大众汽车标准_TL 52476 POM材料规范

- 格式:pdf

- 大小:147.31 KB

- 文档页数:5

Group standardTL 52476Issue 2014-04Class. No.:55118Descriptors:POM, polyoxymethylene, polyacetal, loudspeaker cover, clipPOMMaterials RequirementsPrevious issuesTL 52476: 1997-01, 2006-03ChangesThe following changes have been made to TL 52476: 2006-03:–Melting temperatures changed –Applicable documents updated ScopeThis Technical Supply Specification (TL) specifies materials requirements for finished parts made of polyoxymethylene (POM), e.g., loudspeaker covers and fasteners (clips).DescriptionPOM as per TL 52476RequirementsBasic requirementsApproval of first supply and changes as per Volkswagen standard VW 01155.Emission behavior as per VW 50180 (if required in the drawing; see also section 5.1).Resistance to open-air weathering as per VW 50185.Colorimetric evaluation as per VW 50190 (if required in the drawing).123 3.1Always use the latest version of this standard.This electronically generated standard is authentic and valid without signature.The English translation is believed to be accurate. In case of discrepancies, the German version is alone authoritative and controlling.Page 1 of 6All rights reserved. No part of this document may be provided to third parties or reproduced without the prior consent of one of the Volkswagen Group’s Standards departments.© Volkswagen AktiengesellschaftVWNORM-2014-06a-patch5Q U E L L E : N O L I SPage 2TL 52476: 2014-04Avoidance of hazardous substances as per VW 91101.10 finished parts are required for complete testing; for fasteners (like clips), 20 finished parts are required.PropertiesThe surface and interior of the finished parts must be free of flaws and processing defects such as flow lines, cracks, air traps, or similar defects. Sink marks at the base of ribs and reinforcements are only permissible if they do not adversely affect the function, appearance, and/or assembly of the parts. The finished parts must allow for trouble-free installation.PackagingFinished parts must be packed in a way that allows air circulation. For delivery in large packaging units (cardboard boxes, pallets), the finished parts must be stacked or arranged so that air circula‐tion is possible.Marking as per VDA 260> POM <ConditioningPrior to testing, the specimens must be conditioned in the ISO 554-23/50 standard climate for at least 24 h.Evaluation of the measurement resultsThe required numerical values apply to each individual measurement.MaterialSee section 5.2.Polyoxymethylene (POM) homopolymer or, alternatively, copolymer.ColorAs per drawing and/or release.PropertySee table 1.3.1.13.1.23.2 3.33.43.53.64Page 3TL 52476: 2014-04 Table 1Page 4TL 52476: 2014-04Notes on testing Emission behaviorIf the test results do not comply with the requirements of VW 50180, the parts must be tempered until the limit values are met. The temperature must be selected such that no changes in shape,color, and to the surface occur.MaterialThe identity test is performed with infrared spectroscopy.Melting temperatureIf the differential scanning calorimetry (DSC) method is used to determine the melting temperature,the following procedure must be used:Test equipment such as the DSC 821e from Mettler Toledo can be used. A plane-parallel finished part section with a weight of approx. (5 to 10) mg is used as the specimen.Test parameters: Heat the specimen from +50 °C to +200 °C at a heating rate of 10 °C/min. After‐wards, cool it down to +50 °C at a rate of 5 °C/min and then reheat it at a rate of 10 °C/min to +200 °C. Perform the test under normal atmospheric conditions.Yield stress and yield strainTensile test as per DIN EN ISO 527-2, specimen type 5A, test speed: 50 mm/min. If no 5A speci‐men is available, it is permissible to use S3A tensile specimens (dumb-bell specimen) as per DIN 53504.Impact strengthTest equipment: 4 J pendulum impact tester.If for reasons concerning equipment and/or specimen shape and size a test as per table 1, con‐sec. no. 6 cannot be performed, the following procedure can be used as a substitute:Impact resistance test (broadside impact) as per DIN EN ISO 179-1, but with: specimen length of (50 ± 1) mm, width of (6 ± 0.2) mm, thickness matching the thickness of the finished product (up to a max. of 4 mm); distance between supports: 40 mm; test equipment: 4 J pendulum impact tester.Specimens taken from finished parts grained or painted on one side are placed on the supports of the pendulum impact tester so that the grained or painted side faces the direction of impact.Note that this procedure requires prior agreement.Notched impact strengthTest equipment: 4 J pendulum impact tester.If for reasons concerning equipment and/or specimen shape and size a test as per table 1, con‐sec. no. 7 cannot be performed, the following procedure can be used as a substitute:Impact resistance test (broadside impact) as per DIN EN ISO 179-1, but with: specimen length of (50 ± 1) mm, width of (6 ± 0.2) mm, thickness matching the thickness of the finished product (up to a max. of 4 mm); distance between supports: 40 mm; test equipment: 4 J pendulum impact tester.5 5.15.25.35.45.55.6Page 5TL 52476: 2014-04A 0.8 mm-wide U-shaped notch is made on the broad side of the specimens. The notch depth is 1/3 of the specimen thickness. The edges outlining the notch root must have a curvature radius of < 0.1 mm.Finished parts with one-sided graining must be notched on the grained side and subsequentlyplaced on the pendulum impact tester’s specimen supports in such a manner that the center of the notch is precisely within the impact plane. Care must be taken that the notch is located on the side facing away from the hammer edge. Note that this procedure requires prior agreement.Elevated-temperature behaviorHeat aging test as per DIN 53497, method B, on at least one complete finished part; aging temper‐ature of (+90 ± 1) °C; aging duration of (22 + 2) h.Low-temperature behaviorA minimum of 2 complete finished parts are aged in air at (-30 ± 1) °C; aging period (22 + 2) h.Ball drop testBall drop test as per PV 3905, but with: base plate (specimen support surface) made of steel sheet with a thickness ≥10 mm; no depression on at least three finished parts. Ball drop height:(450 ± 5) mm.LightfastnessIf the number of periods of exposure is not defined in the drawing, the following rule applies:– 3 periods of exposure for components in areas with indirect solar radiation– 5 periods of exposure for components in areas with direct solar radiation (e.g., door waist rail).–10 periods of exposure for components in areas with the highest solar radiation (e.g., rearshelf).Applicable documentsThe following documents cited in this standard are necessary to its application.Some of the cited documents are translations from the German original. The translations of Ger‐man terms in such documents may differ from those used in this standard, resulting in terminologi‐cal inconsistency.Standards whose titles are given in German may be available only in German. Editions in other languages may be available from the institution issuing the standard.PV 1303Non-Metallic Materials; Exposure Test of Passenger Compartment Com‐ponentsPV 3905Organic Materials; Ball Drop TestTL 1010Materials for Vehicle Interiors; Burning Behavior; Material Requirements VW 01155Vehicle Parts; Approval of First Supply and ChangesVW 50180Components in the Passenger Compartment; Emission Behavior VW 50185Vehicle Parts; Resistance to Open-Air Weathering5.75.85.95.106Page 6TL 52476: 2014-04VW 50190Interior Trim Components; Metrological Evaluation of Color and GlossLevel; Visual Evaluation of Chrome SurfacesVW 91101Environmental Standard for Vehicles; Vehicle Parts, Materials, Operat‐ing Fluids; Avoidance of Hazardous SubstancesDIN 53497Testing of Plastics; Hot Storage Test on Mouldings Made of Thermo‐plastic Moulding Materials without External Mechanical StressingDIN 53504Testing of rubber - determination of tensile strength at break, tensilestress at yield, elongation at break and stress values in a tensile test DIN EN 20105-A02Textiles - Tests for colour fastness - Part A02: Grey scale for assessingchange in colourDIN EN ISO 1183-1Plastics - Methods for determining the density of non-cellular plastics -Part 1: Immersion method, liquid pyknometer method and titration meth‐odDIN EN ISO 179-1Plastics - Determination of Charpy impact properties - Part 1: Non-instru‐mented impact testDIN EN ISO 306Plastics - Thermoplastic materials - Determination of Vicat softeningtemperature (VST)DIN EN ISO 3146Plastics - Determination of melting behaviour (melting temperature ormelting range) of semi-crystalline polymers by capillary tube and polariz‐ing-microscope methodsDIN EN ISO 527-2Plastics - Determination of tensile properties - Part 2: Test conditions formoulding and extrusion plasticsISO 554Standard atmospheres for conditioning and/or testing; Specifications VDA 260Components of motor vehicles - Marking of material。

