详细解析加工工艺材料 及 中英文对照

- 格式:doc

- 大小:3.57 MB

- 文档页数:16

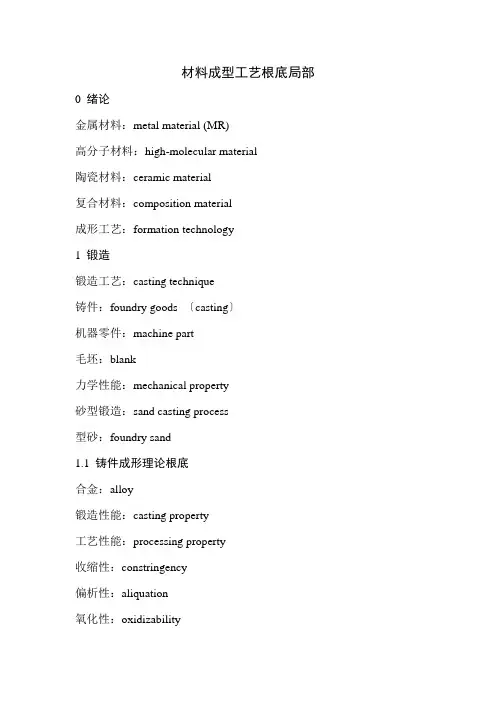

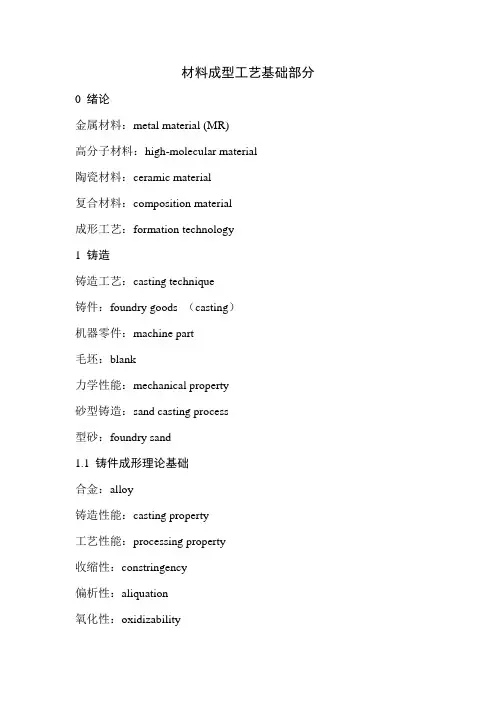

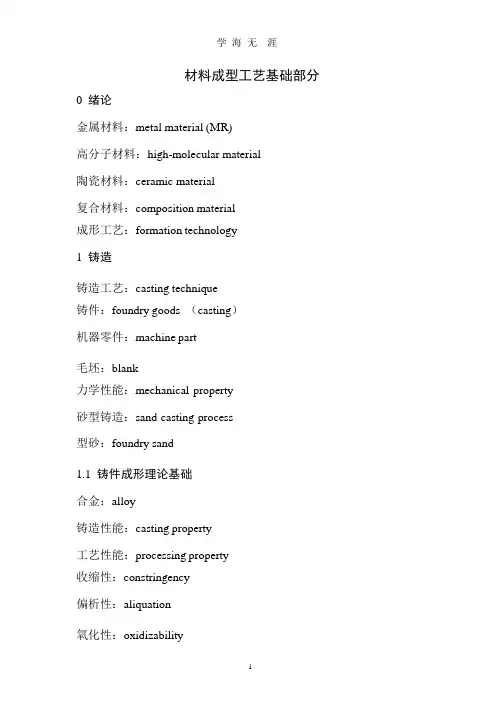

材料成型工艺根底局部0 绪论金属材料:metal material (MR)高分子材料:high-molecular material陶瓷材料:ceramic material复合材料:composition material成形工艺:formation technology1 锻造锻造工艺:casting technique铸件:foundry goods 〔casting〕机器零件:machine part毛坯:blank力学性能:mechanical property砂型锻造:sand casting process型砂:foundry sand1.1 铸件成形理论根底合金:alloy锻造性能:casting property工艺性能:processing property收缩性:constringency偏析性:aliquation氧化性:oxidizability吸气性:inspiratory铸件布局:casting structure使用性能:service performance浇缺乏:misrun冷隔:cold shut夹渣:cinder inclusion粘砂:sand fusion缺陷:flaw, defect, falling流动性:flowing power铸型:cast (foundry mold)蓄热系数:thermal storage capacity 浇注:pouring凝固:freezing收缩性:constringency逐层凝固:layer-by-layer freezing 糊状凝固:mushy freezing结晶:crystal缩孔:shrinkage void缩松:shrinkage porosity挨次凝固:progressive solidification 冷铁:iron chill补缩:feeding等温线法:constant temperature line method 内接圆法:inscribed circle method锻造应力:casting stress变形:deforming裂纹:crack机械应力:mechanical stress热应力:heat stress相变应力:transformation stress气孔:blow hole铸铁:ingot铸钢:cast steel非铁合金:nonferrous alloy灰铸铁:gray cast-iorn孕育处置:inoculation球墨铸铁:spheroidal球化处置:sheroidisation可锻铸铁:ductile cast iron石墨:graphite蠕墨铸铁:vermicular cast iron热处置:heat processing铝合金:Al-alloy熔炼:fusion metallurgy铜合金:copper alloy氢脆:hydrogen brittleness1.2 锻造方法〔casting method〕手工造型:hand moulding机器造型:machine moulding金属型:metal mold casting金属模:permanent mould压力锻造:press casting熔模锻造:investment moulding蜡膜:cere离心锻造:centrifugal casting低压锻造:casting under low pressure 差压锻造:counter-pressure casting 陶瓷型锻造:shaw process1.3 锻造工艺设计浇注位置:pouring position分型面:mould joint活块:loose piece起模:patter drawing型芯:core型芯撑:chaplet工艺参数:processing parameter下芯:core setting合型:mould assembly冒口:casting head尺寸公差:dimensional tolerance尺寸公差带:tolerance zone机械加工余量:machining allowance 铸孔:core hole非尺度:nonstandard label收缩率:rate of contraction线收缩:linear contraction体收缩:volume contraction起模斜度:pattern draft锻造圆角:curving of castings芯头:core register芯头间隙:clearance芯座:core print seat分型线:joint line分模线:die parting line1.4 锻造布局工艺性加强筋:rib reinforcement撒砂:stuccoing内腔:entocoele2 金属塑性加工塑性加工:plastic working塑性:plastic property锻造:forge work冲压:punching轧制:rolling拉拔:drawing挤压:extruding细化晶粒:grain refinement 热锻:hit-forging温锻:warm forging2.1 金属塑性加工理论根底塑性变形:plastic yield加工硬化:work-hardening 韧性:ductility答复温度:return temperature 再结晶:recrystallize再结晶退火:full annealing 冷变形:cold deformation热变性:heat denaturation锻造比:forging ratio镦粗:upset拔长:pull out纤维组织:fibrous tissue锻造性能:forging property可锻性:forgeability变形抗力:resistance of deformation化学成分:chemical constitution热脆性:hot brittleness冷脆性:cold-shortness变形速度:deformation velocity应力状态:stress condition变形温度:deformation temperature过热:overheating过烧:burning脱碳:carbon elimination始锻温度:initiation forging temperature 终锻温度:final forging temperature 2.2 金属塑性加工方法自由锻:flat-die hammer冲孔:jetting弯曲:bend弯曲半径:bending radius切割:cut扭转:twist rotation错移:offsetting锻接:percussion底子工序:basic process辅助工序:auxiliary process精整工序:finishing process模锻:contour forging锻模:forging die胎膜锻:fetal membrane forging剪床:shearing machine冲床:backing-out punch冲裁:blanking弹性变形:elastic distortion塑性变形:plastic yield剪切变形:shearing deformation最小弯曲半径:minimum bending radius 曲率:angularity弯裂:rupture回弹:rebound辊轧:roll forming辊锻:roll forging斜轧:oblique rolling横轧:transverse rolling辗压:tamping drum挤压:extruding拉拔:draft2.3 塑性加工工艺设计工艺规程:process specification锻件图:forging drawing敷料:dressing锻件余量:forging allowance锻件公差:forging tolerance工夹具:clamping apparatus加热设备:firing equipment加热尺度:heating schedule冷却尺度:cooling schedule后续处置:after treatment分模面:die parting face冲孔连皮:punching the wad模锻斜度:draft angle圆角半径:radius of corner圆饼类锻件:circumcresent cake-like forging 长轴类锻件:long axis-like forging2.4 锻件布局工艺性锥体:cone斜面:cant空间曲线:curve in space粗拙度:degree of roughness2.5 冲压件布局工艺性3 焊接焊接:welding铆接:riverting熔焊:fusion welding压焊:press welding钎焊:braze welding3.1 焊接理论根底冶金:metallurgy电弧焊:arc welding气焊:acetylene welding电渣焊:electro-slag welding 高能束焊:high energy welding 电子焊:electronic welding激光焊:laser welding等离子焊:plasma welding电弧:electric arc阳极区:anode region阴极区:negative polarity弧柱区:arc stream正接法:electrode negative method反接法:opposition method脱氧剂:deoxidizing agent焊缝:welded seam焊缝区:weld zone熔合区:fusion area热影响区:heat-affected zone脆性断裂:brittle fracture过热区:overheated zone正火区:normalized zone相变区:phase change zone焊策应力:welding stress收缩变形:contraction distortion角变形:angular deformation弯曲变形:bend deformation扭曲变形:warping deformation波浪变形:wave transformation反变形法:reversible deformation method 刚性固定法:rigid fixing method预热:warming-up缓冷:slow cool焊后热处置:postweld heat treatment矫形处置:shape-righting3.2 焊接方法埋弧焊:hidden arc welding气体庇护焊:gas shielded arc welding氩弧焊:argon welding熔化极氩弧焊:consumable electrode argon welding 钨极氩弧焊:argon tungsten-arc welding二氧化碳气体庇护焊:CO2 gas shielded arc welding 碳弧焊:carbon arc welding碳弧气刨:carbon arc air gouging电渣焊:electro-slag welding高能焊:high grade energy welding等离子弧切割:plasma arc cutting (PAC)堆焊:bead weld电阻焊:resistance welding电焊:electric welding缝焊:seam welding压焊:press welding多点凸焊:multiple projection welding对焊:welding neck摩擦焊:friction welding扩散焊:diffusion welding硬钎料:brazing alloy软钎料:soft solder3.3 常用金属材料的焊接焊接性:weldability焊接方法:welding method 焊接材料:welding material 焊条:electrode焊剂:flux material碳素钢:carbon steel低碳钢:low carbon steel中碳钢:medium carbon steel 高碳钢:high carbon steel低合金钢:lean alloy steel不锈钢:non-corrosive steel 有色金属:nonferrous metal 3.4 焊接工艺设计型材:sectional bar药皮:coating焊丝:soldering wire持续焊缝:continuous weld断续焊缝:intermittent weld应力集中:stress concentration焊接接头:soldered joint坡口:groove对接:abutting joint搭接:lap joint角接:corner joint4 粉末冶金〔power metallurgy〕粉末冶金成品:finished power metallurgical product 铁氧体:ferrite硬质合金:sintered-carbide高熔点金属:high-melting metal陶瓷:ceramic4.1 粉末冶金工艺理论根底压坯:pressed compact扩散:diffusion烧结:agglomeration固溶:solid solubility化合:combination4.2 粉末冶金的工艺流程制备:preparation预处置:anticipation复原法:reduction method电解法:electrolytic method雾化法:atomization粒度:grain size松装密度:loose density流动性:flowing power压缩性:compressibility筛分:screen separation混合:compounding制粒:pelletization过烧:superburning欠烧:underburnt5 金属复合成型技术自蔓延焊接:SHS welding热等静压:HIP准热等静压:PHIP5.1 液态成型技术与固态成型技术的复合高压锻造:high-pressure casting电磁泵:magnetic-pump压射成型:injection molding柱塞:plunger piston冲头:drift pin凝固法:freezing method挤压法:extrusion method转向节:knuckle pivot制动器:arresting gear5.2 金属半凝固、半熔融成型技术凝固:freezing半熔融:semi-vitreous触变锻造:thixotropy casting触变锻造:thixotropy forging打针成型:injection molding5.3 其他金属成型新技术快速凝固:flash set非晶态:amorphous溢流法:press over system喷射沉积:ejecting deposit爆炸复合法:explosion cladding method 扩散焊接:diffusion welding挤压:extruding轧制:roll down6 非金属材料成型技术6.1 高分子材料成型技术高分子材料:non-metal material 耐腐蚀:resistant material绝缘:insulation老化:ageing耐热性:heat-durability粘弹性:viscoelasticity塑料:plastic material橡胶:rubber合成纤维:synthetic fibre涂料:covering material粘结剂:agglomerant粘度:viscosity热塑性塑料:thermoplastic plastics 热固性塑料:thermosetting plastic 通用塑料:general-purpose plastics 工程塑料:engineering plastic薄膜:thin film增强塑料:reinforced plastics浇注塑料:pouring plastics打针塑料:injiection plastics挤出塑料:extrusion plastics吹塑塑料:blowing plastics模压塑料:die pressing plastics聚合物:ploymer semiconductor吸湿性:hygroscopic cargo定向作用:directional action生胶:green glue stock填料:carrier丁苯橡胶:SBR顺丁橡胶:BR氯丁橡胶:CR丁腈橡胶:NBR硅橡胶:Q聚氨酯橡胶:U压延:calender硫化:sulfuration胶粘剂:adhesive胶接:glue joint刹车片:brake block零件修复:parts renewal蜂窝夹层:honeycomb core material 6.2 工业陶瓷成品的成型技术枯燥:drying润滑剂:anti-friction结合剂:binder热压铸:hot injiection moulding 6.3 非金属材料成型技术的新进展热压烧结:hot pressed sintering7 复合材料的成型技术复合材料:composite material树脂:resin7.1 金属复合材料的成型技术硼纤维:boron fiber钛合金:titanium alloy碳纤维:carbon filter等离子喷涂:plasma spraying浸渍法:immersion method锭坯:ingot blank7.2 聚合物基复合材料的成型技术晶须:whisker缠绕成形:enwind forming湿法缠绕:wet method enwind 7.3 陶瓷复合材料成型技术溶胶-凝胶法:sol-gel method化学气相沉积:chemical vapor deposition (CVD) 原位:in situ8 材料成型方法的选择粉末冶金:powder metallurgy工程塑料:engineering plastics工程陶瓷:engineering ceramics。

