专业英语考试试题与答案

- 格式:docx

- 大小:29.50 KB

- 文档页数:5

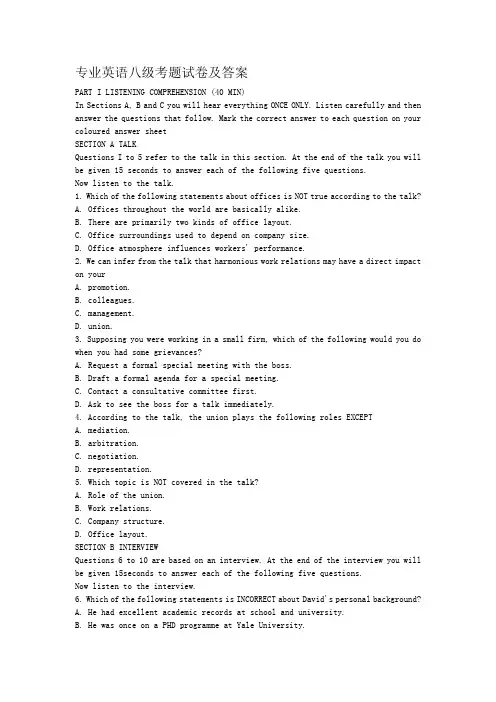

专业英语八级考题试卷及答案PART I LISTENING COMPREHENSION (40 MIN)In Sections A, B and C you will hear everything ONCE ONLY. Listen carefully and then answer the questions that follow. Mark the correct answer to each question on your coloured answer sheetSECTION A TALKQuestions I to 5 refer to the talk in this section. At the end of the talk you will be given 15 seconds to answer each of the following five questions.Now listen to the talk.1. Which of the following statements about offices is NOT true according to the talk?A. Offices throughout the world are basically alike.B. There are primarily two kinds of office layout.C. Office surroundings used to depend on company size.D. Office atmosphere influences workers' performance.2. We can infer from the talk that harmonious work relations may have a direct impact on yourA. promotion.B. colleagues.C. management.D. union.3. Supposing you were working in a small firm, which of the following would you do when you had some grievances?A. Request a formal special meeting with the boss.B. Draft a formal agenda for a special meeting.C. Contact a consultative committee first.D. Ask to see the boss for a talk immediately.4. According to the talk, the union plays the following roles EXCEPTA. mediation.B. arbitration.C. negotiation.D. representation.5. Which topic is NOT covered in the talk?A. Role of the union.B. Work relations.C. Company structure.D. Office layout.SECTION B INTERVIEWQuestions 6 to 10 are based on an interview. At the end of the interview you will be given 15seconds to answer each of the following five questions.Now listen to the interview.6. Which of the following statements is INCORRECT about David's personal background?A. He had excellent academic records at school and university.B. He was once on a PHD programme at Yale University.C. He received professional training in acting.D. He came from a single-parent family.7. David is inclined to believe inA. aliens.B. UFOs.C. the TV character.D. government conspiracies.8. David thinks he is fit for the TV role because of hisA. professional training.B. personality.C. life experience.D. appearance.9. From the interview, we know that at present David feelsA. a sense of frustration.B. haunted by the unknown thingsC. confident but moody.D. successful yet unsatisfied.10. How does David feel about the divorce of his parents?A. He feels a sense of anger.B. He has a sense of sadness.C. It helped him grow up.D. It left no effect on him.SECTION C NEWS BROADCASTQuestion 11 is based on the following news. At the end of the news item, you will be given 15seconds to answer the question.Now listen to the news.11. What is the main idea of the news item?A. US concern over th6 forthcoming peace talks.B. Peace efforts by the Palestinian Authority.C. Recommendations by the Mitchell Commission.D. Bomb attacks aimed at Israeli civilians.Question 12 is based on the following news. At the end of the news item, you will be given 15 seconds to answer the question.Now listen to the news.12. Some voters will waste their ballots becauseA. they like neither candidate.B. they are all ill-informed.C. the candidates do not differ much.D. they do not want to vote twice.Questions 13 to 15 are based on the following news. At the end of the news item, you will be given15 seconds to answer each of the questions.Now listen to the news.13. According to the UN Human Development Report, which is the best place for women in the world?A. Canada.B. The US.C. Australia.D. Scandinavia.14. _______ is in the 12th place in overall ranking.A. BritainB. FranceC. FinlandD. Switzerland15. According to the UN report, the least developed country isA. Ethiopia.B. Mali.C. Sierra Leon.D. Central African Republic.SECTION D NOTE-TAKING AND GAP-FILLINGIn this section you will hear a mini-lecture. You will hear the lecture ONCE ONLY. While listening, take notes on the important points. Your notes will not be marked, but you will need them to complete a 15-minute gap-filling task on ANSWER SHEET ONE after the mini-lecture. Use the blank sheet for note-taking.PART II PROOFREADING & ERROR CORRECTION (15 MIN)Proofread the given passage on ANSWER SHEET TWO as instructed.PART III READING COMPREHENSIOS (40MIN)SECTION A READING COMPREHENSION (30 MIN)In this section there are four reading passages followed by a total of fifteen multiple-choice questions. Read the passages and then mark your answers on your coloured answer sheet~TEXT AHostility to Gypsies has existed almost from the time they first appeared in Europe in the 14th century. The origins of the Gypsies, with little written history, were shrouded in mystery. What is known now from clues in the various dialects of their language, Romany, is that they came from northern India to the Middle East a thousand years ago, working as minstrels and mercenaries, metal-smiths and servants. Europeans misnamed them Egyptians, soon shortened to Gypsies. A clan system, based mostly on their traditional crafts and geography, has made them a deeply fragmented and fractious people, only really unifying in the face of enmity from non-Gypsies, whom they call gadje. Today many Gypsy activists prefer to be called Roma, which comes from the Romany word for “man”. But on my travels among them most still referred to themselves as Gypsies.In Europe their persecution by the gadje began quickly, with the church seeing heresy in their fortune-telling and the state seeing anti-social behaviour in their nomadism. At various times they have been forbidden to wear their distinctive bright clothes, to speak their own language, to travel, to marry one another, or to ply their traditional crafts. In some countries they were reduced to slavery it wasn't until the mid-1800s that Gypsy slaves were freed in Romania. In more recent timesthe Gypsies were caught up in Nazi ethnic hysteria, and perhaps half a million perished in the Holocaust. Their horses have been shot and the wheels removed from their wagons, their names have been changed, their women have been sterilized, and their children have been forcibly given for adoption to non-Gypsy families.But the Gypsies have confounded predictions of their disappearance as a distinct ethnic group and their numbers have burgeoned. Today there are an estimated 8 to 12 million Gypsies scattered across Europe, making them the continent's largest minority. The exact number is hard to pin down. Gypsies have regularly been undercounted, both by regimes anxious to downplay their profile and by Gypsies themselves, seeking to avoid bureaucracies. Attempting to remedy past inequities, activist groups may overcount. Hundreds of thousands more have emigrated to the Americas and elsewhere. With very few exceptions Gypsies have expressed no great desire for a country to call their own -unlike the Jews, to whom the Gypsy experience is often compared. “Romanestan” said Ronald Lee, the Canadian Gypsy writer, "is where my two feet stand."16. Gypsies are united only when theyA are engaged in traditional crafts.B. call themselves Roma.C. live under a clan system.D. face external threats.17. In history hostility to Gypsies in Europe resulted in their persecution by all the followingEXCEPTA. the Egyptians.B the state.C. the church.D. the Nazis.18. According to the passage, the main difference between the Gypsies and the Jews lies in their concepts ofA.language.B. culture.C. identity.D. custom.TEXT BI was just a boy when my father brought me to Harlem for the first time, almost 50 years ago. We stayed at the Hotel Theresa, a grand brick structure at 125th Street and Seventh Avenue. Once, in the hotel restaurant, my father pointed out Joe Louis. He even got Mr. Brown, the hotel manager, to introduce me to him, a bit paunchy but still the champ as far as I was concerned.Much has changed since then. Business and real estate are booming. Some say a new renaissance is under way. Others decry what they see as outside forces running roughshod over the old Harlem.New York meant Harlem to me, and as a young man I visited it whenever I could. But many of my old haunts are gone. The Theresa shut down in 1966. National chains thatonce ignored Harlem now anticipate yuppie money and want pieces of this prime Manhattan real estate. So here I am on a hot August afternoon, sitting in a Starbucks that two years ago opened a block away from the Theresa, snatching at memories between sips of high-priced coffee. I am about to open up a piece of the old Harlem- the New York Amsterdam News—when a tourist asking directions to Sylvia's, a prominent Harlem restaurant, penetrates my daydreaming. He's carrying a book: Touring Historic Harlem.History. I miss Mr. Michaux's bookstore, his House of Common Sense, which was across from the Theresa. He had a big billboard out front with brown and black faces painted on it that said in large letters: "World History Book Outlet on 2,000,000,000 Africans and Nonwhite Peoples." An ugly state office building has swallowed that space.I miss speaker like Carlos Cooks, who was always on the southwest comer of 125th and Seventh, urging listeners to support Africa. Harlem's powerful political electricity seems unplugged-although the sweets are still energized, especially by West African immigrants.Hardworking southern newcomers formed the bulk of the community back in the 1920s and'30s, when Harlem renaissance artists, writers, and intellectuals gave it a glitter and renown that made it the capital of black America. From Harlem, W.E.B. DuBois, Langston Hughes, Paul Robeson, Zora Neal Hurston, and others helped power America's cultural influence around the world.By the 1970s and '80s drugs and crime had ravaged parts of the community. And the life expectancy for men in Harlem was less than that of men in Bangladesh. Harlem had become a symbol of the dangers of inner-city life.Now, you want to shout “Lookin’good!”at this place that has been neglected for so long. Crowds push into Harlem USA, a new shopping centre on 125th, where a Disney store shares space with HMV Records, the New York Sports Club, and a nine-screen Magic Johnson theatre complex. Nearby, a Rite Aid drugstore also opened. Maybe part of the reason Harlem seems to be undergoing a rebirth is that it is finally getting what most people take for granted.Harlem is also part of an “empowerment zone”—a federal designation aimed at fostering economic growth that will bring over half a billion in federal, state, and local dollars. Just the shells of once elegant old brownstones now can cost several hundred thousand dollars. Rents are skyrocketing. An improved economy, tougher law enforcement, and community efforts against drugs have contributed toa 60 percent drop in crime since 1993.19. At the beginning the author seems to indicate that HarlemA. has remained unchanged all these years.B. has undergone drastic changes.C. has become the capital of Black America.D. has remained a symbol of dangers of inner-city life.20. When the author recalls Harlem in the old days, he has a feeling ofA. indifference.B, discomfort.C. delight.D. nostalgia.21. Harlem was called the capital of Black America in the 1920s and '30s mainly because of itsA. art and culture.B. immigrant population.C. political enthusiasm.'D. distinctive