车载点烟器结构.

- 格式:ppt

- 大小:7.56 MB

- 文档页数:15

点烟器工作原理

点烟器是一种用来点燃香烟或者蜡烛的设备。

它主要由以下几个部分组成:电池、火花产生器、点火装置和开关。

点烟器的工作原理如下:当用户按下开关时,电池开始供电。

电池的电能通过火花产生器转化为高压电能。

火花产生器中有一个线圈,当电流通过线圈时,会产生一个强大的磁场。

线圈中的磁场会与火花产生器中的金属杆相互作用,产生高压火花。

高压火花通过点火装置传递给香烟或者蜡烛的燃烧物。

点火装置通常由一个金属引线和一个导电材料组成。

当高压火花接触到导电材料时,它会导致导电材料产生非常高的温度,从而引燃烟草或者蜡烛。

点烟器的开关可以控制电池的通断,从而实现点火和熄火的功能。

当用户松开开关时,电池断开供电,火花产生器停止工作,点火装置不再产生火花,烟草或者蜡烛熄灭。

总之,点烟器通过电池供电,利用火花产生器产生高压火花,再通过点火装置将高压火花传递给烟草或者蜡烛,从而实现点燃的功能。

汽车点烟器的原理

汽车点烟器是一种用来点燃香烟或其他可燃物的设备。

它的工作原理非常简单,主要由以下几个部分组成:

1. 电源:汽车点烟器通常使用车载电源作为电力来源。

当点烟器插入车辆的点烟器插座中时,电源就会提供必要的电能。

2. 发热丝:发热丝是点烟器的核心组件,它由高电阻合金丝制成。

当电流通过发热丝时,丝内的电阻会产生热量,使丝变得非常热。

这样,发热丝就能够点燃可燃物。

3. 点火装置:点火装置通常由发热丝和触发装置组成。

当点烟器处于工作状态时,触发装置会将电流传递到发热丝上,使它迅速升温。

一旦发热丝达到足够高的温度,它就能够使接触到它的可燃物燃烧。

4. 点火开关:点火开关用于控制点烟器的开关状态。

当开关处于打开状态时,电流可以流经点火装置,从而点燃可燃物。

当开关处于关闭状态时,电流将不再流过点火装置,停止点燃燃料。

需要注意的是,汽车点烟器的设计通常考虑到安全性和可靠性。

一些点烟器可能配备了过热保护装置,当温度超过一定阈值时会自动断电,以防止过热引起的安全问题。

此外,在使用点烟器时也要小心保持适当的通风,以避免烟雾积聚和影响驾驶员的视线。

汽车内的点烟器原理

汽车内的点烟器(也称作点烟插座)的原理是利用车辆的电力系统提供电源,为用户提供点烟和使用电子设备的功能。

汽车内的点烟器通常是由以下四个主要部件组成:

1. 点烟器插孔:汽车中配备有一个专门的插孔,用于插入点烟器或其他电子设备。

2. 点烟器线圈:车辆的电源通过点烟器线圈供电,通常是12V的直流电。

3. 熔断器:点烟器线路通常与车辆的熔断器连接,以保护汽车电力系统不被过载或短路所损坏。

4. 点烟器/电源适配器:点烟器/电源适配器是插入插孔的可移动部分,它包含一个或多个电源插座,供用户插入和连接电子设备。

当用户将点烟器或其他设备插入汽车的点烟器插孔时,电源线圈与车辆电源系统连接,车辆电源系统将直流电流(通常为12V)提供给点烟器或其他设备。

一旦电源连接成功,电子设备就可以从点烟器或电源适配器中获得电力。

用户可以使用点烟器来点燃香烟或使用电子设备,如充电手机、导航仪、车载音响等。

需要注意的是,点烟插座通常只能提供有限的功率,并且并非所有的电子设备都可以连接到点烟器上。

因此,在使用点烟器供电的时候,用户需要确保所连接的

设备的功率需求不会超过点烟器插孔的额定功率承载能力。

若功率过大可能导致点烟器烧毁或车辆电源系统过载。

此外,使用点烟器供电时也需要注意电线和连接的安全,避免短路或电源线松动所产生的安全风险。

东风天龙点烟器说明书

摘要:

