扭矩扳手的量程,选取适当的扭矩传感器,安装在校准仪上(见图.1),插好销钉,将电缆线连接好。

图.11.2打开显示器上的电源开关。

电源接通后本设备进行自校,显示器上出现“OK”后,进入正常工作状态。

1.3不同计量单位制的扭矩扳手,可通过单位换算功能键“UNIT”找出相应单位。

1.4根据不同类型的扭矩扳子按“MODE”键选择相应的操作模式:手动示值式扭矩扳子点击“MODE”选择“TRACK”; 手动预臵式扭矩扳子点击“MODE”选择“FIRST PEAK”。

1.5点击标准装臵显示器上的“AUTO CLEAR”键,然后按“VALUE”向上标志待小的液晶显示屏显示“auto”字样时按“ENTER”即可对扭矩扳子进行预检。

1.6长加力杆的定力扳手应用伸展紧固件加载,伸展紧固件的安装见图.2。

1.7在开展大扭矩扳手(200FT·LB以上)校准前,安全屏蔽应已安装牢固、可靠。

1.8将被校扭矩扳手用转接头与传感器作用方体孔相连接,扭矩扳手的手柄与加载装臵立柱相接触,用加载装臵上的调水平机构上下移动,使扭矩扳手处于工作台面平行的位臵。

1.9调好扭矩扳手和校准器显示器上的“零”位,通过加载装臵对扭矩扳手进行预扭。

1.10将数据连接线与电脑连接后打开电脑进入校准软件的主页面,点击“连接”后在出现的窗口中输入用户名“fw”和密码“1111”进行登录。

1.11登录成功后在操作页面中点击“新增”更改记录编号。

更改记录编号时应注意:如果是当月的扭矩扳子则点击“新增”即可,记录编号会自动连续下去;如果是新年新月份的第一把扭矩扳子则点击“新增”后对记录编号的数字进行相对应的修改。

例如2010年1月的第一把扭矩扳子则将记录编号修改为“2010-01-001”。

1.12依次填写“扳手信息”页面中的各类信息。

注:“规格”栏中只须填写扭矩扳子的最大值,不要填写单位。

1.13依次填写“校检设臵”页面中的各类信息。

Chemical Design Inc.PROCESSES • PLANTS • EQUIPMENTPrepared byCHEMICAL DESIGN, INC.285 Market StreetP.O. Box 513Lockport, New York 14095-0513Phone (716) 433-6744 Fax (716) 439-4019 Rev. 0 : September 12, 2007CVD&氢化炉尾气回收装置操作说明目录1.0工艺描述1.1尾气冷凝1.2压缩1.3吸收精馏系统1.4吸附系统1.5设计条件1.6公用工程2.0预开车3.0开车3.1氮气吹扫3.2干燥导热油3.3干燥吸附器3.4循环吸附器3.5干燥物料压缩机3.6用氢气置换氮气3.7定液位3.8启动压缩机3.9循环液体氯硅烷3.10启动制冷系统3.11(HCL解析塔T103的温度剖面图)3.12通物料气4.0停车4.1紧急停车系统4.2短期故障停车4.3长期故障停车4.4正常停车5.0 压缩机维护6.0 安全预防氢气安全操作丙烯安全操作氯化氢安全操作氯硅烷安全操作1.0工艺描述尾气回收单元吸收来自多晶硅还原炉和氢化炉的混合气体并将其分解为液相氯硅烷,液态氯化氢和氢气。

