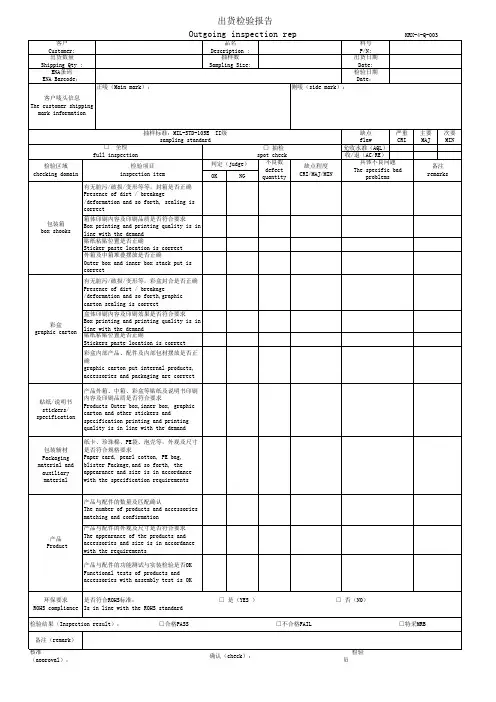

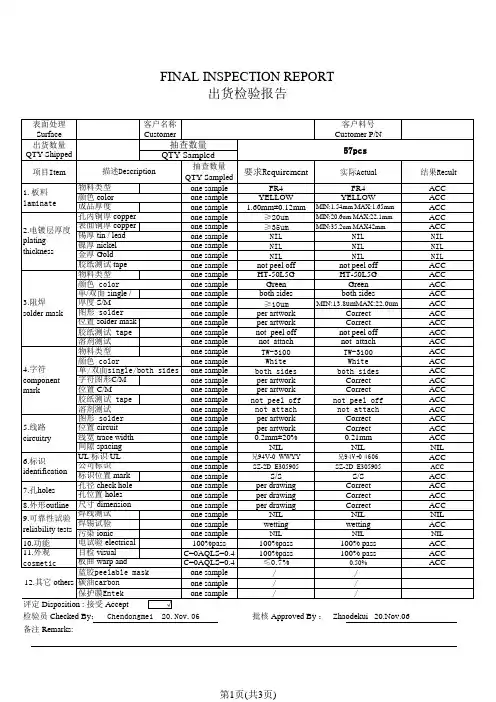

SMT检验报告 中英文版

- 格式:xls

- 大小:37.50 KB

- 文档页数:1

![IPQC(SMT)检验报告1[1].2](https://uimg.taocdn.com/14414ecbaa00b52acfc7ca9e.webp)

