E+H电导率分析仪精讲

- 格式:ppt

- 大小:3.45 MB

- 文档页数:21

电导率分析仪的特点都有哪些分析仪如何操作电导率分析仪(单双通道)是一款接受嵌入式技术,集信号采集、信号处理、显示、数据传输一体的智能化程度、测量精准明确高、操作便利的智能化专用化学仪表,可广泛应电导率分析仪(单双通道)是一款接受嵌入式技术,集信号采集、信号处理、显示、数据传输一体的智能化程度、测量精准明确高、操作便利的智能化专用化学仪表,可广泛应用于电力、冶金、石油、化工、制药等行业水质电导率值的连续测量。

特点1)192×64点阵液晶、多参数显示、内容丰富2)接受先进的嵌入式系统设计、贴片工艺技术提高了产品性能和牢靠性、符合EMC设计要求;3)中、英文双语可编程切换,充分不同用户需求;4)全中、英文引导式操作模式、使用简单、通俗易懂;5)可编程的自动或手动温度补偿方式、使用快捷、便利;6)两路完全隔离的电流信号输出,可分别设定输出电流范围;7)带有上、下限报警功能,可分别设定报警值;8)带有标准的485数字通讯接口,可实现远距离通讯;9)具有历史数据、运行、校准记录存储、查询功能,可查询100000条历史数据、1000条运行记录、100条校准记录;10)防护等级高,达到IP65,可以充分各种多而杂环境应用要求;11)可选择多种电极常数电极,每种电极均有2个量程且量程均可自动切换,最大程度充分用户测量范围和精度要求;—专业分析仪器服务平台,试验室仪器设备交易网,仪器行业专业网络宣扬媒体。

相关热词:等离子清洗机,反应釜,旋转蒸发仪,高精度温湿度计,露点仪,高效液相色谱仪价格,霉菌试验箱,跌落试验台,离子色谱仪价格,噪声计,高压灭菌器,集菌仪,接地电阻测试仪型号,柱温箱,旋涡混合仪,电热套,场强仪万能材料试验机价格,洗瓶机,匀浆机,耐候试验箱,熔融指数仪,透射电子显微镜。

频谱分析仪是扫瞄调谐频谱分析仪,其基本结构仿佛超外差式接收器,工作原理是输入信号经衰减器直接外加到混波器,可调变的本地振荡器经与CRT 同步的扫瞄产生器产生随时间作线性变化的振荡频率,经混波器与输入频谱分析仪是扫瞄调谐频谱分析仪,其基本结构仿佛超外差式接收器,工作原理是输入信号经衰减器直接外加到混波器,可调变的本地振荡器经与CRT 同步的扫瞄产生器产生随时间作线性变化的振荡频率,经混波器与输入信号混波降频后的中频信号(IF)再放大、滤波与检波传送到CRT 的垂直方向板,因此在CRT 的纵轴显示信号振幅与频率的对应关系。

电导率仪的原理及其使用介绍电导率仪主要是测液体介质之间传递电流能力的仪器,一般用于电力、化工、冶金、环保、制药、野外、湖泊、科研、食品和自来水等溶液中电导率值(TDS)的连续监测,同时在水处理,水产养殖试验方面也有应用。

电导率仪的工作原理:电导率是物体传导电流的能力,电导率测量仪的测量原理是将两块平行的极板;放到被测溶液中,在极板的两端加上一定的电势(通常为正弦波电压),然后测量极板间流过的电流。

根据欧姆定律,电导率(G)--电阻(R)的倒数,由导体本身决定的。

电导率的基本单位是西门子(S)。

因为电导池的几何形状影响电导率值,标准的测量中用单位电导率S/m(常用的还有μS/cm)来表示,以补偿各种电极尺寸造成的差别。

单位电导率(C)简单的说是所测电导率(G)与电导池常数(L/A)的乘积.这里的L为两块极板之间的液柱长度,A为极板的面积。

水的电导率与其所含无机酸、碱、盐的量有一定关系。

当它们的浓度较低时,电导率随浓度的增大而增加,因此,该指标常用于推测水中离子的总浓度或含盐量。

电导率仪使用时的注意事项:1、在测量纯水或超纯水时,为了避免测量值的漂移现象,建议采用密封槽;在密封状态下的进行流动测量,如采用烧杯取样测量,则会产生较大的误差。

2、因温度补偿是采用固定的温度系数,所以,超、高纯水的测量,尽量采用温度不补偿方式进行,测量后查表。

3、电极插头座应防止受潮,仪表应安置于干燥环境,避免因为水滴溅射或受潮,引起仪表的漏电或测量误差。

4、测量电极是精密部件,不可以分解,不可以改变电极形状和尺寸,且不可以用强酸、碱清洗,以免改变电极常数,而影响仪表测量的准确性。

5、为确保测量的精度,电极使用前,应用蒸馏水(或去离子水)冲洗二次(铂黑电极干放一段时间后,在使用前,必须在蒸馏水中浸泡),然后用被测试样水冲洗三次后,方可测量。

标签:电导率仪。

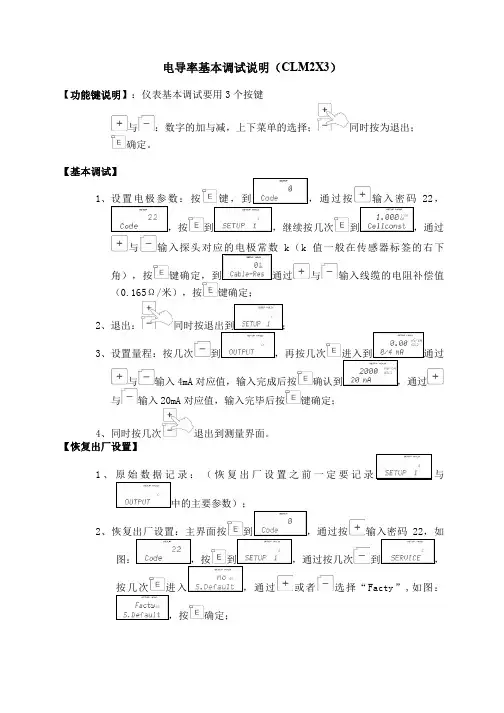

电导率基本调试说明(CLM2X3)

【功能键说明】:仪表基本调试要用3个按键

与:数字的加与减,上下菜单的选择;同时按为退出;