architecture.22. From the passage we can infer that, generally speaking, the authorA. has strong reservations about the changes.B. has slight reservations about the changes,C. welcomes the changes in Harlem.D. is completely opposed to the changes.TEXT CThe senior partner, Oliver Lambert, studied the resume for the hundredth time and again found nothing he disliked about Mitchell Y. McDeere, at least not on paper. He had the brains, the ambition, the good looks. And he was hungry; with his background, he had to be. He was married, and that was mandatory. The firm had never hired an unmarried lawyer, and it frowned heavily on divorce, as well as womanizing and drinking. Drug testing was in the contract. He had a degree in accounting, passed the CPA exam the first time he took it and wanted to be a tax lawyer, which of course was a requirement with a tax firm. He was white, and the firm had never hired a black. They managed this by being secretive and clubbish and never soliciting job applications. Other firms solicited, and hired blacks. This firm recruited, and remained lily white. Plus, the firm was in Memphis, and the top blacks wanted New York or Washington or Chicago. McDeere was a male, and there were no women in the firm. That mistake had been made in the mid-seventies when they recruited the number one grad from Harvard, who happened to be a she and a wizard at taxation. She lasted four turbulent years and was killed in a car wreck.He looked good, on paper. He was their top choice. In fact, for this year there were no other prospects. The list was very short. It was McDeere, or no one.The managing partner, Royce McKnight, studied a dossier labeled "Mitchell Y. McDeere-Harvard." An inch thick with small print and a few photographs; it had been prepared by some ex-CIA agents in a private intelligence outfit in Bethesda. They were clients of the firm and each year did the investigating for no fee. It was easy work, they said, checking out unsuspecting law students. They learned, for instance, that he preferred to leave the Northeast, that he was holding three job offers, two in New York and one in Chicago, and that the highest offer was $76,000 and the lowest was $68,000. He was in demand. He had been given the opportunity to cheat on a securities exam during his second year. He declined, and made the highest grade in the class. Two months ago he had been offered cocaine at a law school party. He said no and left when everyone began snorting. He drank an occasional beer, but drinking was expensive and he had no money. He owed close to $23,000 in student loans. He was hungry.Royce McKnight flipped through the dossier and smiled. McDeere was their man. Lamar Quin was thirty-two and not yet a partner. He had been brought along to look young and act young and project a youthful image for Bendini, Lambert & Locke, which in fact was a young firm, since most of the partners retired in their late forties or early fifties with money to bum. He would make partner in this firm. With a six-figure income guaranteed for the rest of his life, Lamar could enjoy the twelve-hundred-dollar tailored suits that hung so comfortably from his tall, athletic frame. He strolled nonchalantly across the thousand-dollar-a-day suite and poured another cup of decaf. He checked his watch. He glanced at the two partners sitting at the small conference table near the windows.Precisely at two-thirty someone knocked on the door. Lamar looked at the parmers, who slid the resume and dossier into an open briefcase. All three reached for their jackets. Immar buttoned his top button and opened the door.23. Which of the following is NOT the firm’s recruitment requirement?A. Marriage.B. Background.C. Relevant degree.D. Male.24. The details of the private investigation show that the firmA. was interested in his family background.B. intended to check out his other job offers.C. wanted to know something about his preference.D. was interested in any personal detail of the man.25. According to the passage, the main reason Lama Quin was there at the interview was thatA. his image could help impress McDereer.B. he would soon become a partner himself.C. he was good at interviewing applicants.D. his background was similar to MeDereer's.26. We get the impression from the passage that in job recruitment the firm was NOTA. selective.B. secretive.C. perfunctory.D. racially biased.TEXT KFirst read the questions.39. When did Moore receive his first commission?A. In 1948.B. In 1946.C. In 1931.D. In 1928.40. Where did Moore win his first international prize?A. In London.B. In Venice.C. In New York.D. In Hamburg.Now go through TEXT K quickly to answer questions 39 and 40.Henry Moore, the seventh of eight children of Raymond Spencer Moore and his wife Mary, was born in Yorkshire on 30 July 1898. After graduating from secondary school, Moore taught for a short while. Then the First World War began and he enlisted in the army at the age of eighteen. After the war he applied for and received an ex-serviceman's grant to attend Leeds School of Art. At the end of his second year he won a scholarship to the Royal College of Art in London.In 1928 Moore met Irina Radetsky, a painting student at the college, whom he married a year later. The couple then moved into a house which consisted of a small ground-floor studio with an equally small flat above. This remained their London home for ten years.Throughout the 1920's Moore was involved in the art life of London. His first commission, received in 1928, was to produce a sculpture relief for the newly opened headquarters of London Transport. His first one-man exhibition opened at the Warren Gallery in 1928; it was followed by a show at the Leicester Galleries in 1931 and his first sale to a gallery abroad- the Museum fur Kunst und Gewerbe in Hamburg. His success continued.In 1946 Moore had his first foreign retrospective exhibition at the Museum of Modem Art, New York. In 1948 he won the International Sculpture Prize at the 24th Venice Biennale, the first of countless international accolades acquired in succeeding years. At the same time sales of Moore's work around the world increased, as did the demand for his exhibitions. By the end of 1970's the number of exhibitions had grown to an average of forty a year, ranging from the very small to major international retrospectives taking years of detailed planning and preparation. The main themes in Moore's work included the mother and child, the earliest work created in 1922, and the reclining figure dating from 1926. At the end of the 1960's came stringed figures based on mathematical models observed in the Science Museum, and the first helmet head, a subject that later developed into the internal-external theme- variously interpreted as a hard form coveting a soft, like a mother protecting her child or a foetus inside a womb.A few years before his death in 1986 Moore gave the estate at Perry Green with its studios, houses and cottages to the Trustees of the Henry Moore Foundation to promote sculpture and the fine arts within the cultural life of the country and in particular the works of Henry Moore.ANSWER SHEET ONEPART I LISTENING COMPREHENSIONSECTION D NOTE-TAKING & GAPFILING (15 MIN)Fill in each of the gaps with ONE word You may refer to your notes. Make sure the word you fill in is both grammatically and semantically acceptable.Marslow's Hierarchy of NeedsAbraham Maslow has developed a famous theory of human needs, which can be arranged In order of importance.Physiological needs: the most (1)______________ones for survival.They include such needs as food, water, etc. And there is usually one way to satisfy these needs.(2)______________needs: needs for a) physicalsecurity;b)(3)_______________security.The former means no illness or injury, while the latter is concerned with freedom from (4)______________, misfortunes, etc. These needs can be met through a variety of means, e.g. job security, (5)______________________plans, and safe working conditions.Social needs: human requirements for a) love and affection;b) a sense of belonging.There are two ways to satisfy these needs: a) formation of relationships at workplace;b) formation of relationships outside workplace.Esteem needs: a) self-esteem, i.e. one's sense of achievement;b) esteem of others, i.e. others' respect as a result of one's (6__________.These needs can be fulfilled by achievement, promotion, honours, etc.Self-realization needs: need to realize one'spotential.Ways to realize these needs are individually (7)______________________ Features of the hierarchy of needs:a) Social, esteem and self-realization needs are exclusively(8)______________ needs.b) Needs are satisfied in a fixed order from the bottom up.c) (9)_____________for needs comes from the lowest un-met level.d) Different levels of needs may (10)_______________when they come into play. ANSWER SHEET TWOTEST FOR ENGLISH MAJORS [2003]-GRADE EIGIHT-PART II PROOFREADING & ERROR CORRECTION (15 MIN)The passage contains TEN errors. Each indicated line contains a maximum of ONE error. In each case, only ONE word is involved You should proof, read the passage and correct it in the following way:For a wrong word, underline the wrong word and write the correct one in the blank pro-vided at the end of the line.For a missing word, mark the position of the missing word with a "^" sign and write the word you believe to be missing in the blank provided at the end of the line. For an unnecessary word, cross the unnecessary word with a slash "/" and put the word in the blank provided at the end of the line.EXAMPLEWhen ^ art museum wants a new exhibit, it never buys things in finished form and hangs them on the wall. When a natural history museum wants an exhibition, it must often build it.Demographic indicators show that Americans in the postwarperiod were more eager than ever to establish families. They quicklybrought down the age at marriage for both men and women and broughtthe birth rate to a twentieth century height after more than a hundred (1)__ years of a steady decline, producing the “baby boom.”These young (2)__adults established a trend of early marriage and relatively largefamilies that Went for more than two decades and caused a major (3)__but temporary reversal of long-term demographic patterns. Fromthe 1940S through the early 1960s, Americans married at a high rate (4)__and at a younger age than their Europe counterparts.(5)__Less noted but equally more significant, the men and women on who (6)__formed families between 1940 and 1960 nevertheless reduced the (7)__divorce rate after a postwar peak; their marriages remained intact toa greater extent than did that of couples who married in earlier as well (8)__ as later decades. Since the United States maintained its dubious (9)__ distinction of having the highest divorce rate in the world, thetemporary decline in divorce did not occur in the same extent in (10)__ Europe. Contrary to fears of the experts, the role of breadwinner and homemaker was not abandoned.TEST FOR ENGLISH MAJORS (2003)-GRADE EIGHT-PAPER TWOTIME LIMIT: 120 MINPART IV TRANSLATION (60 MIN)SECTION A CHINESE TO ENGLISHTranslate the following text into English. Write your translation on ANSWER SHEET THREE.得病以前,我受父母宠爱,在家中横行霸道,一旦隔离,拘禁在花园山坡上一幢小房子里,我顿觉打入冷宫,十分郁郁不得志起来。

