英语学习的孔子原理 徐火辉老师新著《中国人英语自学方法教程》第一讲第三节

- 格式:pps

- 大小:351.50 KB

- 文档页数:58

LEO“论语”英思力英语内训- 2014 -10次课程安排1.语法概述;主语2.谓语;非谓语3.宾语;宾语从句4.表语;表语从句5.定语;定语从句6. 状语;状语从句7. 补语;同位语8. 语序;倒装9. 疑问句10.强调;省略分组第一节Sep. 9th, 2014教学目标:⑴了解语法体系 10'⑵熟悉英语主语的构成 15'⑶掌握主谓一致的规律 15'⑷书写IT 句型 10'你不得不知的语法术语和规律▪词性▪句子成分▪5大简单句型▪名词、形容词副词、动词、代词、数词变化规律英语语法体系小组活动:找出下列句子的主语▪ESL is a language training institute.▪The rich should help the poor.▪To see is to believe.Seeing is believing.▪I work in ESL.▪Two days is enough .▪What I do is to teach English.思考:1.什么做主语?2.谓语动词是单数还是复数?小组挑战:找出下列句子的主语▪Air as well as water is matter.▪The poet and writer has come.▪ A hammer and a saw are useful tools.▪Every boy and every girl likes to go swimming.▪Each of us has something to say.▪Many a boy likes playing basketball.▪His clothes are good.▪ A pair of glasses is on the desk.▪Most of the apples were rotten.▪Most of the apple was eaten by a rat.▪He or you have taken my pen.▪Mary is one of those people who keep pets.▪Mary is the only one of those people who keeps pets.It 用法It 位于句首的句型▪It is wise of him to make such a decision.▪It’s very dangerous for children to play with fire.▪It is suggested that the book (should) be revised.▪It is a pity that such a thing ( should ) happen in your class.▪It’s no use talking with him, because he won’t listen.▪It took thousands of people many years to build the Great Wall.▪It is 5 minutes since the bus left.▪It was 3 hours before he came back.▪It will be Monday when he comes back.▪It’s (high/about) time (that) we handed in/should hand in our homework.▪It is the third time that I have seen the film.▪It was last week that I met an old friend in the street.▪It was because he was ill that he didn't come to school yesterday▪It is you,rather than he,that are to blame for the accident.▪It was in the restaurant where we had dinner last Sunday that you left you r wallet.练习:口译1.对于我们来说,下班后上课是很智慧的。

LEO“论语”英思力英语内训- 2014 -10次课程安排1.语法概述;主语2.谓语;非谓语3.宾语;宾语从句4.表语;表语从句5.定语;定语从句6. 状语;状语从句7. 补语;同位语8. 语序;倒装9. 疑问句10.强调;省略分组第一节Sep. 9th, 2014教学目标:⑴了解语法体系 10'⑵熟悉英语主语的构成 15'⑶掌握主谓一致的规律 15'⑷书写IT 句型 10'你不得不知的语法术语和规律▪词性▪句子成分▪5大简单句型▪名词、形容词副词、动词、代词、数词变化规律英语语法体系小组活动:找出下列句子的主语▪ESL is a language training institute.▪The rich should help the poor.▪To see is to believe.Seeing is believing.▪I work in ESL.▪Two days is enough .▪What I do is to teach English.思考:1.什么做主语?2.谓语动词是单数还是复数?小组挑战:找出下列句子的主语▪Air as well as water is matter.▪The poet and writer has come.▪ A hammer and a saw are useful tools.▪Every boy and every girl likes to go swimming.▪Each of us has something to say.▪Many a boy likes playing basketball.▪His clothes are good.▪ A pair of glasses is on the desk.▪Most of the apples were rotten.▪Most of the apple was eaten by a rat.▪He or you have taken my pen.▪Mary is one of those people who keep pets.▪Mary is the only one of those people who keeps pets.It 用法It 位于句首的句型▪It is wise of him to make such a decision.▪It’s very dangerous for children to play with fire.▪It is suggested that the book (should) be revised.▪It is a pity that such a thing ( should ) happen in your class.▪It’s no use talking with him, because he won’t listen.▪It took thousands of people many years to build the Great Wall.▪It is 5 minutes since the bus left.▪It was 3 hours before he came back.▪It will be Monday when he comes back.▪It’s (high/about) time (that) we handed in/should hand in our homework.▪It is the third time that I have seen the film.▪It was last week that I met an old friend in the street.▪It was because he was ill that he didn't come to school yesterday▪It is you,rather than he,that are to blame for the accident.▪It was in the restaurant where we had dinner last Sunday that you left you r wallet.练习:口译1.对于我们来说,下班后上课是很智慧的。

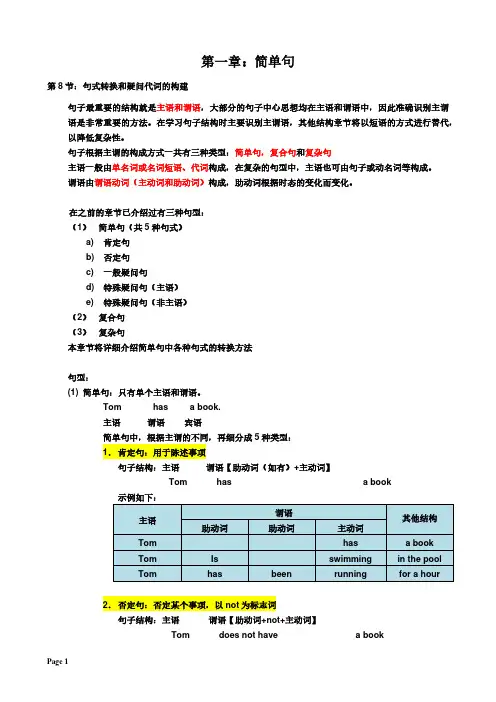

第一章:简单句第8节:句式转换和疑问代词的构建句子最重要的结构就是主语和谓语,大部分的句子中心思想均在主语和谓语中,因此准确识别主谓语是非常重要的方法。

在学习句子结构时主要识别主谓语,其他结构章节将以短语的方式进行替代,以降低复杂性。

句子根据主谓的构成方式一共有三种类型:简单句,复合句和复杂句主语一般由单名词或名词短语、代词构成,在复杂的句型中,主语也可由句子或动名词等构成。

谓语由谓语动词(主动词和助动词)构成,助动词根据时态的变化而变化。

在之前的章节已介绍过有三种句型:(1)简单句(共5种句式)a) 肯定句b) 否定句c) 一般疑问句d) 特殊疑问句(主语)e) 特殊疑问句(非主语)(2)复合句(3)复杂句本章节将详细介绍简单句中各种句式的转换方法句型:(1) 简单句:只有单个主语和谓语。

Tom has a book.主语谓语宾语简单句中,根据主谓的不同,再细分成5种类型:1.肯定句:用于陈述事项句子结构:主语谓语【助动词(如有)+主动词】Tom has a book2.否定句:否定某个事项,以not为标志词句子结构:主语谓语【助动词+not+主动词】Tom does not have a bookPage 1注:一般现在时和一般过去时以be动词作为主动词的,直接加not,主语谓语(主动词)Tom is not nice3.一般疑问句:提出疑问,一般回答为yes/no的问句句子结构:助动词主语主动词,示例如下: Does Tom have a book?注:一般现在时和一般过去时以be动词作为主动词的,直接be 动词提前谓语(主动词)主语Is Tom nice?Page2练习:将下列句子变成否定句和一般疑问句1. My friend likes swimming.否: My friend doesn’t like swimming. 疑: Does my friend like swimming? 2. My friend is nice. 否:疑:3. They go to school on Mondays. 否:疑: 4. They are at home on Mondays. 否:疑:5. They went to school on Monday. 否:疑: 6. They were at home on Monday. 否:疑:7. They often go to school on Mondays. 否:疑: 8. They are always at home on Mondays 否:疑:9. You live near here. 否:疑: 10. I want to be famous 否:疑:4.特殊疑问句(主语):以疑问代词(who, what, how等)作为开头的问句,且疑问代词作为主语。

原典英语自学法(又简称为321X英语学习法),为徐火辉教授20年集哲学、语言学、教育学、认知心理学、心理语言学和社会语言学等多学科交叉研究而成。

该英语自学法操作简单,高中生或大学生坚持使用该方法,多数人能达到雅思听力和阅读7分以上的水平。

★原典法原理与训练方法简介★●哲学文化原理:荷马是西语(一切拼音语言)的祖宗,仓颉是中文的祖宗。

你知道这两位老祖宗的差异吗?荷马是盲人,是聆听的大师;仓颉是四目,是目视的大师。

英语是强调聆听、强调声音的语言,中文是强调目视的语言。

用强调目视(死抠书面语)这种学中文的方法学英语,误导了中国学生100年!强调声音的语言,发展成文字,就变成表音文字。

学习表音文字,掌握了声音(听与说),就离掌握书面语很接近了。

强调目视的语言,发展成象形文字和表意文字,仅仅掌握听说,离掌握书面语还有很大距离。

英语是表音文字,通过聆听掌握声音,在学习英语中具有本原的重要性。

●科学原理:每个英语教授都说学英语要培养语感,若学生追问"怎样培养语感",教授们的回答往往不得要领。

其实非常简单,语言是声音表达的艺术,音乐也是声音表达的艺术。

因此,培养语感与培养乐感原理相通。

培养乐感,学唱歌的白痴方法是什么?培养乐感学唱歌的三大白痴方法:第一,通过读歌谱分析歌词大量做试题学唱歌;第二,学唱"教材"歌曲而不是学唱最好听的经典和流行歌曲;第三,跟着学校老师学而不是跟着原唱大歌星学。

同样,学英语的三大错误方法:第一,通过读书面英文大量做书面试题学英语;第二,跟着中国教材学而不是跟着英美经典学;第三,跟着中国老师学而不是英美的大朗诵家学。

●语言学原理:声音是语言的躯体,文字是语言的外衣。

英文是表音文字,中文是表意文字。

学习表音文字语言,一定要聆听优先、聆听为纲。

●认知心理学原理:最新神经心理学和认知心理语言学研究发现:A. 语言通过声音最易记忆;B. 大脑中不建立独立于母语的目标语言(外语)的语音系统表达,外语学习必然化石化(停滞不前);C. 没有优先强化的聆听,所有"疯狂英语"喊出来的都不是真English,而是伪英语Chinglish.●教育原理和普遍常识:婴幼儿学习母语都是从聆听开始!●神经心理语言学最新科研发现:婴儿在母腹中已开始专注聆听,新生儿就具有强大的"统计分布模式"聆听能力--从环境的声音中概括出母语的语音系统,这种能力连高科技计算机都难以模仿;婴儿专注聆听12个月后才开口说话!!!在神经心理语言学领域领先全球的华盛顿大学P. Kuhl 教授团队的实验与理论,完全证实外语学习必须聆听先行。

外教社中国文化英语教程Chinese Culture: A Journey through History and TraditionIntroductionChinese culture is one of the world’s oldest and most complex cultures, with a rich history that dates back thousands of years. The influence of Chinese culture can be seen in various aspects of everyday life, including art, food, language, and customs. In this lesson, we will take a journey through the history and traditions of Chinese culture, exploring its key components and the impact it has had on the world.Ancient Chinese HistoryThe history of Chinese culture can be traced back to ancient times, with a civilization that dates back to over5,000 years. The earliest written records of Chinese history date back to the Shang dynasty, which ruled from around 1600to 1046 BCE. During this time, the Chinese developed a sophisticated writing system, advanced agricultural techniques, and intricate bronze casting skills. The Zhou dynasty, which succeeded the Shang, further contributed to the development of Chinese philosophy, literature, and art.Key Components of Chinese CultureChinese culture is characterized by a number of key components, including Confucianism, Taoism, and Buddhism. Confucianism, founded by Confucius in the 6th century BCE, emphasizes the importance of social relationships, morality, and filial piety. Taoism, on the other hand, focuses onliving in harmony with nature and the universe, while Buddhism, which originated in India, promotes spiritual enlightenment and the path to nirvana.Another key component of Chinese culture is the Chinese language, which is one of the most widely spoken languages in the world. The Chinese writing system, which consists ofthousands of characters, has a history dating back to ancient times and continues to be a significant aspect of Chinese cultural identity.Cultural Traditions and CelebrationsChinese culture is filled with rich traditions and celebrations that have been passed down through generations. One of the most well-known Chinese traditions is the celebration of the Chinese New Year, which marks the beginning of the lunar new year. During this time, families come together to enjoy special meals, exchange red envelopes filled with money, and participate in traditional lion and dragon dances.Another important tradition is the Mid-Autumn Festival, also known as the Moon Festival, which is celebrated with colorful lanterns, mooncakes, and family reunions. Additionally, the Dragon Boat Festival, the Lantern Festival, and the Qingming Festival are all important culturalcelebrations that reflect the values and beliefs of the Chinese people.Influence on Global CultureThe impact of Chinese culture extends far beyond its borders, with its influence seen in various aspects of global culture. Chinese cuisine, with its diverse flavors andregional specialties, has become popular all around the world. In addition, traditional Chinese medicine, martial arts, and classical Chinese literature have all made significant contributions to global culture and knowledge.ConclusionIn conclusion, Chinese culture is a rich tapestry of history, traditions, and influences that have shaped the wayof life for billions of people. Through its ancient history, key components, cultural traditions, and global influence, Chinese culture continues to be a fascinating and significant part of the world we live in today. By understanding andappreciating Chinese culture, we can gain a deeper insight into the complexities and beauty of human civilization.。