一、引言

二、东风天龙点烟器概述

1.产品简介

2.产品功能

三、使用方法

1.安装点烟器

2.连接点烟器与烟

3.开启与关闭点烟器

四、注意事项

1.使用环境

2.安全操作

3.维护与保养

五、结束语

正文:

【引言】

东风天龙点烟器是一款汽车点烟器,为广大车主提供了便利的抽烟体验。

本说明书将详细介绍东风天龙点烟器的使用方法及注意事项。

【东风天龙点烟器概述】

东风天龙点烟器是一款设计独特、性能优良的汽车点烟器。

它具有以下特

点:

1.产品简介:采用高品质材料制造,外观时尚,耐用性强。

2.产品功能:方便车主在驾驶过程中抽烟,同时具有防滑功能。

【使用方法】

1.安装点烟器:将点烟器插入汽车点烟器插座,确保其牢固。

2.连接点烟器与烟:将烟插入点烟器上的烟孔,确保烟与点烟器紧密连接。

3.开启与关闭点烟器:按压点烟器上的开关,即可实现点烟器的开启与关闭。

【注意事项】

1.使用环境:请勿在潮湿、高温或极寒的环境中使用点烟器,以免影响其使用寿命。

2.安全操作:使用点烟器时,请勿将点烟器过度拉伸,以免造成安全隐患。

3.维护与保养:定期清洁点烟器,保持其清洁,以延长使用寿命。

【结束语】

感谢您选择东风天龙点烟器,希望本说明书能为您提供便利的使用体验。

如有任何问题,请随时与我们的客服联系。

汽车点烟器标准(Standard for automobile cigarette lighter)QCinCentral ChinaHuahuarenPeopleThe people and the peopleCommon RepublicGuo and GuoChina National steamSteam carCar dealerLine industryTrade markStandardSureQC/T 415 - 2006Instead of QC/T 415-1999Cigarette lighter and power socket for automobiletechnical conditionsCigarette, Lighter, and, power, socket, for, automobileTechnical requirements(Draft for comment)200X-XX-XX releases 200X-XX-XX implementationPromulgated by the national development and Reform CommissionQC/T415 - 2006PrefaceThe original standard QC/T 41519991986 released, has not adapted to the present situation of the standard on the basis of the original standard,.Combine the current development of the industry and revise with reference to advanced foreign standards.This standard mainly refers to the foreign advanced standards: Japanese industrial standard JIS D 5807, American Associationof Automotive Engineers standardsSAE/USCAR-4 and related products standards of world famous automobile manufacturing companies.The technical requirements and test methods of this standard are equivalent to the foreign advanced standards, and the technical specifications of this standard are approaching or reaching the international level.This standard is standardized by the national automobile Standardization Technical committee.Responsible for drafting the standard: Wenzhou Huake Industry Development Co Ltd.Chief draftsman:Technical specifications of cigarette lighter and power socket for automobile1 rangeThis standard specifies the technical requirements, test methods, inspection rules, signs, packaging, transportation and storage of cigarette lighters and power outlets for automobilesDeposit.This standard applies to the nominal voltage 12V, 24V systemof various types of automotive cigarette lighter and power outlet.2 normative reference documentsThe terms in the following documents are referenced by this standard and become the provisions of this standard. Any dated reference document, followed by all of themThe amendment (excluding the content of the Corrigendum) or the revised version does not apply to this standard; however, it is encouraged to study in accordance with this standardCan you use the latest version of these files?. Any undated reference document whose latest edition is applicable to this standard.Basic technical specifications of electric equipment for GB/T413 - 2002 automobileISO 16750-3 - 2003 environmental conditions and tests for electrical and electronic equipment for road vehicles Part third: mechanical load3 technical requirements3.1 product drawings and technical documentsCigarette lighter and power outlet shall be manufactured according to the drawings and technical documents approved by the prescribed procedures.3.2 appearance, installation size and material requirements3.2.1 check the installation size with measuring tools, should comply with the requirements of the drawings.3.2.2 visual black metal parts surface should be treated against corrosion, the surface should be crack, rust, deformation, damage.3.2.3 inspect the surface of non-metal parts without damage, crack and deformation.3.2.4 inspection, riveting and screw connections should be reliable contact, not loose or automatic loosening phenomenon.3.2.5 materials should meet the requirements of environmental protection and avoid using harmful substances.3.2.6 material flame resistance: non metallic material combustion speed shall not exceed 100mm/min.3.3 working conditionsOperating temperature range: -40 ~ 70 DEG C.Ambient humidity: relative humidity is not greater than 90%. Rated voltage: 12V/24VOperating voltage range: 9V to 16V/21.6V to 32V3.4 function3.4.1 reset timeWhen the cigarette lighter plug is pushed from the normal position into the hot bimetal seat, it should be in the 18S (after the endurance test should be within 22S)Cut off the power and return to its normal position.3.4.2 insulation propertyWhen the plug of the cigarette lighter is cut off from the power source, the temperature of the plug is not less than 380 DEG C after 20s 10s, and not less than 280 DEG C after the temperature of the plug.3.4.3 operating currentCigarette lighter at rated voltage consumption current is not greater than 10A/12V, not greater