氢气经过HCL吸附塔之后又回到氢化炉。

经过碳吸附器回到CVD还原炉的氢气为高纯氢气,已经去除了杂质(杂质含量<1 vppm)。

剩余物流也被重复用于工艺的其它方面。

CDI负责工艺设计,AS根据P&ID(CDI图纸0622-1A到1J)购买设备并进行安装。

热量及物料平衡见CDI图纸0622-PFD。

1.1 尾气冷凝还原炉尾气经冷却、冷凝以凝缩大部分氯硅烷混合物。

立式壳管换热器利用冷却水逆向冷却气流使温度降低到40℃,然后经气气回冷换热,再经冷冻盐水冷却冷凝。

液体冷凝物被排放到氯硅烷缓冲罐D-101,然后在卧式冷凝器将气体冷冻到-40℃,该冷凝器使用R-22制冷剂。

天威四川硅业有限责任公司C D I-1尾气回收操作规程编写:李伟校核:沈阳审核:审定:批准:2009年4月初稿目录第一章:CDI系统操作规程 (5)第一节:工作目的 (5)第二节:工作原理 (5)一、三级冷却工作原理: (5)二、吸收和解吸工作原理: (5)三、氢气纯化工作原理: (5)第三节:各种物质性质,技术参数 (6)一、原辅材料质量指标 (6)二、原辅材料消耗 (7)三、产品标准 (7)第四节:基本资源 (7)一、人力资源 (7)二、主要设备(单套) (7)四、调节阀和主要切断阀 (10)五、安全阀 (10)第五节:工艺流程图即简介 (12)一、(流程图见附图一) (12)二、工艺简介 (12)第七节:工艺控制 (20)一、主要控制和调节系统 (20)二:连锁说明 (21)第八节:生产操作规程 (28)一、开车前准备 (28)二:开车操作 (32)三:正常运行操作、寻检、记录 (40)四:(CDI无故障停车) (40)五:停车后工作 (42)六:应急开、停车操作 (42)第九节:常见事故处理 (43)一:泵出现问题 (43)二:冷冻机出现问题 (43)三:瞬间停电 (44)第二章R22冷冻系统岗位操作 (46)第一节:工作目的 (46)第二节:设备工作原理 (46)第三节:CDI回收系统制冷剂R22技术参数 (46)第四节:设备资源 (47)第五节:工艺流程图 (47)第六节:工艺控制指标 (48)第七节:生产操作规程 (48)一:开车前准备 (48)二:开车操作 (48)三:巡检、记录 (49)第八节:常见事故处理 (50)第三章:氢压机操作规程 (52)第一节:工作目的 (52)第二节:工作原理 (52)第三节:工艺控制指标 (52)第四节:操作规程 (52)一:润滑油站的操作 (52)二:水站的操作 (53)三:空负荷试车 (53)四:氢压机氮气试车 (54)五:压缩机一、二级气缸的吹洗 (55)六:氢压机氮气负荷试车 (57)七:氢压机正常开车 (59)八:巡检、记录 (61)九:停车操作 (61)十:注意事项与事故处理 (62)第四章:屏蔽泵操作规程 (64)第一节:工作目的 (64)第二节:工作原理 (64)第三节:开车前检查 (65)一:电动机的旋转方向 (65)二:轴承监视器的检查(机械式) (65)第四节:开车操作 (65)一:启动前的准备 (65)二:启动 (66)第五节:巡检、记录 (67)第六节:停车操作 (67)一:正常停车 (67)二:长期停车 (67)第七节:停车后工作 (68)第八节:注意事项与常见事故处理 (68)第五章:热液泵操作规程 (71)第一节:工作目的及原理 (71)第二节:启动前的准备 (72)第三节:运行 (72)第四节:停机 (73)第六章:废气处理操作规程 (73)第一节:工作目的及原理 (73)第二节:各种物质标准 (74)一:原料质量标准 (74)二:废气处理后的废液 (74)第三节:工艺控制指标 (74)第四节:生产操作规程 (74)一:原始开车准备 (74)四:停车后工作 (75)五:巡检 (75)附一:合成尾气回收安全规程 (76)附二:尾气回收工序救援预案 (77)第一章:CDI系统操作规程第一节:工作目的系统经过三级冷却、压缩、吸收、解吸、氢气纯化这几个过程把SiHCL3合成炉排出的尾气分离为液态氯硅烷、氯化氢气体和氢气。

