第三章半导体制造中的化学品

- 格式:ppt

- 大小:52.00 KB

- 文档页数:26

半导体制造耗材半导体制造是现代科技发展中的重要领域之一,而耗材则是半导体制造过程中不可或缺的组成部分。

本文将从人类视角出发,详细描述半导体制造中所使用的耗材的重要性和作用。

半导体制造中的耗材是指在生产过程中需要使用并消耗的材料,包括化学品、气体、液体等。

这些耗材在半导体制造的各个环节都扮演着不可或缺的角色,为整个制造过程提供了必要的支持。

化学品是半导体制造中最常用的耗材之一。

例如,在半导体的制备过程中,需要使用各种化学溶液来清洗、腐蚀和刻蚀硅片。

这些化学品能够有效地去除硅片表面的杂质,保证器件质量的稳定性和可靠性。

气体也是半导体制造中不可或缺的耗材之一。

例如,高纯度的气体如氧气、氮气和氢气等在半导体制造过程中广泛应用。

氧气用于氧化硅片表面,氮气用于气氛控制和保护,而氢气则用于去除表面的氧化物。

这些气体的质量和纯度直接影响到半导体器件的性能和可靠性。

液体耗材也在半导体制造中发挥着重要的作用。

例如,在半导体器件表面的涂覆过程中,需要使用液体耗材来形成保护层或者光刻层。

这些液体耗材能够精确地控制涂覆的厚度和均匀性,确保器件的性能和可靠性。

总的来说,半导体制造中的耗材是确保制造过程顺利进行的关键因素之一。

它们不仅能够提高半导体器件的质量和性能,还能够提高制造效率和降低成本。

因此,半导体制造企业需要高度重视耗材的选择和管理,确保其质量和供应的稳定性。

在面对日益激烈的市场竞争和技术创新的压力下,半导体制造企业需要不断提升耗材的质量和性能,以满足不断变化的需求。

同时,也需要加强与供应商的合作,确保耗材的供应和管理能够与制造过程相互配合,实现整体效益的最大化。

半导体制造中的耗材是不可或缺的组成部分。

它们在制造过程中发挥着重要的作用,为半导体器件的制备提供了必要的支持。

半导体制造企业需要重视耗材的选择和管理,以提高制造效率和降低成本。

只有如此,才能够在激烈的市场竞争中脱颖而出,实现可持续发展。

tmah在半导体中的应用一、引言半导体是现代电子技术的基石,广泛应用于各类电子设备中。

为了提高半导体的性能和稳定性,需要在制造过程中使用各种化学物质对半导体进行处理。

tmah是一种常用的半导体加工化学品,具有广泛的应用。

本文将全面、详细、完整地探讨tmah在半导体中的应用。

二、半导体加工中的化学品2.1 半导体加工的基本步骤半导体加工是一系列复杂的工艺步骤,包括掺杂、蚀刻、沉积、清洗等。

在每个步骤中,需要使用不同的化学品来实现特定的目标。

2.2 高纯度化学品的要求半导体加工对化学品的纯度要求非常高,因为任何微量的杂质都可能对器件性能产生严重影响。

因此,高纯度化学品在半导体制造中的重要性不言而喻。

三、tmah的基本特性3.1 tmah的化学结构tmah(tetramethylammonium hydroxide)是一种有机化合物,化学式为(CH3)4NOH。