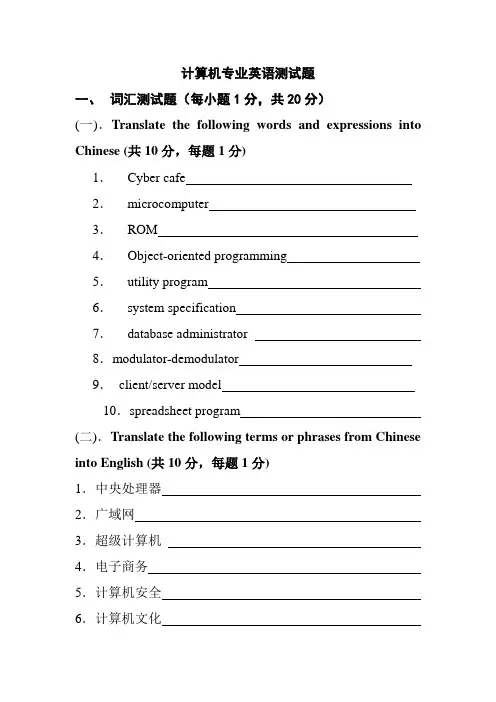

计算机专业英语测试题一、词汇测试题(每小题1分,共20分)(一).Translate the following words and expressions into Chinese (共10分,每题1分)1.Cyber cafe2.microcomputer3.ROM4.Object-oriented programming5.utility program6.system specification7.database administrator8.modulator-demodulator9.client/server model10.spreadsheet program(二).Translate the following terms or phrases from Chinese into English (共10分,每题1分)1.中央处理器2.广域网3.超级计算机4.电子商务5.计算机安全6.计算机文化7.网站8.域名9.数据库管理系统10.软件工程二、完型填空题(每空1分,共20分)Fill in each of the blanks with one of the words given in the list following each paragraph, making changes if necessary:1. Computer hardware is the involved in the of a computer and consists of the that can be physically handled. The function of these components is typically divided into three main categories: , , and . Components in these categories connect to , specifically, the computer’s central unit (CPU), the electronic that provides the computational ability and control of the computer, via wires or circuitry called bus.microprocessors component processing functionoutput equipment input circuitry storage2.In the relational model, data is organized in two-dimensionalcalled . There is no or structure imposed on the data. The tables or relations are, however, related to each other. The database management system (RDBMS) the data so that its external is a of relation or tables. This does not mean that data is stored as tables: the physical of the data is independent of the way in which the is logically organized.hierarchical set organize relational relationdata storage view network table三、英译汉题(每题10分,共20分)Translate the following passage from English into Chinese:1.The field of computer science has grown rapidly since the1950s due to the increase in their use. Computer programs have undergone many changes during this time in response to user need and advances in technology. Newer ideas in computing such as parallel computing, distributed computing, and artificial intelligence, have radically altered the traditional concepts that once determined program form and function. In parallelcomputing parts of a problem are worked on simultaneously by different processors, and this speed up the solution of the problem. Another type of parallel computing called distributed computing use CPUs from many interconnected computers to solve problems. Research into artificial intelligence (AI) has led to several other new styles of programming.2.High-level languages are commonly classified asprocedure-oriented, functional, objected-oriented, logic languages. The most common high-level languages today are procedure-oriented languages. In these languages, one or more related blocks of statements that perform some complete function are grouped together into a program module, or procedure, and given a name such as “procedure A”. If the same sequence of operations is needed elsewhere in the program, a simple statement can be used to refer back to the procedure. In essence, a procedure is just a mini-program. A large program can be constructed by grouping together procedures that perform different tasks.四、汉译英题(20分)最著名的互联网例子是因特网。

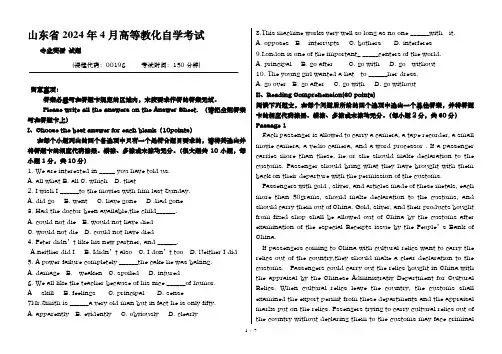

山东省2024年4月高等教化自学考试专业英语试题(课程代码:00196 考试时间:150分钟)留意事项:答案必需写在答题卡规定的区域内,未按要求作答的答案无效。

Please write all the answers on the Answer Sheet.(请把全部答案写在答题卡上)I、Choose the best answer for each blank(10points)在每个小题列出的四个备选项中只有一个是符合题目要求的,请将其选出并将答题卡的相应代码涂黑。

错涂、多涂或未涂均无分。

(很大题共10小题,每小题1分,共10分)1. We are interested in _____ you have told us.A. all whatB. allC. whichD. that2. I wish I ______to the movies with him last Sunday.A. did goB. wentC. have gone D .had gone3. Had the doctor been available,the child______.A. could not dieB. would not have diedC. would not dieD. could not have died4. Peter didn’t like his new partner, and ______.A.neither did IB. Ididn’t alsoC.I don’t tooD. Neither I did5. A power failure completely ______the cake he was baking.A. damageB. weakenC. spoiledD. injured6. We all like the teacher because of his nice ______of humor.A skill B. feelings C. principal D. sense7Mr.Smith is ______a very old man but in fact he is only fifty.A. apparentlyB. evidentlyC. obviouslyD. clearly 8.This machine works very well so long as no one ______with it.A. opposesB. interruptsC. bothersD. interferes9.London is one of the important_ _____centers of the world.A. principalB. go afterC. go withD. go without10. The young girl wanted a hat to ______her dress.A. go overB. go afterC. go withD. go withoutII、Reading Comprehension(30 points)阅读下列短文,在每个问题后所给的四个选项中选出一个最佳答案,并将答题卡的相应代码涂黑。

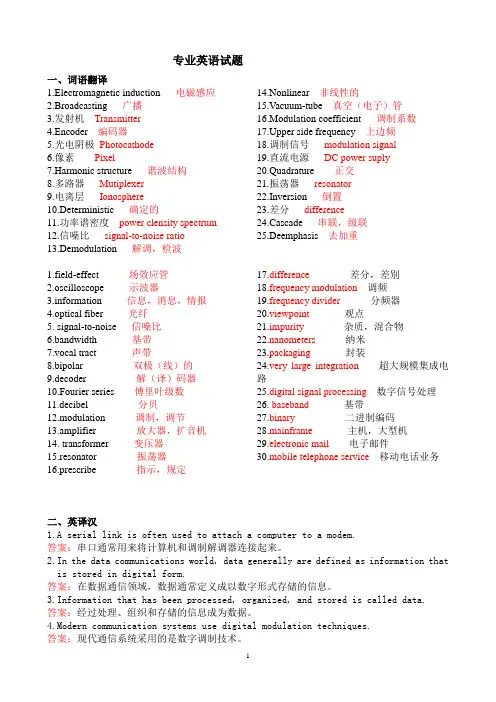

专业英语试题一、词语翻译1.Electromagnetic induction 电磁感应2.Broadcasting 广播3.发射机Transmitter4.Encoder 编码器5.光电阴极Photocathode6.像素Pixel7.Harmonic structure 谐波结构8.多路器Mutiplexer9.电离层Ionosphere10.Deterministic 确定的11.功率谱密度power clensity spectrum12.信噪比signal-to-noise ratio13.Demodulation 解调,检波14.Nonlinear 非线性的15.Vacuum-tube 真空(电子)管16.Modulation coefficient 调制系数17.Upper side frequency 上边频18.调制信号modulation signal19.直流电源DC power suply20.Quadrature 正交21.振荡器resonator22.Inversion 倒置23.差分difference24.Cascade 串联,级联25.Deemphasis 去加重1.field-effect 场效应管2.oscilloscope 示波器rmation 信息,消息,情报4.optical fiber 光纤5. signal-to-noise 信噪比6.bandwidth 基带7.vocal tract 声带8.bipolar 双极(线)的9.decoder 解(译)码器10.Fourier series 傅里叶级数11.decibel 分贝12.modulation 调制,调节13.amplifier 放大器,扩音机14. transformer 变压器15.resonator 振荡器16.prescribe 指示,规定17.difference差分,差别18.frequency modulation调频19.frequency divider分频器20.viewpoint 观点21.impurity杂质,混合物22.nanometers纳米23.packaging封装24.very large integration 超大规模集成电路25.digital signal processing数字信号处理26. baseband 基带27.binary二进制编码28.mainframe 主机,大型机29.electronic mail电子邮件30.mobile telephone service移动电话业务二、英译汉1.A serial link is often used to attach a computer to a modem.答案:串口通常用来将计算机和调制解调器连接起来。