确定。

【基本调试】

1、设置电极参数:按键,到,通过按输入密码22,

,按到,继续按几次到,通过

与输入探头对应的电极常数k(k值一般在传感器标签的右下

角),按键确定,到通过与输入线缆的电阻补偿值

(0.165Ω/米),按键确定;

2、退出:同时按退出到;

3、设置量程:按几次到,再按几次进入到通过

与输入4mA对应值,输入完成后按确认到,通过与输入20mA对应值,输入完毕后按键确定;

4、同时按几次退出到测量界面。

【恢复出厂设置】

1、原始数据记录:(恢复出厂设置之前一定要记录与

中的主要参数);

2、恢复出厂设置:主界面按到,通过按输入密码22,如

图:,按到,通过按几次到,

按几次进入,通过或者选择“Facty”,如图:

,按确定;

3、退出:同时按几次,退出到主界面,然后再按照上述【基本调试】

步骤设置参数。

TI193C/07/en/09.0551500279Technical InformationLiquisys M CLM223/253Conductivity/Resistivity MeasurementTransmitter for conductive and inductive sensorsApplicationThe modular design of the Liquisys M CLM223/253 allows easy adaption of the transmitter to a variety of customerrequirements. Starting with the basic version for "measurement and alarm generation", the transmitter can be equipped with additional software and hardware modules for specialapplications. These modules can also be retrofitted as required.Application•Ultrapure water •Water treatment•Ion exchanger, reverse osmosis •Cooling water desalinisationYour benefits•Field or panel-mounted housing •Universal application •Simple handling–Logically arranged menu structure –Ultrasimple two-point calibration •Safe operation–Overvoltage (lightning) protection–Direct access for manual contact control –User-defined alarm configurationThe basic unit can be extended with:•2 or 4 additional contacts for use as:–Limit contacts (also for temperature)–P(ID) controller–Timer for simple rinse processes–Complete cleaning with Chemoclean •Plus package:–User defined current output characteristics–Automatic cleaning trigger on alarm or limit violation –Ultrapure water monitoring acc. to USP (United States Pharmacopeia) and EP (European Pharmacopoeia) (conductive)–Polarisation detection (conductive)–Concentration measurement–Temperature compensation via table–Process Check System (PCS): live check of the sensor –Adaptive calibration with installation factor (inductive)•HART ® or PROFIBUS-PA/-DP•2nd current output for temperature, main measured value or actuating variable•Current input for flow rate monitoring with controller shut offor for feedforward controlLiquisys M CLM223/253Function and system designFeatures of the basic version Conductive or inductiveTwo instrument versions for measurement with conductive (two electrode) sensors or inductive sensors areavailable. The use of inductive sensors that are less sensitive to soiling than conductive sensors is recommendedfor high conductivity measurement, concentration measurement or adhering media.Measuring of conductivity and resistivity (conductive)This is selected via the menu. During measurement, the value measured can be displayed in the othermeasuring mode. The temperature is displayed at the same time or, if desired, not shown at all.Temperature compensationThe following temperature compensation selections are available:•Linear•NaCl curve according to IEC 746•Ultrapure water NaCl (neutral compensation)•Ultrapure water HCl (acid compensation, also ammonia)The reference temperature is user defined, the standard value is 25 °C (77 °F).ConfigurationDifferent alarms are required depending on application and operator. Therefore the transmitter permitsindependent configuration of the alarm contact and error current for each individual error. Unnecessaryor undesirable alarms can be suppressed in this manner. Up to four contacts can be used as limit contacts(also for temperature), to implement a P(ID) controller or for cleaning functions.Direct manual operation of the contacts (bypassing the menu) provides quick access to limit, control orcleaning contacts, permitting speedy correction of deviations.The serial numbers of the instrument and modules and the order code can be called up on the display.The cell constant can be edited and even calibrated for demanding special applications.Additional functions of the plus package Current output configurationIn order to output wide measuring ranges while still achieving a high resolution in specific ranges, the current output can be configured as required via a table. This permits bilinear or quasi-logarithmic curves, etc. Polarisation detectionPolarisation effects in the boundary layer between the sensor and the medium to be measured limit the measuring range of conductive conductivity sensors.The transmitter can detect polarisation effects using an innovative, intelligent signal evaluation process. Process Check System (PCS)This function checks the measuring signal for stagnation. If the measuring signal does not change for some time (several measured values), an alarm is triggered. Soiling, blockage or similar could be the cause of such behaviour.Ultrapure water monitoring acc. to USP (United States Pharmacopeia) and EP (European Pharmacopoeia)Ultrapure water monitoring according to USP <645> and EP means that the uncompensated conductivity and the temperature are measured and compared to a table.The transmitter (conductive with additional contacts) comes with the following functions:•Monitoring of "Water for Injection" (WFI) according to USP and EP•Monitoring of "Highliy Purified Water" (HPW) according to EP•Monitoring of "Purified Water" (PW) according to EPThe user-adjustable pre-alarm indicates undesirable operating values in due time. Full compliance with USP or EP requires the use of a precisely calibrated sensor, for example, the CLS16.Liquisys M CLM223/253Concentration measuringThe conversion from conductivity to concentration is effected using four user-definable concentration curves . This permits concentrations to be displayed in %, ppm, mg/l or TDS (total dissolved solids).Adaptive calibration for determination of the installation factor (inductive)Inductive measuring sensors must normally be installed in pipes at a required minimum distance from the pipe wall. If this minimum distance is not observed, the measured value changes. The built-in adaptive calibration using the installation factor allows you to compensate for this once the sensor is installed.Second current outputThe second current output can be configured for temperature, main measured value (conductivity, resistivity, concentration) or actuating variable.Current inputThe current input of the transmitter allows two different applications: controller shut-down in case of lower flow rate violation or total failure in the main flow as well as feedforward control. Both functions are also combinable.Explosion proof versions for zone 2Remarks:•Permissible sensors: all conductive conductivity sensors, inductive sensors CLS50 (Non-Ex version) and CLS52.