它具有高度的溶解性和热稳定性,是一种优秀的半导体加工化学品。

3.2 tmah的应用领域tmah在半导体加工中主要用于蚀刻、清洗和湿法制备材料等方面。

下面将分别介绍其在这些领域的应用。

四、tmah在蚀刻中的应用4.1 tmah蚀刻的原理tmah具有强腐蚀性,可以与硅等半导体材料发生化学反应,从而实现蚀刻的目的。

其蚀刻速度与tmah浓度、温度等因素有关。

4.2 tmah蚀刻的应用tmah蚀刻广泛用于制备微电子器件,如集成电路、传感器等。

通过控制蚀刻条件,可以精确制备出所需的结构和形状。

五、tmah在清洗中的应用5.1 tmah清洗的原理半导体加工过程中会产生大量的杂质和副产物,需要通过清洗来去除。

tmah具有良好的清洗性能,可以有效去除表面的有机和无机杂质。

5.2 tmah清洗的应用tmah清洗广泛应用于半导体器件的制造过程中,可以保证器件表面的纯净度和光洁度,提高器件性能和可靠性。

六、tmah在湿法制备材料中的应用6.1 tmah在沉积过程中的应用tmah可以作为一种表面活性剂,用于控制材料的沉积速率和均匀性。

半导体制造耗材

半导体制造耗材是指在半导体制造过程中使用的各种材料和设备。

这些耗材包括化学气相沉积(CVD)和物理气相沉积(PVD)用

的化学品、气体和靶材,光刻胶、光刻机用的光刻胶和光刻机的光

刻版、离子注入用的离子源、掺杂剂和离子注入机的零部件、化学

机械抛光(CMP)用的研磨液和抛光垫,以及各种辅助材料和设备。

从材料的角度来看,半导体制造耗材包括各种高纯度化学品,

如气体(氮气、氢气、氩气等)、溶剂、酸碱等;各种光刻胶和蚀

刻剂等光刻材料;各种用于清洗、去除氧化层和表面处理的化学品;以及用于CMP的研磨液和抛光垫等。

这些材料在半导体制造过程中

起着至关重要的作用,直接影响到芯片的质量和性能。

从设备的角度来看,半导体制造耗材还包括各种用于生产设备

维护和保养的零部件,例如真空泵、阀门、密封件等。

此外,还包

括用于生产设备操作的工装、夹具等辅助工具,以及用于废料处理

和环保的相关设备和材料。

总的来说,半导体制造耗材在半导体生产中扮演着不可或缺的

角色,它们直接影响到芯片的制造质量和成本效益。

随着半导体工

艺的不断发展和升级,对于高性能、高可靠性的半导体制造耗材的需求也在不断增加,这也带动了半导体制造耗材市场的持续扩大。

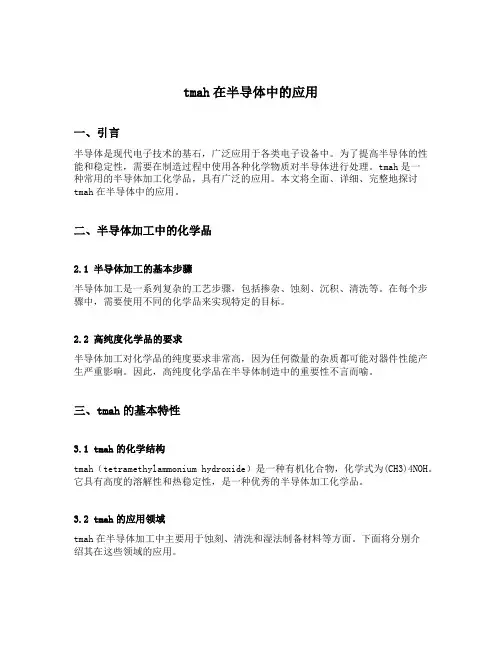

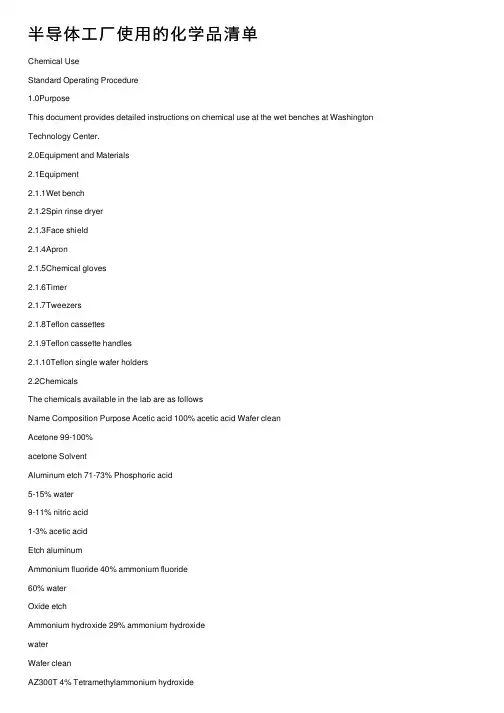

半导体⼯⼚使⽤的化学品清单Chemical UseStandard Operating Procedure1.0PurposeThis document provides detailed instructions on chemical use at the wet benches at Washington Technology Center.2.0Equipment and Materials2.1Equipment2.1.1Wet bench2.1.2Spin rinse dryer2.1.3Face shield2.1.4Apron2.1.5Chemical gloves2.1.6Timer2.1.7Tweezers2.1.8Teflon cassettes2.1.9Teflon cassette handles2.1.10Teflon single wafer holders2.2ChemicalsThe chemicals available in the lab are as followsName Composition Purpose Acetic acid 100% acetic acid Wafer cleanAcetone 99-100%acetone SolventAluminum etch 71-73% Phosphoric acid5-15% water9-11% nitric acid1-3% acetic acidEtch aluminumAmmonium fluoride 40% ammonium fluoride60% waterOxide etchAmmonium hydroxide 29% ammonium hydroxidewaterWafer cleanAZ300T 4% Tetramethylammonium hydroxide41% N-methylpyrrolidone, NMP, 1-methyl-2-pyrrolidinone55% Propylene glycol, 1, 2-propane-diolremove photoresistAZ 351 <10% sodium borates>90% water Developer for 1512 and 1518AZ 400K <15% Potassium borates>85% water Developer for 4620 and 9260AZ 1512 75% 1-methoxy-2-propanol acetate Thin Photoresist <25% Cresol novolak resin<10% diazonapthoquinonesulfoniestersAZ 1518 71% 1-methoxy-2-propanol acetate<30% Cresol novolak resin<10% diazonapthoquinonesulfoniestersThin (~2um) PhotoresistAZ 4620 62% 1-methoxy-2-propanol acetate<35% Cresol novolak resin<5% diazonaphthoquinonesulfoniestersThick photoresistAZ 9260 57% 1-methoxy-2-propanol acetate<40% Cresol-novolak resin<5% DiazonaphthoquinonesulfonicestersThick photoresist10:1 BOE 40% ammonium fluoride5% hydrogen fluoride55% water0.2% surfactantetch oxideChromium etch (TFD) 5-10% Ceric Sulfate5-10% Nitric Acid1-5% Sulfuric Acid75-89% WaterEtch chromiumCopper etch (Type 100/200) 30% ferric chloride3-4% hydrochloric acidwaterEtch copperEKC 830 50-60% 2-(2-Aminoethoxy) Ethanol40-50% N-Methyl PyrrolidoneRemove photoresistFuturrex 2.27% tetramethyl ammoniumhydroxidewaterNegative resist developerGold Etch (TFA) 1-10% iodine complex20-40% potassium iodide50-79% waterEtch goldHMDS 100% Hexamethyl disilazane Adhesion promoter Hydrocholoric acid 37% hydrogen chloride waterremove metalsHydrofluoric acid 49% HFwateretch oxide, nitrideHydrogen peroxide 30% hydrogen peroxidewaterOxidizerIsopropyl alcohol 100% 2-propanol solventNanostrip 90% sulfuric acid5% peroxymonosulfuric acid<1% hydrogen proxideRemoves organics, metals Nickel etch TFB 10 to 20% nitric acid Electroless plating<1% Potassium PerfluoroalkylSulfonate80 to 90% waterNitric acid 70% nitric acid etchantP-20 20% Hexamethyl disilazane80% 1-methoxy-2-propyl acetateAdhesion promoterPad etch 1 31-35% acetic acid12-16% ammonium fluoride51-55% waterOxide etchPad etch 4 30-34% acetic acid11-15% ammonium fluoride4-8% glycol47-51% waterOxide etchPalladium Etch (TFP) 30% ferric chloride3-4% hydrogen chloride66-67% water**this is the