PET印刷膜ROHS测试报告

- 格式:pdf

- 大小:311.58 KB

- 文档页数:6

rohs测试报告:对环保产品的必要性是针对电子电器设备而言的。

随着时代的发展,人们对生态环境保护意识逐渐增强,对环保产品的要求也越来越高。

就是一项检测标准,涵盖了特定物质和元素的含量限制,如铅、汞、镉、六价铬、多溴联苯等。

ROHS测试要求产品不能出现这些元素的含量超标,且测试结果要公开透明。

与环保产品联系密切,下面将对的必要性与优势进行探讨。

一、的必要性1.法律要求ROHS是Restriction of Hazardous Substances的缩写,意为有害物质限制。

这项标准是在2003年7月1日由欧洲议会发布的,旨在限制电子电器产品中有害物质的使用。

自从标准产生之后,逐渐被各国广泛推广。

一些国家和地区还产生了具有相似意义的标准,如日本的JIS C 0950和中国的QC 080000,都规范了产品中可使用有害物质的种类和含量。

在欧盟、美国和中国等国家和地区,ROHS测试已成为一项法律要求。

因此,如果企业想要进入这些市场,就必须严格遵守ROHS标准,并通过ROHS测试获得。

2.符合环保意识并不仅仅是一项法律要求,它更多的是符合当今世界上人们追求绿色环保的社会意识。

环境影响评估(EIA)显示,线路板污染导致全球大约有80%的电子垃圾无法得到回收。

因此,企业如果可以减少电子电器产品中有害物质的使用,对于环保是至关重要的。

二、的优势1.增加产品的市场竞争力是迈向国际市场不可或缺的一步。

随着各国环保法规的加强,消费者对产品的质量和绿色度的要求越来越高。

如果企业可以通过ROHS测试,取得,可以增强企业的公信力和产品的市场竞争力。

2.降低企业的成本通过ROHS测试,可以降低企业的产品质量问题出现的概率。

有害物质降低的同时,产品的运营寿命也相应增加,有利于企业维护自身的声誉和客户的信任。

长期来看,ROHS测试的过程可以帮助企业优化产品设计,提高生产效率,从而降低企业的成本以及时效性。

3.逐步进入本地市场是进入欧美等国际市场的必要条件,同样也是进入本地市场的一步必要过程。

![PET薄膜(ROHS+卤素+PFOS+TBBPA+HBCDD+邻苯二甲酸酯)报告[1]](https://uimg.taocdn.com/173ebf4bc850ad02de8041a5.webp)

Test Report No.: GZ1001004486/CHEM Date: JAN 21, 2010 Page 1 of 14 SICHUAN DONGFANG INSULATING MATERIAL CO.,LTD.NO.6 DONGXING RD., MIANYANG, SICHUAN, CHINAThe following sample(s) was/were submitted and identified on behalf of the applicant as Polyester Terephthalate FilmSGS Job No. : GZ12351182ECSGS Internal Reference No. : 2.1Date of Sample Received : JAN 14, 2010Testing Period : JAN 14, 2010 TO JAN 19, 2010Test Requested : Selected test (s) as requested by client.Test Method : Please refer to next page(s).Test Result(s) : Please refer to next page(s).Conclusion : A: Based on the performed tests on submitted sample(s), the results complywith the RoHS Directive 2002/95/EC and its subsequent amendments. Signed for and on behalf ofSGS-CSTC Ltd.______________________Manson YangSr. EngineerTest ReportNo.: GZ1001004486/CHEMDate: JAN 21, 2010Page 2 of 14Test Results:Description for specimen 1 : Transparent plastic sheetA: RoHS Directive 2002/95/ECTest Item(s) Unit Test Method (Reference) Result MDL Limit Cadmium (Cd) mg/kg IEC 62321: 2008, ICP-OES N.D. 2 100 Lead (Pb) mg/kg IEC 62321: 2008, ICP-OES N.D. 2 1000 Mercury (Hg)mg/kg IEC 62321: 2008, ICP-OES N.D. 2 1000 Hexavalent Chromium (CrVI) by alkaline extraction mg/kg IEC 62321: 2008, UV-Vis N.D. 2 1000 Sum of PBBsmg/kg -N.D. - 1000 Monobromobiphenyl mg/kg IEC 62321: 2008, GC-MS N.D. 5 Dibromobiphenyl mg/kg IEC 62321: 2008, GC-MS N.D. 5 Tribromobiphenyl mg/kg IEC 62321: 2008, GC-MS N.D. 5 Tetrabromobiphenyl mg/kg IEC 62321: 2008, GC-MS N.D. 5 Pentabromobiphenyl mg/kg IEC 62321: 2008, GC-MS N.D. 5 Hexabromobiphenyl mg/kg IEC 62321: 2008, GC-MS N.D. 5 Heptabromobiphenyl mg/kg IEC 62321: 2008, GC-MS N.D. 5 Octabromobiphenyl mg/kg IEC 62321: 2008, GC-MS N.D. 5 Nonabromobiphenyl mg/kg IEC 62321: 2008, GC-MS N.D. 5 Decabromobiphenyl mg/kg IEC 62321: 2008, GC-MSN.D. 5 Sum of PBDEsmg/kg -N.D. - 1000 Monobromodiphenyl ether mg/kg IEC 62321: 2008, GC-MS N.D. 5 Dibromodiphenyl ether mg/kg IEC 62321: 2008, GC-MS N.D. 5 Tribromodiphenyl ether mg/kg IEC 62321: 2008, GC-MS N.D. 5 Tetrabromodiphenyl ether mg/kg IEC 62321: 2008, GC-MS N.D. 5 Pentabromodiphenyl ether mg/kg IEC 62321: 2008, GC-MS N.D. 5 Hexabromodiphenyl ether mg/kg IEC 62321: 2008, GC-MS N.D. 5 Heptabromodiphenyl ether mg/kg IEC 62321: 2008, GC-MS N.D. 5 Octabromodiphenyl ether mg/kg IEC 62321: 2008, GC-MS N.D. 5 Nonabromodiphenyl ether mg/kg IEC 62321: 2008, GC-MS N.D. 5 Decabromodiphenyl ether mg/kgIEC 62321: 2008, GC-MSN.D.5Note:1. mg/kg = ppm2. N.D. = Not Detected (< MDL)3. MDL = Method Detection Limit4. "-" = Not regulatedTest Report No.: GZ1001004486/CHEM Date: JAN 21, 2010 Page 3 of 14B: Phthalate(s)Test Item(s) Unit Test Method (Reference) Result MDL Dimethyl Phthalate (DMP) %(w/w) EN14372: 2004, GC-MS N.D. 0.005 Diethyl Phthalate (DEP) %(w/w) EN14372: 2004, GC-MS N.D. 0.005 Dibutyl Phthalate (DBP) %(w/w) EN14372: 2004, GC-MS N.D. 0.003 Benzylbutyl Phthalate (BBP) %(w/w) EN14372: 2004, GC-MS N.D. 0.003Di-(2-ethylhexyl) Phthalate (DEHP) %(w/w) EN14372: 2004, GC-MS N.D. 0.003 Diisononyl Phthalate (DINP) %(w/w) EN14372: 2004, GC-MS N.D. 0.01Di-n-octyl Phthalate (DNOP) %(w/w) EN14372: 2004, GC-MS N.D. 0.003 Diisodecyl Phthalate (DIDP) %(w/w) EN14372: 2004, GC-MS N.D. 0.01 Diisobutyl Phthalate (DIBP) %(w/w) EN14372: 2004, GC-MS N.D. 0.005 Dinonyl Phthalate (DNP) %(w/w) EN14372: 2004, GC-MS N.D. 0.005 Diisooctyl Phthalate (DIOP) %(w/w) EN14372: 2004, GC-MS N.D. 0.01 Dipropyl Phthalate (DPrP) %(w/w) EN14372: 2004, GC-MS N.D. 0.005 Dicyclohexyl Phthalate (DCHP) %(w/w) EN14372: 2004, GC-MS N.D. 0.005 Dipentyl Phthalate (DPP) %(w/w) EN14372: 2004, GC-MS N.D. 0.005 Dibenzyl Phthalate (DBzP) %(w/w) EN14372: 2004, GC-MS N.D. 0.005 Diphenyl Phthalate (DPhP) %(w/w) EN14372: 2004, GC-MS N.D. 0.005 Note :1. mg/kg = ppm, 0.1% = 1000ppm2. N.D. = Not detected (< MDL)3. MDL= Method Detection LimitFor reference:Entry 51/52 of Regulation (EC) No 552/2009 amending Annex XVII of REACH Regulation (EC) No 1907/2006 (previously restricted under Directive 2005/84/EC):For DBP, BBP, DEHP(1)Shall not be used as substances or in mixtures, in concentrations greater than 0,1 % by weight of the plasticised material, in toys and childcare articles.(2) Toys and childcare articles containing these phthalates in a concentration greater than 0,1 % by weight of the plasticised material shall not be placed on the market.For DINP, DNOP, DIDP(1) Shall not be used as substances or in mixtures, in concentrations greater than 0,1 % by weight of the plasticised material, in toys and childcare articles which can be placed in the mouth by children.(2) Such toys and childcare articles containing these phthalates in a concentration greater than 0,1 % by weight of the plasticised material shall not be placed on the market.Test Report No.: GZ1001004486/CHEM Date: JAN 21, 2010 Page 4 of 14C: PFOS (Perfluorooctane sulfonates)Test Item(s) Unit Test Method (Reference) Result MDL Perfluorooctane sulfonates (PFOS)PFOS – Acidmg/kg EPA 3550C: 2007, LC-MS N.D. 10 PFOS – Metal SaltPFOS – AmideNote:1. mg/kg = ppm2. N.D. = Not Detected (< MDL)3. MDL = Method Detection LimitFor reference: Entry 53 of Regulation (EC) No 552/2009 amending Annex XVII of REACH Regulation (EC) No1907/2006 (previously restricted under Directive 2006/122/EC):(1) May not be placed on the market or used as a substance or constituent of preparations in a concentration equal to or higher than 0,005 % by mass.(2) May not be placed on the market in semi-finished products or articles, or parts thereof, if the concentration of PFOS is equal to or higher than 0,1 % by mass calculated with reference to the mass of structurally or microstructurally distinct parts that contain PFOS or, for textiles or other coated materials, if the amount of PFOS is equal to or higher than 1µg /m2 of the coated material.D: HalogenTest Item(s) Unit Test Method (Reference) Result MDLFluorine (F) mg/kg BS EN 14582:2007, IC N.D. 50Chlorine (Cl) mg/kg BS EN 14582:2007, IC N.D. 50Bromine (Br) mg/kg BS EN 14582:2007, IC N.D. 50Iodine (l) mg/kg BS EN 14582:2007, IC N.D. 50Note:1. mg/kg = ppm2. N.D. = Not Detected (< MDL)3. MDL = Method Detection LimitE: TBBPA (Tetrabromobisphenol A)Test Item(s) Unit Test Method (Reference) Result MDL Tetrabromobisphenol A (TBBPA) mg/kg EPA 3550C: 2007, GC-MS N.D. 10 Note:1. mg/kg = ppm2. N.D. = Not Detected (< MDL)3. MDL = Method Detection LimitTest Report No.: GZ1001004486/CHEM Date: JAN 21, 2010 Page 5 of 14F: HBCDDTest Item(s) Unit Test Method (Reference) Result MDL Hexabromocyclododecane (HBCDD) mg/kg EPA 3550C: 2007, GC-MS N.D. 10 Note:1. mg/kg = ppm2. N.D. = Not Detected (< MDL)3. MDL = Method Detection LimitG: FormaldehydeTest Item(s) Unit Test Method (Reference) Result MDL Formaldehyde Content mg/kg ISO 17226-1: 2008, HPLC N.D. 10 Note:1. mg/kg = ppm2. N.D. = Not Detected (< MDL)3. MDL = Method Detection LimitTest ReportNo.: GZ1001004486/CHEMDate: JAN 21, 2010Page 6 of 14ATTACHMENTS ATTACHMENTSTesting Flow ChartTesting Flow Chart 1) Name of the person who made measurement: Bella Wang 2) Name of the person in charge of measurement: Adams Yu3) These samples were dissolved totally by pre-conditioning method according to below flow chart (Cr 6+ test method excluded) .Test ReportNo.: GZ1001004486/CHEMDate: JAN 21, 2010Page 7 of 14Testing Flow ChartTesting Flow Chart1) Name of the person who made measurement: Tina Zhao2) Name of the person in charge of measurement: Ryan YangTest ReportNo.: GZ1001004486/CHEMDate: JAN 21, 2010Page 8 of 14ATTACHMENTS ATTACHMENTSTesting Flow Chart1) Name of the person who made measurement: Tina Zhao 2) Name of the person in charge of measurement: Ryan YangTest ReportNo.: GZ1001004486/CHEMDate: JAN 21, 2010Page 9 of 14ATTACHMENTS ATTACHMENTSTesting Flow Chart1) Name of the person who made measurement: Cindy Huang 2) Name of the person in charge of measurement: Ryan YangTest ReportNo.: GZ1001004486/CHEMDate: JAN 21, 2010Page 10 of 14ATTACHMENTS ATTACHMENTSTesting Flow Chart1) Name of the person who made measurement: Sawen Chen 2) Name of the person in charge of measurement: Michael TsoTest ReportNo.: GZ1001004486/CHEM Date: JAN 21, 2010 Page 11 of 14ATTACHMENTS ATTACHMENTSTesting Flow Chart Testing Flow Chart1) Name of the person who made measurement: Cutey Yu 2) Name of the person in charge of measurement: Ryan YangTest ReportNo.: GZ1001004486/CHEM Date: JAN 21, 2010 Page 12 of 14Testing Flow Chart Testing Flow Chart 1) Name of the person who made measurement: Cutey Yu 2) Name of the person in charge of measurement: Ryan YangTest ReportNo.: GZ1001004486/CHEM Date: JAN 21, 2010 Page 13 of 14ATTACHMENTS ATTACHMENTSTesting Flow Chart Testing Flow Chart1) Name of the person who made measurement: Michael Tso 2) Name of the person in charge of measurement: Michelle SongTest Report No.: GZ1001004486/CHEM Date: JAN 21, 2010 Page 14 of 14Sample photo :SGS authenticate the photo on original report only*** End of Report ***GZ1001004486/CHEM。