than 5A/24V.3.4.4 voltage dropThe power outlet can withstand more than 10A of current at rated voltage, and its voltage drop is not more than 100mV.3.5 polarity3.5.1 cigarette lighter: the terminal connected with thebimetal shall be the positive pole of the power supply and the case shall be the negative pole.3.5.2 power outlet: the terminal connected with the center contact shall be the positive pole of the power supply and the case shall be the negative pole.3.6 overheating protection3.6.1 cigarette lighter should have overheat protection function to avoid continuous heating when the cigarette lighter can not be reset properly.Overheating protection time should be controlled within 90s.3.6.2 power outlet generally does not have overheating protection function. In addition to special design, cigarette lighter should not be used as power outlet.3.7 mechanical properties3.7.1 plug insertion forceThe power of the cigarette lighter plug in the bimetallic plate shall be no more than 20N.3.7.2 plug pull outThe pulling force of the cigarette lighter plug should be in the range from 13N to 36N.3.7.3 terminal strengthThe wiring terminal shall be able to withstand the 98N static load within a specified time.3.8 electrical performance3.8.1 overvoltage intensityThe cigarette lighter shall comply with the 3.4 functional requirements after the overvoltage test.3.8.2 reverse voltageCigarette lighter in reverse voltage test should comply with 3.4 functional requirements.3.8.3 insulation withstand voltageCigarette lighter and power outlet in the case of breaking, positive and negative between the pressure test does not puncture. The insulation resistance is not less than 20M ohm.3.9 temperature cycleCigarette lighter in the process of temperature cycling test and after testing, should comply with 3.4 functional requirements. At 70 C, 40 DEG C, resetLess than 25s, insulation performance is allowed to decrease.3.10 humidityCigarette lighter in the humidity test process and after testing, should meet 3.4 functional requirements.3.11 vibrationCigarette lighter in the vibration test process and after the test function is normal, must not have deformation, cracks or loose and other defects, should be in line with 3.4 functionsO.3.12 durabilityThe service life of cigarette lighter shall be no less than 8000 times.The service life of power socket shall be no less than 10000 times.4 test method4.1 test conditions4.1.1 test voltage: 14V + 0.2V/12V; 28V + 0.2V/24V4.1.2 environment temperature is 23 + 5;The accuracy of 4.1.3 voltmeter and ammeter should be no less than 0.2, the ripple factor of regulated power supply is notgreater than 0.1%, and the temperature meter accuracy is 0.01 degrees centigrade.4.2 reset time4.2.1 cigarette lighter plug from the normal position into the double metal seat, should be automatically cut off the power supply in 18S, and restored to normal position.4.2.2 cigarette lighter after endurance test, then reset test, the reset time should be in 22s.4.3 heat preservation performanceAfter the cigarette lighter is reset 10s, the insulation performance is measured by a point thermometer. The reset action is performed at least three times, and the measured mean is calculated. TimeStopwatch available.4.4 socket voltage dropThe power outlet is connected with a 10A to measure the pressure drop between the positive terminal of the socket and the positive contact and the pressure drop between the negative terminal and the outer sleeveThe total sum shall not exceed 100mV.4.5 overheating protectionIf the cigarette lighter is controlled in a state that can not be normally reset and continuously heated, the power supply shall be cut off in 90s.The power outlet is in the normal working position, the power on the 10A work continuously, 1H should not happenshort-circuit phenomenon.4.6 mechanical properties4.6.1 plug insertion forceApplying the insertion force of the cigarette lighter button at the top, measured with a dynamometer. For each measurement, the plug is rotated 120 degrees, measured three times, and calculatedAverage value.4.6.2 plug pull outApplied in cigarette lighter output dial button neck, measured with a dynamometer. For each measurement, the plug is rotated 120 degrees, measured three times, and calculatedAverage value.4.6.3 terminal strengthIn the axial terminal applied 98N static Heli negative 1min.The insert shall be free of distortion.4.7 electrical performance4.7.1 overvoltage intensityCigarette lighter in loading 24V + 0.5V/48V + 0.5V voltage, press the cigar lighter plug work, and then automatically reset. 