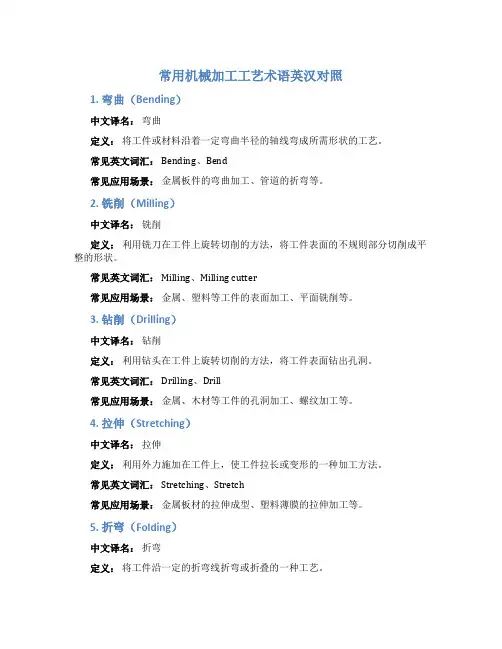

常用机械加工工艺术语英汉对照1. 弯曲(Bending)中文译名:弯曲定义:将工件或材料沿着一定弯曲半径的轴线弯成所需形状的工艺。

常见英文词汇: Bending、Bend常见应用场景:金属板件的弯曲加工、管道的折弯等。

2. 铣削(Milling)中文译名:铣削定义:利用铣刀在工件上旋转切削的方法,将工件表面的不规则部分切削成平整的形状。

常见英文词汇: Milling、Milling cutter常见应用场景:金属、塑料等工件的表面加工、平面铣削等。

3. 钻削(Drilling)中文译名:钻削定义:利用钻头在工件上旋转切削的方法,将工件表面钻出孔洞。

常见英文词汇: Drilling、Drill常见应用场景:金属、木材等工件的孔洞加工、螺纹加工等。

4. 拉伸(Stretching)中文译名:拉伸定义:利用外力施加在工件上,使工件拉长或变形的一种加工方法。

常见英文词汇: Stretching、Stretch常见应用场景:金属板材的拉伸成型、塑料薄膜的拉伸加工等。

5. 折弯(Folding)中文译名:折弯定义:将工件沿一定的折弯线折弯或折叠的一种工艺。

常见英文词汇: Folding、Fold常见应用场景:金属片的折叠加工、纸张等的折叠加工等。

6. 车削(Turning)中文译名:车削定义:利用车床上旋转的工件,通过刀具的切削将工件外形加工成所需形状的一种方法。

常见英文词汇: Turning、Turn常见应用场景:圆柱形工件的精密加工、内外圆柱的加工等。

7. 切削(Cutting)中文译名:切削定义:利用刀具沿工件表面进行切削的过程,将工件切割、修整或产生新的形状。

常见英文词汇: Cutting、Cut常见应用场景:金属、木材等工件的切割、修整等。

8. 研磨(Grinding)中文译名:研磨定义:利用磨料通过相对运动与工件表面进行切削、磨削的一种加工方法。

常见英文词汇: Grinding、Grind常见应用场景:金属、陶瓷等材料的表面处理、精加工等。

材料成型工艺基础部分0 绪论金属材料:metal material (MR)高分子材料:high-molecular material陶瓷材料:ceramic material复合材料:composition material成形工艺:formation technology1 铸造铸造工艺:casting technique铸件:foundry goods (casting)机器零件:machine part毛坯:blank力学性能:mechanical property砂型铸造:sand casting process型砂:foundry sand1.1 铸件成形理论基础合金:alloy铸造性能:casting property工艺性能:processing property收缩性:constringency偏析性:aliquation氧化性:oxidizability吸气性:inspiratory铸件结构:casting structure使用性能:service performance浇不足:misrun冷隔:cold shut夹渣:cinder inclusion粘砂:sand fusion缺陷:flaw, defect, falling流动性:flowing power铸型:cast (foundry mold)蓄热系数:thermal storage capacity 浇注:pouring凝固:freezing收缩性:constringency逐层凝固:layer-by-layer freezing 糊状凝固:mushy freezing结晶:crystal缩孔:shrinkage void缩松:shrinkage porosity顺序凝固:progressive solidification 冷铁:iron chill补缩:feeding等温线法:constant temperature line method 内接圆法:inscribed circle method铸造应力:casting stress变形:deforming裂纹:crack机械应力:mechanical stress热应力:heat stress相变应力:transformation stress气孔:blow hole铸铁:ingot铸钢:cast steel非铁合金:nonferrous alloy灰铸铁:gray cast-iorn孕育处理:inoculation球墨铸铁:spheroidal球化处理:sheroidisation可锻铸铁:ductile cast iron石墨:graphite蠕墨铸铁:vermicular cast iron热处理:heat processing铝合金:Al-alloy熔炼:fusion metallurgy铜合金:copper alloy氢脆:hydrogen brittleness1.2 铸造方法(casting method)手工造型:hand moulding机器造型:machine moulding金属型:metal mold casting金属模:permanent mould压力铸造:press casting熔模铸造:investment moulding蜡膜:cere离心铸造:centrifugal casting低压铸造:casting under low pressure 差压铸造:counter-pressure casting 陶瓷型铸造:shaw process1.3 铸造工艺设计浇注位置:pouring position分型面:mould joint活块:loose piece起模:patter drawing型芯:core型芯撑:chaplet工艺参数:processing parameter下芯:core setting合型:mould assembly冒口:casting head尺寸公差:dimensional tolerance尺寸公差带:tolerance zone机械加工余量:machining allowance 铸孔:core hole非标准:nonstandard label收缩率:rate of contraction线收缩:linear contraction体收缩:volume contraction起模斜度:pattern draft铸造圆角:curving of castings芯头:core register芯头间隙:clearance芯座:core print seat分型线:joint line分模线:die parting line1.4 铸造结构工艺性加强筋:rib reinforcement撒砂:stuccoing内腔:entocoele2 金属塑性加工塑性加工:plastic working塑性:plastic property锻造:forge work冲压:punching轧制:rolling拉拔:drawing挤压:extruding细化晶粒:grain refinement 热锻:hit-forging温锻:warm forging2.1 金属塑性加工理论基础塑性变形:plastic yield加工硬化:work-hardening 韧性:ductility回复温度:return temperature 再结晶:recrystallize再结晶退火:full annealing 冷变形:cold deformation热变性:heat denaturation锻造比:forging ratio镦粗:upset拔长:pull out纤维组织:fibrous tissue锻造性能:forging property可锻性:forgeability变形抗力:resistance of deformation化学成分:chemical constitution热脆性:hot brittleness冷脆性:cold-shortness变形速度:deformation velocity应力状态:stress condition变形温度:deformation temperature过热:overheating过烧:burning脱碳:carbon elimination始锻温度:initiation forging temperature 终锻温度:final forging temperature 2.2 金属塑性加工方法自由锻:flat-die hammer冲孔:jetting弯曲:bend弯曲半径:bending radius切割:cut扭转:twist rotation错移:offsetting锻接:percussion基本工序:basic process辅助工序:auxiliary process精整工序:finishing process模锻:contour forging锻模:forging die胎膜锻:fetal membrane forging剪床:shearing machine冲床:backing-out punch冲裁:blanking弹性变形:elastic distortion塑性变形:plastic yield剪切变形:shearing deformation最小弯曲半径:minimum bending radius 曲率:angularity弯裂:rupture回弹:rebound辊轧:roll forming辊锻:roll forging斜轧:oblique rolling横轧:transverse rolling辗压:tamping drum挤压:extruding拉拔:draft2.3 塑性加工工艺设计工艺规程:process specification锻件图:forging drawing敷料:dressing锻件余量:forging allowance锻件公差:forging tolerance工夹具:clamping apparatus加热设备:firing equipment加热规范:heating schedule冷却规范:cooling schedule后续处理:after treatment分模面:die parting face冲孔连皮:punching the wad模锻斜度:draft angle圆角半径:radius of corner圆饼类锻件:circumcresent cake-like forging 长轴类锻件:long axis-like forging2.4 锻件结构工艺性锥体:cone斜面:cant空间曲线:curve in space粗糙度:degree of roughness2.5 冲压件结构工艺性3 焊接焊接:welding铆接:riverting熔焊:fusion welding压焊:press welding钎焊:braze welding3.1 焊接理论基础冶金:metallurgy电弧焊:arc welding气焊:acetylene welding电渣焊:electro-slag welding 高能束焊:high energy welding 电子焊:electronic welding激光焊:laser welding等离子焊:plasma welding电弧:electric arc阳极区:anode region阴极区:negative polarity弧柱区:arc stream正接法:electrode negative method反接法:opposition method脱氧剂:deoxidizing agent焊缝:welded seam焊缝区:weld zone熔合区:fusion area热影响区:heat-affected zone脆性断裂:brittle fracture过热区:overheated zone正火区:normalized zone相变区:phase change zone焊接应力:welding stress收缩变形:contraction distortion角变形:angular deformation弯曲变形:bend deformation扭曲变形:warping deformation波浪变形:wave transformation反变形法:reversible deformation method 刚性固定法:rigid fixing method预热:warming-up缓冷:slow cool焊后热处理:postweld heat treatment矫形处理:shape-righting3.2 焊接方法埋弧焊:hidden arc welding气体保护焊:gas shielded arc welding氩弧焊:argon welding熔化极氩弧焊:consumable electrode argon welding 钨极氩弧焊:argon tungsten-arc welding二氧化碳气体保护焊:CO2 gas shielded arc welding 碳弧焊:carbon arc welding碳弧气刨:carbon arc air gouging电渣焊:electro-slag welding高能焊:high grade energy welding等离子弧切割:plasma arc cutting (PAC)堆焊:bead weld电阻焊:resistance welding电焊:electric welding缝焊:seam welding压焊:press welding多点凸焊:multiple projection welding对焊:welding neck摩擦焊:friction welding扩散焊:diffusion welding硬钎料:brazing alloy软钎料:soft solder3.3 常用金属材料的焊接焊接性:weldability焊接方法:welding method 焊接材料:welding material 焊条:electrode焊剂:flux material碳素钢:carbon steel低碳钢:low carbon steel中碳钢:medium carbon steel 高碳钢:high carbon steel低合金钢:lean alloy steel不锈钢:non-corrosive steel 有色金属:nonferrous metal 3.4 焊接工艺设计型材:sectional bar药皮:coating焊丝:soldering wire连续焊缝:continuous weld断续焊缝:intermittent weld应力集中:stress concentration焊接接头:soldered joint坡口:groove对接:abutting joint搭接:lap joint角接:corner joint4 粉末冶金(power metallurgy)粉末冶金成品:finished power metallurgical product 铁氧体:ferrite硬质合金:sintered-carbide高熔点金属:high-melting metal陶瓷:ceramic4.1 粉末冶金工艺理论基础压坯:pressed compact扩散:diffusion烧结:agglomeration固溶:solid solubility化合:combination4.2 粉末冶金的工艺流程制备:preparation预处理:anticipation还原法:reduction method电解法:electrolytic method雾化法:atomization粒度:grain size松装密度:loose density流动性:flowing power压缩性:compressibility筛分:screen separation混合:compounding制粒:pelletization过烧:superburning欠烧:underburnt5 金属复合成型技术自蔓延焊接:SHS welding热等静压:HIP准热等静压:PHIP5.1 液态成型技术与固态成型技术的复合高压铸造:high-pressure casting电磁泵:magnetic-pump压射成型:injection molding柱塞:plunger piston冲头:drift pin凝固法:freezing method挤压法:extrusion method转向节:knuckle pivot制动器:arresting gear5.2 金属半凝固、半熔融成型技术凝固:freezing半熔融:semi-vitreous触变铸造:thixotropy casting触变锻造:thixotropy forging注射成型:injection molding5.3 其他金属成型新技术快速凝固:flash set非晶态:amorphous溢流法:press over system喷射沉积:ejecting deposit爆炸复合法:explosion cladding method 扩散焊接:diffusion welding挤压:extruding轧制:roll down6 非金属材料成型技术6.1 高分子材料成型技术高分子材料:non-metal material 耐腐蚀:resistant material绝缘:insulation老化:ageing耐热性:heat-durability粘弹性:viscoelasticity塑料:plastic material橡胶:rubber合成纤维:synthetic fibre涂料:covering material粘结剂:agglomerant粘度:viscosity热塑性塑料:thermoplastic plastics 热固性塑料:thermosetting plastic 通用塑料:general-purpose plastics 工程塑料:engineering plastic薄膜:thin film增强塑料:reinforced plastics浇注塑料:pouring plastics注射塑料:injiection plastics挤出塑料:extrusion plastics吹塑塑料:blowing plastics模压塑料:die pressing plastics聚合物:ploymer semiconductor吸湿性:hygroscopic cargo定向作用:directional action生胶:green glue stock填料:carrier丁苯橡胶:SBR顺丁橡胶:BR氯丁橡胶:CR丁腈橡胶:NBR硅橡胶:Q聚氨酯橡胶:U压延:calender硫化:sulfuration胶粘剂:adhesive胶接:glue joint刹车片:brake block零件修复:parts renewal蜂窝夹层:honeycomb core material 6.2 工业陶瓷制品的成型技术干燥:drying润滑剂:anti-friction结合剂:binder热压铸:hot injiection moulding 6.3 非金属材料成型技术的新进展热压烧结:hot pressed sintering7 复合材料的成型技术复合材料:composite material树脂:resin7.1 金属复合材料的成型技术硼纤维:boron fiber钛合金:titanium alloy碳纤维:carbon filter等离子喷涂:plasma spraying浸渍法:immersion method锭坯:ingot blank7.2 聚合物基复合材料的成型技术晶须:whisker缠绕成形:enwind forming湿法缠绕:wet method enwind 7.3 陶瓷复合材料成型技术溶胶-凝胶法:sol-gel method化学气相沉积:chemical vapor deposition (CVD) 原位:in situ8 材料成型方法的选择粉末冶金:powder metallurgy工程塑料:engineering plastics工程陶瓷:engineering ceramics。