如何解读RoHS检测报告Intertek Testing Services Shanghai Ltd.上海天祥质量技术服务有限公司Smile Liu刘思明目录•RoHS指令简介•关于均质材料的指导性解释及拆样方法•RoHS检测的不同参考方法•RoHS测试报告的解读•R estriction o f the Use of Certain H azardousS ubstances in Electrical and Electronic Equipment (RoHS) Directive 2002/95/EC.•2003年2月公布于官方杂志•减少由电子电气设备中的有害物质引起的对环境和健康构成的风险•作为对WEEE指令的补充并与之平行执行•2004年8月13日转换成各成员国的国家法令.•正式生效:2006年7月1日.•仅对于2006年7月1日起投放市场的新产品。

•8类WEEE产品范围(不包括WEEE中8和9,医疗设备和监控设备)•包括家用的白炙灯泡和光源。

•不包括:–医用器材或监控设备(WEEE指令第8,9类)–在2006年7月1日前投放市场的维修备件。

–2006年7月1日前原先投放市场的再利用产品RoHS和WEEE范围–分类1.大型家用器具,如冰箱、洗衣机、微波炉;2.小型家用器具,如吸尘器、熨斗、钟表;3.信息技术和远程通讯设备,如电脑、复印机、打印机;4.用户设备,如电视机;5.照明设备,如荧光灯;WEEE : 不包含RoHS:包括家用的白炙灯泡和光源6.电气和电子工具,如电锯、缝纫机;7.玩具、休闲和运动设备;8.医疗设备(不适用于RoHS)9.监控设备(不适用于RoHS)10.自动售货机RoHS 指令要求–概要2006年7月1日后,新投放市场的电子电气设备不得含有如下受管制的有害物质:•重金属:–Lead 铅(Pb), Cadmium 镉(Cd), Mercury 汞(Hg), Chromium (VI) (Cr 6+).六价铬•某些含溴的阻燃剂–Polybrominated biphenyls (PBB’s);多溴联苯C 12H 10-X Br X (X= 1 to 10)–Polybrominated diphenyl ethers (PBDE’s).多溴二苯醚C 12H 10-X Br X O (X= 1 to 10)RoHS指令要求–概要•EU Technical Adaptation Committee (TAC)欧盟技术采用委员会已经制定基于“均质物质(单一物质)”重量的各有害物质允许的最大浓度(2005/618/EC):•镉0.01 % (100 ppm)•铅,汞,六价铬,多溴联苯(PBBs)和多溴联苯醚(PBDEs)0.1 % (1000 ppm)TAC提议的定义TAC已经提议的关键定义:均质物质(单一物质):不能被机械地分成不同物质的一种物质.均质的(均相的):完全一致的组成成分.如单一的塑胶、金属、玻璃等等机械性分拆:原则上物质可用机械的方法分离拆解例如旋开、切断、压碎、磨碎和研磨等过程实例1 :Printed Circuit Board 印刷电路板1.Coatings(green,white,lacquer) onepoxy resin board环氧树脂板上的表面涂层(绿色,白色和光油) 2.Copper metal in epoxy resin board环氧树脂板上的印刷电路铜片3.Epoxy resin board excluding coatingsand coppermetal不包括涂层及铜片在内的环氧树脂板实例2 : Electrolytic Capacitor电解电容1.silver colour metal (terminal pin)银色金属(接脚)2.plastic with coatings (external sleeve)塑料连同表面涂层(外套管)3.silver colour metal (internal sleeve)银色金属(内套管)4.black rubber (pad of sleeve)黑色橡胶(套管垫)5.internal electrolytic paper withelectrolytic oil内电解纸连同电解油6.internal electrolytic aluminium内电解铝箔电子元件的拆解案例实例3 :Cable Wire Covering 外电源线-Black plastic wire covering with whiteprinting连同白色印刷的黑色塑料外线Internal Metal Cable Line 金属电源内线-Copper metal with transparent coatedpolymer连同透明高聚物被服层的铜金属请列举3种不需要RoHS检测的带电产品•香烟报警器•电子秤•测试仪器•医疗器械RoHS检测的不同参考方法RoHS检测的不同参考方法重金属分析(铅, 镉, 汞)仪器•Inductively coupled argon plasma optical emission spectrometry (ICP-AES)等离子耦合原子发射光谱仪•Inductively coupled argon plasma mass spectrometry (ICP-MS)等离子耦合原子发射光谱质谱仪•Flame atomic absorption spectrometry (FAAS)火焰原子吸收光谱仪•Graphite furnace atomic absorption spectrometry (GFAAS)石墨炉原子吸收光谱仪适用的方法•测试材料需要被完全消解(溶解)成液体形态.•测试材料中的重金属可被定量测试. (达百万分之一(ppm)级或更低)NHCONHNH NHDiphenylcarbazideCr 6++二苯卡巴肼选择性地与六价铬反应生成紫红色复合物,但是不与三价铬反应。

