OIW Training Manual水中油测油仪说明书

- 格式:doc

- 大小:301.00 KB

- 文档页数:15

水中油检测仪原理及分析方法水中油在线监测仪器专]设计连接油冷却器或冷却循环水,OMD系列为适应较高的水温而专门]进行了改进。

而且测量范围已经根据预期的油的浓度进行了修正。

该仪器依据IMOResolutionMEPC.107(49)标准制造。

仪器出厂配有2个报警点,两点出厂值10ppm,其他数值的设定(20ppm或30ppm)可以在现场随时通过仪器前部面板的按钮进行调整,如果测量值超过报警点,在仪器前部的面板上发出明显的信号,同时通过继电器传出。

另外配有0(4)-20mA(等同于0-100ppm测量值)的测量信号输出,可以连接外部选定的记录器。

在线水中油分析仪测试原理:采用几个光学传感器,侦测通过水流样品中油滴对光的折射和反射光的强度,然后传感器的信号通过微处理系统计算水中油份的含量并形成线性读数输出。

如果一一个报警器(出厂设置10ppm)发出报警,第二报警器将会在超过设置时间后运行。

微处理系统会不间断的检测传感器部件及相关的电子元件,以确保在超过维修时间或极端的条件下测量的准确度。

水体中总含油量检测(水体中石油类/动植物油类含量)是近年来水质监测的新热点,可以覆盖油田、石化、炼油,采油、输油、工业冷却水、循环水、锅炉用水、中水回用等很多领域,实时、快速、准确地检测技术成为新的应用需要。

水中油分析技术常用的分析方法主要集中在:重量法、红外分光光度法、非分散红外法、紫外分光光度法、荧光光度法、色谱法、超声法、浊度法、光散射法,经过多年的应用,其存在的局限性如体积庞大、结构操作复杂、灵敏度低、选择性差、分析速度慢、分析时间长、或为实验室专用、或需要添加吸附剂等都限制了他们的应用领域。

紫外吸收水体总含油量分析仪,以期满足水中油检测更广泛的现场应用需求。

紫外吸收水体总含油量分析仪设计理念依据“国准方法GB/T16488-1996,国家环保总局标准(HJ/T92—2002)《水污染物排放总量监测技术规范》石油类、动植物油监测方法的自动在线监测法为(红外法、荧光法)”,利用矿物油/动植物油类受到紫外光激发会产生可见光波段的荧光特性,在仪器设计上不仅可用于在线监测,也可以实验室应用。

水样的萃取过程用HcL调PH<2,将一定体积(一般500ml)的水样全部倾入分液漏斗中,先用50ml四氯化碳洗涤采样瓶后移入分液漏斗中,摇晃振荡3min。

在摇的过程中要开启活塞排气。

静置分层后,将下层萃取液放入150ml带有磨口瓶塞的锥形瓶内。

并加入5克的无水硫酸钠摇晃数次直到无水硫酸钠没有完全结晶即可取下清液等待测试(总油),震荡20min,若浑浊,用40mlG-1型玻璃砂芯漏斗过滤,即可测试样品。

然后再把剩余的水样放入量筒测量体积等待输入软件测试计算。

如果测试石油类继续往锥形瓶加5克的硅酸镁摇晃数次后过滤等待测试石油类。

(详情参照国家标准)样品测定方法1> 在测定样品前,先打开电脑及测油仪电源开关,预热10-15min,此时可以先取一个比色皿,倒入空白(四氯化碳)后放入比色池中,进入软件界面,选择“空白测试”,重复3次,点击“开始”,让其自动调零,待空白谱图比较重合时,就可以进行样品测定了;如果不重合,点左上方“清屏”,重新点“开始”测试。

直到空白调零谱图重合方可测试样品。

2>在软件界面,选择“样品测试”,把萃取好的样品倒入比色皿,放入比色池,再进入软件右上方界面把溶剂定容体积(萃取过程中四氯化碳用量),水样体积(萃取完成后分液漏斗中剩余水样的体积)输入,再从软件界面从标准曲线方框内选择“标准曲线”;之后再样品名称栏内修改样品名字,点击“开始”,就可以进行测定了。

测定结束后,结果显示在下边的表格中。

(样品横向最后一行 RSD/DL 必须小于0.2或2%.如超出需重测或重新空白调零)。

国家质量技术监督局和国家环境保护总局联合发布了中华人民共和国国家标准“水质、石油类和动植物油的测定——红外光度法”。

从而统一了油类测试的标准问题。

标准中不但明确了油类物质测定时所用的萃取剂是四氯化碳,而且对四氯化碳的质量提出了一定的要求,在红外吸收光谱中,不但考虑了亚甲基CH2基团中C-H键的伸缩振动(波数为2930cm-1),甲基CH3基团中C-H键的伸缩振动(波数为2960cm-1),也考虑了芳香环中C-H键的伸缩振动(波数为3030cm-1)。

BQSY-3010型水中油在线分析仪声明在开箱、安装和操作此设备之前,请完整地阅读本手册。

特别要注意所有的危险警告和注意事项。

否则,可能会对操作者造成严重的人身伤害,或者对设备造成损坏。

要确保本设备所提供的防护措施不受破坏,请不要使用本手册规定之外的方法来安装或者使用本设备。

目录第一章安全事项 (5)1.1 电气安全 (5)1.2 腐蚀性安全 (5)第二章系统概述 (6)2.1 主要特点 (6)2.2技术参数 (7)2.3 主要零配件清单 (7)第三章仪器安装 (9)3.1 拆箱和检查 (9)3.2 外观及尺寸 (9)3.3 位置要求 (10)3.4 机械安装 (10)3.5 管道连接 (12)3.5 电气连接 (14)3.6 通信连接 (15)第四章标准溶液配置 (16)4.1 注意事项 (16)4.2 配置试剂 (17)4.2.1 所需药品 (17)4.2.2 所需器皿 (17)4.2.3 标准溶液配置 (17)4.2.4 试剂瓶放置 (17)第五章使用入门 (18)5.1 认识在线分析仪 (18)5.2 工作原理 (18)第六章软件操作 (19)6.1 初始登录 (19)6.1.1 主界面 (19)6.1.2 操作登录 (19)6.1.3 功能菜单 (20)6.2 系统设置 (20)6.2.1 功能概述 (20)6.2.2 操作说明 (21)6.3 系统状态 (27)6.3.1 功能概述 (27)6.3.2 操作说明 (27)6.4 数据管理 (28)6.4.1 功能概述 (28)6.4.2 操作说明 (28)6.5 功能测试 (30)6.5.1 功能概述 (30)6.5.2 操作说明 (31)第七章维护 (32)7.1 维护安排 (32)7.2 系统清洗 (32)7.3 系统报警与故障处理 (33)第八章保修 (34)第一章安全事项请阅读以下简明的规则。