•Do not use blue sensor cables. Electric circuits are not intrinsically safe according to EN 50039.Application of transmitter and sensor in hazardous area zone 2Field housing CLM253 with power supply 24 VApplication of transmitter as relatedelectrical equipment in non-hazardous area or in simple pressurised apparatus; application of sensor in hazardous area zone 2Field housing CLM253 with power supply 230 V orPanel mounted housing CLM223 with power supply 230V or 24 VLiquisys M CLM223/253Measuring systemA complete measuring systems comprises:•The transmitter Liquisys M CLM223 or CLM253•A sensor with or without an integrated temperature sensor•A measuring cable CYK71 (conductive), CPK9 for Condumax H CLS16 or CLK5 (inductive)Options: extension cable, junction box VBMComplete measuring system Liquisys M CLM223/2531234Conductive sensor CLS15Liquisys M CLM253Liquisys M CLM223Inductive sensor CLS52567Inductive sensor CLS50Conductive sensor CLS21Immersion assembly CLA111Liquisys M CLM223/253InputMeasured variables Conductivity, resistivity, temperature Measuring rangeCable specificationCell constantTemperature sensors Pt 100, Pt 1000, NTC 30KMeasuring frequencyBinary inputsCurrent input4...20mA, galvanically separated Load: 260Ω at 20mA (voltage drop5.2V)OutputCurrent range 0/4 ... 20 mA, galvanically separated, active Error current 2.4 or 22 mA in case of an error Loadmaximum 500 Ω Linearisation transmission behaviourResolutionmax. 700 digits/mAConductivity (conductive):0 ... 60 mS/cm (uncompensated)Conductivity (inductive):0 ... 2000 mS/cm (uncompensated)Resistivity:0 ... 200 M Ω⋅cmConcentration:0 ... 9999 (%, ppm, mg/l, TDS)Temperature:-35 ... +250 °C (-31 ... +482 °F)Cable length (conductive):conductivity: max. 100 m (328.1 ft) (CYK71)resistivity: max 15 m (49.22 ft) (CYK71)Cable length (inductive):max 55 m (180.46 ft) (CLK5)Cable resistance CYK71:165 Ω/km (conductivity measurement)Adjustable cell constant:k = 0.0025 ... 99.99 cm -1Conductivity, resistivity (conductive):170 Hz ... 2 kHz Conductivity (inductive): 2 kHz Voltage:10...50V Power consumption:max. 10mAConductivity:Resistivity:Concentration:Actuating variable:Temperature:adjustable adjustable adjustable adjustableadjustableLiquisys M CLM223/253Min. distance for 0/4...20mA signalIsolation voltage max. 350 V RMS /500 V DC Overvoltage protection according to EN 61000-4-5Auxiliary voltage outputContact outputsLimit contactorControllerAlarmConductivity:Measured value 0 ... 1.999 µS/cm 0.2 µS/cm Measured value 0 ... 19.99 µS/cm 2 µS/cm Measured value 20 ... 199.9 µS/cm 20 µS/cm Measured value 200 ... 1999 µS/cm 200 µS/cm Measured value 2 ... 19.99 mS/cm 2 mS/cm Measured value 20 ... 2000 mS/cm 20 mS/cmResistivityMeasured value 0 ... 199.9 k Ω⋅cm 20 k Ω⋅cm Measured value 200 ... 1999 k Ω⋅cm 200 k Ω⋅cm Measured value 2 ... 19.99 M Ω⋅cm 2.0 M Ω⋅cm Measured value 20 ... 200 M Ω⋅cm 20 M Ω⋅cmConcentration no minimum distance Temperature15 °COutput voltage:15V ± 0.6Output current:max. 10mASwitching current with ohmic load (cos ϕ= 1):max. 2A Switching current with inductive load (cos ϕ = 0.4):max. 2ASwitching voltage:max. 250V AC, 30V DC Switching power with ohmic load (cos ϕ = 1):max. 500 VA AC, 60W DC Switching power with inductive load (cos ϕ = 0.4):max. 500VA AC, 60W DC Pickup/dropout delay:0...2000sFunction (adjustable):pulse length/pulse frequency controller Controller response:PIDControl gain K p :0.01...20.00Integral action time T n :0.0...999.9min Derivative action time T v :0.0...999.9min Period for pulse length controller:0.5...999.9 s Frequency for pulse frequency controller:60...180 min -1Basic load:0...40% of max. set valueFunction (selectable):Latching/momentary contactAlarm threshold adjustment range:Conductivity, resistivity, concentration,temperature, USP, EP: complete measuring range Alarm delay:0 (2000)s (min)Liquisys M CLM223/253Power supplyElectrical connectionThe instrument has protection class II and is generally operated without protective earth connection. To ensure the measuring stability and the function for conductive sensors you have to connect the outer screen of the sensor cable to the PE terminal.Electrical connetion of the transmitterA B C D E F G H Sensor (conductive)Sensor (inductive)Temperature sensor Signal output 1 conductivity Signal output 2 variable Binary input 1 (Hold)Binary input 2 (Chemoclean)Aux. voltage outputIJ K L M N O Alarm (current-free contact position)Relay 1 (current-free contact position)Relay 2 (current-free contact position)Relay 3 (current-free contact position)Relay 4 (current-free contact position)Current input 4...20mA Power supplyConnection of sensorYou require screened special measuring cables to connect conductivity sensors to the transmitter. To extend the measuring cable, use junction box and extension cable (see accessories).Power supplyDepending on ordered version:100/115/230 V AC +10/-15 %, 48 ... 62 Hz 24 V AC/DC +20/-15 %Power consumption max. 7.5 VAMains protectionFine-wire fuse, medium-slow blow 250 V/3.15 APerformance characteristicResolutionDeviation of indication aRepeatability aTemperature compensationReference temperature 25 °C (77 °F); adjustable for the compensation of the medium temperature Temperature offset±5 °C; for the adjustment of the temperature displayConnection of conductive sensorsConnection of inductive sensorsConductivity:Temperature:depending on the measuring range: 0.001 µS/cm to 1.999µS/cm and k ≤ 0.5 cm -10.1 °Ca) acc. to IEC 746-1, for nominal operating conditionsConductivity:Display:max. 0.5 % of measured value ± 4 digits Conductivity signal output:max. 0.75 % of current output range Resistivity:Display:max. 0.5 % of measured value ± 4 digits Resistivity signal output:max. 0.75 % of current output range Temperature:Display:max. 1.0 % of measuring range Temperature signal output:max. 1.25 % of current output range Conductivity:max. 0.2 % of measured value ± 2 digits Resistivity:max. 0.2 % of measured value ± 2 digitsRange:-35 ... +250 °C (-31 ... +482 °F)Types of compensation:uncompensated, linear, NaCl, table;conductive only: ultrapure water NaCl, ultrapure water HClEnvironmentAmbient temperature -10 ... +55 °C (+14 ... +131 °F)Ambient temperature limit –20 ... +60 °C (-4 ... +140 °F)Storage and transport temperature–25 ... +65 °C (-13 ... +149 °F)Electromagnetic compatibility Interference emission and interference immunity acc. to EN 61326: 1997 / A1: 1998Ingress protectionRelative humidity10 ... 