rohs检测报告为了确保产品对环境和人类健康的安全,许多国家和地区都引入了不同的环保标准和法规。

其中,RoHS(限制使用某些有害物质指令)是一个重要的检测标准,旨在限制电子和电气设备中使用的一些有害物质。

本文将探讨RoHS检测报告的重要性以及它在保护环境方面的作用。

首先,RoHS检测报告是一份非常重要的文件。

它记录了产品中所含有害物质的含量,如铅、镉、汞、六价铬等。

这些物质在产品的制造和使用过程中可能对环境和人类健康产生负面影响。

通过对产品进行RoHS检测并获得合格的检测报告,消费者可以放心购买并使用这些产品,而不必担心其中的有害物质会对自己或环境造成伤害。

其次,RoHS检测报告对保护环境具有重要意义。

有害物质的使用和排放是环境污染的主要原因之一。

通过引入RoHS检测标准,可以有效降低产品制造和使用过程中有害物质的释放量。

产品制造商必须在生产过程中严格控制有害物质的使用,以符合相应的检测标准。

这不仅可以降低污染物排放,减少土壤、空气和水资源的污染,也有助于保护生态系统的平衡和人类健康。

此外,RoHS检测报告也对产品质量和可持续发展具有积极作用。

产品中的有害物质不仅对环境有害,而且可能对产品的功能和质量产生负面影响。

通过对产品进行RoHS检测并获得合格报告,制造商可以确保其产品符合环保标准,同时提供高质量的产品给消费者。

这有助于提升企业的声誉和竞争力,推动可持续发展。

然而,RoHS检测并非一项简单的任务。

由于现代电子产品的复杂性和多样性,确保每个部件都符合RoHS标准是一项挑战。

生产商需要与供应商密切合作,确保所使用的材料和零部件符合相应的标准。

此外,RoHS检测的准确性和可靠性也是一个关键问题。

为了避免不符合RoHS标准的产品进入市场,监管机构和第三方检测机构需要严格执行检测程序,保证结果的准确性和可信度。

综上所述,RoHS检测报告在产品质量保证、环境保护和可持续发展方面都具有重要作用。

通过RoHS检测,消费者可以放心使用符合环保标准的产品,同时保护环境和人类健康。

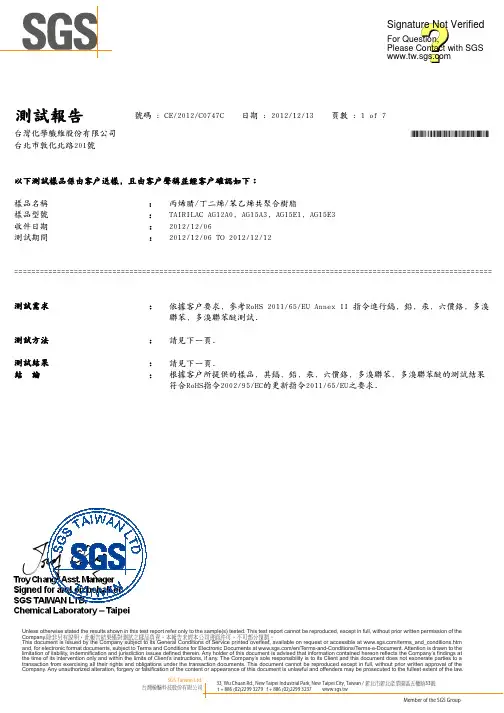

Signature Not VerifiedFor Question, Please Contact with SGS 測試報告台灣化學纖維股份有限公司 台北市敦化北路201號號碼 : CE/2012/C0747C日期 : 2012/12/13頁數 : 1 of 7 *CE/2012/C0747C*以下測試樣品係由客戶送樣, 且由客戶聲稱並經客戶確認如下: 樣品名稱 樣品型號 收件日期 測試期間 : : : : 丙烯腈/丁二烯/苯乙烯共聚合樹脂 TAIRILAC AG12A0, AG15A3, AG15E1, AG15E3 2012/12/06 2012/12/06 TO 2012/12/12===================================================================================================================測試需求:依據客戶要求, 參考RoHS 2011/65/EU Annex II 指令進行鎘, 鉛, 汞, 六價鉻, 多溴 聯苯, 多溴聯苯醚測試. 請見下一頁. 請見下一頁. 根據客戶所提供的樣品, 其鎘, 鉛, 汞, 六價鉻, 多溴聯苯, 多溴聯苯醚的測試結果 符合RoHS指令2002/95/EC的更新指令2011/65/EU之要求.測試方法 測試結果 結 論: : :Unless otherwise stated the results shown in this test report refer only to the sample(s) tested. This test report cannot be reproduced, except in full, without prior written permission of the Company. This document is issued by the Company subject to its General Conditions of Service printed overleaf, available on request or accessible at /terms_and_conditions.htm and, for electronic format documents, subject to Terms and Conditions for Electronic Documents at /en/Terms-and-Conditions/Terms-e-Document. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. This document cannot be reproduced except in full, without prior written approval of the Company. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.SGS Taiwan Ltd.33, Wu Chuan Rd., New Taipei Industrial Park, New Taipei City, Taiwan / t + 886 (02)2299 3279 f + 886 (02)2299 3237 www.sgs.tw 33Member of the SGS Grouplly signed by wmholetech.2012.12.13 :32 CST測試報告台灣化學纖維股份有限公司 台北市敦化北路201號號碼 : CE/2012/C0747C日期 : 2012/12/13頁數 : 2 of 7 *CE/2012/C0747C*測試結果 測試部位 測試部位 測試部位 測試部位 No.1 No.2 No.3 No.4 測試項目 鎘 鉛 汞 六價鉻 多溴聯苯總和 一溴聯苯 二溴聯苯 三溴聯苯 四溴聯苯 五溴聯苯 六溴聯苯 七溴聯苯 八溴聯苯 九溴聯苯 十溴聯苯 多溴聯苯醚總和 一溴聯苯醚 二溴聯苯醚 三溴聯苯醚 四溴聯苯醚 五溴聯苯醚 六溴聯苯醚 七溴聯苯醚 八溴聯苯醚 九溴聯苯醚 十溴聯苯醚 : : : : 單位 mg/kg mg/kg mg/kg mg/kg 米色塑膠粒 米色塑膠粒 米色塑膠粒 米色塑膠粒 (AG12A0) (AG15A3) (AG15E1) (AG15E3) 測試方法 參考IEC 62321: 2008方法, 以 感應耦合電漿原子發射光譜儀 (ICP-AES)檢測. 參考IEC 62321: 2008方法, 以 UV-VIS檢測. 方法偵測 極限值 2 2 2 2 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 5 結果 No.2 No.3 n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. 法規 限值 100 1000 1000 1000 1000 1000 -No.1 n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d.No.4 n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d.mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg 參考IEC 62321: 2008方法, 以 mg/kg 氣相層析/質譜儀(GC/MS)檢測. mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg mg/kg mg/kgUnless otherwise stated the results shown in this test report refer only to the sample(s) tested. This test report cannot be reproduced, except in full, without prior written permission of the Company. This document is issued by the Company subject to its General Conditions of Service printed overleaf, available on request or accessible at /terms_and_conditions.htm and, for electronic format documents, subject to Terms and Conditions for Electronic Documents at /en/Terms-and-Conditions/Terms-e-Document. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. This document cannot be reproduced except in full, without prior written approval of the Company. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.SGS Taiwan Ltd.33, Wu Chuan Rd., New Taipei Industrial Park, New Taipei City, Taiwan / t + 886 (02)2299 3279 f + 886 (02)2299 3237 www.sgs.tw 33Member of the SGS Group測試報告台灣化學纖維股份有限公司 台北市敦化北路201號號碼 : CE/2012/C0747C日期 : 2012/12/13頁數 : 3 of 7 *CE/2012/C0747C*備註: 1. 2. 3. 4. 5.mg/kg = ppm;0.1wt% = 1000ppm n.d. = Not Detected / 未檢出 MDL = Method Detection Limit / 方法偵測極限值 "-" = Not Regulated / 無規格值 此份報告取代CE/2012/C0747A報告.Unless otherwise stated the results shown in this test report refer only to the sample(s) tested. This test report cannot be reproduced, except in full, without prior written permission of the Company. This document is issued by the Company subject to its General Conditions of Service printed overleaf, available on request or accessible at /terms_and_conditions.htm and, for electronic format documents, subject to Terms and Conditions for Electronic Documents at /en/Terms-and-Conditions/Terms-e-Document. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. This document cannot be reproduced except in full, without prior written approval of the Company. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.SGS Taiwan Ltd.33, Wu Chuan Rd., New Taipei Industrial Park, New Taipei City, Taiwan / t + 886 (02)2299 3279 f + 886 (02)2299 3237 www.sgs.tw 33Member of the SGS Group測試報告台灣化學纖維股份有限公司 台北市敦化北路201號號碼 : CE/2012/C0747C日期 : 2012/12/13頁數 : 4 of 7 *CE/2012/C0747C*1) 根據以下的流程圖之條件,樣品已完全溶解。

rohs测试报告近年来,随着环保意识的不断提升,ROHS测试报告成为了企业必备的一份重要文件。

ROHS(Restriction of Hazardous Substances)指令是欧洲议会和理事会制定的,旨在限制和防止电子电气设备中有害物质对人体健康和环境造成的危害。