FLEXIBLE FURLER INSTRUCTIONSFF2WARNING: READ BEFORE INSTALLING OR USING FURLER Improper installation of your CDI Flexible Furler or reinstallation of your current headstay may result in the loss of your mast and may cause injury to those onboard.INDEX-Specifications… Page 1-Diagram…Page 2-Parts list…Page 2-Uncoiling instructions…Page 3-Straightening instructions…Page 4-Assembly instructions…Page 5-8 -Sailmaker i nstructions…Page 9-Rigger instructions…Page 9-Notes about Sailing…Page 9-Notes about Trailering…Page 10 -Maintenance and Storage…Page 10 -Warranty…Page 10 SPECIFICATIONS-Max Headstay Length: 29’-Max Wire Size: 3/16”-Max Turnbuckle Pin Size: 5/16”-Headstay: Threaded swaged stud turnbuckle with toggle at the bottom, a toggle at the top isrecommended but any secure fitting like a T-bolt atthe top will work. Must be secured by cotter pins.Navtec turnbuckles are not compatible.-Furling line: 3/16” double braided line or any low-stretch line, twice your boat length. Not included.-Mounting: must not be mounted above theturnbuckle. Link plates can be used for clearance.TOOLS-Hacksaw-Measuring tape-Phillips head screwdriverDiagramPARTS LISTA Halyard Top Fitting 2011B Luff Extrusion/Foil LFF2C Halyard Assembly 1932D Furling Drum/Spool 2010E Shackle (2) 2007F Anchor Pin (2) 1998G Luff Support Pin 2009H Cup 1807I Anti-Rotation Strap 1081J Tack Tension Line 7022-4 - Main Bearing 1033 - Ball Bearing Assembly 1276 - Thrust Washer 1253 UNCOILING INSTRUCTIONSCAUTION: READ BEFORE OPENINGCoiled luffs have a lot of stored energy and can spring open with force when restraining tape is cut. It is recommended to wear face and eye protection. Please refer to instructions below.The sooner you begin the uncoiling and straightening process, the faster and easier it will be to straighten the luff.*The luff should remain coiled for no longer than 2 weeksInstructions for uncoiling the luff:Note: it’s best to have one person cutting the bands with at least one other person holding onto the luff firmly, ensuring it doesn’t spring out1) Stand the luff on its side with the tail at the top2) Have one person stand with one foot on the inside of the luff while holding onto the tail firmly3) The second person should then cut the band of tape near the tail, while the first person is firmly holding onto the tail and gently letting out the luff4) Proceed to cut the next bands one at a time using the same process5) Carefully cut the last band, ensuring everyone is clearSTRAIGHTENING INSTRUCTIONSInstructions for straightening the luff:Note: laying the luff on the ground with weights will not work but will form kinks instead and also void the warranty.1) With approximately one person every 8 feet, recoil the luff in the opposite direction2) Tape the end of the curved side to the straight side3) Lay the luff on the ground for at least 3 hours4) After that time, test to see if it has straightened out5) If not, repeat the same process. Warmer temperatures will help to speed up the straightening6) The luff can have a slight bend to it, the headstay tension will eventually straighten it out ASSEMBLY INSTRUCTIONSAssembly can be done with the mast up but is easiest to do with the mast down.1. Measure the length of your headstay from pin-to-pin with your turnbuckle in its normal setting. If the mast is up, raise a measuring tape attached to the jib halyard to the top of the mast and add the length to the top pin on the headstay.2. With this measurement, deduct 13” and cut the top of the luff using a saw. Do not cut end with the sail-feed slot.Note: In 2017, we updated the FF2 halyard top fittings with a metal sheave to prevent friction when hoisting your sail, this new design requires a deduction of 13” instead of 12.25”.3. Take the halyard top fittingand push the cored end of thehalyard (without the metalferrule) up through the bottomof the off-center hole, not inthe center. Push the halyardover the sheave and out theside of the top fitting.4. Using the de-cored (hollow)end of the halyard with the metal ferrule, pass the ferrule down through the slot at the top of the luff extrusion on the opposite end of the sail feed slot. Trimming the halyard to the correct length will happenonce the entire furler is setup.5. Attach the halyard top fittingto the luff, ensuring that theside with the halyard comingthrough the fitting is on thesame side as the sail feed sloton the bottom of the luff.Tighten the set screw so it firmlypresses against the luff.Note: we updated the line halyards with a metal ferrule instead of the plastic traveller which would become brittle. 6. Using a spare line the length of your luff (not included), tie this messenger line to the de-cored end of the halyard external of the luff, this will beused to raise the sail.7. Unscrew both ends of theturnbuckle completely.8. Pass the swage-end of theheadstay down through thehalyard top fitting and the luff.Using locking pliers, hold the luffabove the threaded pin and screw on the turnbuckle body.9. Using your T-bolt, add additional washers to reduce the clearance between the T-bolt and the bottom of the cup. 10. Add the anti-rotation strap to the T-bolt and washers.11. Place the T-bolt and the anti-rotation strap through the bottom of the cup, then add the bearing (plastic or ball-bearing) to the T-bolt on the inside of the cup.12. Align the holes of the cup with the ant-rotation strap depending on the set-up of your furling line and screw the assembly together.13. Slide the furling drum/spool onto the luff, lining up the sail-feed slot with the anchor shackle. Ensure that the thrust washer stays inside the bottom opening of the spool.14. If mast is up, take the T-bolt assembly and screw into the turnbuckle body, adjust to the correct length. Ensure that all cotter pins are replaced in the turnbuckle.15. Lower the spool/drum over the bearing then raise the luff and insert the luff support pin with the cotter ring into the spool.Note:DO NOT DRILL A HOLE THROUGH THE LUFF EXTRUSION The luff rests on top of the luff support pin, not through it. 16. If mast is down, step the mast and attach headstay. 