95%, non-condensingMechanical constructionDimensionsWeightMaterialsTerminalsPanel mounted instrument:IP 54 (front), IP 30 (housing)Field instrument:IP 65Panel mounted instrument:96x 96x 145mm (3.78 x 3.78 x 5.71 inches)Installation depth: approx. 165mm (6.50")Field instrument:247x 170x 115mm (9.72 x 6.69 x 4.53 inches)Panel mounted instrument:max. 0.7kg (1.5 lb)Field instrument:max.2.3kg (5.1 lb)Housing of panel mounted instrument:Polycarbonate Field housing:ABS PC FrFront membrane:Polyester, UV-resistant Cross sectionmax. 2.5 mm2Liquisys M CLM223/253Human interfaceDisplay elementsOperating elements 1LC display for display of measured values, configuration data and current menu field 2Field for user labeling34 main control keys for calibration and instrument configuration 4Key for switching between automatic/manual operation of the relays 5LED indicators for limit contactor relay (switch status)6LED indicator for alarm function7Display of active contact and key for relay switching in manual modeThe display simultaneously shows the current measured value and the temperature - the essential process data. Brief information texts in the configuration menu provide assistance with parameter configuration.Instrument control functionsAll instrument control functions are arranged in a logical menu structure. Following access code entry, the individual parameters can be easily selected and modified as needed.Certificates and approvals4 symbolDeclaration of conformityThe product meets the legal requirements of the harmonized European standards. The manufacturer confirms compliance with the standards by affixing the 4 symbol.Ex approval for zone 2Explosion protection for Zone 2CLM253-..6...ATEX II 3G EEx nA[L] IIC T4CLM253-..4...CLM223-..4...CLM223-..6...ATEX II 3G [EEx nAL] IICLiquisys M CLM223/25314Endress+HauserOrdering informationProduct structure Additional functions of thePlus package •Current output table to cover large areas with varying resolution, fields O33x •Process Check System (PCS): live check of the sensor, function group P•Ultrapure water monitoring for "Water for injection" (WFI) and "Purified water" (PW) acc. to United States Pharmacopeia (USP) and European Pharmacopoeia (EP) with pre-alarm (conductive, additional contacts necessary), fields R26x and R27x•Polarisation detection (conductive), function group P•Concentration measurement, function group K•Temperature compensation via coefficient table, function group T•Adaptive calibration with installation factor (inductive), fields C13x•Automatic cleaning function start, field F8Scope of deliveryThe delivery of the field instrument includes:•1 transmitter CLM253•1 plug-in screw terminal•1 cable gland Pg 7•1 cable gland Pg 16 reduced•2 cable glands Pg 13.5•1 operating instructions BA 193C/07/en•versions with HART communication:1 operating instructions Field Communication with HART, BA 208C/07/en•versions with PROFIBUS communication:1 operating instructions Field Communication with PROFIBUS PA/DP, BA 209C/07/en•versions with explosion protection for hazardous area zone II (ATEX II 3G):Safety instructions for use in explosion-hazardous areas, XA 194C/07/a3The delivery of the panel mounted instrument includes:•1 transmitter CLM223•1 set of plug-in screw terminals VersionCDConductivity/resistivity measurement (conductive two-electrode sensor)CSConductivity/resistivity measurement (conductive two-electrode sensor) with additional functions (Plus package)IDConductivity measurement (inductive sensor)IS Conductivity measurement (inductive sensor) with additional functions (Plus package)Power supply; approval 0230V AC 1115V AC 2230V AC; CSA Gen. Purp.3115V AC; CSA Gen. Purp.4230V AC; ATEX II 3G [EEx nAL] IIC 5100VAC 624V AC/DC; ATEX II 3G [EEx nAL] IIC for CPM223, EEx nA[L] IIC T4 for CPM253724V AC/DC; CSA Gen. Purp.824V AC/DCOutput1 x 20 mA, conductivity/resistivity 12 x 20 mA, conductivity/resistivity and temperature/main measured value/actuating variable 3PROFIBUS PA 4PROFIBUS DP 51 x 20 mA, conductivity/resistivity HART ®62 x 20 mA, conductivity/resistivity HART ® and temp./main measured value/actuating variableAdditional contacts; analogue input05Not selected 102 x relay (limit/controller/timer)154 x relay (limit/controller/Chemoclean)164 x relay (limit/controller/timer)202 x relay (limit/controller/timer); current input 254 x relay with cleaning (limit/controller/timer/Chemoclean); current input 264 x relay with timer (limit/controller/timer); current inputCLM253-complete order codeCLM223-Liquisys M CLM223/253Endress+Hauser 15•2 tensioning screws•1 operating instructions BA 193C/07/en•versions with HART communication:1 operating instructions Field Communication with HART, BA 208C/07/en•versions with PROFIBUS communication:1 operating instructions Field Communication with PROFIBUS PA/DP, BA 209C/07/en •versions with explosion protection for hazardous area zone II (ATEX II 3G):Safety instructions for use in explosion-hazardous areas, XA 194C/07/a3AccessoriesSensors •Condumax W CLS12Conductive conductivity sensor for standard, Ex and high temperature applications;Ordering acc. to version, see Technical Information TI 082/C07/en•Condumax W CLS13Conductive conductivity sensor for standard, Ex and high temperature applications;Ordering acc. to version, see Technical Information TI 083/C07/en•Condumax W CLS15Conductive conductivity sensor for pure and ultra-pure water applications (incl. Ex);Ordering acc. to version, see Technical Information TI 109/C07/en•Condumax H CLS16Hygienic conductive conductivity sensor for pure and ultra-pure water applications (incl. Ex);Ordering acc. to version, see Technical Information TI 227/C07/en•Condumax W CLS19Conductive conductivity sensor for pure and ultra-pure water applications;Ordering acc. to version, see Technical Information TI 110/C07/en•Condumax W CLS21Conductive conductivity sensor for applications with middle to high conductivity (incl. Ex); Ordering acc. to version, see Technical Information TI 085/C07/en•Indumax P CLS50Inductive conductivity sensor for standard, Ex and high temperature applications;Ordering acc. to the sensor version, see Technical Information (TI118C/07/en)•Indumax H CLS52Inductive conductivity sensor with short response time in hygienic design;Ordering acc. to the sensor version, see Technical Information (TI167C/07/en)。