不遵守这些规则可能会导致危险或损坏仪器。

石油测定仪使用说明书一、介绍石油测定仪是一种重要的实验设备,用于测定石油样品的密度、粘度、闪点等物理特性。

本使用说明书将详细介绍石油测定仪的操作方法和注意事项,以确保用户正确、安全地操作该设备。

二、设备介绍1. 外观描述石油测定仪外观简洁精致,仪器表面平整,颜色为灰色。

仪器上含有操作按钮、显示屏幕、控制面板等部分。

2. 功能石油测定仪的功能主要包括密度测定、粘度测定、闪点测定等。

用户可以通过操作按钮选择所需的测试项目,并通过显示屏幕查看测定结果。

三、操作方法1. 准备工作(1) 将石油测定仪放置在平稳、通风的台面上,确保其稳定性和安全性。

(2) 将所需测定的石油样品装入专用容器中,容器需要干净、无杂质。

(3) 接通电源,待仪器正常开机后,进行测试前的准备工作。

2. 密度测定(1) 打开仪器电源,仪器进入待机状态。

(2) 选择密度测定功能,并根据提示在显示屏幕上输入相应参数。

(3) 将样品容器放置在石油测定仪的测试台上,并按照仪器指示操作完成密度测定。

(4) 结果将显示在显示屏幕上,记录并保留测定结果。

3. 粘度测定(1) 在待机状态下,选择粘度测定功能,并输入相应参数。

(2) 将样品容器放置在石油测定仪的测试台上,并按照仪器指示操作完成粘度测定。

(3) 结果将显示在显示屏幕上,记录并保留测定结果。

4. 闪点测定(1) 选择闪点测定功能,并在显示屏幕上输入相应参数。

(2) 将样品容器放置在石油测定仪的测试台上,并根据仪器操作提示完成闪点测定。

(3) 最终测定结果将显示在显示屏幕上,记录并保留测定结果。

四、注意事项1. 在操作石油测定仪之前,确保仪器外表干净整洁,并检查电源线、通风孔等部分是否正常。

2. 样品容器必须干净,无杂质,以确保测定结果准确。

3. 操作过程中应根据仪器提示输入相应参数,保证操作的准确性。

4. 在进行闪点测定时,应注意避免与火源、易燃物品等接触,确保操作安全。

5. 操作完毕后,及时关闭仪器电源,保持设备干燥。

水中油份浓度分析仪技术要求1、技术总则:1.1本技术规格书提供的是最低限度的技术要求,并未对一切技术细节作出了规定,也未充分引述有关标准和规范的条文,投标人应保证提供符合技术规格书和有关工业标准的优质产品。

1.2本技术规格书所使用的标准和规范与投标人所执行的标准发生矛盾时,按较高的标准执行。

1.3投标人所提供的所有技术文件的内容和产品图纸、制造工艺、试验检查依据等,除非在技术规格中另作规定外,均应使用相应的国际标准化组织标准和/或其他先进国际标准。

这些标准应为合同签定日为止最新公布的标准。

1.4投标人提供货物所使用的度量衡单位除技术规格中另有规定外,应统一用公制单位。

1.5投标人提供货物制造商/或生产厂家通过ISO9000及以上标准认证证明,或通过其他国际/国家/地区认证机构的认证证明。

1.6交货期:合同鉴定后6周。

1.7货物数量:水中油份浓度分析仪及其配套萃取装置一套。

2、设备用途及总体要求2.1用于工业循环水(含废水)中油浓度的分析。

2.2设备应保证有较高的检测精密度和准确性。

2.3设备操作、维修简便,造型美观,售后服务优良,消耗低。

2.4设备必须具有国际上同行业中近年内的先进设计、制造水平,采用新的工艺、新材料、新技术。

2.5设备必须具有质量的高可靠性,能稳定连续地工作,且具有尽可能长的使用寿命。

*2.6投标方必须提供对应于被分析材质的国际标准或国家标准或地区标准及其规程和方法。

*2.7设备必须具备数据自动上网传输功能,合同一旦签订,供方务必提供其通信协议、数据格式和安装准备需求。

2.8设备必须具有良好的操作性、可维修性、安全性,不污染环境及危害人身健康。

3、主要技术要求3.1工作环境除技术规格另有规定外,投标设备应能在以下环境里长期地工作。

单相电源:(220±22)V ,(50±1)Hz环境温度:10℃—30℃相对湿度:20~80%3.2设备总体要求所有技术规格与参数至少应满足生产用水、工业废水中油浓度(石油类及动植物油)的检验要求。