铸件及产品表面处理工艺:压铸件:Die castingsZinc Die castings电铸件:Electrical castings不锈钢铸件:stainless steel castings铸件表面处理Surface finish for the castings:做黑:blacking镀锌:Zinc plating镀铬:chrome plating镀镍:nickel plating磨砂面处理:grit satin finishSatin finish titanium抛光处理:tumble bright手工拉丝(圆形拉丝,放射线拉丝, 对角线拉丝):brushed metal surface/drawbench(circular metal brushed texture, radius metal brushed texture, diagonal metal brushed texture)Cell phone with brushed metal surface哑光面处理:hand dull polished finish镜面抛光处理:mirror polished finish金属孔:metallic holes氧化铬钝化处理:passivation treatment电抛光处理:electrolytic polished喷砂处理(玻璃砂,钢玉沙,石英砂):sandblasting(glass bead blasting, corundum-sand blasting, quartz-sand blasting)Satin finished surfaceTPU或橡胶凹刻: TPU,rubber text intaglioCell phone TPU text intaglioCD纹样:CD patternCell phone navigation key used CD pattern镀枪色:gun color platinggun color plated真空镀:PVD vacuum plating(PVD: Physical vapor deposition)PVDtechnics UV coating+PVD technics紫外固化(增加表面耐磨层及使用寿命):UV curingUV coating字符镭雕:Laser carving textSilicone rubber keypad numbers by laser carving technics 字符丝印:Silk-screen printingPhone text silkscreen printed一般电镀:electroplating effectsElectroplated mobile手机壳使用材料:ABS+PC(塑料) Zinc Alloy(锌合金),Aluminum Alloy(铝合金)ABS+PC Zinc AlloyAlumium Alloy按键材料: Keypad made of PC plasticPC plastic镜片屏幕材料:Lens, screen made of PMMA(亚克力),PVC plasticPMMA material Clear PVC FilmUSB软胶塞材料:USB stopper made of Rubber, TPUTPO material cover电镀可用在ABS和金属材料,真空镀可用在PMMA和任何材料上,真空镀价格相对便宜:Electroplating can be done by ABS and metal materials, PVD vaccum plating can be donw on any other materila such as PMMA亚克力,PVD plating cheaper不导电真空镀处理:Non conductive PVD vacuum platingNon conductive PVD plated注塑材料:injection molding plastic喷漆处理:paint sprayingPaint-spraying+UV coating模具蚀纹(手机壳花纹工艺):in-mould metal etching techniqueComputer cover etching不锈钢拉丝电镀处理:stainless steel brushed surface by chrome plating阳极氧化处理:anodic oxidation treatmentAluminum Anoidc oxidation treatment on surface表面电镀:surface electroplating电泳处理:Electrophoresis不导电真空溅镀工艺(和电镀效果一样都是在塑料表面镀金属色,但是有镜面效果非常亮):Non conductive vacuum metallization technics(It is similar to electroplating effects, but colors can be mirror finish)PVD vacuum metallization不锈钢表面进行处理(表面本色白化处理,表面镜石光亮处,表面着色处理,光亮处理方法,喷砂处理法,机械抛光,化学抛光,电化学抛光):Stainless steel surface treatment(color bleaching treatment, mirror finish treatment, sand blasting, mechanical polishing finish, chemical polishing finish, electrochemical polishing finish).Chemical polished喇叭网,布织网:Speaker mesh,netting双色注塑:two-color injection molding technics底面镀膜:underside coating with thin film钢板花纹镭雕:Steel sheet with laser engraving treatmentLaser Engraving texture部分纹理突起:Texture bump不锈钢冲压:Precision stainless steel stamping part.彩镀:color plating电池盖常用材料:battery cap made of aluminum alloy, ABS+PCAlumium Alloy cap表面腐蚀纹:Electrochemisty corrosion pattern finishLighter metal corrosion texture表面氧化处理:Surface oxidation treatment沙面处理:satin finish亮面处理:glossy finishHigh glossy finish car body with black paint spray+UV coating 哑光面处理:matte finish批花纹处理:radiation pattern功能键镀膜效果:function keys made of transparent PC with coating effect手机壳体分件:上壳:Front Housing壳上装饰件:cap decorative pieces中壳:middle cover后壳:Rear Housing按键:keypad天线:Antenna电池盖:battery cover侧按键:side function key导航键:navigation key功能键:function key喇叭孔:Mic振动器:Vibrater测试端口:Test port and 嗡鸣器:Buzzer常用材料及应用ABS:汽车(仪表板,工具舱门,车轮盖,反光镜,冰箱,大强度工具如头发烘干机,搅拌器,食品加工机,割草机,电话机壳体,打字机键盘,娱乐用车辆如高尔夫球手推车,喷气式雪橇车。

材料成型工艺基础部分中英文词汇对照材料成型工艺基础部分0 绪论金属材料:metal material (MR)高分子材料:high-molecular material陶瓷材料:ceramic material复合材料:composition material成形工艺:formation technology1 铸造铸造工艺:casting technique铸件:foundry goods (casting)机器零件:machine part毛坯:blank力学性能:mechanical property砂型铸造:sand casting process型砂:foundry sand1.1 铸件成形理论基础合金:alloy铸造性能:casting property工艺性能:processing property 收缩性:constringency偏析性:aliquation氧化性:oxidizability吸气性:inspiratory铸件结构:casting structure 使用性能:service performance 浇不足:misrun冷隔:cold shut夹渣:cinder inclusion粘砂:sand fusion缺陷:flaw, defect, falling流动性:flowing power铸型:cast (foundry mold)蓄热系数:thermal storage capacity浇注:pouring凝固:freezing收缩性:constringency逐层凝固:layer-by-layer freezing糊状凝固:mushy freezing结晶:crystal缩孔:shrinkage void缩松:shrinkage porosity顺序凝固:progressive solidification冷铁:iron chill补缩:feeding等温线法:constant temperature line method内接圆法:inscribed circle method 铸造应力:casting stress 变形:deforming裂纹:crack机械应力:mechanical stress热应力:heat stress相变应力:transformation stress 气孔:blow hole铸铁:ingot铸钢:cast steel非铁合金:nonferrous alloy灰铸铁:gray cast-iorn孕育处理:inoculation球墨铸铁:spheroidal球化处理:sheroidisation可锻铸铁:ductile cast iron石墨:graphite蠕墨铸铁:vermicular cast iron 热处理:heat processing铝合金:Al-alloy熔炼:fusion metallurgy铜合金:copper alloy氢脆:hydrogen brittleness1.2 铸造方法(casting method)手工造型:hand moulding机器造型:machine moulding金属型:metal mold casting金属模:permanent mould压力铸造:press casting熔模铸造:investment moulding蜡膜:cere离心铸造:centrifugal casting低压铸造:casting under low pressure 差压铸造:counter-pressure casting 陶瓷型铸造:shaw process1.3 铸造工艺设计浇注位置:pouring position分型面:mould joint活块:loose piece起模:patter drawing型芯:core型芯撑:chaplet工艺参数:processing parameter下芯:core setting合型:mould assembly冒口:casting head尺寸公差:dimensional tolerance 尺寸公差带:tolerance zone 机械加工余量:machining allowance 铸孔:core hole非标准:nonstandard label收缩率:rate of contraction线收缩:linear contraction体收缩:volume contraction起模斜度:pattern draft铸造圆角:curving of castings芯头:core register芯头间隙:clearance芯座:core print seat分型线:joint line分模线:die parting line 1.4 铸造结构工艺性加强筋:rib reinforcement 撒砂:stuccoing内腔:entocoele2 金属塑性加工塑性加工:plastic working 塑性:plastic property锻造:forge work冲压:punching轧制:rolling拉拔:drawing挤压:extruding细化晶粒:grain refinement 热锻:hit-forging2.1 金属塑性加工理论基础塑性变形:plastic yield加工硬化:work-hardening韧性:ductility回复温度:return temperature 再结晶:recrystallize 再结晶退火:full annealing 冷变形:cold deformation 热变性:heat denaturation锻造比:forging ratio镦粗:upset拔长:pull out纤维组织:fibrous tissue锻造性能:forging property变形抗力:resistance of deformation化学成分:chemical constitution热脆性:hot brittleness冷脆性:cold-shortness变形速度:deformation velocity应力状态:stress condition变形温度:deformation temperature过热:overheating过烧:burning脱碳:carbon elimination始锻温度:initiation forging temperature 终锻温度:final forging temperature2.2 金属塑性加工方法自由锻:flat-die hammer弯曲:bend弯曲半径:bending radius切割:cut扭转:twist rotation错移:offsetting锻接:percussion基本工序:basic process辅助工序:auxiliary process精整工序:finishing process模锻:contour forging锻模:forging die胎膜锻:fetal membrane forging 剪床:shearing machine冲床:backing-out punch弹性变形:elastic distortion塑性变形:plastic yield剪切变形:shearing deformation最小弯曲半径:minimum bending radius 曲率:angularity弯裂:rupture回弹:rebound辊轧:roll forming辊锻:roll forging斜轧:oblique rolling横轧:transverse rolling辗压:tamping drum挤压:extruding拉拔:draft2.3 塑性加工工艺设计工艺规程:process specification 锻件图:forging drawing敷料:dressing锻件余量:forging allowance锻件公差:forging tolerance工夹具:clamping apparatus加热设备:firing equipment加热规范:heating schedule冷却规范:cooling schedule后续处理:after treatment分模面:die parting face冲孔连皮:punching the wad模锻斜度:draft angle圆角半径:radius of corner圆饼类锻件:circumcresent cake-like forging 长轴类锻件:long axis-like forging2.4 锻件结构工艺性锥体:cone斜面:cant空间曲线:curve in space粗糙度:degree of roughness2.5 冲压件结构工艺性3 焊接焊接:welding铆接:riverting熔焊:fusion welding压焊:press welding钎焊:braze welding3.1 焊接理论基础冶金:metallurgy电弧焊:arc welding气焊:acetylene welding电渣焊:electro-slag welding高能束焊:high energy welding电子焊:electronic welding激光焊:laser welding等离子焊:plasma welding电弧:electric arc阳极区:anode region阴极区:negative polarity弧柱区:arc stream正接法:electrode negative method 反接法:opposition method脱氧剂:deoxidizing agent焊缝:welded seam焊缝区:weld zone熔合区:fusion area热影响区:heat-affected zone脆性断裂:brittle fracture过热区:overheated zone正火区:normalized zone相变区:phase change zone焊接应力:welding stress收缩变形:contraction distortion角变形:angular deformation弯曲变形:bend deformation扭曲变形:warping deformation波浪变形:wave transformation反变形法:reversible deformation method刚性固定法:rigid fixing method预热:warming-up缓冷:slow cool焊后热处理:postweld heat treatment矫形处理:shape-righting3.2 焊接方法埋弧焊:hidden arc welding气体保护焊:gas shielded arc welding氩弧焊:argon welding熔化极氩弧焊:consumable electrode argon welding 钨极氩弧焊:argon tungsten-arc weldinggas shielded arc welding 二氧化碳气体保护焊:CO2碳弧焊:carbon arc welding碳弧气刨:carbon arc air gouging电渣焊:electro-slag welding高能焊:high grade energy welding等离子弧切割:plasma arc cutting (PAC)堆焊:bead weld电阻焊:resistance welding电焊:electric welding缝焊:seam welding压焊:press welding多点凸焊:multiple projection welding 对焊:welding neck 摩擦焊:friction welding扩散焊:diffusion welding硬钎料:brazing alloy软钎料:soft solder3.3 常用金属材料的焊接焊接性:weldability焊接方法:welding method焊接材料:welding material 焊条:electrode焊剂:flux material碳素钢:carbon steel低碳钢:low carbon steel中碳钢:medium carbon steel 高碳钢:high carbon steel 低合金钢:lean alloy steel 不锈钢:non-corrosive steel 有色金属:nonferrous metal 3.4 焊接工艺设计型材:sectional bar药皮:coating焊丝:soldering wire。