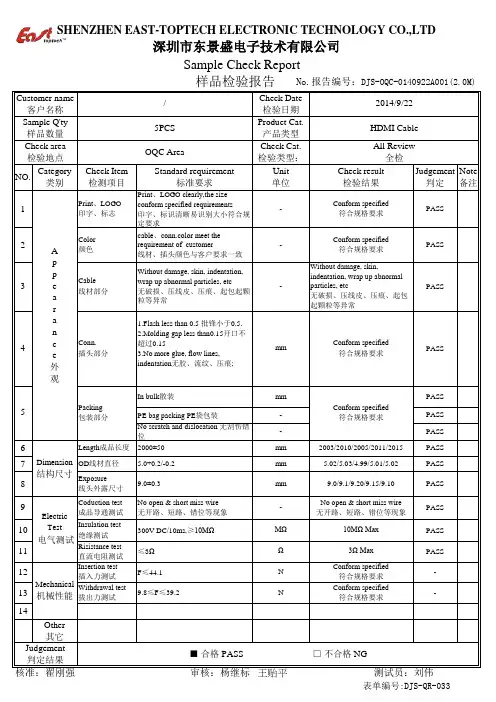

NO.Category 类别Standard requirement标准要求Judgement 判定Note 备注1Print 、LOGO clearly,the size conform specified requirements 印字、标识清晰易识别大小符合规定要求PASS2cable 、conn.color meet the requirement of customer线材、插头颜色与客户要求一致PASS3Without damage, skin, indentation,wrap up abnormal particles, etc 无破损、压线皮、压痕、起包起颗粒等异常PASS41.Flash less than 0.5 批锋小于0.5.2.Molding gap less than0.15开口不超过0.153.No more glue, flow lines,indentation 无胶、流纹、压痕;PASSIn bulk 散装PASS PE bag packing PE 袋包装PASS No scratch and dislocation 无刮伤错位PASS 62000±50PASS 7 5.0+0.2/-0.2PASS 89.0±0.3PASS 9No open & short miss wire无开路、短路、错位等现象PASS 10300V DC/10ms,≥10MΩPASS 11≤3ΩPASS 12F ≤44.1-139.8≤F ≤39.2-14Other 其它 Sample Check Reportmm Coduction test 成品导通测试A p p e a r a n c e 外观Dimension 结构尺寸Judgement 判定结果■ 合格 PASS □ 不合格 NGSHENZHEN EAST-TOPTECH ELECTRONIC TECHNOLOGY CO.,LTD深圳市东景盛电子技术有限公司Conform specified 符合规格要求Mechanical 机械性能-3Ω Max 5.02/5.03/4.99/5.01/5.02Conform specified 符合规格要求9.0/9.1/9.20/9.15/9.10No open & short miss wire 无开路、短路、错位等现象2003/2010/2005/2011/2015-Electric Tes t电气测试-Insulation test 绝缘测试MΩOD 线材直径Conform specified 符合规格要求Color 颜色Cable 线材部分-10MΩ Max Conform specified 符合规格要求Conform specified 符合规格要求Without damage, skin,indentation, wrap up abnormal particles, etc无破损、压线皮、压痕、起包起颗粒等异常mm Check result 检验结果Check Date 检验日期2014-9-22Check Cat.检验类型:All Review 全检-Product Cat.产品类型HDMI CableCheck area 检验地点Unit 单位-Length 成品长度mm mmExposure线头外露尺寸mm OQC AreaCustomer name 客户名称Check Item 检测项目5Conn.插头部分Print 、LOGO 印字、标志Sample Q'ty 样品数量/5PCS Packing 包装部分Conform specified 符合规格要求Risistance test 直流电阻测试Withdrawal test 拔出力测试ΩInsertion test 插入力测试N NNo.报告编号:DJS-OQC-0140922A001(2.0M)表单编号:DJS-QR-033。