石油产品水分测定仪操作规程

1.1操作前准备

a.根据所测油品含水多少,按GB/T260-77 (88)方法所规定的称取试样。

b.用缠在铜丝上的干燥软布将冷凝管擦净,按GB/T260-77 (88)方法规定安装好圆底烧瓶与接受器。

打开水源,接通电源。

1.2操作程序

a.打开电源开关,根据实验方法和要求,严格控制回流速度,直至接受器含水体积不变或接受器内液体呈透明状。

b.实验结束,切断电源,关闭水源。

c.待仪器冷却至室温,取下仪器读含水体积,填写记录,洗涤仪器。

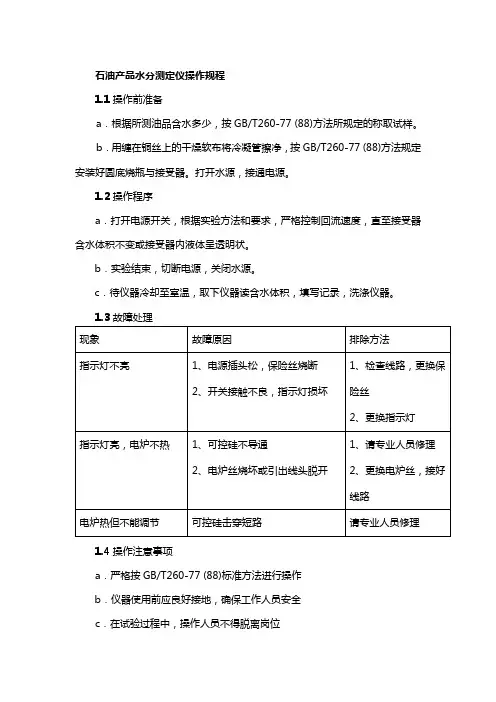

1.3故障处理

1.4操作注意事项

a.严格按GB/T260-77 (88)标准方法进行操作

b.仪器使用前应良好接地,确保工作人员安全

c.在试验过程中,操作人员不得脱离岗位

d.严格按照“先通水,后加热”,“先断电,后关水”的原则进行操作

e.必须待仪器冷却后,拆下仪器,防止烫伤

f.洗涤玻璃仪器时,应戴耐腐蚀手套。

RIVERTRACE ENGINEERING LTDINSTRUCTION MANUALBILGE OIL ALARMUNIT P KINGSFIELD BUSINESS CENTRE,PHILANTHROPIC ROADREDHILL, SURREY, RH1 4DPTELEPHONE: +44(0)870 7702721 FAX: +44(0)870 7702722 Email: service@IMPORTANT NOTICERe: Replacement components for Oil Content MetersGeneralAll monitors in our range are inspected and tested at our factory prior to delivery.In normal use the units should operate correctly and without fault over a long period of time requiring only small amounts of maintenance to be carried out as outlined in the instruction manual.Rivertrace Limited only recommends the use of fast breaking cleaner fluids.Component Replacement/RepairWhen replacing or repairing electronic components (except fuses) please note that due to varying component characteristics it may be necessary to re-adjust or calibrate the monitor.Failure to carry out the correct procedure could result in the monitor over or under reading which in turn could lead to oil pollution and the consequences that follow.In order to avoid this potential problem we can only advise that a service exchange unit be supplied.CONTENTSSECTION TITLE PAGE NO.1. Introduction 42. Important Notes 53. Principle of Operation 64. Specification 75. Constructional Details 86. Autoclean System 97. Installation 118. Wiring 129. Commissioning 1410. Operating Instructions 1811. Trouble Shooting Guide1912. Operator Maintenance 2013. Spares 211. INTRODUCTIONThe OCD CW Oil Content Meter has been designed for use as a detector of hydrocarbons in sample streams, up to 99 ppm. It has a specification and performance that meets thecurrent international requirements for cooling water applications as laid down byGermanischer Lloyd.2. IMPORTANT NOTESa) This equipment must be installed and operated in strict accordance withthe instructions contained in this manual. Failure to do so will impair theprotection provided.b) A competent and suitably skilled person must undertake installation andservicing.b) The equipment must be provided with a sound electrical earth connection.d) The unit must be isolated from the electrical supply before anymaintenance of the equipment is attempted.c) All National or local codes of practice or regulations must be observedand, where applicable, are deemed to take precedence over any directiveor information contained in this manual.d) Hazardous voltages are present within the monitor enclosure3. PRINCIPLE OF OPERATIONA set of optical sensors measures a combination of light scattered and absorbed by oildroplets in the sample stream. The sensor signals are then used to calculate a PPM value by a microprocessor. The micro processor also drives a 0-5v, 1-5V, 0 – 20mA, 4 – 20mA dc linearised output, two seven segment displays, six light emitting diodes, two oil alarmrelays (at adjustable 1 – 99 ppm set points) and one fault relay.The microprocessor continuously monitors the condition of the sensor components andassociated electronics to ensure that calibration accuracy is maintained over time andextremes of environmental conditions.In the event of a failure the oil alarm relays and fault relay are set to the alarm state (de-energised) and both alarm status indicators and fault indicator are set to RED. An errorcode is displayed on the two seven segment displays relating to the fault identity.4. SPECIFICATIONRange : 0-99 ppmAccuracy : +/- 10 PPM up to 50 ppm and 20%thereafterConcentration Indication : 2 x 7 segment LEDAlarm Operating Points : 1 – 99 ppm (adjustable)Alarm 1 Operating Delay : 0-60 sec (adjustable)Alarm 2 Operating Delay : 10-240 sec (adjustable)Alarm Contact Rating : 8A @ 240V ACAlarm Relay Mode : De-energised in Alarm StateZero Oil/Fault Indication : Alphanumeric codeOutput Signal : 0–20mA, 4–20mA (820 Ω max load),0–5V & 1–5V DC (50 KΩ min load) Projected Life (Electronics) : > 50,000 HoursAmbient Temperature : +1°C to +55°CHumidity : 90% RH Max @ 55°CSample Temperature : +1°C TO +40°CSample Flow : 0.1 to 2 Litre/MinuteSample Pressure : 0.1 to 10 BarClean Water Requirement : As for SampleWeight : 2.25kgSize : 215 x 242 x 73 mmSupply Voltage : 2 models available 230V/115V ac and24V acSupply Variation : ± 10% of Nom. VoltageSupply Frequency : 50/60 HzConsumption : 10 VA Max AlarmDegree of Protection : IP 55Electrical installation (overvoltage)classification : EN61010-1EC664 category 115. CONSTRUCTION DETAILS (Refer to Fig 5.1)The OCD CW, in common with other versions of the OCD series, is a veryrobust instrument ideally suited to the aggressive environments of marine engine rooms.The measuring cell is a sealed unit set to the right hand side of the enclosure. The inletpipe is situated on the bottom of the cell (8) and the outlet pipe is situated on the top right hand side of the cell (3). A desiccator (7) to eliminate moisture around the outside of theglass tube and a throttle (6) to regulate flow and maintain pressure are also fitted to thecell.The main electronics are all contained within the enclosure on two printed circuit boards.Additionally a small PCB containing transmitters and sensors is contained within themeasuring cell. The display board (2) is mounted to the front cover and provides the PPM display (4) and the six light emitting diodes. The mother board (1) is mounted to the back of the enclosure and contains the power supply, alarm relays, digital to analogue andamplification circuitry.The front of the monitor is fitted with a membrane user interface containing three pushbuttons (9), and windows for the LED displays.Fig 5.1 CW Construction Configuration75ITEM No. DESCRIPTION ITEM No. DESCRIPTION1 MAIN P.C.B. ASSEMBLY 6 THROTTLE2 DISPLAY P.C.B. ASSEMBLY 7 DESICCATOR3 SAMPLE OUTLET ¼ “ BSPP 8 SAMPLE INLET ¼ “ BSPP4 PPM DISPLAY 9 PUSHBUTTONS5 CELL CAP6. Autoclean System (where fitted) (refer to Fig 6.1)The Autoclean System adds another level of reliability to the OCD CW through theautomation of the cell cleaning process. The assembly is designed to clean the cell tube every 5 – 60 minutes (user selectable see section 9 sub section 7) to reduce the build up of scale and other deposits on the inside of the glass.The OCD CW is mounted onto a stainless steel back plate (4). Two conduits providepassage for wiring between the monitor and the customer terminal enclosure (3). Wiring is also provided to connect the solenoid valve (2) to the terminal enclosure, which in turn is connected to the autoclean control relay (fault relay on stand-alone monitor). The solenoid valve controls the airflow to the autoclean cylinder (1), which