教育新理念:积极、阳光、自信、感恩、成功!小升初英语简单易记英语三字经内部教材主编:张万红【英语成功最大的秘诀在于坚持】张万红老师分享:在英语的学习上,不管你的学习方法是什么,也不论你有多聪明,如果你想获得真正的成功,你必须坚持操练。

你必须每天利用每分钟空闲的时间不断操练。

你必须一遍一遍地重复同一个句子,直到你可以自然而然地脱口而出。

你必须强迫你自己不停地练习、不停地努力、不停地奋斗来提高。

永远没有一个时候你可以真正说出:“我已经掌握了英语。

”总是有更多的东西要学,总还有提高的空间。

你总能够变得更好一点,你的发音会变得更清晰一点,你的句子能变得更有力一点。

不管你在英语学习上有什么特殊的目标,坚持是达到成功的根本秘诀。

征服你的孤独!征服你的害羞!征服你的懒惰!征服你所有内心的邪念!你一定会成功!【疯狂学习篇】Lesson 1第一节课:突破单词和发音关a发音规律1经典例句:The c a t is so f a t译文:这只猫太肥了.发音规律:辅音+a+辅音,读成/æ/疯狂90度裂嘴音:食指和中指劈个叉.发音闯关:读准/æ/,独创手势突破发音,无比夸张,把嘴巴咧到最大,一起加油,只要勤练习,一定可以实现说一口流利的英语,掌握发音手势.词汇闯关1:我家d a d(爸爸),脾气b a d(坏的),让我s a d(伤心的).词汇闯关2:有只c a t(猫咪),非常f a t(肥的),专吃r a t(老鼠).句子闯关:The c a t is so f a t.语法闯关: .翻译闯关: .夸张闯关:把每个单词慢速夸张朗读到位,充分练习自己的口腔,让嘴巴更加灵活.最大声闯关:要求朗读时声音要洪亮,要富有激情,锻造自己的胆量.一口气闯关:首先,深呼一口气,争取在一口气之内尽量多读,直到想呼下一口气为止,练就说英语的底气.全新理念破解英语难题高效速成解除英语魔咒 1教育新理念:积极、阳光、自信、感恩、成功!最快速闯关:朗读英语要字正腔圆,争取在准确的情况下,尽量练习语速,使口腔肌肉得以充分锻炼,练就自己说英语的速度,比播音员的速度还快.背诵闯关:把所学内容,能当堂消化,并熟背,当堂问题,当堂消化,必须在课堂上解决所有问题.说唱闯关:把英语三字经顺口溜单词以说唱的形式表演出来,锻造孩子的表演能力,给孩子足够的空间施展自己的才华.演讲闯关:把所学内容以国际演讲的形式向全班发表演讲,锻造自己国际自信.考核过关:要求每堂课及时考核,及时过关,过关者才能进入下一阶段的学习,每天要不断地向目标发起挑战,你一定可以做到.自然拼读法额外奉献:b a g 袋子/包 j a m果酱 c a p帽子 m a p地图 h a ppy高兴的.a发音规律2经典例句:I h a te to be l a te.译文:我可不想迟到.发音规律: a+辅音+e,读成/ei/,特别注意尾字母e不发音.发音闯关:读准/ei/,疯狂外号:“嘴角咧到耳朵上音”嘴角要咧开到耳朵上!中国人发得最不好的一个音!词汇闯关1:放下plate(盘子),赶到gate(门口),已经late(晚了).词汇闯关2:清晨wake(醒来),来到lake(湖边),钓上snake(蛇).句子闯关:I h a te to be l a te.语法闯关: .翻译闯关: .夸张闯关:把每个单词慢速夸张朗读到位,充分练习自己的口腔,让嘴巴更加灵活.最大声闯关:要求朗读时声音要洪亮,要富有激情,锻造自己的胆量.一口气闯关:首先,深呼一口气,争取在一口气之内尽量多读,直到想呼下一口气为止,练就说英语的底气.最快速闯关:朗读英语要字正腔圆,争取在准确的情况下,尽量练习语速,使口腔肌肉得以充分锻炼,练就自己说英语的速度,比播音员的速度还快.背诵闯关:把所学内容,能当堂消化,并熟背,当堂问题,当堂消化,必须在课堂上解决所有问题.说唱闯关:把英语三字经顺口溜单词以说唱的形式表演出来,锻造孩子的表演能力,给孩子足够的空间施展自己的才华.演讲闯关:把所学内容以国际演讲的形式向全班发表演讲,锻造自己国际自信.考核过关:要求每堂课及时考核,及时过关,过关者才能进入下一阶段的学习,每天要不断地向目标发起挑战,你一定可以做到.自然拼读法额外奉献:n a me 名字 g a me游戏 l a dy女士 pl a ne飞机 p a per 纸 mist a ke错误.第二节课:突破国际演讲关Our Class Oath班级宣言We study together. 我们一起学习.We speak together. 我们一起说英语.全新理念破解英语难题高效速成解除英语魔咒 2教育新理念:积极、阳光、自信、感恩、成功!We yell together. 我们一起大喊英语.We practice together. 我们一起疯狂操练英语. We persist together. 我们一起坚持不懈.We suffer together. 我们一起受苦.We struggle together. 我们一起顽强奋斗.We succeed together. 我们一起成功.We win together. 我们一起胜利.张万红老师国际演讲要求:挑战1:读准划横线的单词,读准就可以轻松记住,读准单词比记忆单词更重要.挑战2:单词中英互译训练.挑战3:一口气读完所有生词.挑战4:完美发音,音标读准,音节读清,重音读对.挑战5:语法手势突破,按照语法手势背诵,简单易记,秘诀:“结构清,句意明,理解快,背诵易”.挑战6:句子中英互译.挑战7:演绎同声传译现场.挑战8:全篇背诵.挑战9:国际演讲.【每日疯狂日记篇及单词拼写篇】第1次课疯狂日记【疯狂考核篇】第1次英语学习通关日记考核(学生专用)年月日全新理念破解英语难题高效速成解除英语魔咒 3教育新理念:积极、阳光、自信、感恩、成功!【奇迹见证篇】全新理念破解英语难题高效速成解除英语魔咒 4教育新理念:积极、阳光、自信、感恩、成功!第1次英语课程个人成长日记(学员专用)全新理念破解英语难题高效速成解除英语魔咒 5教育新理念:积极、阳光、自信、感恩、成功!【能量加持】张万红老师的话:英语再难,只是因为你努力不够,只是因为你偷懒、懦弱、找借口!想想父母终日不停地操劳,日渐增多的白发,越来越粗糙的双手,你就应该每时每刻地全力以赴去学好英语,报答父母.从今天开始,我将参与习惯养成教育,逐渐完善自我.每当我完成了一天,也就意味着向杰出青少年迈进了一步,也将向未来的智者靠拢.从今天开始,我决不浪费一天,因为时光一去不复返.失去的日子将不再来临.我要珍惜自己的身体,因为在这个世界上,没有第二个人和我的头脑、身材、相貌、心灵、耳朵一模一样。