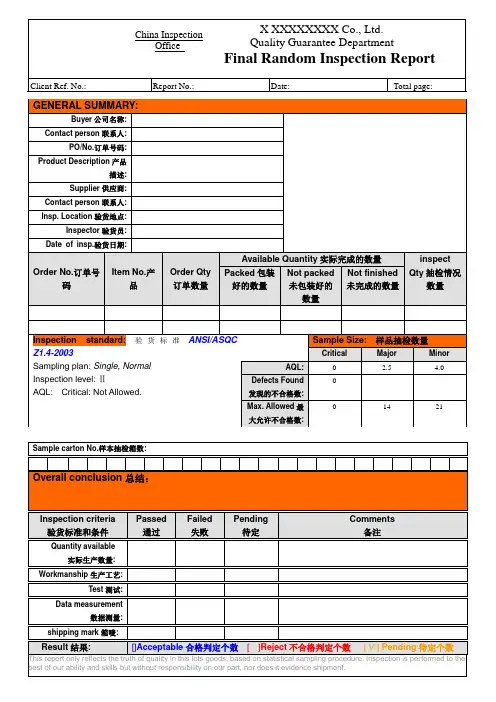

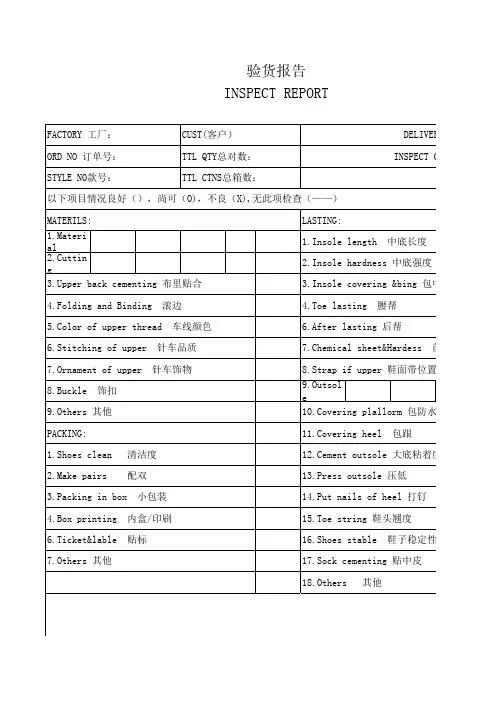

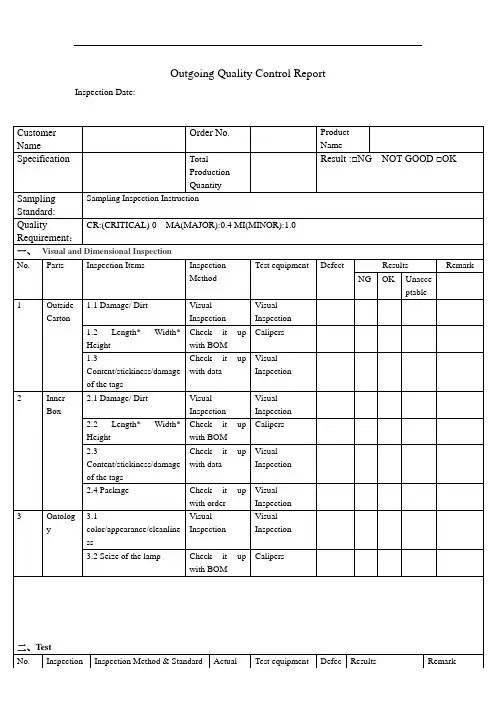

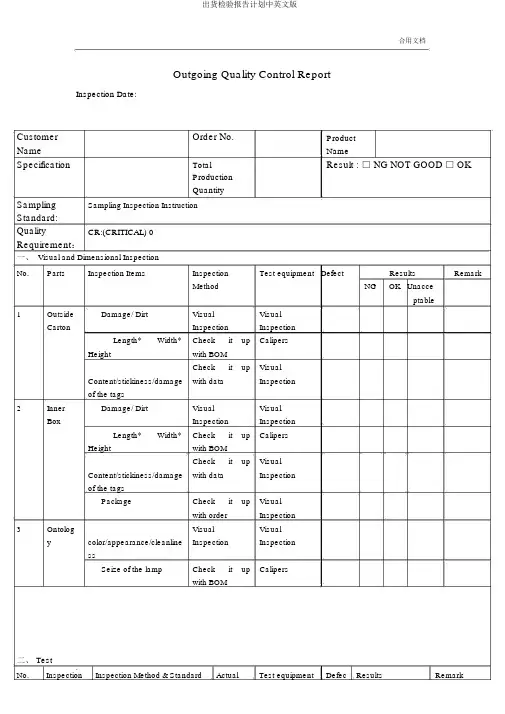

合用文档Outgoing Quality Control ReportInspection Date:Customer Order No.ProductName NameSpecification Total Result : □ NG NOT GOOD □ OKProductionQuantitySampling Sampling Inspection InstructionStandard:Quality CR:(CRITICAL) 0Requirement:一、 Visual and Dimensional InspectionNo.Parts Inspection Items Inspection Test equipment Defect Results RemarkMethod NG OK Unacceptable1Outside Damage/ Dirt Visual VisualCarton Inspection InspectionLength*Width*Check it up CalipersHeight with BOMCheck it up VisualContent/stickiness/damage with data Inspectionof the tags2Inner Damage/ Dirt Visual VisualBox Inspection InspectionLength*Width*Check it up CalipersHeight with BOMCheck it up VisualContent/stickiness/damage with data Inspectionof the tagsPackage Check it up Visualwith order Inspection3Ontolog Visual Visualy color/appearance/cleanline Inspection InspectionssSeize of the lamp Check it up Caliperswith BOM二、 TestItems Paramet t NG OK Unacer ceptable 4Aging Test Under the punch of aging Aging Machinemachine ﹥ 4H5Puncture Under the punch of aging Aging MachineTest machine﹥ 4H6Power The use of power meter+ — 1W Power Meter6Color The same as customer’ s IntegratingTemperatu requirement Spherere7CRI The same as customer’ s Integratingrequirement Sphere8Angle The same as customer’ s Integratingrequirement SphereInspector:出货检验报告检验日期:检验员 QC:客户名称定单号产品名称产品规格生产总数结论:□ NG□ OKInspection抽样检验指导书Standard质量要求:致命瑕疵〔 CR:0)严重瑕疵〔 MA:0.4 〕略微瑕疵〔 MI:1.0 〕一、外观尺寸检验序号部检验内容检查方法检验设备缺点检验结果说明位别NG OK不接受1外外箱表面破坏、脏污目测目测箱外箱的长 *宽*高与 BOM 表核对卷尺贴纸内容、粘性、破坏与数据检验目测2内内盒表面破坏,脏污目测目测盒内盒的长 *宽*高与 BOM 表核对卷尺贴纸内容、粘性、破坏与数据检验目测内盒包装物与定单核对目测3本颜色、外观、洁净度目测目测体整灯的尺寸与 BOM 表核对卡尺二、测试检验序号检验内容检查方法及标准实际参检验设备缺点检验结果说明数别NG OK不接受4老化测试使用老化机冲压状态下﹥4H老化机5耐压测试使用老化机脉压冲击状态下老化机﹥ 4H6功率测试使用功率测试仪 +—1W功率测试仪6色温测试积分球测试与客户所须一致积分球7显指测试积分球测试与客户所须一致积分球8角度测试积分球测试与客户所须一致积分球。