drives a wiper up and down to clean the cell tube. The air inlet fitting is 1/8” BSPT and flow should be regulated between 4 and 6 bar.It is important to note that all the existing wiring on the panel is essential to the operation of the autoclean system and that removal of any such connections will impair the operation of the monitor.Fig 6.1 CW Autoclean Construction ConfigurationITEM No.DESCRIPTION1 AUTOCLEAN CYLINDER2 SOLENOID VALVE3 CUSTOMERS TERMINAL ENCLOSURE4 MOUNTING PLATEBelow is shown an expanded view of the customer terminal enclosure. Terminal identities match with those shown in section 8 (Fig 8.1) except for the fault relay which is not available with the autoclean option.Fig 6.2 CW Autoclean Terminal EnclosureAll remaining connections to the OCD CW can be made as shown in the following sections.7. INSTALLATION (Refer to Fig 7.1)See section 2 for important notes . LocationThe OCD CW monitor should be located on or in close proximity to the oily-water separator to minimise response delays. Under no circumstances should the distance between the monitor and the separator exceed 8 metres since this would result in a response time of more than 20 seconds and breach IMO regulations.MountingMount the OCD CW by means of 4 x M4 screws on to a rigid vertical surface and preferably with the display panel of the monitor at eye level.Fig 7.1 Installation GuidelinesCLEAN WATER2 M MIN10 mm PIPING8. WIRING (Refer to Fig 8.1)See Section 2 for important notes concerning wiring.This unit must be connected to the mains supply via a suitably rated and approved fusedisolator unless such fusing/isolation is provided by associated equipment. When fitted the isolator should be close by, readily accessible and marked as to function.Cable entries can accept cables from 6 to 12mm² diameters. The terminal block will accept cable cores of up to 4mm² and cables carrying hazardous voltages must be at least0.75mm² csa. When terminating mains cabling at monitor and electrical source, the earthconductor must be made longer than the live and neutral conductors.To select between 230V and 115V supply a link (or two in the case of 115 V), is attachedon JP1 and JP2 in the relative formations shown in fig 8.1. The link must be electricallyinsulated and at least 0.50mm² csa.Note to make connections to J11, J12, JP1 and JP2 terminals may be pulled out of PCBconnections via tags or links provided.Precise wiring details will vary dependent upon the control system to be employed but the most frequently used systems employ Alarm relay 1 for control purposes and Alarm relay 2 for alarm annunciation only.Connections to the cables should be made as shown in Fig 8.1Fig 8.1 Terminal Connections OCD CWALARM 2 MAINS IN9. COMMISSIONINGSee section 2 for important notes.Fig 9.1 User Interface guidelineOn completion of the installation, wiring and piping carry out the following checks: -1) Electrical•Check that the power supply voltage on cables 1 and 2 are within limits.•Check to confirm that a good connection to earth has been made.2) Piping•Check all piping connections for leaks and rectify as appropriate. Functional Tests (refer to Fig 9.1)•Turn the supply voltage to the Monitor on; the display (1) should read FC (Factory Calibration) for 3 Seconds. (*Note this will only change to CC if a full-scale calibration is performed outside factory conditions).•The monitor will then run through a self-diagnostic and initialisation routine.During this time the display will count down from 40 to 0 and back up to 40again. Alarm LED’s will extinguish + illuminate at alarm set points.•Run oil free water through the instrument for a short period to purge the system of air and dirt.•Adjust the Throttle screw (Fig 5.1 – 6) in the cell cap so that the flow rate through the cell is between 0.5 and 2 litres/min. NB. The flow rate should bechecked on both the clean water supply and the separator sample supply. If theclean water supply is obtained from a high pressure source, it may be necessaryto restrict this at a point up-stream of the clean water/sample 3-way selectorvalve.•Switch the clean water supply to the instrument and after 2 minutes set zero in accordance with the Operating Instructions (see sect 9.5).•Set-up the monitor to give a 0 – 5V analogue output and connect a voltmeter across + V out and – V out(see sect 9.6). The reading should not vary bymore than 0.25v above zero (equivalent to + 1.5ppm). If the reading varies by agreater amount, air entrapment is almost certainly present and changes to thesample piping or sampling take-off point may be necessary.3) Setting Alarm points (refer to Fig 9.1)•Alarm 1 and alarm 2 are both factory set to 15 PPM. To adjust these points the following procedure should be followed.•To adjust alarm 1 set pointPress & release the DOWN or UP KEY (10 or 9) repeatedly until the PPM LED(3) and the ALARM 1 ADJUST LED (6) are both on, the alarm 1 PPM set point isnow displayed.Press & release the SET/ZERO KEY (8).Adjust the PPM value by pressing the UP or DOWN KEY (10 or 9) until thedesired value is displayed. Acknowledge the desired value by pressingand releasing the SET/ZERO KEY (8)•To adjust alarm 2 set pointPress & release the DOWN or UP KEY (10 or 9) repeatedly until the PPM LED(3) and the ALARM 2 ADJUST LED (7) are both on, the alarm 2 PPM set point isnow displayed.Press & release the SET/ZERO KEY (8).Adjust the PPM value by pressing the UP or DOWN KEY (10 or 9) until thedesired value is displayed. Acknowledge the desired value by pressingand releasing the SET/ZERO KEY (8)4) Setting Alarm delays (refer to Fig 9.1.)• Alarm 1 and alarm 2 delays are factory set to 0 and 10 seconds respectively . To adjust these delays the following procedure should be followed.•To adjust alarm 1 delayPress & release the DOWN or UP KEY (10 or 9) repeatedly until the SECONDS LED (2) and the ALARM 1 ADJUST LED (6) are both on, the alarm 1 delay is now shown on the display (1). Press & release the SET/ZERO KEY (8). Adjust the SECONDS value by pressing the UP or DOWN KEY (10 or 9) until the desired value is displayed . Acknowledge the desired value by pressing and releasing the SET/ZERO KEY (8)•To adjust alarm 2 delayPress & release the DOWN or UP KEY (10 or 9) repeatedly until the SECONDS LED (2) and the ALARM 2 ADJUST LED (7) are both on, the alarm 2 delay is now shown on the display (1). Press & release the SET/ZERO KEY (8). Adjust the SECONDS value by pressing the UP or DOWN KEY (10 or 9) until the desired value is displayed . Acknowledge the desired value by pressing and releasing the SET/ZERO KEY (8)5)Calibrating for clean water (refer to Fig 9.1)• Insure that there is no flow through the cell. Remove cell cap and clean the inside of the cell tube with bottlebrush provided. Replace the cell cap. • To calibrate the monitor to local clean water ensure that clean water is passing through the measuring cell then Press & hold the SET/ZERO KEY (8) for 3 seconds in PPM monitor mode (i.e. LEDS 2,4,5,6 and 7 are all off). • The display (1) will flash alternately CL and blank for 8 seconds after which the display will read 0 PPM•If calibration was not successful bC will appear on the display. To clear this error simply press the SET/ZERO KEY and the original calibration will be retained.6) Output range Selection (refer to Fig 9.1)•To select the output range, the correct cable connections should be made first.