IAEA-TECDOC-1182Quality assurance standards: comparison between IAEA 50-C/SG-Qand ISO 9001:1994November 2000The originating Section of this publication in the IAEA was:Nuclear Power Engineering SectionInternational Atomic Energy AgencyWagramer Strasse 5P.O. Box 100A-1400 Vienna, AustriaQUALITY ASSURANCE STANDARDS: COMPARISON BETWEEN IAEA 50-C/SG-Q AND ISO 9001:1994IAEA, VIENNA, 2000IAEA-TECDOC-1182ISSN 1011–4289© IAEA, 2000Printed by the IAEA in AustriaNovember 2000FOREWORDThe International Atomic Energy Agency (IAEA) and the International Organization for Standardization (ISO) agreement regarding the scope and coverage of documents published by both organizations points out that the standards of safety developed by the IAEA are recommendations for use by its Member States in the framework of national regulations for the safe utilization of nuclear energy. Such standards should be considered as nuclear safety regulatory documents. The standards developed by the ISO are complementary technical documents emphasizing industrial application and contractual aspects. Regarding the quality assurance topic, the IAEA standards 50-C/SG-Q are mostly used directly or indirectly to establish the nuclear safety requirements at the utility–regulatory interface. The industrial ISO 9001 standards have progressively been used to implement the quality assurance requirements at the interface utility–supplier.The relationship between both standards is growing in significance owing to the impact upon the owners/operators of nuclear facilities and their contractors/suppliers. The relationship between the IAEA and ISO standards is considered critical, in particular regarding suppliers with a small range of nuclear supplies. These organizations are not always willing to prepare special quality assurance programmes based on nuclear safety standards. On the other hand, these organizations may be qualified on the basis of the ISO quality assurance standards. In any case, for delivering nuclear items and services the quality assurance programme must comply with the requirements established in the nuclear safety regulatory standards. This implies that the utility–supplier will have to demonstrate that the acceptable degree of quality assurance in relation to nuclear safety is accomplished. This may be achieved by imposing additional requirements on the supplier over and above those contained within the ISO.In order to provide a description of the differences between the IAEA and ISO standards when applied in nuclear installations, and to support the practical way of fulfilling nuclear safety, the IAEA established a project for producing a guidance report. Valuable contributions from the European Atomic Forum (FORATOM) were committed and contractual arrangements made, with the target of finalizing the report in the shortest feasible timeframe commensurable with available resources.The issue as to which ISO 9001 standard should be used for the comparison, i.e. the current version 1994 or future version 2000, was discussed quite extensively by the members of the initial consultants meeting held in Vienna in January 1999. The consultants recommended proceeding with the use of ISO 9001 version 1994 on the grounds that some time would still be needed before the next version 2000 is adopted and effectively implemented. In the meantime guidance based upon the ISO 9001 version 1994 was considered to be applicable and the efforts expended in the preparation of the guidance report worthwhile. The report will subsequently be updated to include the new ISO 9001 version 2000 standard.In thanking the contributors to this report, the IAEA wishes to acknowledge the efforts and assistance provided by FORATOM and by the participants at the preparatory and review meetings, who are listed at the end of the report. Special acknowledgement is due to K.-P. Kleinert (Germany), E. Glauser (Switzerland), M. Hille (Germany) and N. Redman (United Kingdom) for their contributions. The IAEA officer responsible for this work was N. Pieroni of the Division of Nuclear Power.EDITORIAL NOTEThe use of particul ar designations of countries or territories does not impl y any judgement by the publ isher, the IAEA, as to the l egal status of such countries or territories, of their authorities and institutions or of the delimitation of their boundaries.The mention of names of specific companies or products (whether or not indicated as registered) does not imply any intention to infringe proprietary rights, nor should it be construed as an endorsement or recommendation on the part of the IAEA.CONTENTS1. INTRODUCTION (1)1.1. Background (1)1.2. Objective (1)1.3. Scope (1)2. STANDARDS USED IN THE COMPARISON (1)2.1. IAEA Code and Safety Guides on Quality Assurance 50-C/SG-Q (1)2.2. Quality System Standard ISO 9001:1994 (3)3. MAJOR DIFFERENCES AND LINKAGES (4)3.1. IAEA Code 50-C-Q basic requirements and IAEA Safety Guides50-SG-Q1 to Q14 (4)3.2. IAEA Code 50-C-Q basic requirements and clauses of ISO 9001:1994 (4)3.2.1. Underlying approaches (4)3.2.2. Identification of the customer (4)3.2.3. Additional requirements (5)3.3. Linkages between the IAEA Safety Guides 50-SG-Q1 to Q14 andclauses of ISO 9001:1994 (7)4. GUIDANCE WHEN USING ISO 9001:1994 (8)4.1. Additional requirements of the IAEA Code 50-C-Q (8)4.2. Additional guidance of the IAEA Safety Guides (11)APPENDIX: CORRELATION MATRICES (21)Matrix 1: IAEA Code 50-C-Q basic requirements coverage in the IAEASafety Guides 50-SG-Q1 to Q14 (21)Matrix 2: Correlation between the clauses of ISO 9001:1994 and the IAEA Code50-C-Q basic requirements (22)Matrix 3: Correlation between the clauses of ISO 9001:1994 and the IAEA SafetyGuides 50-SG-Q1 to Q14 (23)REFERENCES (24)CONTRIBUTORS TO DRAFTING AND REVIEW (25)IAEA PUBLICATIONS ON QUALITY ASSURANCE/QUALITY MANAGEMENT (27).1. INTRO DUCTIO N1.1. BackgroundThe International Atomic Energy Agency (IAEA) Code and Safety Guides contained in the Safety Series No. 50-C/SG-Q [1] define basic quality assurance requirements, which must be considered to ensure safety, and provides recommendations on how to fulfil these basic requirements. The IAEA 50-C/SG-Q standard reflects the performance based approach to quality assurance covering all aspects of plant safety, economics and efficiency. The IAEA requirements and recommendations are generally used at the nuclear utility–regulator interface.The International Organization for Standardization (ISO) International Standard ISO 9001:1994 [2] specifies quality system requirements for use where any supplier’s capability to design and supply a conforming product needs to be demonstrated. The requirements specified are aimed primarily at achieving customer satisfaction by preventing non-conformity at all stages from design through to servicing. The ISO 9001:1994 standard is sometimes used at the nuclear utility–supplier interface.1.2. O bjectiveThe objective of this report is to compare the requirements of IAEA 50-C/SG-Q (1996) [1] with ISO 9001:1994 [2] in order to identify the main differences and additional requirements contained within [1]. The report also provides information and guidance, which may be considered when ISO 9001:1994 is utilized by the nuclear industry.1.3. ScopeThe comparison is made with the following publications:IAEA Safety Series No. 50-C/SG-Q (1996), Quality Assurance for Safety in Nuclear Power Plants and other Nuclear Installations, Code and Safety Guides Q1–Q14 [1].ISO 9001:1994, Quality Systems — Model for Quality Assurance in Design, Development, Production, Installation and Servicing [2].ISO 9002:1994, Quality Systems — Model for Quality Assurance in Production, Installation and Servicing [3].ISO 9003:1994, Quality Systems — Model for Quality Assurance in Final Inspection and Test [4].Throughout this report, the comparison discussed is the comparison against ISO 9001:1994 only, as it contains all the requirements contained in ISO 9002:1994 and ISO 9003:1994. Suppliers, utilities, regulatory bodies, as well as research and development organizations could use this report when considering using ISO 9001:1994 to procure items and services for use in the nuclear industry.2. STANDARDS USED IN THE COMPARISON2.1. IAEA Code and Safety Guides on Quality Assurance 50-C/SG-QThe IAEA Safety Series includes one Code 50-C-Q on quality assurance and 14 related Safety Guides 50-SG-Q1 to Q14 [1].The quality assurance Code 50-C-Q establishes the basic requirements that must be met to ensure adequate safety of nuclear power plants and other nuclear installations.The Code consists of 10 basic requirements (BR) to be adopted by the responsible organization as the foundation for establishing and implementing a comprehensive quality assurance programme related to the safety of nuclear power plants. The basic requirements are presented in three functional categories:I. ManagementBR 1: Quality Assurance ProgrammeBR 2: Training and QualificationBR 3: Non-Conformance Control and Corrective ActionsBR 4: Document Control and RecordsII. PerformanceBR 5: WorkBR 6: DesignBR 7: ProcurementBR 8: Inspection and Testing for AcceptanceIII. AssessmentBR 9: Management Self-AssessmentBR 10: Independent AssessmentThe Code includes an annex, which provides guidance to aid the understanding and implementation of the basic requirements. The content of this annex is included in this comparison.The Safety Guides describe acceptable methods of implementing particular parts of the Code. The Safety Guides 50-SG-Q1 to Q14 are one of two types:· Basic requirement related Safety GuidesThese Safety Guides provide recommendations and guidance on how to fulfil the basic requirements of the Code that are relevant in all of the life-cycle stages of nuclear power plants and other nuclear installations.The BR related guides are:Safety Guide Q1: Establishing and Implementing a Quality Assurance ProgrammeSafety Guide Q2: Non-conformance Control and Corrective ActionsSafety Guide Q3: Document Control and RecordsSafety Guide Q4: Inspection and Testing for AcceptanceSafety Guide Q5: Assessment of the Implementation of the Quality Assurance Programme Safety Guide Q6: Quality Assurance in Procurement of Items and ServicesSafety Guide Q7: Quality Assurance in Manufacturing· Stage related Safety GuidesThese Safety Guides provide specific recommendations and guidance on how to implement the Code during the different life-cycle stages of nuclear power plants and other nuclear installations.The Stage related guides are:Safety Guide Q8: Quality Assurance in Research and DevelopmentSafety Guide Q9: Quality Assurance in SitingSafety Guide Q10: Quality Assurance in Design (this specific guide may also be used as a BR related Guide when the design activities are carried out in any stage). Safety Guide Q11: Quality Assurance in ConstructionSafety Guide Q12: Quality Assurance in CommissioningSafety Guide Q13: Quality Assurance in OperationSafety Guide Q14: Quality Assurance in Decommissioning2.2. Quality System Standard ISO 9001:1994The ISO 9001:1994 standard defines the requirements for a quality management system in clauses 4.1 to 4.20. The clauses are sequentially numbered to reflect the sequence of events and activities supporting production, from developing the quality policy to the after sales service.The clauses of ISO 9001:1994 are:4.1 Management Responsibility4.2 Quality System4.3 Contract Review4.4 Design Control4.5 Document and Data Control4.6 Purchasing4.7 Control of Customer-Supplied Product4.8 Product Identification and Traceability4.9 Process Control4.10 Inspection and Testing4.11 Control of Inspection, Measuring and Test Equipment4.12 Inspection and Test Status4.13 Control of Nonconforming Product4.14 Corrective and Preventive Action4.15 Handling, Storage, Packaging, Preservation and Delivery4.16 Control of Quality Records4.17 Internal Quality Audits4.18 Training4.19 Servicing4.20 Statistical TechniquesThese 20 clauses have a relationship with and are comparable to the 10 basic requirements of the IAEA Code 50-C-Q. The ISO 9001:1994 standard, however, does not give any guidance or recommendations on how the defined requirements can be implemented.3. MAJOR DIFFERENCES AND LINKAGES3.1. IAEA Code 50-C-Q basic requirements and IAEA Safety Guides 50-SG-Q1 to Q14While the IAEA Code 50-C-Q specifies the ten basic requirements for quality assurance in nuclear power plants and other nuclear installations, the Safety Guides provide recommendations relative to the fulfilment of these basic requirements for different topics and life-cycle stages. An overview showing how each Safety Guide addresses the basic requirements is given in the Appendix: Matrix 1.3.2. IAEA Code 50-C-Q basic requirements and clauses of ISO 9001:1994The linkages between the ten basic requirements of the IAEA Code 50-C-Q and the 20 clauses of ISO 9001:1994 are provided in the Appendix: Matrix 2. In general the basic requirements of the IAEA Code 50-C-Q are addressed by one or more clauses of ISO 9001:1994. However the IAEA Safety Guides provide more detailed and comprehensive guidance and recommendations on how to implement the basic requirements of the IAEA Code.Each basic requirement of the IAEA Code 50-C-Q addresses one or more of the clauses of ISO 9001:1994. However there are some significant differences in the approaches, identification of the customer and additional requirements.3.2.1. Underlying approachesThe IAEA Code 50-C-Q provides the basic requirements to be adopted for establishing and implementing quality assurance programmes related to the safety of nuclear power plants and other nuclear installations. These basic requirements apply to the overall quality assurance programme of the responsible organization, i.e. the organization having overall responsibility for the nuclear power plant, as well as to any other separate quality assurance programmes in each stage of the life of a nuclear power plant.The objective of the IAEA Code is to establish basic requirements for quality assurance in order to enhance nuclear safety by continuously improving the methods employed to achieve quality. The Code recognizes that all work is a process that can be planned, performed, assessed and improved.The quality assurance model set out in ISO 9001:1994 provides the framework for the quality assurance programme of a supplier, which enables the supplier to demonstrate the capability to produce a quality product and provides a vehicle for assessment by external parties. The requirements specified are aimed primarily at achieving customer satisfaction by preventing non-conformity at all stages from design to servicing. They are generic and independent of any specific industry sector.The comparison suggests that the IAEA Code 50-C-Q is a top-down approach focused on meeting the overall safety requirements for the plant, personnel and the society in general whilst ISO 9001:1994 is a bottom-up approach focusing on satisfying the specific requirements of the immediate customer.3.2.2. Identification of the customerThe nuclear utility in meeting national regulatory requirements satisfies the safety requirements of its customer: society at large. The regulator, representing the customer in thiscase, utilizes the IAEA Code 50-C-Q to define the requirements for the quality assurance programme of its supplier, the nuclear utility. The nuclear utility also fulfils the role of the customer utilizing, where appropriate, ISO 9001:1994 plus any additional requirements to define the quality assurance programme of its suppliers of items and services. The supplier satisfies the nuclear utility (the customer) by supplying a quality product. (See Figure 1)_______ Requirement path............... Satisfaction pathFig. 1: Application of IAEA Code 50-C-Q and ISO 9001:1994.3.2.3. Additional requirements 3.2.3.1. Management self-assessmentThe IAEA Code 50-C-Q defines specific requirements for “Management self-assessment”, an activity not required by ISO 9001:1994.“Manag ement at all levels shall reg ularly assess the processes for which it is responsible. Manag ement shall determine its effectiveness in establishing , promoting and achieving nuclear safety objectives. Management process weaknesses and barriers that hinder the achievement of the nuclear safety objectives shall be identified and corrected.” (Section 401)Regulator (Customer) Supplier (Items or Services)This statement in the Code is further clarified in the Annex:“The thrust of manag ement self-assessment is to identify, correct and prevent management problems that hinder the achievement of the organization's objectives. This Code establishes the requirement for a routine and continuing assessment of the management system by the organization's managers.This self-assessment methodology is in addition to the traditional audit/appraisal that determines the adequacy and extent of the QA programme development, documentation and implementation in accordance with specified requirements. This basic requirement improves on the standard stipulation in many QA prog rammes, which requires that management regularly assess the adequacy of the portion of the programme for which it is responsible and ensure its effective implementation. This standard requirement is typically achieved, on an annual basis, by an independent consultant or g roup of consultants on behalf of management, and it addresses compliance issues rather than broad categ ories of manag ement issues. Manag ement self-assessment g oes beyond such matters as conformance to regulations, item standards or established procedures.An effective management self-assessment evaluates issues such as:— mission of the organization— whether employees understand the mission— what is expected of the organization— whether the expectations are being met— opportunities for improving quality and enhancement safety— how to make better use of human resources.The results of the management self-assessment are documented. Decisions and related actions resulting from the recommendations are promptly followed up to evaluate their effectiveness.The assessment process involves all levels of manag ement, but senior manag ement retains the overall responsibility for manag ement self-assessments. It is essential that senior management directly participate in this process.”3.2.3.2. GradingThe IAEA QA Code 50-C-Q recommends a graded approach for the application of quality assurance during the various stages of a nuclear power plant life cycle.All items, services and processes have various controls built in to ensure they perform correctly. The grading process is a means of determining what types and extent of controls are applied to specific items, services and processes.Applying controls costs money, therefore they should be applied and focused where necessary and not applied or applied to a lesser degree for less important activities. Errors in more significant activities can potentially cost huge amounts of money, could shut down a plant or production line and could cause a threat to the staff and the environment. Additional controls that may reduce or eliminate such errors are therefore a good investment.“Nuclear safety shall be the fundamental consideration in the identification of the items, services and processes to which the quality assurance prog ramme applies. A g raded approach based on the relative importance to nuclear safety of each item, service orprocess shall be used. The g raded approach shall reflect a planned and recog nized difference in the applications of specific quality assurance requirements.In g eneral, the hig hest g rade should require the most string ent application of the quality assurance requirements; the lowest grade the least stringent.The following are examples of topic areas where grading should be applied:— Type and content of training— Amount of detail and degree of review and approval of instructions— Need for and detail of inspection plans,— Degree of in-process reviews and controls,— Requirements for material traceability— Type of assessment,— Records to be generated and retained. (Section 210).When items, processes or services are modified, the assigned grade of quality assurance requirements could become more string ent or less string ent depending on whether a change in nuclear safety significance has occurred.” (Section 211)Safety Guide 50-SG-Q1 explains what the “graded approach” in relation to nuclear safety means:“Whilst the quality assurance principles remain the same, the extent to which the quality assurance requirements are to be applied shall be consistent with the importance to nuclear safety of the item, service or process. A graded approach which can satisfy the necessary requirements and ensure the required quality and safety shall be used.” (Section 209)ISO 9001:1994 does not specify or define a graded approach for applying the controls specified in the quality system.3.2.3.3. Independence of inspection and testing personnelThe IAEA Code 50-C-Q requires that inspection and testing of specified items, services and processes shall be conducted using established acceptance and performance criteria. The level of inspection and testing and the degree of independence of personnel shall be established.ISO 9001:1994 does not specifically cover the independence of inspection and testing personnel.3.3. Linkages between the IAEA Safety Guides 50-SG-Q1 to Q14 and clauses of ISO9001:1994The linkages between the content of the IAEA Safety Guides and the ISO clauses are presented in the Appendix: Matrix 3.Matrix 3 supports the following observations:· The IAEA Safety Guides do not directly consider the customer-related requirements of ISO 9001 defined in Clauses 4.3 Contract Review, 4.7 Control of Customer-Supplied Product and 4.19 Servicing.· Similar requirements defined under the clauses ‘management responsibility’ and ‘quality system’ in ISO 9001 can be found in all of the Safety Guides.· Stage related Safety Guides in general address the majority of subjects in the ISO clauses.4. GUIDANCE WHEN USING ISO 9001:1994A detailed comparison of the IAEA Code 50-C-Q and BR related Safety Guides with ISO 9001:1994 to identify all additional requirements and guidance was carried out. In this comparison the annexes of the IAEA publications 50-C/SG-Q have not been considered as they contain examples illustrative of how the guidance could be implemented. The stage related Safety Guides, with exception of the Safety Guide “Quality Assurance in Design” (50-SG-Q10), were not included in this comparison as they provide specific recommendations for the content of the quality systems at each of the life-cycle stages. The Safety Guide 50-SG-Q10 was included as it provides guidance that may be relevant to the design activity of all stages.The detailed results of the comparison are included in Sections 4.1 and 4.2. These sections identify additional requirements or guidance found in the IAEA publications 50-C/SG-Q that are not found in ISO 9001:1994. Where the additional requirement or guidance is not self-explanatory some additional notes on application to suppliers are provided.The application of additional requirements or guidance from the IAEA Code and Safety Guides 50-C/SG-Q should be considered by the nuclear utility from two points of view:— Should the nuclear power plant/utility address this difference within its own quality assurance programme?— Should the nuclear power plant/utility require its suppliers to address the difference as an additional requirement in the procurement documents?The consideration should also take into account the regulatory requirements of each Member State.4.1. Additional requirements of the IAEA Code 50-C-QThe following table identifies additional or more detailed requirements in the IAEA Code 50-C-Q that are not contained within ISO 9001:1994.Section Additional Requirement Notes to aid application101 to 108 Introduction104 The responsible organization has to demonstrate the effective fulfilment of the quality assurancerequirements to the satisfaction of the regulatorybody… The utility should demonstrate that its quality programme takes account of and incorporates any requirements from the regulatory body. The utility should require its suppliers to apply any of these specific requirements where necessary.201 to 205 BR 1: Quality Assurance Programme204 Nuclear safety shall be the fundamentalconsideration in the identification of the items,services and processes to which the qualityassurance programme applies. A gradedapproach based on the relative importance tonuclear safety of each item, service or processshall be used. The graded approach shall reflecta planned and recognized difference in theapplications of specific quality assurancerequirements. The graded approach for activities and items, including procurement, should be described within the utility quality programme. The application of grading to supplier activities should be clarified. The utility should consider whether its supplier should adopt complimentary grading and provide guidance.Section Additional Requirement Notes to aid application 206 BR 2: Training and Qualification206 Personnel shall be trained and qualified so thatthey are competent to perform their assignedwork and understand the safety consequences oftheir activities. The utility should identify personnel involved with safety matters and provide the related training and qualification programme. The utility should notify its suppliers when their personnel are involved with safety matters and ensure they are trained appropriately.206 to 208 BR 3: Non-Conformance Control andCorrective Actions Non-conformance (as per IAEA Code 50-C-Q) covers non-conforming product, system and process non-conformity as per the ISO standard.304 to 305 BR 6: Design305 The adequacy of design, including design tools and design inputs and outputs shall be verifiedor validated by individuals or groups other thanthose who originally performed the work.Verification, validation and approval shall becompleted before implementation of the design. The utility quality programme addressing design should specify that persons in charge of safety related design verification and validation should be different from those performing the work. The utility should notify the relevant requirements to suppliers when they perform safety related design activities. Any design verification and approval should be performed before implementation of design. Generally design validation is performed through commissioning under defined operating conditions and specific dispositions should be applied for accidental conditions.Annex …Design inputs include all requirements for thedesign, such as the technical bases for thedesign (design basis), performancerequirements, reliability requirements, andsafety and security requirements. …... Computer programs used in design arevalidated through testing or simulation prior touse if not proven through previous use.—306 to 308 BR 7: Procurement Suppliers in IAEA terms are equivalent tosubcontractors.308 Requirements for reporting deviations fromprocurement requirements shall be specified inthe procurement documents. The option contained within ISO 9001:1994 for reporting deviations (non-conforming product) should be identified as being necessary.309 to 310 BR 8: Inspection and Testing for Acceptance309 Inspection and testing of specified items,services and processes shall be conducted usingestablished acceptance and performance criteria.The level of inspection and testing and thedegree of independence of personnel shall beestablished. It is recommended that utilities request suppliers to include this requirement in their quality programme, when appropriate.401 BR 9: Management Self-Assessment Management Self-Assessment is more complexand detailed than the ISO Management-Review.Management Self-Assessment focuses on theachievement of the nuclear safety objectives.Although ISO 9001:1994 covers themanagement review and internal audit processesit does not cover management self-assessment.(It is therefore recommended that suppliersproviding items and services to ISO Standardalso include management self-assessment intheir quality assurance programme.)。