征求意见日期截至2005年6月22日应用注释由于最终形成的标准可能不同于草案,因此在原则上不按标准草案进行加工,如在特殊情况下需要采用草案,标准的使用者之间应达成协议。

修订对TL 52284:2000-10版作了如下修订:-增加了VW 50190;-增加了Veslic耐磨性能;-增加了组合试验(结合折叠负荷的老化;-对标准重新作了划分。

以前的版本1984年8月、1990年2月、1996年9月、2000年10月1 应用范围本技术条件规定了例如用于开关和手动制动杆(B、C、E、F型)或转向柱(D型)内饰的泡沫人造革的材料要求。

2 标记棉针织物截体人造革的标记示例:泡沫人造革根据TL 522 84-B3 要求3.1 基本要求首次供货的批准和修改根据VW 01155的规定。

发放性能根据VW 50180的规定。

色度评定根据VW 50190的规定。

有害物质的避免根据VW 91101的规定。

一次完整分析至少需要10个成型件和2 m2的布匹。

要求的数值适用于每一次测量。

3.2 质地粒面和色调必须均匀。

表面不得有疵点和划痕。

3.3 处理性能泡沫人造革的缝制必须完好。

3.4 使用性能材料碰皱(用手弯)时,在-40℃~ +90℃温度范围内,如接触油脂,也不得影响所希望“皮革的柔软性”。

不允许出现吱吱声和面层受损现象。

对所讲的“抗尖锐声型”(E和F型),其背面必须光滑(如磨平)并具有符合本要求的漆系。

耐水解表层或PUR面层必须能用普通的不变色清洗剂加以清洗。

3.5 对人的亲和性材料成分和部件对人的生理应无影响,不得引起皮肤炎症或发出重味。

在高温下挥发的成分必须是无毒的。

3.6 状态调节试验前,试样必须在标准气候DIN 50014-23/50下至少停放24 h。

3.7 色调和粒面根据经批准的样品。

3.8 类型-TL 52284-B 棉针织物载体上的人造革、轻型-TL 52284-C 棉针织物载体上的人造革、重型-TL 52284-D 聚凝人造革、硬型-TL 52284-E 聚凝人造革、抗尖锐声软型-TL 52284-F 聚凝人造革、抗尖锐声软厚型3.9 材料和结构TL 52284-B和TL 52284-C 发泡乳胶基聚酯-PUR面层,涂在棉针织物上(涂复系);表面:批准的聚酯-PUR末道漆载体:棉针织物TL 52284-D 双面包聚酯-PUR织物(凝固系),背面不打磨;表面:批准的聚酯-PUR末道漆(软漆系)载体:棉/聚酯针织物TL 52284-E和TL 52284-F 双面包聚酯-PUR织物(凝固系),背面打磨;表面:批准的聚酯-PUR末道漆(软漆系)载体:棉/聚酯针织物支数:经向>18、纬向>103.10 按VDA 260的标识TL 52284-B和TL 52284-C >PUR + SBR + CO<TL 52284-D >PUR + CO + PET<TL 52284-E和TL 52284-F >PUR + CO + PET<4 性能见表1。