ROHS指令禁止使用六种有害物质:铅(Pb)、汞(Hg)、镉(Cd)、六价铬(Cr6+)、多溴联苯(PBBs)和多溴二苯醚(PBDEs)。

这些物质被广泛应用于电子电气设备中,如计算机、手机、家电等。

然而,经过科学研究和实践证明,这些物质对人体健康和环境都存在潜在的危险。

ROHS测试报告的核心内容是对产品中这些有害物质的检测结果。

首先,专业的实验室会采集样本,包括产品中的关键部件和材料。

然后,通过一系列的分析方法,如X射线荧光光谱分析、火焰原子吸收光谱分析等,对样本中的有害物质进行定量检测。

最后,将检测结果用报告的形式呈现给客户。

ROHS测试报告的重要性不言而喻。

首先,它是企业进入国际市场的必要条件。

许多国家和地区都对进口产品的ROHS合规性提出了严格要求。

持有ROHS测试报告,可以证明企业的产品符合相关标准,有助于消除贸易壁垒,提高产品的国际竞争力。

其次,ROHS测试报告也是企业实施环保策略的重要手段。

在我们的生活中,电子电气设备无处不在。

然而,对于过去被广泛使用的有害物质,我们不得不承认其带来的环境和健康问题。

ROHS指令的出台,促使企业转变生产和经营方式,采用更环保的材料和工艺。

ROHS测试报告成为了企业自我监督和维护形象的方式之一。

同时,ROHS测试报告也为消费者提供了重要的参考信息。

在购买电子电气设备时,如何判断产品是否真正符合环保要求,是否存在潜在的危害物质?ROHS测试报告可以为消费者提供权威的数据依据,让消费者更加放心和明智地选购产品。

然而,ROHS测试报告也存在一些挑战和争议。

首先,测试过程可能存在一定的复杂性和成本。

rohs检测报告目录1. 检测报告的重要性1.1 保障产品质量1.1.1 符合法律法规要求1.1.2 保护消费者权益1.2 开拓市场1.2.1 提升品牌形象1.2.2 满足客户需求2. ROHS检测方法2.1 环保标准2.1.1 检测范围2.1.2 检测过程2.2 检测仪器2.2.1 XRF仪器2.2.2 FTIR仪器3. 报告结果解读3.1 合格与不合格3.1.1 各项指标标准3.1.2 需改进的地方3.2 未来改进方向3.2.1 替代材料选择3.2.2 生产工艺改进检测报告的重要性保障产品质量符合法律法规要求ROHS检测报告对产品进行严格检测,确保产品在材料使用上符合国家相关法律法规的要求,避免因使用禁用物质而引发风险。

