最新PCB制程设备能力稽核资料

- 格式:doc

- 大小:157.50 KB

- 文档页数:12

PCB制程能力要求PCB制程能力要求(Printed Circuit Board Process Capability Requirements)是指评估和控制印制电路板(PCB)制造过程中各项关键参数的能力和稳定性的要求。

这些参数包括材料选择、设计规范、加工工艺以及质量控制等方面。

PCB制程能力要求的好坏直接影响到最终产品的质量和可靠性。

首先,材料选择是PCB制程中的重要环节。

材料的选择应根据设计要求和应用场景来确定。

常见的PCB材料有FR-4玻璃纤维层压板、聚酰亚胺(PI)板、塑料CCL以及金属基板等。

不同材料拥有不同的性能和特点,制程能力要求应确保所选材料符合设计和质量要求。

其次,设计规范也是PCB制程能力要求的关键内容之一、设计规范涉及到PCB板的层次结构、线宽线距、焊盘剂量、排布规则等方面。

设计规范应与PCB制造过程相匹配,确保制造过程的可控性和稳定性。

设计规范的好坏直接影响到PCB板的制程能力和产品性能。

加工工艺是PCB制造过程中的核心环节。

加工工艺涉及到PCB的制备、成型、打孔、切割、压装、钻孔、镀铜等。

制程能力要求应确保加工工艺的准确性和稳定性,以确保PCB板的精度、可靠性和耐用性。

质量控制是PCB制造过程中的重要环节。

质量控制涉及到PCB的各项指标的测量、分析和监控。

制程能力要求应确保质量控制的有效性和稳定性。

常见的质量控制指标包括PCB板的尺寸误差、线宽线距误差、板厚误差、表面光洁度等。

针对这些要求,制程能力评估是评估制程能力的方法之一、制程能力评估是通过对制程数据的统计分析,确定制程过程的稳定性和可控性。

常见的制程能力评估方法有过程能力指数(Cpk)、过程性能指数(Ppk)、过程交叉性能指数(Pp/Ppk)等。

针对不同的应用场景和要求,PCB制程能力要求也有所不同。

例如,在高频应用中,对PCB板的信号损耗和传输特性要求较高;在高可靠性应用中,对PCB板的可靠性和耐用性要求较高。

益阳天格印业高新区分公司1.目的明确制程稽核作业流程,完善制程稽核作业,使生产部作业严格按照QC工程图和相关制程文件要求进行生产,保证成品品质符合要求。

2.范围适用于生产车间、产成品仓库、出货站台区域管制。

3.名词解释稽核:制程品管按QC工程图的项目、频率检查生产人员的首检和自检,各制程参数的执行状况:如:糊化温度、粘度,模切压力,油墨粘度等。

4.职责4.1 生产部:生产自主检查、调试,控制,异常处理;4.2 质控部:稽核生产相关人员的执行状况、工艺参数执行状况稽核、产成品及半成品规格符合性以及出现异常时进行反馈、处理及改善追踪。

5.作业内容:5.1 制程稽核作业流程图见附件一;5.2 制程调试和控制:生产部班组根据《QC工程图》和相关制程文件要求,调整制程参数,使其控制点在允许的误差范围之内。

5.3 稽核内容和频次:质控部质控员组根据《QC工程图》规定的项目和频次对制程工艺和半成品及成品品质进行检查,并将稽核结果记录在《平板线稽核巡检表》、《水印稽核巡检表》、《后工序巡检记录表》上。

5.4 过程异常及处理:质控部质检在稽核过程中发现控制点异常应立即通知相关生产人员进行调整,直到调整至规定要求,并填写《制程异常改善通知单》提报质控部主管。

如果该员不予以配合,应报告生产主管进行协调,并将情况如实记录。

5.5制程品异常处理:质控部制程稽核人员在稽核过程中发现制程品异常,对已生产或入库的产成品进行检查,并通知制造人员追溯全部不良品,依《不合格品控制程序》作业。

5.6稽核异常的处罚:质控部主管依据异常情况发现制程品质异常进行分析,如果异常是人为原因造成,依据《品质奖惩作业办法》进行提报处罚,并会签相关责任部门主管。

非人为原因则不予处罚。

发现制程品异常,经复查仍未改善的则应依据《品质奖惩作业办法》进行处罚。

5.7 特殊情况下的制程稽核5.7.1 首检时发现的异常项目或者异常机台作为本班的重点稽核点;5.7.2 在本月制程稽核异常中排列前三位的稽核项目,应列为下一个月的稽核重点,稽核频次加倍。

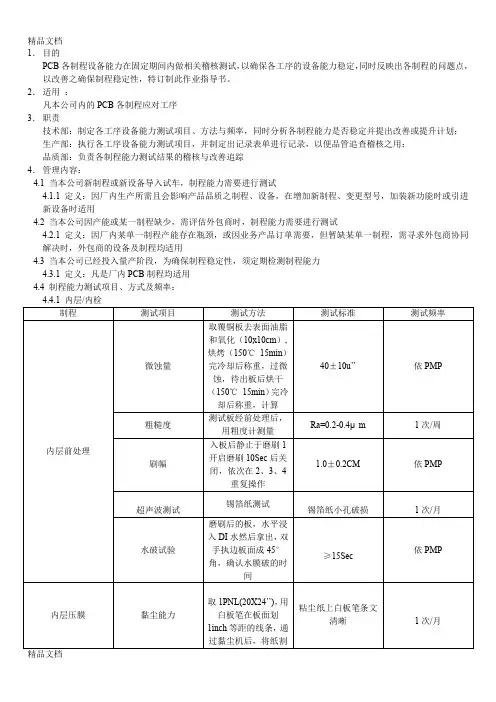

1.目的

PCB各制程设备能力在固定期间内做相关稽核测试,以确保各工序的设备能力稳定,同时反映出各制程的问题点,以改善之确保制程稳定性,特订制此作业指导书。

2.适用:

凡本公司内的PCB各制程应对工序

3.职责

技术部:制定各工序设备能力测试项目、方法与频率,同时分析各制程能力是否稳定并提出改善或提升计划;

生产部:执行各工序设备能力测试项目,并制定出记录表单进行记录,以便品管追查稽核之用;

品质部:负责各制程能力测试结果的稽核与改善追踪

4.管理内容:

4.1 当本公司新制程或新设备导入试车,制程能力需要进行测试

4.1.1 定义:因厂内生产所需且会影响产品品质之制程、设备,在增加新制程、变更型号,加装新功能时或引进

新设备时适用

4.2 当本公司因产能或某一制程缺少,需评估外包商时,制程能力需要进行测试

4.2.1 定义:因厂内某单一制程产能存在瓶颈,或因业务产品订单需要,但暂缺某单一制程,需寻求外包商协同

解决时,外包商的设备及制程均适用

4.3 当本公司已经投入量产阶段,为确保制程稳定性,须定期检测制程能力

4.3.1 定义:凡是厂内PCB制程均适用

4.4 制程能力测试项目、方式及频率:

4.4.5防焊

5.1 制程管理计划作业指导书

6.附件

______________课制程能力测试点检表。

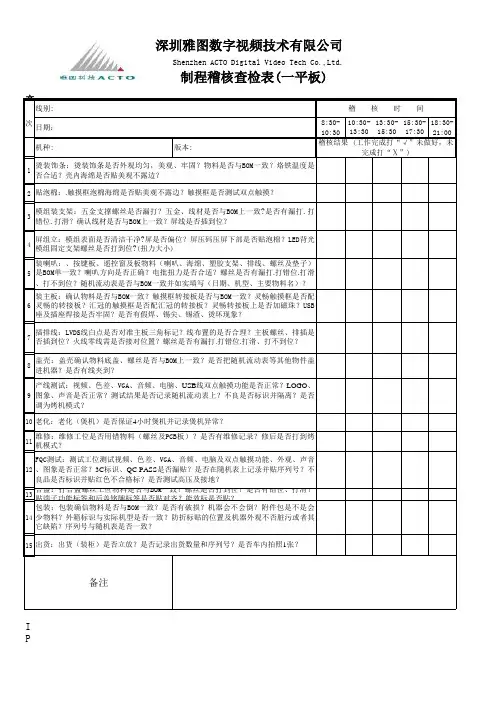

文件编号:AT-D-质-022(B/1) 序列号:8:30-10:3018:30-21:00机种:版本:123456789101112131415 IPQC: 审核: 制造部确认: 核准:次出货:出货(装柜)是否立放?是否记录出货数量和序列号?是否车内拍照1张?备注合盖:打合盖螺丝工位物料是否与BOM 一致?螺丝是否打到位?是否有错位、打滑?贴端子功能标签和后盖铭牌标签是否贴对齐?能效标是否贴?包装:包装确信物料是否与BOM 一致?是否有破损?机器会不会倒?附件包是不是会少物料?外箱标识与实际机型是否一致?防折标贴的位置及机器外观不否脏污或者其它缺陷?序列号与隨机表是否一致?维修:维修工位是否用错物料(螺丝及PCB 板)?是否有维修记录?修后是否打到烤机模式?FQC 测试:测试工位测试视频、色差、VGA 、音频、电脑及双点触摸功能、外观、声音、图象是否正常?3C 标识、QC PASS 是否漏贴?是否在隨机表上记录并贴序列号?不良品是否标识并贴红色不合格标?是否测试高压及接地?产线测试:视频、色差、VGA 、音频、电脑、USB 线双点触摸功能是否正常?LOGO 、图象、声音是否正常?测试结果是否记录随机流动表上?不良是否标识并隔离?是否调为烤机模式?老化:老化(煲机)是否保证4小时煲机并记录煲机异常?装主板:确认物料是否与BOM 一致?触摸框转接板是否与BOM 一致?灵畅触摸框是否配灵畅的转接板?汇冠的触摸框是否配汇冠的转接板?灵畅转接板上是否加磁珠?USB座及插座焊接是否牢固?是否有假焊、锡尖、锡渣、烫坏现象?插排线:LVDS 线白点是否对准主板三角标记?线布置的是否合理?主板螺丝、排插是否插到位?火线零线需是否接对位置?螺丝是否有漏打.打错位.打滑、打不到位?盖壳:盖壳确认物料底盖、螺丝是否与BOM 上一致?是否把随机流动表等其他物件盖进机器?是否有线夹到?模组装支架:五金支撑螺丝是否漏打?五金、线材是否与BOM 上一致?是否有漏打.打错位.打滑?确认线材是否与BOM上一致?屏线是否插到位?屏组立:模组表面是否清洁干净?屏是否偏位?屏压码压屏下部是否贴泡棉?LED 背光模组固定支架螺丝是否打到位?(扭力大小)装喇叭:、按键板、遥控窗及板物料(喇叭、海绵、塑胶支架、排线、螺丝及垫子)是BOM 单一致?喇叭方向是否正确?电批扭力是否合适?螺丝是否有漏打.打错位.打滑、打不到位?随机流动表是否与BOM一致并如实填写(日期、机型、主要物料名)?稽核结果 (工作完成打“√”未做好,未完成打“Ⅹ”)烫装饰条:烫装饰条是否外观均匀,美观、牢固?物料是否与BOM 一致?烙铁温度是否合适?壳内海绵是否贴美观不露边?贴泡棉:.触摸框泡棉海绵是否贴美观不露边?触摸框是否测试双点触摸?线别:稽 核 时 间日期:10:30-13:3013:30-15:3015:30-17:30深圳雅图数字视频技术有限公司Shenzhen ACTO Digital Video Tech Co.,Ltd.制程稽核查检表(一平板)。

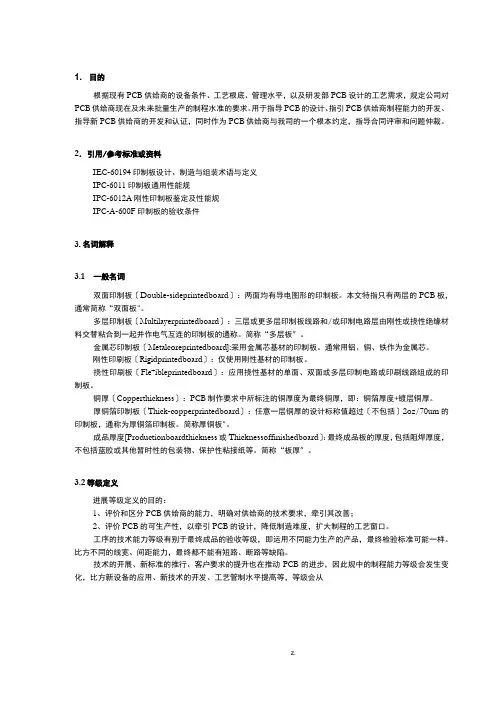

1. 目的根据现有PCB供给商的设备条件、工艺根底、管理水平,以及研发部PCB设计的工艺需求,规定公司对PCB供给商现在及未来批量生产的制程水准的要求。

用于指导PCB的设计、指引PCB供给商制程能力的开发、指导新PCB供给商的开发和认证,同时作为PCB供给商与我司的一个根本约定,指导合同评审和问题仲裁。

2.引用/参考标准或资料IEC-60194印制板设计、制造与组装术语与定义IPC-6011印制板通用性能规IPC-6012A刚性印制板鉴定及性能规IPC-A-600F印制板的验收条件3.名词解释3.1一般名词双面印制板〔Double-sideprintedboard〕:两面均有导电图形的印制板。

本文特指只有两层的PCB板,通常简称“双面板"。

多层印制板〔Multilayerprintedboard〕:三层或更多层印制板线路和/或印制电路层由刚性或挠性绝缘材料交替粘合到一起并作电气互连的印制板的通称。

简称“多层板〞。

金属芯印制板〔Metalcoreprintedboard]:采用金属芯基材的印制板。

通常用铝、铜、铁作为金属芯。

刚性印刷板〔Rigidprintedboard〕:仅使用刚性基材的印制板。

挠性印刷板〔Fle*ibleprintedboard〕:应用挠性基材的单面、双面或多层印制电路或印刷线路组成的印制板。

铜厚〔Copperthickness〕:PCB制作要求中所标注的铜厚度为最终铜厚,即:铜箔厚度+镀层铜厚。

厚铜箔印制板〔Thick-copperprintedboard〕:任意一层铜厚的设计标称值超过〔不包括〕2oz/70um的印制板,通称为厚铜箔印制板。

简称厚铜板"。

成品厚度[Productionboardthickness或Thicknessoffinishedboard〕:最终成品板的厚度,包括阻焊厚度,不包括蓝胶或其他暂时性的包装物、保护性粘接纸等。