Confidential. All rights reserved. No part of this document may be transmitted or reproduced without prior permission of a Standards Department of the Volkswagen Group.Parties to a contract can only obtain this standard via the B2B supplier platform “”VOLKSWAGEN AGPage 2TL 524 76: 2006-03D3.1.2 PackagingFinished part packaging shall not be air tight to allow air circulation. In case of delivery in large packaging units (cardboard boxes, pallets), they should be stacked or arranged so that air circulation is possible.3.2 Marking according to VDA 260>POM<3.3 ConditioningPrior to testing, the specimens required for the individual tests must be conditioned for at least 48 h in the DIN 50014 – 23/50-2 standard climate.3.4 Evaluation of the measuring resultsThe required numerical values apply to each individual measurement.3.5 MaterialSee Section 5.2.Polyoxymethylene (POM) homopolymer, or copolymer alternatively.3.6 ColorAccording to drawing and/or release.4 PropertiesSee Table 1.Table 1No. Property Requirement1 Density acc. to DIN EN ISO 1183-1, buoyancy(1,42 ± 0,02) g/cm3method2 Melting temperature acc. to DIN EN ISO 3146,+166 °C to +179 °Calternatively with DSCsee Section 5.33 Dimensional stability under heat acc. to Vicat and≥ 145 °CDIN EN ISO 306, method B50≥ 60 MPa4 Yield stress acc. to DIN EN ISO 527-2see Section 5.45 Elongation acc. to DIN EN ISO 527-2≥ 6,5%see Section 5.46 Impact resistance acc. to DIN EN ISO 179-1/1eUNo fracture (kJ/m2)see Section 5.57 Notched impact strength acc. to DIN EN ISO 179-≥ 4,5 kJ/m21/1eA.see Section 5.6Page 3TL 524 76: 2006-035 Notes on testingbehavior5.1 EmissionIf the test results do not comply with the requirements of VW 50180, the parts shall be tempered until the limit values are met. The temperature shall be selected such that no changes in form, color, and surface occur.5.2 MaterialThe identity test is performed using infrared spectroscopy.temperature5.3 MeltingIf the DSC method is chosen to identify the melting temperature, the following procedure shall be applied:Test equipment such as the DSC 821e from Mettler Toledo can be used. A plane parallel finished part section of a weight of approx. 5 mg to 10 mg serves as specimen.Testing parameters: The specimen is heated from +50 °C to +200 °C at a heating rate of 10 °C/min. Afterwards, it is cooled with 5° C/min to +50° C and reheated with 10° C/min to +200° C. The test is carried out in normal atmosphere.Page 4TL 524 76: 2006-03D5.4 Yield stress and elongationTensile test according to DIN EN ISO 527-2, 5A specimen, test rate 50 mm/min. In case the 5A specimen cannot be prepared, it is permissible to use S3A tensile specimens (standard test specimens) acc. to DIN 53504.strength5.5 ImpactTest equipment: pendulum impact tester 4J.If for reasons concerning equipment and/or specimen shape and size a test according to Table 1 No. 6 cannot be performed, the following procedure may be substituted:Impact resistance test (broadside impact) according to DIN EN ISO 179-1; deviating specimen length: (50 ± 1) mm, width: (6 ± 0,2) mm, thickness according to product thickness (up to max.4 mm); mounting flange interval (support separation): 40 mm, test equipment: pendulum impact tester 4J.Specimens taken from finished parts grained or painted on one side are placed on the mounting flange of the pendulum impact tester so that the grained or painted side faces the direction of impact.Note that this procedure requires prior agreement.5.6 Notched impact strengthTest equipment: pendulum impact tester 4J.If for reasons concerning equipment and/or specimen shape and size a test according to Table 1 No. 7 cannot be performed, the following procedure may be substituted:Impact resistance test (broadside impact) according to DIN EN ISO 179-1; deviating specimen length: (50 ± 1) mm, width: (6 ± 0,2) mm, thickness according to product thickness (up to max. 4 mm); mounting flange interval (support separation): 40 mm, test equipment: pendulum impact tester 4J.The specimens are given a 0.8 mm wide U-shaped notch on the broad side. The notch depth shall be 1/3 the specimen thickness. The edges adjoining the base of the notch shall have a curvature radius of < 0,1 mm.Finished parts with one-sided graining shall be notched on the grained side and subsequently placed on the pendulum impact tester’s mounting flanges in such a manner that the center of the notch is precisely within the impact plane. Care shall be taken that the notch is located on the side away from the direction of impact. Note that this procedure requires prior agreement.behavior5.7 Elevated-temperatureAging test at elevated temperature according to DIN 53497, method B, on at least one complete finished part; aging temperature (+90 ± 1) °C; aging period (22 + 2) h.behavior5.8 Low-temperatureA minimum of two complete finished parts are aged in air at (-30 ± 1) °C; aging period (22 + 2) h.5.9 Ball drop testBall drop test acc. to PV 3905, however, base plate (specimen support) made from 10 mm thick sheet steel without recess on at least three finished parts. Ball drop height (450 ± 5) mm.Page 5TL 524 76: 2006-03D 5.10 LightfastnessIf the number of exposure periods is not defined in the drawing, the following rule applies:─ 3 periods of exposure for components in areas with indirect sun radiation.─ 5 periods of exposure for components in areas with direct sun radiation (e.g. door upper trim).─10 periods of exposure for components in areas subject to the highest sun radiation (e.g. rear shelf).standards16 ReferencedTL 1010 Materials for Vehicle Interiors; Flammability, Material RequirementsPV 1303 Non-Metallic Materials;Exposure Test of Passenger Compartment ComponentsPV 3905 Organic Materials; Ball Drop TestVW 01155 Vehicle Supply Parts; Approval of First Supply and ChangesVW 50180 Components in Passenger Compartment; Emission BehaviorVW 50185 Vehicle Components; Resistance to Open Air WeatheringVW 50190 Components of the Vehicle Interior Trim; Colorimetric EvaluationVW 91101 Environmental Standard for Vehicles; Vehicle Parts, Materials, Operating Fluids; Avoidance of Hazardous SubstancesDIN 50014 Climates and Their Technical Application; Standard AtmospheresDIN 53497 Testing of Plastics; Hot Storage Test on Mouldings Made of Thermoplastic Moulding Materials without External Mechanical StressingDIN 53504 Testing of Rubber; Determination of Tensile Strength at Break, Tensile Stress at Yield, Elongation at Break and Stress Values in a Tensile TestDIN EN ISO 179-1 Plastics; Determination of Charpy Impact Properties, Part 1: Non-Instrumented Impact TestDIN EN ISO 306 Plastics – Thermoplastic Materials – Determination of Vicat Softening Temperature (VST)DIN EN ISO 527-2 Plastics - Determination of Tensile Properties – Part 2: Test Conditions for Moulding and Extrusion PlasticsDIN EN ISO 1183-1 Plastics – Methods for Determining the Density of Non-Cellular Plastics – Part 1: Immersion Method, Liquid Pyknometer Method and Titration Method DIN EN ISO 3146 Plastics, Determination of Melting Behaviour (Melting Temperature or Melting Range) of Semi-Crystalline Polymers by Capillary Tube andPolarizing-Microscope MethodsDIN EN 20105-A02 Textiles – Tests for Colour Fastness – Part A02: Grey Scale for Assessing Change in ColourVDA 260 Motor Vehicle Components; Marking of Materials1 In this section terminological inconsistencies may occur as the original titles are used.。

57 22 5共 27页第 1页资料 标准中心请注意:首次供货和更改的批准按:VW 011 55“汽车配件概述”VW 911 11环境汽车标准PV 1401 PV 1437 为了使传动机构畅通无阻,特别是为了使自动变速箱, 变速齿轮和带圆柱齿轮啮合(锥形齿轮传动除外)的主传 动畅通无阻,保证它们的寿命满期,本标准 TL 特为它们 规定了各项技术要求。

这些要求是由费希特尔及萨希斯 (F&S)股份公司和弗里德里斯哈费股份公司齿轮制造厂 (ZF)通力合作研制出来的PV 1442 PV 1444 PV 1448 PV 3323 VW 501 07 VW 911 11 DIN 10 964 DIN 50 049 DIN 51 354-01 DIN 51 363-02 DIN 51 381 DIN 51 398 DIN 51 400-06 DIN 51 451 DIN 51 562 DIN 51 581 DIN 51 757 DIN 51 777-01 DIN 53 504 DIN ISO 2592 DIN ISO 2909 DIN ISO 3016 ISO 4406 对ATF 液的评价由VW 股份公司的VW 中心实验室10 I和VW 传动机构试验室200 I共同作出,此外还提供关于下列技术要求的证明书 如果以后ATF 液的表达方式有改变,则评价结论随 之失效。