same as copper etch 100*Etch palladiumPhosphoric acid 74-95%waterEtch nitridePolyimide Coating 30-60% n-methyl-2-pyrollidone5-10% tetraethylene glycol diacrylate30-60% photosensitive polimide resin1-5% proprietary ingredientsPlanarization “oxide”Polyimide Developer (HD Microsystems) >60% cyclohexanone 30-40% 4-butyrolactoneDeveloperPolyimide Rinse 10-30% cyclohexanone>60% butyl acetaterinsePotassium hydroxide 45% potassium hydroxidewater Etch silicon with nitride maskQZ3501 polyimide developer 60-80% dihydrofuranone20-40% butyl acetatedeveloperR19180 polyimide developer 10-30% cyclohexanone>60% butyl acetatedeveloperRD6 Negative Resist Developer 97-98% water2-3% tetramethyl ammoniumhydroxidedeveloperSilver Etch (TFS) 3-10% iodine complex18-42% potassium iodide48-79% waterEtch silverSPR 220 30-52% Ethyl lactate15-25% anisole1-10% diazo photoactive compound14-40% Cresol Novolak Resin1-5% 2-Methyl Butyl Acetate2-7% n-amyl acetateThick resistSTR 1075 48-53% Ethyl lactate1-5% n-butyl acetate1-10% diazo photoactive compound30-40% Cresol Novolak Resin1-5% xylene<1% organic siloxane surfactantThick resistSU8 developer 100% methoxy-2propyl acetate developerSulfuric acid 98% sulfuric acid remove organics, metalsSylgard silicone elastomer curing agent 59% Dimethyl, methyl hydrogen siloxane13% Dimethyl vinylated andtrimethylated silicaCuring agentXP SU-8 10 40-45% Gamma butyrolactone55-60% Mixed triarylsulfonium/hexafluoroantimonate saltNegative photoresistXP SU-8 developer 98-100% 1-methoxy-2-propyl acetate DeveloperTMAH 25% tetramethylammonium hydroxide75% waterAnisotropic etch3.0SafetyA buddy system applies to the use of chemicals after normal working hours: another knowledgeable user should be in the clean room, aware of your situation, and close enough to be of assistance if you have an accident.3.1 Heat3.1.1 Hot plates used for heating chemicals must be attended. You must be in the clean room and near the hot plate when it is on.3.1.2Check that each container you use on a hotplate is approved for hotplate use.3.1.3 The wafer baking hot plates are not to be used with chemicals.3.2 Chemical Vapor3.2.1 When working with chemicals, always use the vented chemical hoods.3.2.2 Wear appropriate personal protective equipment.3.2.3 Keep your head above the Plexiglas especially when mixing, pouring, and heating.3.2.4 Pour only approved chemical mixtures.3.2.5 If you can smell chemicals while you are processing wafers, find out why. You may have chemicals on your lab coat or gloves. Fresh gloves are available on topof the resist cabinet. Fresh lab coats are available in the gowning room. Theremay also be contaminated trash in the unvented waste basket. Be sure to work toward the back of the fume hood. Clean the outside of bottles thoroughly, before putting them back in the chemical cabinet.3.3 Fire3.3.1 When working with chemicals, always use the vented chemical hoods.3.3.2 Check chemical flashpoints before heating. Do not heat chemicals to temperatures near their flashpoints. Do not heat solvents above 120 degrees C.3.3.3 Chemicals on hotplates must be attended.3.3.4 Be particularly careful with solvents like acetone around heat sources or oxidizers (peroxide or nitric acid).3.4 Contact burns3.4.1 Wear appropriate personal protective equipment.3.4.2 Keep work area clean and dry.3.4.3 Add acid to water. Do not add water to acid.3.4.4 Add peroxide to sulphuric, when pouring pirahna.3.4.5 Pour only approved chemical mixtures.3.5 Reproductive effectsUsers who are pregnant should discuss laboratory use with the lab manager assoon as possible. This need not severely restrict laboratory use but shouldnonetheless be discussed (see MSDS of photoresist). Be aware that there aremany different names for the same photoresist solvents4.0Supplies4.1Personal Protective EquipmentAprons, orange chemical resistant gloves, and face shields are available for use at thechemical hoods. Select an appropriate size orange