机械制造工艺基本术语中英文常用工艺术语1工艺基本概念1.1一般概念1.1.1数控加工:numerical control machining根据被加工零件图样和工艺要求,编制成以数码表示的程序输入到机床的数控装置或控制计算机中,以控制工件和工具的相对运动,使之加工出合格零件的方法。

1.2生产对象1.2.1原材料:raw material投入生产过程以创新产品的物质。

1.2.2主要材料:primary material。

direct material构成产品实体的材料。

1.2.3辅助材料:auxiliary material。

indirect material在生产中起辅助作用而不构成产品实体的材料。

1.2.4代用材料:substituent在使用功能上能够代替原设计要求的材料。

它具有被代替材料所具备的全部或主要性能。

1.2.5易损材料:quick-wear material在正常使用条件下,容易损坏或失效的材料。

1.2.6废物:waste material在制造某种产品过程中,剩下的而对本生产对象不再有用的材料。

1.2.7型材:n金属或非金属资料通过拉制、轧制或压制等方法所获得的具有特定多少形状截面的资料。

1.2.8板材:plate金属或非金属资料通过轧制或压制等方法而获得的各类不同厚度的板状资料。

1.2.9棒材:bar stock金属或非金属材料通过拉延、轧制工艺获得的圆、方、六角形截面的材料。

1.2.10铸件:casting将熔融金属浇入铸型,凝固后所得到的金属制件或毛坯。

1.2.11锻件:ings金属材料经过锻造变形而得到的工件或毛坯。

1.2.12焊接件:XXX用焊接方法而得到的联合件。

1.2.13模压件:molded parts利用模具压制的工件。

1.2.14冲压件:stamping用冲压的方法制成的工件或毛坯。

1.2.15合格品:accepted product。

conforming article通过检验质量特性吻合标准请求的制品。

常用机械加工工艺术语(英汉对照)1 工艺基本概念1.1 一般概念1.1.1数控加工:numerical control machining根据被加工零件图样和工艺要求,编制成以数码表示的程序输入到机床的数控装置或控制计算机中,以控制工件和工具的相对运动,使之加工出合格零件的方法。

1.2生产对象1.2.1 原材料:raw material投入生产过程以创新产品的物质。

1.2.2主要材料:primary material; direct material构成产品实体的材料。

1.2.3辅助材料:auxiliary material; indirect material在生产中起辅助作用而不构成产品实体的材料。

1.2.4代用材料:substituent在使用功能上能够代替原设计要求的材料。

它具有被代替材料所具备的全部或主要性能。

1.2.5易损材料:quick-wear material在正常使用条件下,容易损坏或失效的材料。

1.2.6废料:waste material在制造某种产品过程中,剩下的而对本生产对象不再有用的材料。

1.2.7型材:section金属或非金属材料通过拉制、轧制或压制等方法所获得的具有特定几何形状截面的材料。

1.2.8板材:plate金属或非金属材料通过轧制或压制等方法而获得的各种不同厚度的板状材料。

1.2.9棒材:bar stock金属或非金属材料通过拉延、轧制工艺获得的圆、方、六角形截面的材料。

1.2.10铸件:casting将熔融金属浇入铸型,凝固后所得到的金属制件或毛坯。

1.2.11锻件:forgings金属材料经过锻造变形而得到的工件或毛坯。

1.2.12焊接件:weldment用焊接方法而得到的结合件。

1.2.13模压件:molded parts利用模具压制的工件。

1.2.14冲压件:stamping用冲压的方法制成的工件或毛坯。

1.2.15合格品:accepted product;;conforming article通过检验质量特性符合标准要求的制品。

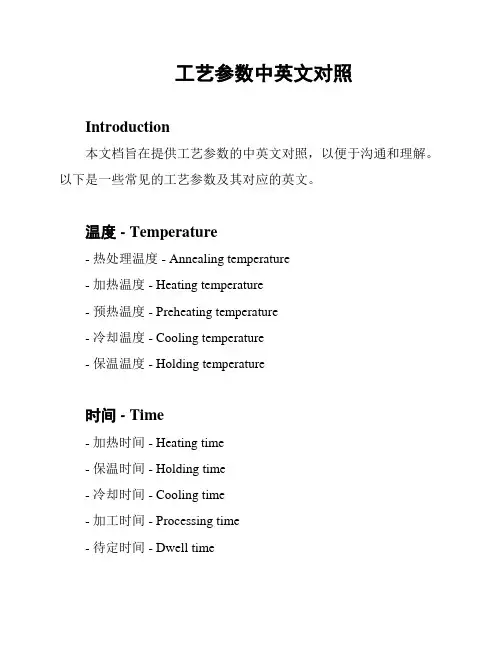

工艺参数中英文对照Introduction本文档旨在提供工艺参数的中英文对照,以便于沟通和理解。

以下是一些常见的工艺参数及其对应的英文。

温度 - Temperature- 热处理温度 - Annealing temperature- 加热温度 - Heating temperature- 预热温度 - Preheating temperature- 冷却温度 - Cooling temperature- 保温温度 - Holding temperature时间 - Time- 加热时间 - Heating time- 保温时间 - Holding time- 冷却时间 - Cooling time- 加工时间 - Processing time- 待定时间 - Dwell time压力 - Pressure- 切削力 - Cutting force- 压力展开 - Pressure expansion - 拉伸力 - Tensile force- 进给力 - Feed force速度 - Speed- 旋转速度 - Rotational speed - 前进速度 - Forward speed- 后退速度 - Reverse speed- 加工速度 - Machining speed - 进给速度 - Feed speed流量 - Flow- 流速 - Flow velocity- 流量控制 - Flow control- 气体流量 - Gas flow rate- 液体流量 - Liquid flow rate - 进料流量 - Feed flow rate倾斜度 - Inclination- 倾斜角度 - Tilt angle- 倾斜方向 - Tilt direction- 高度倾斜 - Height tilt- 横向倾斜 - Lateral tilt- 纵向倾斜 - Vertical tilt螺旋 - Spiral- 螺旋角度 - Spiral angle- 螺旋方向 - Spiral direction- 螺旋间距 - Spiral pitch- 旋转螺旋 - Rotational spiral- 平行螺旋 - Parallel spiral测量 - Measurement- 尺寸测量 - Dimensional measurement - 温度测量 - Temperature measurement - 压力测量 - Pressure measurement- 速度测量 - Speed measurement- 流量测量 - Flow rate measurement结论通过此文档,我们提供了一份工艺参数中英文对照表,涵盖了温度、时间、压力、速度、流量、倾斜度、螺旋和测量等方面。

铸件及产品表面处理工艺:压铸件:Die castingsZinc Die castings电铸件:Electrical castings不锈钢铸件:stainless steel castings铸件表面处理Surface finish for the castings:做黑:blacking镀锌:Zinc plating镀铬:chrome plating镀镍:nickel plating磨砂面处理:grit satin finishSatin finish titanium抛光处理:tumble bright手工拉丝(圆形拉丝,放射线拉丝, 对角线拉丝):brushed metal surface/drawbench(circular metal brushed texture, radius metal brushed texture, diagonal metal brushed texture)Cell phone with brushed metal surface哑光面处理:hand dull polished finish镜面抛光处理:mirror polished finish金属孔:metallic holes氧化铬钝化处理:passivation treatment电抛光处理:electrolytic polished喷砂处理(玻璃砂,钢玉沙,石英砂):sandblasting(glass bead blasting, corundum-sand blasting, quartz-sand blasting)Satin finished surfaceTPU或橡胶凹刻:TPU,rubber text intaglioCell phone TPU text intaglioCD纹样:CD patternCell phone navigation key used CD pattern镀枪色:gun color platinggun color plated真空镀:PVD vacuum plating(PVD: Physical vapor deposition)PVDtechnics UVcoating+PVD technics紫外固化(增加表面耐磨层及使用寿命):UV curingUV coating字符镭雕:Laser carving textSilicone rubber keypad numbers by laser carving technics 字符丝印:Silk-screen printingPhone text silkscreen printed一般电镀:electroplating effectsElectroplated mobile手机壳使用材料:ABS+PC(塑料)Zinc Alloy(锌合金),Aluminum Alloy(铝合金)ABS+PC Zinc AlloyAlumium Alloy按键材料: Keypad made of PC plasticPC plastic镜片屏幕材料:Lens, screen made of PMMA(亚克力),PVC plasticPMMA material Clear PVC FilmUSB软胶塞材料:USB stopper made of Rubber, TPUTPO material cover电镀可用在ABS和金属材料,真空镀可用在PMMA和任何材料上,真空镀价格相对便宜:Electroplating can be done by ABS and metal materials, PVD vaccum plating can be donw on any other materila such as PMMA亚克力,PVD plating cheaper不导电真空镀处理:Non conductive PVD vacuum platingNon conductive PVD plated注塑材料:injection molding plastic喷漆处理:paint sprayingPaint-spraying+UV coating模具蚀纹(手机壳花纹工艺):in-mould metal etching techniqueComputer cover etching不锈钢拉丝电镀处理:stainless steel brushed surface by chrome plating阳极氧化处理:anodic oxidation treatmentAluminum Anoidc oxidation treatment on surface表面电镀:surface electroplating电泳处理:Electrophoresis不导电真空溅镀工艺(和电镀效果一样都是在塑料表面镀金属色,但是有镜面效果非常亮):Non conductive vacuum metallization technics(It is similar to electroplating effects, but colors can be mirror finish)PVD vacuum metallization不锈钢表面进行处理(表面本色白化处理,表面镜石光亮处,表面着色处理,光亮处理方法,喷砂处理法,机械抛光,化学抛光,电化学抛光):Stainless steel surface treatment(color bleachingtreatment, mirror finish treatment, sand blasting, mechanical polishing finish, chemical polishing finish, electrochemical polishing finish).Chemical polished喇叭网,布织网:Speaker mesh,netting双色注塑:two-color injection molding technics底面镀膜:underside coating with thin film钢板花纹镭雕:Steel sheet with laser engraving treatmentLaser Engraving texture部分纹理突起:Texture bump不锈钢冲压:Precision stainless steel stamping part.彩镀:color plating电池盖常用材料:battery cap made of aluminum alloy, ABS+PCAlumium Alloy cap表面腐蚀纹:Electrochemisty corrosion pattern finishLighter metal corrosion texture表面氧化处理:Surface oxidation treatment沙面处理:satin finish亮面处理:glossy finishHigh glossy finish car body with black paint spray+UV coating哑光面处理:matte finish批花纹处理:radiation pattern功能键镀膜效果:function keys made of transparent PC with coating effect手机壳体分件:上壳:Front Housing壳上装饰件:cap decorative pieces中壳:middle cover后壳:Rear Housing按键:keypad天线:Antenna电池盖:battery cover侧按键:side function key导航键:navigation key功能键:function key喇叭孔:Mic振动器:Vibrater测试端口:Test port and 嗡鸣器:Buzzer常用材料及应用ABS:汽车(仪表板,工具舱门,车轮盖,反光镜,冰箱,大强度工具如头发烘干机,搅拌器,食品加工机,割草机,电话机壳体,打字机键盘,娱乐用车辆如高尔夫球手推车,喷气式雪橇车。

常用机械加工工艺术语(英汉对照)1 工艺基本概念1.1 一般概念1.1.1数控加工:numerical control machining根据被加工零件图样和工艺要求,编制成以数码表示的程序输入到机床的数控装置或控制计算机中,以控制工件和工具的相对运动,使之加工出合格零件的方法。