表达方式的改变,要由VW 中心实验室发出书面通知, 并且重新附上样品及书面批准抽走批准书是供货人的责任,但要把情况通报给 VW 康 采恩有关单位的供货人1 概述 ASTM D 664 ASTM D 892 ASTM D 3228 CEC-L-48-T-94/B EN 10 2041.1适用范围按本TL 标准的规定,ATF 液在自动变速箱中,以及在 变速齿轮和不带锥形齿轮传动的主传动中运行,无论 是夏季或冬季,都具有最佳的传动性能3.更改 2.更改 1.更改 日 期 专业负责 批准 专业负责 首次采用 采用 03.95共27页第2页1.2 类型ATF得克斯隆®III号油-其工艺规程系以石油工艺为基础,它是一种异乎寻常的人造碳水化合物,其摩擦系数特征粘度/温度特性,抗磨损性能,抗氧化性能,起泡性以及抗腐蚀性,由于添加剂的加入而获得了可喜的改善。

检具技术要求目录1. 目的 (3)2. 适用范围 (3)3. 责任 (3)4. 规定 (3)4.1 检具(测量支架)的概述 (3)4.2 检具设计与4.3 检具 (4) (12)5. 存档 (13)6. 评审与更改 (14)7. 分发 (14)8. 附件清单 (14) (15)附件一:关于检具定位销1. 检具定位销概述 (15)2. 定位销 A1的结构形式 (16)3. 定位销 A2的结构形式 (19)4 . 零件检查销的结构 (23)5. 轴套结构图示介绍 (26)附件二:检具(测量支架)认可流程 (28)附件三: 检具(测量支架)设计认可报 (29)附件四:检具(测量支架) (30)1. 目的通过《检具(测量支架)技术要求》,使检具(测量支架)在规划、设计与、验收与使用时,能够遵循统一的技术标准2.适用范围。

本技术要求适用于车身检具及对零件型面尺寸或装配尺寸与车身坐标系统有关联的内外饰件的检具。

3. 责任***负责本技术要求的编、维护、升级及分发等工作。

***零件供应商负责本技术要求在检具(测量支架)规划、设计、、验收中的贯彻。

4. 规定4.1 检具(测量支架)的概述4.1.1检具(测量支架)的定义检具是一种用来测量。

在零件生产现场, 通过检具实现对零件的在线检测,为此需要将零件准确地安装于检具上, 然后通过目测,或测量表,或卡尺对零件型面, ,也可以借对零件上不同性质的孔及零件与零件之间的联接位置进行目检,从而保证在试生产及起步生产时实现零件质量状态的快速判断。