glove. Check gloves for holes before each use; discard them if they have holes. Wear gloves to open cabinets, sign the log.Wash gloves when they become contaminated. Do not touch door knobs, notebooks,phone or microscope with gloves on. Wash and dry gloves when you are done; hangthem up on the rack. Wipe off aprons as needed and return them to the rack.4.2LabwareClean glassware and plastic ware are available for lab users. To prevent crosscontamination, many dishes are labeled. When you are done with your glassware, please empty it into the appropriate container, clean it, rinse three times, dry it and leave itupside down on the glassware shelf. Do not store WTC supplies on your own shelf.You may bring in your own labware labeled with your name; glassware not labeled with anyone’s name belongs to WTC. 4.3ChemicalsThe lab stocks and supplies the chemicals commonly required for processing in thefacility. As we have limited storage, please get staff approval to store custom solutions.Mix only enough to use each day. In most cases, the shelf life of these chemicals is very short anyway. All special chemicals and solutions must be labeled with the arrival dateand the owner's name and phone number. Expired chemicals or chemicals older than 1year will be periodically disposed of.The exception is with photoresist, where each group may have a few private smallbottles of resist; these are kept in several small plastic boxes in the yellow vented cabinet next to the spinners. Before you decide to use your own bottles, consider that positiveresist has a very limited life at room temperature. Those people using the WTC bottlesare getting much fresher resist than those who use their own bottles to store a six-month supply. Please clean the outside ofall resist bottles thoroughly after each use tominimize solvent odor in the resist cabinet.Working stocks of chemicals are kept in the chemical cabinets near each chemical area.Extra stock is kept in several chemical bunkers outside the lab. When a chemical hasbeen used up, write it on the white board in the gowning room, so staff can replenish the clean room stock from the bunker.4.4Emergency Response Equipment4.4.1Phone systemPhones are located at the entrance to the laboratory, as well as severalplaces within the laboratory. These are part of the university phonesystem. In an emergency, dial 9-911. You may request help for largechemical spills, accidents, medical emergencies, injuries, etc. For minoremergencies, staff contact information is available next to each phone.4.4.2Chemical spill cartSpill control pads are available on the spill cart for absorbing liquidchemical spills. Bottles of neutralization liquid are available for use onacid spills. Gloves, full protective coveralls, a squeegee, scoop pan,calcium gluconate gel and other useful items are located in or near thechemical spill cart. It is located in the grey area. A vacuum cleaner is alsoavailable for cleaning up powdered residue from neutralized chemicalspills.4.4.3Emergency showersEmergency showers and eye washes are located in each room of thelaboratory. Most chemical burns, particularly in the eyes, should bewashed for 15 minutes before seeking further medical attention.4.4.4First aid kitA first aid kit is available on the wall of the gowning room. Tubes ofcalcium gluconate gel are available at the HF wet bench and on thechemical spill cart for application to HF burns. This should be appliedpromptly, but is not a substitute for medical attention.5.0Operating Procedures5.1 Set up5.1.1 Get approval for any new chemicalIf your exact chemical is not currently in use in the lab, you must get approvalfrom the lab manager before bringing the chemical into the lab. You will beexpected to supply the appropriate MSDS, a reason why this chemical should beused in the lab, and an explanation of how it is compatible with lab usage.5.1.2 Read the MSDS for each chemical you plan to use.PPEappropriate5.1.3 