e+h电导率仪中文说明书(实用版)目录1.e+h 电导率仪简介2.e+h 电导率仪的工作原理3.e+h 电导率仪的操作方法4.e+h 电导率仪的维护与保养5.e+h 电导率仪的注意事项6.e+h 电导率仪的技术参数7.e+h 电导率仪的故障排除与处理正文一、e+h 电导率仪简介e+h 电导率仪是一款高精度、高可靠性的电导率测量仪器,适用于各种工业、科研和实验室的电导率测量需求。

该仪器具有测量范围宽、精度高、操作简便等特点,广泛应用于水质、化工、电力、环保等领域。

二、e+h 电导率仪的工作原理e+h 电导率仪的工作原理基于电导率的测量。

电导率是指在单位长度、单位截面积的条件下,电解质溶液导电的能力。

e+h 电导率仪通过测量电解质溶液中的电流和电压,计算出电导率。

三、e+h 电导率仪的操作方法1.开机:连接电源线,打开仪器电源开关,仪器自检并显示初始界面。

2.准备测量:将电极插入待测溶液中,确保电极与溶液充分接触。

3.测量:按下测量键,仪器开始测量并显示电导率值。

4.结束测量:测量完成后,按下停止键,仪器返回初始界面。

四、e+h 电导率仪的维护与保养1.定期校准:为了保证测量精度,建议每隔一段时间进行一次校准。

2.清洁电极:使用后,及时清洁电极以避免污染。

3.存储:长时间不使用时,请将仪器存放在干燥、通风的地方。

五、e+h 电导率仪的注意事项1.使用时,请勿将电极插入过于浑浊或含有颗粒的溶液中,以免损坏电极。

2.不使用时,请关闭电源,以免造成不必要的损耗。

3.仪器工作时,请勿让液体进入仪器内部,以免损坏电路。

六、e+h 电导率仪的技术参数1.测量范围:0-1000000 μS/cm2.测量精度:±1%FS3.温度补偿:自动4.输出信号:4-20mA/0-10V5.电源:AC 220V/50Hz七、e+h 电导率仪的故障排除与处理1.无法开机:检查电源线是否连接良好,电源是否正常。

2.测量不准确:检查电极是否污染,校准是否准确。

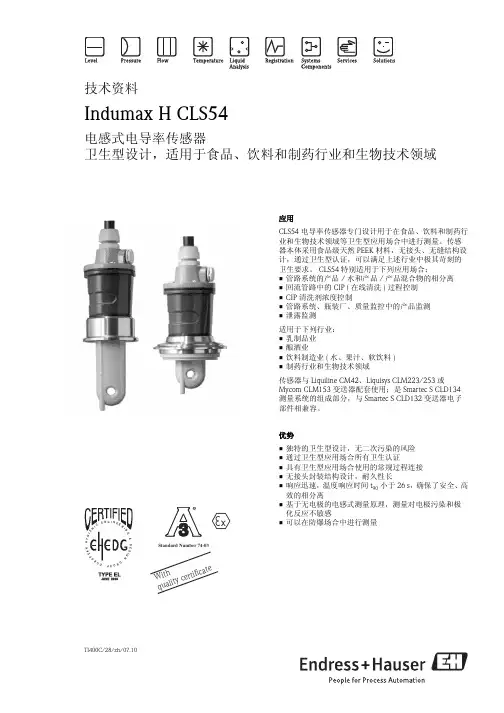

Smartec S CLD 132 (E+H)电导率测量仪目录第一章慨述一.产品型号及类型二.外型图三.用途及适用范围四.主要技术规范及技术参数1. 技术参数2.主要技术规范第二章测量原理第三章安装、调试与应用一.安装1.管线安装2.电气安装3.注意事项3.1 Smartec S CLD 132 环境温度与被测介质之间的关系3.2 被测介质压力与温度之间的关系二.调试(校验)与应用1.屏幕显示内容2.操作步骤第一章慨述一.产品型号及类型Smartec S电导率测量仪与电感式传感器相接,是一种一体化电感式电导率测量仪,适用于高电导率液体。

多种过程连接可以适用于不同的安装方式。

一个完整的测量系统有两种形式:1、分离型:由变送器 Smartec S CLD 132和带温度传感器及连接电缆的电导率传感器CLS52组成;2、一体化:电导率传感器CLS 52和变送器紧凑安装的Smartec S CLD 132 。

二.外型图三.用途及适用范围•酸碱浓度控制•管路系统中物/水或物/物相位分离•监视和控制罐清洗系统•啤酒和牛奶等产品的生产监测•CIP系统控制四.主要技术规范及技术参数1. 技术参数2.主要技术规范测量技术依照卫生型标准传感器由高度化学性、机械性和耐高温的PEEK材料铸成,无接头或裂缝,符合卫生型标准。

温度感应器Pt 100通过不锈钢导热钢套与被测介质接触,这保证了快速的温度回应(t90 < 5 s),特殊材料的使用使传感器耐温达+125 °C,消毒时耐温达+140 °C最多30分钟。

第二章测量原理在测量电导率时,一个发送线圈产生一个交变的磁场,它在液体中产生一个电场,液体中存在的离子就形成一个随离子浓度升高而增大的电流,该变化的电流在接收线圈中产生一个交变磁场,由此测量接收线圈产生的感应电流可得到电导率值,电导率值取决于离子的浓度。