在此情况下,通过目检或测量可以判断: 零件轮廓大小CAD/CAM直接。

对于零件上的某些极其重要的,还能利用检具进行数值检测。

通常不能借检具直接获得零件基于车身坐标系统精确的坐标值, 而是将零件置于检具上通过三坐标测量机测量方才获得。

现代检具的结构在设计时同时考虑其可以作为测量支架使用。

但是当检具的在线检查,应首先满足检具的在线检查。

Q U E L L E : N O L I SSeite 2TL 524 86: 2004-123.4 KennzeichnungNach Zeichnung.3.5 Auswertung der MessergebnisseDie geforderten Zahlenwerte gelten für jede Einzelmessung.3.6 AufbauVon innen nach außen:─Elastomer─Gestrick─Elastomer3.7 WerkstoffVon innen nach außen:─Polyethylen-Acrylat-Elastomer (AEM)─Aromatisches Polyamid─Polyethylen-Acrylat-Elastomer (AEM)3.8 Glührückstandin%Innen- und Außenlage nach Muster; Toleranzen nach VDA 675 130.4 EigenschaftenSiehe Abschnitt 5.1 und Tabelle 1.Tabelle 1Nr. Eigenschaft Einheit AnforderungInnenlage Außenlage 1 Dichte nach DIN EN ISO 1183-1 g/cm3 nachMuster 2 Härte nach DIN 535052.1 Anlieferung ShoreA 70 ± 52.2 nachWärmelagerungsiehe Abschnitt 5.294 h bei +160 °C Shore A 0 bis +8 gegenüber Anlieferung504 h bei +160 °C Shore A 0 bis +15 gegenüber Anlieferung2.3 nachMotorenöllagerung siehe Abschnitt 5.3 Shore A +10 gegenüberAnlieferung-2.4 nachDieselkraftstofflagerung siehe Abschnitt 5.4 Shore A - 0 bis -25 gegenüberAnlieferung3 Gewichtsänderung3.1 nachMotorenöllagerungsiehe Abschnitt 5.3% -2 bis +12 -3.2 nachDieselkraftstofflagerung siehe Abschnitt 5.4 % - 0 bis +35 gegenüberAnlieferungSeite 3TL 524 86: 2004-12 Nr. Eigenschaft Einheit AnforderungInnenlage Außenlage 4 Zugfestigkeit nach DIN 535044.1 Anlieferung N/mm2≥ 12,04.2 nachWärmelagerungsiehe Abschnitt 5.294 h bei +160 °C N/mm2≥ 12,0504 h bei +160 °C N/mm2≥ 12,04.3 nachMotorenöllagerungsiehe Abschnitt 5.3N/mm2≥ 12,0 -4.4 nachDieselkraftstofflagerungsiehe Abschnitt 5.4N/mm2 - ≥ 8,05 Reißdehnung nach DIN 535045.1 Anlieferung % 200 bis 4005.2 nachWärmelagerungsiehe Abschnitt 5.294 h bei +160 °C % ≥ 200504 h bei +160 °C % ≥ 1505.3 nachMotorenöllagerungsiehe Abschnitt 5.3% ≥ 2005.4 nachDieselkraftstofflagerungsiehe Abschnitt 5.4% - ≥ 1506 Bleibende Verformung nach PV 330794 h bei +120 °C % ≤ 807 Weiterreißwiderstand nach DIN ISO 34-1, Methode A7.1 Anlieferung N/mm ≥ 5,07.2 nachWärmelagerungsiehe Abschnitt 5.294 h bei +160 °CN/mm ≥ 5,07.3 nachMotorenöllagerungsiehe Abschnitt 5.3N/mm ≥ 3,0 -8 Kälteverhalten nach VW 2.8.122 h bei -35 °C keinBruch9 Korrosionswirkung auf Kupfer nachVDA 675 241max. Stufe 2 zulässig10 Ozonbeständigkeit nach VW 2.8.1Knickbeanspruchung10.1 Anlieferung rissfrei10.2 nachWärmelagerungsiehe Abschnitt 5.2rissfrei10.3 nachMotorenöllagerungsiehe Abschnitt 5.3rissfrei11 Trennwiderstand der Außenlagen vomGewebe-Innenlage-Verbund nach DIN 5353011.1 Anlieferung N/mm ≥ 3,0Sofern die Proben in der Gummischichtreißen, gilt die jeweils höchste Kraftspitze imMessdiagramm.Seite 4TL 524 86: 2004-125 Prüfungshinweise5.1 ProbenFür die durchzuführenden Untersuchungen werden die angelieferten Schläuche mittels Bandmes-serspaltmaschine in die einzelnen Lagen getrennt.5.2 WärmelagerungNormstäbe S3A sind über die genannte Zeit bei +160 °C im Wärmeschrank mit Zwangsdurchlüf-tung nach DIN 53508 zu lagern.Die Messungen erfolgen 30 min nach Entnahme.5.3 MotorenöllagerungNormstäbe S3A werden 94 h bei +150 °C in ein durch ein Uhrglas verschlossenes Gefäß in Refe-rence Engine Oil C.20 nach TL 521 85 (Fa. Mobil AG, Hamburg) bzw. Castrol SLX long life 0W-30 nach TL 521 83 gelagert. Nach Entnahme aus der Prüfflüssigkeit sind die Prüflinge mittels Lappen von anhaftendem Restöl zu befreien.Die Messungen erfolgen 30 min nach Entnahme.5.4 DieselkraftstofflagerungNormstäbe S3A werden 46 h bei +23 °C in einem Gemisch aus 95 Vol.-% Dieselkraftstoff AP20/NP II (Fa. Haltermann) und 5 Vol.-% RME nach DIN EN 14214 gelagert. Nach Ablauf der Einwirkzeit werden die Teile entnommen, mittels Lappen von anhaftender Prüfflüssigkeit befreit und 15 min nach Entnahme aus dem Medium ausgewertet.Unterlagen6 MitgeltendePV 3307 Elastomerteile, Weichkunststoffteile, Plastische, elastische Verformbarkeit TL 521 83 Erstbetriebsmotorenöl SAE 0W-30 mit kraftstoffsparenden Eigenschaften für verlängerte Ölwechselintervalle; Anforderung, PrüfungTL 521 85 Reference Engine Oil C.20 SAE 5W-40, Verträglichkeitsprüfung Motoröl-Elastomerwerkstoffe; Anforderung, PrüfungenVW 2.8.1 Elastomere; Werkstoffanforderungen und -prüfungenVW 011 55 Fahrzeug-Zulieferteile allgemein; Genehmigung von Erstlieferung und Än-derungVW 911 01 Umweltnorm Fahrzeug, Fahrzeugteile, Werkstoffe, Betriebsstoffe; Schad-stoffvermeidungDIN 53504 Prüfung von Kautschuk und Elastomeren; Bestimmung von Reißfestigkeit, Zugfestigkeit, Reißdehnung und Spannungswerten im ZugversuchDIN 53505 Prüfung von Kautschuk und Elastomeren; Härteprüfung nach Shore A und Shore DDIN 53508 Prüfung von Kautschuk und Elastomeren; Künstliche AlterungDIN 53530 Prüfung organischer Werkstoffe; Trennversuch an haftend verbundenen GewebelagenSeite 5TL 524 86: 2004-12 DIN EN ISO 1183-1 Kunststoffe; Verfahren zur Bestimmung der Dichte von nicht verschäumten Kunststoffen - Teil 1: Eintauchverfahren, Verfahren mit Flüssigkeitspykno-meter und TitrationsverfahrenDIN EN 14214 Kraftstoffe für Kraftfahrzeuge ¸Fettsäure-Methylester (FAME) für Dieselmo-toren, Anforderungen und PrüfverfahrenDIN ISO 34-1 Elastomere oder thermoplastische Elastomere - Bestimmung des Weiter-reißwiderstandes - Teil 1: Streifen-, winkel- und bogenförmige Probekörper VDA 675 130 Elastomer-Bauteile in Kraftfahrzeugen; Prüfverfahren zur Identifikation;Glührückstand ohne chemische BehandlungVDA 675 241 Elastomer-Bauteile in Kraftfahrzeugen; Prüfverfahren zur Eigenschaftsbe-stimmung; Korrosionswirkung auf Kupfer。

共5页第 1 页耐自然老化依据VW 501 85,避免有害物质依据VW 911 01,要求提供10件成品,在有连接部件(例如夹子)情况下20件成品用于一个完整试验。

3.1.1 特性成品必须在表面上和内部无缺陷处和加工缺陷,如屈服线,条痕,砂眼,裂纹和类似的现象。

只有当既不影响功能,又不影响外观和可安装性能时才允许在附加物范围内有肋条和加强筋以及连接管存在。

成品必须能够进行完好安装。

3.1.2与人类的相容性所用材料必须是对人体无毒的。

有关在较高温度下挥发的物质必须经受毒物学的安全性考验。

3.1.3包装必须透气的包装成品并且在供货时用较大的包装单位(纸版箱包装,货盘)进行堆放或排列,以便空气能够环流。

3.2制作压铸方法。

3.3 规格-TL 524 76,规格无索引:有关例如扩音器保护层,油泵单元和连接部件(夹子)的POM-标准-压铸型号-TL 524 76,规格A:POM,防流入酸性介质添加的,例如有关相对于柴油分解产物,在稳定性上有较高要求柴油车的油泵单元。

3.4 识别标记按照VDA 260两个规格:>POM<3.5 温度调节对于有个别试验要求的试样必须在做试验之前至少在DIN 50 014-23/50-2的标准气候中进行48小时的温度调节。

3.6 要求的适用性所要求的数值适用每个单项试验。

3.7 材料见第5.1节。

-规格无索引:聚甲醛(POM)-Homo-选择性的可共聚单体。

-规格A:聚甲醛(POM)-可共聚单体,添加防流入酸性介质。

3.8 颜色-规格无索引:按照图纸。

-规格A:为了较好的辨别无索引的规格首选着橙色。

4 性能见表1。

表 1编号性能单位要求规格无索引规格A 1 密度按照DIN 53 479,浮力方法g/cm³ 1.42±0.02 1.42±0.02 2 溶化温度按照DIN EN ISO 3146选择方式。

DSC按照第5.2节℃ 166~179 166~1753 球压硬度按照DIN EN ISO 2039-1和第5.3节N/mm²≥150≥1304 拉伸应力按照DIN EN ISO 527-2和第5.4节MPa ≥60 ≥655 延伸率按照DIN EN ISO 527-2和第5.4节%≥6.5 ≥8.06 冲击韧性按照DIN EN ISO 179-1和第5.5节kJ/m²无折断 无折断7 缺口冲击韧性按照DIN EN ISO 179-1和第5.6节kJ/m²≥4.5 ≥6.08 热性能按照DIN 53 497和第5.7节成品既不不允许出现变脆也不可见的和/或有损坏功能的形状、颜色和表面改变现象。