SelectSafety glasses should be worn at all times in the laboratory. When pouring chemicals, wear face shield, orange gloves, acid apron. When moving wafers from acids to dump rinsers, operators should wear orange gloves and acid apron. stationappropriate5.1.4 SelectAcids are used at wet bench #3. Bases and acids are used at wet benches #4 Solvents may only be used at the solvent station (bench #12) and resist coating stations, never at the acid station. Log in to workbench as necessary.5.1.5 Decide whether it is necessary for you to pour your own chemicals, or whether you can safely use chemicals maintained by staff for lab users. In general, it is safer to use lab solutions than to pour your own. If you are concerned about the age of the solution or potential cross-contamination, you may be able to schedule your work, so that you use the lab chemicals immediately after they are poured (every two weeks). If you see obvious contamination in the chemical, notify lab staff, so that fresh chemicals can be poured.5.1.6 Select appropriate containerSelect a dish labeled with the specific chemical name you will be using. Do notput chemicals in a dish that is labeled with another chemical name. If there is no dish for your chemical, use an unlabeled, compatible dish. To conserve on chemicals, select the smallest dish that is appropriate for the job. Do not pour HF into glass or metal dishes. Dishes for heated solutions must be hotplate-compatible.5.1.7 Label containerLabel dish with a Sharpie (your name, chemical name, concentration, date, and phone number)5.1.8Select chemical bottleWhen selecting a bottle to pour, finish any open bottles before opening new ones. Be sure the concentration of the chemical is correct.5.1.9Pour solutionbottle. Replace chemical bottles in the appropriate place in the cabinet. Coverany chemical not immediately in use.5.1.10 Wash bottles that you have emptied.Cross out the label on any chemical bottle you have emptied, rinse three times,and write “rinsed” with a Sharpie at the top of the bottle. Place rinsed bottles onthe bottom shelf of the waste chemical cabinet.5.1.11 Prepare hotplateHot plate controllers are located above the Plexiglass shield. Set temperature. Putchemical solution on the hotplate. Use an appropriate thermometer to monitor thetemperature. Do not leave the lab when the hotplate is on.5.2 Dip—Acid or Base5.2.1 Select appropriate sample holderParts to be dipped in chemicals should be in a holder. When immersing wafers inchemicals, 3” and 4” Teflon cassettes are available. Attach a Teflon handle to thecassettes. Single wafer Teflon carriers can also be used. For parts that are notwhole wafers, there are perforated Teflon ladles, as well as a small Teflon rack for tiny parts. Tweezers may be sufficient for immersing single wafers in a smallamount of developer, but are not appropriate for use in acids.5.2.2 Ensure proper PPEWhen moving wafers from acids to dump rinsers, operators should wear safetyglasses, orange gloves and an apron.5.2.3 Determine appropriate dip timeYou can determine proper time by checking in reference material, checkingprevious entries in the log book, or doing an etch rate check. To do an etch ratecheck, use a silicon wafer with the same film you are trying to etch. Measure film thickness with the Nanospec. Etch the wafer for a specified time (say, 1 minute).Then re-measure the wafer on the Nanospec. You can then calculate etch rate inAngstroms/minute. Calculate etch time by dividing film thickness on yoursample by etch rate.5.2.4 Dip sampleSet timer for the proper time, then start timer as you lower sample into thesolution. Do not sit down at the hood while processing wafers, as this positiondoes not protect your face from fume exposure.5.2.5 Remove sample from solution5.2.6 Place sample still in its container into dump rinser or cascade rinserControllers are located in the control panel above the Plexiglass. Set dump rinser for at least