原典英语学习法的解惑为了便于典友相对方便地就运用原典法中的种种问题提问交流,徐老师就建设这个小楼,讨论回答原典法运用中的种种问题。

问-1:原典法特别特别强调聆听,能不能用最简练的话语说明其道理所在?否则,教我怎么相信你?问-2:原典英语学习法适用的对象有哪些?问-3:原典英语学习法强调运用第一流的原典音频素材,我从哪里可以获取这些素材?问-4:原典英语学习法中的321X 训练程序,是不是只能在一个连续的时间段内一次连续地完成,例如,5分钟的原典素材,我先听4遍,用20分钟,再读3遍,用25分钟,最后再听2遍,用10分钟,加起来一共是55分钟,约一个小时,这个训练过程,是否需要在一个小时内连续完成?因为我是高中生,很少有完整的时间,不知道该怎么用.问-5 原典法的训练过程中需要记忆单词吗?问-6:原典法虽然有效,但它不能立竿见影地提升考试成绩,而现在学校内的英语教学都是考试全面导向的,对教师的评估也是如此,我该怎么办?我对用原典法提升学生的英语考试成绩比较缺乏信心。

问-7:用中央九台的英语节目做学习素材好不好?它的节目内容有很多学生比较熟悉,容易理解。

问-8:我是一个新来者,不知什么是原典英语?能不能说说什么是原典英语?问-9:家里正好有一套―牛津书虫‖彩绘版外研社的书,而且是带CD的,请问可以作为学习素材用吗?另外还有一整套剑桥国际英语教程可以当做学习素材吗?问-10、请问怎么掌握到英语的韵律学习?有什么方法?问11、英语基础几乎零,是否要在聆听之前,把元音与辅音的音标发音都掌握好,然后再进行?问-12、为了应付中国的垃圾英语考试,英语语法要怎么学习问-13 上周才开始了解到徐老师的原典英语学习方法,准备让上小学五年级的儿子采用该方法学习英语,已经选好了Black Cat的Earlyreads作为启蒙教材。

孩子的英语基础较差,除了学校的COCO英语之外,还没学习过其他教材,不知道这个教材是否合适?另外,请教这里的前辈,在使用原典法听这个故事之前,是否要先预习并背诵故事中的生词?问-14 再请教个问题。