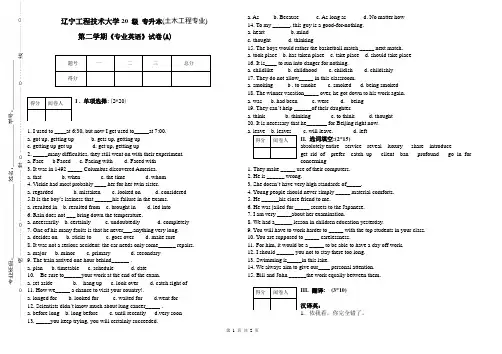

辽宁工程技术大学20 级专升本(土木工程专业)第二学期《专业英语》试卷(A)题号一二三总分得分I .单项选择:(2*20)1. I used to ____at 6:30, but now I get used to_____at 7:00.a. got up, getting upb. gets up, getting upc. getting up get upd. get up, getting up2. _____many difficulties, they still went on with their experiment.a. Face b Faced c. Facing with d. Faced with3. It was in 1492 _____ Columbus discovered America.a. thatb. whenc. the timed. whom4. Vickie had most probably ____ her for her twin sister.a. regardedb. mistakenc. looked ond. considered5.It is the boy’s laziness that ______his failure in the exams.a. resulted inb. resulted fromc. brought ind. led into6. Rain does not ___ bring down the temperature.a. necessarilyb. certainlyc. undoubtedlyd. completely7. One of his many faults is that he never___.anything very long.a. decides onb. sticks toc. goes overd. make sure8. It was not a serious accident: the car needs only some______ repairs.a. majorb. minorc. primaryd. secondary9. The train arrived one hour behind______ .a. planb. timetablec. scheduled. date10. Be sure to______your work at the end of the exam.a. set asideb. hang upc. look overd. catch sight of11. How we_____ a chance to visit your country!.a. longed forb. looked forc. waited ford.went for12. Scientists didn’t know much about lung cancer_____ .a. before longb. long beforec. until recentlyd.very soon13. _____you keep trying, you will certainly succeeded. a. As b. Because c. As long as d. No matter how14. To my ______, this guy is a good-for-nothing.a. heartb. mindc. thoughtd. thinking15. The boys would rather the basketball match _____ next match.a. took placeb. has taken placec. take placed. should take place16. It is____ to run into danger for nothing.a. childlikeb. childhoodc. childishd. childishly17. They do not allow_____ in this classroom.a. smoking b . to smoke c. smoked d. being smoked18. The winner vacation_____ over, he got down to his work again.a. wasb. had beenc. wered. being19. They can’t help ______of their daughter.a. thinkb. thinkingc. to thinkd. thought20. It is necessary that he_______ for Beijing right now.c. will leave.d. leftII. 选词填空:(2*15)absolutely entire service reveal luxury share introduceget rid of prefer catch up client ban profound go in forconcerning1. They make _____ use of their computers.2. He is ______ wrong.3. She doesn’t have very high standards of_____.4. Young people should never simply _____ material comforts.5. He ______his close friend to me.6. He was jailed for _____ secrets to the Japanese.7. I am very _____about her examination.8. We had a______ lesson in children education yesterday.9. You will have to work harder to _____ with the top students in your class.10. You are supposed to _____ carelessness.11. For him, it would be a _____ to be able to have a day off work.12. I should ______ you not to stay there too long.13. Swimming is_____in this lake.14. We always aim to give our____ personal attention.15. Bill and John ______the work equally between them.III. 翻译: (3*10)汉译英:1.依我看,你完全错了。

职称英语试题及答案职称英语是国内普遍的一项专业资格认证考试,旨在评估英语能力,提升职业技能。

下面将介绍一些职称英语试题及其答案,希望对备考的人员有所帮助。

第一部分:选词填空1. Many people believe that the key to success lies in _______ (持久性) and hard work.答案:perseverance解析:这道题目考查对于词汇的理解能力。

根据题干的语境,我们可以推测到空格处应该填一个表示“持久性、坚持不懈”的词语,所以正确答案是perseverance(坚持)。

2. The team was _______ (没表达自己的感受) when they lost the match.答案:mute解析:这道题目考查对于词组的理解能力。

根据题干的语境,我们可以推测到空格处应该填一个表示“没表达自己的感受”的词语,所以正确答案是mute(沉默)。

第二部分:阅读理解阅读下列短文,然后根据短文的内容选择最佳答案。

Passage 1:Nowadays, with the rise of electronic devices, the habit of reading seems to be declining among young people. Many argue that traditional books will soon become obsolete. However, a study conducted by the University of Sussex suggests otherwise.According to the study, reading books not only provides entertainment but also has numerous mental health benefits. Regular reading can improve cognitive abilities, enhance concentration, and even prevent cognitive decline in old age. The study also indicates that reading fiction can improve empathy and enhance social skills.Furthermore, reading physical books promotes better sleep quality. Unlike electronic devices such as tablets or smartphones, which emit blue light and disrupt sleep patterns, traditional books do not have such negative effects on sleep. This makes reading before bedtime an excellent option for achieving sound and restful sleep.In conclusion, while electronic devices offer convenience, there are still significant benefits to be gained from reading traditional books. Therefore, it is essential to encourage and cultivate the habit of reading among young people.3. According to the study conducted by the University of Sussex, reading books can _______.A. improve physical healthB. prevent cognitive declineC. enhance concentration答案:B. prevent cognitive decline解析:这道题目要求根据文章的内容选择正确答案。

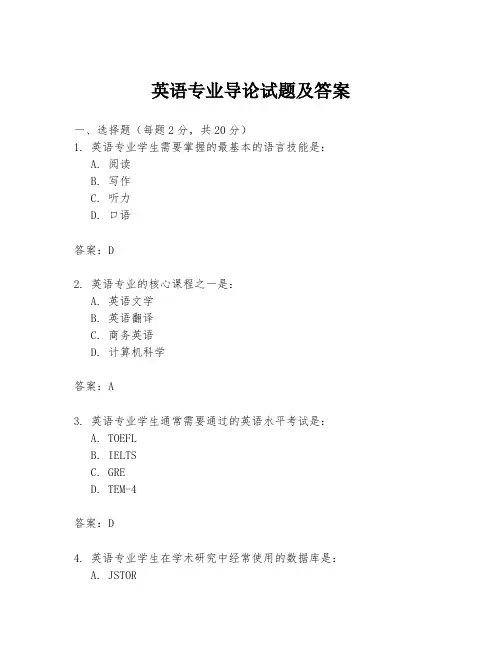

英语专业导论试题及答案一、选择题(每题2分,共20分)1. 英语专业学生需要掌握的最基本的语言技能是:A. 阅读B. 写作C. 听力D. 口语答案:D2. 英语专业的核心课程之一是:A. 英语文学B. 英语翻译C. 商务英语D. 计算机科学答案:A3. 英语专业学生通常需要通过的英语水平考试是:A. TOEFLB. IELTSC. GRED. TEM-4答案:D4. 英语专业学生在学术研究中经常使用的数据库是:A. JSTORB. PubMedC. IEEE XploreD. ScienceDirect答案:A5. 英语专业学生在进行文学分析时,通常需要参考的文学理论包括:A. 马克思主义B. 女性主义C. 后殖民主义D. 所有以上选项答案:D6. 英语专业学生在进行跨文化交际学习时,需要了解的内容包括:A. 语言差异B. 文化习俗C. 社会规范D. 所有以上选项答案:D7. 英语专业学生在进行口译训练时,需要掌握的技能包括:A. 笔记技巧B. 同声传译C. 交替传译D. 所有以上选项答案:D8. 英语专业学生在进行写作训练时,通常需要遵循的写作原则包括:A. 清晰性B. 连贯性C. 逻辑性D. 所有以上选项答案:D9. 英语专业学生在进行翻译实践时,需要遵循的原则包括:A. 忠实性B. 通顺性C. 文化适应性D. 所有以上选项答案:D10. 英语专业学生在进行学术写作时,通常需要遵循的格式包括:A. MLAB. APAC. ChicagoD. 所有以上选项答案:D二、填空题(每空1分,共10分)11. 英语专业学生在进行文学研究时,经常使用的分析方法是________。