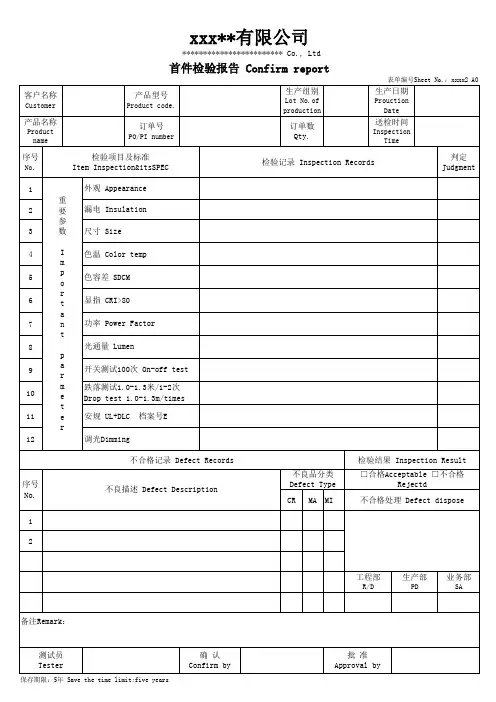

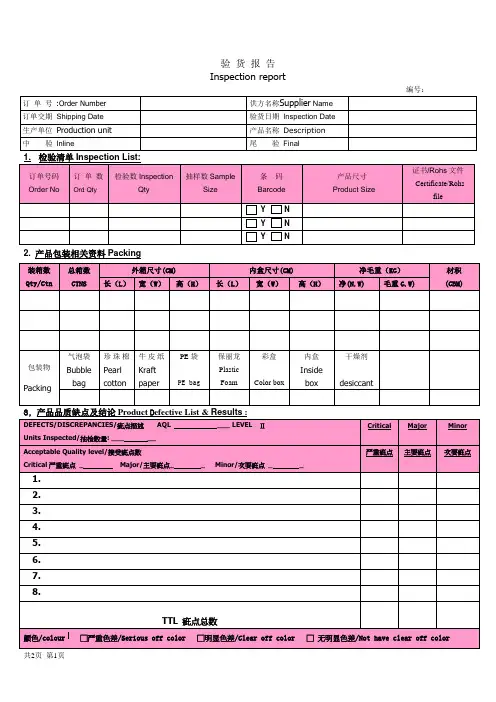

中英版产品检验报告模版产品检验报告模板 Product Inspection Report Template1. 报告概述 Report Overview本报告旨在对以下产品进行质量检验,并提供相关测试结果和质量评估。

This report aims to conduct quality inspection on the following products and provide corresponding test results and quality assessment.2. 产品信息 Product Information产品名称:(中文) Product Name: [Chinese](英文) Product Name: [English]生产商:(中文) Manufacturer: [Chinese](英文) Manufacturer: [English]供应商:(中文) Supplier: [Chinese](英文) Supplier: [English]订单号: Order Number:检验日期: Inspection Date:3. 检验项目 Inspection Items本次检验涵盖的项目包括但不限于以下内容: The following items are covered in this inspection but not limited to:3.1 外观检查 Appearance Inspection对产品的外观进行检查,包括颜色、图案、工艺等方面的评估。

Evaluate the appearance of the product, including color, patterns, craftsmanship, etc.结果: Results:3.2 尺寸检查 Dimension Inspection对产品的尺寸进行检查,包括长度、宽度、高度等方面的测量。