保护消费者权益ROHS检测报告可以保证产品的材料安全性,消费者在购买时可以放心使用,避免对健康造成潜在威胁。

开拓市场提升品牌形象ROHS检测合格的产品可以证明企业对环保和消费者健康的重视,提升品牌形象,吸引更多消费者购买。

满足客户需求ROHS检测报告可以向客户证明产品的安全性和环保性,满足客户对产品质量的要求,提升客户满意度,促进销售。

ROHS检测方法环保标准检测范围ROHS检测主要针对电子电气产品,检测包括铅、汞、镉、六价铬等有害物质的含量,确保产品材料符合环保标准。

检测过程ROHS检测过程包括取样、样品制备、检测仪器分析等步骤,通过专业仪器对样品进行分析,得出检测结果。

检测仪器XRF仪器XRF仪器可以快速准确地检测出样品中的有害物质元素含量,是ROHS检测过程中常用的仪器之一。

FTIR仪器FTIR仪器可以通过样品的红外光谱特征来检测出样品中的物质成分,用于辅助ROHS检测结果的分析。

报告结果解读合格与不合格各项指标标准ROHS检测报告中包括各项有害物质的含量标准,产品在各项指标上符合标准即为合格,否则为不合格。

需改进的地方ROHS检测报告会指出产品中存在的不合格项,企业需要根据报告中的数据和建议进行改进,以达到合格标准。

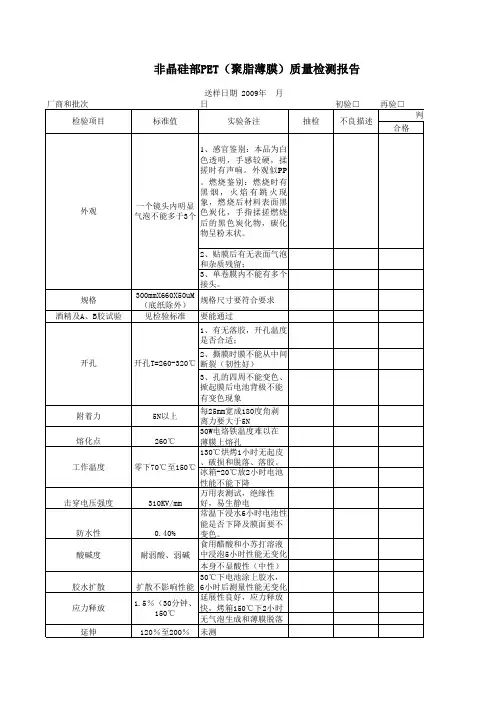

PET膜检验报告PET膜是一种常用的塑料膜材料,广泛应用于包装、印刷、电子等领域。

为了确保PET膜的质量符合相关标准和客户要求,需要进行严格的检验。

本报告旨在对PET膜的检验结果进行详细的介绍和分析。

一、PET膜外观检验PET膜外观检验是通过观察PET膜的表面质量、色泽等方面来判断其是否符合要求。

在本次检验中,我们对PET膜进行了外观检验,并将检验结果如下:1.表面平整度:PET膜表面应平整、光滑,不应有明显的皱纹、褶皱、气泡等缺陷。

经过观察,本次检验的PET膜表面平整度良好,没有出现明显的缺陷。

2.厚度均匀性:PET膜的厚度应均匀一致,不应有过厚或过薄的现象。

通过测量多个样品的厚度,并求得平均值,本次检验的PET膜厚度均匀性符合要求。

3.色泽一致性:PET膜的色泽应一致,不应有明显的色差。

我们对多个样品的颜色进行了比对,发现本次检验的PET膜色泽一致,没有出现色差现象。

综上所述,PET膜在外观检验方面通过了检验,表面平整度良好,厚度均匀性和色泽一致性符合要求。

二、PET膜物理性能检验PET膜的物理性能检验包括拉伸强度、撕裂强度、热收缩率等指标的测定。

为了保证PET膜的使用性能,我们对PET膜的物理性能进行了测定和分析,具体结果如下:1.拉伸强度:PET膜的拉伸强度是衡量其抗拉性能的重要指标。

我们通过拉伸试验仪对多个样品进行了拉伸强度测试,得到了它们的拉伸强度值。

经过计算和比对,本次检验的PET膜拉伸强度符合标准要求。

2.撕裂强度:PET膜的撕裂强度是衡量其耐撕裂性能的指标。

我们选取了多个样品进行撕裂强度测试,并对测试结果进行了分析。

经过比对,本次检验的PET膜撕裂强度符合标准要求。

3.热收缩率:PET膜的热收缩率是指在一定温度下PET膜的收缩变化。

我们对多个样品进行了热收缩率测试,并按照相关标准要求进行了计算和比对。

经过分析,本次检验的PET膜热收缩率在合理范围之内,符合要求。

综上所述,PET膜在物理性能检验方面也通过了检验,拉伸强度、撕裂强度和热收缩率符合标准要求。

rohs检测报告模板篇一:SGS RoHS测试报告模板Test ReportNo. CANEC13Date: 12 May 20XXPagel of 5 Co.,LTD.SHANGMEILIN District .ShenzhenThe following sample was/were submitted and identified on behalf of the clients as : SGS Job No :Date of SampleReceived :Testing Period :Test Requested :Test Method :Test Results :Conclusion :CP13-- GZ09 May 20XX09 May 20XX -12 May 20XXSelected test as requested by clientPlease refer to next pagePlease refer to next pageBased on the performed tests on submitted samples, the results of Lead, Mercury, Cadmium, Hexavalent chromium, Polybrominated biphenyls , Polybrominated diphenyl ethers xxply with the limits as set by RoHS Directive20XX/65/EU Annex II; recasting 20XX/95/ECSigned for and on behalf of SGS-CSTC Ltd.MErry Lv Approved SignatoryTest ReportTest Results :No. CANEC13Date: 12 May 20XXPage 2 of 5Specimen Sample IDDescription1CAN13- Green fluidRemarks : 1 mg/kg = 1 ppm= %MDL= Method Detection Limit ND = Not Detected "-" = Not RegulatedRoHS Directive 20XX/65/EUTest Method :With reference to IEC 62321:20XX:Determination of Cadmium by ICP-OES.Determination of Lead by ICP-OES. Determination of Mercury by ICP-OES.Determination of Hexavalent Chromium by Colorimetric Method using UV-Vis. Determination of PBBs / PBDEs content by GC-MS.Test ItemCadmium Lead Mercury Hexavalent Chromium Sum of PBBsMonobromobiphenylDibromobiphenylTribromobipheny ITetrabromobiphenylPentabromobiphenylHexabromobiphe nylHeptabromobiphenylOctabromobiphenylNonabromobiph enyl DecabromobiphenylSum of PBDEsMonobromodiphenyl etherLimitlOO 1,000 1,000 1,000 1,000 --------------- 1,000 -Unitmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgmg/kgMDL2 2 2 2 - 5 5 5 5 5 5 5 5 5 5 - 5002ND ND ND ND ND ND ND ND ND ND ND ND ND ND ND ND NDTest ReportTest ItemDibromodiphenyl etherTribromodiphenyl etherTetrabromodiphenyl etherPentabromodiphenyl etherHexabromodiphenyl etherHeptabromodiphenyl etherOctabromodiphenyl etherNonabromodiphenyl etherDecabromodiphenyl etherNotes :No. CANEC13Date: 12 May 20XXPage 3 of 5Limit- --------------- -- -Unitmg/kg5 mg/kg5 mg/kg5 mg/kg5mg/kg5 mg/kg5 mg/kg5 mg/kg5 mg/kg5NDND ND ND ND ND ND ND NDThe maximum permissible limit is quoted from the directive20XX/65/EU, Annex IINote: the results shown for the content of totalweight in wet sample..Test ReportATTACHMENTSNo. CANEC13Date: 12 May 20XXPage 4 of 5RoHS Testing Flow Chart1) Nameof the person who made testing : Michael Tso / Cutey Yu / Dayi Zhan 2) Name of the person in charge of testing : Adams Yu / Yolanda Wei3) These samples were dissolved totally by pre -conditioning method according to below flow chart .Sample PreparationTest ReportSample photo:No. CANEC13Date: 12 May 20XXPage 5 of 5SGSauthenticate the photo on original report only*** End of Report ***篇二:rohs检测认证,rohs检测标准,rohs检测报告rohs检测认证,rohs检测标准,rohs检测报告ROHS检测方法将相关产品送往专业实验室进行检测,要将产品拆分为单一材质既均一材质后进行测试,其中铅、镉、汞、六价铬、多溴联苯、多溴二苯醚等六种有害物质是否符合RoHS指令要求,若符合就可获得RoHS合格报告和证书,若不符合,就得另找符合要求的产品进行替代。

rohs检测报告ROHS检测报告。

ROHS指令是欧盟针对电子电气产品中的有害物质所制定的指令,全称为限制使用某些有害物质在电子电气设备中的使用指令。

该指令规定了在欧盟境内销售的电子电气产品中,禁止或者限制使用铅、汞、镉、六价铬、多溴联苯、多溴二苯醚等有害物质。

为了确保产品符合ROHS指令的要求,需要进行ROHS检测,并出具ROHS检测报告。

ROHS检测报告是对产品中有害物质含量的检测结果进行汇总和分析的报告,是产品是否符合ROHS指令的重要依据。

ROHS检测报告通常包括以下内容:1. 产品信息,包括产品名称、型号、规格、生产日期等基本信息。

2. 检测标准,列出了本次检测所采用的标准和方法,通常是欧盟ROHS指令的相关标准。

3. 检测结果,对产品中有害物质的含量进行检测,包括铅、汞、镉、六价铬、多溴联苯、多溴二苯醚等物质的含量测试结果。

4. 结论,根据检测结果,对产品是否符合ROHS指令的要求进行结论性陈述,明确指出产品是否合格。

ROHS检测报告的编制需要严格按照相关标准和方法进行,确保检测结果的准确性和可靠性。

一般来说,ROHS检测报告由专业的第三方检测机构出具,具有权威性和可信度。

ROHS检测报告的作用主要体现在以下几个方面:首先,ROHS检测报告是产品进入欧盟市场的必备文件之一。

欧盟对产品的ROHS指令要求非常严格,产品如果没有ROHS检测报告,将无法进入欧盟市场销售。

其次,ROHS检测报告是产品质量的重要证明。

ROHS指令是为了保护人类健康和环境安全而制定的,产品通过ROHS检测并出具合格的ROHS检测报告,可以证明产品不含有害物质,对人体和环境无害。

最后,ROHS检测报告也是企业产品质量管理的重要依据。

通过ROHS检测,企业可以了解产品中有害物质的含量情况,及时采取措施进行改进,提高产品质量,增强市场竞争力。

总之,ROHS检测报告是产品符合ROHS指令要求的重要证明文件,对于产品进入欧盟市场、保障产品质量、提升企业竞争力都具有重要意义。

ROHS检测报告样本1. 引言ROHS (Restriction of Hazardous Substances) 检测报告是一份用于证明产品是否符合欧盟ROHS指令要求的文件。

ROHS指令旨在限制和禁止电子电气设备中使用的有害物质,从而保护人体健康和环境。

本文将介绍ROHS检测报告样本的主要内容和编写步骤。

2. 报告标题ROHS检测报告样本的标题应准确而简洁,以便清楚地传达报告的目的和内容。

一个好的标题可以吸引读者的注意力,并帮助他们快速了解报告的主要信息。

3. 报告正文3.1 测试目的在ROHS检测报告样本中,首先需要明确测试的目的。

这通常是为了验证产品是否符合ROHS指令中规定的限制物质的含量要求,从而确保产品的质量和安全性。

3.2 测试范围测试范围部分应包含检测的具体内容和方法。

它可以包括被测物的种类、测试的数量和质量标准等信息。

此外,还应提供测试所使用的设备和方法的相关细节。

3.3 测试结果测试结果是ROHS检测报告样本的核心内容。

在这一部分,应列出每种限制物质的测试结果,并与ROHS指令的要求进行对比。

测试结果通常以数值或百分比的形式呈现,并附有相关的单位和测试标准。

3.4 结果分析结果分析部分用于解释测试结果的含义和影响。

它可以讨论是否符合ROHS指令的要求,以及若不符合,可能引发的问题和风险。

此外,还应提供建议和措施,以满足ROHS指令的要求。

结论部分是对测试结果和分析的总结。

根据测试结果,判断产品是否符合ROHS指令的要求,并指出所测试物质是否超过允许的限制。

如果产品符合要求,应明确表示产品是ROHS合规的。

3.6 附录附录部分用于提供与ROHS检测报告相关的额外信息和支持文件。

这可以包括测试记录、数据表、照片等。

附录可以帮助读者更好地理解报告中提供的信息,并验证测试结果的可靠性。

4. 编写步骤根据上述内容,以下是编写ROHS检测报告样本的一般步骤:4.1 标题选择一个准确而简洁的标题,概括报告的主要内容和目的。

rohs报告ROHS报告。

ROHS指令是欧盟针对电子电气产品的限制使用有害物质的指令,全称为限制使用某些有害物质在电子电气设备中指令。

该指令于2003年2月13日正式颁布,要求在欧盟市场上销售的电子电气产品和电子电气设备不得含有铅、汞、镉、六价铬、多溴联苯、多溴二苯醚等有害物质。

ROHS指令的实施,对电子电气产品和电子电气设备的生产、销售和进口都提出了严格的要求。

ROHS报告是对产品是否符合ROHS指令的一种证明,也是进入欧盟市场的必备文件之一。

ROHS报告需要由专业的认证机构进行检测和评估,确保产品不含有限制使用的有害物质,符合ROHS指令的要求。

ROHS报告的编制需要严格按照相关标准和规定进行,主要包括以下几个方面的内容:首先,ROHS报告需要包括产品的基本信息,如产品名称、型号、生产日期、生产厂家等。

这些信息对于产品的追溯和识别至关重要,也是ROHS报告的基础信息。

其次,ROHS报告需要包括产品的检测结果,主要是针对限制使用的有害物质进行检测。

检测结果需要明确列出各项有害物质的含量,确保产品不含有限制使用的有害物质,符合ROHS指令的要求。

另外,ROHS报告还需要包括产品的合规性评价,对产品是否符合ROHS指令的要求进行评价和总结。

评价内容需要客观、准确地反映产品的合规性情况,为产品的进入欧盟市场提供有力的证明。

最后,ROHS报告需要由专业的认证机构进行签发,确保报告的真实性和可靠性。

签发机构需要具备一定的资质和信誉,对产品的合规性进行严格的审核和评定。

总的来说,ROHS报告是产品进入欧盟市场的重要凭证之一,对于生产厂家和出口商来说,及时编制和获取ROHS报告,确保产品符合ROHS指令的要求,是非常重要的。

同时,ROHS报告的编制需要严格按照相关标准和规定进行,确保报告的真实性和可靠性。

只有这样,产品才能顺利进入欧盟市场,获得更多的商机和发展空间。

在这个全球化的时代,产品的合规性和质量安全问题越来越受到重视,ROHS 报告的编制和获取对于企业来说是一项必不可少的工作。

rohs分析报告ROHS 分析报告一、ROHS 简介ROHS,即《关于限制在电子电气设备中使用某些有害成分的指令》,是由欧盟立法制定的一项强制性标准。

其旨在限制电子电气产品中六种有害物质的使用,包括铅(Pb)、汞(Hg)、镉(Cd)、六价铬(Cr6+)、多溴联苯(PBB)和多溴二苯醚(PBDE)。

ROHS 指令的出台,对于保护环境、保障人类健康以及促进电子电气行业的可持续发展具有重要意义。

二、ROHS 检测的重要性1、环境保护这些被限制的有害物质在电子电气产品废弃后,如果处理不当,可能会进入土壤、水源和大气中,对生态环境造成严重污染。

例如,铅会损害神经系统和肾脏功能,汞会对中枢神经系统和肾脏造成损害,镉会导致骨骼和肾脏损伤,六价铬具有致癌性,而多溴联苯和多溴二苯醚则是持久性有机污染物,对环境和生物具有长期的危害。