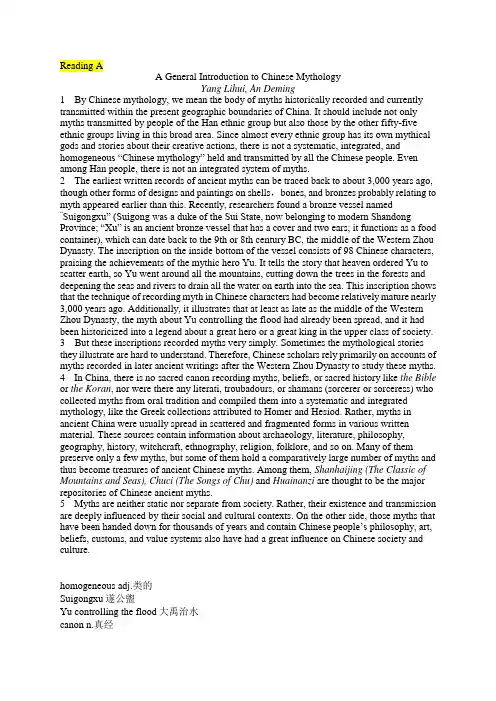

Reading AA General Introduction to Chinese MythologyYang Lihui, An Deming1 By Chinese mythology, we mean the body of myths historically recorded and currently transmitted within the present geographic boundaries of China. It should include not only myths transmitted by people of the Han ethnic group but also those by the other fifty-five ethnic groups living in this broad area. Since almost every ethnic group has its own mythical gods and stories about their creative actions, there is not a systematic, integrated, and homogeneous “Chinese mythology” held and transmitted by all the Chinese people. Even among Han people, there is not an integrated system of myths.2 The earliest written records of ancient myths can be traced back to about 3,000 years ago, though other forms of designs and paintings on shells,bones, and bronzes probably relating to myth appeared earlier than this. Recently, researchers found a bronze vessel named “Suigongxu” (Suigong was a duke of the Sui State, now belonging to modern ShandongProvince; “Xu” is an ancient bronze vessel that h as a cover and two ears; it functions as a food container), which can date back to the 9th or 8th century BC, the middle of the Western Zhou Dynasty. The inscription on the inside bottom of the vessel consists of 98 Chinese characters, praising the achievements of the mythic hero Yu. It tells the story that heaven ordered Yu to scatter earth, so Yu went around all the mountains, cutting down the trees in the forests and deepening the seas and rivers to drain all the water on earth into the sea. This inscription shows that the technique of recording myth in Chinese characters had become relatively mature nearly 3,000 years ago. Additionally, it illustrates that at least as late as the middle of the Western Zhou Dynasty, the myth about Yu controlling the flood had already been spread, and it had been historicized into a legend about a great hero or a great king in the upper class of society.3 But these inscriptions recorded myths very simply. Sometimes the mythological stories they illustrate are hard to understand. Therefore, Chinese scholars rely primarily on accounts of myths recorded in later ancient writings after the Western Zhou Dynasty to study these myths.4 In China, there is no sacred canon recording myths, beliefs, or sacred history like the Bible or the Koran, nor were there any literati, troubadours, or shamans (sorcerer or sorceress) who collected myths from oral tradition and compiled them into a systematic and integrated mythology, like the Greek collections attributed to Homer and Hesiod. Rather, myths in ancient China were usually spread in scattered and fragmented forms in various written material. These sources contain information about archaeology, literature, philosophy, geography, history, witchcraft, ethnography, religion, folklore, and so on. Many of them preserve only a few myths, but some of them hold a comparatively large number of myths and thus become treasures of ancient Chinese myths. Among them, Shanhaijing (The Classic of Mountains and Seas), Chuci (The Songs of Chu) and Huainanzi are thought to be the major repositories of Chinese ancient myths.5 Myths are neither static nor separate from society. Rather, their existence and transmission are deeply influenced by their social and cultural contexts. On the other side, those myths that have been handed down for thousands of years and contain Chinese people’s philosophy, art, beliefs, customs, and value systems also have had a great influence on Chinese society and culture.homogeneous adj.类的Suigongxu遂公盥Yu controlling the flood大禹治水canon n.真经Koran (古兰经> ,伊斯兰教经典troubadours n.游吟诗人shaman n.巫师Homer荷马,希腊史诗作者Hesiod赭西奥德,希腊最旱的诗人之一ethnography n.人种志Shanhaijing (山海经》Chuci 《楚辞》Huainanzi《淮南子》repository n.宝库,宝藏Reading BNüwa Creates PeopleIrene Dea Collier1 Nüwa is briefly mentioned in several ancient Chinese texts, A Classic of History (8th century BC), A Classic of Mountains and Seas (3rd century BC), and Questions of Heaven (4th century BC).2 In addition, many images of Nüwa have been uncovered on ancient Chinese bronze sculptures and paintings. Like many of the early Chinese gods, Nüwa was half animal, half divine. Most often, Nüwa had the face and arms of a human but the body of a snake or dragon. She could change her shape at will. Modern Chinese books prefer to show her as a beautiful woman.3 It appeared that women in China had no social standing of their own. However, in their roles as mothers and wives, they were extremely powerful. Since women generally outlived their husbands, they often asserted themselves and ran the household after their spouses’ death. Even in politics,several women (empresses) became extremely powerful after the death of their husbands, the emperors.4 Although most gods were male, Nüwa is a very powerful female goddess in early mythology. She creates mankind and is responsible for repairing the heavens.5 The world was indeed a sparkling jewel. Sturdy pine trees dotted the mountains, and weeping willows lined the streams. Apple, quince, and plum blossoms burst into bloom and later yielded ripe, heavy fruit. Birds flitted about in the azure sky, leaving their black, crimson, and iridescent green feathers drifting in the wind. Silverfish and carp splashed gleefully in the waterways. Fierce beasts like tigers and gentle creatures like deer roamed with equal abandon across the rocky hills.6 Nüwa, a goddess, stumbled accidentally upon this vibrant world during her travels. The earth was humming and teeming with life. She marveled at its many wondrous creatures. Everywhere she looked, she found a creature more marvelous than the one before. She saw every type of fur and fin, feather and scale, horn, hoof, and stinger. Creatures lumbered, crawled, and slithered upon the earth. They jumped, darted, and roiled in the sea. Scented flowers like jasmine, hyacinth, and narcissus wrapped the entire world in their warm, strong perfume.7 But as she explored its niches and crannies, Nüwa began to feel strangely dissatisfied with the budding world. The goddess found it to be enchanting, but empty. It felt lonely to Nüwa, who sat by a river to ponder her feelings. She gazed at her reflection in the water, and suddenly she knew what was missing: She wanted the world to be filled with thinking, laughing creatures like herself.8 The river stretched out before her, its waves slapping the shore. The cloudy green waters left a rim of thick yellow earth along its banks. Nüwa felt its slippery texture with her fingertips and scooped out a ball of clay. The cool, sticky earth deposited by the river was perfect for her task,and she rolled the damp clay into a doll, giving it a head, shoulders, chest, and arms like her own. For the doll’s lower body,she hesitated. Nüwa considered giving it scales and claws like a lizard, or fins and tails like a fish. Both shapes were quite useful, since the goddess frequently changed the shape of her own lower body to be able to get around the oceans and the heavens quickly. Finally, she decided to attach legs to the new creature so it could both walk on land and paddle about in the sea.9 From the many shades of yellow earth, Nüwa made tall dolls and short dolls. She made thin dolls and fat dolls. She made curly-haired dolls and straight-haired dolls. She made dolls with eyes as round and large as cherries, some with eyes as long andnarrow as a mosquito’s wing. She made some with eyes so dark they loo ked like the midnight sky, others so light they looked like liquid honey. Each creature was different, so the goddess could recognize her creations. Then,as she breathed on each doll, it sprang to life, giggling and hopping about.10 Nüwa was so delighted with her handiwork that she wanted to make more. But she neededa quicker method. Along the riverbanks, slender reeds arched their graceful stems over the water. Nüwa rolled up her sleeves, cut a reed, and dipped it into the river mud like a spoon. Expertly, she flicked her wrist and dropped blobs of mud on the ground. When they dried, she breathed a huge puff of air into each blob, and instantly they became round, smiling creatures. The cheerful laughter of her creatures filled the goddess with happiness and pride.11 However, Nüwa was tired. As much as she loved her new creations, she knew she could not watch over these humans every second. What would happen to these creatures when they grew old and died? Nüwa did not relish making repairs, nor did she wish to repeat the tiring task of making new people. She thought and thought. How could these creatures reproduce without her?12 With a twist and a poke, she made some of the clay creatures male and some of them female. Then she gathered up all the noisy creatures who were slipping and falling in the mud. In the hubbub, she began to deliver her most important instructions. As Nüwa spoke, the clamor died down to a silent hush. The humans listened solemnly to her words. She spoke of the importance of marriage and a couple’s obligations to each other. She told them how to make children and how to raise them. She wished them a long and joyful existence on their earth. As the goddess left, she expressed her fervent hope that they would make new people and live happily without her. Then she ascended to the sky seated in a thundering chariot pulled by six winged dragons.13 To this day, people continue to marry and have children who brighten the world with their joyous laughter, just as the dancing mud dolls did in the days of Nüwa.A Classic of History《尚书》Questions of Heaven《天问》(屈原的代表作,收录于西汉刘向编辑的《楚辞》中)divine n.神social standing 社会地位outlive v.活得比……长assert oneself 坚持己见,表现出自信而受到注意和尊重sturdy adj.强健结实的weeping willow 垂柳quince n.揾悖(似梨)flit v.掠过iridescent adj.色彩斑斓的,闪亮的roam v.漫步abandon n.放纵,自由humming and teeming with life:活跃,富有生机niches and crannies:单数形式分别为niche和cranny,同义词叠加,意为“小小天地、一席之地、犄角旮旯”fin n.(鱼)鳍scale n.鳞片horn n.角hoof n.蹄stinger n.刺,螫针lumber v.缓慢地行走roil v. 搅浑hyacinth n.风信子a rim of 一圈scoop v.挖,舀,掏paddle v.划水,涉水reed n.芦苇arch v.弯,呈拱形flick v.快而轻地动blob n.(浓液的)一滴puff n. —口(气)relish v.享受,从……中获得乐趣poke n.捅,戳hubbub n.喧闹clamor n.嘈杂fervent adj.强烈的ascend n.升(天)thunder v.隆隆作响,呼啸而来chariot n.马车Reading CThe Chinese Dragon vs. The Western DragonZhu Beijing1 The Chinese dragon is a far different beast from its Western counterpart. Smaug from J. R. R. Tolkien’s “The Hobbit” is perhaps the most widely known dragon from recent Western fiction, a cruel, avaricious and bloodthirsty creature whose lair under the Lonely Mountain identifies him as a creature of the earth. Tolkien drew much of his inspiration for Smaug from the dragon in the Old English epic of “Beowulf”, penned more than a thousand years earlier, which gives some indication of the depth of the European tradition of portraying dragons as bad news.2 By contrast, the Chinese dragon is an auspicious creature, symbolizing strength, wisdom, good luck and power over the elements of wind and water. As such, Chinese people proudlyclaim they are the descendants of the dragon, a story that is firmly rooted in national folklore and history. For example, an anecdote in the “Records of the Grand Historian” (Shiji) traces the birth of Liu Bang, the first emperor of the Western Han Dynasty (206 BC-25 AD): One day, his mother falls asleep at a riverside and dreams of a dragon lying on her body, only to wake up and find herself pregnant. Traces of the anecdote survived in the belief that a dragon appearing in a pregnant mother’s dream was an auspicious sign indicating she would give birth to a future emperor.3 Indeed, China’s feudal rulers did everything they could to maintain this mythic association, surrounding themselves with dragon-related ornamentation, ruling from a Dragon Throne and waging war under a dragon flag. Pretty much everything related to the emperor would be tagged with the character “龙”, for example, “龙袍” (imperial robes embroidered with curling dragons), “龙椅” (the emperor’s seat), “龙床” (t he emperor’s bed) and “龙颜” (the look of an emperor).4 While Smaug and other European dragons have a solid, serpentine connection to the earth, Chinese dragons are indisputably rulers of the sky. The dragon was worshiped as the God of Rain, and in times of drought or flooding, locals would visit a dragon-king temple (龙王庙)and burn incense to pray for more favorable conditions. It is also said that natural disasters such as floods or tornados (龙卷风, literally, the dragon rolls up the wind) indicate the dragon king is in bad temper.5 Dragons’ association with thunder,lightning and rain may have prompted the widespread belief that there are more likely to be a flurry of natural disasters in a Dragon year, and Chinese New Year celebrations the world over will include ceremonies and prayers dedicated to warding off the possibility of such a calamity striking people’s homes.6 The dragon’s power to control rain and waves is also closely related to its rank in the pantheon of 12 zodiac animals (rat, ox, tiger, rabbit, dragon, snake, horse, sheep, monkey, cock, dog and pig). Various tales describe the race of these 12 animals to secure their place on the list, but the sequence is determined by the time of day the animal is most active, at least in the eyes of the ancient Chinese. The dragon corresponds to7 am to 9 am, when it is most likely to be foggy, allowing the dragon to ride atop clouds and mist. However, parts of the dragon are usually hidden in the heavy fog, giving rise to the phrase “神龙见首不见尾” (you see the head of the mystical dragon but not its tail), which now refers to someone who has no fixed whereabouts and is difficult for others to trace.7 In Chinese folk art paper-cuts, a typical pattern shows the dragon riding on clouds. Another depicts two dragons playing with a pearl (双龙戏珠), which is often inlaid with a dark, comma-like symbol running through the middle, thought to represent the unification of yin and yang. In Chinese calligraphy, the flying dragon is an aesthetically appealing analogy for cursive and elegant handwriting known as “龙飞凤舞”, literally, “dragons flying andphoeni xes dancing.” Given all the positive associations of “龙”, it’s no wonder the character is a top choice for people’s names, including martial arts superstars Jackie Chan (成龙)and Bruce Lee (李小龙). There is also the Chinese idiom, “望子成龙” (literally, hoping one’s son will become a dragon), which roughly means parents have high expectations of their children.8 However,few parents would want their children to be aggressive leaders involved in violence. Unfortunately, this is the image that struck many Chinese upon seeing the new dragon stamp issued by China Post in early January, 2012. “Evil and frightening”(凶神恶煞), “baring fangs and brandishing paws” (张牙舞爪)and “bristling with anger”(怒发冲冠)were just a few of the phrases people responded with when being asked for their first impression of the new stamp. The design has also triggered heated debates among micro bloggers on Sina Weibo,one of whom even compares the image to “China’s notorious city inspectors, who ar esometimes caught on camera beating up street vendors,” according to The Wall Street Journal’s China Real Time Report.9 People born in the year of the dragon are said to be natural leaders ——charismatic, innovative, free-spirited, and flamboyant, and as such Dragon years are notorious for coinciding with spikes in the birth rate. It remains to be seen whether modern Chinese remain as much in the thrall of dragon worship as their ancestors, and if the phenomenon holds true in the 21st century.counterpart n.对应的人或物Smaug《霍比特人》中的带翼火龙The Hobbit《霍比特人》 (小说、电影)avaricious adj.贪婪的lair n.巢穴epic n.史诗pen v.创作.撰写auspicious adj.吉祥的J. R. R. Tolkien: John Ronald Reuel Tolkien (约翰•罗纳德•待埃尔•托尔金)(1892-1973), was an English writer, poet, philologist, and university professor, best known as the author of the classic high fantasy works The Hobbit and The Lord of the Rings.Beowulf: heroic poem set in Scandinavia, the highest achievement of Old English literature and the earliest European vernacular epic.feudal adj.封建的ornamentation n.装饰tag v.貼标签serpentine adj.蜿蜒的.似蛇的incense n.香a flurry of 一阵(风、雨、雷等)ward off避幵,挡住calamity n.灾难,灾祸pantheon n.众神庙whereabouts n.下落,所在地inlaid adj.镶嵌的analogy n.类比fang n.长而尖的牙brandish v.挥舞notorious adj.臭名昭著的city inspector 城管charismatic adj.富有领袖魅力的flamboyant adj.神气的spike n.峰值thrall n.奴隶,束缚。

外语(英语)学习的孔子原理徐老师新著《中国人英语自学方法教程》简介讲座什么是外语学习的孔子原理外语学习的孔夫子原理《中国人英语自学方法教程》中国金融出版社预期2011年春季出版《英语学习的革命——论中国人学英语》中国金融出版社2010年春季出版《英语学习的革命——论中国人学英语》全面提供了中国人外语学习的理论框架与操作指南将有三个版本完全版/ 简化版/ 口袋版原典英语学习法简称为原典法原典英语自学法官方网站三大核心特征:第一.在教育哲学上强调充分发挥个体与生俱来的语言自学能力。