答案:文本分析12. 英语专业学生在进行语言教学时,常用的教学法包括________。

答案:交际法13. 英语专业学生在进行学术写作时,需要遵循的引用标准是________。

答案:MLA或APA14. 英语专业学生在进行口译训练时,需要掌握的口译类型包括________。

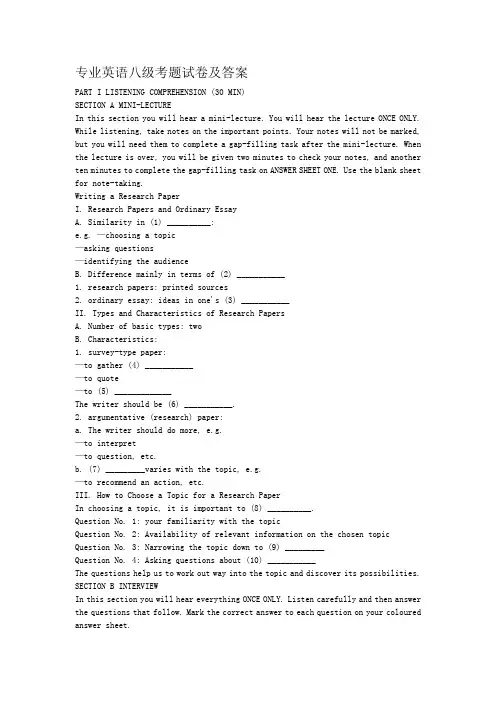

专业英语八级考题试卷及答案PART I LISTENING COMPREHENSION (30 MIN)SECTION A MINI-LECTUREIn this section you will hear a mini-lecture. You will hear the lecture ONCE ONLY. While listening, take notes on the important points. Your notes will not be marked, but you will need them to complete a gap-filling task after the mini-lecture. When the lecture is over, you will be given two minutes to check your notes, and another ten minutes to complete the gap-filling task on ANSWER SHEET ONE. Use the blank sheet for note-taking.Writing a Research PaperI. Research Papers and Ordinary EssayA. Similarity in (1) __________:e.g. —choosing a topic—asking questions—identifying the audienceB. Difference mainly in terms of (2) ___________1. research papers: printed sources2. ordinary essay: ideas in one's (3) ___________II. Types and Characteristics of Research PapersA. Number of basic types: twoB. Characteristics:1. survey-type paper:—to gather (4) ___________—to quote—to (5) _____________The writer should be (6) ___________.2. argumentative (research) paper:a. The writer should do more, e.g.—to interpret—to question, etc.b. (7) _________varies with the topic, e.g.—to recommend an action, etc.III. How to Choose a Topic for a Research PaperIn choosing a topic, it is important to (8) __________.Question No. 1: your familiarity with the topicQuestion No. 2: Availability of relevant information on the chosen topic Question No. 3: Narrowing the topic down to (9) _________Question No. 4: Asking questions about (10) ___________The questions help us to work out way into the topic and discover its possibilities. SECTION B INTERVIEWIn this section you will hear everything ONCE ONLY. Listen carefully and then answer the questions that follow. Mark the correct answer to each question on your coloured answer sheet.Questions 1 to 5 are based on an interview. At the end of the interview you will be given 10 seconds to answer each of the following five questions.Now listen to the interview.1. What is the purpose of Professor McKay's report?A. To look into the mental health of old people.B. To explain why people have negative views on old age.C. To help correct some false beliefs about old age.D. To identify the various problems of old age2. Which of the following is NOT Professor McKay's view?A. People change in old age a lot more than at the age of 21.B. There are as many sick people in old age as in middle age.C. We should not expect more physical illness among old people.D. We should not expect to find old people unattractive as a group.3. According to Professor McKay's report,A. family love is gradually disappearing.B. it is hard to comment on family feeling.C. more children are indifferent to their parents.D. family love remains as strong as ever.4. Professor McKay is ________ towards the tendency of more parents living apart from their children.A. negativeB. positiveC. ambiguousD. neutral5. The only popular belief that Professor McKay is unable to provide evidence against isA. old-age sickness.B. loose family ties.C. poor mental abilities.D. difficulities in maths.SECTION C NEWS BROADCASTIn this section you will hear everything ONCE ONLY. Listen carefully and then answer the questions that follow. Mark the correct answer to each question on your coloured answer sheet.Question 6 is based on the following news. At the end of the news item, you will be given 10 seconds to answer the question. Now listen to the news.6. Scientists in Brazil have used frog skin toA. eliminate bacteria.B. treat burns.C. Speed up recovery.D. reduce treatment cost.Question 7 is based on the following news. At the end of the news item, you will be given 10 seconds to answer the question. Now listen to the news.7. What is NOT a feature of the new karaoke machine?A. It is featured by high technology.B. It allows you to imitate famous singers.C. It can automatically alter the tempo and tone of a song.D. It can be placed in specially designed theme rooms.Question 8 is based on the following news. At the end of the news item, you will be given 10 seconds to answer the question. Now listen to the news.8. China's Internet users had reached _________ by the end of June.A. 68 millionB. 8.9 millionC. 10 millionD. 1.5 millionQuestion 9 and 10 are based on the following news. At the end of the news item, you will be given 20 seconds to answer the question. Now listen to the news.9. According to the WTO, Chinese exports rose _________ last year.A. 21%B. 10%C. 22%D. 4.7310. According to the news, which trading nation in the top 10 has reported a 5 per cent fall in exports?A. The UK.B. The US.C. Japan.D. Germany.PART II READING COMPREHENSION (30 MIN)TEXT AI remember meeting him one evening with his pushcart. I had managed to sell all my papers and was coming home in the snow. It was that strange hour in downtown New York when the workers were pouring homeward in the twilight. I marched among thousands of tired men and women whom the factory whistles had unyoked. They flowed in rivers through the clothing factory districts, then down along the avenues to the East Side.I met my father near Cooper Union. I recognized him, a hunched, frozen figure in an old overcoat standing by a banana cart. He looked so lonely, the tears came to my eyes. Then he saw me, and his face lit with his sad, beautiful smile -Charlie Chaplin's smile."Arch, it's Mikey," he said. "So you have sold your papers! Come and eat a banana." He offered me one. I refused it. I felt it crucial that my father sell his bananas, not give them away. He thought I was shy, and coaxed and joked with me, and made me eat the banana. It smelled of wet straw and snow."You haven't sold many bananas today, pop," I said anxiously.He shrugged his shoulders."What can I do? No one seems to want them."It was true. The work crowds pushed home morosely over the pavements. The rusty skydarkened over New York building, the tall street lamps were lit, innumerable trucks, street cars and elevated trains clattered by. Nobody and nothing in the great city stopped for my father's bananas."I ought to yell," said my father dolefully. "I ought to make a big noise like other peddlers, but it makes my throat sore. Anyway, I'm ashamed of yelling, it makes me feel like a fool. "I had eaten one of his bananas. My sick conscience told me that I ought to pay for it somehow. I must remain here and help my father."I'll yell for you, pop," I volunteered."Arch, no," he said, "go home; you have worked enough today. Just tell momma I'll be late."But I yelled and yelled. My father, standing by, spoke occasional words of praise, and said I was a wonderful yeller. Nobody else paid attention. The workers drifted past us wearily, endlessly; a defeated army wrapped in dreams of home. Elevated trains crashed; the Cooper Union clock burned above us; the sky grew black, the wind poured, the slush burned through our shoes. There were thousands of strange, silent figures pouring over the sidewalks in snow. None of them stopped to buy bananas.I yelled and yelled, nobody listened.My father tried to stop me at last. "Nu," he said smiling to console me, "that was wonderful yelling. Mikey. But it's plain we are unlucky today! Let's go home."I was frantic, and almost in tears. I insisted on keeping up my desperate yells. But at last my father persuaded me to leave with him.11. "unyoked" in the first paragraph is closest in meaning toA. sent outB. releasedC. dispatchedD. removed12. Which of the following in the first paragraph does NOT indicated crowds of people?A.Thousands ofB. FlowedC. PouringD. Unyoked13. Which of the following is intended to be a pair of contrast in the passage?A. Huge crowds and lonely individuals.B. Weather conditions and street lamps.C. Clattering trains and peddlers' yells.D. Moving crowds and street traffic.14. Which of the following words is NOT suitable to describe the character of the son?A. CompassionateB. ResponsibleC. ShyD. Determined15. What is the theme of the story?A. The misery of the factory workers.B. How to survive in a harsh environment.C. Generation gap between the father and the son.D. Love between the father and the son.16. What is the author's attitude towards the father and the son?A. IndifferentB. SympatheticC. AppreciativeD. Difficult to tellTEXT B提示:原文出自美国时代杂志(TIME)日期Jan. 29, 2001文章标题No Fall Insurance 作者AN K. SMITH, M.D.When former President Ronald Reagan fell and broke his hip two weeks ago, he joined a group of more than 350,000 elderly Americans who fracture their hips each year. At 89 and suffering from advanced Alzheimer's disease, Reagan is in one of the highest-risk groups for this type of accident. The incidence of hip fractures not only increases after age 50 but doubles every five to six years as the risk of falling increases. Slipping and tumbling are not the only causes of hip fractures; weakened bones sometimes break spontaneously. But falling is the major cause, representing 90% of all hip fractures. These... ...17. The following are all specific measures to guard against injuries with the EXCEPTION ofA. removal of throw rugs.B. easy access to devicesC. installation of grab barsD. re-arrangement of furniture18. In which paragraph does the author state his purpose of writing?A. The third paragraphB. The first paragraphC. The last paragraphD. The last but one paragraph19. The main purpose of the passage is toA. offer advice on how to prevent hip fracturesB. emphasize the importance of health precautionsC. discuss the seriousness of hip fractures.D. identify the causes of hip fractures.TEXT C提示:原文同专八英译汉翻译试题相同In his classic novel, "The Pioneers", James Fenimore Cooper has his hero, a land developer, take his cousin on a tour of the city he is building. He describes the broad streets, rows of houses, a teeming metropolis. But his cousin looks around bewildered. All she sees is a forest. "Where are the beauties and improvements which you were to show me?" she asks. He's astonished she can't see them. "Where! Everywhere," he replies. For though they are not yet built on earth, he has builtthem in his mind, and they as concrete to him as if they were already constructed and finished.Cooper was illustrating a distinctly American trait, future-mindedness: the ability to see the present from the vantage point of the future; the freedom to feel unencumbered by the past and more emotionally attached to things to come. As Albert Einstein once said, "Life for the American is always becoming, never being."... ...20. The third paragraph examines America's future-mindedness from the _________ perspective.A. futureB. realisticC. historicalD. present21. According to the passage, which of the following is NOT brought about by future-mindedness?A. Economic stagnationB. Environmental destructionC. High divorce ratesD. Neglect of history22. The word "pooh-pooh" in the sixth paragraph meansA. appreciateB. praiseC. shunD. ridicule23. According to the passage, people at present can forecast ________ of a new round of future-mindedness.A. the natureB. the locationC. the varietyD. the features24. The author predicts in the last paragraph that the study of future-mindedness will focus onA. how it comes into beingB. how it functionsC. what it brings aboutD. what it is related to.TEXT D25. The phrase "men's sureness of their sex role" in the first paragraph suggests that theyA. are confident in their ability to charm women.B. take the initiative in courtship.C. have a clear idea of what is considered "manly".D. tend to be more immoral than women are.26. The third paragraph does NOT claim that menA. prevent women from taking up certain professions.B. secretly admire women's intellect and resolution.C. doubt whether women really mean to succeed in business.D. forbid women to join certain clubs and societies.27. The third paragraphA. generally agrees with the first paragraphB. has no connection with the first paragraphC. repeats the argument of the second paragraphD. contradicts the last paragraph28. At the end of the last paragraph the author uses humorous exaggeration in order toA. show that men are stronger than womenB. carry further the ideas of the earliest paragraphsC. support the first sentence of the same paragraphD. disown the ideas he is expressing29. The usual idea of the cave man in the last paragraphA. is based on the study of archaeologyB. illustrates how people expect men to behaveC. is dismissed by the author as an irrelevant jokeD. proves that the man, not woman, should be the wooer30. The opening quotation from Margaret Mead sums up a relationship between man and woman which the authorA. approves ofB. argues is naturalC. completely rejectsD. expects to go on changingPART III GENERAL KNOWLEDGE (10 MIN)31. ______ is the capital city of Canada.A. VancouverB. OttawaC. MontrealD. York32. U.S. presidents normally serves a (an) _________term.A. two-yearB. four-yearC. six-yearD. eight-year33. Which of the following cities is NOT located in the Northeast, U.S.?A. Huston.B. Boston.C. Baltimore.D. Philadelphia.34. ________ is the state church in England.A. The Roman Catholic Church.B. The Baptist ChurchC. The Protestant ChurchD. The Church of England注:The Church of England is the officially established Christian church in England and acts as the mother and senior branch of the worldwide Anglican Communion as well as a founding member of the Porvoo Communion.35. The novel Emma is written byA. Mary Shelley.B. Charlotte Brontë.C. Elizabeth C. Gaskell.D. Jane Austen.36. Which of following is NOT a romantic poet?A. William Wordsworth.B. George Elliot.C. George G. Byron.D. Percy B. Shelley.37. William Sidney Porter, known as O. Henry, is most famous forA. his poems.B. his plays.C. his short stories.D. his novels注:O. Henry was the pen name of William Sydney Porter (September 11, 1862 - June 5, 1910), He was famous for his short stories and a master of the surprise ending, O. Henry is remembered best for such enduring favorites as "The Gift of the Magi" and "The Ransom of Red Chief." The combination of humor and sentiment found in his stories is the basis of their universal appeal.38. Syntax is the study ofA. language functions.B. sentence structures.C. textual organization.D. word formation.注:Definition of Syntax:a. The study of the rules whereby words or other elements of sentence structure are combined to form grammatical sentences.b. A publication, such as a book, that presents such rules.c. The pattern of formation of sentences or phrases in a language.d. Such a pattern in a particular sentence or discourse.39. Which of the following is NOT a distinctive feature of human language?A. Arbitrariness. 任意性B. Productivity. 丰富性C. Cultural transmission. 文化传播性D. Finiteness. 局限性?注:design feature: features that define our human languages,such as arbitrariness,duality,creativity,displacement,cultural transmission,etc.相关内容请点击查看:胡壮麟《语言学教程》课后答案40. The speech act theory was first put forward byA. John Searle.B. John Austin.C. Noam Chomsky.D. M.A.K. Halliday.注:John Langshaw Austin (March 28, 1911 - February 8, 1960) was a philosopher of language, who developed much of the current theory of speech acts. He was born in Lancaster and educated at Balliol College, Oxford. After serving in MI6 during World War II, Austin became White's Professor of Moral Philosophy at Oxford. He occupies a place in the British philosophy of language alongside Wittgenstein in staunchly advocating the examination of the way words are used in order to elucidate meaning. 【改错】The University as BusinessA number of colleges and universities have announced steeptuition increases for next year much steeper than the current,very low, rate of inflation. They say the increases are needed becauseof a loss in value of university endowments' heavily investing in common ___1 stock. I am skeptical. A business firm chooses the price that maximizesits net revenues, irrespective fluctuations in income; and increasingly the ___2 outlook of universities in the United States is indistinguishable from those of ___3 business firms. The rise in tuitions mayreflect the fact economic uncertainty ___4 increases the demand for education. The biggest cost of beingin the school is foregoing income from a job (this isprimarily a factor in ___5 graduate and professional-school tuition); the poor one' s job prospects, ___6 the more sense it makes to reallocate time from the job market to education,in order to make oneself more marketable. The ways which universities make themselves attractive to students ___7include soft majors, student evaluations of teachers, giving studentsa governance role, and eliminate required courses. ___8Sky-high tuitions have caused universities to regard their students as customers. Just as business firms sometimes collude to shorten the ___9rigors of competition, universities collude to minimize the cost to them of the athletes whom they recruit in order to stimulate alumni donations, so the best athletes now often bypass higher education in order to obtain salaries earlier from professional teams. And until they were stopped by the antitrust authorities, the Ivy League schools colluded to limit competition for the best students, by agreeing not to award scholarships on the basis of merit rather than purelyof need-just like business firms agreeing not to give discounts on their best ___10 customer.PART V TRANSLATION (60 MIN)提示:今年专八翻译部分的选材均出自《散文佳作108篇(汉英•英汉对照)》作者:乔萍翟淑蓉宋洪玮,建议大家熟读此书。