three cycles by pushing “cycle count” until the display reads thenumber of cycles you want (at least 3). Push “start.” When wafers are doneprocessing, push “stop,” and remove the wafers.Cascade rinser can be started by pushing “run.” When carrying wafers from onebench to another, put the wafer container in a tub to avoid dripping. If wafers areespecially fragile, you can manually rinse them in tubs of water. Use at least fivechanges of water.5.2.7 Dry sample in spin rinse dryer or under nitrogen gun.After a complete rinse, whole wafers can be put in the spin rinse dryer. Do notput unrinsed wafers in the spin rinse dryer. Substrates other than whole waferscan be dried with a nitrogen gun. Check the pressure coming out of the nitrogengun before using it on your substrate, as some have a gentle flow, and others areforceful. Fragile wafers can be dried in the vacuum oven located under theBranson barrel asher.5.3 Dip—solvent5.3.1 Use heated EKC830 and AZ 300T to strip positive photoresist. Temperatureshould be set at 75 degrees for the EKC and 90 degrees for the AZ300T.5.3.2 Allowed materials in this tank are silicon, quartz, aluminum, and positivephotoresist. Materials not allowed in this tank are water, negative photoresist andother polymers like polyimide. Water will form hydroxyls that will pit aluminum,creating a problem for some users.5.3.3 Typical strip times are 10 minutes in EKC, and 10 minutes in AZ300T.5.3.4 If you would like to use EKC, but your wafer has a material not allowed, you maypour up your own batch in a separate container, but you may not use the general tank.5.3.5 Be sure to use Teflon cassettes.5.3.6 Bring a tub of plain water over to the station to use to carry your wafers to the dump rinser.5.4 Clean up5.4.1 Squirt wet deck with DI water, and wipe down with squeegee, then towel 5.4.2 Dispose of solutionPlease dispose of chemicals as soon as you are finished. Chemicals left in the hood for more than 24 hours are subject to disposal. Hot or reacting mixtures may be left a reasonable amount of time to settle down.5.4.2.1 Aspirate acids and basesAspirator is located in the Microvision wet bench. Put the aspirator tubein the solution, and step on the pedal on the floor. Aspirator will suck up chemical into the acid neutralization system. Do NOT aspirate solvents,as they are an explosion hazard in the acid neutralization system.5.4.2.2 Put solvents in designated carboysPut the carboy in the dishwashing sink, or the vented chemical cabinet to pour. Use a funnel. Wipe sides of container. Return it to the properstorage area. The acetone/IPA waste is located on the bottom shelf of the yellow, ventilated cabinet next to the spinners.5.4.2.3 Put other chemicals into labeled containers in waste chemical storage. 5.4.2.3.1.1Using the bottle labeled for your chemical.Carry the waste bottle to the appropriate sink, and use afunnel to transfer your waste. Leave two inches at the topfor thermal expansion, and put the cap on. Do not put solidcaps on any bottle containing hydrogen peroxide (H2O2). Itcontinues to decompose for months and must be stored in avented container. Wash any residue from the outside of thecontainer. Return waste container to the waste cabinet. Ifyou have filled the existing waste bottle, make a new one.5.4.2.3.1.2Making a new waste chemical bottle.If there is no bottle with the proper chemical name, get aclean, dry bottle from the bottom shelf of the chemical wastecabinet, get an EH&S label, and label the bottle properly. Besure that the bottle type is compatible with the chemical youare disposing; if in doubt, ask! Chemicals left withoutproperly labeling will be assayed by Environmental Healthand Safety, and your budget number will be billed.5.4.2.4 Do not pour anything except rinse water and AZ developer down the drain.5.4.3 Wash and dry lab ware and return it to the proper shelf5.4.4 Final checkRemove beakers, towels, chemical and liquid residue from the wet