• If an output range of 0-20mA or 4-20mA is required terminals +I OUT and -I OUT should be connected on J11 (see section 8 fig 8.1).•If an output range of 0 – 5 V or 1 – 5 V is required terminals +V OUT and – V OUT should be connected on J12 (see section 8 fig 8.1).•Using the user interface Press & release the DOWN or UP KEY (10 or 9) repeatedly until the display (1) shows OP for Output range selection •To adjust the output press & release the SET/ZERO KEY (8)•The present range is now shown (r0 or r4). Refer to table below to see which output range is selected with different combinations of connections.Table 9.1 Output Range Selection Reference+ I OUT and – I OUT r0 0 – 20 mA+ V OUT and – V OUT r0 0 – 5 V dc+ I OUT and – I OUT r4 4 – 20 mA+ V OUT and – V OUT r4 1 – 5 V dc7) Auto clean cycle frequency (where fitted)•Using the user interface Press & release the DOWN or UP KEY (10 or 9) repeatedly until the display shows AC.•To view the current frequency Press & release the SET/ZERO KEY (8). The auto clean frequency is now shown in minutes on the display.•Adjust the frequency by pressing the UP or DOWN KEY (10 or 9) until the desired value is displayed.•Acknowledge the desired value by pressing and releasing the SET/ZERO KEY (8).10. OPERATING INSTRUCTIONS (Refer to Fig. 9.1)a)Switch on the power supply.b)Allow 2 minutes for the instrument to warm up.c)Flow oil free water through the system for a few minutes. If the display is greaterthan zero clean water calibration will need to be performed (see section 9 subsection 5).d)Switch the instrument sample supply valve from the clean water supply tothe separator sampling point connection.The instrument is now ready for use.e)When the sample is flowing through the monitor the display will adjust to show thecurrent oil content of the samplef)If the oil concentration exceeds any of the alarm set points (PPM), the Alarm 1 or 2indicator (4 & 5) will be illuminated and the corresponding alarm relay will operateas soon as the set delay time for each alarm has expired.g) If an error code is displayed on the screen. The fault relay and both alarm relayswill be activated. The error codes translate as followsTable 10.1 Error code translation tableOr PPM value out of rangeSH Excessive solids contentbC Bad clean water calibration see page 15 sect.5E1 No Scatter signalE2 No Transmission signalE3 Scatter signal out of rangeE4 Transmission signal out of rangeFor trouble shooting on these errors see section 11.11. TROUBLE SHOOTING GUIDEMonitor is switched on but there are no indicators illuminated. Failure of mains fuse.Incorrect mains jumper setting.Loose ribbon cable between mainPCB and display PCB.Check fuse (F3). See page 13 figure 8.1Insure jumper settings are correct. Seepage 12, Wiring. Note: if jumpers havebeen fitted incorrectly F3 may need to bereplaced.Check Ribbon cable connection J10. Seepage 13, figure 8.1Monitor stays in alarmor reading isinaccurate.Dirty measuring cell.Zero reference needs to be reset.Excessive Contaminates present insample I.E.: rust, bacteria, emulsifiedoils, detergents, discoloration of water.Sample flow control orifice blocked.Sample flow blocked or restricted.Cell not connected to monitor. Clean cell. See page 17, Calibrating for clean water.Reset zero. See page 17,Calibrating for clean water.Correct cause of contaminants. Clean and flush bilge, monitor and oil in water separator.Clean orifice.Remove blockage or restriction.Check J14 connects to cell. See page 13.Monitor stays in overboard even when oil content is known to be above 15 PPM. Flush valve is open allowing sample tobe diluted.Sample flow control orifice blocked.Sample flow blocked or restricted.Autoclean is in wipe positioncontinuouslyThe monitor has alarm delays toprevent excessive valve switching.Close flush valve.Clean orifice.Remove blockage or restriction.Check all airlines are connected correctly.Fig 6.1Check solenoid valve is connected correctly.Fig 6.2Change delay times. See page 14. Settingalarm delays. Alarm 1 delay cannot be setbeyond IMO specifications.Monitor is in alarm condition but overboard valve is open. Foreign material lodged in valve.Poor or non-existent connection toalarm relay.Component fault on main PCB.Clean or replace valve.Check relay connections. See page13,figure 8.1Replace main PCB. See page 23, Spares12. OPERATOR MAINTENANCE (Refer to Fig. 5.1)See section 2 for important notes.AT WEEKLY intervals: -a)Check the zero with oil free water flowing through the instrument and reset ifnecessary (see section 9 sub section 5).b)Flush the cell with oil free water.c)Isolate the instrument from both sample and oil free water supply.d)Unscrew and remove the cell cap (5).e)Insert a bottle brush into the cell using an upwards and downwards motionthrough the entire length of the cell several times.f)Remove the bottlebrush and replace the cap (5).g)Re-connect the oil free water supply and allow this to flow through the instrument fora few minutes.h)Re-check the zero calibration againi)Re-connect the instrument to the separator sampling pointAT MONTHLY intervals: -a) Check the colour of the DESICCATOR window (7) to ensure it is blue, indicatingcorrect moisture content of cell. Replace Desiccator if colour is either PINK orWHITE.b) Install new Desiccator by unscrewing the old Desiccator unit (7) and inserting a newone. DO NOT OVERTIGHTEN DESICATOR – Finger tight is sufficient. Ensure theO ring seats properly against the cell housing.AT YEARLY intervals (units with autoclean / manual clean only): -At yearly intervals (or where necessary) the wiper ring on the autoclean / manualclean assembly (where fitted) should be replaced. This can be ordered from RTEdirectly as part no. 103136INSTRUCTION MANUAL Doc. 107542 Rev D OIL CONTENT METER – TYPE OCD CWRIVERTRACE ENGINEERING LIMITEDPAGE 21 OF 2113.SPARESWhen ordering spares, it is important to supply details of the type of monitor, serial number of monitor, part number of each spare required, its description and any other relevant information.RECOMMENDED SPARESItem Qty Part NumberDesicator packed 1 107413Bottle brush 1 100244Fuse (115/230 V Version) 1 106989 Fuse (24 V Version) 1 101877OTHER SPARES Item Qty Part Number Cell assembly 1 106970 Main PCB 1 107053 Display PCB 1 107037 Cable Gland 1 106883 OCD CW Membrane Overlay 1 107481 Manual Clean Unit 1 107229 Manual/Auto Clean Wiper Ring 1 103136 O-Ring 1 107560 Solenoid valve 240 volts AC 1 106096 Solenoid valve 115 volts AC 1 108357 Solenoid valve 24volts AC 1 108356Double acting cylinder1101740。