简称“板厚〞。

PCBA Quality Process AuditInformation and InstructionsRev. 3 PURPOSEThis document was developed as an Audit Tool to assess PCBA Manufacturing Process Capability.本文件用來作為評估PCBA工厂制程能力的Audit工具.It is intended to provide an assessment of PCBA Manufacturing Capability based on PCBA Manufacturing Complexity.此文件的目的, 是提供一個基于PCBA制造复雜性的對PCBA制程能力的評估方法.Less complex PCBAs will not require the same manufacturing capability as more complex PCBAs.較簡單的PCBA並不要求其具有跟較复雜PCBA一樣高的制程能力Thus by matching capability with complexity, the most economic manufacturing solution can be determined for a sustained quality performance.因此, 通過制程能力与PCBA的复雜性相匹配, 就可以采用最經濟的制造方法達到持久的品質效能.The tool may also be used to assess RMA/Repair Capability.這個工具也可以用來評估RMA和維修能力.A qualified auditor may also use this tool as a guideline to conduct a process 'Gap Analysis' based on product complexity.合格的稽核員也可以用這個工具作指導對一制程進行"缺陷分析(Gap Analysis)", ----應根据此制程所生產產品的复雜性來進行.SCOPEThe PCBA Audit Document is primarily intended to be used for suppliers/manufacturers of PCBA Products for Dell.此PCBA稽核文件供DELL公司的PCBA產品供應商/制造商使用.The audit document may also be used to assess the manufacturing process for any PCBA that is incorporated into a Dell assembly.此稽核文件也可用來評估任何在DELL組裝中使用的PCBA的制造制程.When used to assess RMA/Repair Capability, the tool may be used at any location where RMA/Repair activity takes place.當用于評估RMA和維修能力時, 無論RMA和維修在哪里進行, 此工具均可運用.PCBA COMPLEXITY and CAPABILITY MATCHINGPCBA复雜性和能力匹配The SQE Auditor will decide what PCBA Complexity category to audit a supplier facility or potential supplier facility against.由SQE稽核員決定對供應商工廠或潛在供應商的工廠适用哪個級別的复雜性等級.This determination is made based on the complexity of the PCBA product to be outsourced or evaluated這是基于PCBA產品的复雜性決定的.To do this, the complexity of the product must first be calculated using Dell Tool COR.40.WWP.SQ.0229. This is available on Valuechain.為了決定适用哪個复雜性等級, 首先須用DELL TOOL COR.40.WWP.SQ.0229這個工具對產品的复雜性進行評估. 這可以在Valuechain上取得.Knowing the product complexity, it is then possible to use this tool to make an assessment of the line installed for a product of that complexity.知道了產品的复雜性, 然后才可能用這個工具對生產此复雜性的產品的生產線進行評估.There are 10 categories of complexity used by Dell, ranging from 1 (Most Complex) to 10 (Least Complex).DELL所用的复雜性种類分10個等級, 范圍從1(最高复雜性)到10(最低复雜性).In this audit, complexity categories are grouped into five categories as can be seen on the individual audit worksheets.但在此稽核中, 复雜性等級被合并成只有5種, 這在后面的各個稽核表中可以看到.AUDIT BY SELF ASSESSMENT自我稽核A supplier's facility is required to complete a self assessment using this tool in advance of the Dell Audit.要求在DELL稽核之前, 供應商用這個工具進行自我評估先..)It is expected that during the self-assessment process, that the supplier will use this opportunity to ask questions for either clarification or to better understand intent of the audit criteria. Waiting for the formal Dell audit to ask these types of questions is too late. It is also expected that based on self audit results, a supplier will inform the Dell team of their readiness for a formal Dell audit.DELL希望供應商在自我評估的時候問那些不太清楚或是對此稽核標准比較深入的問題. 等到DELL正式稽核的時候來問, 將顯得太遲了. DELL也希望供應商基于自我稽核的結果, 來通知DELL他們是否已准備好了.A self assessment is completed by adding a score to the relevant column in each worksheet once product complexity has been determined.确定了產品的复雜性, 就可以進行自我評估了. 每完成一項評估, 就在相應欄位打上分數.If a facility has multiple lines building Dell product of the same complexity, the supplier shall ensure all lines are available to be audited.如果一個工廠有多條線生產同一复雜性等級的DELL產品, 供應商應保証所有的線都可以被稽核.The SQE Auditor will randomly select one line to be audited for the product complexity to be assessed.對某一复雜度的產品, SQE稽核員將隨机選擇一條線稽核.During the audit process, the Dell SQE may wish to review every question/criterion listed on the audit document, or alternatively the SQE may chooseto focus only on those questions for which the supplier awarded themselves a score of 1 by self-assessment. The path taken is left to SQE discretion.稽核過程中, DELL SQE會稽核列在此稽核文件上的每一個問題/標准, 或者會只集中于供應商在自我評估中給自己打了" 1 "分的項目, 具体如何作, 由SQE自己決定. The score awarded by the SQE Auditor will be entered in the 'Actual' column on each worksheet.SQE稽核員所打的分輸入每張工作表的 "Actual" 一欄In this way the delta between the self assessment and the actual score is known. The size of this delta is a measure of audit preparedness and understanding. The difference between "self score" and "actual score" will be approximately 5% if preparation and understanding is good.這樣, 就可以看出自我評估与實際分數之間的差別(用delta表示). 差別(delta)的大小量度出了供應商對這份文件的理解程度和對這次Audit的准備程度. 如果對DELL QPA理解得好並作了充分准備的話, 自我評分与實際分數之間的差別大約會是5%.AUDIT RESULTS稽核結果The SQE Auditor must complete at least 6 of the 13 processes before an Audit Result can be declared.SQE 稽核員至少應稽核完本文件列出的13段制程中的6段, 否則不可以發布稽核結果.It is strongly recommended that all 13 sections of the audit be completed for suppliers who have no previous experience with manufacturing PCBAs for Dell or for existing Dell suppliers who are attempting to build a higher complexity PCBA product for the first time.強烈建議那些以前沒有為DELL制造PCBA經驗的供應商或是DELL的既有供應商但卻是第一次制造更高复雜度的產品時, 應全部完成13個部分的稽核.The overall process average result determines the Audit score achieved for the PCBA Supplier assessed.PCBA供應商取得的分數由全部制程稽核的平均結果決定.The 'Pass' score for the Audit is 80% for all PCBA Products irrespective of complexity.任何PCBA產品(無論什么复雜度)的'PASS'分是80%.If an overall process average score of equal or greater than 80% is achieved, and no individual processes have failed, a 'Pass' result is awarded.如果全制程平均分等于或大于80%, 并且沒有單項制程fail, 就可以得到'PASS'.If one or more individual processes have failed, but an overall Audit score of equal or greater than 80% was achieved, either a "Conditional Pass" or a "Fail" Result shall be awarded. The determination of this audit result is at the discretion of the Lead SQE Auditor, based on the severity of the issues for any of the failing sections. If the overall process average score is less than 80%, a "Fail" result is awarded.