1.2生产对象1.2.1 原材料:raw material投入生产过程以创新产品的物质。

1.2.2主要材料:primary material; direct material构成产品实体的材料。

1.2.3辅助材料:auxiliary material; indirect material在生产中起辅助作用而不构成产品实体的材料。

1.2.4代用材料:substituent在使用功能上能够代替原设计要求的材料。

它具有被代替材料所具备的全部或主要性能。

1.2.5易损材料:quick-wear material在正常使用条件下,容易损坏或失效的材料。

1.2.6废料:waste material在制造某种产品过程中,剩下的而对本生产对象不再有用的材料。

1.2.7型材:section金属或非金属材料通过拉制、轧制或压制等方法所获得的具有特定几何形状截面的材料。

1.2.8板材:plate金属或非金属材料通过轧制或压制等方法而获得的各种不同厚度的板状材料。

1.2.9棒材:bar stock金属或非金属材料通过拉延、轧制工艺获得的圆、方、六角形截面的材料。

1.2.10铸件:casting将熔融金属浇入铸型,凝固后所得到的金属制件或毛坯。

1.2.11锻件:forgings金属材料经过锻造变形而得到的工件或毛坯。

1.2.12焊接件:weldment用焊接方法而得到的结合件。

1.2.13模压件:molded parts利用模具压制的工件。

1.2.14冲压件:stamping用冲压的方法制成的工件或毛坯。

1.2.15合格品:accepted product;;conforming article通过检验质量特性符合标准要求的制品。

工艺中英文对照Part # 件号Part name件名:tube evaporator jacket Material材料301Funds quoted(RMB/US$):RMB报价币种(人民币/美元)Material Weight 材料重量Base Material Cost 材料单价Total Material Cost材料总费用Process Flow工艺流程(简要):Process Cost:加工费用OP10 下料(unloading)OP20 车加工OP30 钻孔(boring)OP40 去毛刺(deburring)OP50 抛光(polishing)OP60 检验(checking)OP70 清洗包装(washing and packing) Total Process Cost加工总费用:Other Cost其它费用:Packaging Cost包装费Shipping Cost运输费Administration Cost管理费equipment depreciation设备折旧power rate电费low priced and easily wornarticles低值易耗品scrap报废Profit Margin 利润率Margin cost 利润Unit Price(Not included VAT)单价(不含税)/件:Value Added Tax增值税17%Total Unit Price(included VAT)总价(含税/件:Tooling:工装模具:Tooling Cost 模具费:Lead time模具制造周期:Tooling Life 模具使用寿命:Fixture&Guage:Fixture&Guage Cost:Lead time夹具&检具制造周期:Life使用寿命: Total Charge ofMoudle/Fixture/Guage:First Parts Delivery 首件交货周期:prototype quote:leadtime:minimum qty:Tooling Cost 模具费:Tooling Life 模具使用寿命:。

材料成型工艺基础部分中英文词汇对照材料成型工艺基础部分中英文词汇对照Document serial number【NL89WT-NY98YT-NC8CB-NNUUT-NUT108】材料成型工艺基础部分0绪论金属材料:metalmaterial(MR)高分子材料:high-molecularmaterial陶瓷材料:ceramicmaterial复合材料:compositionmaterial成形工艺:formationtechnology1铸造铸造工艺:castingtechnique铸件:foundrygoods(casting)机器零件:machinepart毛坯:blank力学性能:mechanicalproperty砂型铸造:sandcastingprocess型砂:foundrysand1.1铸件成形理论基础合金:alloy铸造性能:castingproperty工艺性能:processingproperty收缩性:constringency偏析性:aliquation氧化性:oxidizability吸气性:inspiratory铸件结构:castingstructure使用性能:serviceperformance浇不足:misrun冷隔:coldshut夹渣:cinderinclusion粘砂:sandfusion缺陷:flaw,defect,falling流动性:flowingpower铸型:cast(foundrymold)蓄热系数:thermalstoragecapacity浇注:pouring凝固:freezing收缩性:constringency逐层凝固:layer-by-layerfreezing糊状凝固:mushyfreezing结晶:crystal缩孔:shrinkagevoid缩松:shrinkageporosity顺序凝固:progressivesolidification冷铁:ironchill补缩:feeding等温线法:constanttemperaturelinemethod内接圆法:inscribedcirclemethod 铸造应力:castingstress 变形:deforming裂纹:crack机械应力:mechanicalstress热应力:heatstress相变应力:transformationstress 气孔:blowhole铸铁:ingot铸钢:caststeel非铁合金:nonferrousalloy灰铸铁:graycast-iorn孕育处理:inoculation球墨铸铁:spheroidal球化处理:sheroidisation可锻铸铁:ductilecastiron石墨:graphite蠕墨铸铁:vermicularcastiron热处理:heatprocessing铝合金:Al-alloy熔炼:fusionmetallurgy铜合金:copperalloy氢脆:hydrogenbrittleness1.2铸造方法(castingmethod)手工造型:handmoulding机器造型:machinemoulding金属型:metalmoldcasting金属模:permanentmould压力铸造:presscasting熔模铸造:investmentmoulding蜡膜:cere离心铸造:centrifugalcasting低压铸造:castingunderlowpressure 差压铸造:counter-pressurecasting 陶瓷型铸造:shawprocess1.3铸造工艺设计浇注位置:pouringposition分型面:mouldjoint活块:loosepiece起模:patterdrawing型芯:core型芯撑:chaplet工艺参数:processingparameter下芯:coresetting合型:mouldassembly冒口:castinghead尺寸公差:dimensionaltolerance 尺寸公差带:tolerancezone 机械加工余量:machiningallowance 铸孔:corehole非标准:nonstandardlabel收缩率:rateofcontraction线收缩:linearcontraction体收缩:volumecontraction起模斜度:patterndraft铸造圆角:curvingofcastings芯头:coreregister芯头间隙:clearance芯座:coreprintseat分型线:jointline分模线:diepartingline1.4铸造结构工艺性加强筋:ribreinforcement撒砂:stuccoing内腔:entocoele2金属塑性加工塑性加工:plasticworking塑性:plasticproperty锻造:forgework冲压:punching轧制:rolling拉拔:drawing挤压:extruding细化晶粒:grainrefinement热锻:hit-forging温锻:warmforging2.1金属塑性加工理论基础塑性变形:plasticyield加工硬化:work-hardening韧性:ductility回复温度:returntemperature再结晶:recrystallize再结晶退火:fullannealing冷变形:colddeformation热变性:heatdenaturation锻造比:forgingratio镦粗:upset拔长:pullout纤维组织:fibroustissue锻造性能:forgingproperty可锻性:forgeability变形抗力:resistanceofdeformation化学成分:chemicalconstitution热脆性:hotbrittleness冷脆性:cold-shortness变形速度:deformationvelocity应力状态:stresscondition变形温度:deformationtemperature过热:overheating过烧:burning脱碳:carbonelimination始锻温度:initiationforgingtemperature 终锻温度:finalforgingtemperature2.2金属塑性加工方法自由锻:flat-diehammer冲孔:jetting弯曲:bend弯曲半径:bendingradius切割:cut扭转:twistrotation错移:offsetting锻接:percussion基本工序:basicprocess辅助工序:auxiliaryprocess精整工序:finishingprocess模锻:contourforging锻模:forgingdie胎膜锻:fetalmembraneforging剪床:shearingmachine冲床:backing-outpunch冲裁:blanking弹性变形:elasticdistortion塑性变形:plasticyield剪切变形:shearingdeformation最小弯曲半径:minimumbendingradius 曲率:angularity 弯裂:rupture回弹:rebound辊轧:rollforming辊锻:rollforging斜轧:obliquerolling横轧:transverserolling辗压:tampingdrum挤压:extruding拉拔:draft2.3塑性加工工艺设计工艺规程:processspecification锻件图:forgingdrawing敷料:dressing锻件余量:forgingallowance锻件公差:forgingtolerance工夹具:clampingapparatus加热设备:firingequipment加热规范:heatingschedule冷却规范:coolingschedule后续处理:aftertreatment分模面:diepartingface冲孔连皮:punchingthewad模锻斜度:draftangle圆角半径:radiusofcorner圆饼类锻件:circumcresentcake-likeforging 长轴类锻件:longaxis-likeforging2.4锻件结构工艺性锥体:cone斜面:cant空间曲线:curveinspace粗糙度:degreeofroughness2.5冲压件结构工艺性3焊接焊接:welding铆接:riverting熔焊:fusionwelding压焊:presswelding钎焊:brazewelding3.1焊接理论基础冶金:metallurgy电弧焊:arcwelding气焊:acetylenewelding电渣焊:electro-slagwelding高能束焊:highenergywelding电子焊:electronicwelding激光焊:laserwelding等离子焊:plasmawelding电弧:electricarc阳极区:anoderegion阴极区:negativepolarity弧柱区:arcstream正接法:electrodenegativemethod 反接法:oppositionmethod脱氧剂:deoxidizingagent焊缝:weldedseam焊缝区:weldzone熔合区:fusionarea热影响区:heat-affectedzone脆性断裂:brittlefracture过热区:overheatedzone正火区:normalizedzone相变区:phasechangezone焊接应力:weldingstress收缩变形:contractiondistortion角变形:angulardeformation弯曲变形:benddeformation扭曲变形:warpingdeformation波浪变形:wavetransformation反变形法:reversibledeformationmethod刚性固定法:rigidfixingmethod预热:warming-up缓冷:slowcool焊后热处理:postweldheattreatment矫形处理:shape-righting3.2焊接方法埋弧焊:hiddenarcwelding气体保护焊:gasshieldedarcwelding氩弧焊:argonwelding熔化极氩弧焊:consumableelectrodeargonwelding 钨极氩弧焊:argontungsten-arcwelding二氧化碳气体保护焊:CO2gasshieldedarcwelding碳弧焊:carbonarcwelding碳弧气刨:carbonarcairgouging电渣焊:electro-slagwelding高能焊:highgradeenergywelding等离子弧切割:plasmaarccutting(PAC)堆焊:beadweld电阻焊:resistancewelding电焊:electricwelding缝焊:seamwelding压焊:presswelding多点凸焊:multipleprojectionwelding 对焊:weldingneck摩擦焊:frictionwelding扩散焊:diffusionwelding硬钎料:brazingalloy软钎料:softsolder3.3常用金属材料的焊接焊接性:weldability焊接方法:weldingmethod焊接材料:weldingmaterial焊条:electrode焊剂:fluxmaterial碳素钢:carbonsteel低碳钢:lowcarbonsteel中碳钢:mediumcarbonsteel高碳钢:highcarbonsteel低合金钢:leanalloysteel不锈钢:non-corrosivesteel有色金属:nonferrousmetal3.4焊接工艺设计型材:sectionalbar药皮:coating焊丝:solderingwire连续焊缝:continuousweld断续焊缝:intermittentweld应力集中:stressconcentration焊接接头:solderedjoint坡口:groove对接:abuttingjoint搭接:lapjoint角接:cornerjoint4粉末冶金(powermetallurgy)粉末冶金成品:finishedpowermetallurgicalproduct 铁氧体:ferrite硬质合金:sintered-carbide高熔点金属:high-meltingmetal陶瓷:ceramic4.1粉末冶金工艺理论基础压坯:pressedcompact扩散:diffusion烧结:agglomeration固溶:solidsolubility化合:combination4.2粉末冶金的工艺流程制备:preparation预处理:anticipation还原法:reductionmethod电解法:electrolyticmethod 雾化法:atomization粒度:grainsize松装密度:loosedensity流动性:flowingpower压缩性:compressibility筛分:screenseparation混合:compounding制粒:pelletization过烧:superburning欠烧:underburnt5金属复合成型技术自蔓延焊接:SHSwelding热等静压:HIP准热等静压:PHIP5.1液态成型技术与固态成型技术的复合高压铸造:high-pressurecasting电磁泵:magnetic-pump压射成型:injectionmolding柱塞:plungerpiston冲头:driftpin凝固法:freezingmethod挤压法:extrusionmethod转向节:knucklepivot制动器:arrestinggear5.2金属半凝固、半熔融成型技术凝固:freezing半熔融:semi-vitreous触变铸造:thixotropycasting触变锻造:thixotropyforging注射成型:injectionmolding5.3其他金属成型新技术快速凝固:flashset非晶态:amorphous溢流法:pressoversystem喷射沉积:ejectingdeposit爆炸复合法:explosioncladdingmethod 扩散焊接:diffusionwelding挤压:extruding轧制:rolldown6非金属材料成型技术6.1高分子材料成型技术高分子材料:non-metalmaterial耐腐蚀:resistantmaterial绝缘:insulation老化:ageing耐热性:heat-durability粘弹性:viscoelasticity塑料:plasticmaterial橡胶:rubber合成纤维:syntheticfibre涂料:coveringmaterial粘结剂:agglomerant粘度:viscosity热塑性塑料:thermoplasticplastics 热固性塑料:thermosettingplastic通用塑料:general-purposeplastics 工程塑料:engineeringplastic薄膜:thinfilm增强塑料:reinforcedplastics 浇注塑料:pouringplastics注射塑料:injiectionplastics 挤出塑料:extrusionplastics 吹塑塑料:blowingplastics模压塑料:diepressingplastics 聚合物:ploymersemiconductor 吸湿性:hygroscopiccargo定向作用:directionalaction 生胶:greengluestock填料:carrier丁苯橡胶:SBR顺丁橡胶:BR氯丁橡胶:CR丁腈橡胶:NBR硅橡胶:Q聚氨酯橡胶:U压延:calender硫化:sulfuration胶粘剂:adhesive胶接:gluejoint刹车片:brakeblock。