decks. The work surface should be clean and dry when you leave.5.5 Accidents5.5.1 Spills5.5.1.1 You are primarily responsible for cleaning up any minor chemical spill you cause, using safe and approved procedures. Do not dispose of contaminated rags and broken chemically laden glass in the normal waste baskets. You should rinse the waste articles and bag them. Bags arelocated in the gowning room in the large cabinet. Label the bags, leavethem in a ventilated area and seek assistance from a staff member onfurther disposal.5.5.1.2 Request assistance from staff for any significant spill. We will assist you, using the materials on the chemical spill cart located in the grey area nextto the tool box, which has supplies like tape to block off spill area, spillcontrol pads, and neutralizers.5.5.2.3 For major chemical spills and for any unanticipated chemical reaction, evacuate the area, and call the staff. You must remain available to provide information. Any user may call for an evacuation of the laboratory at any time. These "requests" must be honored by all users until such time as the situation is evaluated. Alternatively, you may evacuate the laboratoryusing the fire alarm in justified instances. You must first exit thelaboratory to find an alarm pull box next to the building exits.5.5.3.4 Significant events must be reported in writing, so that corrective action can be taken to prevent future problems, on a time scale appropriate to the severity of the event.5.5.2 Chemical Exposure5.5.2.1 Flush affected area immediately with large quantities of water for at leastfifteen minutes. Use the sink, the safety shower, or the eyewash station as appropriate.5.5.2.2 Remove any contaminated clothing immediately.5.5.2.3 For HF exposures only, after flushing the area for a couple of minutes with water, spread affected area liberally with calcium gluconate gel, located atthe HF wet bench and on the chemical spill cart. Wear clean gloves when applying the gel to prevent secondary HF burns to the hands.All HFburns, no matter how seemingly trivial, should be considered serious and proper medical treatment sought. Note: BOE is a dilute solution of HF.5.5.2.4 Minor medical treatment is available from Hall Health occupational health and safety staff. Major medical treatment is available from HarborviewMedical Center. If you go for medical treatment, take the MSDS of therelevant chemicals from the gowning room to the medical staff to aid in prompt, appropriate medical treatment. Paramedic services are availableby dialing 9-911 from the lab phone.5.5.2.5 Notify lab staff immediately about any chemical exposures, and provide written documentation as necessary, so that proper follow up can be done.6.0 Chemical Mixtures Approved for Lab UseDo not mix solvents with acids (potentially flammable). Do not mix organicswith peroxides (potentially explosive). You may not arbitrarily mix chemicals together. Only specifically approved solutions can be made. Solutions not on this chart should be checked with the lab manager.Name CompositionTemperature(°C)Removes Silicon etch 6parts acetic acid19 parts nitric acid1 part hydrofluoricacidRoom temperature siliconPiranha 4 part sulphuric acid1 parts hydrogenperoxide Reaction isexothermic will raisetemp to 110-140°organicsSC1 1 part ammoniumhydroxide1 parts hydrogenperoxide5 parts DI water 70 particles,organics(Makes surfacehydrophilic)SC2 1 part hydrochloricacid1 part Hydrogenperoxide5 parts DI water70 metallicsAqua regia 3.896 parts HCl(37%)1 part nitric acid(70%) etchesgold,platinumTitanium etch 20 parts DI water1 part H2O21 part HFRoom Temp Etches titanium7.0 Processes Approved for Lab Use7.0.1Prefurnace clean: Nanostrip (5 min), BOE (10 sec), SCI (5 min) and SC2 (5 min)8.0RevisionsRevision Initials Date PurposeA ACT 8/28/2003 format, waste chemical procedure, chemical contents, mixtures, revisionsB ACT 1/20/2004 Add wet strip criteriaC MEH 8/31/2005 Updated chemical list。