第二. 在学习过程上强调遵循人类语言获得的本原程序——聆听先行。

第三.在学习素材上强调遵循人类语言的经典;强调聆听优质的原版朗诵;从感受优美的声韵而非分析文本来学好语言。

更简略地概括原典法的核心理念,就是“听书”大道至简提倡知行合一,行知合一。

给自己许一个愿:做好一件事改变你一生2007年由深圳海天出版社出版《徐老师原典英语自学法》2011年出版的新书《中国人英语自学方法教程》大部分篇幅都是全新的内容朗读《徐老师原典英语自学法》一书的“前言”的开首两段超越大学教授???徐老师吹大牛???徐老师特别期望帮到“农村户口”的学生对英语学习的正确方法学生和家长了解太少经常被错误的理念误导教育专家能够觉悟吗?授人以渔而非授人以鱼强调思想方法和学习方法“道”VS “术”今天的讲座有三大内容第一部分,介绍一个案例第二部分,深入浅出地讲解外语学习的正确方法的原理第三部分,原典法主干训练程序的概要介绍太阳底下没有新鲜事人类一思考上帝就发笑大道至简语言学习方法的基本原理孔子早就说清楚了!!!外语学习在中国耗费了儿童少年的生命时光效果却很差英语学习并不难关键是你习以为常的学习方法错了大错特错没有启蒙,愚昧长存。

对真正想要学好英语的学生,根本的问题不是应试,不是词汇,句型等等,而应该是观念的启蒙和更新,学习方法真伪优劣的鉴识。

如果不反省关于英语学习的种种荒谬成见,不警觉“被学习”多年而根深蒂固的错误习惯,学习方法必然南辕北辙,学校效果必定少慢差费。

徐火辉原典英语自学法Xu Huohui's Original Classical English Self-Learning MethodIn the realm of English language acquisition, Xu Huohui's Original Classical English Self-Learning Method stands out as an innovative and effective approach that has garnered attention among learners. This method emphasizes the importance of engaging with authentic, classical Englishtexts to develop a deep understanding of the language's nuances and cultural context.The cornerstone of Xu's method is the belief that by immersing oneself in the works of great English authors, learners can not only improve their vocabulary and grammar but also gain insights into the historical and cultural significance of the texts. This approach is particularly appealing to those who are passionate about literature and wish to appreciate English in its purest and most artistic form.Here's a closer look at the key components of Xu Huohui's method:1. Reading Classical Texts: The method encourages learners to read works from the canon of English literature, starting with simpler texts and gradually progressing to more complex works. This helps build a strong foundation in thelanguage.2. Comprehension Before Translation: Xu advises against relying on translations too early in the learning process. Instead, learners should attempt to understand the text inits original language, which fosters a more authentic connection with the material.3. Cultural Context: Understanding the cultural and historical context in which a text was written is crucial. This helps learners to grasp the subtleties of the language and the intentions of the author.4. Vocabulary Building: Through exposure to classical texts, learners naturally encounter a wide range of vocabulary. Xu's method involves not just memorizing words but understanding their usage within the context of the text.5. Grammar Through Reading: Rather than focusing on grammar rules in isolation, Xu's method uses the reading of classical texts to illustrate grammatical structures, making them more memorable and applicable.6. Active Engagement: Learners are encouraged to take an active role in their learning process. This includes annotating texts, discussing themes with peers, and writing essays or reflections on the readings.7. Long-Term Commitment: Xu emphasizes that mastering English through this method requires time and dedication.It's not a quick fix but a journey of continuous learning andimprovement.8. Integration of Skills: The method integrates listening, speaking, reading, and writing skills by using the classical texts as a common source for all language practice.Xu Huohui's Original Classical English Self-Learning Method is not just about language acquisition; it's about cultural immersion and a deeper appreciation for the English language. It's a method that can be particularly beneficialfor those who seek a comprehensive and enriched learning experience.。