17. Adjust the backstay to normal tension. If headstay needsadjusting, remove the luff support pin and raise the spool to adjust, afterwards reinserting the luff support pin.18. Use a furling line (not included) to go through the opening in the cup and up through the hole on thetop flange of the spool, tie a knot to secure the line in place.19. Before raising your sail, manually rotate the spool/drum 20 times to load the furling line. If your furling line will be going starboard, wrap the line counter clockwise. If your furling line will be going port side, wrap the line clockwise. Note: the furling line should be low-stretch and no larger than 3/16” twice your boat length and trimmed down if needed. 20. Position the first fairlead or block (not included) so the furling line exits the middle of the cup to avoid any friction. To adjust where the opening of the cup is pointing, repeat step 14 to get the correct alignment.21. Place a cleat (not included) near the cockpit in an easily accessible spot to tie off the furling line.22. To trim the halyard, ensure the messenger line is attached then pull the halyard so the end with the ferrule reaches the top of the forestay at the halyard top fitting.23. For sails that are at or near full hoist, cut the halyard so the head of the sail would be just below the sail feed slot on the extrusion.24. For sails that are not full hoist, estimate the distance between the top of the stay and the head of the sail when it’s raised (A in diagram) and add this to the length of the halyard before cutting 25. Cut the halyard end with scissors and melt the end to prevent fraying.26. Attach the halyard to the head of the sail using either a halyard shackle (not included) or tying a knot directly to it.27. Feed the luff of the sail into the sail-feed slot while hoisting the sail by pulling on the messenger line which is attached to the de-cored end of the halyard (step 6). 28. Remove the messenger line once the sail is fully hoisted and tie off the halyard on the anchor shackle on the spool. Note: Always remember to reattach the messenger line when lowering your sail.29. Tension the sail by tightening the tack tension line to the second shackle on the spool and hoisting the sail tight by pulling on the halyard at a vertical angle, straight down. Note: Using a winch should never be required.30. Furl in the sail by pulling on the furling line and keeping tension on the jib sheet.ASAILMAKER INSTRUCTIONSSails require a #6 luff tape to becompatible with all CDI furlers.Webbing at the head and tack ofthe sail is recommended instead ofmetal grommets for smootherfurling but is not required.A: Overall length of the spool = 9.5”B: Length from the shackle to thetop of the spool = 4”Length of the halyard top fitting = 4”RIGGING INSTRUCTIONSThe CDI flexible furler system cannot be mounted above the turnbuckle as it can cause it to unscrew and dismast. If more clearance is required, it’s recommended to add link plates.The FF2 systems are compatible with 1/4”and 5/16”turnbuckles with a threaded swage-end and a T-bolt toggle.Most Navtec turnbuckles do not work and are not recommended as they’re often too big to fit inside the drum. Cotter pins should be used to lock the turnbuckle, not locknuts as these can unscrew and cause dismasting.Toggles are required at the bottom of the headstay, any secure fitting at the top of the forestay will work but a toggle is also recommended.NOTES ABOUT SAILINGThe tension on the luff doesn’t need to be high and should only be tight enough to removes any creases in the sail, use of a winch usu ally isn’t necessary.When sailing reefed, the jib leads should be moved forward to maintain proper sail shape and avoid the furler from rising off the bearing.To furl your sail, always keep tension on your jib sheet while reefing the furling line. NOTES ABOUT TRAILERINGWhen trailering, strap the furler to the mast in a horizontal position and support the end with the hardware by using a support. ie. 2x4 or PVC tubeKeep the extrusion as straight as possible, do not let either end sag or twist.MAINTENANCEThe only maintenance required is to rinse the furler system including the ball-bearing assembly if applicable, with fresh water 1-2 times per year. Clear out any salt or dirt that may have accumulated.Note: Lubricants are not required but Teflon sprays or dry lubricants are acceptable on the luff if needed.STORING YOUR FURLERStorage is best accomplished by strapping the furler to the mast in a horizontal position and supporting the end with the hardware by using a support ie. 2x4 or PVC tubeWhen storing, avoid making sharp bends in the extrusion. This can become permanent after a period of time and is not covered under warranty.It is not necessary to remove or recoil your extrusion, doing this over long periods of time can become permanent or cause it to break and is not recommended as the furler ages. Avoid exposing the furler in temperatures above 140F/60CWARRANTYThe CDI Flexible Furler comes with a 10-year limited warranty In order for the warranty to be valid, you must be the original owner of the system and have proof of purchase which clearly indicates the date of purchase.If any part becomes non-functional during this time, CDI will repair or replace it free of charge, not including shipping. Note: this warranty does not cover damage incurred from weather, trailering or transporting, collisions at sea, improper storage, improper uncoiling or straightening of the luff including using weights or heat guns, etc.NOTES:21 SOUTH LANDING DR – OAK BLUFF, CANADAP: 844-379-2407 | F: 204-896-6969*******************2022。