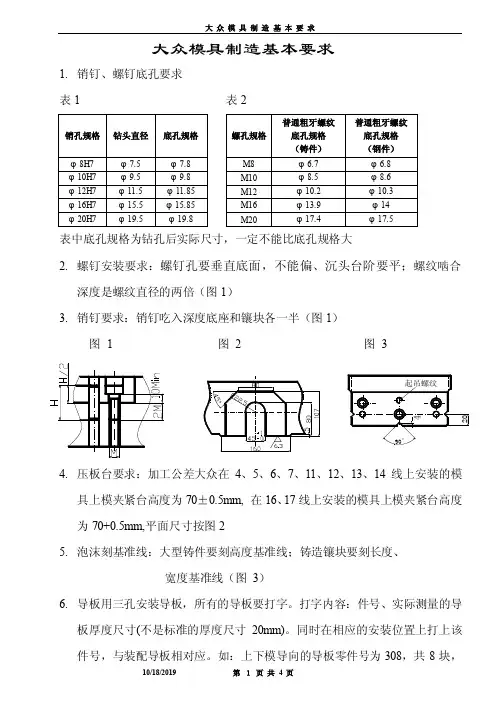

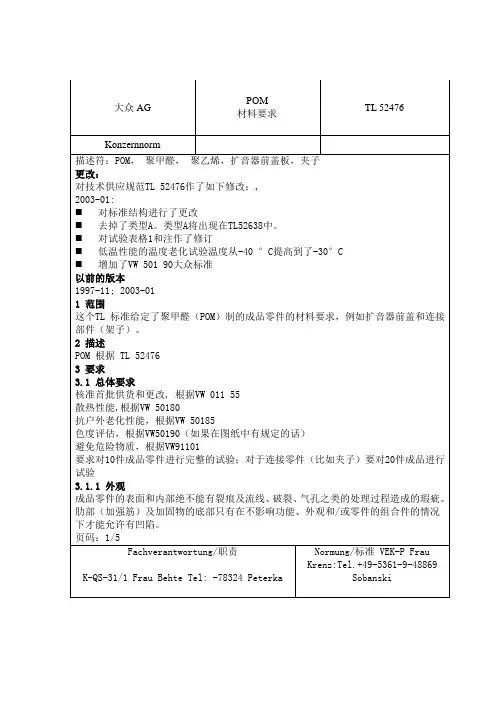

大众模具制造基本要求1. 销钉、螺钉底孔要求表1 表2表中底孔规格为钻孔后实际尺寸,一定不能比底孔规格大2. 螺钉安装要求:螺钉孔要垂直底面,不能偏、沉头台阶要平;螺纹啮合深度是螺纹直径的两倍(图1)3. 销钉要求:销钉吃入深度底座和镶块各一半(图1) 图 1 图 2 图 34. 压板台要求:加工公差大众在4、5、6、7、11、12、13、14线上安装的模具上模夹紧台高度为70±0.5mm, 在16、17线上安装的模具上模夹紧台高度为70+0.5mm,平面尺寸按图25. 泡沫刻基准线:大型铸件要刻高度基准线;铸造镶块要刻长度、宽度基准线(图 3)6. 导板用三孔安装导板,所有的导板要打字。

打字内容:件号、实际测量的导板厚度尺寸(不是标准的厚度尺寸20mm)。

同时在相应的安装位置上打上该件号,与装配导板相对应。

如:上下模导向的导板零件号为308,共8块,则8块导板也要编号,分别为308-1、308-2、308-3。

308-8;在上下底板上对应的308-1、308-2。

308-8这8块导板安装位置处也要分别打上308-1、308-2。

308-8的编号7. 所有的垫片、键、打杆等安装件都要打字,打字内容:件号,同时在相应的安装位置上打上该件号,与装配件对应,象导板编号一样。

一定要在淬火之前打字。

垫片要用螺钉固定,打上实际测量的厚度尺寸。

8. 导板、镶块等不允许使用调整垫片9. 侧插销要求:大众的侧插销孔和轴的配合是H7/e8 见图4和表3图4 表3 图510. 所有镶块无论铸造镶块还是钢块,中心位置都要打起吊螺纹M12见图3,起吊螺纹为M10 或M12,深2.5倍的螺纹直径 11. .挡键中间要按要求钻起吊螺纹,供拔出。

12. 刀块镶块打字标记要求:铸造镶块、钢块要在醒目位置打字, 打 字内容是模具号、件号。

一定要在淬火之前打字13. 所有镶块无论铸造镶块还是钢块,镶块接合面间隙最大为0.03mm14. 导板安装面、镶块底面研配要求: 镶块底面与底座的研合率达到80%、要平整,四角都要与底面接束.15. 修边刀块淬火要求:凹模刀块的淬火硬度为:HRC58±2 ; 凸模刀块的淬火硬度为:HRC56±216.废料孔要求:废料孔要按要求制作。