徐老师原典英语自学法.txt这是一个禁忌相继崩溃的时代,没人拦得着你,只有你自己拦着自己,你的禁忌越多成就就越少。

自卑有多种档次,最高档次的自卑表现为吹嘘自己干什么都是天才。

电驴资源下面是用户共享的文件列表,安装电驴后,您可以点击这些文件名进行下载徐老师原典英语自学法官方网 /郑重声明:本素材系列经众多师生整理,转载请经楼主同意,仅供学习用,严禁商用【徐老师原典英语自学法】理论与实践《超越哈佛》(徐老师原典英语自学法)节选精华版.pdf 详情 2.5MB《原典月刊》特刊——原典英语实践成果.pdf 详情 1.4MB【徐火辉老师教育随笔】徐火辉老师教育随笔——被“枪毙”了的序言.pdf 详情 229.1KB徐火辉老师教育随笔——向各位青年教师和大学生推荐书目?.pdf 详情 157.7KB徐火辉老师教育随笔——为什么中国英语教学会犯方向性错误.pdf 详情 304.7KB徐火辉老师教育随笔——苏格拉底VS老子VS.少正卯.pdf 详情 185.8KB徐火辉老师教育随笔——上帝之音——“外语学习当以聆听为纲”系列.pdf 详情 165.8KB 徐火辉老师教育随笔——挑刺大翻译家.(.原典法网站上线后写给大学生一小帖.).pdf 详情142.4KB徐火辉老师教育随笔——推荐Twilight?.pdf 详情 129.1KB徐火辉老师教育随笔——答网友文昌之问——邀网友共创作《超越哈佛》第三版.pdf 详情104.6KB【原典英语推荐初级素材】Earlyreads系列(全部为英音)【意大利黑猫出版社Earlyreads系列】使用指南.pdf 详情 408.1KBEarlyreads系列 LEVEL 1(词汇量 100~550)PDF电子书+mp3音频完整下载)【全彩扫描PDF】【Earlyreads】(LEVEL.1).The.Ugly.Duckling.pdf 详情 11.1MB【全文录音MP3】【Earlyreads】(LEVEL.1).The.Ugly.Duckling.rar 详情 2.3MB【全彩扫描PDF】【Earlyreads】(LEVEL.1).The.Enormous.Turnip.pdf 详情 7.7MB【全文录音MP3】【Earlyreads】(LEVEL.1)The.Enormous.Turnip.rar 详情 4.1MB【全彩扫描PDF】【Earlyreads】(LEVEL.1).Dorothy.pdf 详情 6.7MB【全文录音MP3】【Earlyreads】(LEVEL.1).Dorothy.rar 详情 3.2MB【全彩扫描PDF】【Earlyreads】(LEVEL.1).A.Trip.to.the.Safari.Park.pdf 详情 5.2MB 【全文录音MP3】【Earlyreads】(LEVEL.1).A.Trip.to.the.Safari.Park.rar 详情 5.3MB Earlyreads系列 LEVEL 2(词汇量 150~700)(PDF电子书+mp3音频完整下载)【全彩扫描PDF】【Earlyreads】(LEVEL.2).The.Mad.Teacher.pdf 详情 7.6MB【全文录音MP3】【Earlyreads】(LEVEL.2).The.Mad.Teacher.rar 详情 16.6MB【全彩扫描PDF】【Earlyreads】(LEVEL.2).Little.Red.Riding.Hood.pdf 详情 6.7MB 【全文录音MP3】【Earlyreads】(LEVEL.2).Little.Red.Riding.Hood.rar 详情 2.6MB 【全彩扫描PDF】【Earlyreads】(LEVEL.2).Mowgli.learns.to.swim.pdf 详情 6.4MB【全文录音MP3】【Earlyreads】(LEVEL.2).Mowgli.learns.to.swim.rar 详情 16.2MB Earlyreads系列 LEVEL 3(词汇量 200~850)(PDF电子书+mp3音频完整下载)【全彩扫描PDF】【Earlyreads】(LEVEL.3).Cinderella.pdf 详情 7.4MB【全文录音MP3】【Earlyreads】(LEVEL.3).Cinderella.rar 详情 5.5MB【全彩扫描PDF】【Earlyreads】(LEVEL.3).The.Little.Mermaid.pdf 详情 9.3MB【全文录音MP3】【Earlyreads】(LEVEL.3).The.Little.Mermaid.rar 详情 7.4MB【全彩扫描PDF】【Earlyreads】(LEVEL.3).Bugaboo.the.Wicked.Witch.pdf 详情 10MB【全文录音MP3】【Earlyreads】(LEVEL.3).Bugaboo.the.Wicked.Witch.rar 详情 17.1MB 【全彩扫描PDF】【Earlyreads】(LEVEL.3).The.Jungle.Book.pdf 详情 7.6MB【全文录音MP3】【Earlyreads】(LEVEL.3).The.Jungle.Book.rar 详情 13MB【全彩扫描PDF】【Earlyreads】(LEVEL.3).Monster.in.the.Box.pdf 详情 8.6MB【全文录音MP3】【Earlyreads】(LEVEL.3).Monster.in.the.Box.rar 详情 16.9MB Earlyreads系列.LEVEL.4(词汇量.850~1000)(PDF电子书.mp3音频.完整下载)【全彩扫描PDF】【Earlyreads】(LEVEL.4).Aesop's.Fables.pdf 详情 14.2MB【全文录音MP3】【Earlyreads】(LEVEL.4).Aesop's.Fables.rar 详情 5.6MB【全彩扫描PDF】【Earlyreads】(LEVEL.4).Christmas.Fun.pdf 详情 11MB【全文录音MP3】【Earlyreads】(LEVEL.4).Christmas.Fun.rar 详情 14.7MB【全彩扫描PDF】【Earlyreads】(LEVEL.4).Festivals!.pdf 详情 10.5MB【全文录音MP3】【Earlyreads】(LEVEL.4).Festivals!.rar 详情 11.8MB【全彩扫描PDF】【Earlyreads】(LEVEL.4).Puss.in.Boots.pdf 详情 8.1MB【全文录音MP3】【Earlyreads】(LEVEL.4).Puss.in.Boots.rar 详情 6.5MB【全文录音MP3】【Earlyreads】(LEVEL.4).Sleeping.Beauty.rar 详情 7.5MB【原典英语推荐中级素材】04版Black Cat黑猫英语“纯文字版”PDF电子书全下载(共40本书)英国的作品为英音,美国的作品为美音(2004版.Black.Cat黑猫英语).level.1.PDF电子书.rar 详情 3.3MB(2004版.Black.Cat黑猫英语).level.2.PDF电子书.rar 详情 3.4MB(2004版.Black.Cat黑猫英语).level.3.PDF电子书.rar 详情 3.9MB(2004版.Black.Cat黑猫英语).level.4.PDF电子书.rar 详情 8MB(2004版.Black.Cat黑猫英语).level.5.PDF电子书.rar 详情 8.2MB(2004版.Black.Cat黑猫英语).level.6.PDF电子书.rar 详情 4.2MB【原典英语推荐中级素材】04版Black Cat黑猫英语“彩印版”PDF电子书全下载(共40本书)英国的作品为英音,美国的作品为美音【1】1.Peter.Pan.彼得.潘.pdf 详情 17.7MB【1】2.Zorro.蒙面侠佐罗.pdf 详情 16.3MB【1】3.American.Folk.Tales.美国传奇故事.pdf 详情 20.9MB【1】4.Davy.Crockett.美国英雄.pdf 详情 17.7MB【1】5.The.True.Story.of.Pocahontas.风中奇缘.pdf 详情 16.4MB【2】1.British.and.American.Festivities.欢乐体验洋节日.pdf 详情 30.8MB【2】2.King.Arthur.and.his.Knights.亚瑟王与圆桌骑士.pdf 详情 20.2MB【2】3.Oliver.Twist.雾都孤儿.pdf 详情 27.2MB【2】4.The.Jumping.Frog.卡城名蛙.pdf 详情 20.7MB【2】5.Robin.Hood.罗宾汉.pdf 详情 23.3MB【3】1.Great.English.Monarchs.and.their.Times.昔日的英国王室1.pdf 详情 37MB 【3】2.Alic's.Adventures.in.Wonderland.艾丽丝漫游奇境记.pdf 详情 33.3MB【3】3.Oscar.Wilde's.Short.Stories.王尔德短篇故事.pdf 详情 27.6MB【3】4.Hamlet.王子复仇记.pdf 详情 27.6MB【3】5.The.Secret.Garden.秘密花园.pdf 详情 27MB【4】1.The.£1,000,000.Bank.Note.百万英镑.pdf 详情 28.3MB【4】2.Jane.Eyre.简?爱.pdf 详情 36.2MB【4】3.Sherlock.Holmes.Investigates.福尔摩斯探案记.pdf 详情 40.1MB【4】4.Gulliver's.Travel.格利佛游记.pdf 详情 30.6MB【4】5.The.strange.Case.of.Dr.Jekyll.And.Mr.Hyde.化身博士.pdf 详情 28.4MB 【4】6.Classic.Detective.Stories.经典侦探故事.pdf 详情 40.3MB【4】7.The.Phantom.of.the.Opera.歌声魅影.pdf 详情 36.8MB【4】8.Alien.at.School.校园的天外来客.pdf 详情 27.4MB【4】9.Romeo.and.Juliet.罗密欧与朱丽叶.pdf 详情 32.3MB【4】10.Treasure.Island.金银岛.pdf 详情 34.7MB【5】1.A.Christmas.Carol.小气财神.pdf 详情 33.3MB【5】2.The.Tragedy.of.Dr.Faustus.浮士德的悲剧.pdf 详情 40.9MB【5】3.Washington.Square.华盛顿广场.pdf 详情 49MB【5】4.A.Midsummer.Night's.Dream.仲夏夜之梦.pdf 详情 26.7MB【5】5.American.Horror.爱伦.坡恐怖故事.pdf 详情 33.3MB【5】6.Much.Ado.About.Nothing.无事生非.pdf 详情 41.2MB【5】7.The.Canterbury.Tales.坎特伯雷故事.pdf 详情 36.7MB【5】8.Dracula.吸血伯爵.pdf 详情 41.3MB【5】st.of.the.Mohicans.最后的莫希干人.pdf 详情 40.5MB【5】10.The.Big.Mistake.and.Qther.Stories.当代悬疑故事.pdf 详情 39.2MB 【6】1.Frankenstein.科学怪人.pdf 详情 43.8MB【6】2.Pride.and.Prejudice.傲慢与偏见.pdf 详情 46.3MB【6】3.Robinson.Crusoe.鲁滨逊漂流记.pdf 详情 42.9MB【6】4.A.Tale.of.Two.Cities.双城记.pdf 详情 55.8MB【6】5.The.X-Files.Squeeze.X档案之突变异种.pdf 详情 35.6MB【原典英语推荐中级素材】04版Black Cat黑猫英语 mp3音频全下载(共40本书)英国的作品为英音,美国的作品为美音【1】1.Peter.Pan.彼得.潘.mp3.zip 详情 34.8MB【1】2.Zorro.蒙面侠佐罗.mp3.zip 详情 33.6MB【1】3.American.Folk.Tales.美国传奇故事.mp3.zip 详情 34.9MB【1】4.Davy.Crockett.美国英雄.mp3.zip 详情 26.9MB【1】5.The.True.Story.of.Pocahontas.风中奇缘.mp3.zip 详情 33.5MB【2】1.British.and.American.Festivit.乐体验洋节日.mp3.zip 详情 68.4MB 【2】2.King.Arthur.and.his.Knights.亚瑟王与圆桌骑士.mp3.zip 详情 31.8MB 【2】3.Oliver.Twist.雾都孤儿.mp3.zip 详情 51.4MB【2】4.The.Jumping.Frog.卡城名蛙.mp3.zip 详情 31.9MB【2】5.Robin.Hood.罗宾汉.mp3.zip 详情 34.9MB【3】1.Great.English.Monarchs.and.th.日的英国王室.mp3.zip 详情 70.7MB 【3】2.Alic's.Adventures.in.Wonderla.丝漫游奇境记.mp3.zip 详情 60.9MB 【3】3.Oscar.Wilde's.Short.Stories.王尔德短篇故事.mp3.zip 详情 62.8MB 【3】4.Hamlet.王子复仇记.mp3.zip 详情 33MB【3】5.The.Secret.Garden.秘密花园.mp3.zip 详情 39.3MB【4】1.The.£1,000,000.Bank.Note.百万英镑.mp3.zip 详情 41.5MB【4】2.Jane.Eyre.简?爱.mp3.zip 详情 60.2MB【4】3.Sherlock.Holmes.Investigates.福尔摩斯探案记.mp3.zip 详情 61.7MB 【4】4.Gulliver's.Travel.格利佛游记.mp3.zip 详情 53.7MB【4】5.The.strange.Case.of.Dr.Jekyll.yde.化身博士.mp3.zip 详情 63.5MB【4】6.Classic.Detective.Stories.经典侦探故事.mp3.zip 详情 67.3MB【4】7.The.Phantom.of.the.Opera.歌声魅影.mp3.zip 详情 67.4MB【4】8.Alien.at.School.校园的天外来客.mp3.zip 详情 46.5MB【4】9.Romeo.and.Juliet.罗密欧与朱丽叶.mp3.zip 详情 55.1MB【4】10.Treasure.Island.金银岛.mp3.zip 详情 72.3MB【5】1.A.Christmas.Carol.小气财神.mp3.zip 详情 55.6MB【5】2.The.Tragedy.of.Dr.Faustus.浮士德的悲剧.mp3.zip 详情 71.8MB【5】3.Washington.Square.华盛顿广场.mp3.zip 详情 71MB【5】4.A.Midsummer.Night's.Dream.仲夏夜之梦.mp3.zip 详情 56.7MB【5】5.American.Horror.爱伦.坡恐怖故事.mp3.zip 详情 31.9MB【5】6.Much.Ado.About.Nothing.无事生非.mp3.zip 详情 71.6MB【5】7.The.Canterbury.Tales.坎特伯雷故事.mp3.zip 详情 71.7MB【5】8.Dracula.吸血伯爵.mp3.zip 详情 72.7MB【5】st.of.the.Mohicans.最后的莫希干人.mp3.zip 详情 72.3MB【5】10.The.Big.Mistake.and.Qther.St.当代悬疑故事.mp3.zip 详情 47.1MB【6】1.Frankenstein.科学怪人.mp3.zip 详情 68.8MB【6】2.Pride.and.Prejudice.傲慢与偏见.mp3.zip 详情 67.9MB【6】3.Robinson.Crusoe.鲁滨逊漂流记.mp3.zip 详情 62.7MB【6】4.A.Tale.of.Two.Cities.双城记.mp3.zip 详情 69.1MB【6】5.The.X-Files.Squeeze.X档案之突变异种.mp3.zip 详情 50.5MB【原典英语推荐中级素材】Black cat有声名著阶梯阅读(2009年7月版,比04年新增24本)英国的作品为英音,美国的作品为美音徐老师原典英语自学法官方网 /【1】6.Great.Expectations.远大前程.pdf 详情 789.1KB【1】6.Great.Expectations.远大前程.mp3.rar 详情 51.1MB【1】7.Rip.Van.Winkle.and.The.Legend.Hollow.睡谷传奇.pdf 详情 786.9KB【1】7.Rip.Van.Winkle.and.The.Legend.low.睡谷传奇.mp3.rar 详情 36.8MB【1】8.The.Happy.Prince.and.The.Self.王子与自私的巨人.pdf 详情 1MB【1】8.The.Happy.Prince.and.The.Self.与自私的巨人.mp3.rar 详情 31.4MB【1】9.The.American.West.美国西部探险.pdf 详情 722.4KB【1】9.The.American.West.美国西部探险.mp3.rar 详情 24.6MB【1】10.Halloween.Horror.万圣节奇遇记.pdf 详情 765KB【1】10.Halloween.Horror.万圣节奇遇记.mp3.rar 详情 39.9MB【1】12.The.Adventures.of.Huckleberry.哈克贝利?费恩历险记.pdf 详情 22.5MB 【1】12.The.Adventures.of.Huckleberry.哈克贝利?费恩历险记.mp3.rar 详情 36.6MB 【1】13.The.Wonderful.Wizard.of.Oz.绿野仙踪.pdf 详情 787.5KB【1】13.The.Wonderful.Wizard.of.Oz.绿野仙踪.mp3.rar 详情 33.5MB【1】15.The.Wind.in.the.Willows.柳林风声.pdf 详情 769.1KB【1】15.The.Wind.in.the.Willows.柳林风声.mp3.rar 详情 35.5MB【1】18.Little.Women.小妇人.pdf 详情 809.7KB【1】18.Little.Women.小妇人.mp3.rar 详情 53.2MB【1】19.Beauty.and.the.Beast.美女与野兽.pdf 详情 777.5KB【1】19.Beauty.and.the.Beast.美女与野兽.mp3.rar 详情 35.6MB【2】10.Ghastly.Ghosts.鬼魅传奇.pdf 详情 764.4KB【2】10.Ghastly.Ghosts.鬼魅传奇.mp3.rar 详情 45.1MB【6】5.The.Problems.of.Cell.13.十三号死刑牢房.pdf 详情 828.4KB【6】5.The.Problems.of.Cell.13.十三号死刑牢房.mp3.rar 详情 51.3MB文本还没有完全弄好,先传mp3,文本整理好会继续上传,请理解:)【1】14.The.Secret.of.the.Stones.石头的秘密.mp3.rar 详情 39.1MB【1】17.Around.the.World.in.Eighty.Days.八十天环游世界.mp3.rar 详情 61.8MB 【1】20.Black.Beauty.黑骏马.mp3.rar 详情 49.8MB【1】16.The.Black.Arrow.黑箭.mp3.rar 详情 56.1MB【原典英语推荐高级素材一】Gone With the Wind.飘.PDF电子书+mp3音频完整下载(美音)作者:Margaret Michell 朗读:Linda Stevens[飘.ebook]Gone.With.the.Wind.pdf 详情 4.2MB[飘.mp3]Gone.With.The.Wind-1.zip 详情 114.3MB[飘.mp3]Gone.With.The.Wind-2.zip 详情 107MB[飘.mp3]Gone.With.The.Wind-3.zip 详情 113.6MB[飘.mp3]Gone.With.The.Wind-4.zip 详情 112.2MB[飘.mp3]Gone.With.The.Wind-5.zip 详情 108.2MB[飘.mp3]Gone.With.The.Wind-6.zip 详情 107.7MB[飘.mp3]Gone.With.The.Wind-7.zip 详情 109.4MB[飘.mp3]Gone.With.The.Wind-8.zip 详情 104.5MB[飘.mp3]Gone.With.The.Wind-9.zip 详情 102.3MB【原典英语推荐高级素材二】A.Short.History.of.Nearly.Everything.万物简史.PDF电子书+mp3音频完整下载(英音)[万物简史.ebook].A.Short.History.of.Nearly.Everything.pdf 详情 2.7MB[万物简史.mp3].A.Short.History.of.Nearly.Everything.rar 详情 244.4MB《万物简史》(中译本).[美]比尔?布莱森.[译者]严维明.陈.邕.pdf 详情 13.6MB【原典英语推荐学习软件】mp3切割_MP3Cutter4.0.zip 详情 328.8KB电子词典_金山词霸2009牛津版PowerWord_2009_Oxford.zip 详情 794MBmp3播放_暴风影音2009_3.9.5.29.exe 详情 30.2MBPDF阅读器_AdobeReader_9.1.exe 详情 42.8MB【原典英语拓展素材一】Pride and Prejudice 傲慢与偏见.PDF电子书+mp3音频完整下载(英音)[傲慢与偏见.ebook]Pride_and_Prejudice.pdf 详情 5MB[傲慢与偏见.mp3]Pride.and.Prejudice.zip 详情 365.7MB【原典英语拓展素材二】Walden.瓦尔登湖..PDF电子书+mp3音频完整下载(英音)作者:Henry David Thoreau 朗读:William Hope[瓦尔登湖.ebook]Walden.pdf 详情 719.1KB[瓦尔登湖.mp3]Walden.rar 详情 284MB【原典英语拓展素材三】A Tale of Two Cities 双城记.PDF电子书+mp3音频.完整下载(英音)[双城记.ebook]A.Tale.of.Two.Cities.pdf 详情 1.5MB[双城记.mp3]A.Tale.of.Two.Cities.rar 详情 550.6MB【原典英语拓展素材四】The Twilight Saga.暮光之城 .PDF电子书+mp3音频完整下载(美音)[【徐老师原典英语自学法素材库】原版英文有声分级读物(英音和美音)audiobooks.(Black.Cat有声名著阶梯阅读等)不断更新].Stephanie.Meyer.Twilight.Saga.(Book.1).Twilight.pdf 详情 526.2KB[【徐老师原典英语自学法素材库】原版英文有声分级读物(英音和美音)audiobooks.(Black.Cat有声名著阶梯阅读等)不断更新].Stephanie.Meyer.Twilight.Saga.(Book.2).New.Moon.pdf 详情 681.9KB[【徐老师原典英语自学法素材库】原版英文有声分级读物(英音和美音)audiobooks.(Black.Cat有声名著阶梯阅读等)不断更新].Stephanie.Meyer.Twilight.Saga.(Book.3).Eclipse.pdf 详情 1.1MB[【徐老师原典英语自学法素材库】原版英文有声分级读物(英音和美音)audiobooks.(Black.Cat有声名著阶梯阅读等)不断更新].Stephanie.Meyer.Twilight.Saga.(Book.4).Breaking.Dawn.pdf 详情 1.7MB[【徐老师原典英语自学法素材库】原版英文有声分级读物(英音和美音)audiobooks.(Black.Cat有声名著阶梯阅读等)不断更新].Stephanie.Meyer.Twilight.Saga.(Book.1).Twilight.Mp3-VBR.rar 详情 141MB [【徐老师原典英语自学法素材库】原版英文有声分级读物免费下载(英音美音)audiobooks.(Black.Cat有声名著阶梯阅读)更新中].Stephanie.Meyer.Twilight.Saga.(Book.2).New.Moon.Mp3-48kbps.rar 详情 293.9MB [【徐老师原典英语自学法素材库】原版英文有声分级读物(英音和美音)audiobooks.(Black.Cat有声名著阶梯阅读等)不断更新].Stephanie.Meyer.Twilight.Saga.(Book.3).Eclipse.Mp3-32kbps.rar 详情 197.9MB [【徐老师原典英语自学法素材库】原版英文有声分级读物免费下载(英音美音)audiobooks.(Black.Cat有声名著阶梯阅读)更新中].Stephanie.Meyer.Twilight.Saga.(Book.4).Breaking.Dawn.Mp3-48kbps.rar 详情382.3MB【说明】亲爱的网友您好,本帖素材来源于原典英语网站,所以更新晚于论坛您可以前往原典英语交流论坛下载 PDF 和 MP3下载地址: /bbs/showtopic-269.aspx【EARLYREADS系列】学习交流QQ群:19066170【EARLYREADS系列】素材交流论坛(原典英语自学法交流论坛)/bbs声明:以上资源均来自互联网,如需看书,请购买正版书。