半导体化学品半导体化学品是一类在半导体制造过程中广泛应用的化学物质。

作为半导体行业的重要组成部分,半导体化学品不仅在半导体芯片的制造中起到关键作用,同时也在光电子、光伏、电子封装等领域发挥着重要的作用。

半导体化学品的种类繁多,包括了溶剂、清洗剂、蚀刻剂、涂覆剂等。

这些化学品在半导体制造过程中扮演着不同的角色。

首先,溶剂在半导体制造过程中用于溶解和稀释其他化学物质,以调节反应体系的浓度和比例。

其次,清洗剂用于清洗半导体表面,去除污染物和不良杂质,以保证半导体材料的纯净度和质量。

蚀刻剂则用于半导体材料的蚀刻和刻蚀,以形成所需的结构和形状。

而涂覆剂则用于在半导体表面形成保护膜或光刻胶层,以便进行后续的加工和制造。

半导体化学品的研发和生产需要高度精密的实验条件和严格的质量控制。

首先,半导体化学品的纯度要求非常高,通常需要达到99.999%以上。

这是因为半导体材料的纯净度直接关系到半导体器件的性能和可靠性。

其次,半导体化学品的稳定性和可控性也非常重要,以确保反应的准确性和可重复性。

此外,半导体化学品的环境友好性也是一个重要考虑因素,要求尽量减少对环境的污染和对人体的危害。

在半导体行业的发展过程中,半导体化学品的需求也在不断增加。

随着半导体技术的不断进步,对半导体化学品的要求也在不断提高。

例如,随着集成电路的密度不断增加,对半导体材料的纯净度要求也越来越高。

此外,随着新一代半导体材料的开发和应用,对新型半导体化学品的需求也在逐渐增加。

然而,半导体化学品的研发和生产仍然面临一些挑战。

首先,半导体化学品的研发周期长、成本高。

由于半导体制造过程的复杂性和高度精密性,研发一种新型的半导体化学品需要耗费大量的时间和资源。

其次,半导体化学品的生产过程中存在风险和安全隐患。

由于半导体化学品的特殊性,一旦发生泄漏或事故,可能对环境和人体造成严重影响。

因此,严格的安全管理和控制措施是必不可少的。

半导体化学品作为半导体行业的重要组成部分,在半导体制造过程中起到了不可或缺的作用。

半导体用化学品1. 引言半导体材料在现代电子技术中起着至关重要的作用。

半导体器件的制造过程需要使用各种化学品,这些化学品在半导体工业中被称为半导体用化学品。

半导体用化学品的质量和纯度对于半导体器件的性能和可靠性有着重要的影响。

本文将介绍半导体用化学品的种类、应用以及其在半导体制造过程中的重要性。

2. 半导体用化学品的种类半导体用化学品的种类繁多,根据其应用和功能可以分为以下几类:2.1 清洗剂清洗剂是半导体用化学品中最常见的一类。

它们用于去除半导体表面的杂质和污染物,以确保器件的性能和可靠性。

常见的清洗剂包括有机溶剂、酸碱溶液和超纯水等。

有机溶剂可溶解有机污染物,酸碱溶液可中和表面的酸碱物质,而超纯水则用于冲洗和去除残留物。

2.2 蚀刻剂蚀刻剂用于在半导体材料表面进行选择性腐蚀,以形成特定的结构和图案。

常见的蚀刻剂包括氢氟酸、氯化氢和硝酸等。

不同材料需要使用不同的蚀刻剂,以实现所需的蚀刻效果。

2.3 沉积剂沉积剂用于在半导体表面沉积薄膜,以改变材料的性能和结构。

常见的沉积剂包括化学气相沉积(CVD)和物理气相沉积(PVD)等。

CVD使用气体反应产生沉积物,而PVD使用物理方法将材料蒸发或溅射到表面。

2.4 阻挡剂阻挡剂用于在半导体制造过程中保护某些区域不受化学反应的影响。

常见的阻挡剂包括光刻胶和电子束曝光胶等。

它们在暴露后可以形成图案,以控制材料的沉积、蚀刻和清洗等过程。

3. 半导体用化学品的应用半导体用化学品在半导体工业中扮演着重要的角色。

它们的应用涵盖了半导体器件制造的各个方面。

3.1 清洗和预处理在半导体器件的制造过程中,清洗和预处理是不可或缺的步骤。

清洗剂用于去除器件表面的有机和无机杂质,以提高器件的可靠性和性能。

预处理化学品用于改变器件表面的化学性质,以便于后续的蚀刻、沉积和阻挡等工艺步骤。

3.2 蚀刻和沉积蚀刻剂和沉积剂在半导体制造过程中起着至关重要的作用。

蚀刻剂可用于制造微细结构和图案,如通道、电极和孔洞等。