Q U E L L E : N O L I SSeite 2TL 524 76: 2003-01D3.1.2 HumanverträglichkeitDie verwendeten Materialien müssen physiologisch unbedenklich sein. Bezüglich der bei höheren Temperaturen ausdünstenden Substanzen muss toxikologische Unbedenklichkeit bestehen.3.1.3 VerpackungDie Fertigteile müssen luftdurchlässig verpackt sein und bei Anlieferung in größeren Verpackungs-einheiten (Kartonagen, Paletten) dort auch so gestapelt oder angeordnet sein, dass eine Luftzirku-lation möglich ist.3.2 HerstellungSpritzgießverfahren3.3 Ausführungen─TL 524 76, Ausführung ohne Index:POM-Standard-Spritzgusstyp für z. B. Lautsprecherabdeckungen, Kraftstoff-Fördereinheiten und Verbindungselemente (Clips).─TL 524 76, Ausführung A:POM, gegen den Einfluss saurer Medien additiviert, für z. B. Kraftstoff-Fördereinheiten von Dieselfahrzeugen mit erhöhter Anforderung an die Beständigkeit gegenüber Dieselkraftstoff-Abbauprodukten.3.4 Kennzeichnung nach VDA 260Beide Ausführungen: >POM<3.5 KonditionierungDie für die einzelnen Prüfungen erforderlichen Proben sind vor den Prüfungen mindestens 48 h im Normalklima DIN 50 014 - 23/50-2 zu konditionieren.3.6 Gültigkeit der AnforderungenDie geforderten Zahlenwerte gelten für jede Einzelmessung.3.7 WerkstoffSiehe Abschnitt 5.1.─Ausführung ohne Index:Polyoxymethylen (POM)-Homo- wahlweise Copolymerisat.─Ausführung A:Polyoxymethylen (POM)-Copolymerisat, gegen den Einfluss saurer Medien additiviert.3.8 Farbton─Ausführung ohne Index:Nach Zeichnung.─Ausführung A:Zur besseren Unterscheidung zur Ausführung ohne Index vorzugsweise orangefarben pigmen-tiert.Seite 3TL 524 76: 2003-01D 4 EigenschaftenSiehe Tabelle 1.Tabelle 1Seite 4TL 524 76: 2003-01D5 Prüfungshinweise5.1 WerkstoffDie Identitätsprüfung erfolgt infrarotspektroskopisch.5.2 SchmelztemperaturWird zur Bestimmung der Schmelztemperatur die DSC-Methode gewählt, ist wie folgt zu verfahren: Als Prüfgerät kann z. B. das DSC7 der Firma Perking Elmer verwendet werden. Als Probe dient ein planparalleler Fertigteilabschnitt mit einer Masse von ca. 10 mg.Prüfparameter: Die Probe wird von 50 °C auf 180 °C mit einer Aufheizrate von 10 °C/min aufge-heizt. Die Untersuchung findet unter Raumatmosphäre statt.5.3 KugeldruckhärteDie Messungen sind an mindestens drei (20 x 20) mm großen Probekörpern auszuführen (2 Mes-sungen je Probe). Bei Proben, die aus einseitig genarbten Fertigteilen herausgearbeitet wurden, ist mit Hilfe eines Planschleifgerätes die Narbung zu entfernen. Die so geschaffene plane Fläche dient als Auflagefläche. Die Messung erfolgt auf der unbearbeiteten Rückseite. Messzeit 10 s.5.4 Streckspannung und StreckdehnungZugversuch nach DIN EN ISO 527-2, Probekörper 5A, Prüfgeschwindigkeit 50 mm/min. Ist die Entnahme des Probekörpers 5A nicht möglich, ist die Verwendung von S3A-Zugproben (Schulter-stab) nach DIN 53 504 zulässig.5.5 SchlagzähigkeitSchlagbiegeversuch (breitseitiger Schlag) gemäß DIN EN ISO 179-1, jedoch Probekörper Länge: (50 ± 1) mm, Breite: (6 ± 0,2) mm, Dicke entsprechend der Erzeugnisdicke (bis max. 4 mm); Wider-lagerabstand (Stützweite): 40 mm, Prüfgerät Pendelschlagwerk 4J.Aus einseitig genarbten oder lackierten Fertigteilen hergestellte Proben sind so auf die Widerlager des Pendelschlagwerkes zu legen, dass die genarbte oder lackierte Seite gegen die Hammer-schneide zeigt.5.6 KerbschlagzähigkeitSchlagbiegeversuch (breitseitiger Schlag) gemäß DIN EN ISO 179-1, jedoch Probekörper Länge: (50 ± 1) mm, Breite: (6 ± 0,2) mm, Dicke entsprechend der Erzeugnisdicke (bis max. 4 mm); Wider-lagerabstand (Stützweite): 40 mm, Prüfgerät Pendelschlagwerk 4J.Die Proben werden breitseitig mit einer 0,8 mm breiten U-förmigen Kerbe versehen. Die Kerbtiefe beträgt 1/3 der Probendicke. Die den Kerbgrund begrenzenden Kanten müssen einen Rundungs-halbmesser von < 0,1 mm aufweisen.Aus einseitig genarbten Fertigteilen hergestellte Proben werden auf der genarbten Seite gekerbt. 5.7 WärmeverhaltenWarmlagerungsversuch nach DIN 53 497, Verfahren B, an mindestens einem kompletten Fertigteil; Lagerungstemperatur (90 ± 1) °C; Lagerungsdauer (22 + 2) h.Seite 5TL 524 76: 2003-01D 5.8 KälteverhaltenLagerung von mindestens zwei kompletten Fertigteilen in Luft bei (-40 ±1) °C; Lagerungsdauer (22 + 2) h.Kugelfallprüfung5.9 Kälteverhalten,Kugelfallprüfung nach PV 3905, jedoch Grundplatte (Probenauflagefläche) aus ≥ 10 mm dickem Stahlblech ohne Vertiefung an mindestens drei Fertigteilen. Kugelfallhöhe (450 ± 5) mm.5.10 LichtechtheitFalls in der Zeichnung die Anzahl von Belichtungsperioden nicht definiert ist, gilt folgende Rege-lung:─ 3 Belichtungsperioden für Bauteile im Bereich indirekter Sonneneinstrahlung.─ 5 Belichtungsperioden für Bauteile im Bereich direkter Sonneneinstrahlung (z. B. Türbrüstung). ─10 Belichtungsperioden für Bauteile im Bereich höchster Sonneneinstrahlung (z. B. Heckabla-ge).Unterlagen6 MitgeltendeTL 1010 Innenausstattungsmaterialien, Brennverhalten; WerkstoffanforderungenPV 1303 Nichtmetallische Werkstoffe; Belichtungsprüfung für Bauteile des Fahrzeu-ginnenraumesPV 3905 Organische Werkstoffe; KugelfallprüfungVW 011 55 Fahrzeug-Zulieferteile allgemein; Genehmigung von Erstlieferung und Än-derungVW 501 80 Bauteile des Fahrzeuginnenraumes; EmissionsverhaltenVW 501 85 Fahrzeugbauteile; FreibewitterungsbeständigkeitVW 911 01 Umweltnorm Fahrzeug, Fahrzeugteile, Werkstoffe, Betriebsstoffe; Schad-stoffvermeidungDIN 50 014 Klimate und ihre technische Anwendung; NormalklimateDIN 53 479 Prüfung von Kunststoffen und Elastomeren; Bestimmung der DichteDIN 53 497 Prüfung von Kunststoffen; Warmlagerungsversuch an Formteilen aus ther-moplastischen Formmassen ohne äußere mechanische Beanspruchung DIN 53 504 Prüfung von Kautschuk und Elastomeren; Bestimmung von Reißfestigkeit, Zugfestigkeit, Reißdehnung und Spannungswerten im ZugversuchDIN EN ISO 179-1 Kunststoffe; Bestimmung der Charpy-Schlagzähigkeit; Teil 1: Nicht instru-mentierte SchlagzähigkeitsprüfungDIN EN ISO 527-2 Kunststoffe; Bestimmung der Zugeigenschaften; Prüfbedingungen für Form- und Extrusionsmassen.DIN EN ISO 2039-1 Kunststoffe; Bestimmung der Härte, Teil 1: KugeleindruckversuchDIN EN ISO 3146 Kunststoffe; Bestimmung des Schmelzverhaltens (Schmelztemperatur oder Schmelzbereich) von teilkristallinen PolymerenDIN EN 20 105-A02 Textilien; Farbechtheitsprüfungen, Teil A02: Graumaßstab zur Bewertung der Änderung der FarbeVDA 260 Bauteile von Kraftfahrzeugen, Kennzeichnung der Werkstoffe。