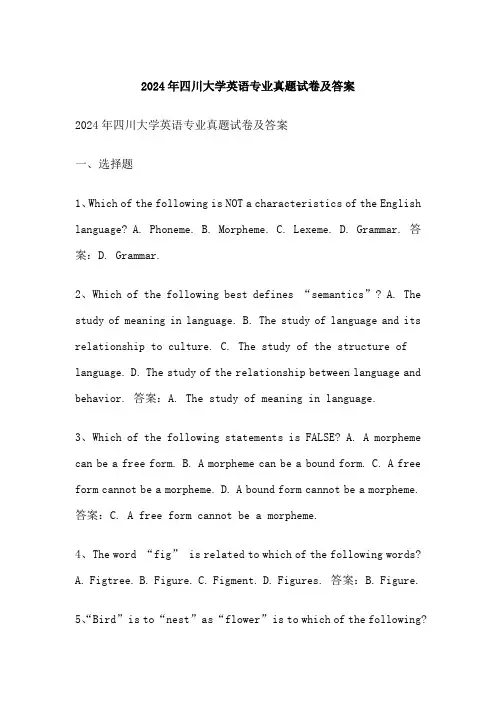

2024年四川大学英语专业真题试卷及答案2024年四川大学英语专业真题试卷及答案一、选择题1、Which of the following is NOT a characteristics of the English language? A. Phoneme. B. Morpheme. C. Lexeme. D. Grammar. 答案:D. Grammar.2、Which of the following best defines “semantics”? A. The study of meaning in language. B. The study of language and its relationship to culture. C. The study of the structure of language. D. The study of the relationship between language and behavior. 答案:A. The study of meaning in language.3、Which of the following statements is FALSE? A. A morpheme can be a free form. B. A morpheme can be a bound form. C. A free form cannot be a morpheme. D. A bound form cannot be a morpheme. 答案:C. A free form cannot be a morpheme.4、The word “fig” is related to which of the following words?A. Figtree.B. Figure.C. Figment.D. Figures. 答案:B. Figure.5、“Bird” is to “nest” as “flower” is to which of the following?A. garden.B. petal.C. bloom.D. rose. 答案:A. garden.二、判断题1、A syllable in English contains both a consonant and a vowel sound. 答案:正确。

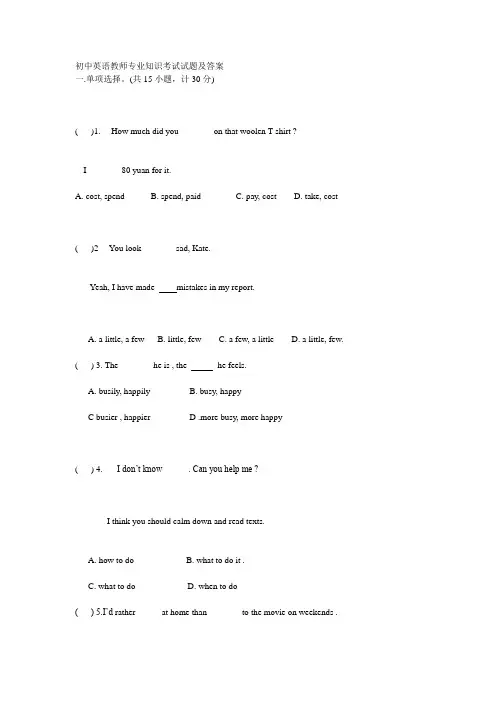

初中英语教师专业知识考试试题及答案一.单项选择。

(共15小题,计30分)( )1. ---How much did you _______ on that woolen T-shirt ?---I _______ 80 yuan for it.A. cost, spendB. spend, paidC. pay, costD. take, cost ( )2 ---You look _______ sad, Kate.--- Yeah, I have made mistakes in my report.A. a little, a fewB. little, fewC. a few, a littleD. a little, few. ( ) 3. The _______ he is , the he feels.A. busily, happilyB. busy, happyC busier , happierD .more busy, more happy( ) 4.-----I don’t know . Can you help me ?-----I think you should calm down and read texts.A. how to doB. what to do it .C. what to doD. when to do( ) 5.I’d rather _____ at home than _______ to the movie on weekends .A. staying, goingB. to stay, to goC. stay, goD. stayed, went( )6. Not only I but also Tom and Jack _____ interested in English because it _____ useful.A. is, isB. i s, areC. are, isD. are, are ( )7. I can’t go _____ because I have to go home at once.A. else anywhereB. anywhere elseC. else nowhereD. somewhere else( )8. Why does this woman decided _____ these places?A. not goB. doesn’t goC. not goingD. not to go( )9. Would you please help me _____ the picture on the wall?A. put upB. put onC. put intoD. put off( )10. Excuse me, could you _____ me your new dictionary?A. borrowB. keepC. lendD. take( )11.The box is ________ heavy ________ I can’t lift it.A. too, toB. so, thatC. very, thatD. too, that( )12. Tom has made many friends since he________ to China.A. cameB. comesC. has comeD. will come( )13.He gave up ______two years ago. That’s to say, he is a non-smoker now.A. smokeB. smokingC. to smokeD. smoked( )14.Do you need ________ to read on the train?A. special anythingB. any special thingC. anything speciallyD. anything special( )15. The children were made ____ homework first.A. doB. to doC. didD. doing二.完形填空(20分)Food is very important. Everyone needs to 16 well if he or she wants to have a strong body .Our minds also need a kind of food. This kind of food is 17 . We begin to get knowledge even when we are very young. Small children are 18 in everything around them. They learn 19 while they are watching and listening. when they are getting older , they begin to 20 story books , science books …anything they like . When they find something new, they love to ask questions and 21 to find out the answers.What is the best 22 to get knowledge? If we learn 23 ourselves, we will get the most knowledge. If we are 24 getting answers from others and do not ask why, we will never learn well. When we study in the right way, we will learn more and understand 25 .()16. A. sleep B. read C. drink D. eat()17. A. start B. exercise C. knowledge D. meat()18. A. interested B. interesting C. weak D. better()19. A. everything B. something C. nothing D. anything()20. A. lend B. read C. learn D. write()21. A. try B. have C. think D. wait)22. A. place B. name C. way D. news()23. A. on B. with C. to D. by()24. A. often B. always C. usually D. sometimes()25 .A. harder B. much C. better D. well三.阅读理解。

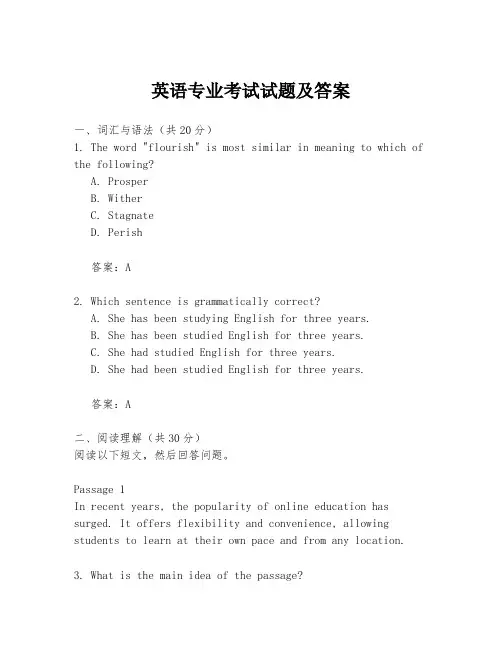

英语专业考试试题及答案一、词汇与语法(共20分)1. The word "flourish" is most similar in meaning to which of the following?A. ProsperB. WitherC. StagnateD. Perish答案:A2. Which sentence is grammatically correct?A. She has been studying English for three years.B. She has been studied English for three years.C. She had studied English for three years.D. She had been studied English for three years.答案:A二、阅读理解(共30分)阅读以下短文,然后回答问题。