这种测量原理有以下优点:●没有电极, 因此没有偏极化;●在测量介质中保持一个方向保证了测量无误;●在测量仪和被测介质之间实现电磁隔离。

电导率测定仪的原理如何电导率测定仪工作原理电导率测定仪是一款多量程仪器,能够满足从去离子水到海水等多种应用检测要求。

这款仪器能够提供自动温度补偿,并能设置温度系数,因此能够用于测量温度系数与水不同的液体样品。

它能够提供三个量程并具有量程自动选择功能,能够在检测时自动选择较为合适的量程。

随仪器提供一支双插头不锈钢电导率电极且内置温度传感器(用于自动温度补偿),一个橡胶防滑套,4节碱性AAA电池,仪器操作手册和一个便携软包。

电导率测定仪是一款面向于医用多效蒸馏水系统,锅炉底水、凝结水,热交换系统,机械零部件的工业热清洗,工业循环水等在较高温度环境运行的高端水质管理和自动化控制而开发的一款宽温度范围的在线水质分析仪表。

电导率测定仪工作原理电导率是以数字表示溶液传导电流的能力。

水的电导率与其所含无机酸、碱、盐的量有一定的关系,当它们的浓度较低时,电导率随着浓度的增大而增加,因此,该指标常用于推测水中离子的总浓度或含盐量。

电导率与水的硬度水溶液的电导率直接和溶解固体量浓度成正比,而且固体量浓度越高,电导率越大。

电导率和溶解固体量浓度的关系近似表示为:1.4μS/cm=1ppm或2μS/cm=1ppm(每百万单位CaCO3)。

利用电导率仪或总固体溶解量计可以间接得到水的总硬度值,如前述,为了近似换算方便,1μs/cm电导率 = 0.5ppm硬度。

电导率测定仪的原理如何?电导率测定仪是一款多量程仪器,能够满足从去离子水到海水等多种应用检测要求。

这款仪器能够提供自动温度补偿,并能设置温度系数,因此能够用于测量温度系数与水不同的液体样品。

它能够提供三个量程并具有量程自动选择功能,能够在检测时自动选择较为合适的量程。

随仪器提供一支双插头不锈钢电导率电极且内置温度传感器(用于自动温度补偿),一个橡胶防滑套,4节碱性AAA电池,仪器操作手册和一个便携软包。

电导率测定仪是一款面向于医用多效蒸馏水系统,锅炉底水、凝结水,热交换系统,机械零部件的工业热清洗,工业循环水等在较高温度环境运行的高端水质管理和自动化控制而开发的一款宽温度范围的在线水质分析仪表。