30s recoveryReturn to test voltage, test function.4.7.2 reverse voltageAs specified in QC/T 413, the 12V rated voltage applies a reverse voltage of 14V + 0.2V, a nominal voltage of 24V, and a reverse voltage is applied to the 3.7.128V + 0.2V. After 1min, disconnect, resume the positive connection, test function.4.7.3 insulation withstand voltageMeasurement method according to QC/T 413 in accordance with the provisions of 3.8.1, between positive and negative poles applied 550V, 50Hz alternating current, which lasted 1min. Employing a trillionMeasurement of insulation resistance.4.8 temperature cycleAccording to table 1 for temperature cycle, according to the required frequency to test the maximum current, insulation performance. The temperature conversion time shall not exceed 30min.Table 1 temperature cycle programOrder I, II, III, IVOperating temperature 7050-18 -40Hold time, H 2111Test interval, min 5555Test times, times 55554.9 humidityPut the cigarette lighter in the high and low humidity test chamber, keep 4H at 65 98%RH relative humidity, and then reduce the humidity to 50%RH,Keep 4H; during this period, work cycle once per hour.4.10 vibrationTurn the cigarette lighter on the vibration test stand and press ISO 16750-3 - 2003 for 4.1.2.4 test IV. (Figure 1) at X, Y, ZThree directions of vibration 2h, after testing meet 3.4 requirements.Frequency range: 10Hz to 1000Hz, acceleration 27.8m/s 2Fig. 1 vibration curve4.11 durability4.11.1 cigarette lighter4.11.1.1 put the cigarette lighter on the durability test stand, in the normal working position, once every closed circuit, the button should be finished from the socketFully pulled out about 15 degrees around the axis;4.11.1.2 to be naturally cooled to room temperature (allowing forced cooling), then proceed to the next closure test;Interruption is allowed during the 4.11.1.3 test, but each successive test shall be no less than 4h;4.11.1.4 performed 8000 closed trials and tested the function after the test.4.11.2 socketThe 4.11.2.1 socket is placed on the durability test bench, in normal working position, and loaded with 10A current;4.11.2.2 each time the plug is inserted into the 6S, then the plug is pulled out and the 10s is disconnected, and the plug is inserted and pulled out at no more speed6.5cm/s once the circuit is closed, the plug should be completely removed from the socket and rotated about 15 degrees around the axis;Interruption is allowed during the 4.11.2.3 test, but each successive test shall be no less than 4h.4.11.2.4 cycle 10000 times, test after detection function.5 inspection rulesThe product must be inspected and qualified to leave the factory and is accompanied by a document showing the quality of the product.5.1 factory inspectionFactory inspection items: appearance and installation size, reset time, work current, insulation performance.5.2 type inspection5.2.1 type inspection itemsFor type inspection items, cigarette lighter is shown in Table 2, and power outlets are shown in table 3.5.2.2 sampling methodFrom the factory inspection of the same batch of products extracted 24 pieces, divided into four groups. After checking the factory inspection items, according to table 2 and form 3.5.2.3 decision principleThe type inspection of the product must meet all the requirements. If the durability item is not up to standard, the type test shall be deemed to be unqualifiedEligible items may be double extracted and re examined for unqualified items. If there are still unqualified, the type inspection shall be deemed to be unqualified.Table 2 type inspection items for cigar lighterSerial number inspection itemsSample groupingI, II, III, IVTick tick tick tick 1 appearance2 V - Mounting dimensionsTick tick tick tick 3 reset timePlease tick tick tick 4 working current5 plug - tick6 - V - voltage strength7 - V - reverse voltage8 - tick - Insulation9 V - Vibration10 - V - temperature cycling11 humidity - tick -12 terminal strength - V13 durability - B.14 - V - overheating protection15 - tick tick tick insulationTable 3 type inspection items of power supply socket Serial number inspection itemsSample groupingI, II, III, IVTick tick tick tick 1 appearanceTick tick tick tick 2 voltage drop3 - tick - Insulation4 V - Vibration5 - V - temperature cycling6 humidity - tick -7 terminal strength - V8 durability - B.Tick tick tick tick 9 voltage drop6 signs, packaging, transportation and storage6.1 product markThe product mark shall conform to the relevant regulations of the state on the marking of products, and shall indicate the product name, model number, date of manufacture and system in the packageThe name, site and standard of this product are standard number, packing number, gross or net weight, shock proof and moisture proof.6.2 product packagingProduct packing should be firm, and anti vibration, moisture-proof, to ensure that in normal transportation without damage.6.3 product storageProducts should be stored in ventilated, dry, no harmful gas, chemicals warehouse.Product inspection valid for two years (from the date of warehousing), expired products should be re examined, qualified factory.。