GB/T 780-1979 汽油发动机化油器出口凸缘尺寸Carbureters for automobile engines--Dimensions of outlet flanges2 GB/T 983-1995 不锈钢焊条Stainless steel covered electrodes3 GB/T 984-1985 堆焊焊条Covered electrodes for hardfacing4 GB/T 985-1988 气焊、手工电弧焊及气体保护焊焊缝坡口的基本形式与尺寸Basic forms and sizes of weld grooves for gas welding manual arc welding and gas-Shielded arc welding5 GB/T 986-1988 埋弧焊焊缝坡口的基本形式和尺寸Basic forms and sizes of weld grooves for submerged arc welding6 GB/T 1173-1995 铸造铝合金Casting aluminium alloys7 GB/T 1174-1992 铸造轴承合金cast bearing metals8 GB/T 1176-1987 铸造铜合金技术条件Specification for cast copper alloys9 GB/T 1177-1991 铸造镁合金Casting magnesium alloys10 GB/T 1348-1988 球墨铸铁件Spheroidal graphite iron castings11 GB/T 1954-1980 铬镍奥氏体不锈钢焊缝铁素体含量测量方法Determination of the weldign seam iron element contentin chromium,nickel austenitic stainless steel12 GB/T 2100-1980 不锈耐酸钢铸件技术条件Stainless acid-resistant steel castings--Specifications13 GB/T 2649-1989 焊接接头机械性能试验取样方法Methods of sampling for mechanical properties tests of welded joint14 GB/T 2650-1989 焊接接头冲击试验方法Method of impact test for welded joint15 GB/T 2651-1989 焊接接头拉伸试验方法Method of tensile test for welded joint16 GB/T 2652-1989 焊缝及熔敷金属拉伸试验方法Method of tensile tests for weld and deposited metal17 GB/T 2653-1989 焊接接头弯曲及压扁试验方法Methods of bend and compression tests for welded joint18 GB/T 2654-1989 焊接接头及堆焊金属硬度试验方法Methods of hardness tests for welded joint and surfacing metal19 GB/T 2655-1989 焊接接头应变时效敏感性试验方法Method of strain-age sensibillity test for welded joint20 GB/T 2656-1981 焊缝金属和焊接接头的疲劳试验法Weld beads metal and welds--Fatigue tests21 GB/T 2684-1981 铸造用原砂及混合料试验方法Foundry sands and sand mixtures for casting--Method of testing22 GB/T 3180-1982 中锰抗磨球墨铸铁件技术条件Specification for medium manganese wear-resistant spheroidal iron castings23 GB/T 3375-1994 焊接术语Welding terminology24 GB/T 3669-1983 铝及铝合金焊条Coated electrodes for aluminium and aluminium alloys25 GB/T 3670-1995 铜及铜合金焊条Coated electrodes for copper and copper alloys26 GB/T 3731-1983 涂料焊条效率、金属回收率和熔敷系数的测定Covered electrodes--Determination of the efficiency, metal recovery and deposition coefficient27 GB/T 3934-1983 普通螺纹量规Gauges for general purpose screw threads28 GB/T 3965-1995 熔敷金属中扩散氢测定方法Methods for determination of diffusible hydrogen in deposited metal29 GB/T 4675.1-1984 焊接性试验斜Y型坡口焊接裂纹试验方法Weldability testing--Method of Y-groove cracking test30 GB/T 4675.2-1984 焊接性试验搭接接头(CTS) 焊接裂纹试验方法Weldability testing--Method of controlled thermal severity cracking test31 GB/T 4675.3-1984 焊接性试验T型接头焊接裂纹试验方法Weldability testing--Method of cracking test for welded tee joint32 GB/T 4675.4-1984 焊接性试验压板对接(FISCO) 焊接裂纹试验方法Weldability testing--Method of FISCO cracking test33 GB/T 4675.5-1984 焊接性试验焊接热影响区最高硬度试验方法Weldability testing--Testing method of maximum hard ness in weld heat-affected zone34 GB/T 4863-1985 机械制造工艺基本术语General terminology of machine-building technology35 GB/T 5117-1995 碳钢焊条Carbon steel covered electrodes36 GB/T 5118-1995 低合金钢焊条Low alloy steel covered electrodes37 GB/T 5185-1985 金属焊接及钎焊方法在图样上的表示代号Welding, brazing, braze welding and soldering of metals--List of processes for symbolic representation on drawings38 GB/T 5293-1985 碳素钢埋弧焊用焊剂Fluxes for the submerged arc welding of carbon steel39 GB/T 5613-1995 铸钢牌号表示方法Code for representing cast steels40 GB/T 5614-1985 铸铁件热处理状态的名称、定义及代号The designations definitions and symbols for heat treatment tempers of iron castings41 GB/T 5615-1985 铸钢件热处理状态的名称、定义及代号The designations, definitions and symbols for heat treatment tempers of steel castings42 GB/T 5676-1985 一般工程用铸造碳钢Cast carbon steels for general engineering purposes43 GB/T 5677-1985 铸钢件射线照相及底片等级分类方法Methods of radiographic testing and classification of radiographs for steel castings44 GB/T 5678-1985 铸造合金光谱分析取样方法The method for sampling cast alloys for spectrochemical analysis45 GB/T 6208-1995 钎料型号表示方法Filler metal for soft soldering and brazing--Designation46 GB/T 6296-1986 灰铸铁冲击试验方法Grey cast iron impact test47 GB/T 6416-1986 影响钢熔化焊接头质量的技术因素Technical factors influencing the quality of the fusion welded joints in steel48 GB/T 6417-1986 金属熔化焊焊缝缺陷分类及说明Classification of imperfections in metallic fusion welds, with explanations49 GB/T 6418-1993 铜基钎料Copper base brazing filler metals50 GB/T 6967-1986 工程结构用中、高强度不锈钢铸件Medium and high strength stainless steel castings for engineering structure purposes51 GB/T 7032-1986 T型角焊接头弯曲试验方法Method of bend test for T type fillet welded joint52 GB/T 7143-1986 铸造用硅砂化学分析方法Methods for chemical analysis of silica sand for foundry53 GB/T 7216-1987 灰铸铁金相Gray cast iron metallography54 GB/T 7232-1987 金属热处理工艺术语Terminology of metal heat treatment55 GB/T 7233-1987 铸钢件超声探伤及质量评级标准Methods for ultrasonic testing and for specifying quality levels of steel castings56 GB/T 7659-1987 焊接结构用碳素钢铸件Carbon steel castings suitable for welded structure57 GB/T 8063-1994 铸造有色金属及其合金牌号表示方法Designation of cast nonferrous metals and their alloys58 GB/T 8110-1995 气体保护电弧焊用碳钢、低合金钢焊丝Welding wires for gas shielding arc welding of carbon and low alloy steels59 GB/T 8121-1987 热处理工艺材料名词术语The terminology of technological materials for heat treatment60 GB/T 8263-1987 抗磨白口铸铁技术条件Specification for abrasion resistant white cast irons61 GB/T 8454-1987 焊条用还原钛铁矿粉中亚铁量的测定Determination of ferrous iron content in reduced ilmenite powder for welding rod62 GB/T 8491-1987 高硅耐蚀铸铁件Corrosion resistant high silicon iron castings63 GB/T 8492-1987 耐热钢铸件Heat resistant steel castings64 GB/T 8493-1987 一般工程用铸造碳钢金相Metallograph of cast carbon steels for general engineering purposes65 GB/T 8539-1987 齿轮材料及热处理质量检验的一般规定General specification for quality inspection of gear materials and their heat treatment66 GB/T 8619-1988 钎缝强度试验方法Method of the strength test for brazed and soldered seam67 GB/T 9437-1988 耐热铸铁件Heat resistant iron castings68 GB/T 9438-1988 铝合金铸件技术条件Aluminium alloy castings--Technical specification69 GB/T 9439-1988 灰铸铁件Grey iron castings70 GB/T 9440-1988 可锻铸铁件Malleable iron castings71 GB/T 9441-1988 球墨铸铁金相检验Metallographic test for spheroidal graphite cast iron72 GB/T 9446-1988 焊接用插销冷裂纹试验方法Welding--Cold cracking test method using implants73 GB/T 9447-1988 焊接接头疲劳裂纹扩展速率试验方法Test method for fatigue crack growth rates of welded joints74 GB 9448-1988 焊接与切割安全Safety in welding and cutting75 GB/T 9450-1988 钢件渗碳淬火有效硬化层深度的测定和校核Determination and verification of the effective depth of carburizod and hardened cases of steel parts76 GB/T 9451-1988 钢件薄表面总硬化层深度或有效硬化层深度的测定Determination of total or effective thickness of thin surface hardened layers of steel parts77 GB/T 9452-1988 热处理炉有效加热区测定方法Testing method for working zone of heat treating furnace78 GB/T 9460-1988 铜及铜合金焊丝Welding wire and rods of copper and copper alloys79 GB/T 10044-1988 铸铁焊条及焊丝Covered electrodes and welding rods for welding cast iron80 GB/T 10045-1988 碳钢药芯焊丝Carbon steel flux cored wires for arc welding81 GB/T 10046-1988 银基钎料Silver brazing filler metals82 GB/T 10858-1989 铝及铝合金焊丝Aluminium and aluminium alloy welding rods and wires83 GB/T 10859-1989 镍基钎料Nickel base brazing filler metals84 GB/T 11350-1989 铸件机械加工余量Machining allowances on castings85 GB/T 11351-1989 铸件重量公差Mass tolerances for castings86 GB/T 11352-1989 一般工程用铸造碳钢件Carbon steel castings for general engineering purposes87 GB/T 11354-1989 钢铁零件渗氮层深度测定和金相组织检验Steel-iron parts—Determination of nitrided case depth and metallographic examination of nitriding structure88 GB/T 11363-1989 钎焊接头强度试验方法Methods of the strength tests for brazed and soldered joint89 GB/T 11364-1989 钎料铺展性及填缝性试验方法Test method of spreadability and clearance filling ability for filler metal90 GB/T 12214-1990 熔模铸造用硅砂、粉Silica sand and flour for investment casting91 GB/T 12215-1990 熔模铸造用铝矾土砂、粉Bauxite sand and flour for investment casting92 GB/T 12216-1990 铸造用合脂粘结剂The residue from distillation of synthetic fatty acids as binder for foundry93 GB/T 12361-1990 钢质模锻件通用技术条件General specification of steel die forgings94 GB/T 12362-1990 钢质模锻件公差及机械加工余量Tolerances and machining allowances of steel die forgings95 GB/T 12363-1990 锻件功能分类Classification of forging functions96 GB/T 12469-1990 焊接质量保证钢熔化焊接头的要求和缺陷分级Quality assurance of welding—Requirement for fusion welding joint of steel and classification for imperfection97 GB/T 12470-1990 低合金钢埋弧焊用焊剂Fluxes for the submerged arc welding of low alloy steel98 GB/T 12603-1990 金属热处理工艺分类及代号Classification and designation on metal heat treatment99 GB 12935-1991 焊条烘干炉运行能耗标准Energy consumption standard in operation of covered electrode furnace100 GB/T 13311-1991 锅炉受压元件焊接接头机械性能试验方法Boiler pressure parts—Mechanical test for welded joints101 GB/T 13320-1991 钢质模锻件金相组织评级图及评定方法Metallographic grading atlas and assessing method for steel die forgings102 GB/T 13450-1992 对接焊接头宽板拉伸试验方法Method of wide plate tension test for butt welded joint103 GB/T 13679-1992 锰基钎料Manganese base brazing filler metals104 GB/T 13814-1992 镍及镍合金焊条Nickel and nickel alloy covered welding electrodes105 GB/T 13815-1992 铝基钎料Aluminium base brazing filler metals106 GB/T 13816-1992 焊接接头脉动拉伸疲劳试验方法Test method for pulsed tensile fatigue of welded joints107 GB/T 13817-1992 对接接头刚性拘束焊接裂纹试验方法Method of rigid restraint cracking test for welding butt joint108 GB/T 13818-1992 压铸锌合金Zinc die-casting alloys109 GB/T 13819-1992 铜合金铸件Copper alloy castings110 GB/T 13820-1992 镁合金铸件Magnesium alloy castings111 GB/T 13821-1992 锌合金压铸件Zinc alloy die castings112 GB/T 13822-1992 压铸有色合金试样Test specimens for non ferrous diecasting alloys113 GB/T 13914-1992 冲压件尺寸公差Tolerance of dimensions for stampings114 GB/T 13915-1992 冲压件角度公差Tolerance of angles for stampings115 GB/T 13916-1992 冲压件形状和位置未注公差Unnoted tolerance of shape and position for stampings116 GB/T 13925-1992 铸造高锰钢金相Metallographs for high manganese cast steel117 GB/T 14235.1-1993 熔模铸造模料熔点测定方法(冷却曲线法) Testing method for melting point of pattern materials in investment casting 118 GB/T 14235.2-1993 熔模铸造模料抗弯强度测定方法Testing method for bending strength of pattern materials in investment casting 119 GB/T 14235.3-1993 熔模铸造模料灰分测定方法Testing method for ash content of pattern materials in investment casting120 GB/T 14235.4-1993 熔模铸造模料线收缩率测定方法Testing method for linear contraction of pattern materials in investment casting121 GB/T 14235.5-1993 熔模铸造模料表面硬度测定方法Testing method for surface hardness of pattern materials in investment casting 122 GB/T 14235.6-1993 熔模铸造模料酸值测定方法Testing method for acid number of pattern materials in investment casting123 GB/T 14235.7-1993 熔模铸造模料流动性测定方法Testing method for fluidity of pattern materials in investment casting124 GB/T 14235.8-1993 熔模铸造模料粘度测定方法Testing method for viscosity of pattern materials in investment casting125 GB/T 14235.9-1993 熔模铸造模料热稳定性测定方法Testing method for thermal stability of pattern materials in investment casting126 GB/T 14408-1993 一般工程与结构用低合金铸钢件Low alloy steel castings for general engineering and structural purposes127 GB/T 15055-1994 冲压件未注公差尺寸极限偏差Permissible stamping varitions in dimensions without tolerance indication128 GB/T 15056-1994 铸造表面粗糙度评定方法Evaluation method on cast surface roughness129 GB/T 15111-1994 点焊接头剪切拉伸疲劳试验方法Test method for shear tensile fatigue of spot welded joints130 GB/T 15114-1994 铝合金压铸件Aluminium alloy die-castings131 GB/T 15115-1994 压铸铝合金Die casting aluminium alloys132 GB/T 15116-1994 压铸铜合金Die casting copper alloys133 GB/T 15117-1994 铜合金压铸件Copper alloy die castings134 GB/T 15169-1994 钢熔化焊手焊工资格考核方法Approval testing of manual welders--Fusion welding-steel135 GB/T 15620-1995 镍及镍合金焊丝Nickel and nickel alloy welding wires136 GB 15735-1995 金属热处理生产过程安全卫生要求Requirements for the safety and health in production process of metal heat treatment 137 GB/T 15747-1995 正面角焊缝接头拉伸试验方法Method of tension test for front fillet welded joint138 GB/T 15825.1-1995 金属薄板成形性能与试验方法成形性能和指标Sheet metal formability and test methods--Formability and indexes 139 GB/T 15825.2-1995 金属薄板成形性能与试验方法通用试验规程Sheet metal formability and test methods--General test rules140 GB/T 15825.3-1995 金属薄板成形性能与试验方法拉深与拉深载荷试验Sheet metal formability and test methods--Drawing and drawing load test141 GB/T 15825.4-1995 金属薄板成形性能和试验方法扩孔试验Sheet metal formability and test methods--Hole expanding test142 GB/T 15825.5-1995 金属薄板成形性能与试验方法弯曲试验Sheet metal formability and test methods--Bending test143 GB/T 15825.6-1995 金属薄板成形性能与试验方法锥杯试验Sheet metal formability and test methods--Conical cup test144 GB/T 15825.7-1995 金属薄板成形性能与试验方法凸耳试验Sheet metal formability and test methods--Earing test145 GB/T 15825.8-1995 金属薄板成形性能与试验方法成形极限图(FLD)试验Sheet metal formability and test methods--Forming limit diagram(FLD) test146 GB/T 15826.1-1995 锤上钢质自由锻件机械加工余量与公差一般要求Machining allowances and tolerances for steel open die forgings on hammer--General reguirement147 GB/T 15826.2-1995 锤上钢质自由锻件机械加工余量与公差盘、柱类Machining allowances and tolerances for steel open die forgings on hammer--Disks and columns148 GB/T 15826.3-1995 锤上钢质自由锻件机械加工余量与公差带孔圆盘类Machining allowances and tolerances for steel open die forgings on hammer--Disk swith holes149 GB/T 15826.4-1995 锤上钢质自由锻件机械加工余量与公差圆环类Machining allowances and tolerances for steel open die forgings on hammer--Rings150 GB/T 15826.5-1995 锤上钢质自由锻件机械加工余量与公差套筒类Machining allowances and tolerances for steel open die forgings on hammer--Seamles cylinder hushings151 GB/T 15826.6-1995 锤上钢质自由锻件机械加工余量与公差光轴类Machining allowances and tolerances for steel open die forgings on hammer--Shaft without steps152 GB/T 15826.7-1995 锤上钢质自由锻件机械加工余量与公差台阶轴类Machining allowances and tolerances for steel open die forgings on hammer--Shaft with steps153 GB/T 15826.8-1995 锤上钢质自由锻件机械加工余量与公差单拐曲轴类Machining allowances and tolerances for steel open dle forgings on hammer--Single throw crankshaft154 GB/T 15826.9-1995 锤上钢质自由锻件机械加工余量与公差黑皮锻件Machining allowances and tolerances for steel open die forgings on hammer--Forging without machining155 GB/T 15829.1-1995 软钎焊用钎剂分类、标记与包装Soldering fluxes--Classification, labelling and packaging156 GB/T 15829.2-1995 软钎焊用钎剂树脂类钎剂Soldering fluxes--Resin basis fluxes157 GB/T 15829.3-1995 软钎焊用钎剂有机物类钎剂Soldering fluxes--Organic fluxes158 GB/T 15829.4-1995 软钎焊用钎剂无机物类钎剂Soldering fluxes--Inorganic fluxes159 GB/T 16253-1996 承压钢铸件Steel castings for pressure purposes160 GB/T 16672-1996 焊缝工作位置倾角和转角的定义Welds--Working positions--Definitions of angles of slope and rotation161 GB/T 8541-1997 锻压术语Terminolgy of forging and stamping162 GB/T 16743-1997 冲裁间隙Blanking clearance163 GB/T 16746-1997 锌合金铸件Zinc alloy castings164 GB/T 1175-1997 铸造锌合金Casting zinc alloys165 GB/T 16923-1997 钢件的正火与退火Normalizing and annealing of steel parts166 GB/T 16924-1997 钢件的淬火与回火Quenching and tempering of steel parts167 GB/T 16957-1997 复合钢板焊接接头力学性能试验方法Mechanical tests on welded joints in clad plates168 GB/T 6060.1-1997 表面粗糙度比较样块铸造表面Roughness comparison specimens Cast surfaces169 GB/T 5611-1998 铸造术语Foundry terminology170 GB/T 5680-1998 高锰钢铸件Austenitic manganese steel castings171 GB/T 9442-1998 铸造用硅砂Foundry silica sand172 GB/T 17445-1998 铸造磨球Cast grinding balls173 GB/T 12467.1-1998 焊接质量要求金属材料的熔化焊第一部分: 选择及使用指南Quality requirements for welding--Fusion welding of metallic materials--Part 1: Guidelines for selection and use174 GB/T 12467.2-1998 焊接质量要求金属材料的熔化焊第二部分: 完整质量要求Quality requirements for welding--Fusion welding of metallic materials--Part 2: Comprehensive quality requirements175 GB/T 12467.3-1998 焊接质量要求金属材料的熔化焊第三部分: 一般质量要求Quality requirements for welding--Fusion welding of metallic materials--Part 3: Standards quality requirements176 GB/T 12467.4-1998 焊接质量要求金属材料的熔化焊第四部分: 基本质量要求Quality requirements for welding--Fusion welding of metallic materials--Part 4: Elementary quality requirements177 GB/T 17493-1998 低合金钢药芯焊丝Low alloy steel flux cored electrodes for arc welding。