2、人类健康消费者在长期使用含有这些有害物质的电子电气产品时,可能会通过皮肤接触、呼吸或误食等途径摄入有害物质,从而对身体健康产生潜在威胁。

尤其是儿童、孕妇和老年人等敏感人群,更容易受到这些有害物质的影响。

3、市场准入许多国家和地区都将符合 ROHS 标准作为电子电气产品进入市场的必要条件。

如果产品不符合 ROHS 要求,将面临被召回、罚款甚至禁止销售的风险,这将给企业带来巨大的经济损失。

三、ROHS 检测方法1、化学分析方法如原子吸收光谱法(AAS)、电感耦合等离子体发射光谱法(ICPOES)和电感耦合等离子体质谱法(ICPMS)等,这些方法可以准确测定样品中各种元素的含量。

2、色谱分析方法用于检测多溴联苯和多溴二苯醚等有机污染物,如气相色谱法(GC)和高效液相色谱法(HPLC)。

3、 X 射线荧光光谱法(XRF)这是一种快速筛选方法,可以初步判断样品中是否含有被限制的元素,但对于含量较低的情况可能不够准确,需要进一步采用化学分析方法进行确认。

四、ROHS 检测流程1、样品采集根据产品的类型和特点,选择具有代表性的样品进行检测。

rohs检测报告ROHS指的是欧洲有害物质限制指令,旨在限制电子电气产品中有害物质的使用,以保护人们的健康和环境。

ROHS检测报告是对产品进行检测,以确定其是否符合ROHS指令的要求。

以下是一份700字的ROHS检测报告范例:ROHS检测报告产品名称:XXXXXX检测编号:XXXX1. 检测标准本次检测参照欧洲有害物质限制指令(ROHS)2011/65/EU的要求进行,包括以下有害物质的限制:- 铅 (Pb)- 汞 (Hg)- 镉 (Cd)- 六价铬 (Cr6+)- 多溴联苯 (PBB)- 多溴二苯醚 (PBDE)2. 检测方法检测采用X射线荧光分析(XRF)仪器进行,该方法可快速、准确地检测样品中的有害物质含量。

3. 检测结果以下是该产品中各有害物质的含量,并与ROHS指令的要求进行对比:- 铅 (Pb): 该产品中铅的含量为300 ppm,低于ROHS指令要求的1000 ppm。

- 汞 (Hg): 该产品中汞的含量为未检测到,远低于ROHS指令要求的1000 ppm。

- 镉 (Cd): 该产品中镉的含量为未检测到,远低于ROHS指令要求的100 ppm。

- 六价铬 (Cr6+): 该产品中六价铬的含量为150 ppm,低于ROHS指令要求的1000 ppm。

- 多溴联苯 (PBB): 该产品中多溴联苯的含量为未检测到,符合ROHS指令要求的1000 ppm以下。

- 多溴二苯醚(PBDE): 该产品中多溴二苯醚的含量为未检测到,符合ROHS指令要求的1000 ppm以下。

根据以上检测结果,该产品符合ROHS指令的要求,可安全地投入市场和使用。

4. 检测日期本次检测的日期为XX年XX月XX日。

5. 检测机构本次检测由XXX检测机构进行,该机构具备相关资质和设备,可提供准确可靠的检测结果。

6. 结论根据本次ROHS检测结果,该产品中的铅、汞、镉、六价铬、多溴联苯和多溴二苯醚等有害物质的含量均符合ROHS指令的要求。

Test Report No. 2410007/TY Date : Feb 22 2012 Page 1 of 3This document is issued by the Company subject to its General Conditions of Service printed overleaf, available on request or accessible at /terms_and_conditions.htm and, for electronic format documents, subject to Terms and Conditions for Electronic Documents at /terms_e-document.htm. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. This document cannot be reproduced except in full, without prior written approval of the Company. Any unauthorized alteration, forgery or falsification of the content orEVER BRIGHT PRINTING MACHINE FTY. LTD.18/F. SOUTH CHINA IND. BLDG.NO.1 CHUNG PIN STREETKWAI CHUNGHONG KONGThe following samples were submitted and identified on behalf of the client asDIC - 811 NEW UPPNO# S/11, 13NT, S/14, 15NT, S/23, 25NT, S/33, 38G, S/41, S/48, S/53, S/55, S/69, S/75, S/81, 83, 14, 42, 53, 57, 59, 77, 95SGS Job No. : 4142570Style / Item No. : 811 NEW UPPManufacturer : DIC ASIA PACIFIC PTE LTDCountry of Origin : SINGAPORESample Receiving Date : FEB 17 2012Testing Period : FEB 17 – 22 2012Test Requested : Please refer to the result summary.Test Method & Results : Please refer to next page(s).Result Summary :Test RequestedConclusionEuropean RoHS Directive 2011/65/EU Annex II; recasting 2002/95/EC(As per client’s request)PASSSigned for and on behalf ofSGS Hong Kong Ltd.Choi Man Kit, AndySection ManagerTest Report No. 2410007/TY Date : Feb 22 2012 Page 2 of 3This document is issued by the Company subject to its General Conditions of Service printed overleaf, available on request or accessible at /terms_and_conditions.htm and, for electronic format documents, subject to Terms and Conditions for Electronic Documents at /terms_e-document.htm. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. This document cannot be reproduced except in full, without prior written approval of the Company. Any unauthorized alteration, forgery or falsification of the content orTest Results :European RoHS Directive 2011/65/EU Annex II; recasting 2002/95/ECCadmium, Lead, Mercury, Hexavalent Chromium, Polybromobiphenyl (PBB) and Polybromodiphenyl ether (PBDE) contentMethod : With reference to IEC 62321:2008. Lead, Cadmium and Mercury were analyzed by InductivelyCoupled Argon Plasma Spectrometry, Chromium (VI) was analyzed by UV-Visible Spectroscopy and PBB, PBDE were analyzed by Gas Chromatography – Mass Spectrometry (GC-MS). Result (mg/kg) Test Item 1Reporting Limit (mg/kg) Permissible Limit (mg/kg) Cadmium (Cd) ND 5 100 Lead (Pb) ND 5 1000 Mercury (Hg) ND 5 1000 Hexavalent Chromium (Cr(VI)) ND 5 1000 Sum of PBBs ND -- 1000 Monobromobiphenyl ND 5 -- Dibromobiphenyl ND 5 -- Tribromobiphenyl ND 5 -- Tetrabromobiphenyl ND 5 -- Pentabromobiphenyl ND 5 -- Hexabromobiphenyl ND 5 -- Heptabromobiphenyl ND 5 -- Octabromobiphenyl ND 5 -- Nonabromobiphenyl ND 5 -- Decabromobiphenyl ND 5 -- Sum of PBDEs ND -- 1000 Monobromodiphenyl ether ND 5 -- Dibromodiphenyl ether ND 5 -- Tribromodiphenyl ether ND 5 -- Tetrabromodiphenyl ether ND 5 -- Pentabromodiphenyl ether ND 5 -- Hexabromodiphenyl ether ND 5 -- Heptabromodiphenyl ether ND 5 -- Octabromodiphenyl ether ND 5 -- Nonabromodiphenyl ether ND 5 -- Decabromodiphenyl ether ND 5 -- Comment PASS -- --Sample Description:1. Dk. Grey InkNote : 1. mg/kg = milligram per kilogram2. ND = Not DetectedTest Report No. 2410007/TY Date : Feb 22 2012 Page 3 of 3This document is issued by the Company subject to its General Conditions of Service printed overleaf, available on request or accessible at /terms_and_conditions.htm and, for electronic format documents, subject to Terms and Conditions for Electronic Documents at /terms_e-document.htm. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this document is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. This document cannot be reproduced except in full, without prior written approval of the Company. Any unauthorized alteration, forgery or falsification of the content or*** End of Report ***。

rohs测试报告

ROHS测试报告

ROHS指令是欧盟制订的一项标准,旨在限制和禁止在电子和电气设备中使用对人类健康和环境有害的物质。

ROHS测试报告是对产品进行ROHS指令要求的检测和评估后所生成的报告。

ROHS测试报告通常包括以下内容:

1. 产品信息:报告中包含了被测试产品的详细信息,如产品名称、型号、生产日期等。

2. 测试对象:报告中会说明被测试产品所包含的各种物质和材料,并对其进行分析和测试。

3. 测试方法:报告会详细说明测试所采用的方法和标准,以确保测试的准确性和可靠性。

4. 检测结果:报告中会列出每种物质或材料测试的结果,以及结果是否符合ROHS指令的要求。

5. 符合性声明:如果测试结果符合ROHS指令的要求,报告中会包含一份符合性声明,证明产品是符合标准的。

ROHS测试报告是一份重要的文件,可以证明产品在使用过程中不会对人类健康和环境造成危害。

对于出口至欧盟国家的电子和电气设备来说,ROHS测试报告是必备的文件,否则产品

将无法通过海关检查。

为了确保产品符合ROHS指令的要求,企业可以委托认可的实验室进行ROHS测试,并获得该实验室出具的ROHS测试报告。

这将有助于企业证明产品的合规性,并提高产品的市场竞争力。

Signature Not VerifiedFor Question, Please Contact with SGS 測試報告 Test Report高冠企業股份有限公司 KK ENTERPRISE CO., LTD.號碼(No.) : CE/2010/83662A日期(Date) : 2010/08/30頁數(Page) : 1 of 16*CE/2010/83662A*南投市南崗工業區自強三路1號 NANKANG INDUSTRIAL PARK NO. 1 TSUCHIANG 3RD. RD. NAN-TOU CITY 以下測試樣品係由客戶送樣, 且由客戶聲稱並經客戶確認如下 (The following samples was/were submitted and identified by/on behalf of the client as): 樣品名稱(Sample Description) 樣品型號(Style/Item No.)收件日期(Sample Receiving Date): PET合成膜 (SYNTHETIC WHITE POLYESTER FILM) : TYP50.TYP25.TYP75、TYPJ50、TYPJ75 : 2010/08/19 : 2010/08/19 TO 2010/08/25 AND 2010/08/26 TO 2010/08/30測試期間(Testing Period)==================================================================================================================== 測試結果(Test Results) : 結論(Conclusion) : 請見下一頁 (Please refer to next pages). 1. 根據客戶所提供的樣品, 其多苯環芳香族化合物的測試結果符合德國ZLS的ZEK 01.2-08及 其相關修訂文件中的第1類PAHs要求 (Base upon the performed tests by submitted samples, the test results of PAHs comply with the PAHs requirement according to (Category 1) of ZEK 01.2-08 of German ZLS and its amendments.) 2. 根據客戶所提供的樣品, 其鎘、鉛、汞、六價鉻、多溴聯苯及多溴聯苯醚的測試結果符合 RoHS(2002/95/EC)及其修定指令之要求 (Based upon the performed tests by submitted samples, the test results of Cadmium, Lead, Mercury, Hexavalent Chromium Cr(VI), PBBs and PBDEs comply with the limits of RoHS Directive 2002/95/EC and its subsequent amendments).此份報告為加測及合併 CE/2010/83662 之報告 * (This report is added testing and combined with CE/2010/83662)Unless otherwise stated the results shown in this test report refer only to the sample(s) tested. This test report cannot be reproduced, except in full, without prior written permission of the Company. This Test Report is issued by the Company under its General Conditions of Service printed overleaf or available on request and accessible at /terms_and_conditions.htm. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this Test Report is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.SGS Taiwan Ltd.Chemical-Taipei 33 WuChyuan Road, Wuku Industrial Zone, Taipei County, Taiwan /33t + 886 (02)2299 3279 f + 886 (02)2299 3237 Member of the SGS Group (SGS SA)y signed by wmholetech.c2010.08.30 11 08:00測試報告 Test Report高冠企業股份有限公司 KK ENTERPRISE CO., LTD.號碼(No.) : CE/2010/83662A日期(Date) : 2010/08/30頁數(Page) : 2 of 16*CE/2010/83662A*南投市南崗工業區自強三路1號 NANKANG INDUSTRIAL PARK NO. 1 TSUCHIANG 3RD. RD. NAN-TOU CITY 測試結果(Test Results) 測試部位(PART NAME)No.1 : 白色塑膠膜 (WHITE PLASTIC FILM) 方法偵測 極限值 (MDL) 2 結果 (Result) No.1 n.d.法規 限值 (Limit)測試項目 (Test Items) 鎘 / Cadmium (Cd)單位 (Unit)測試方法 (Method)鉛 / Lead (Pb)汞 / Mercury (Hg)六價鉻 / Hexavalent Chromium Cr(VI) by alkaline extraction 聚氯乙烯 / PVC 六溴環十二烷 / Hexabromocyclododecane (HBCDD) (CAS No.: 025637-99-4) 全氟辛烷磺酸 / Perfluorooctane sulfonates (PFOS) PFOS – Acid PFOS – Metal Salt PFOS – Amidemg/kg 參考IEC 62321: 2008方法, 以感應耦合電 漿原子發射光譜儀檢測. / With reference to IEC 62321: 2008 and performed by ICP-AES. mg/kg 參考IEC 62321: 2008方法, 以感應耦合電 漿原子發射光譜儀檢測. / With reference to IEC 62321: 2008 and performed by ICP-AES. mg/kg 參考IEC 62321: 2008方法, 以感應耦合電 漿原子發射光譜儀檢測. / With reference to IEC 62321: 2008 and performed by ICP-AES. mg/kg 參考IEC 62321: 2008方法, 以UV-VIS檢測. / With reference to IEC 62321: 2008 and performed by UV-VIS. ** 以紅外光譜分析及焰色法檢測. / Analysis was performed by FTIR and FLAME Test. mg/kg 參考US EPA 3540C方法, 以氣相層析/質譜 儀檢測. / With reference to US EPA 3540C method. Analysis was performed by GC/MS. mg/kg 參考US EPA 3540C: 1996方法, 以液相層析 /質譜儀檢測全氟辛烷磺酸含量. / With reference to US EPA 3540C: 1996 method for PFOS Content. Analysis was performed by LC/MS.1002n.d.10002n.d.10002n.d.10005Negative n.d.-10n.d.-Unless otherwise stated the results shown in this test report refer only to the sample(s) tested. This test report cannot be reproduced, except in full, without prior written permission of the Company. This Test Report is issued by the Company under its General Conditions of Service printed overleaf or available on request and accessible at /terms_and_conditions.htm. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this Test Report is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.SGS Taiwan Ltd.Chemical-Taipei 33 WuChyuan Road, Wuku Industrial Zone, Taipei County, Taiwan /33t + 886 (02)2299 3279 f + 886 (02)2299 3237 Member of the SGS Group (SGS SA)測試報告 Test Report高冠企業股份有限公司 KK ENTERPRISE CO., LTD.號碼(No.) : CE/2010/83662A日期(Date) : 2010/08/30頁數(Page) : 3 of 16*CE/2010/83662A*南投市南崗工業區自強三路1號 NANKANG INDUSTRIAL PARK NO. 1 TSUCHIANG 3RD. RD. NAN-TOU CITY 方法偵測 極限值 (MDL) mg/kg 參考US EPA 3540C: 1996方法, 以液相層析 10 /質譜儀檢測全氟辛酸(銨)含量. / With reference to US EPA 3540C: 1996 method for PFOA Content. Analysis was performed by LC/MS. mg/kg 參考DIN 53313方法, 以氣相層析儀/質譜儀 10 檢測. / With reference to DIN 53313 method. Analysis was performed by GC/MS. 測試方法 (Method) 0.003 結果 (Result) No.1 n.d.法規 限值 (Limit)測試項目 (Test Items) 全氟辛酸(銨) / PFOA (CAS No.: 000335-67-1)單位 (Unit)-四溴雙酚-A / Tetrabromobisphenol A (TBBP-A) (CAS No.: 000079-94-7)n.d.-可塑劑定量分析 / Phthalates 鄰苯二甲酸甲苯基丁酯 / BBP (Benzyl butyl phthalate) (CAS No.: 000085-68-7) 鄰苯二甲酸二 (2-乙基己基)酯 / DEHP (Di- (2-ethylhexyl) phthalate) (CAS No.: 000117-81-7) 鄰苯二甲酸二異癸酯 / DIDP (Diisodecyl phthalate) (CAS No.: 026761-40-0) 鄰苯二甲酸二異壬酯 / DINP (Diisononyl phthalate) (CAS No.: 028553-12-0) 鄰苯二甲酸二正辛酯 / DNOP (Di-noctyl phthalate) (CAS No.: 000117-84-0) 鄰苯二甲酸二丁酯 / DBP (Dibutyl phthalate) (CAS No.: 000084-74-2) 鄰苯二甲酸二甲酯 / DMP (Di-methyl phathalate) (CAS No.: 000131-113) 鄰苯二甲酸二己酯 / DNHP (Di-nhexyl phthalate) (CAS No.: 000084-75-3) n.d. -0.003n.d.-0.01n.d.-0.01 % 參考EN 14372, 以氣相層析儀/質譜儀檢測 之. / With reference to EN 14372. Analysis was performed by GC/MS.n.d.-0.003n.d.-0.003 0.003n.d. n.d.-0.003n.d.-Unless otherwise stated the results shown in this test report refer only to the sample(s) tested. This test report cannot be reproduced, except in full, without prior written permission of the Company. This Test Report is issued by the Company under its General Conditions of Service printed overleaf or available on request and accessible at /terms_and_conditions.htm. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this Test Report is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.SGS Taiwan Ltd.Chemical-Taipei 33 WuChyuan Road, Wuku Industrial Zone, Taipei County, Taiwan /33t + 886 (02)2299 3279 f + 886 (02)2299 3237 Member of the SGS Group (SGS SA)測試報告 Test Report高冠企業股份有限公司 KK ENTERPRISE CO., LTD.號碼(No.) : CE/2010/83662A日期(Date) : 2010/08/30頁數(Page) : 4 of 16*CE/2010/83662A*南投市南崗工業區自強三路1號 NANKANG INDUSTRIAL PARK NO. 1 TSUCHIANG 3RD. RD. NAN-TOU CITY 方法偵測 極限值 (MDL) 5 5 5 5 5 5 5 5 5 參考IEC 62321: 2008方法, 以氣相層析儀/ 5 mg/kg 質譜儀檢測. / With reference to IEC 62321: 2008 and performed by GC/MS. 5 5 5 5 5 5 5 5 5 5 測試方法 (Method) 50 參考BS EN 14582:2007, 以離子層析儀分 析. / With reference to BS EN mg/kg 14582:2007. Analysis was performed by IC. 50 50 50 結果 (Result) No.1 n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d.