e+h电导率仪中文说明书欢迎使用e+h电导率仪!本说明书将为您提供有关电导率仪的相关参考内容,帮助您快速了解和操作该设备。

1. 仪器基本介绍e+h电导率仪是一种用于测量溶液电导率的仪器,主要应用于各类工业和实验室环境中的水质监测和处理过程。

它可以用于监测水中的杂质含量、盐度、离子浓度等信息。

2. 仪器特点e+h电导率仪具有以下特点:- 精密测量:采用高灵敏度的探头,可以准确地测量不同溶液的电导率。

- 宽测量范围:适用于不同浓度的溶液,从纯水到高浓度盐水都可以进行测量。

- 易于操作:仪器配备了直观的操作界面和易于理解的菜单,使操作更加方便快捷。

- 多种输出方式:可以通过RS232接口、4-20mA模拟输出等方式将测量值传输给计算机或控制系统。

- 耐用可靠:仪器采用优质材料制造,具有较高的耐用性和可靠性,适合长时间的连续工作环境。

3. 仪器使用方法- 连接电源:将电导率仪连接到电源,并确保电源线正常接地。

- 连接测量电极:根据仪器类型和测量要求,正确连接电极到相应的接口上。

- 打开电源:按下电源开关,待仪器自检通过后进入待机状态。

- 设置参数:通过菜单界面,设置测量范围、单位、输出方式等参数。

- 测量操作:将电极插入待测液体中,等待电导率仪测量完成,并在显示屏上显示结果。

- 结果处理:根据测量结果进行相应的处理或记录,并进行必要的校准和维护。

4. 注意事项- 请按照说明书中的要求连接和操作仪器,避免过度拉扯导线和触摸电极部分。

- 请避免将电导率仪放置在潮湿、高温或有腐蚀性气体的环境中,以防止仪器受损。

- 在测量之前,请确保电极的清洁和校准,以保证测量结果的准确性。

- 建议定期对电导率仪进行维护和校准,以保持仪器的精度和长期稳定性。

以上内容是对e+h电导率仪的相关参考内容的介绍。

如果您需要更详细的信息和操作指南,请参考附带的用户手册或联系仪器供应商。

祝您使用愉快!。

E+H仪表技术指标说明书高工:022-********E+H仪表技术指标说明书A.概述功能:测量、指示和传送过程检测介质的PH值信号形式:玻璃复合电极(测量电极、参比电极和Pt100温度电极复合一体)组合:测量、变送、元件及全部安装附件B.性能:测量范围:1~12PH测量精度:0.5%信号输出精度:0.75%重复性:0.2%指示器:LCD数字显示,可现场操作,可同时输出温度信号4~20mA防护等级:IP65C.变送器隔离输出信号:两路4~20mA HART协议电源:220VAC,50Hz断电自动储存系统数据故障报警:开关量输出自身报警220VAC,5A(2路)安装方式:墙挂式D.检测方式:浸没式或流通式(取样式)E.电缆:型号:由制造厂提供长度:由承包商确定A.概述功能:测量、指示和传送过程检测介质中的浊度形式:90度散射光原理组成:测量、变送元件及全部安装附件和清洗装置B.性能测量范围:见仪表清单测量精度:1%信号输出精度:1%重复性:1%防护等级:IP65指示器:LCD数字并有现场操作,带温度补偿,并可同时输出温度信号4~20mA气泡:要求具备气泡消除系统清洗装置:机械(电刷)自清洗,C.变送器隔离输出信号:两路4~20mA HART协议电源:220VAC,50Hz断电自动储存系统数据故障报警:开关量输出自身报警220VAC,5A(2路)安装方式:墙挂式D.检测方式:流通式(取样式)E.电缆型号:仪表厂家确定长度:承包商确定污泥浓度测量传感器、变送器A.概述功能:测量、指示和传送过程检测介质中的浊度形式:90度散射光组成:测量、变送、元件及附件安装附件和清洗装置B.性能测量范围:见仪表清单测量精度:1%信号输出精度:1%重复性:1%防护等级:IP65指示器:LCD数字并有现场操作,带温度补偿,并可输出4~ 20mA温度信号清洗装置:机械(电刷)自清洗C.变送器隔离输出信号:两路4~20mA HART协议电源:220VAC,50Hz断电自动储存系统数据故障报警:开关量输出自身报警220VAC,5A(2路)安装方式:墙挂式D.检测方式:浸没式,浸没深度2米E.电缆:型号:仪表厂家确定长度:承包商确定A.概述功能:测量、指示和传送过程检测介质中的溶解氧信号形式:覆膜式组成:测量、变送元件及全部安装附件和清洗装置B.性能测量范围:见仪表清单测量精度:0.5%信号输出精度:0.75%重复性:0.2%防护等级:IP65指示器:LCD数字并有现场操作,带温度补偿,并可输出温度值4~20mAC.变送器隔离信号输出:两路4-20mA HART 协议电源:220VAC、50HZ断电自动储存系统数据故障报警:开关量输出自身报警220VAC,5A (2路)安装方式:墙挂式D.检测方式:浸没式E.电缆:型号:仪表厂家确定长度:承包商确定A. 概述功能:测量、指示和传送过程检测介质中的电导率信号形式:电感式组成:测量、变送元件及全部安装附件B. 性能测量范围:见仪表清单测量精度:0.5%信号输出精度:0.75%重复性:0.2%防护等级:IP65指示器:LCD数字并有现场操作,带温度补偿,并可输出温度值4~20mAC.变送器隔离输出信号:两路4~20mA HART协议电源:220VAC、50HZ断电自动储存系统数据故障报警:开关量输出自身报警220VAC,5A (2路)安装方式:墙挂式D.检测方式:浸没式E.电缆:型号:仪表厂家确定长度:承包商确定余氯测量传感器、变送器A.概述功能:测量、指示和传送过程检测介质中的余氯信号形式:极化法组成:测量、变送元件及全部安装附件B.性能测量范围: 0~5mg/l测量精度:0.5%信号输出精度:0.75%重复性:0.2%防护等级:IP65指示器:LCD数字并有现场操作信号补偿:带PH和温度补偿C.变送器隔离输出信号:两路4~20mA HART协议电源:220VAC,50Hz断电自动储存系统数据故障报警:开关量输出自身报警220VAC,5A(2路)安装方式:墙挂式D.检测方式:流通式E.电缆:型号:仪表厂家确定长度:承包商确定自动采样站A.概述功能:定时自动取出过程介质样品,供化验分析形式:真空法组成:定时及控制装置和样品容器B.特点取样距离:30m取样高度:6m带12个3升容器和样品分配器可自动取样带温度调节,可在现场运行断电自动储存系统数据C.技术参数环境温度:-15°C~+40°C防护等级:IP55电源:220VAC、50Hz /60HzD.尺寸(HXWXD):800 x 1300 x 700mmA.概述功能:测量、指示和传送压力信号形式:干式陶瓷传感器,两线制变送器B.性能测量范围:见仪表清单测量精度:0.2%环境温度:-20°C~60°C稳定性:十二个月0.1%量程比:10:1零点迁移:满量程90%防护等级:IP65C.特点安装位置:任选、带现场显示线性度:>=0.1%结构:变送器、测量元件一体安装D.变送器隔离输出信号:4~20mA, DC 带HART协议电源:12.5~30VDC安装方式:直接安装或柱装或墙装A.概述功能:测量、指示和传送差压信号形式:干式陶瓷或扩散硅传感器,两线制变送器B.性能测量范围:见仪表清单测量精度:0.2%环境温度:-20°C~60°C稳定性:十二个月0.1%量程比:20 : 1零点迁移:满量程90%防护等级:IP65C.特点安装位置:任选、带现场显示线性度:>=0.1%结构:变送器、测量元件一体安装D.变送器隔离输出信号:4~20mA,DC 带HART协议电源:12.5~30VDC安装方式:墙装或柱装数字显示表A.概述功能:接收一个过程变量并以工程单位显示其数值形式:盘装式LCD数字显示器B.性能测量范围:见仪表清单测量精度:0.05%输出精度:0.04%环境温度:-10°C ~+ 50°C保护等级:IP65显示:5位LED数字显示C.信号界面:输入:4~20mA.DC、1~5V.DC或Pt100输出:4~20mA.DC / 0~10V接点输出信号:2个继电器接点输出用于上下限报警,接点容量为220VAC,3AD. 电源:220VAC,50Hz或24VDCE. 外形尺寸:48 X 96mmF. 数字显示表的数量和安装位置:见仪表设备清单电磁流量测量传感器、变送器(分体型)A.概述功能:测量、指示和传送管道内导电液体的流量形式:利用法拉第电磁感应测量原理组成:传感器、变送器,全部安装附件和电缆B.性能:测量范围:见仪表清单测量精度:0.2%重复性:0.1%环境温度:-20~+60°C介质温度:0~ +80°C保护等级:传感器:IP68 变送器:IP67C.特点:指示器:LCD数字指示,可现场操作、设置变送单元:微处理器、积分自动校零、自诊断、故障报警和小信号切除D.测量传感器衬里材料:硬橡胶4电极测量系统:测量电极、参比电极、空管检测电极电极材料:1.4435不锈钢E.隔离输出信号:4~20mA, HART和频率信号输出F.电源:220VAC,50HzG.安装方式:管道法兰安装涡街流量测量传感器、变送器A. 概述功能:测量、指示和传送管道内液体或气体的流量形式:利用卡门涡街原理组成:一体化传感器及变送器B. 性能:测量范围:见仪表清单测量精度:1%(气体),0.75%(液体)重复性:0.2%环境温度:-40~+80°C介质温度:-200~+400°C保护等级:IP65C. 特点:指示器:LCD数字指示,可现场操作、设置变送单元:微处理器、自诊断、故障报警和小信号切除抗振性:各方向1g/500Hz 振动D. 测量传感器材料:316L不锈钢形式:差动电容E. 隔离输出信号:4~20mADC,HART及频率信号输出F. 电源:24VDCG.安装方式:管道法兰安装热式气体质量流量计A. 概述功能:测量,指示传送管道内气体的质量流量形式:利用热式原理组成:一体化传感器、变送器及安装附件(带切断球阀)B. 性能:测量范围:见仪表清单测量精度:0.5%重复性:0.25%环境温度:-30~+80°C介质温度:-10~+100°C保护等级:IP65C. 特点:指示器:LCD数字指示,可现场操作、设置变送单元:微处理器、自诊断、故障报警和小信号切除量程比:100 : 1D. 接液部分材料:316L不锈钢(哈氏合金可选)E. 隔离输出信号:4~20mADC,HART协议F. 电源:20~30VDCG.安装方式:插入式管道安装超声波流量测量传感器、变送器(分体型)A.概述功能:测量、指示和传送管道内液体的流量和声速形式:时差法组成:传感器、变送器,全部安装附件和电缆B.性能:测量范围:见仪表清单测量精度:0.5%重复性:+/-0.4%环境温度:-20~+60°C介质温度:-40~+170°C保护等级:传感器:IP68 变送器:IP67C.变送器显示:两行背光LC指示,可现场操作、设置变送单元:微处理器、自诊断、故障报警和小信号切除输入:双通道4~20mA信号输出:隔离4~20mA及继电器接点信号电源:86~260VAC(50~60Hz)或16~62VDC安装方式:墙装或柱装D.测量传感器材料:304不锈钢及塑料安装方式:管道夹装E.电缆型号:仪表厂家确定长度:由承包商确定(长度可达30米)Pitot管流量计A.概述功能:测量、指示和传送管道内气体,蒸汽及液体的流量值形式:Pitot管差压法组成:一体化Pitot管,差压变送器及连接附件B.性能:测量范围:0.5~150 m/s(气体),0.025~40 m/s(液体)测量精度:1.5%FS重复性:0.1%FS过程温度:-20~+300°C过程压力:0~420bar环境温度:-20~+60°C量程比:3 : 1材料:316Ti不锈钢C.特点可带一体化温度探头进行补偿管道直接安装,可测量圆形及方形管道中介质流量管道口径范围为DN25~DN12000流量计算机A. 概述功能:对来自流量、压力、温度及密度传感器的信号应用内置公式计算质量或体积流量等重要参数并显示其数值。