●概述:水中油在线分析仪是基于紫外法的新一代全自动水中油在线分析仪,该产品是本公司在多年水质分析类产品研究的基础上推出的一款免维护在线监测仪器。

水样通过在线萃取技术将水中油溶解在特殊溶剂中,然后通过紫外光照射产生光学信号,仪器通过光学信号处理电路将溶液中油的含量与电信号建立稳健的数学关系,通过对电信号的检测便可直接测定出水样的油浓度。

分析仪结构简单、测量范围宽、测量速度快、运行成本极低、无二次污染。

能够对自来水、地表水、雨水、工业污水以及水处理过程等进行直接测量。

可广泛应用于水环境自动监测站、污水处理厂、自来水厂、排污监控点、地区水界点、水质分析室以及各级环境监管机构对水环境的监测。

●工作原理水样通过在线萃取技术将水中油溶解在特殊溶剂中,然后通过紫外光照射产生光学信号,仪器通过光学信号处理电路将溶液中油的含量与电信号建立稳健的数学关系,通过对电信号的检测便可直接测定出水样的油浓度。

●操作手册当仪器上电后,系统自动启动仪器,系统初始化之后液晶屏会显示主界面,主界面显示的内容包括水中油测量值、测量时间、系统当前过程及状态,还包括系统时间、操作登录按钮等。

系统的主界面为一般用户显示测量数据,但若要对系统进行一些设置和管理的操作,需要密码登录进入操作界面方可对系统进行设置操作。

功能菜单的四个选项是四个操作子系统的入口,点击“向上”、“向下”按钮选择“系统设置”选项并点击确定按钮,可以进入系统设置的子菜单界面(见下图),依次可以对“标液一设置、标液二设置、温度设置、反应时间、测量设置、标定设置、量程设置、日期设置、时间设置、系统语言、密码设置、屏保设置、当前版本”进行设置,进入相应的设置界面设置完毕后点击“确认”完成相应的设置功能操作。

系统设置选择系统设置内容标液设置下图是标液一设置界面,为了测量范围的可选择性,用户可以根据具体的标液一配方浓度,通过触摸屏数字按键输入标液一浓度数值,最后点击“确定”按钮即可完成设置。

石油分析仪器使用说明书使用说明书1. 石油分析仪器概述石油分析仪器是一种用于测试和分析原油、石油产品以及相关样品的专用设备。

本使用说明书旨在详细介绍石油分析仪器的操作步骤和注意事项,以确保用户能够正确、安全地使用该仪器。

2. 安全操作指南2.1 仪器操作前的准备在操作仪器之前,确保所处环境稳定、整洁,并检查仪器是否完好。

如遇到异常情况或仪器故障,请联系专业维修人员进行维护。

2.2 个人防护措施在操作仪器时,建议佩戴合适的个人防护设备,如手套、护目镜等。

同时,注意避免直接接触样品,避免产生有害物质飞溅。

2.3 电源及电气安全仪器应连接至稳定的电源,并请勿触摸电器部件,以免发生触电危险。

如发现电气故障或线缆破损,请立即停止使用并联系售后服务。

3. 仪器操作步骤3.1 样品准备将待测样品按照要求准备好,并确保样品不受污染。

若需要稀释或配制试剂,请按照标准程序进行。

3.2 仪器开机与校准连接仪器电源,并按照操作界面上的提示进行开机操作。

根据仪器要求,进行校准步骤,确保仪器的准确度和稳定性。

3.3 样品测试将样品放置在仪器的测试台上,并按照操作界面上的指示选择相应的测试方法。

启动测试程序后,等待仪器自动完成测试。

3.4 数据分析与记录仪器完成测试后,将自动显示测试结果,并可导出为数据文件。

根据需要,用户还可将结果打印或保存到电脑或其他存储设备上进行进一步分析和比较。

4. 维护与保养4.1 定期清洁根据使用频率,定期对仪器进行清洁,以保持其正常运行和延长使用寿命。

使用柔软的湿布和专用清洁剂擦拭外壳和测试台面。

切勿将清洗剂直接喷洒到仪器内部。

4.2 保养注意事项在使用过程中,应注意仪器的散热、防尘和防潮。

避免长时间进行连续测试,以免过度使用导致仪器损坏。

若发现仪器有异常噪音或异常操作,请及时联系售后服务。

4.3 维修与更换部件在需要维修或更换仪器部件时,务必由专业人员进行操作。

若需要更换零部件,请使用原厂配件,以确保仪器的正常运行。

水中油分析仪及系统操作指导步骤详细操作流程技术指标注意事项开机 1.松开门上螺丝,打开仪表门,调节均化器旋钮至6002.打开N2或者仪表风开关,调节PR101;P<10psi3.观察仪表左侧压力表值和流量;P>0.25"H2O请严格按照顺序操作4.旋转加热器开关(备注:仅供环境温度低于10℃开启);各开关。