如果有一個或多個制程fail, 但總的稽核分數仍等于或大于80%, 結果將是"條件性PASS"(Conditional Pass)或"FAIL". 究竟給那個, 由首席SQE稽核者根据fail部分問題的嚴重程度決定. 如果全製程的平均分不到80%, 那么結果就是"Fail".NOTE: An individual process fails when the section score is below 80% OR if an "non-negotiable" question scores 0. (see "Audit Mechanics" instructions for additional information.)備注: 當分數低于80%或只要有一個"必達" 項分數為 0, 此項製程就得"Fail".If a "Conditional Pass" or "Fail" Result is awarded, a Corrective Action Plan is due from the supplier within two weeks of the date of audit completion.如果所得結果是"條件性Pass"或"Fail", 從稽核完成之日起兩周內, 供應商須給出改善計划(Corrective Action Plan).The Corrective Action Plan must contain a timeline to 'bridge' to a Pass status and must propose a target date for a Dell follow-up Audit.改善計划必須包含通向"Pass"狀態的分階段時間表; 必須給一個DELL下一次稽核的目標日期.Failure to achieve a Pass Result on the follow up Audit may impact business award decisions.稽核中不能獲得"Pass"結果將影響到DELL給供應商的商業回報決策(business award decisions).A PASS RESULTOnce a supplier's facility has passed the Audit for a particular product complexity, the facility's process is approved for all products of that complexity.如果供應商的工厂通過了對某一复雜度產品的稽核, 那么此工厂的製程就可以生產所有此复雜度的產品.Thus, the facility has proven their capability to build a product of that complexity for the line audited. As long as the same process capabilityis deployed for any new lines, there is no need to do 'official' audits for any additional lines added for product of that complexity.通過了稽核, 就証明這家工厂具備了在所稽核的生產線上生產此复雜度產品的能力.只要此製程被應用于新的生產線, 就不必對新增加的同樣生產此复雜度產品的產線再作"正式"的稽核.NOTE: While it is not an 'official' requirement to use the audit tool for additional lines, it is strongly advised that the SQE utilize the audit tool to verify that the capability of any new line is matched to the existing capability of the existing lines for a given PCBA complexity.備注: 對新增加的生產線, 雖然不"官方地"要求用此工具專門稽核, 但是強烈建議SQE用此稽核工具去确認對一既定复雜度的PCBA來說, 新線的制程能力是否与已存在線的制程能力相當.NOTE: For the purpose of "proven capability to build a product", a "facility" is defined as the same physical building, AND the same product complexity, AND the same supplier production and quality management team resources.備注: 為了闡述"制造一种產品的已獲証明的能力", 一個"工廠", 定義為: 位于同一棟建筑物內, 具有相同的產品复雜度, 具有同一供應商的生產和品質管理團隊資源.If a facility is approved for the most complex PCBA product, this does NOT necessarily mean they are automatically approved for all less complex products at that facility. Regardless of product complexity level, any test processes related to a new product should be audited because test processes are unique, based on product type, not PCBA process complexity.如果一個工廠已經被認可生產最复雜的PCBA產品, 這並不一定意味著在那個工廠生產較低复雜度的產品就自動獲得認可. 不管產品的复雜度等級, 任何與新產品有關的測詴製程都應予以稽核, 因為測詴制程是獨特的, 它基于具体的產品類型, 而不是PCBA的制程复雜性.An Audit will need to be conducted to ensure the capability deployed at least meets the minimum requirements for the less complex product.需要進行一次稽核, 以确保配置的能力至少符合較低复雜度產品的最低要求.AUDIT MECHANICS and QUESTIONS稽核机制和問題The Audit breaks down the PCBA Manufacturing Process into individual process steps, each of which is represented by an individual worksheet.此稽核把PCBA制造過程分成一些單個的制程, 每一單個制程都用一張單個的工作表進行說明.Within each worksheet is contained a series of questions specifically pertaining to the process being examined.每一張工作表都包含一系列特定的与此段制程有關的問題.These questions are focused on evaluating Process Disciplines, Control Methods, Process Capability/Technology, and Attention to Detail.這些問題集中于評估制程素質, 控制方法, 制程能力/工藝, 並關注到細節.The questions were devised and developed as closed questions with every attempt to avoid ambiguity.這些問題經過設計和發展已經穩定下來. 為了避免問題歧義, 我們已經盡了所有的嘗詴和努力.Because of the closed nature of the questions, there can only be one of two answers to any question, i.e. Yes (1) or No (0).因為這些問題具有穩定性, 每一個問題都只有一個确定的答案, 即: 要么是 Yes(1分), 要么是No(0分).Thus, the criterion is either fully met or it is not. If the Criterion is met, a score of 1 is obtained. If the Criterion is not met, a score of 0 is obtained.因此, 對一個標准, 要么是完全達到要么就是沒達到. 如果標准達到了, 就得1分; 沒達到, 0 分.If there is any doubt as to the score to award for any given Criterion, a score of zero shall be awarded by default.如果對一個標准的打分有猶豫, 那么這一項就默認為0分.Any Criterion that scores 1 shall be clearly demonstrated, followed, and be beyond reproach.任何得1分的項目都應有明确的証明, 領會, 并且沒有爭議.In the event that a supplier clearly meets the intent of the audit question, but does not exactly do what the question asks, a score of 1 shall be given.如果供應商明顯達到了稽核問題的意圖, 則即使沒有恰好地按此問題所要求的做, 也應給1分.There are cells within the audit document that are shaded in gray. These cells may be coded as Not Applicable (NA) under certain conditions.這份文件中有一些標成灰色的單元格, 這些格子在一定的條件下可以表示 "不适用(NA)".If coded NA, the denominator in the score percentage calculation will automatically be adjusted to account for this NA allocation to the cell.對編碼成NA的格元, 計算分數時會自動對其作出調整.The conditions under which NA may be allocated are as follows:-會分配作NA的情況有下面几种:1. NA may be allocated to a cell if the question is not applicable to the product due to some 'real' physical reason.1. 如果由于一些客觀的原因, 某問題不适用于某產品, 可以對其對應格元分配為NA.For example, if there are no MSD devices are on a product, then the questions pertaining to MSDs would be coded NA.舉例來說, 如果某產品上沒有濕度敏感元件(MSD), 那么有關濕度敏感元件(MSD)的問題就可以標為NA.2. NA may be allocated to a cell if the question is not applicable to the product because the physical product does not undergo a specific process.2. 有的產品會不經過某個制程, 所以有的問題就可能不适用于此產品. 這是就可以給其分配NA.For example, if there are no press fit connectors on a product, then the questions pertaining to the press fit process may be coded NA.舉例來說, 如果有的產品上沒有壓力適配插槽(press fit connector)的話, 那么屬于壓力適配插槽(press fit connector)的問題就將標識成NA.3. NA may be allocated to a cell if by answering some questions 'yes', other questions become redundant or irrelevant.3. 