CDI系统操作手册字体大小:大| 中| 小2006-07-06 21:42 - 阅读:386 - 评论:0采用IP—LXM30X-3的CDI纯水处理系统IP-LX是CDI技术的先锋IONPURE公司开发的最新产品, 2000年投放市场。

IP-LX集合了15年的商业实践,比以前的产品更可靠且成本更低。

本章将介绍相关技术,并将阐述IP-LX与以前原型号产品及竞争伙伴目前同类产品的区别。

CDI指用离子交换膜,离子交换树脂,在直流电场的作用下,从水中去离子的过程,自从1987年Millipore的水处理部,著名的Ionpure(现归属Usfilter公司)将此技术推向市场后,不断进行改进,以降低成本和提高去离子度。

市场上大多数的CDI产品由交替放置的阳离子膜和阴离子膜构成,水从其中的膜隙流过。

这些交替放置的阴、阳离子交换膜被固定在两个带有进出水口的装置之间,水从其中的膜间隙流过。

面向正极的阴离子膜与面向负极的阳离子膜之间构成浓水室,面向负极的阴离子膜与面向正极的阳离子膜之间组成淡水室。

为了便于在弱电解质溶液中强化离子交换过程,在淡水室,有时在浓水室添加离子交换树脂。

在CDI装置机架两端的电极提供了横向的直流电场,直流电场驱动水中的离子运动穿过离子交换膜。

其结果是降低了淡水室中的离子浓度和增加了浓水室的离子浓度。

图1显示的是两个淡水室和一个浓水室离子交换过程。

大型的CDI装置,要由许多这样的基本单元组合在一起,并联工作。

设备参数CDI 单元进水流量( m3/h):22.7产水流量( m3/h) :20.4浓水流量( m3/h) : 2.3CDI 模块型号IP-LXM30X-3CDI 模块数量6设备外形2000*1600*2400设备自重2吨进水接口客户定义产水接口客户定义动力配备电压交流380伏特50赫兹功率42KW主要设备以及功能设备名称设备功能i.计算系统回收率,与设计值比较。

j.缓慢调节直流电源至需要数值。

内蒙古盾安光伏科技有限公司806尾气回收操作规程编写:赵涛校核:审核:审定:批准:2011年2月初稿目录第一章:CDI系统操作规程 .......................................................................... 错误!未定义书签。

第一节:工作目的................................................................................... 错误!未定义书签。

第二节:工作原理................................................................................... 错误!未定义书签。

一、三级冷却工作原理:............................................................... 错误!未定义书签。

二、吸收和解吸工作原理:........................................................... 错误!未定义书签。

三、氢气纯化工作原理:............................................................... 错误!未定义书签。

第三节:各种物质性质,技术参数....................................................... 错误!未定义书签。

一、原辅材料质量指标........................................................... 错误!未定义书签。

二、原辅材料消耗........................................................................... 错误!未定义书签。