车载点烟器怎么用

车载点烟器是一种电子设备,用于给车辆提供电源以供使用其他电子设备充电或工作。

以下是使用车载点烟器的一般步骤:

1. 找到车辆上的点烟器插孔,它通常位于驾驶员座位附近的中控台上。

2. 将点烟器插头插入点烟器插孔。

插头通常有圆柱形或类似于圆锥形的形状,并且应与插孔大小相匹配。

插头插入时需要一定的插入力。

3. 在插入插头后,点烟器电源将开始为插入的设备提供电源。

4. 现在,您可以将需要充电或使用电源的设备插入点烟器插座上的USB端口或电源输出。

请注意,根据不同的车型和点烟器品牌,使用方法可能会有所不同。

因此,在使用车载点烟器之前,您应该先阅读所附的说明书,以了解具体的使用指南。

车载点烟器原理

车载点烟器是一种用于给汽车提供电力的设备。

它通过汽车的点烟器插座来提供直流电源,以便连接和使用各种电子设备。

车载点烟器的工作原理是利用汽车电路中的直流电,将其转换为适合电子设备使用的电压。

当点烟器插头插入汽车的点烟器插座时,电流从汽车电路系统进入点烟器内部。

在点烟器内部,电流经过一个转换器(通常是一个DC-DC转换器),将汽车电路中的12伏直流电转换为低电压,如5伏或3.3伏。

这样的低电压适用于许多电子设备,如手机、平板电脑、导航系统、充电宝等。

此外,车载点烟器通常还配备了多个USB插口,以便同时给多个设备充电。

有些车载点烟器还具有额外的功能,如LED 电压显示器,通过显示器可以实时监测并显示汽车电路的电压情况。

总之,车载点烟器通过转换汽车电路中的直流电,为电子设备提供适合的电压,使其可以在汽车上使用。

它为驾驶者和乘客提供了便利,使他们能够在车上使用各种电子设备,同时保持设备的电池充电。

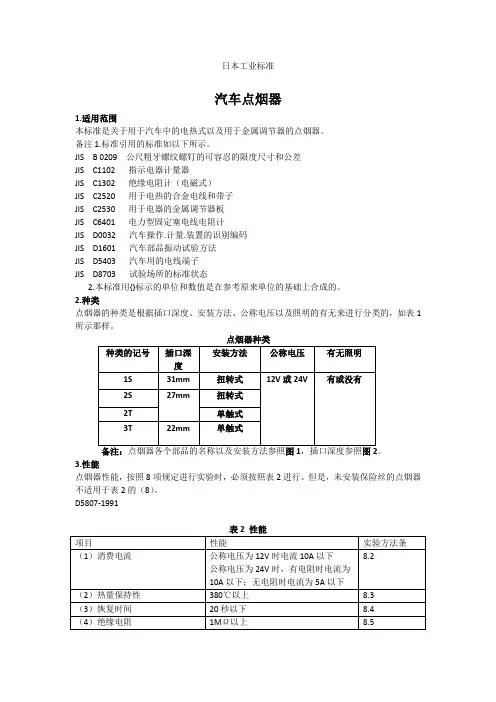

日本工业标准汽车点烟器1.适用范围本标准是关于用于汽车中的电热式以及用于金属调节器的点烟器。

备注1.标准引用的标准如以下所示。

JIS B 0209 公尺粗牙螺纹螺钉的可容忍的限度尺寸和公差 JIS C1102 指示电器计量器JIS C1302 绝缘电阻计(电磁式) JIS C2520 用于电热的合金电线和带子 JIS C2530 用于电器的金属调节器板 JIS C6401 电力型固定塞电线电阻计JIS D0032 汽车操作.计量.装置的识别编码 JIS D1601 汽车部品振动试验方法 JIS D5403 汽车用的电线端子 JIS D8703 试验场所的标准状态2.本标准用{}标示的单位和数值是在参考原来单位的基础上合成的。