材料成型工艺基础部分0 绪论金属材料:metal material (MR)高分子材料:high-molecular material陶瓷材料:ceramic material复合材料:composition material成形工艺:formation technology1 铸造铸造工艺:casting technique铸件:foundry goods (casting)机器零件:machine part毛坯:blank力学性能:mechanical property砂型铸造:sand casting process型砂:foundry sand1.1 铸件成形理论基础合金:alloy铸造性能:casting property工艺性能:processing property收缩性:constringency偏析性:aliquation氧化性:oxidizability—吸气性:inspiratory铸件结构:casting structure使用性能:service performance浇不足:misrun冷隔:cold shut夹渣:cinder inclusion粘砂:sand fusion缺陷:flaw, defect, falling流动性:flowing power铸型:cast (foundry mold)蓄热系数:thermal storage capacity浇注:pouring凝固:freezing收缩性:constringency逐层凝固:layer-by-layer freezing糊状凝固:mushy freezing结晶:crystal缩孔:shrinkage void缩松:shrinkage porosity顺序凝固:progressive solidification冷铁:iron chill补缩:feeding—等温线法:constant temperature line method内接圆法:inscribed circle method铸造应力:casting stress变形:deforming裂纹:crack机械应力:mechanical stress热应力:heat stress相变应力:transformation stress气孔:blow hole铸铁:ingot铸钢:cast steel非铁合金:nonferrous alloy灰铸铁:gray cast-iorn孕育处理:inoculation球墨铸铁:spheroidal球化处理:sheroidisation可锻铸铁:ductile cast iron石墨:graphite蠕墨铸铁:vermicular cast iron热处理:heat processing铝合金:Al-alloy熔炼:fusion metallurgy—铜合金:copper alloy氢脆:hydrogen brittleness1.2 铸造方法(casting method)手工造型:hand moulding机器造型:machine moulding金属型:metal mold casting金属模:permanent mould压力铸造:press casting熔模铸造:investment moulding蜡膜:cere离心铸造:centrifugal casting低压铸造:casting under low pressure差压铸造:counter-pressure casting陶瓷型铸造:shaw process1.3 铸造工艺设计浇注位置:pouring position分型面:mould joint活块:loose piece起模:patter drawing型芯:core型芯撑:chaplet工艺参数:processing parameter—下芯:core setting合型:mould assembly冒口:casting head尺寸公差:dimensional tolerance尺寸公差带:tolerance zone机械加工余量:machining allowance铸孔:core hole非标准:nonstandard label收缩率:rate of contraction线收缩:linear contraction体收缩:volume contraction起模斜度:pattern draft铸造圆角:curving of castings芯头:core register芯头间隙:clearance芯座:core print seat分型线:joint line分模线:die parting line1.4 铸造结构工艺性加强筋:rib reinforcement撒砂:stuccoing内腔:entocoele—2 金属塑性加工塑性加工:plastic working塑性:plastic property锻造:forge work冲压:punching轧制:rolling拉拔:drawing挤压:extruding细化晶粒:grain refinement热锻:hit-forging温锻:warm forging2.1 金属塑性加工理论基础塑性变形:plastic yield加工硬化:work-hardening韧性:ductility回复温度:return temperature再结晶:recrystallize再结晶退火:full annealing冷变形:cold deformation热变性:heat denaturation锻造比:forging ratio镦粗:upset—拔长:pull out纤维组织:fibrous tissue锻造性能:forging property可锻性:forgeability变形抗力:resistance of deformation化学成分:chemical constitution热脆性:hot brittleness冷脆性:cold-shortness变形速度:deformation velocity应力状态:stress condition变形温度:deformation temperature过热:overheating过烧:burning脱碳:carbon elimination始锻温度:initiation forging temperature终锻温度:final forging temperature2.2 金属塑性加工方法自由锻:flat-die hammer冲孔:jetting弯曲:bend弯曲半径:bending radius切割:cut—扭转:twist rotation错移:offsetting锻接:percussion基本工序:basic process辅助工序:auxiliary process精整工序:finishing process模锻:contour forging锻模:forging die胎膜锻:fetal membrane forging剪床:shearing machine冲床:backing-out punch冲裁:blanking弹性变形:elastic distortion塑性变形:plastic yield剪切变形:shearing deformation最小弯曲半径:minimum bending radius曲率:angularity弯裂:rupture回弹:rebound辊轧:roll forming辊锻:roll forging斜轧:oblique rolling—横轧:transverse rolling辗压:tamping drum挤压:extruding拉拔:draft2.3 塑性加工工艺设计工艺规程:process specification锻件图:forging drawing敷料:dressing锻件余量:forging allowance锻件公差:forging tolerance工夹具:clamping apparatus加热设备:firing equipment加热规范:heating schedule冷却规范:cooling schedule后续处理:after treatment分模面:die parting face冲孔连皮:punching the wad模锻斜度:draft angle圆角半径:radius of corner圆饼类锻件:circumcresent cake-like forging长轴类锻件:long axis-like forging2.4 锻件结构工艺性—锥体:cone斜面:cant空间曲线:curve in space粗糙度:degree of roughness2.5 冲压件结构工艺性3 焊接焊接:welding铆接:riverting熔焊:fusion welding压焊:press welding钎焊:braze welding3.1 焊接理论基础冶金:metallurgy电弧焊:arc welding气焊:acetylene welding电渣焊:electro-slag welding高能束焊:high energy welding电子焊:electronic welding激光焊:laser welding等离子焊:plasma welding电弧:electric arc阳极区:anode region—阴极区:negative polarity弧柱区:arc stream正接法:electrode negative method反接法:opposition method脱氧剂:deoxidizing agent焊缝:welded seam焊缝区:weld zone熔合区:fusion area热影响区:heat-affected zone脆性断裂:brittle fracture过热区:overheated zone正火区:normalized zone相变区:phase change zone焊接应力:welding stress收缩变形:contraction distortion角变形:angular deformation弯曲变形:bend deformation扭曲变形:warping deformation波浪变形:wave transformation反变形法:reversible deformation method刚性固定法:rigid fixing method预热:warming-up—缓冷:slow cool焊后热处理:postweld heat treatment矫形处理:shape-righting3.2 焊接方法埋弧焊:hidden arc welding气体保护焊:gas shielded arc welding氩弧焊:argon welding熔化极氩弧焊:consumable electrode argon welding钨极氩弧焊:argon tungsten-arc welding二氧化碳气体保护焊:CO2 gas shielded arc welding碳弧焊:carbon arc welding碳弧气刨:carbon arc air gouging电渣焊:electro-slag welding高能焊:high grade energy welding等离子弧切割:plasma arc cutting (PAC)堆焊:bead weld电阻焊:resistance welding电焊:electric welding缝焊:seam welding压焊:press welding多点凸焊:multiple projection welding对焊:welding neck—摩擦焊:friction welding扩散焊:diffusion welding硬钎料:brazing alloy软钎料:soft solder3.3 常用金属材料的焊接焊接性:weldability焊接方法:welding method焊接材料:welding material焊条:electrode焊剂:flux material碳素钢:carbon steel低碳钢:low carbon steel中碳钢:medium carbon steel高碳钢:high carbon steel低合金钢:lean alloy steel不锈钢:non-corrosive steel有色金属:nonferrous metal3.4 焊接工艺设计型材:sectional bar药皮:coating焊丝:soldering wire连续焊缝:continuous weld—断续焊缝:intermittent weld应力集中:stress concentration焊接接头:soldered joint坡口:groove对接:abutting joint搭接:lap joint角接:corner joint4 粉末冶金(power metallurgy)粉末冶金成品:finished power metallurgical product铁氧体:ferrite硬质合金:sintered-carbide高熔点金属:high-melting metal陶瓷:ceramic4.1 粉末冶金工艺理论基础压坯:pressed compact扩散:diffusion烧结:agglomeration固溶:solid solubility化合:combination4.2 粉末冶金的工艺流程制备:preparation预处理:anticipation—还原法:reduction method电解法:electrolytic method雾化法:atomization粒度:grain size松装密度:loose density流动性:flowing power压缩性:compressibility筛分:screen separation混合:compounding制粒:pelletization过烧:superburning欠烧:underburnt5 金属复合成型技术自蔓延焊接:SHS welding热等静压:HIP准热等静压:PHIP5.1 液态成型技术与固态成型技术的复合高压铸造:high-pressure casting电磁泵:magnetic-pump压射成型:injection molding柱塞:plunger piston—冲头:drift pin凝固法:freezing method挤压法:extrusion method转向节:knuckle pivot制动器:arresting gear5.2 金属半凝固、半熔融成型技术凝固:freezing半熔融:semi-vitreous触变铸造:thixotropy casting触变锻造:thixotropy forging注射成型:injection molding5.3 其他金属成型新技术快速凝固:flash set非晶态:amorphous溢流法:press over system喷射沉积:ejecting deposit爆炸复合法:explosion cladding method扩散焊接:diffusion welding挤压:extruding轧制:roll down6 非金属材料成型技术—6.1 高分子材料成型技术高分子材料:non-metal material耐腐蚀:resistant material绝缘:insulation老化:ageing耐热性:heat-durability粘弹性:viscoelasticity塑料:plastic material橡胶:rubber合成纤维:synthetic fibre涂料:covering material粘结剂:agglomerant粘度:viscosity热塑性塑料:thermoplastic plastics热固性塑料:thermosetting plastic通用塑料:general-purpose plastics工程塑料:engineering plastic薄膜:thin film增强塑料:reinforced plastics浇注塑料:pouring plastics注射塑料:injiection plastics挤出塑料:extrusion plastics—吹塑塑料:blowing plastics模压塑料:die pressing plastics聚合物:ploymer semiconductor吸湿性:hygroscopic cargo定向作用:directional action生胶:green glue stock填料:carrier丁苯橡胶:SBR顺丁橡胶:BR氯丁橡胶:CR丁腈橡胶:NBR硅橡胶:Q聚氨酯橡胶:U压延:calender硫化:sulfuration胶粘剂:adhesive胶接:glue joint刹车片:brake block零件修复:parts renewal蜂窝夹层:honeycomb core material6.2 工业陶瓷制品的成型技术干燥:drying润滑剂:anti-friction结合剂:binder热压铸:hot injiection moulding 6.3 非金属材料成型技术的新进展热压烧结:hot pressed sintering7 复合材料的成型技术复合材料:composite material树脂:resin7.1 金属复合材料的成型技术硼纤维:boron fiber钛合金:titanium alloy碳纤维:carbon filter等离子喷涂:plasma spraying浸渍法:immersion method锭坯:ingot blank7.2 聚合物基复合材料的成型技术晶须:whisker缠绕成形:enwind forming湿法缠绕:wet method enwind 7.3 陶瓷复合材料成型技术溶胶-凝胶法:sol-gel method化学气相沉积:chemical vapor deposition (CVD) 原位:in situ8 材料成型方法的选择粉末冶金:powder metallurgy工程塑料:engineering plastics工程陶瓷:engineering ceramics。