Passage 1In recent years, the popularity of online education has surged. It offers flexibility and convenience, allowing students to learn at their own pace and from any location.3. What is the main idea of the passage?A. The drawbacks of online education.B. The benefits of online education.C. The challenges faced by traditional schools.D. The decline in the popularity of traditional schools.答案:B4. According to the passage, what is one advantage of online education?A. It is less expensive.B. It requires students to be present in a classroom.C. It provides a structured learning environment.D. It allows for flexibility and convenience.答案:DPassage 2The environmental impact of plastic waste is a growing concern worldwide. Many countries are implementing policies to reduce plastic use and promote recycling.5. What is the focus of the passage?A. The economic impact of plastic waste.B. The environmental impact of plastic waste.C. The technological advancements in plastic production.D. The history of plastic production.答案:B6. What action are countries taking in response to the issue mentioned in the passage?A. Increasing plastic production.B. Encouraging the use of plastic bags.C. Implementing policies to reduce plastic use.D. Ignoring the issue of plastic waste.答案:C三、完形填空(共20分)Read the following passage and fill in the blanks with the correct options.Passage 3The internet has transformed the way we communicate and access information. It has made our lives more convenient, but it has also brought about new challenges.7. The internet has _______ the way we communicate.A. simplifiedB. complicatedC. revolutionizedD. limited答案:C8. The passage suggests that the internet has both advantages and _______.A. opportunitiesB. disadvantagesC. benefitsD. drawbacks答案:D四、翻译(共15分)Translate the following sentences from English to Chinese.9. With the development of technology, robots are becoming more and more intelligent.答案:随着技术的发展,机器人变得越来越智能。

考研专业英语试题及答案一、选择题(每题2分,共20分)1. The phrase "break a leg" is commonly used to mean ________.A. To cause someone to fallB. To wish someone good luckC. To cause a failureD. To cause a break in a performance答案:B2. Which of the following is NOT a characteristic of academic writing?A. Formal languageB. Clear structureC. Personal opinionsD. Evidence-based arguments答案:C3. In the context of scientific research, "hypothesis" refers to a ________.A. Final conclusionB. Tentative explanationC. Unproven theoryD. Confirmed fact答案:B4. The term "sustainability" in environmental studies usually implies ________.A. The ability to be maintainedB. The ability to be soldC. The ability to be recycledD. The ability to be ignored答案:A5. The word "disseminate" in academic context means to________.A. Spread information or knowledgeB. Gather information or knowledgeC. Hide information or knowledgeD. Analyze information or knowledge答案:A6. Which of the following is the correct way to cite a book in APA format?A. Author, A. A. (Year). Title of the book. Publisher.B. Author, A. A. (Year). Title of the book. Journal.C. Author, A. A. (Year). Title of the book. Website.D. Author, A. A. (Year). Title of the book. Conference.答案:A7. In the field of economics, "opportunity cost" refers to________.A. The cost of the next best alternativeB. The cost of the best alternativeC. The cost of the worst alternativeD. The cost of the same alternative答案:A8. The phrase "pro bono" is used to describe ________.A. Legal services provided at no costB. Legal services provided for free to friendsC. Legal services provided for a reduced feeD. Legal services provided for a profit答案:A9. In the context of literature, "allegory" is a narrative technique that ________.A. Describes a real eventB. Tells a story with a hidden meaningC. Is based on a true storyD. Is a personal account答案:B10. The term "peer review" in academic publishing refers to the process of ________.A. Reviewing by the general publicB. Reviewing by the author's peersC. Reviewing by the author's studentsD. Reviewing by the author's colleagues答案:B二、填空题(每题2分,共20分)1. The ________ of a scientific paper typically includes the research question, hypothesis, and methodology.答案:abstract2. In a research study, the ________ is the group that receives the standard treatment or no treatment at all.答案:control group3. The ________ is the process of systematically collecting and analyzing data to answer a research question.答案:research methodology4. A ________ is a type of literature review that synthesizes findings from multiple studies on a topic.答案:meta-analysis5. The ________ is the part of a research paper where the writer discusses the implications of the findings.答案:discussion6. In statistics, the ________ is a measure of the extent to which two variables are linearly related.答案:correlation coefficient7. ________ is the process of making a formal request for permission to use someone else's work.答案:copyright clearance8. A ________ is a formal statement of a problem or question that is to be solved or answered.答案:research problem9. In a research study, the ________ is the group that receives the treatment or intervention being tested.答案:experimental group10. ________ is the process of evaluating the quality of a research study based on established criteria.答案:methodological critique三、简答题(每题10分,共30分)1. Explain the difference between qualitative andquantitative research methods.答案:Qualitative research methods focus on understanding social phenomena through non-numerical data, such as interviews, observations, and documents. It aims to explore and describe complex social behaviors and experiences. On the other hand, quantitative research methods involve collecting numerical data and using statistical techniques to test hypotheses and make generalizations. It aims to measure and quantify relationships between variables.2. What is the significance of a literature review in a research paper?答案:A literature review in a research paper is significant because it provides a comprehensive overview of existing knowledge on a topic. It helps to establish the context of the research, identifies gaps in the。

学历类《自考》自考专业(英语)《英语词汇学》考试试题及答案解析姓名:_____________ 年级:____________ 学号:______________l A、blamedforB、blamedtoC、blamedonD、blamedat正确答案:C答案解析:此题考查固定词组blamesth.onsb.把...怪到...头上。

3、Police are ________ the disappearance of two children.A、lookingupB、lookingthroughC、lookingintoD、lookingon正确答案:C答案解析:A(在书中)查找B仔细查阅,审查,(对某人)视而不见C调查,研究,查问D.观看,旁观,看待4、Each of us should _______ aside a few minutes to have a rest every day.A、pushB、provideC、turnD、set正确答案:D答案解析:setaside:留出,拨出。

是固定搭配。

5、We were told that the stone figure _______ back to the 16th century was of great value.A、datedB、datingC、comingD、kept正确答案:B答案解析:本句中含有be+of+n.这个结构。

datingbacktothe16thcentury的逻辑主语是stonefigure。

6、Perseverance is a kind of quality and that is _______ it takes to do anything well.A、whatB、thatC、whichD、why正确答案:A答案解析:what在表语从句中作takes的宾语,构成”Ittakessth.todosth.”的句型。

插本英语专业试题及答案一、选择题(每题2分,共20分)1. The new policy will come into _______ next month.A. effectB. effortC. affectD. afford答案:A2. Despite the heavy rain, they managed to reach the airport on _______.A. timeB. scheduleC. chanceD. occasion答案:B3. The teacher asked the students to _______ the text carefully before answering the questions.A. glance atB. look overC. stare atD. focus on答案:B4. The _______ of the meeting has been postponed due to the bad weather.A. commencementB. conclusionC. cancellationD. termination答案:A5. She is _______ for her honesty and kindness.A. knownB. famousC. renownedD. notorious答案:C6. The _______ of the old building was a great loss to the community.A. destructionB. constructionC. restorationD. foundation答案:A7. He _______ the opportunity to study abroad but decided to stay at home.A. missedB. graspedC. seizedD. rejected答案:D8. The _______ of the new product was a success, and it quickly gained popularity.A. launchB. releaseC. introductionD. promotion答案:C9. The company is trying to _______ its market share in the face of fierce competition.A. maintainB. expandC. reduceD. stabilize答案:B10. The _______ of the old bridge is a matter of great concern to the local authorities.A. safetyB. securityC. healthD. welfare答案:A二、填空题(每题1分,共10分)根据所给词的适当形式填空。

生物专业英语试题及答案一、选择题(每题2分,共20分)1. Which of the following is not a type of cell organelle?A. MitochondriaB. NucleusC. RibosomeD. Cell wall2. The process of DNA replication is catalyzed by:A. PolymeraseB. TransposaseC. LigaseD. Helicase3. In eukaryotic cells, where is the transcription of DNA primarily carried out?A. CytoplasmB. MitochondriaC. NucleusD. Ribosomes4. What is the basic unit of heredity in all living organisms?A. GeneB. ChromosomeC. DNA moleculeD. Protein5. The term "genome" refers to:A. The complete set of genes of an organismB. The entire DNA of an organismC. The sum of all the proteins in an organismD. The collection of all the cells in an organism6. Which of the following is a method of genetic engineering?A. CrossbreedingB. CloningC. CRISPR-Cas9D. Natural selection7. What is the role of tRNA in protein synthesis?A. To provide the energy for the processB. To carry specific amino acids to the ribosomeC. To serve as the template for protein synthesisD. To catalyze the formation of peptide bonds8. The Hardy-Weinberg principle states that the allele frequencies in a population will remain constant in the absence of:A. MigrationB. Genetic driftC. Natural selectionD. All of the above9. Which of the following is not a type of mutation?A. DeletionB. InsertionC. TranslocationD. Translation10. The process of photosynthesis primarily occurs in the:A. Cell wallB. CytoplasmC. ChloroplastsD. Nucleus二、填空题(每空1分,共10分)1. The chemical structure of DNA is a double ________ helix.2. The process by which a fertilized egg develops into a mature organism is called ________.3. In genetics, the term "dominant" refers to an allele that expresses its effect when ________.4. The scientific name for a species is composed of two parts: the genus name and the ________ name.5. The primary function of the Golgi apparatus is to ________, modify, and package proteins for secretion or delivery toother organelles.三、简答题(每题10分,共20分)1. Explain the difference between prokaryotic and eukaryotic cells.2. Describe the process of mitosis and its significance incell division.四、翻译题(每题15分,共30分)1. Translate the following sentence into English:"基因编辑技术,如CRISPR-Cas9,为研究和治疗遗传性疾病提供了新的可能性。

英语专业面试试题及答案一、自我介绍1. 请用英语简单介绍一下你自己。

答案:My name is [Your Name], and I am a senior English major student at [Your University]. I have a passion for languages and cultures, which led me to choose English as my major.二、专业知识2. 请解释什么是“语义场”。

答案:Semantic field, also known as "semantic domain" or "semantic field theory," refers to a group of words that are related in meaning and often belong to the same conceptual domain.3. 请列举并解释三种不同的英语时态。

答案:Three different English tenses are:- Simple Present: Used for habitual actions or general truths.- Past Perfect: Used to describe an action completed before another past action.- Future Continuous: Used to describe an action that will be ongoing at a specific time in the future.三、情景对话4. 如果你被问到“Why do you want to work for our company?”,请给出你的答案。

答案:I am attracted to your company because of its innovative approach and commitment to excellence. I believemy skills and passion for the English language align with your company's values and goals.四、翻译能力5. 请将以下句子从英语翻译成中文:"The early bird catches the worm."答案:早起的鸟儿有虫吃。