2.种类点烟器的种类是根据插口深度、安装方法、公称电压以及照明的有无来进行分类的,如表1所示那样。

备注:点烟器各个部品的名称以及安装方法参照图1,插口深度参照图2。

3.性能点烟器性能,按照8项规定进行实验时,必须按照表2进行。

但是,未安装保险丝的点烟器不适用于表2的(8)。

D5807-19914.构造4.1一般构造点烟器的一般构造如下所示。

(1)点烟器是把金属调节器内藏于点烟器插座处。

带有发热装置的点烟器插塞。

以及根据各部分安装用的底座来构成。

此外,点烟器要是能够简便安装且足够坚固,各部位不能出现松散。

(2)24V带电阻的点烟器要是能够在12V点火器接续电阻的构造,其电阻要为JIS C6401的1.2—1.45Ω,必须使用30W以上或与其等同的电阻计。

(3)插塞上安装有护盖的,在从插足取出插塞时,盖子要牢固地缠绕发热器以及发热器盖子。

(4)安装在插座上照明的东西要标明是从插座底部照明还是其外部绿色的环状照明。

4.2操作方式点烟器的操作方法根据下述。

(1)将插塞插入底座时,插到点火位置时通电,插塞尖端处成炽热状态时,插塞要自动地从点火位置恢复到原来的位置。

此外,不要超过原始位置飞出来了。

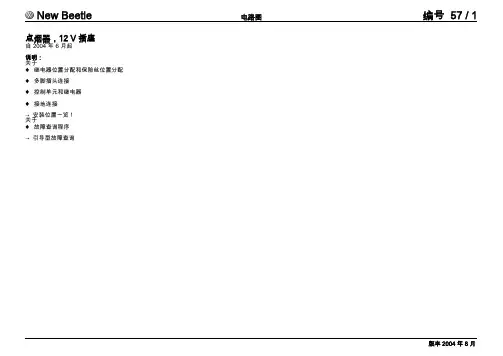

点烟器,12 V 插座

自 2004 年 6 月起

说明:

关于

♦继电器位置分配和保险丝位置分配♦多脚插头连接

♦控制单元和继电器

♦接地连接

→ 安装位置一览!

关于

♦故障查询程序

→ 引导型故障查询

97-63496

1

2

3

4

5

6

7

8

9

10

11

12

13

14

U ws =白色sw =黑色ro =红色br =褐色gn =绿色bl =蓝色gr =灰色li =淡紫色ge =黄色or =橘黄色rs

=粉红色

点烟器,12 V 插座

E1车灯开关

L28点烟器照明灯泡L42插座照明灯泡

S235保险丝座内的保险丝S241保险丝座内的保险丝T3 3 芯插头连接T1313 芯插头连接T1717 芯插头连接U1点烟器U512 V 插座U10拖车行驶插座

U1912 V 插座 3 (在行李箱内)U25

点烟器 2

42接地点,在转向柱附近81接地连接 1,在仪表板导线束中501

继电器板上的螺栓连接 2(30)A1正极连接(30a),在仪表板导线束中A4正极连接(58b),在仪表板导线束中A32

正极连接(30),在仪表板导线束中A40

正极连接 1(30),在仪表板导线束中

A189正极连接 5(30a),在仪表板导线束中

仅用于方向盘右置的车辆

仅用于方向盘左置的汽车*仅用于带 U5 的车辆**

仅用于带 U10 的车辆。

点烟器工作原理

点烟器是一种电子设备,通过加热烟草产生烟雾,用于吸烟。

它的工作原理如下:

1. 供电:点烟器通常使用可充电电池或外部电源供电。

电池提供所需的电力。

2. 加热元件:点烟器内部有一个加热元件,通常是一个电热丝或加热片。

当启动点烟器时,加热元件开始加热。

3. 点燃烟草:用户将烟草放置在点烟器内部的加热区域,加热元件将烟草加热至点燃温度。

这时,烟草产生烟雾。

4. 吸烟:用户通过烟嘴或吸嘴吸入烟雾。

点烟器通常会有一个开关或传感器,用于控制加热元件的开关,用户可以根据需要调整加热温度和烟雾产量。

5. 安全保护:点烟器通常也配备了一些安全保护措施,例如过热保护和短路保护,以防止过热或电路故障引发火灾或其他安全事故。

总的来说,点烟器通过加热烟草产生烟雾,使用户能够吸烟,同时采取安全措施确保使用过程中不会引起火灾或其他意外。

车载点烟器原理

车载点烟器是车辆上常见的一个小配件,它的作用是为乘车人员提供方便,可以在车内使用电子设备或者点烟。

那么,车载点烟器是如何工作的呢?接下来,我们将从原理方面进行介绍。

首先,车载点烟器的工作原理是利用汽车电源系统提供的直流电。

当车辆点火启动后,车载点烟器的电源就会被连接上。

车载点烟器通常是通过汽车点烟器插座连接到车辆电源系统的,它会将车辆电源系统提供的直流电转换成符合手机、电脑等电子设备充电需求的电压和电流。

其次,车载点烟器内部主要由电路板和一些元器件组成。

电路板上通常会有一个稳压电路和一个充电管理电路,稳压电路可以将车辆电源系统提供的不稳定电压转换成稳定的输出电压,以保证充电时电压稳定;充电管理电路则可以对充电电流进行管理,避免对充电设备造成损坏。