有時, 當對一些問題回答了'Yes'后, 有一些其它的問題就會變得多余或不再相關, 這時也會對一些格元分配'NA'.For example, if AOI is deployed, then the questions pertaining to Manual Inspection may be scored NA舉例而言, 如果用了AOI的話, 那么与人工檢查有關的問題就可以記作NA.Note 1: Not all gray shaded questions will be coded NA. The NA status is conditional on the above and SQE discretion.備注1: 並不是所有標成灰色的問題都是NA. 是否NA請參考上面的條件並取決于SQE的判斷.Note 2: Gray shaded cells are applicable when the process is deployed, and may still score zero if the above conditions are not satisfied.備注2: 如果標成灰色的格元所對應的項目, 制程仍适用, 就按正常的方法打分.For example, AOI is not required for complexity 5 PCBAs, but it may be deployed based on supplier preference比如, 复雜度5級的PCBA產品不要求AOI, 但是供應商可能會使用.If AOI is deployed, AOI questions must be scored 1 or 0, not NA.如果用了AOI, 那么有關AOI的問題就要么打1分要么打0分, 而不能打NA.Note 3: No other questions, other than those that have been predetermined by the gray shading, can be considered to be NA.備注3: 除了那些事先已經標示為灰色的問題, 其它問題的答案不可以是NA.There are certain questions in each section, (shaded in blue), that are considered non negotiable. In other words the question must score a 1.每一部分中都有一些問題(標示成藍色)是必達項, 即沒有商量余地的. 換句話說, 這些問題必須得1分.If any of these questions score a 0, then the process section under review will automatically fail, regardless of overall score.如果任何一個這种問題得0分, 那么此製程部分稽核結果就是fail, 不管總分是多少.For example, if the overall result for a section is equal to or greater than 80% and if any one of the "non negotiable" questions scored a zero, then the overall result for that section will be Fail, irrespective of the overall score.舉例而言, 如果某部分的總結果是等于或大于80%, 但是卻有一道"必達項"問題得0分, 那么這部分的總結果就是'Fail', 與總分無關.AUDITING A NEW SUPPLIER OR A NEW SUPPLIER FACILITY稽核一家新供應商或供應商的一家新工廠If a potential supplier or new supplier facility is required to be audited then the category to be completed in the audit document shallappropriately reflect the complexity of the product to be manufactured.如果一家潛在的供應商或供應商的一家新工廠需要稽核, 那么在此稽核文件中將完成的种類應适當地反映將要制造產品的复雜度.However, since such a supplier/facility will not be manufacturing a Dell product the SQE Auditor will have to select a line with a product whichmost closely matches the product to be manufactured and which is representative of the production line that the supplier intends to use to build Dell product.然而, 因為那樣一家供應商或工廠現在並未生產DELL產品, SQE稽核員將不得不選擇一條最接近于即將生產的產品的線進行稽核, 并且這條產線應該是供應商將用來建造DELL產品的典型的線.The SQE will not consider auditing a 'virtual' line based on some future installed capability.SQE不會考慮稽核那种"虛擬"的產線, 即計划在將來安裝但現在還沒實現的產線.AUDITING FOR RMA/REPAIR對RMA/維修的稽核This tool may also be used to assess capability of RMA/Repair facilities.這個工具也可以用來評估 RMA/維修的能力.All process highlighted on the Menu page are relevant for when it is necessary to conduct a Manufacturing Process QPA當有必要進行制造制程QPA時所有在'Menu'頁中突出強調(Highlight)的制程都与其相關.However, only those menu buttons highlighted in 'blue' may be used for a Repair/RMA QPA Audit.然而只有用'藍色'突出強調的菜單按鈕才可以被用來作為維修/RMA 的稽核.TRAINING培訓The PCBA Process Audit is very technical in content.PCBA制程稽核的內容非常具有技巧性.SQEs who use this tool are considered within Dell as being sufficiently qualified to conduct this audit.DELL用此工具作稽核的SQE都須經過充分的資格認証.To obtain this qualification, an SQE will have participated in at least three audits and lead a fourth under the supervision of a qualified auditor.欲獲得此資格, SQE至少需要參加3次實地稽核並在已獲資格稽核員的監督下主導一次稽核.SQEs wishing to use this tool should contact their regional champion to arrange for training, qualification and certification.希望用此工具的SQE應該通過以下三個步驟:首先聯系他們所在地的主管安排對其培訓, 然后進行資格認証, 最后取得証書.AUDIT SCHEDULE稽核安排The Audit may be used as and when the need arises. However, Dell will conduct an official audit at least annually for key suppliers. Before conductingan audit, the auditor must ensure the Dell commodity management team responsible for the relationship are advised of the audit schedule.只要有必要, 就可以Audit. 然而, DELL會對主要供應商每年至少作一次正式的稽核.稽核之前, 稽核員必須确保DELL產品的窗口管理團隊知道稽核排程表.It is also intended for suppliers to conduct internal audits by self assessment every quarter so progress may be reported to Dell.也希望供應商每個季度能作一次內部的自我評估, 並把進展情況報告給DELL.ADDITIONAL QUESTIONS其他問題Please contact Eric Hoh at eric_hoh@ for additional information or if there are any specific questions with regard to the technical content.如欲咨詢其它信息或有關于此文件的技術上的特別的問題要問, 請聯系Eric Hoh( eric_hoh@).REVISION HISTORY修訂歷程A00 Initial Release. Oct 1996 (EMF Controlled Document). Authored by William RyanA00 首次發布. 1996年10月(EMF控制檔). 作者: William RyanA01 Minor corrections. Dec 1996. (EMF Controlled Document). Changes by William RyanA01 微小改動. 1996年12月. (EMF 控制檔). 改動者: William Ryan.Rev 1.4 Addition of RMA and Test Update. Jan 1999. (Initial Release as a Corporate Document). Changes by Wallace Ables.Rev 2.0 Extensive Review and Re-Write. July 2002. Authored by William Ryan.Rev 2.0 擴充和重寫. 2002年7月. 作者: William RyanRev 3.0 Changes Listed Below. Authored by William Ryan.Rev 3.0 改動列出如下.Listed the non-negotiable items for PCBA Manufacturing.列出PCBA制造的必達項目.Added details and rules to the instruction sheet for clarity.為更明确, 在Instruction一章中增加詳細的規定和說明.Edited approximately 50% questions to increase clarity.為增加明确性, 校訂了大約50%的問題.Removed hard NAs and placed rules in place for the use of NA.移除不很恰當的NA項目, 並增加了對NA适用規則的說明.Removed requirement for self-calibrating soldering irons,去除自校烙鐵的要求.Added rules on how many sections to be audited before a result can be declared.增加在結果得出之前多少項目應該被稽核的規則.Remove AOI requirements for Desktops.移除對桌上型電腦的AOI要求.Removed any inference to specific machinery/equipment manufacturers.移除任何對特定机器/設備制造商的推論.Changed PCBA categories to align with the Complexity Model.改變PCBA分類以与复雜度模型一致.Added MSD requirements to meet latest JEDEC standard.增加對MSD的要求以配合最新的JEDEC標准.。