汽车面料技术标准1 范围规定了汽车内饰人造革材料的分类、要求、试验方法、检验规则、标志、包装、运输与贮存。

本部分适用于汽车座椅套、座/靠垫、头枕、扶手、装饰性衬板、里衬等装饰用的各类聚氯乙烯、聚氨酯、聚酰胺、聚烯烃人造革的成品、半成品及原料等。

2 规范性引用文件下列文件对于本文件的应用是必不可少的。

凡是注日期的引用文件,仅所注日期的版本适用于本文件。

凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T 4689.20 皮革涂层粘着牢度测定方法GB/T 4694 皮革成品的包装、标志、运输和保管GB/T 8948 聚氯乙烯人造革GB/T 19941 皮革和毛皮化学试验甲醛含量的测定GB/T 19942 皮革和毛皮化学试验禁用偶氮染料的测定GB/T 20400 皮革和毛皮有害物质限量QB/T 2537 皮革色牢度试验往复式摩擦色牢度QB/T 2710 皮革物理和机械试验抗张强度和伸长率的测定QB/T 2711 皮革物理和机械试验撕裂力的测定:双边撕裂QB/T 2714 皮革物理和机械试验耐折牢度的测定QB/T 2724 皮革化学试验 pH 值的测定QB/T 2725 皮革气味的测定QB/T 2726 皮革物理和机械试验耐磨性能的测定QB/T 2727 皮革色牢度试验耐光色牢度:氙弧QB/T 2729 皮革物理和机械试验水平燃烧性能的测定QB/T 2779 鞋面用聚氯乙烯人造革3 分类产品按布基编织方法分类,见表 1。

4 要求4.1 外观质量外观质量应符合表2要求。

4.2 理化性能理化性能应符合表 3 的规定。

5 试验方法5.1 外观质量5.1.1 一般采用灯光检验,用 40W 青光或白光日光灯两支,上面加灯罩,灯罩与检验中心垂直距离为 80cm±5cm,或在 D65光源下。

5.1.2 如在室内利用自然光,光源射入方向为北向左(或右)上角,不能使阳光直射产品。

5.1.3 检验时,应将产品平摊在检验台上,台面铺一层白布,检验人员视线应正视平摊产品的表面,目视距离为 35cm 以上。

一、焊接标准VW 01101类似国标中描述焊接类型并用图例表示的标准。

对各种焊接进行了概括的介绍,并规定了各种标准的图示符号,是焊接里很概括的一章。

eg:VW 01103凸点焊标准(weld projection),图示表示了不同的凸点焊情况,规定了不同厚度的板件进行凸点焊时凸点的直径、高度等。

eg:VW 01105点焊标准(spot weld),详细介绍了点焊的设计思想、焊点排布、强度计算和校合,以及焊接头的布置和形状参考,有图示、查表表格和例题,教科书般的详尽标准。

规定了焊接点的熔深要求、焊接头大小标准、缩印要求。

焊接后表面等级OG1\OG2\OG3的定义。

规定了图纸表注标准。

使用此标准焊接的熔深、劈凿(或者母材撕裂)都以VW01105为认可标准(Acceptance criteria)。

实验方法也定义为VW01105,实际上此标准内第3 章有具体的实验标准比如PV6702等。

考虑到VW01105比较全面而且大众认可,所以不把具体的小标准作为实验方法。

VW 01105-2 针对铝制金属的特殊焊接要求,包括特殊的熔深、劈凿要求。

eg:VW 01105-3 镀锌合金的特殊焊接要求,对焊板、焊接头有比较详细的描述,对校合计算过程有详细介绍,熔深和劈凿依然参考VW01105-1。

VW 01105-4 针对大厚度钢和高强度钢的焊接标准,介绍了特殊的技术要求和过程控制。

介绍了“焊接强度——焊接时间”图,介绍了标准的图纸表注方法。

eg:VW 01106弧焊、二氧化碳保护焊、熔焊标准。

规定了图纸标注的标准。

详尽规定了不同钢板焊接时的要求和标准,图例表示了各种焊接情况下焊缝的形式。

介绍了应力计算标准、涂层材料。

规定了不同钢材焊接时焊缝的评估标准。

认可标准和实验方法均为VW 01106。

eg:VW 01141激光焊接。

标准不详,POLO上有使用,总体使用较少。

二、表面处理标准VW 13750详细描述了针对不同零件的表面处理方式的要求,介绍了图纸标注方法。

大众常用标准汇总LG GROUP system office room 【LGA16H-LGYY-LGUA8Q8-LGA162】一、焊接标准VW 01101类似国标中描述焊接类型并用图例表示的标准。

对各种焊接进行了概括的介绍,并规定了各种标准的图示符号,是焊接里很概括的一章。

eg:VW 01103凸点焊标准(weld projection),图示表示了不同的凸点焊情况,规定了不同厚度的板件进行凸点焊时凸点的直径、高度等。

eg:VW 01105点焊标准(spot weld),详细介绍了点焊的设计思想、焊点排布、强度计算和校合,以及焊接头的布置和形状参考,有图示、查表表格和例题,教科书般的详尽标准。

规定了焊接点的熔深要求、焊接头大小标准、缩印要求。

焊接后表面等级OG1\OG2\OG3的定义。

规定了图纸表注标准。

使用此标准焊接的熔深、劈凿(或者母材撕裂)都以VW01105为认可标准(Acceptance criteria)。

实验方法也定义为VW01105,实际上此标准内第3 章有具体的实验标准比如PV6702等。

考虑到VW01105比较全面而且大众认可,所以不把具体的小标准作为实验方法。

VW 01105-2 针对铝制金属的特殊焊接要求,包括特殊的熔深、劈凿要求。

eg:VW 01105-3 镀锌合金的特殊焊接要求,对焊板、焊接头有比较详细的描述,对校合计算过程有详细介绍,熔深和劈凿依然参考VW01105-1。

VW 01105-4 针对大厚度钢和高强度钢的焊接标准,介绍了特殊的技术要求和过程控制。

介绍了“焊接强度——焊接时间”图,介绍了标准的图纸表注方法。

eg:VW 01106弧焊、二氧化碳保护焊、熔焊标准。

规定了图纸标注的标准。

详尽规定了不同钢板焊接时的要求和标准,图例表示了各种焊接情况下焊缝的形式。

介绍了应力计算标准、涂层材料。

规定了不同钢材焊接时焊缝的评估标准。

认可标准和实验方法均为VW 01106。