E+H分析仪都有哪些检测方法E+H是一个全球领先的工业自动化和工艺测量仪器制造商。

其生产的分析仪器在力学、重量、压力、液位、流量、温度等物理量方面拥有广泛的应用。

本文将介绍E+H分析仪的主要检测方法,以及各种方法的特点和优点。

液位检测E+H液位测量技术主要包括以下几种方法:•振荡器技术•雷达技术•电容器技术•通用浮子技术•电极法其中,振荡器技术和雷达技术具有非接触式测量的优点,适用于高温、高压、强腐蚀等恶劣环境的液位检测。

电容器技术和通用浮子技术则更适用于常规液位检测场合。

流量检测E+H流量测量技术主要包括以下几种方法:•电磁式流量计•质量式流量计•超声波流量计•涡街流量计•热式流量计其中,电磁式流量计具有广泛的应用,可适用于液态、气态等各种介质的流量测量,精度高,稳定性好。

质量式流量计可实现高精度的质量流量测量,适用于高纯度、高温、高压或易燃易爆介质的流量检测。

超声波流量计则适用于含有气泡、杂质等非均匀介质的流量测量。

压力检测E+H压力测量技术主要包括以下几种方法:•压力差计•压力变送器•压力传感器其中,压力差计适用于液位测量、流量测量等场合。

压力变送器可在较宽的压力范围内进行准确可靠的测量,并可提供标准信号输出。

压力传感器则主要用于车辆、飞机、船舶等领域的压力检测。

温度检测E+H温度测量技术主要包括以下几种方法:•RTD温度传感器•热电偶•红外线温度计•热电阻其中,RTD温度传感器可以精确测量常见温度范围内的温度变化,精度高,可靠性好。

热电偶具有较高的测量温度范围,可测量高温介质。

红外线温度计则适用于高温、高压、易燃易爆等危险环境下的温度检测。

精密称重E+H提供多种适用于工业称重领域的仪器,包括:•货车秤•轨道衡•料斗秤•桶秤•汽车衡其中,货车秤、轨道衡等适用于大规模的物流仓储领域,具有高精度、高稳定性等特点,广泛应用于重要的称重场合。

料斗秤、桶秤、汽车衡则适用于工业生产线的生产计量等场合。

TI193C/28/zh/13.11技术资料Liquisys M CLM223/253电导率/电阻率变送器与电导式和电感式电导率传感器配套使用应用Liquisys M CLM223/253变送器采用模块化结构设计,应用广泛,可以满足用户的各种不同要求。

基本型变送器能完成简单测量,并具有报警功能;通过安装扩展软件和添加硬件模块,变送器可以满足特殊应用条件的要求。

用户可以根据需要选择合适的功能扩展模块。

•超纯水•水处理•离子交换器,反渗透处理•冷却水脱盐处理•污水优势•现场型外壳或盘装型外壳•应用范围广泛•操作简便- 简单的菜单结构- 便捷的两点标定•测量安全- 过电压(防雷击)保护- 直接进行手动触点输出控制- 用户自定义报警设置基本型变送器可以进行下列功能扩展:•两个或四个附加触点,可用于:- 限位触点(也可用于温度测量)- P(ID)控制器- 简单清洗过程的定时器- 使用Chemoclean 清洗单元进行完全清洗•扩展软件包:- 用户自定义电流输出特征参数- 故障报警或超极限值时自动启动清洗功能- 超纯水监控,符合USP (美国药典)和EP (欧洲药典)标准(电导式传感器)- 极化检测(电导式传感器)- 浓度测量- 基于温度系数表进行温度补偿- 过程检测系统(PCS):传感器在线检测- 安装因子的自适应标定(电感式传感器)•HART 或PROFIBUS-PA/-DP 通信•第二电流输出适用于温度、主要测量值或动作变量•电流输入用于带控制器关闭的流速监控或前馈控制Liquisys M CLM223/253功能与系统设计基本型变送器的特点电导式或电感式测量两种类型的变送器都可连接电导式(双电极)或电感式传感器进行测量。

电导式传感器的污染敏感度高于电感式传感器。

因此,进行高电导率、浓度或粘附性介质测量时,建议选用电感式传感器。

电导率和电阻率测量(电导式)通过菜单选择测量值。

可以在其他测量模式下的测量过程中显示当前测量值。