PCB制程能力要求PCB制程能力是指PCB(Printed Circuit Board,印刷电路板)制造过程中所要求的技术和能力。

它涵盖了从设计到制造的各个环节,包括材料选择、PCB设计、印刷、装配等过程。

制程能力的好坏直接影响到PCB的质量、性能以及稳定性,因此,掌握和提升制程能力对于PCB制造企业来说是非常重要的。

首先,制程能力要求需要考虑到PCB材料的选择。

PCB的材料直接决定了电路板的性能和可靠性。

常用的PCB材料有硬质纸质基材、玻璃纤维布质基材、陶瓷质基材等。

不同的应用场景对PCB材料的要求也有所不同。

例如,高频电路需要使用具有较小介电损耗和较低介电常数的材料,而高温环境下的电路则要求使用可以承受高温的材料。

因此,制程能力要求需要对不同材料的性能进行了解,并根据应用场景选择合适的材料。

其次,PCB设计是制程能力要求的另一个重要方面。

好的设计可以提高电路板的可靠性和性能。

在设计过程中,需要考虑排线的长度、宽度、间隔等参数的选择,以及掌握PCB设计软件的使用方法。

此外,还需要熟悉阻抗匹配的方法和原理,避免因为阻抗不匹配而导致信号衰减和干扰。

在PCB设计过程中,还需要保证设计的可制造性,即能够在实际制造过程中顺利实施。

因此,制程能力要求需要对PCB设计方面的技术和方法有深入的了解。

在PCB制造过程中,制程能力要求还包括PCB的印刷、装配等环节。

印刷过程需要掌握好涂布、曝光、脱模等技术,保证PCB上的线路图案的精确度和清晰度。

装配过程需要掌握焊接技术和检测技术,保证元器件能够正确焊接在电路板上,并且通过检测能够发现并修复可能存在的问题。

此外,在制程能力要求中还需要注意质量控制和质量管理的问题,建立完善的质量体系,确保生产出来的PCB具有稳定的性能和质量。

为了提高制程能力,并满足不同的要求,PCB制造企业可以进行相关的技术培训和知识更新。

培训可以包括PCB制造流程和工艺的学习,以及新材料、新工艺的掌握。

PCB行业现场稽查要点"Is there a pre-startup checklist for the preclean line? Is itcurrent(completely filled in)?针对预清洁线是否有建立预先点检表单?是否已经执行(已经填写)?""Is there objective evidence that the scrub/preclean chemistries are being analyzed by the laboratory on the documented frequency?刷磨/预清洁化学药水是否有证据证明其有按照实验室文件规定的频率进行分析?""Are Dump and Remake schedules documented for the preclean line and objective evidence exist that they are being adhered too?是否有证据证明预清洗倾槽与更曹计划有符合文件要求?""Is there an evidence to demonstrate that all chemicals are monitored and controlled as listed in WI?是否有证据证明所有的化学品与WI上管控的物质有监督并管控?""Is all in-process WIP and materials properly identified and controlled in designate area?所有制程上的WIP与相应制定材料是否管控在制定的工作区内?""Is a water break test performed every shift to ensure quality of pre-clean?槽液测试是否每班测试一次以确保预清洁品质良好?""Is their positive air pressure from the cleanroom at the preclean line entrance into the cleanroom?无尘室的预清洁线入口到无尘室是否有良好的压力?"Imaging 干膜"Is the cleanroom well controlled by temperature, humidityand particles which meet 10K Max. requirement and out of control notification? Review objective evidence.无尘室的温度,湿度与尘埃粒子是否按照10K最高要求管控,并且有管控实效通知系统?审核客观证据.""Are the resist lamination and exposure areas in the cleanroom utilizing yellow lighting and do all exterior windows have UV blocking film?无尘室的压膜与曝光区是否用的是黄灯并且所有的外部窗户使用的是UV膜?" "Is there objective evidence to demonstrate that all dry films and/or liquid resist are stored in temperature and humidity control environment? Also, inventoried under FIFO with expired date control?是否有证据可以证明干膜或是湿膜储存在温度与湿度管控的环境内?并且,到期管控有先进先出目录?""Are there tacky roller clean machines in front of the laminator?在压膜前是否有粘尘滚轮清洁机器?""For dry film lamination, is the temperature of the lamination roller checked and verified using an infrared meter?针对干膜压膜,是否检查了压膜滚轮的温度并使用红外线表进行确认?""Is there a documented resist inspection criteria with pass/fail guidelines?是否有文件规定的干膜检验标准指导书以判定接受或判退?""Is all in-process WIP and materials properly identified and controlled in designate area? Including expiration date on age sensitive material?所有的制程WIP与材料是否有相应的定义并管控在制定区域?包括老化敏感材料有效期过期?""Is there a documented resist strip/rework procedure with the maximum number of reworks identified?是否有文件规定干膜剥膜/重工程序有定义最大的重工次数?""For dry film lamination, is the temperature of the lamination roller checked and verified using an infrared meter?对干膜压膜,是否有对压膜滚轮温度进行检验并对红外线表表进行确认?""Is there a latest revision control on working film?是否对工作菲林的最新版本进行管控?""Is there an evidence that a maximum number of exposures has been established and the number of exposure times of working film is monitored? 是否有证据表明管控了曝光的最大次数并对工作菲林曝光次数进行监控?""Is the artwork cleaned after defined exposure times using tacky roller? Review the condition of the tacky rollers.在确定曝光次数后,是否使用粘尘滚轮对底片进行清洁?审核粘尘滚轮的状况?""Are there tools and procedures with tolerance limits in place for front-to-back registration verification during the artwork setup? Is it identified as a critical SPC parameter?在底片设计阶段,是否确认了前后对准度的工具/制程最大公差?是否被定义为关键SPC参数?"" Is the front to back verified during this process?在这些制程是否对上下对准度进行确认?""Is the maximum number of permissible exposures documented with a system to track the number of exposures?可允许的最大曝光次数是否有文件规定并有相应的系统对其跟踪?""Is there an evidence that the number of exposure times ofworking film is monitored and the artwork is not being used beyond documented useful life?是否能证明菲林的曝光次数有进行监控并且底片没有超出文件规定的使用期限?"" Is the max holding time between expose and develop documented and followed?曝光和显影之间是否文件规定最大的静置时间并有按照此要求执行?""Is their a pre-startup checklist for the DES line? Is itcurrent(completely filled in)?DES 线是否有预启动点检表?是否已经进行(有完整地填写)?""Is there an evidence to demonstrate that all chemicals are monitored andcontrolled as listed in WI?是否能证明所有的化学品有进行监控并有管控WI清单?""Are all in-process WIP and materials properly identified and controlled in designate area?所有的制程上WIP与材料是否有定义并管控在指定的区域?""Are defectives and rework schedules documented for the DES line and objective evidence exist that they are being follow?DES线是否有文件规定不良品与重工计划,并且有客观证据说明有按照其要求执行?""Is a first article run prior to etching the lot to confirm etcher settings and linewidths?在批量蚀刻前是否先进行首件确认,以保证蚀刻机设备与线径?""Is the etch unifomity monitored at least monthly and records maintained as a quality document?是否至少定期稽核一次蚀刻站并有相应的维护记录作为品质文件?""Are the etcher conveyor speeds defined and documentedby copper weight/thickness?蚀刻机运作速度是否有规定并且有文件规定铜重量/厚度?""Is the filtration system adequate? What's the clean frequency and renew frequency?过滤系统是否完善?清洁频率与更换频率是多少?""Are there documented maximum final rinse water contamination levels, rinse flow rates and are these verified by conductivity measurements? 是否有文件规定最大水洗污染水准,水洗流动率与对传导性进行确认?""Are the cores observed coming off the DES line clean, dry and stain free? 是否有专门的对DES线清洁,烘干与无沾污进行检验?""Does the stripping module contain a filtering system for the removal of the dry film resist?剥膜机是否有过滤系统以去除干膜膜屑?""Are seperators used to separate each core (signals & power/grounds) to prevent scratches?是否有作业员单独操作每个重要项目(信号,电能,地面)以防止刮伤?" "Are there identified schedule of cleaning the seperaors?是否规定作业员的清洁计划?""Is there a system in place to identify which linewidths to be measured on a core?现场是否有系统规定主要测试哪条线径?""Are linewidth measurement frequency documented and is the frequency at a minimum of the first core, middle and last core off the line in the lot? 是否有文件规定线径测试的频率?"Subsection scores部分得分Section 6 - AOI of innerlayer 外层AOI"Is AOI perform 100% inspection for all signal layers?所有層數是否100%进行AOI检测?""Are all WIP properly identified and place in the desinated area?所有的WIP是否有相应的规定并放置在指定的区域?""Are the power / ground layer inspected per historical statistics sampling plan?是否对能源/接地层进行检验并按照抽样计划定期统计?""Are the AOI programs data base on customer's data and are all the critical AOI settings and programs established by Engineering?是否根据客户资料制定AOI程序,并且由工程建立所与的AOI关键参数设备与程序?""Does the AOI program have appropriate parameters programed to cover minimum linewidths, minimum spacing, dishdowns, etc?AOI程序是否有相应的参数,其涉及到最小线径,最小间距,等?""Is a standard defect board used to verify each AOI machine is catching all defects at the beginning of each shift?是否有不良标准板用于确认每台AOI机是否能够在开始每批测试前测出所有的不良?""Is there a system in place to notify the Image Area for first articles with repeat defects?现场是否系统要求干膜首件发现重复不良时作出相应的通知?""If excess random defects are detected on a lot is this information immediately fed back to the DES operation for review and action? i.e. excess copper, nicks, shorts, opens?若一批内出现了各种不良,此信息是否立即反馈给DES作业员并审核其作业动作?例如:残铜,线路缺口,短路,断路?""Is the AOI defect verification performed on separate verification stations and defect data collected and reported in a meaningful manner? AOI不良确认是否有独立的确认站并且有收集不良资料并进行有意义的报告?" "Are repaired panels re-AOI to confirm all defects were found and repaired? 修补后的板子是否有重新过AOI确认找出的不良已经全部修补OK?""Are yields tracked daily at AOI and feedback loop to I/L process improvement team established? Are first pass yield and final yield targets defined?AOI站的产率是否每日进行跟踪并及时反馈给I/L制程建立相应的改善小组?是否对直通率与最终生产率目标进行定义?""Are corrective actions taken if yields fall below target?若产量低于目标,是否采取相应的改善措施?""Is pareto analysis used to determine the top defects? Is effective continuous improvement used to eliminate top defects?是否针对最高不良项目有要求使用柏拉图进行分析?