測試項目 (Test Items)多溴聯苯總和 / Sum of PBBs 一溴聯苯 / Monobromobiphenyl 二溴聯苯 / Dibromobiphenyl 三溴聯苯 / Tribromobiphenyl 四溴聯苯 / Tetrabromobiphenyl 五溴聯苯 / Pentabromobiphenyl 六溴聯苯 / Hexabromobiphenyl 七溴聯苯 / Heptabromobiphenyl 八溴聯苯 / Octabromobiphenyl 九溴聯苯 / Nonabromobiphenyl 十溴聯苯 / Decabromobiphenyl 多溴聯苯醚總和 / Sum of PBDEs 一溴聯苯醚 / Monobromodiphenyl ether 二溴聯苯醚 / Dibromodiphenyl ether 三溴聯苯醚 / Tribromodiphenyl ether 四溴聯苯醚 / Tetrabromodiphenyl ether 五溴聯苯醚 / Pentabromodiphenyl ether 六溴聯苯醚 / Hexabromodiphenyl ether 七溴聯苯醚 / Heptabromodiphenyl ether 八溴聯苯醚 / Octabromodiphenyl ether 九溴聯苯醚 / Nonabromodiphenyl ether 十溴聯苯醚 / Decabromodiphenyl ether單位 (Unit)法規 限值 (Limit)1000 1000 -鹵素 鹵素 (CAS 鹵素 (CAS 鹵素 (CAS 鹵素 (CAS/ Halogen (氟) / Halogen-Fluorine (F) No.: 014762-94-8) (氯) / Halogen-Chlorine (Cl) No.: 022537-15-1) (溴) / Halogen-Bromine (Br) No.: 010097-32-2) (碘) / Halogen-Iodine (I) No.: 014362-44-8)Unless otherwise stated the results shown in this test report refer only to the sample(s) tested. This test report cannot be reproduced, except in full, without prior written permission of the Company. This Test Report is issued by the Company under its General Conditions of Service printed overleaf or available on request and accessible at /terms_and_conditions.htm. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this Test Report is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.SGS Taiwan Ltd.Chemical-Taipei 33 WuChyuan Road, Wuku Industrial Zone, Taipei County, Taiwan /33t + 886 (02)2299 3279 f + 886 (02)2299 3237 Member of the SGS Group (SGS SA)測試報告 Test Report高冠企業股份有限公司 KK ENTERPRISE CO., LTD.號碼(No.) : CE/2010/83662A日期(Date) : 2010/08/30頁數(Page) : 5 of 16*CE/2010/83662A*南投市南崗工業區自強三路1號 NANKANG INDUSTRIAL PARK NO. 1 TSUCHIANG 3RD. RD. NAN-TOU CITY 方法偵測 極限值 (MDL) 結果 (Result) No.1測試項目 (Test Items) 多苯環芳香族化合物 / Polynuclear Aromatic Hydrocarbons (PAHs) Acenaphthene (CAS No.: 000083-329) Acenaphthylene (CAS No.: 00020896-8) Anthracene (CAS No.: 000120-12-7) Benzo[a]anthracene (CAS No.: 000056-55-3) Benzo[a]pyrene (CAS No.: 00005032-8) Benzo[b]fluoranthene (CAS No.: 000205-99-2) Benzo[g,h,i]perylene (CAS No.: 000191-24-2) Benzo[k]fluoranthene (CAS No.: 000207-08-9) Chrysene (CAS No.: 000218-01-9) Dibenzo[a,h]anthracene (CAS No.: 000053-70-3) Fluoranthene (CAS No.: 000206-440) Fluorene (CAS No.: 000086-73-7) Indeno[1,2,3-c,d] pyrene (CAS No.: 000193-39-5) Naphthalene (CAS No.: 000091-203) Phenanthrene (CAS No.: 000085-018) Pyrene (CAS No.: 000129-00-0) 多苯環芳香族化合物16項總和 / Sum of 16 PAHs單位 (Unit)測試方法 (Method)法規 限值 (Limit)0.2 0.2 0.2 0.2 0.2 0.2 0.2 參考ZLS standard ZEK 01.2-08方法, 以氣 相層析/質譜儀檢測. / With reference to mg/kg ZLS standard ZEK 01.2-08 method. Analysis was performed by GC/MS. 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.2 -n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d. n.d.-Unless otherwise stated the results shown in this test report refer only to the sample(s) tested. This test report cannot be reproduced, except in full, without prior written permission of the Company. This Test Report is issued by the Company under its General Conditions of Service printed overleaf or available on request and accessible at /terms_and_conditions.htm. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this Test Report is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.SGS Taiwan Ltd.Chemical-Taipei 33 WuChyuan Road, Wuku Industrial Zone, Taipei County, Taiwan /33t + 886 (02)2299 3279 f + 886 (02)2299 3237 Member of the SGS Group (SGS SA)測試報告 Test Report高冠企業股份有限公司 KK ENTERPRISE CO., LTD.號碼(No.) : CE/2010/83662A日期(Date) : 2010/08/30頁數(Page) : 6 of 16*CE/2010/83662A*南投市南崗工業區自強三路1號 NANKANG INDUSTRIAL PARK NO. 1 TSUCHIANG 3RD. RD. NAN-TOU CITY備註(Note): 1. mg/kg = ppm;0.1wt% = 1000ppm 2. n.d. = Not Detected (未檢出) 3. MDL = Method Detection Limit (方法偵測極限值) 4. "-" = Not Regulated (無規格值) 5. **= Qualitative analysis (No Unit) 定性分析(無單位) 6. Negative = Undetectable 陰性(未偵測到); Positive = Detectable 陽性(已偵測到) PFOS參考資訊(Reference Information) : 指令 2006/122/EC (Directive 2006/122/EC) (1) 該物質不可置於市場上或使用於特殊物質或配置成分重量濃度等於或大於0.005%. (May not be placed on the market or used as a substance or constituent of preparations in a concentration equal to or higher than 0.005% by mass.) (2) 該物質不可置於市場上的半成品或商品或其物件; 假若零件上明顯地具有PFOS並參照結構上及微細構造上計 算PFOS重量濃度等於或大於0.1%, 而紡織品或其他覆蓋物質, 如果PFOS在覆蓋物質中含量等於或大於1µ g/m². (May not be placed on the market in semi-finished products or articles, or parts thereof, if the concentration of PFOS is equal to or higher than 0.1% by mass calculated with reference to the mass of structurally or microstructurally distinct parts that contain PFOS or, for textiles or other coated materials, if the amount of PFOS is equal to or higher than 1µ g/m² of the coated material.)Unless otherwise stated the results shown in this test report refer only to the sample(s) tested. This test report cannot be reproduced, except in full, without prior written permission of the Company. This Test Report is issued by the Company under its General Conditions of Service printed overleaf or available on request and accessible at /terms_and_conditions.htm. Attention is drawn to the limitation of liability, indemnification and jurisdiction issues defined therein. Any holder of this Test Report is advised that information contained hereon reflects the Company’s findings at the time of its intervention only and within the limits of Client’s instructions, if any. The Company’s sole responsibility is to its Client and this document does not exonerate parties to a transaction from exercising all their rights and obligations under the transaction documents. Any unauthorized alteration, forgery or falsification of the content or appearance of this document is unlawful and offenders may be prosecuted to the fullest extent of the law.SGS Taiwan Ltd.Chemical-Taipei 33 WuChyuan Road, Wuku Industrial Zone, Taipei County, Taiwan /33t + 886 (02)2299 3279 f + 886 (02)2299 3237 Member of the SGS Group (SGS SA)測試報告 Test Report高冠企業股份有限公司 KK ENTERPRISE CO., LTD.號碼(No.) : CE/2010/83662A日期(Date) : 2010/08/30頁數(Page) : 7 of 16*CE/2010/83662A*南投市南崗工業區自強三路1號 NANKANG INDUSTRIAL PARK NO. 1 TSUCHIANG 3RD. RD. NAN-TOU CITY PAHs參考資料(Reference information) : 依據ZEK 01.2-08之要求: 產品中最大值為 (Requirement of ZEK 01.2-08 : Restraining maximum values for products)項目 (Parameter) 第1 類 (Category 1) 與食品接觸或放入嘴內的 材料, 以及給三歲以下的 幼兒使用的玩具 . (Materials in contact with foodstuff or materials which are meant to put in the mouth as well as toys for children <36 months.) 苯駢(a)芘 Benzo[a]pyrene (mg/kg) 環保署規範16項PAH 總濃度 (Sum of 16 EPA-PAH) (mg/kg)* <MDL (<0.2)** 10 200 <MDL (<0.2)** 第 2類 (Category 2) 持續地(長時間 )與皮膚接 觸逾 30秒 , 以及不屬第 1 類的玩具. (Materials with foreseeable skin contact >30 s (prolonged skin contact) and toys not covered by category 1.) 第 3類 (Category 3) 暫時地( 短時間)與皮膚接 觸但不逾30秒或不會與 皮膚接觸. (Materials with foreseeable skin contact <30 s (short time skin contact) or without skin contact.)120注意(Remark): * = PAH濃度大於0.2mg/kg時,則須計算PAH總濃度值. (Only PAH substances >0.2 mg/kg are taken into account while calculating the sum of PAHs.) ** = 最大濃度值超出等級一的限制,但在等級二的濃度限制值內時,可能需要確認測試材質是否合適於食品容器或是依照 DIN EN1186ff/ §64 LFGB 80.30-1方法,針對特定PAH的遷移測試進行測試。