出厂质检报告模板英文IntroductionThis report presents the findings of the quality inspection conducted at the factory. The purpose of this inspection is to ensure that the products meet the required standards and specifications before they are shipped to the customers. The inspection was carried out on [date] by a team of experienced inspectors.Product Information- Product Name: [Name of the product]- Product Model: [Model number]- Batch Number: [Batch number]- Quantity Inspected: [Number of units]Inspection CriteriaThe inspection was conducted based on the following criteria:- International standards and regulations- Customer specifications and requirements- Industry best practicesInspection Process1. Initial assessment of product documentation2. Visual inspection of the products3. Measurement of product dimensions and specifications4. Testing of product functionalities and performance5. Assessment of packaging and labelingFindingsBased on the inspection conducted, the following findings were identified:1. Visual Inspection- The overall appearance of the products is in conformity with the specified requirements.- No visible scratches or damages were observed on the surface of the products.- The color consistency across the products is satisfactory.2. Measurement of Dimensions and Specifications- All the measured dimensions are within the specified tolerances.- The weight of the products matches the required specifications.- The materials used in the products are of the specified quality.3. Testing of Functionalities and Performance- The products function satisfactorily according to the specified requirements.- All the functions and features of the products were tested and found to be in working order.- The safety features incorporated in the products operate as intended.4. Assessment of Packaging and Labeling- The products were packed securely to prevent any damage duringtransportation.- The labeling on the packaging is clear, accurate, and in accordance with the customer requirements.- The packaging materials used are of good quality and provide adequate protection.ConclusionBased on the findings of the inspection, it is concluded that the products meet the required standards and specifications. The quality of the products is satisfactory and they are suitable for shipment to the customers.RecommendationsNo major issues were identified during the inspection. However, minor improvements in packaging design and labeling clarity are suggested to enhance the overall customer experience.AcknowledgmentWe would like to express our gratitude to the factory management and staff for their cooperation and support during the inspection. Appendix- Photographs of the inspected products- Test results and measurements data。

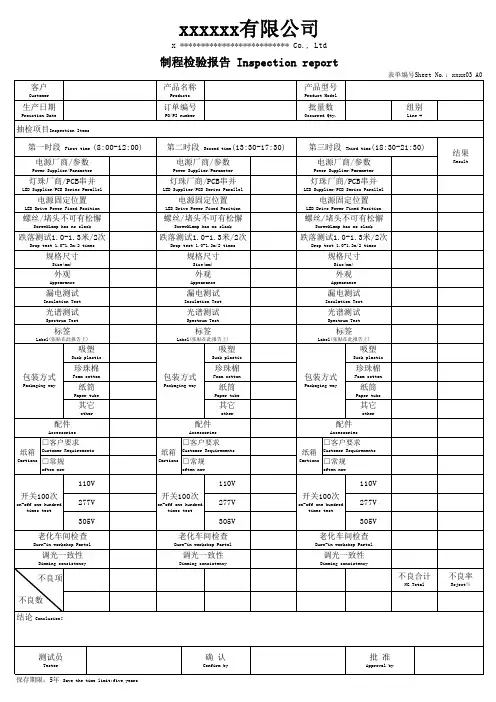

SMT Production Practice reportpersonal informationName :X X X Time :10.7~10.12/2015practice contents1.SMT technologySMT full name is Surface Mounted Technology,SMT is more popular and more advanced technology and process in the electronic assembly industry currently.It is a short lead or leadless chip components mounted on the surface of the printing plate,Again through reflow soldering assembly of electrical connection technology.Its main advantages are:①High density assembly, electronic products small size, light weight,Due to the volumeand weight of the patch element is only about 1/10 of the traditional instrumentation components,After the general use of SMT, electronic products smaller 40% ~ 60%, 60% ~ 80% reduction in weight;②High reliability, ability to carry vibration, solder joint defect rate is low;③Good ability of high frequency, reduce the electromagnetic and radio frequency interference;④Easy to realize automation,improve production efficiency,save material,energy, equipment, manpower, time, etc.,reduce the production cost.2、SMT processSolder paste printing Models:Component placement Models:Reflow soldering process:Temperature curve testAOI test<1>printingPrinting is that the solder paste is printed on the PCB pads in preparation for welding components.<2> PatchIts role is to install surface mount components accurately to a fixed position on the PCB.<3> weldingIts role is to melt the solder paste to make surface mount components and PCB board firmly welded together,then fairly strict demands on temperature。