是否采取持续有效的改善方法以减少最高不良?""Does the rework instruction comply with Synaptics Spec and IPC specification?重工指导书是否符合synaptics规格与IPC规范?""Is there clear instruction to scrap the parts if more than three open circuit found at rework?是否有明确的说明若重工时超过3条线路断路,则报废?""Is the tape test and resistance measurement performed on the welded traces to ensure the reliability of repair?是否针对已经焊接的线路进行胶带测试,以确保修补板的信赖性?" Subsection scores部分得分Section 7 - Lamination 压合"Is there evidence exist that the Oxide Chemistry supplier hasaudited the line in the previous three months? If so, were actions taken?是否能证明棕化药水供应商在3个月前有对棕化线进行稽核?若有这样做,是否采取了相应的措施?""Have DOEs been conducted to verify the optimum oxide thickness to ensure no delamination after thermal stress test?是否有进行DOE确保最好的棕化厚度以保证在热压测试制程发生分层?""Are all in-process WIP and materials properly identified and controlled in designate area?所有在制品WIP与材料是否有定义并管控在指定的地方?""Is the microetch rate monitored? Is it under SPC control with calculated control limits and are the charts & actions current?是否对微蚀率进行监控?其是否有SPC图管控并有正在进行的措施?""Are oxide bond strength test performed for all material types for each oxide line used on Synaptics Product on a weekly basis?氧化粘合强度测试是否针对synaptica产品的所有材料类型的每条线每周进行一次测试?""Are the oxide chemistries on a auto-dosing system?棕化药水是否有定量给料系统?""Is DI water used for rinses?是否使用DI水进行水洗?"Are the cores exiting the machine dry and stainfree?机器是否干燥并无污染?"Is there an evidence that black oxide thickness is well controlled? 是否能证明黑化厚度有很好的管控?""Are the oxided panels uniform in color, appearance and freeof scratches/handling damage?氧化板是否颜色统一,外表无刮伤/或操作导致损坏?""Is ionic contamination test conducted once/shift as defined in the Synaptics specification?离子污染测试是否按照synaptics规范要求每次换班执行一次?""Are cores reworked at oxide? If so, is there a documented rework procedure with the maximum number of reworks established?氧化线是否重工?若有重工,是否有文件规定最大重工次数?""Is the lay-up done in a clean room with adequate temperature and humidity control?叠合线无尘室是否有相应的温度与湿度管控?""Are there established hold-times for oxide cores in tha layup operation? 是否规定氧化线-叠合作业的静置时间? ""Are all in-process WIP and materials properly identified and controlled in designate area?所有在制品WIP与材料是否有定义并管控在指定的地方?""Is there a procedure in place to insure the stack-up is performed per layup provided and approved by Synaptics?现场是否有文件以确保每对预叠有按照synaptics承认的要求执行?""Is the material profile done regularly to ensure the actual cooldown rate not exceed 5 deg C / minute? What is the heat rise and cool down rate? 是否定期检查以确保实际降温率不超过5度/分?温度升温与降温速率是多少?""Are steel plates cleaned for each cycle and polished periodically? Is the thickness of the steel plate checked regularly?每批钢板是否定期清洁并打磨?钢板的厚度是否定期检查其厚度?""Is there an evidence that lamination press platenflatness/parallelism is checked a minimum of once/six months?是否能证明压合平台是否平整/平行并至少1-6个月检查一次?""Is board thickness measured after lamination on all panels or on appropriate sample size at a min 5 points on each panel?压合后的板厚是否进行抽樣检验, 对每PNL至少检验的5个点?""Is there X-ray punch with accuracy compensation design for registration control?X-RAY冲床是否管控对准度的设计补偿精确度?""Is there a documented quality inspection procedure for resin spots on laminated panels?是否有品质检验程序文件对压合板数脂沾污进行定义?""Is the Tg and delta Tg checked weekly for all material types used for Synaptics product on each lamination press?所有用于synaptics型号的板材,是否每周对压合产品检测一次TG与△TG?" "Does there exist a documented accept/reject criteria at pre-drill x-ray for misregistration?是否有文件规定X-RAY钻孔对准度的接受/判退标准?""Is there a documented routine dimensional measurement confirmation performed on the x-ray pre-drill measurement system?是否有文件定义对X-RAY钻孔系统进行尺寸测量确认?"Subsection scores部分得分Section 8 - Drilling 钻孔"Does the drilling machine have broken bit and wrong bit size detection capability?钻孔机是否有破损钻咀与不良钻咀尺寸鉴定能力?""Does the traveller clearly define all the drilling parameters including stack height?钻孔机是否能够清楚地定义钻孔参数,包括堆叠厚度?""Is the drilling program checked prior to being released forproduction? 是否在开始生产国产前,对钻孔程序进行检验?""Is there evidence to demonstrate that spindle run-out is well controlled? 是否能证明钻轴偏移管控良好?""Is the stack height, maximum hit per drill bit, and feeds and speeds as a function of laminate type, board thickness, layer count and hole size controlled properly?堆叠高度,每钻咀的最大钻次,进刀速度是否对板材类型,板厚,曾数,与孔尺寸进行管控?""Are drill bit registration checked by cross-section or X-ray? What is the frequency?是否通过切片或X-RAY对钻咀对准度进行检验?频率是多少?""Do action plans exist for investigating and reducing broken bits? Does objective evidence exist that this is in control?是否对钻咀破损有调查改善计划并减少了不良次数?是否有客观证据证明已经有管控此项?""Is there a documented drill rework/repair procedure with quality checks? 是否有文件规定钻孔重工/修补程序并有相关品质点检表?""Are PCB's with missing holes placed back on the drill machine and drilled? 所有PCB漏钻孔位于钻孔机台面上已经钻过的位置?""Are resharpened drill bit inspected and identified prior to use?再次研磨的钻咀是否在使用前进行检验与确认?""Are the maximum number of re-sharpens documented & controlled?是否有文件规定并对最大研磨次数进行管控?""Are Aluminum plates inspected for dents and scratches before use?在使用之前是否对铝板进行检验,以确保无凹陷与刮伤?""Are output boards at the bottom of each spindle inspected on the hole size & location, hole registration and hole quantity etc?每轴底部的板子是否检验其孔尺寸,孔位,孔对准度与孔数量等?""Is there a general inspection procedure with Drilling accuracy, Hole size, Hole quantity, Hole location and Copper surface appearance defined?对钻孔精确度,孔径,孔数量,孔位与铜箔表面确认,是否有相应的检验程序?""Are drill machines capability data for hole position accuracy traceable for each machine and spindle?钻孔机孔位对准度能力数据是否对每台机器/每轴进行跟踪?""Are drill machines capability data for runout traceable for each machine and spindle?钻孔机偏移度是否追踪到每台机器/每轴?""Is registration monitored by Perfect Test machine or X-ray check after Drilling?在钻孔后是否通过良品测试机器或X-RAY检验其对准度?""Is SPC used in Drilling process?钻孔制程是否使用SPC?""Are all passed/rejected boards properly labeled and segregated to avoid mixing or missing?所有的PASS/REJECT板是否贴有相应的标签以避免混料或遗失?""Does all in process WIP and materials be properly identified and controlled?所有的WIP制程是否有相应的定义并进行管控?""Is there a SPC control implemented and control chartupdated for critical parameters?是否有SPC管控并有最近更新关键参数管控?""Are relevant corrective actions taken toward all the out of control points?所有超出管控的项目是否有相应的改善对策?"Subsection scores部分得分Section 9 - Electroless 化学沉铜"Is there a pre-startup checklist for the Deburr line? Is itcurrent(completely filled in)?去毛刺线是否有启动前点检表?是否已经运行(完整填写)?""Are there air knives, fluid heads & ultrasonics on the deburr machine? 去毛刺机器是否有风刀,流动性&超声波?""Are all in-process WIP and materials properly identified and controlled in designate area?所有在制品WIP与材料是否有定义并管控在指定的区域?""Is a hole inspection/checker used after deburr for plugged holes? If so,are the data used for continuous improvement activities.在去冲孔孔内毛刺后,是否检验孔?若有,是否有持续改善的资料?""Are the surface of the boards and holes completely dry after deburr process?去毛刺后,板面与孔是否完全干燥?""Is there a pre-startup checklist for the Desmear line? Is it current? 去毛刺线是否有开机点检表?目前是否运行?""Are all in-process WIP and materials properly identified and controlled in designate area?所有在制品WIP与材料是否有定义并管控在指定的区域?""Are the temperatures, pumps, bath condition, tanks/sumps and process times on the line within the process specifications?生产线上的温度,抽水机,槽液条件等是否管控在制程规范内?""Is there an evidence that chemical analysis is performed periodically? 是否能证明化学药水分析有定期完成?""Is there a pre-startup checklist for the electroless line? Is it current (completely filled in)?化学沉铜线是否有开机点检表?目前是否运行(完整填写)?""Are all in-process WIP and materials properly identified and controlled in designate area?所有在制品WIP与材料是否有定义并管控在指定的区域?""Is backlight inspection performed to check the coverage of the electroless copper including both sides of the hole?是否检查化学沉铜的孔两面的背光?""Is dummy-plating performed as part of the start-up procedure before electroless copper plating product?化学沉铜在开始生产前是否有进行是试镀?""Is there a documented quality conformance procedure with accept/reject criteria for electroless plating line malfuctions(hoist, time, temperature, etc. interuptions) to insure the quality of the product in the line at the time of malfunction?化学沉铜线生产是否有规定的品质确认程序的判定接受/判退标准。