专业四级英语试题及答案一、听力理解(共20分)1. 根据所听对话或短文,选择正确答案。

A. 选项AB. 选项BC. 选项CD. 选项D[样例题目]根据对话内容,下列哪项是正确的?A. 他们计划去看电影。

B. 他们决定去图书馆。

C. 他们正在讨论作业。

D. 他们打算去公园。

[样例答案]B2. 根据所听短文,完成下列信息填空。

[样例题目]根据短文内容,填写以下信息:- 短文中提到的主要人物是________。

- 事件发生的时间是________。

[样例答案]- 主要人物:John Smith- 事件发生时间:2023年3月15日二、阅读理解(共30分)1. 阅读下列短文,回答后面的问题。

[短文内容][此处为短文正文][样例问题]根据短文内容,以下哪项是正确的?A. 选项AB. 选项BC. 选项CD. 选项D[样例答案]C2. 阅读下列短文,选择最佳标题。

A. 选项AB. 选项BC. 选项CD. 选项D[样例答案]B三、词汇与语法(共20分)1. 选择适当的单词或短语填空。

[样例题目]In the _______ of the meeting, he made an important announcement.A. presenceB. absenceC. silenceD. chaos[样例答案]A2. 根据句子结构,选择正确的语法形式。

[样例题目]If she _______ earlier, she would have caught the train.A. leavesB. leftC. is leavingD. had left[样例答案]D四、完形填空(共15分)[样例题目]阅读下面的短文,从所给选项中选择最佳答案填空。

[此处为短文正文][样例选项]A. 选项AB. 选项BC. 选项CD. 选项D[样例答案]1. B2. A3. D...10. C五、翻译(共15分)1. 将下列句子从中文翻译成英文。

1.Why are cast metal sheet ingots hot-rolled first instead of being cold-rolled?Because of cold rolling is to use hot rolled steel coils as the raw material, after acid pickling to remove oxide skin for cold rolling, the finished product is hard roll, because of cold work hardening caused by deformation of continuous cold rolling hard roll strength, increase hardness, toughness and plastic index decreased, so the stamping performance will deteriorate, can only be used for simple deformation of the parts2.What type of heat treatment is given to the rolled metal sheet after hot and“warm” rolling? What is its purpose?轧钢的热处理的类型?轧钢热处理的目的?Heat treatment of the main types are annealing, normalizing, quenching and tempering, solution treatment and aging treatment, cold treatment, chemical treatment, etc.Annealing:The steel is heated to a certain temperature and heat preservation for a period of time, and then make it slowly cooling, called annealing. Steel annealing is a heat the steel to the phase change or part of the phase change temperature, slow cooling after heat preservation heat treatment method. The purpose of annealing is to eliminate tissue defects, improve the organization make composition uniformity and fine grains, increase mechanical properties of the steel, reduce residual stress; Can decrease the hardness at the same time, improve the plasticity and toughness, improve machinability. So before annealing in order to eliminate and improve both the legacy of tissue defects and internal stress, and to prepare for the follow-up process, so the annealing is belong to the intermediate heat treatment, also called heat treatment in advance Normalizing:Normalizing is heated to above the critical temperature of steel, to all into homogeneous austenitic steel, heat treatment and natural cooling in air. It can eliminate hypereutectoid steel mesh cementite, for hyposteel normalizing can refine crystal lattice, improve comprehensive mechanical properties, low requirements for the parts use the normalized instead of the annealing process is more economic.Quenching:Quenching is the steel is heated to above the critical temperature, heat preservation for a period of time, then quickly into the quenching medium, the temperature plummeted, rapid cooling at greater than the critical cooling rate of speed, which is mainly composed of martensite and unbalanced heat treatment method of the organization. Can increase strength and hardness of the steel quenching, but to reduce its plasticity. That is commonly used in quenching hardening agent are: water, oil, caustic soda, and salt solution, etc3.How are metal alloys made by the casting process? (b) Distinguish betweenwrought alloy products and cast alloy products.金属铸造合金的过程是怎样的?区分可锻合金产品和铸造合金产品。

First stage: liquid contraction, the metal liquid from a cooled to near liquidus temperature contraction, when the falling of the liquid surface in the casting.The second stage: solidification shrinkage, the metal solidification, the contraction of the shift from liquid into solidThe third stage: solid shrinkage, i.e., the shrinkage of metal during solidification cooling to room temperature after, this process of contraction is not uniform, because in the process of phase change.Forging belongs to building materials industry, has many USES, from the concept: forging is a metal pressure, through the shape of the plastic deformation shape requirements or suitable compression force. Forgings in the process of manufacturing is to use a hammer or pressure that power. And in the process of casting, change the structure and physical properties of metal particlesAccording to the model of sand mold, material according to your drawings to melt into a liquid, pour the liquid into the sand mould, unpacking after solidification, out from the sand, and the model of object is casting4.Distinguish between elastic and plastic deformation (use schematics).弹性应变和塑性应变的区别Material deformation under the external force, when the external force to cancel, mate rial deformation can disappear and be able to fully recover the original shape of prope rty is called elasticity.This recoverable deformation is called elastic deformation. Plastic deformation is the material - including fluid and solid under certain conditions, deformation under the action of external force, when imposed by external forces to re move or disappear after the object cannot be reinstated a physical phenomenon.5.Define (a) engineering stress and strain, and (b) true stress and strain, (c)Distinguish between tensile/compressive stress (also called normal stress) and shear stress, (d) Distinguish between tensile/compressive strain (also called normal strain) and shear strain.定义工程应变和应力、真应力应变、区分拉伸/压缩应力和剪切应力、区分拉伸/压缩应变和剪切应变The shape of the curve reaction material under the action of external force of brittleness, plasticity, yield, such as the deformation fracture process.The stress-straincurve is usually referred to as the engineering stress-strain curve.True stress - strain curve, because the area of the sample at any instant in the process of drawing A and gage length L (L = L0 + delta L) are changing frequently, the nominal stress and the nominal strain is calculated on the initial area of A0 and standard of L0.At the exit of specimens under tensile stress, the value of the force imposed by the ratio of the sample of the original cross-sectional area, the unit for the MPaIn the process of compression test, and try them on compression load divided by the value of the original cross-sectional area of the sample unit of MPaDue to external objects (load, temperature, etc.) and deformation, in which any section (shear plane) on both sides of the internal forces, known as "internal".Set of internal force, namely, per unit area of the internal force is called the "stress".Stress can be decomposed into component perpendicular to the section (shear plane), known as "asymmetric" or "method to stress";Tangent to section (shear plane) component is called "shear stress.6.Define the hardness of a metal. (b) How is the hardness of a material determined by ahardness testing machine?定义金属的硬度,金属硬度是怎样测试的?When HB > 450 or sample hours, brinell hardness test and will not be used to switch to rockwel l hardness measurement.It is a diamond cone apex Angle 120 ° or 1.59 and 3.18 mm steel ball d iameter, under certain load down into the material surface under test, the hardness of materials b y indentation depth.7.What are the load used in (a) Rockwell B hardness test, and (b) Rockwell C hardness test?8.What is the difference between Vickers and Knoop hardness tests?I n Vickers hardness test the for used is much lighter than the force used in Rockwell hardness test, The Rockwell hardness test is the considered to be the most routinely used technique to measure the hardness of materials because of its simplicity and because it does not require specific skills in order to perform it.9.Describe the slip mechanism that enables a metal to be plastically deformed withoutfracture.10.Why does slip in metals usually take place on the densest-packed planes?11.Why does slip in metals usually take place in the closest-packed directions?Slip always take place along the atomic density maximum directions (closest-pack ed)and the density on the largest crystal(closest-packed directions),This is due to th e close, close direction between surface spacing between maximum, binding force is wea kest.So the slip plane is the secret of the crystal surface, on the surface of the sliding di rection for the close direction.12.What are the principal slip planes and slip directions for FCC metals? (b) What are theprincipal slip planes and slip directions for BCC metals? (c) What are the principal slip planes and slip directions for HCP metals?13.Describe the deformation twinning process that occurs in some metals when they areplastically deformed.14.What is the difference between the slip and twinning mechanisms of plastic deformation ofmetals?15.What important role does twinning play in the plastic deformation of metalswith regard to deformation of metals by slip?16.Define the critical resolved shear stress for a pure metal single crystal? What happens to themetal from the macroscale point of view and behavior point of view once critical resolved shear stress is exceeded?17.By what mechanism do grain boundaries strengthen metals?18.What is solid-solution strengthening? Describe the two main types, (b) What are twoimportant factors that affect solid-solution hardening?19.What experimental evidence shows that grain boundaries arrest slip in polycrystallinemetals?20.Describe the grain shape changes that occur when a sheet of alloyed copper with anoriginal equiaxed grain structure is cold-rolled with 30 and 50 percent cold reductions, (b) What happens to die dislocation substructure?21.How is the ductility of a metal normally affected by cold working? Why?22.What are the three main metallurgical stages that a sheet of cold-worked metal such asaluminum or copper goes through as it is heated from room temperature to an elevated temperature just below its melting point?23.When a cold-worked metal is heated into the tenperature range whererecrystallization takes place, how are the following affected: (a) internal residualstresses, (6) strength, (c) ductility, and (d) hardness?24.When a cold-worked metal is heated into the temperature range where recoverytakes place, how are the following affected: (a) internal residual stresses, (b)strength, (c) ductility, and (d) hardness?25.Describe what occurs microscopically when a cold-worked sheet of metal suchas aluminum undergoes a recovery heat treatment.26.Describe what occurs microscopically when a cold-worked sheet of metal suchas aluminum undergoes a recrystallization heat treatment.27.What generalizations can be made about the recrystallization temperature withrespect to (a) the degree of deformation, (b) the temperature, (c) the time ofheating at temperature, {d) the final grain size, and (e) the purity of the metal?28.What are five important factors that affect the recrystallization process in metals?29.Why are nanocrystalline materials stronger? Answer based on dislocationactivity.30.(a) Draw a generic engineering stress-strain diagram for a ductile metal andhighlight the key strength points (yield, ultimate, and fracture strength) on thecurve. Schematically, show what happens if you load the specimen just below itsultimate tensile strength point and then unload to zero, (b) Will the specimenbehave differently if you load it again? Explain31.In the rolling process, the selection of the roll material is critical. Based on yourknowledge of both hot and cold rolling, what properties should the roller materialhave?。