除了电路板和元器件,车载点烟器还包括一个点烟器插座和一个USB插口。

点烟器插座可以连接点烟器,USB插口则可以连接USB充电线,用于给手机、电脑等设备充电。

当插入点烟器或USB充电线时,车载点烟器会自动识别设备的充电需求,并输出相应的电压和电流。

最后,车载点烟器还具有过载保护和短路保护功能。

当充电设备过载或者发生短路时,车载点烟器会自动断开输出电源,以保护充电设备和车载点烟器本身不受损坏。

综上所述,车载点烟器的工作原理主要是利用汽车电源系统提供的直流电,通过内部的电路板和元器件进行电压转换和充电管理,最终为乘车人员提供便利的充电服务。

同时,车载点烟器还具有过载保护和短路保护功能,保障充电设备和车载点烟器的安全使用。

希望本文能够帮助大家更加了解车载点烟器的工作原理。

车载点烟器原理车载点烟器是一种常见的汽车配件,它为驾驶员和乘客提供了方便的充电和点烟功能。

那么,车载点烟器的原理是什么呢?下面我们就来详细了解一下。

首先,车载点烟器的原理是利用汽车的电源系统来提供电力。

汽车的电源系统一般由蓄电池、发电机和电气设备组成。

当汽车发动机运转时,发电机会产生电力,同时为蓄电池充电。

而车载点烟器就是通过连接到汽车电源系统,利用这个电力来实现充电和点烟的功能。

其次,车载点烟器内部主要包括一个点烟器插座和一个USB接口。

点烟器插座可以接入点烟器插头,用来点烟或者连接其他电子设备。

而USB接口则可以连接USB充电线,为手机、平板等设备提供充电功能。

通过这两个接口,车载点烟器可以满足不同设备的充电需求,提供了便利的使用体验。

另外,车载点烟器还配备了保险丝和LED指示灯。

保险丝的作用是在电路发生短路或过载时,起到保护作用,防止汽车电路损坏。

而LED指示灯则可以显示车载点烟器的工作状态,方便用户进行观察和判断。

总的来说,车载点烟器的原理是利用汽车电源系统提供电力,通过点烟器插座和USB接口实现充电和点烟功能,同时配备保险丝和LED指示灯,确保安全可靠地使用。

这种设计简单实用,为驾驶员和乘客提供了便利,成为了汽车上不可或缺的配件之一。

通过对车载点烟器的原理进行了解,我们可以更加深入地了解它的工作原理和使用方法,从而更好地利用这一汽车配件,为我们的生活出行带来更多的便利和舒适。

希望本文能够帮助大家更好地了解车载点烟器的原理,让我们在驾驶和乘坐汽车时,能够更加方便地使用电子设备和点烟功能。

车载蓝牙点烟器原理

车载蓝牙点烟器是一种利用蓝牙技术连接车辆电源并通过手机进行远程控制的设备。

它主要由两部分组成:点烟器模块和蓝牙模块。

点烟器模块通常由一个电加热器和一个加热线圈组成。

当电源接通时,加热线圈产生热量,将烟草点燃并产生烟雾。

同时,点烟器上还有一个传感器用于检测烟草燃烧状态,确保点烟器的正常工作。

蓝牙模块是连接点烟器和手机的桥梁。

它通过蓝牙无线技术与手机进行通信,实现手机对点烟器的控制。

用户可以通过手机上的应用程序来启动或关闭点烟器,调节点烟器的加热功率或监控烟草燃烧状态。

在使用车载蓝牙点烟器时,用户需要先将点烟器插入车辆的点烟孔,并连接到车辆的电源。

然后,打开手机上的应用程序,与点烟器进行蓝牙配对并建立连接。

一旦连接成功,用户就可以通过应用程序控制点烟器的工作。

总的来说,车载蓝牙点烟器利用蓝牙技术和电热加热器实现了对车辆点烟器的远程控制。

它为用户提供了方便和个性化的吸烟体验,同时也增加了驾驶过程中的安全性。

钨丝点烟器的原理

钨丝点烟器的原理是利用电流通过钨丝产生高温而点燃烟草或者其它可燃物质。

钨丝点烟器包含一个金属外壳和一个钨丝灯丝,灯丝是由纯钨制成的,并且具有很高的熔点和耐高温的特性。

当点烟器被打开时,一个电路会连接到电源,并且通过灯丝流过电流。

此时,灯丝会变得非常热,高温足以点燃烟草。

一般来说,点烟器会设计一个保护装置,可以在持续使用一段时间后自动关闭点烟器,防止过热。

钨丝点烟器相比于传统的火柴或打火机具有一些优点。

首先,它无需火焰,避免了甲醛、苯和其他有害物质的释放。

其次,由于没有火焰,钨丝点烟器也可以在风雨天气中使用,并且不会被熄灭。

此外,钨丝点烟器的灯丝不会磨损,因此使用寿命非常长。

polo点烟器拆卸最简单方法嘿,朋友们!今天咱就来讲讲 polo 点烟器拆卸的那档子事儿。

你说这玩意儿,有时候还真得摆弄摆弄它呢!

想象一下,你开着你的 polo 车,正哼着小曲儿在路上跑着,突然想起来点烟器好像有点不太对劲。

这时候你就得知道怎么把它拆下来瞧瞧呀!其实啊,拆卸 polo 点烟器真没那么难,就跟解开一个小谜题似的。

首先呢,你得找到点烟器在车里面的那个小窝窝。

一般就在中控台附近,你可别找错地儿啦!然后呢,仔细瞅瞅周围,看看有没有什么小机关或者卡扣啥的。

嘿,这就跟找宝藏似的,得有点耐心呢!

当你找到那些小机关或者卡扣后,轻轻一按,或者一掰,就好像打开了一个小秘密通道一样。

这时候点烟器可能就有点松动啦!别急,慢慢来,别毛手毛脚的,不然把别的地方给碰坏了可就得不偿失咯!

接着呢,你就可以试着把点烟器往外拽一拽啦。

就像拔萝卜一样,嘿哟嘿哟,慢慢用力。

要是感觉有点紧,别硬来呀,再看看是不是还有什么地方没弄对。

你说这拆卸点烟器简单不简单?其实只要你细心点,耐心点,真的不难。

就好像你解一道数学题,一步一步来,总能找到答案的嘛!

哎呀,可别小看了这小小的点烟器拆卸,这可是你了解你爱车的一个小窗口呢!你对它多了解一点,它就能更好地为你服务呀!要是你连这点小事情都搞不定,那以后遇到更大的问题可咋办哟!

所以啊,朋友们,别害怕动手,大胆去尝试吧!说不定你会发现自己还挺有这方面天赋的呢!等你成功把点烟器拆下来,你肯定会有一种小小的成就感,就像打赢了一场小游戏一样开心呢!

总之呢,polo 点烟器拆卸真的没那么复杂,大家都可以试试呀!别再觉得这是个很难的事儿啦,勇敢迈出第一步,你就能搞定它!加油吧!。