1.目的

PCB各制程设备能力在固定期间内做相关稽核测试,以确保各工序的设备能力稳定,同时反映出各制程的问题点,以改善之确保制程稳定性,特订制此作业指导书。

2.适用:

凡本公司内的PCB各制程应对工序

3.职责

技术部:制定各工序设备能力测试项目、方法与频率,同时分析各制程能力是否稳定并提出改善或提升计划;

生产部:执行各工序设备能力测试项目,并制定出记录表单进行记录,以便品管追查稽核之用;

品质部:负责各制程能力测试结果的稽核与改善追踪

4.管理内容:

4.1 当本公司新制程或新设备导入试车,制程能力需要进行测试

4.1.1 定义:因厂内生产所需且会影响产品品质之制程、设备,在增加新制程、变更型号,加装新功能时或引进

新设备时适用

4.2 当本公司因产能或某一制程缺少,需评估外包商时,制程能力需要进行测试

4.2.1 定义:因厂内某单一制程产能存在瓶颈,或因业务产品订单需要,但暂缺某单一制程,需寻求外包商协同

解决时,外包商的设备及制程均适用

4.3 当本公司已经投入量产阶段,为确保制程稳定性,须定期检测制程能力

4.3.1 定义:凡是厂内PCB制程均适用

4.4 制程能力测试项目、方式及频率:

4.4.5防焊

5.1 制程管理计划作业指导书

6.附件

______________课制程能力测试点检表。