CDI系统操作手册

字体大小:大| 中| 小2006-07-06 21:42 - 阅读:386 - 评论:0

采用IP—LXM30X-3的CDI纯水处理系统IP-LX是CDI技术的先锋IONPURE公司开发的最新产品, 2000年投放市场。

IP-LX集合了15年的商业实践,比以前的产品更可靠且成本更低。

本章将介绍相关技术,并将阐述IP-LX与以前原型号产品及竞争伙伴目前同类产品的区别。

CDI指用离子交换膜,离子交换树脂,在直流电场的作用下,从水中去离子的过程,自从1987年Millipore的水处理部,著名的Ionpure(现归属Usfilter公司)将此技术推向市场后,不断进行改进,以降低成本和提高去离子度。

市场上大多数的CDI产品由交替放置的阳离子膜和阴离子膜构成,水从其中的膜隙流过。

这些交替放置的阴、阳离子交换膜被固定在两个带有进出水口的装置之间,水从其中的膜间隙流过。

面向正极的阴离子膜与面向负极的阳离子膜之间构成浓水室,面向负极的阴离子膜与面向正极的阳离子膜之间组成淡水室。

为了便于在弱电解质溶液中强化离子交换过程,在淡水室,有时在浓水室添加离子交换树脂。

在CDI装置机架两端的电极提供了横向的直流电场,直流电场驱动水中的离子运动穿过离子交换膜。

其结果是降低了淡水室中的离子浓度和增加了浓水室的离子浓度。

图1显示的是两个淡水室和一个浓水室离子交换过程。

大型的CDI装置,要由许多这样的基本单元组合在一起,并联工作。

设备参数

CDI 单元

进水流量( m3/h):22.7

产水流量( m3/h) :20.4

浓水流量( m3/h) : 2.3

CDI 模块型号IP-LXM30X-3

CDI 模块数量6

设备外形2000*1600*2400

设备自重2吨

进水接口客户定义

产水接口客户定义

动力配备

电压交流380伏特

50赫兹

功率42KW

主要设备以及功能

设备名称设备功能

i.计算系统回收率,与设计值比较。

j.缓慢调节直流电源至需要数值。

注意观察出水水质。

k.记录所有运行数据。

l.测试所有流量限位开关和相关连锁动作。

确保当浓水循环流量不足时,CDI供电模块断电。

m.继续将CDI处于循环状态,直至产水指标达到要求。

n.一旦CDI出水指标达标,将CDI产水阀(至后级水箱)打开,将CDI产水回流阀(至RO水箱)关闭。

再次确认产水压力比浓水排放压力高2-5psig。

o.将系统运行值与设计值比较;

p.在系统运行稳定后(水质和流量),在日常运行数据记录表中记录运行数据。

q.将运行模式选定在自动模式。

在系统运行的第1周,定期检查系统的运行情况以确保系统正常可靠的运行。

运行启动

一旦CDI系统已经启动,然而,实际上,CDI系统不可避免的会或多或少的停机和重启动。

每次的停机和重启动都意味着压力和流量的变化,以及对CDI模块的机械性冲击。

因此,系统的停机和重启动的次数应当尽可能的少,以保证CDI系统的平稳运行。

在系统启动之前和过程中的检查应当作为一种日常工作进行,并且做好工作记录。

仪表的校正,报警,安全设备和管路泄漏性检查也应当作为一种日常工作进行。

停机

1, 关闭CDI模块的供电电源,电压和电流都将自动下降直至零。

2,停运RO产水输送泵。

3, 关闭每个CDI模块的进水阀。

4,关闭CDI模块的隔离阀

系统停机后的再次开机

1, 将CDI系统阀门运行状态处于CDI循环状态;

2,启动RO产水输送泵;

3, 按照CDI启动程序逐项检查,启动CDI系统;

4, 如果有必要,请参见CDI供应商文件对CDI进行杀菌消毒处理;

记录数据

介绍

为了能够更好的跟踪CDI的运行情况,必须收集CDI的运行的相关数据,并记录在日常运行表格中。

除了能够跟踪CDI的运行情况,运行数据对于CDI故障的判断和排除,都非常有价值。

本节是一些推荐的需要记录的运行指标。

CDI 运行数据记录表(样品)。