铸件及产品表面处理工艺:压铸件:Die castingsZinc Die castings 电铸件:Electrical castings不锈钢铸件:stainless steel castings铸件表面处理Surface finish for the castings: 做黑:blacking镀锌:Zinc plating镀铬:chrome plating镀镍:nickel plating磨砂面处理:grit satin finishSatin finish titanium抛光处理:tumble bright手工拉丝(圆形拉丝,放射线拉丝, 对角线拉丝):brushed metal surface/drawbench(circular metal brushed texture, radius metal brushed texture, diagonal metal brushed texture)Cell phone with brushed metal surface哑光面处理:hand dull polished finish镜面抛光处理:mirror polished finish金属孔:metallic holes氧化铬钝化处理:passivation treatment电抛光处理:electrolytic polished喷砂处理(玻璃砂,钢玉沙,石英砂):sandblasting(glass bead blasting, corundum-sand blasting, quartz-sand blasting)Satin finished surfaceTPU或橡胶凹刻:TPU,rubber text intaglioCell phone TPU text intaglioCD纹样:CD patternCell phone navigation key used CD pattern镀枪色:gun color platinggun color plated真空镀:PVD vacuum plating(PVD: Physical vapor deposition)PVDtechnics UV coating+PVD technics紫外固化(增加表面耐磨层及使用寿命):UV curingUV coating字符镭雕:Laser carving textSilicone rubber keypad numbers by laser carving technics字符丝印:Silk-screen printingPhone text silkscreen printed一般电镀:electroplating effectsElectroplated mobile手机壳使用材料:ABS+PC(塑料)Zinc Alloy(锌合金),Aluminum Alloy(铝合金)ABS+PC Zinc AlloyAlumium Alloy按键材料: Keypad made of PC plasticPC plastic镜片屏幕材料:Lens, screen made of PMMA(亚克力),PVC plasticPMMA material Clear PVC Film USB软胶塞材料:USB stopper made of Rubber, TPUTPO material cover电镀可用在ABS和金属材料,真空镀可用在PMMA和任何材料上,真空镀价格相对便宜:Electroplating can be done by ABS and metal materials, PVD vaccum plating can be donw on any other materila such as PMMA亚克力,PVD plating cheaper不导电真空镀处理:Non conductive PVD vacuum platingNon conductive PVD plated注塑材料:injection molding plastic喷漆处理:paint sprayingPaint-spraying+UV coating模具蚀纹(手机壳花纹工艺):in-mould metal etching techniqueComputer cover etching不锈钢拉丝电镀处理:stainless steel brushed surface by chrome plating阳极氧化处理:anodic oxidation treatmentAluminum Anoidc oxidation treatment on surface表面电镀:surface electroplating电泳处理:Electrophoresis不导电真空溅镀工艺(和电镀效果一样都是在塑料表面镀金属色,但是有镜面效果非常亮):Non conductive vacuum metallization technics(It is similar to electroplating effects, but colors can be mirror finish)PVD vacuum metallization不锈钢表面进行处理(表面本色白化处理,表面镜石光亮处,表面着色处理,光亮处理方法,喷砂处理法,机械抛光,化学抛光,电化学抛光):Stainless steel surface treatment(color bleaching treatment, mirror finish treatment, sand blasting, mechanical polishing finish, chemical polishing finish, electrochemical polishing finish).Chemical polished喇叭网,布织网:Speaker mesh,netting双色注塑:two-color injection molding technics底面镀膜:underside coating with thin film钢板花纹镭雕:Steel sheet with laser engraving treatmentLaser Engraving texture部分纹理突起:Texture bump不锈钢冲压:Precision stainless steel stamping part.彩镀:color plating电池盖常用材料:battery cap made of aluminum alloy, ABS+PCAlumium Alloy cap表面腐蚀纹:Electrochemisty corrosion pattern finishLighter metal corrosion texture表面氧化处理:Surface oxidation treatment沙面处理:satin finish亮面处理:glossy finishHigh glossy finish car body with black paint spray+UV coating 哑光面处理:matte finish批花纹处理:radiation pattern功能键镀膜效果:function keys made of transparent PC with coating effect手机壳体分件:上壳:Front Housing壳上装饰件:cap decorative pieces中壳:middle cover后壳:Rear Housing按键:keypad天线:Antenna电池盖:battery cover侧按键:side function key 导航键:navigation key功能键:function key喇叭孔:Mic振动器:Vibrater测试端口:Test port and 嗡鸣器:Buzzer常用材料及应用ABS:汽车(仪表板,工具舱门,车轮盖,反光镜,冰箱,大强度工具如头发烘干机,搅拌器,食品加工机,割草机,电话机壳体,打字机键盘,娱乐用车辆如高尔夫球手推车,喷气式雪橇车。

SA:电气插座/壳体,日用商品(厨房器械,冰箱设置,电视机底座,卡带盒),汽车工业(车头灯盒,反光镜,仪表盘),家庭用品(餐具,食品刀具等),化妆品包装等。

PVC:供水管道,家用管道,房屋墙板,商用机器壳体,电子产品包装,医疗器械,食品包装等。

PS:产品包装,家庭用品(餐具,托盘等),电气(透明容器,光源散热器,绝缘薄膜等)。

POM:耐高温特性,管道器件(管道阀门,泵壳体),草坪设备等。

PMMA:汽车工业(信号灯设备,仪表盘等),医药行业(储血容器等),工业应用(影碟,灯光散射器),日用消费品(饮料杯,文具等)。

PC:电气和商业设备(计算机元件,连接器等),器具(食品加工机,电冰箱抽屉等),交通运输行业(车辆的前后灯,仪表板等)。

PC/ABS:计算机和商业机器的壳体,电气设备,草坪和园艺机器,汽车零件(仪表板,内部装修以及车轮盖)。

PC/PBT:齿轮箱,汽车保险杠以及要求具有抗化学反应和耐腐蚀性,热稳定性,抗冲击性以及几何稳定性的产品。

PP:挤塑制品,纺织纤维和单丝,容器,密封其,汽车股方面,家庭用具用品,玩具及消费品市场。

ASA:汽车外侧视镜壳体,保险杆封皮/装饰,游泳池泵过滤器外壳。

PPS:电器材料,结构材料,防腐蚀材料,作为电气构件用量约占60%。

PPO:电子仪表,汽车,机械设备零件。

PA66尼龙:各种齿轮,凸轮,蜗轮,轴套,轴瓦等耐磨零件。

工艺化表面处理镀膜效果:Film plated橡胶材质:P+R, Rubber.字符凹刻:markings engraved氧化枪色:anodizing dark color斜面镜面:bevel glossy finish透明材质:PMMA,PC, transparent materialsClear PC功能键数字镭雕:character laser etching模具纹理:in-mould etching textureIn-mold etching 透明PC:PC(clear)注塑镜片:injected lens切割镜片:cut lens表面电镀:chrome plated表面凸起纹样:Embossed patternEmbossed texture on carbon fiber bag电镀放射线:chrome plated thread氧化:anodizing按键装饰物:Keypad decorative pieces前壳/中壳/后壳/电池盖/天线塞/:front cover/middle cover/base/battery cap/antenna cap 听筒:receiver酸腐蚀金属:Acid erode metal凹槽:concaveMobile phone concave波形起皱:corrugation/wavy texture防滑条/防磨点:antiskid电铸:eletroforming局部模具纹理:local in-mould entching texture表面拉丝处理:drawbench/brushed texture喷油:spray纹理:texture/pattern配色方案:color shceme工艺说明:Artwork specifications六视图和细节工艺图:2D final rendering and artwork specification 细节和参考图片:details and reference常用注塑方式:注塑:injection molding吹塑:blow molding常用印刷工艺:网印:Silkscreen printing移印:Movable printing热转印:Hot stamping常用材料电镀处理:电镀:Electroplating真空电镀处理:Vacuum metalizing阴极溅射法:Cathode sputtering金属喷射法:Metal spraying阳极溅镀法:anodizeanodize screen装饰工艺解析:IMD装饰工艺,常用材料(PC,PET,high-flow optical resin):In-Mould Decoration(IMD),materials(PC,PET,high-flow optical resin).IML装饰工艺:In-Mold LabellingIMD和IML可做高光,磨砂,部分磨砂处理,表面已经coating处理,无须再做UV:IMD,IML capable for glossy finish, satin finish, local matte finish, coating finish, UV curing is not necessary.镀膜的材质选用(Film coating materials):PC,PMMA,Polyester, Formable PETIML decoration cell phone cap。