5.将采样阀BV301切至Sample In位置时,旋转采样泵开关。

6.确保有样品流过进样流量计时,旋转仪表开关,给仪表上电。

初次上电,仪表至少需要预热1小时以上关机请按照相反的顺序关掉各开关。

仪表自检仪表上电后,右旋<ESCAPE/ENTER>旋钮,松手,仪表自动进入自检状态,待自检完成后,会出现四个“OK”字符,表明仪表各参数设定正确,然后随便旋任意键,仪表进入分析状态。

系统操作 1.增压泵开启后,需要调节NV101,以使泵处于正常工作状态;2.调节进样流量计FI101;建议15L/H保证各流量计流量稳3.其余的通过旁通流量计FI102排放;定,保证分析时各阀4.自动采样分析过程中,SV1和SV2为3,1通,样品可正常流过;位正确。

5.BV302和BV303的阀位必须正确,BV302应为SAMPLE位置,BV303应为CAL only位置。

标定仪表 6.零点标定6.1将零点样液倒入标定杯,半杯以上即可,右旋<ESCAPE/ENTER>旋钮,松手,仪表菜单列出,左旋<UP/DOWN>旋钮两次,当光标停留为了准确的标定零点, 在ZERO位置时,右旋<ESCAPE/ENTER>旋钮两次,这时N2或者仪表零点液最好为与测量风被吸合的电磁阀反向引入测量池,冲洗测量池及管路,历时15秒;样相同背景的无油液6.2注意观察显示屛,反吹期间,屛显示为“Air Purging”,当15体。

秒后,电磁阀自动释放,N2或者仪表风被切断,这时迅速将BV302零点标定为系统自动旋转至标定(Calibration)位置,BV303旋转至(Safe Vent)位进行的,需耐心等待置仪表自动进入零点标定状态,待标定结束后,仪表将显示0.006.3初次开机,可以反复标定几次;6.4待零点标定结束后,可通过BV303和NV102从Grap Sample回收。

油中水分检测仪仪器概述油中水分检测仪是一种用于检测液态和固态油品中水分含量的测试设备,它可以测量各种类型的油,如润滑油、变压器油、液压油、燃料油等等。

该设备采用了脉冲灌注红外技术,能够在短时间内快速、准确地检测油中水分含量。

仪器原理油中水分检测仪采用了脉冲灌注红外技术。

在测试时,仪器将一定质量的油经过光束,并使用红外线来检测它们之间的差异,然后使用置换算法来计算油中的水分含量。

这种技术可以避免测量过程中的任何杂质或气泡,从而确保测试结果的准确性和可靠性。

技术特点1.脉冲灌注红外技术保证了测试结果的准确性和可靠性。

2.使用置换算法计算油中水分含量,不受杂质或气泡的影响。

3.精度高、响应时间快,可快速检测油中水分含量。

4.能够测量多种油品,具有广泛的适用性。

应用范围油中水分检测仪是一种广泛应用于工业和实验室中的测试设备。

其应用范围包括但不限于以下领域:1.石化行业:用于检测润滑油、燃料油、液压油、变压器油等中的水分含量。

2.航空航天领域:用于检测航空机油中的水分含量。

3.汽车制造业:用于检测发动机油中的水分含量。

4.实验室应用:用于研究脂肪酸或生化制品中的水分含量。

操作步骤1.准备样品:根据测试要求,准备适量的待测试样品,并确保样品中的杂质和气泡已经去除。

2.打开仪器:使用电源开关启动仪器,打开屏幕显示。

3.校正:根据设备说明书,进行仪器的校正。

4.测试:将样品注入设备中进行测试,等待设备进行自动测试并记录结果。

5.结果分析:根据设备显示的结果进行分析并记录测试结果。

维护保养油中水分检测仪需要定期进行维护保养,以确保设备的正常及准确工作。

具体维护保养步骤如下:1.清洁设备外壳。

2.定期更换仪器装置中的耗材,包括片式摆动阀,瓶式反应精度等。

3.定期进行仪器的校正,并更换校正标准品。

4.使用过程中定期清洗测试前部件。

总结油中水分检测仪是一种用于测量油品中水分含量的测试设备,它采用了脉冲灌注红外技术,具有高精度、快速响应和广泛适用性。

〖使用说明〗目录1. 综述General2. 正常测试Test Routine3. 功能使用说明Function Operation4. 功能部件Components to be combined5. 设置操作说明Setup Operation6. 维护及操作指令Maintenance1. 综述 GeneralM393951系列水中油在线分析仪是基于双通道光度计原理的技术。