英文版电影《孔子》中国学经典引语英译在对外汉语教学中的运用戚宇光一.英文配音版电影《孔子》及其国学经典引语2010年胡玫执导的电影《孔子》以史诗般波澜壮阔的叙事再现了中华儒圣孔子后半生周游列国推行仁政,至晚年结庐桑梓,著述《春秋》的生命历程,众多情节更是见诸史端,为后人所津津乐道,如“觐见鲁公”,“问礼老子”,“子见南子”,“夹谷会盟”,“陈蔡绝粮”等。

影片以其独特的历史背景和文化关注表现了公元前六世纪这个华夏文明滥觞时代围绕孔子的一系列历史事件和人物,成为新世纪国学题材电影不可多得的亮点,在东亚地区掀起了一股争睹的狂潮,并波及欧美诸国。

2012年英文DVD版《孔子》的问世,标志着该片在北美市场占有一席之地。

作为中国大陆制作罕见能打入好莱坞DVD电影市场的作品,其作品主题的不可替代性起到的作用不言而喻。

作为高度浓缩的反映传统文化的影视精品,将其引入对外汉语专业的课堂,并结合其国学经典引语的英译讨论中国文化主题,具有独特的意义。

电影《孔子》一个突出的特点就是国学经典引语的引用,散见于“觐见鲁公”(孔子面见鲁定公推行仁政的主张),“问礼老子”(孔子与老子在虚拟的山巅论道的对话,老子劝孔子参透名利),“子见南子”(戏剧化的孔子婉拒卫国荡妇南子的引诱的场景),“夹谷会盟”(齐鲁在夹骨会盟,孔子施展外交才能为鲁国争回汶上失城),“陈蔡绝粮”(孔子和门徒在陈蔡边境陷入绝粮困顿), “释奴之辩”(虚构的孔子在鲁国朝堂为私藏的小奴辩护赢回人身自由,表现孔子的仁义思想)等六个片段中。

二. 英文版《孔子》电影中国学经典引语的英译及不足影视台词翻译的要遵从“经济原则”,“同步原则”和“通俗原则”(么孝颖:140-141),对于打入好莱坞市场的英文版《孔子》自然也不例外,让我们分场景一一考察以上国学经典引语的台词翻译,并进行其与通行权威出版物译文的差异分析:(“觐见鲁公”一幕)不在其位不谋其政。

(《论语·泰伯》)I have no say without position.本句翻译表达原意,符合口语化的原则,而坊间流行的杨殿爵译文作如下处理:I will not concern myself with matters of government unless they are the responsibility of my office. 是为处理《论语》原意的理想译文。

LEO“论语”英思力英语内训- 2014 -10次课程安排1.语法概述;主语2.谓语;非谓语3.宾语;宾语从句4.表语;表语从句5.定语;定语从句6. 状语;状语从句7. 补语;同位语8. 语序;倒装9. 疑问句10.强调;省略分组第一节Sep. 9th, 2014教学目标:⑴了解语法体系 10'⑵熟悉英语主语的构成 15'⑶掌握主谓一致的规律 15'⑷书写IT 句型 10'你不得不知的语法术语和规律▪词性▪句子成分▪5大简单句型▪名词、形容词副词、动词、代词、数词变化规律英语语法体系小组活动:找出下列句子的主语▪ESL is a language training institute.▪The rich should help the poor.▪To see is to believe.Seeing is believing.▪I work in ESL.▪Two days is enough .▪What I do is to teach English.思考:1.什么做主语?2.谓语动词是单数还是复数?小组挑战:找出下列句子的主语▪Air as well as water is matter.▪The poet and writer has come.▪ A hammer and a saw are useful tools.▪Every boy and every girl likes to go swimming.▪Each of us has something to say.▪Many a boy likes playing basketball.▪His clothes are good.▪ A pair of glasses is on the desk.▪Most of the apples were rotten.▪Most of the apple was eaten by a rat.▪He or you have taken my pen.▪Mary is one of those people who keep pets.▪Mary is the only one of those people who keeps pets.It 用法It 位于句首的句型▪It is wise of him to make such a decision.▪It’s very dangerous for children to play with fire.▪It is suggested that the book (should) be revised.▪It is a pity that such a thing ( should ) happen in your class.▪It’s no use talking with him, because he won’t listen.▪It took thousands of people many years to build the Great Wall.▪It is 5 minutes since the bus left.▪It was 3 hours before he came back.▪It will be Monday when he comes back.▪It’s (high/about) time (that) we handed in/should hand in our homework.▪It is the third time that I have seen the film.▪It was last week that I met an old friend in the street.▪It was because he was ill that he didn't come to school yesterday▪It is you,rather than he,that are to blame for the accident.▪It was in the restaurant where we had dinner last Sunday that you left you r wallet.练习:口译1.对于我们来说,下班后上课是很智慧的。

外语(英语)学习的孔子原理

徐老师新著

《中国人英语自学方法教程》

第一讲第三节

今天讲座的最后一个内容

什么是原典英语自学法——

它的核心训练程序简称为321X 法什么是3-2-1-X 法?

语言是人与生俱来的自学能力,这是亘古的常识。

轻蔑亘古智慧,而“发明”出各种各样弄巧成拙的教学法,是外语教学“少慢差费”的主要原因。

原典英语自学法,顾名思义

就是强调

第一. 在学习过程上遵循人类语言获得的本原程序——聆听先行;

第二. 在学习素材上遵循人类语言的经典;

第三. 经典文本必须通过英美专业演员的经典朗诵来表达,学生从感受声情并茂的朗诵而非语法分析文本来学习语言;

第四. 在学习方式上充分发掘人类天赋的语言自学能力。

在以上大前提下,把原典法简称为

3-2-1-X 法

321X

先专注聆听多于3

遍认真读

多于2遍

再欣赏

聆听多

于1遍

自由选择

扩展提高

训练,例

如精听,

跟读,朗

诵,口语3-2-1-X 法

即训练程序为:

1.一定要先聆听,而不要先阅读;

2. 必须重复聆听;

3. 聆听之后跟进阅读听过的内容;

4. 然后再循环聆听读过的内容;

5. 最后选择性地就听-读-听过的素材做扩展训练。

3-2-1分别为听-读-听的最低重复次数

若学生基础弱,则可用632X法。

随着学习者程度提高,聆听或阅读的重复次数可以减少,321X法可以调整为311X法或300X法,等等。

初学者应该从分级的原版英语儿童有声书或多媒体书入手。

不宜用国内专家编写或改编的教材

如果原文较长则不须一次全部听完,宜分成5-20分钟段落聆听。

程度越低,分段时间越短,初学者以2-5分钟一

段为宜。

但也不宜过短。

每听完一段,即专注聆听多于三遍,就可进入下一步训练阶段,即认真阅读。

然后再次循环聆听。

初学者要集中在前三步听-读-听的

训练,X 扩展训练可适当延后。

原典英语一体化训练法概括

3-2-1循环操作

只听不读→单纯阅读或边听边读

→只听不读→

(扩展提高:精读、朗诵、说与写)

非常简单!!!

几大注意事项

1.向婴儿学习;听不清听不懂也要坚持无烦躁无挫折地静心聆听。

婴儿聆听了整整一年才逐步开口说话

婴儿学语言的特点:

越复杂的语音流越自发专注聆听

(一个纠正,讲座中说“婴儿听不清”是口误,婴儿能够听清,但很长的

时间内听不懂)

学外语的最大主观障碍之一

听不清听不懂

三分钟开始烦躁

五分钟倍感挫折

十分钟抓狂

解决办法:

向婴儿学习,调整心态,听不清听

不懂也要无烦躁无挫折地静心聆听。

2.部分学生求成心切,或者为着降低聆听时的难度,往往喜欢先细读英文文本,甚至先读中译本,等弄懂了素材的意思之后,再尝试聆听音频文件。

这种做法是根本错误的。

绝对不要颠倒顺序,即决不可

×先读文本,再听

××先读中文,再读英文,最后听这种方法可以称作是“英语自杀学习法”。

3. 可用MP3在非专注的活动中同步聆听,充分利用零星片段时间,积少成多。

同时提醒两点:

A. 保护听力。

B. 与其他活动同步聆听时注意安全。

4.聆听要英式音美式音并用,口语盯住一种发音训练。

初始训练时不必急于练口语,先用321X法训练达到两个月以上,再开始训练口语比较合适。

后续会详细介绍口语训练的方法。

讲座重点在于引导你掌握

正确的高效率的英语学习方法。

徐老师蒙人???

外语学习的孔子原理呢???

当代科学多学科前沿研究的结论:

聆听(语音加工)是人类语言的自学能力赖以存在、维系和发展的基础技能,它在语言学习中具有本原的重要性和绝对的优先性。

语言学习的荷马原理(Homer Principle)应当是一切高效率的外语教学体系的基准原理。

缺乏对荷马原理的深刻理解,是各种外语教学法效果不佳的主因。

本讲座的“谜底”语言学习的荷马原理

就是

语言学习的孔子原理

我们不要数典忘祖现在徐老师跟各位一起回顾中华文化的原典

诗言志,歌永言,声依永,律和声,八音克谐,无相夺伦,神人以和。

(春秋)孔子:《尚书》

诗为乐心,声为乐礼。

乐辞曰诗,诗声曰歌。

刘勰:《文心雕龙》

近现代中国人经常犯傻???

当代的教育专家不明白

孔子首先是一个古典的贝多芬

《墨子·公孟篇》曰:

“诵诗三百,弦诗三百,歌诗三百,舞诗三百。

”

司马迁《史记》言:

“诗三百五篇,孔子皆弦歌之”。

孔子是三位一体的大师

音乐大师+ 语言大师+教育大师

孔子是古典的歌坛巨星乐坛巨星是古典的贝多芬+ 迈克·杰克逊

孔子晚年四处讲学

而他的的讲学传教中,“歌坛巨星”式的传教最为可爱,史书对此多有明确记载。

《吕氏春秋·慎人》曰:

孔子穷于陈蔡之间……

孔子弦歌于室,颜回择菜于外;

《孔子家语·困誓》曰:

孔子遭厄于陈蔡之间,绝粮七日,弟子馁病,孔子弦歌。

子路入见……子路悦,援戚而舞,三终而出。

1000年后的

南宋的郑樵在《通志·乐略》中

《通志》也是一部重要的经典著作

已严厉批评华夏的语言教育渐入歧途:

“诗为声也,不为文也。

凡律其辞则谓之诗声,其诗则谓之歌,作诗未有不歌者也,诗者乐章也。

诗三百篇皆可歌可诵可舞可弦,大师世守其业以教国子,自成童至既冠皆往习焉,诵之则习其文,歌之则识其声,舞之则见其容,弦之则寓其意……后之弦歌与舞者皆废,直诵其文而已,且不能言其义,故论者多失诗之意。

”

(南宋)郑樵《通志·乐略》

当代的所谓教学专家,歌不能歌,舞不能舞,弦不能弦,只能用什么支离破碎的,甚至碎尸万段的多项选择题填空题来教语言,什么CLOZE TEST,什么克漏字。

想想一千年中国大学者的评论:

“诗为声也,不为文也”。

语言是声音,语言是音乐,语言根本不是什么克漏字。

什么是原典法?就是语言学习的荷马原理。

什么是语言学习的荷马原理?就是语言学习的孔子原理。

西方的原典文化与东方的原典文化西方的原典大师与东方的原典大师在最根本的方面,是完全相通的。

结论:

外语学习的根本原理

对西方人是荷马原理

对中国人就是孔子原理

从一个真实案例开始以一个真实案例结束

读者北京礼来贸易公司的李全喜先生对原典法的评论。