系统测试365nm处的光吸收度,参比473nm, 计算出水体综合污染指数。

仪器设计了2个层面的标定:第1层为基本标定。

用“零样”和一个标准浓度样品(50mg/l左右)对仪器进行标定, 运用比尔定律计算出主通道(254)的消光系数Em, 和参比通道(473)的消光系数Er。

其中需要设置光程,即两个玻璃之间的距离。

往往这个标定就可以保障仪器的正常使用。

第2层为三维标定,可以在光度计测试的基础上再一次克服非线性,漂移,或温度特性的影响。

仪器启动时必须在#7通道用邻苯二甲酸氢钾首先进行基本标定。

参考《6.1.4. Photo4120型光度计基本标定》。

有了#7通道的基本标定,其它个通道都可以正常测试。

如果其它参数不进行基本标定,所选通道就借用#7通道的基本测试结果。

如果当前参数与#7通道的数据需要换算,可以通过两个样品通过3D标定表进行重新量化。

参考6.1.3. 3D标定表标定操作选择(Calibration)》。

任何通道,如果觉得数据不够准确,到可以在自己通道建立3D标定。

如果您需要温度补偿,在进行3D标定时,将样品温度慢速升高到可能的最高使用温度。

系统会收录适当的温度补偿点,以便以后测试时自动补偿。

系统通常显示一个主要参数,悬浮物浓度和温度。

主要参数可以用键盘C1-8选择。

如果发现测试流量不准,可以进入3D标定程式进行校准标定。

重新进行3D标定前需要删除表中的数据。

这种删除并不删除基本标定数据。

BD5系列智能变送器提供标准信号输出,基本电气规格为0/4-20mA. 输出信号满量程所代表的数值可以通过键盘设置。

BQSY-3010型水中油在线分析仪声明在开箱、安装和操作此设备之前,请完整地阅读本手册。

特别要注意所有的危险警告和注意事项。

否则,可能会对操作者造成严重的人身伤害,或者对设备造成损坏。

要确保本设备所提供的防护措施不受破坏,请不要使用本手册规定之外的方法来安装或者使用本设备。

目录第一章安全事项 (5)1.1 电气安全 (5)1.2 腐蚀性安全 (5)第二章系统概述 (6)2.1 主要特点 (6)2.2技术参数 (7)2.3 主要零配件清单 (7)第三章仪器安装 (9)3.1 拆箱和检查 (9)3.2 外观及尺寸 (9)3.3 位置要求 (10)3.4 机械安装 (10)3.5 管道连接 (12)3.5 电气连接 (14)3.6 通信连接 (15)第四章标准溶液配置 (16)4.1 注意事项 (16)4.2 配置试剂 (17)4.2.1 所需药品 (17)4.2.2 所需器皿 (17)4.2.3 标准溶液配置 (17)4.2.4 试剂瓶放置 (17)第五章使用入门 (18)5.1 认识在线分析仪 (18)5.2 工作原理 (18)第六章软件操作 (19)6.1 初始登录 (19)6.1.1 主界面 (19)6.1.2 操作登录 (19)6.1.3 功能菜单 (20)6.2 系统设置 (20)6.2.1 功能概述 (20)6.2.2 操作说明 (21)6.3 系统状态 (27)6.3.1 功能概述 (27)6.3.2 操作说明 (27)6.4 数据管理 (28)6.4.1 功能概述 (28)6.4.2 操作说明 (28)6.5 功能测试 (30)6.5.1 功能概述 (30)6.5.2 操作说明 (31)第七章维护 (32)7.1 维护安排 (32)7.2 系统清洗 (32)7.3 系统报警与故障处理 (33)第八章保修 (34)第一章安全事项请阅读以下简明的规则。

不遵守这些规则可能会导致危险或损坏仪器。

石油测量仪使用方法说明书一、产品概述石油测量仪是一种用于测量石油和石油产品质量与流量的仪器,具有高精度、可靠性强等特点。

本说明书将详细介绍石油测量仪的使用方法,以帮助用户正确操作并获得准确的测量结果。

二、安全注意事项1. 在使用前,请仔细阅读本说明书,了解使用方法和注意事项。

2. 使用石油测量仪之前,确保设备和环境符合相关安全规定。

3. 在操作过程中,严禁触摸设备内部部件,避免发生触电或其他安全事故。

4. 如发现异常情况或设备故障,请及时停止使用并联系售后服务。

三、设备组成石油测量仪主要由以下几个部件组成:1. 主机:包括显示屏、操作面板、测量模块等,用于实现测量功能。

2. 传感器:用于感知石油的流量和质量信息,并将其转化为电信号。

3. 电源装置:提供电力供应,确保设备正常运行。

4. 数据存储模块:用于存储测量数据,便于后续分析和处理。

四、使用步骤1. 准备工作a. 确保电源连接正确,并检查设备是否处于正常工作状态。

b. 检查传感器是否安装牢固,且与管道连接紧密,确保传感器能够准确感知石油流量。

c. 启动设备,待显示屏显示正常后,即可进入下一步操作。

2. 测量前设置a. 根据实际需要,选择相应的测量模式,可选项包括质量测量模式和流量测量模式。

b. 针对不同类型的石油产品,需要设置相应的密度或粘度参数。

c. 根据测量要求,设定相关的测量单位和参考值。

3. 测量操作a. 将待测量的石油产品通过管道导入测量仪,确保流体流动平稳。

b. 监控显示屏上的测量数值,确保读数稳定后,记录测量结果。

c. 如需连续测量,可根据实际需要设置测量间隔时间。

4. 数据处理与存储a. 将测量结果导出至计算机或移动存储设备,方便后续数据处理。

b. 对测量数据进行分析,如需生成报告或图表,可使用数据分析软件进行处理。

c. 定期备份测量数据,确保数据安全性。

五、维护与保养1. 每次使用后,应及时清理测量仪表面的污垢,保持设备干净整洁。

前 言1.1 说 明OilTech121是用来检测水及土壤中矿物油的荧光计,使用相关方法或标准液校准,可以快速、简单、准确的确定未知待测样品的浓度。

1.2 主要用途、适用范围z油田、油井、海上石油平台z石油化工z石油环保z海运、海事z水电站、发电厂z海洋、渔业监测z环境监测z污水处理厂z自来水厂z水文z地质调查z农业土壤矿物油z工厂冷却循环水1.3 检验与安装1.3.1 校验收到仪器后,仔细检查,确定所订购的货物齐全。

货物包括:1OilTech 121 Handheld Oil in Water Analyzer仪器2OilTech 121 操作手册3订购的备件。

诸如:试管适配器、试管、QuickAdjust校准器模块1.3.2 安装图1使用OilTech121前,先安装电池1 拧开仪器背面镙丝,打开电池盒盖,并放入电池(见图1)。

2 安装4节AAA 电池。

3 盖上电池盒盖,并拧紧镙丝。

总则及注意事项z试管适配器可分别装入直径5mm 试管和直径8mm 试管两种 样品API°<45°时,建议使用直径5mm 试管 样品API°>45°时,建议使用直径8mm 试管 5.131API -相对密度141.5=o ——数值越大,原油越轻z 直径5mm 试管容积至少需要75μl z 直径8mm 试管容积至少需要1ml z 不要让样品中出现气泡z 正己烷溶剂应为光谱纯试剂,特别是分析低浓度样品及API°>45°的样品时z 仪器读数直接为水中矿物油浓度zOilTech121操作手册应与OilTech 分析方法指南一起使用。

快视图返回标准校验空白确认调整数值读数测量移动光标3.1 启动仪器按住(ON/OFF)键2秒钟后,打开仪器,显示3.2 校准仪器建议客户在进行试样分析前,要对仪器进行校准。

通过空白的溶剂及已知浓度的标准液,或者使用QuickAdjust 校准模块,对仪器进行校准。